Method and device for strengthened ozone treatment of nitrobenzene waste water in high gravity filed

An ozone treatment, supergravity technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

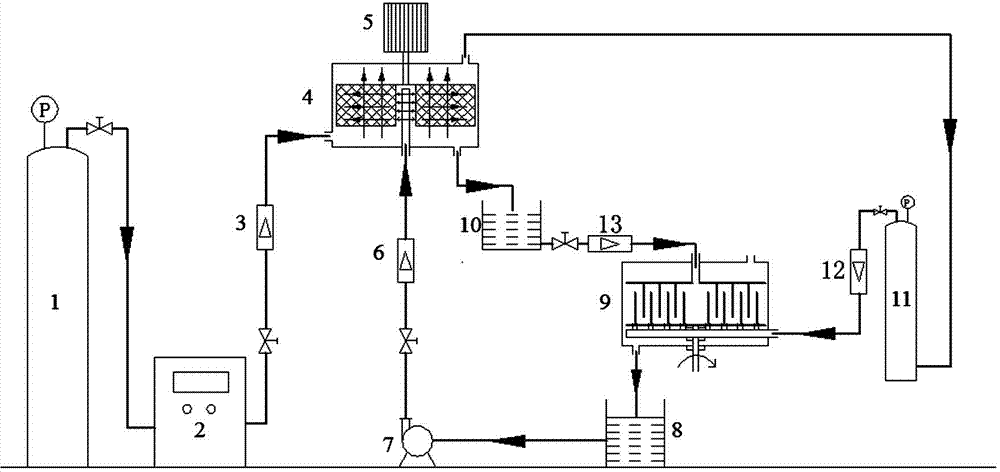

[0036] Example 1: Using figure 1 The flow shown is for the treatment of wastewater containing nitrobenzene. COD in wastewater is 600mg / L. First, wastewater and ozone gas enter the high gravity rotating packed bed 4 to carry out the ozone oxidation unit. Gas volume ratio (liquid flow to gas flow) is 600 L / m 3 . After the reaction, the tail gas and wastewater enter the supergravity-electrolysis unit for electrolysis reaction. The electrolysis voltage is controlled at 2V, the speed is 600 rpm, and the liquid-gas volume ratio is 650 L / m 3 . The wastewater (containing hydrogen peroxide) after the electrolysis reaction is pumped into the high-gravity rotating packed bed 4, and then undergoes ozonation reaction with ozone gas again, and the cycle is like this. Finally, the effluent of the ozone oxidation unit is obtained, the COD is 60~80 mg / L, and the ozone in the tail gas discharged from the supergravity-electrolysis unit is lower than 0.1 ppm. The COD of the same wastewater...

Embodiment 2

[0037] Example 2: Using figure 1 The flow shown is for the treatment of DNT-containing wastewater. COD in wastewater is 1000mg / L. First, waste water and ozone gas enter the high gravity rotating packed bed 4 to carry out the ozone oxidation unit. The rotating speed of the high gravity rotating packed bed is 600 rpm, and the inlet gas phase ozone concentration is 45 mg / L. Gas volume ratio (liquid flow to gas flow) is 80 L / m 3 . After the reaction, the tail gas and wastewater enter the supergravity-electrolysis unit for electrolysis reaction. The electrolysis voltage is controlled at 14V, the speed is 400 rpm, and the liquid-gas volume ratio is 150 L / m 3 . The wastewater (containing hydrogen peroxide) after the electrolysis reaction is pumped into the high-gravity rotating packed bed 4, and then undergoes ozonation reaction with ozone gas again, and the cycle is like this. Finally, the effluent of the ozone oxidation unit is obtained, the COD is 80~100 mg / L, and the ozone ...

Embodiment 3

[0038] Example 3: Using figure 1 The flow shown is for treating wastewater containing TNT. COD in wastewater is 800 mg / L. First, the wastewater and ozone gas enter the high gravity rotating packed bed oxidation unit, the rotating speed of the high gravity rotating packed bed is 1000 rpm, the inlet gas phase ozone concentration is 25 mg / L, the liquid-gas volume ratio of wastewater to ozone in the high gravity rotating packed bed ( Liquid flow and gas flow) is 200 L / m 3 . After the reaction, the tail gas and wastewater enter the supergravity-electrolysis unit for electrolysis reaction. The electrolysis voltage is controlled at 8V, the speed is 300 rpm, and the liquid-gas volume ratio is 300 L / m 3 . The wastewater (containing hydrogen peroxide) after the electrolysis reaction is pumped into the high-gravity rotating packed bed 4, and then undergoes ozonation reaction with ozone gas again, and so on. Finally, the effluent of the ozone oxidation unit is obtained, the COD is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com