Continuous feeding mechanism for processing medical materials

A feeding mechanism and medicinal material processing technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inability to realize long-term continuous feeding, scattered medicinal materials, and many manpower, and achieve simple structure and low cost. The effect of less manpower and continuous feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

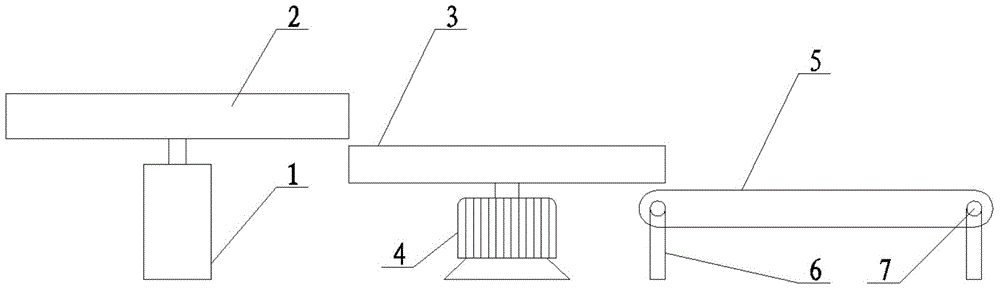

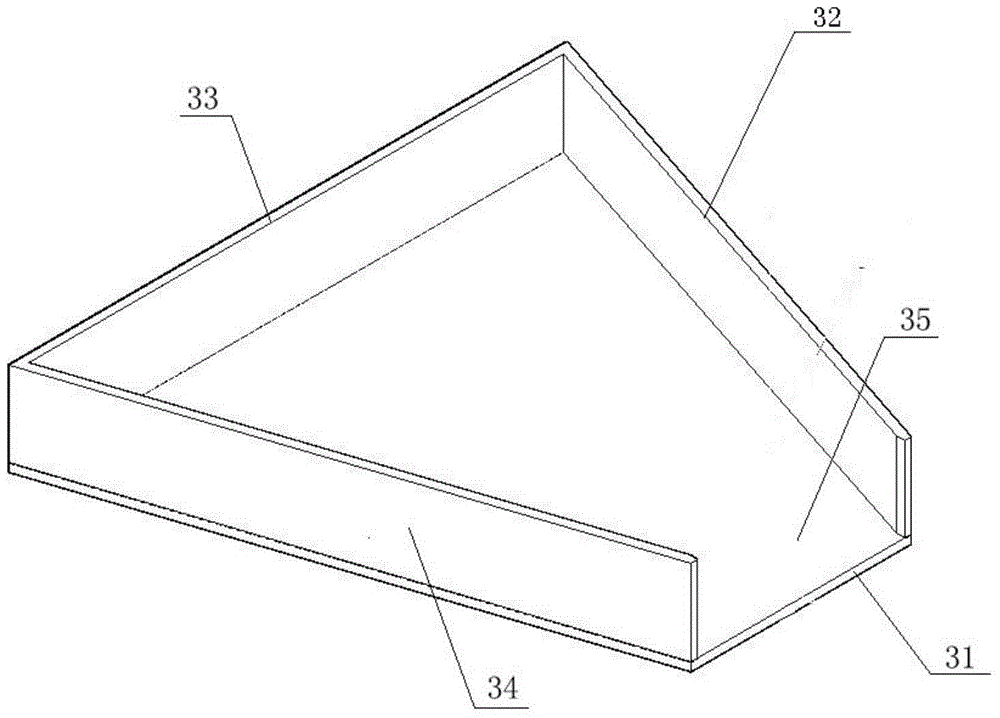

[0020] Such as figure 1 and figure 2 As described, the continuous feeding mechanism for medicinal material processing of the present invention includes a lifting platform 2, a conveyor belt 5, and a feeding trough 3 arranged between the lifting platform 2 and the conveyor belt 5. The bottom of the lifting platform 2 is equipped with a The cylinder 1 for lifting movement, the lifting platform 2 is positioned above the feeding chute 3 after it is fully raised, the bottom of the feeding chute 3 is equipped with a vibration motor 4 for driving the feeding chute 3 to vibrate, and the feeding trough 3 includes The groove bottom 31 and the first groove wall 32 , the second groove wall 33 and the third groove wall 34 arranged in sequence, between the first groove wall 32 , the second groove wall 33 , the third groove wall 34 and the groove bottom 3 A cavity is formed, a discharge opening 35 is opened between the first groove wall 32 and the third groove wall 34, the conveying belt 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com