Device capable of enhancing absorption of methyl iodide in acetic acid tail gas and technology adopting same

A technology for strengthening absorption and acetic acid, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of poor absorption effect, low space utilization, large equipment volume, etc., to achieve fast update speed, start and stop time The effect of short, small device size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example example 1

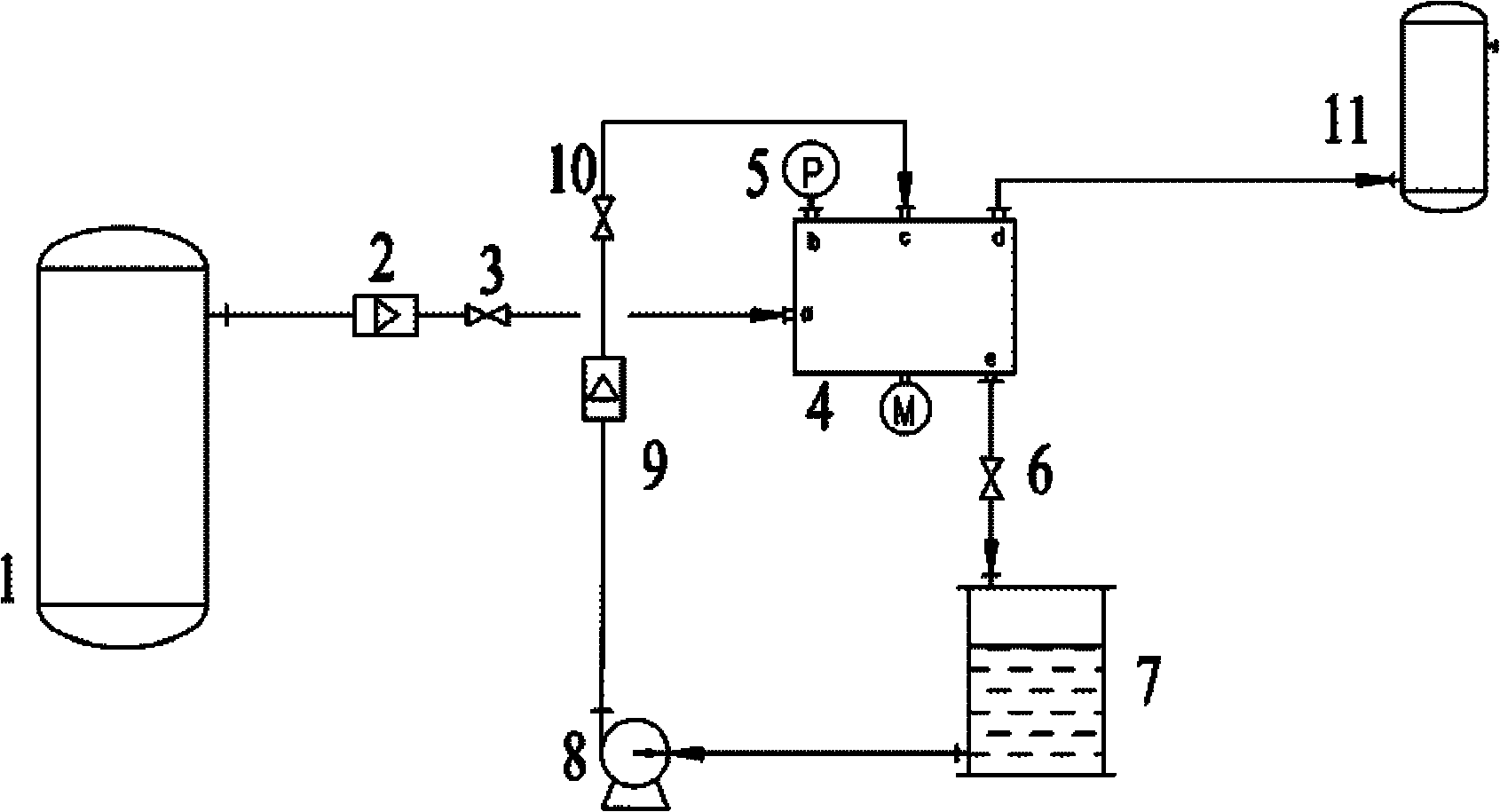

[0026] Start the enhanced absorption equipment 4, adjust the rotating packing speed to 300r / min, and stabilize for 5 minutes, adjust the inlet valve 3 to introduce the acetic acid tail gas from the acetic acid absorption tower 1 into the enhanced absorption equipment 4 through the gas flow meter 2, and the tail gas flow rate is 18Nm 3 / h; At the same time, adjust the inlet valve 10 to send the acetic acid absorption liquid from the absorption liquid storage tank 7 to the enhanced absorption device 4 via the feed pump 8 and the liquid flow meter 9, and the flow rate of the acetic acid absorption liquid is 100 kg / h. After the system was stable for 30 minutes, the mass content of methyl iodide in the acetic acid absorption solution at the outlet was measured to be 430 ppm.

example example 2

[0028] Under the operation of Example 1, the rotational speed of the rotating packed bed was adjusted to 600r / min, and other conditions were unchanged. After the system was stable for 30 minutes, the mass content of methyl iodide in the acetic acid absorption solution at the outlet was measured to be 500 ppm.

example example 3

[0030] Under the operation of Example 1, the flow rate of the pure acetic acid absorption liquid was adjusted to 300 kg / h, and other conditions were unchanged. After the system was stable for 30 minutes, the mass content of methyl iodide in the acetic acid absorption liquid at the outlet was measured to be 220 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com