Patents

Literature

185results about How to "Less manpower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

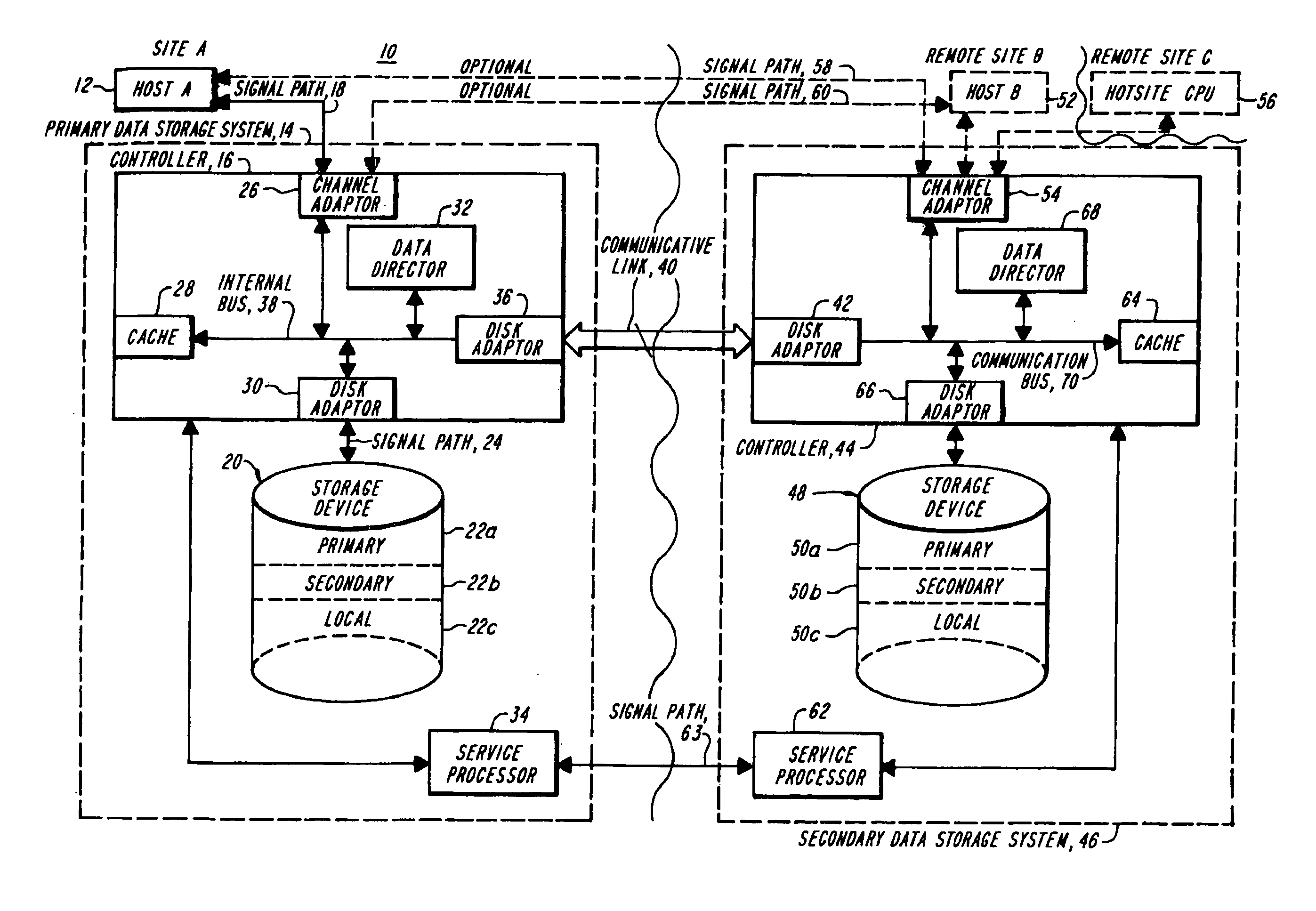

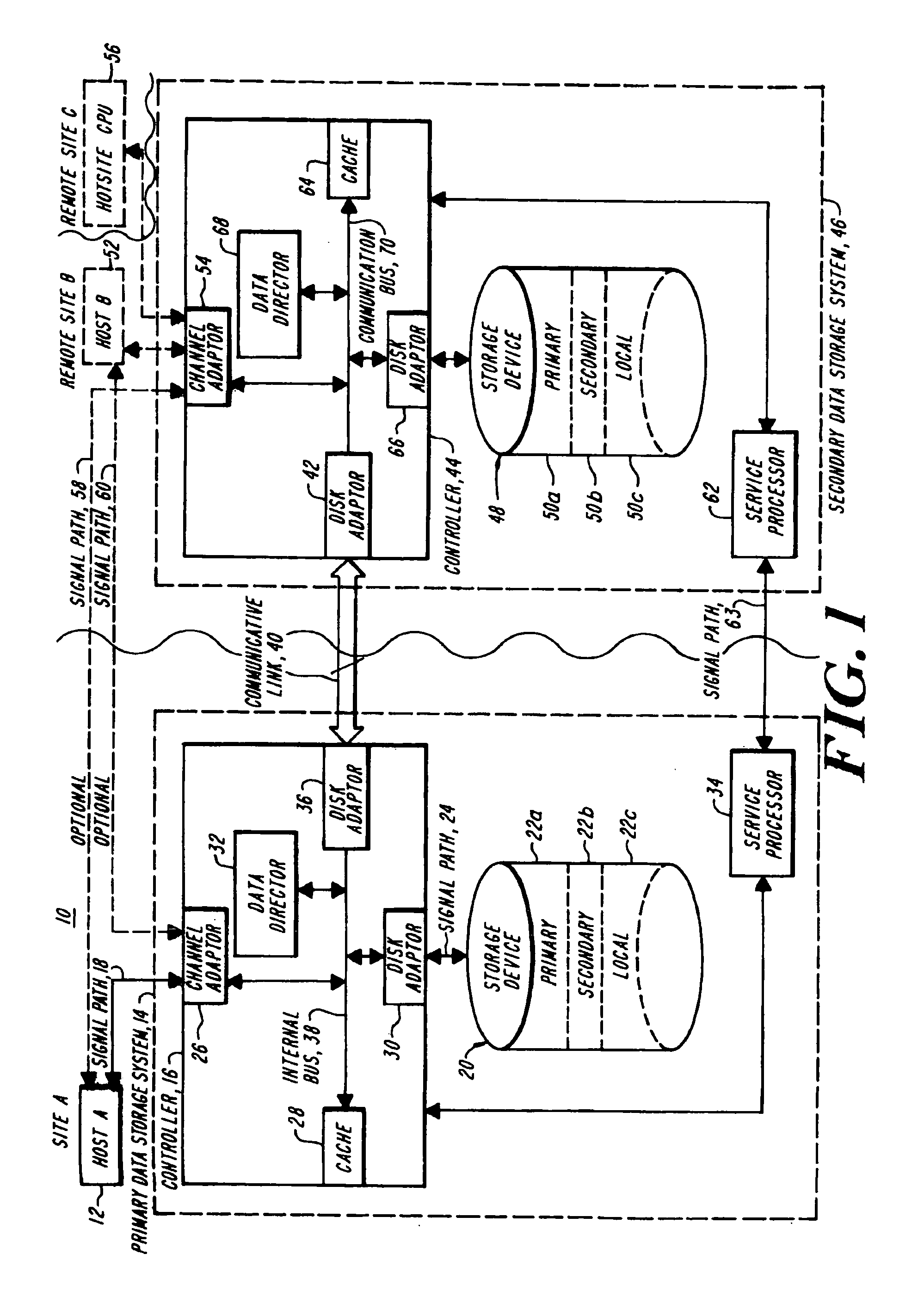

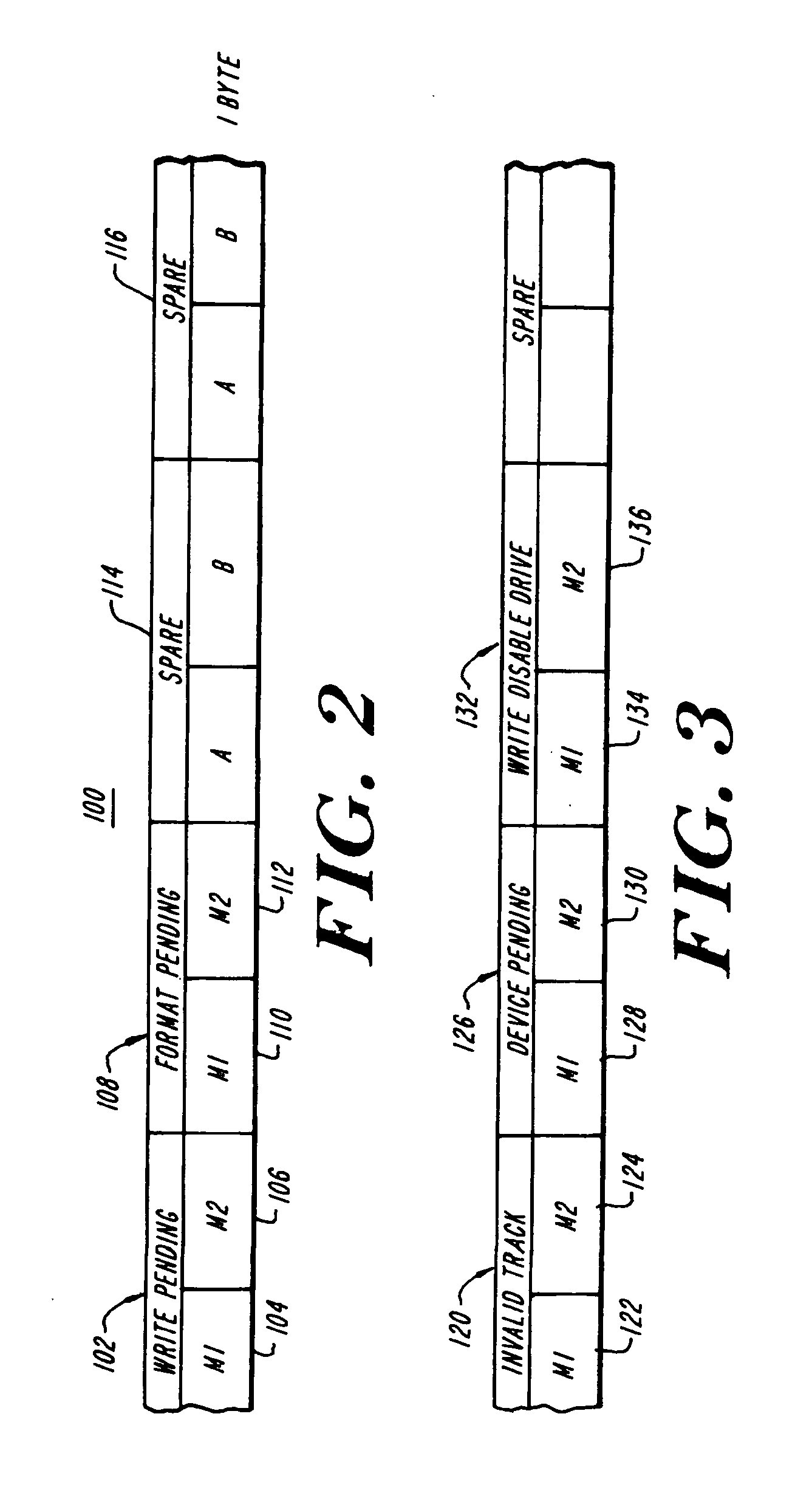

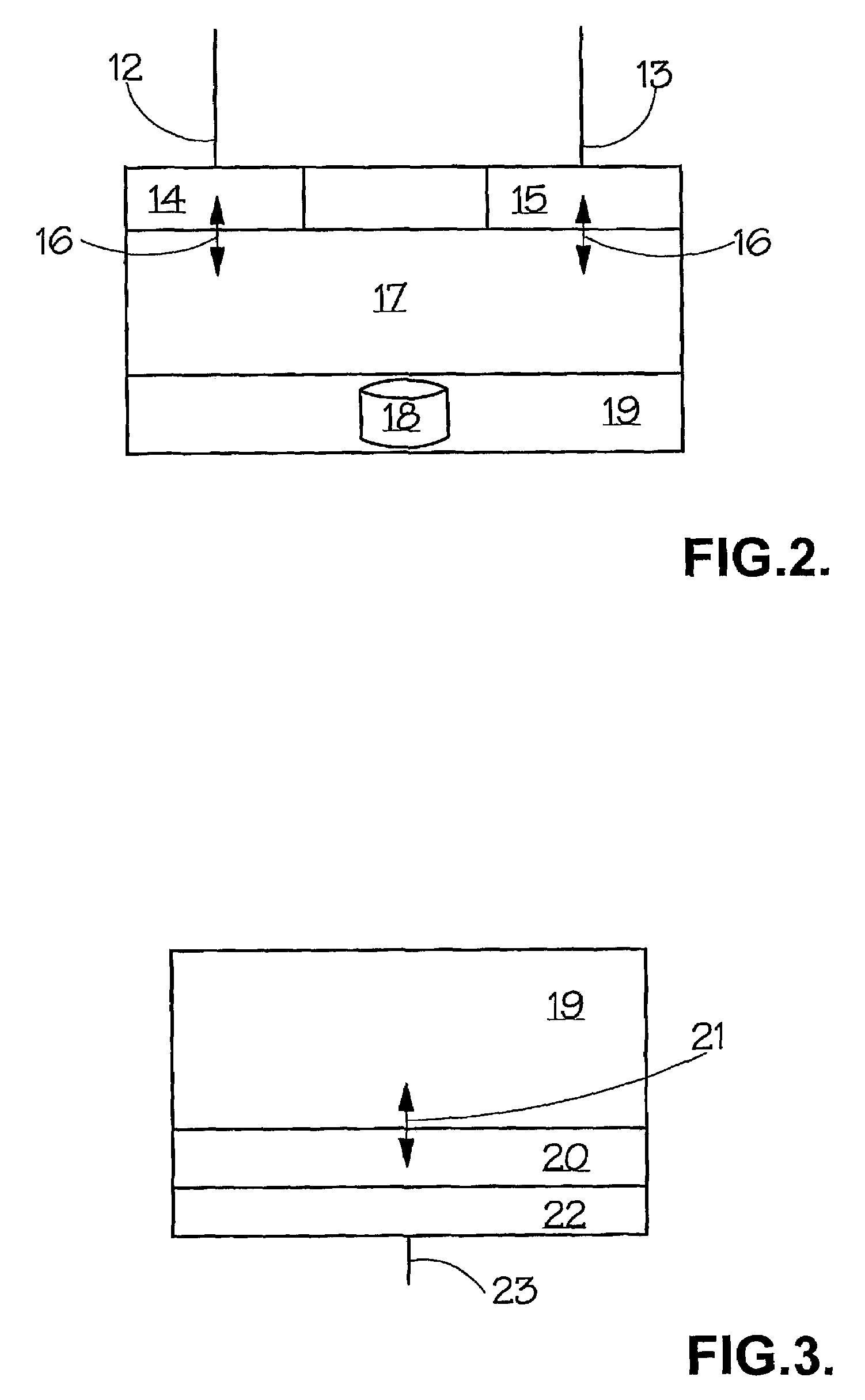

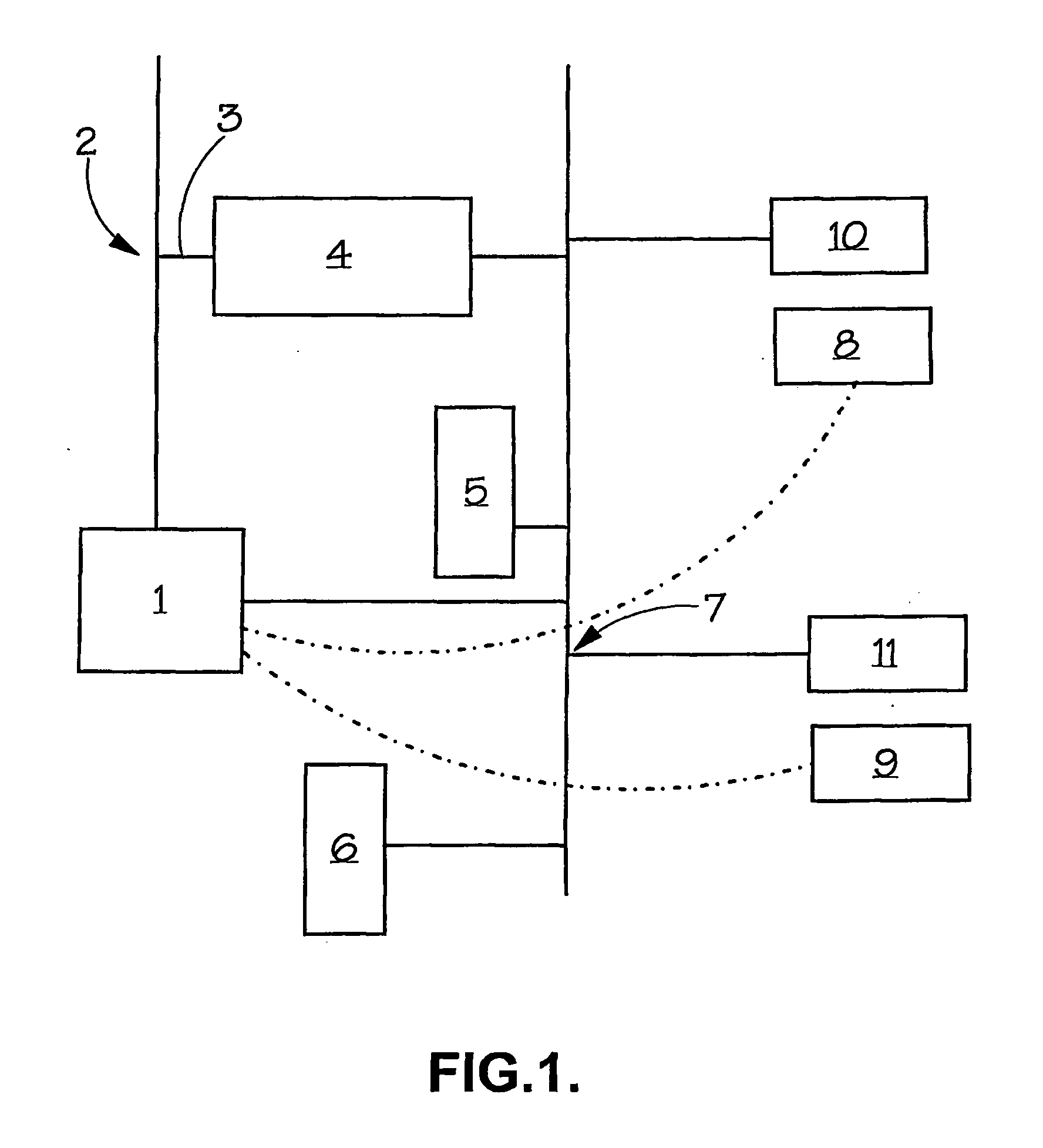

Remote data mirroring

InactiveUS20060005074A1Low costLess manpowerInput/output to record carriersData processing applicationsSelf adaptiveData store

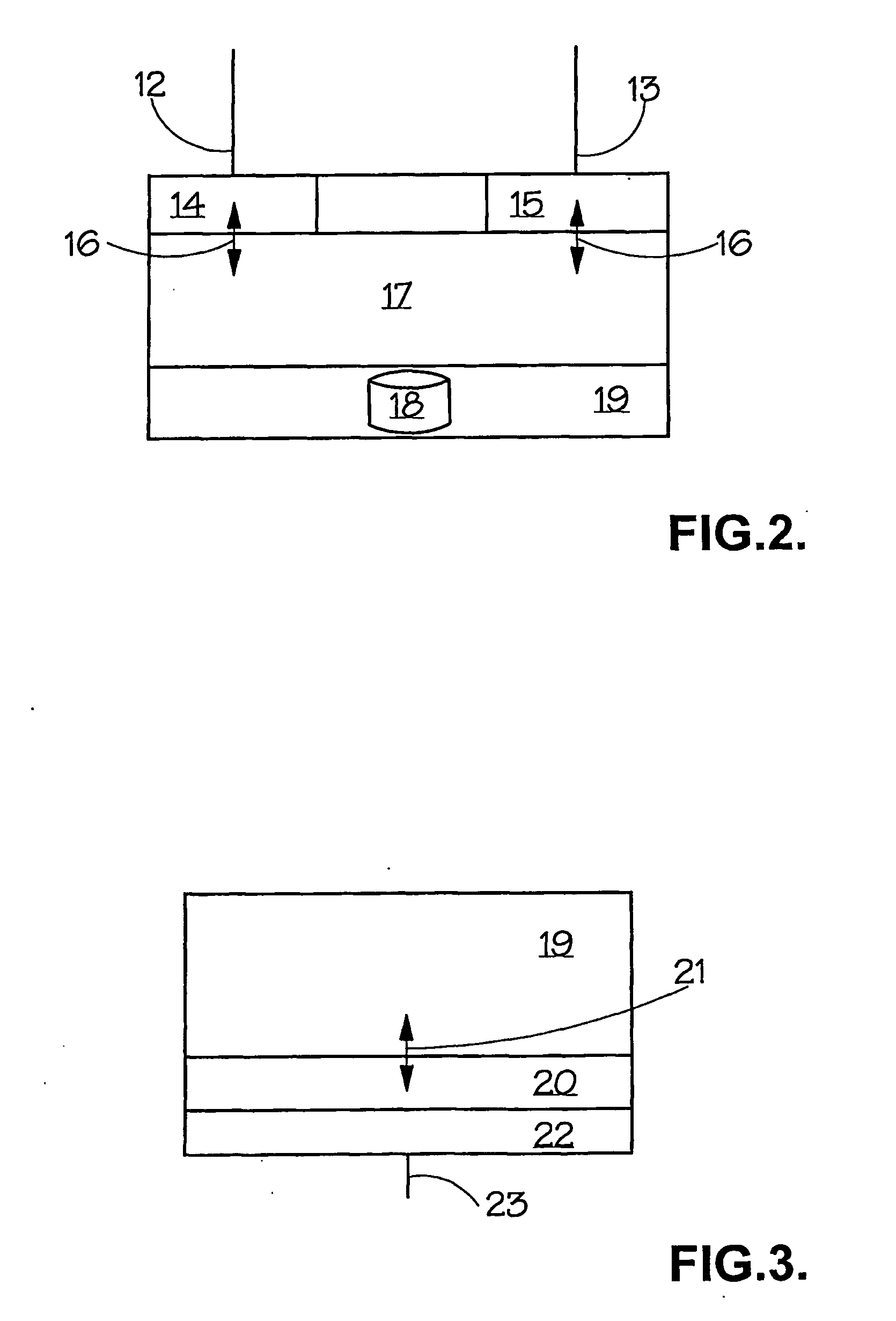

Two data storage systems are interconnected by a data link for remote mirroring of data. Each volume of data is configured as local, primary in a remotely mirrored volume pair, or secondary in a remotely mirrored volume pair. Normally, a host computer directly accesses either a local or a primary volume, and data written to a primary volume is automatically sent over the link to a corresponding secondary volume. Each remotely mirrored volume pair can operate in a selected synchronization mode including synchronous, semi-synchronous, adaptive copy-remote write pending, and adaptive copy-disk. Direct write access to a secondary volume is denied if a “sync required” attribute is set for the volume and the volume is not synchronized.

Owner:EMC CORP

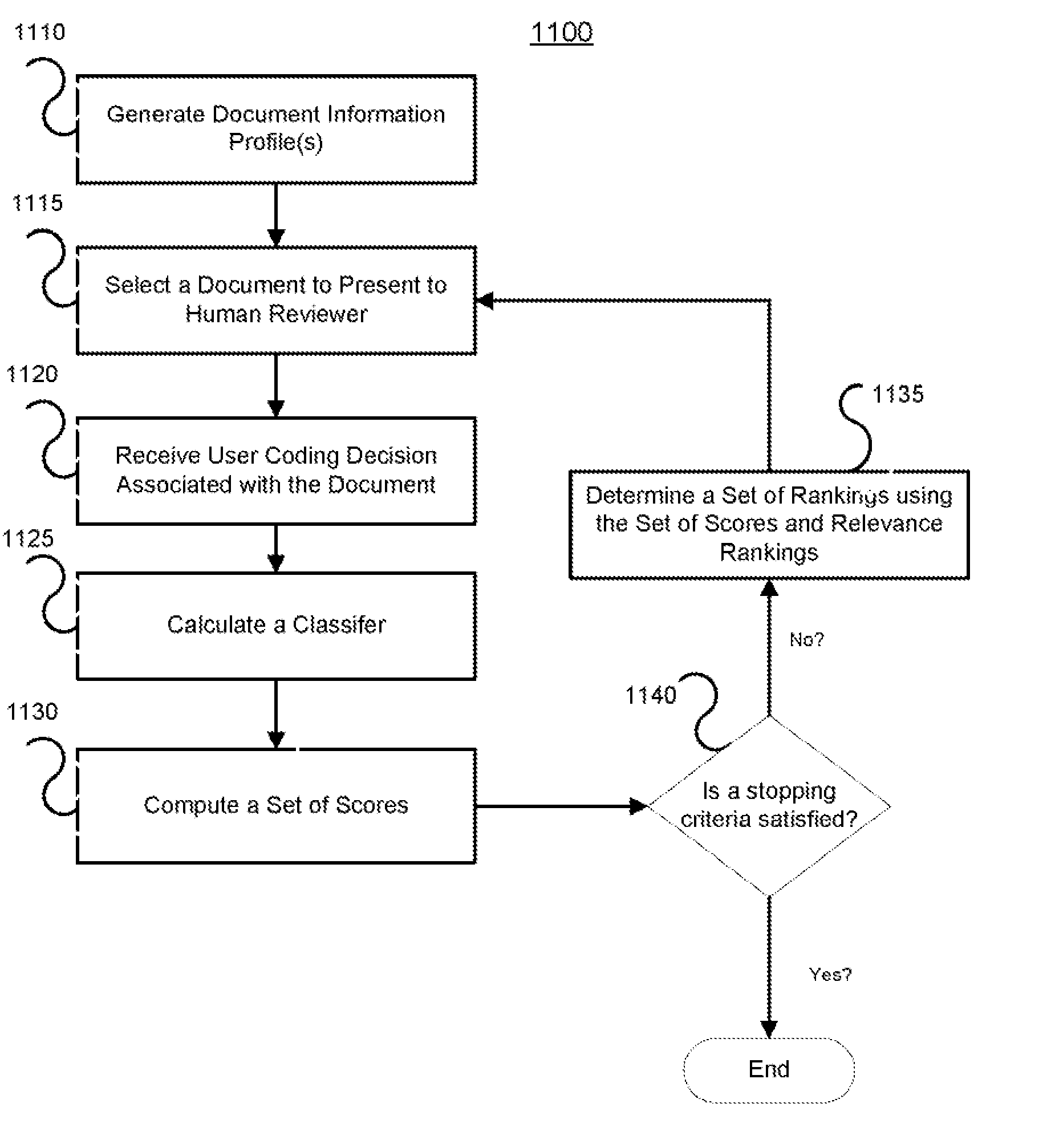

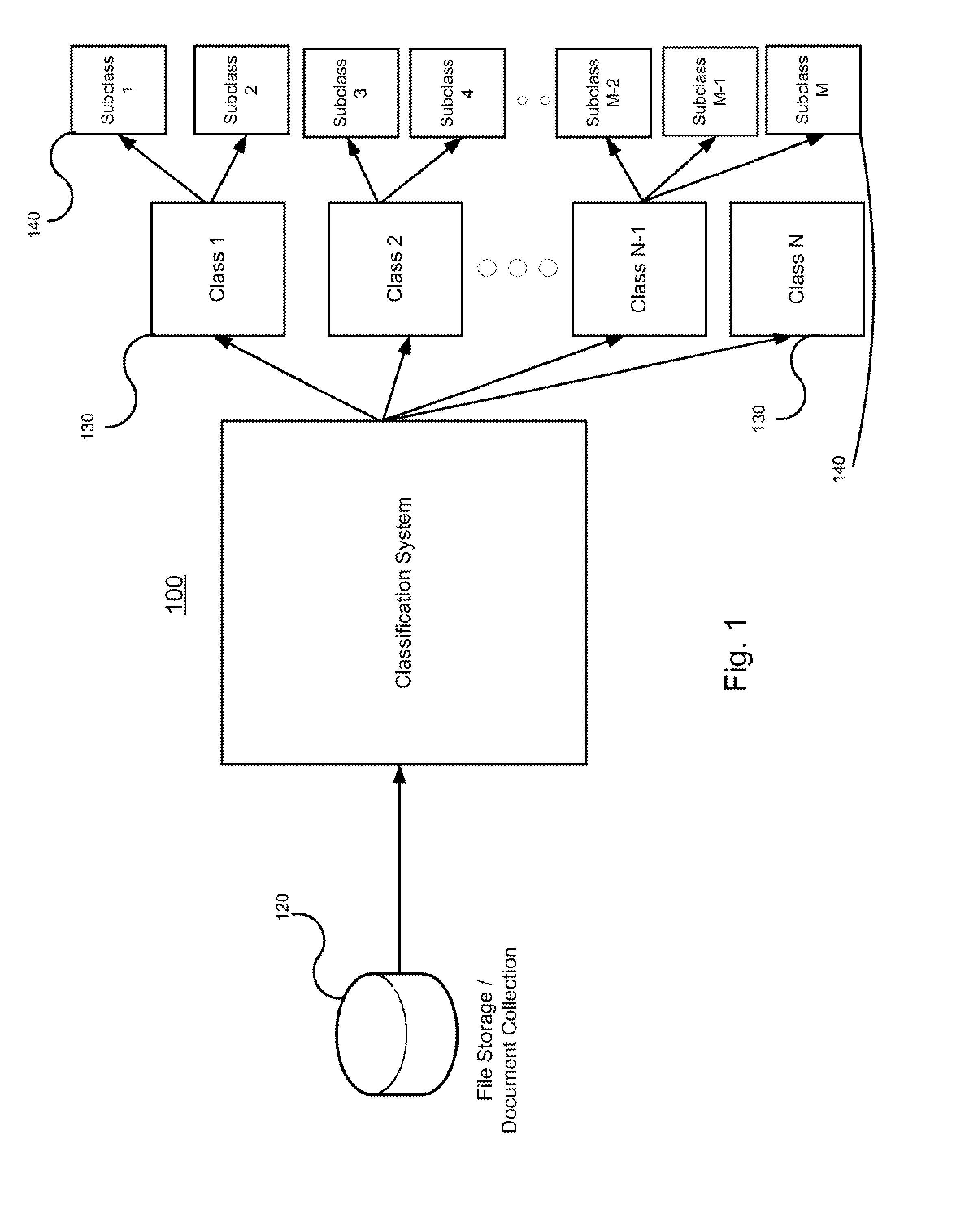

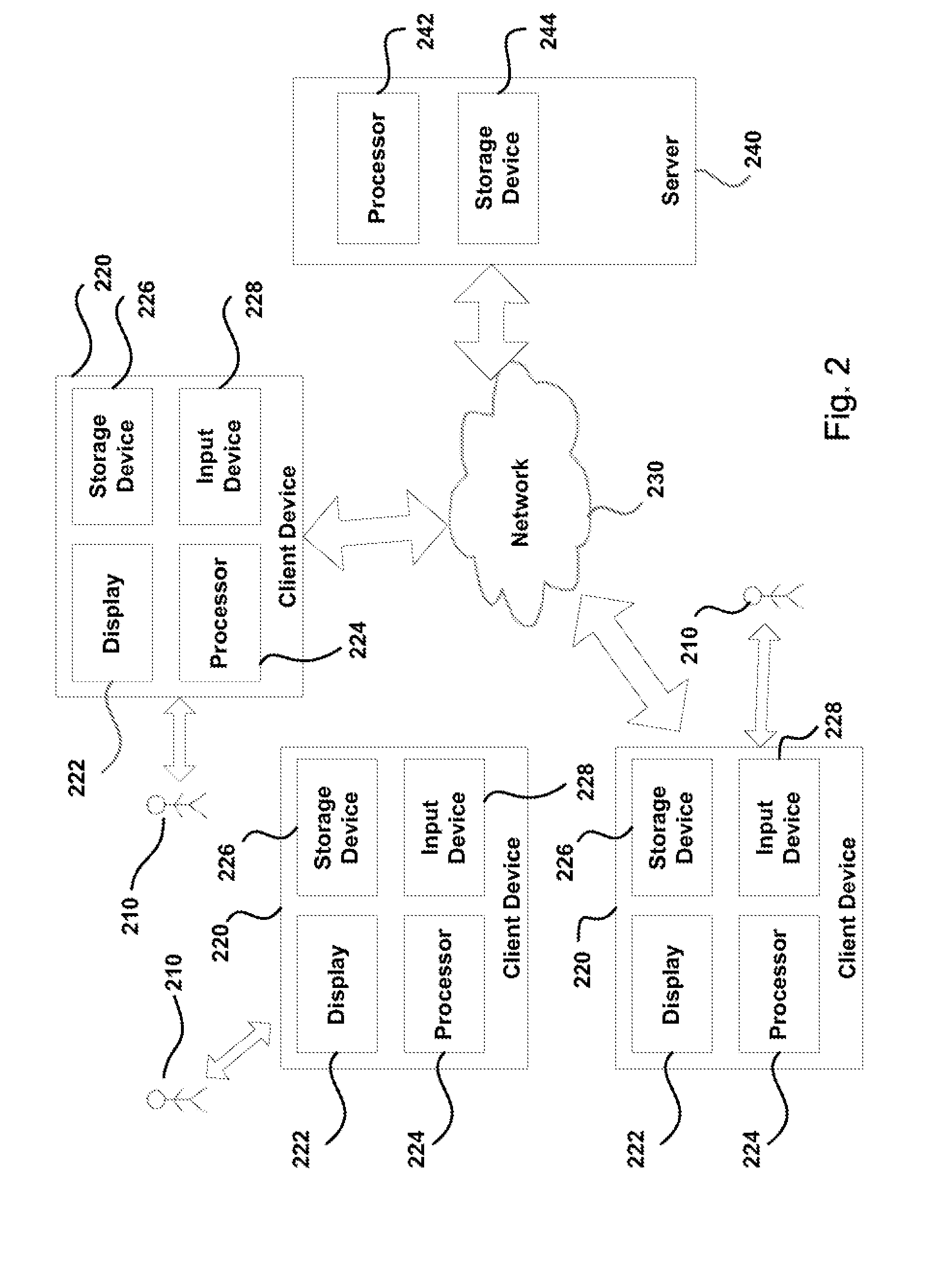

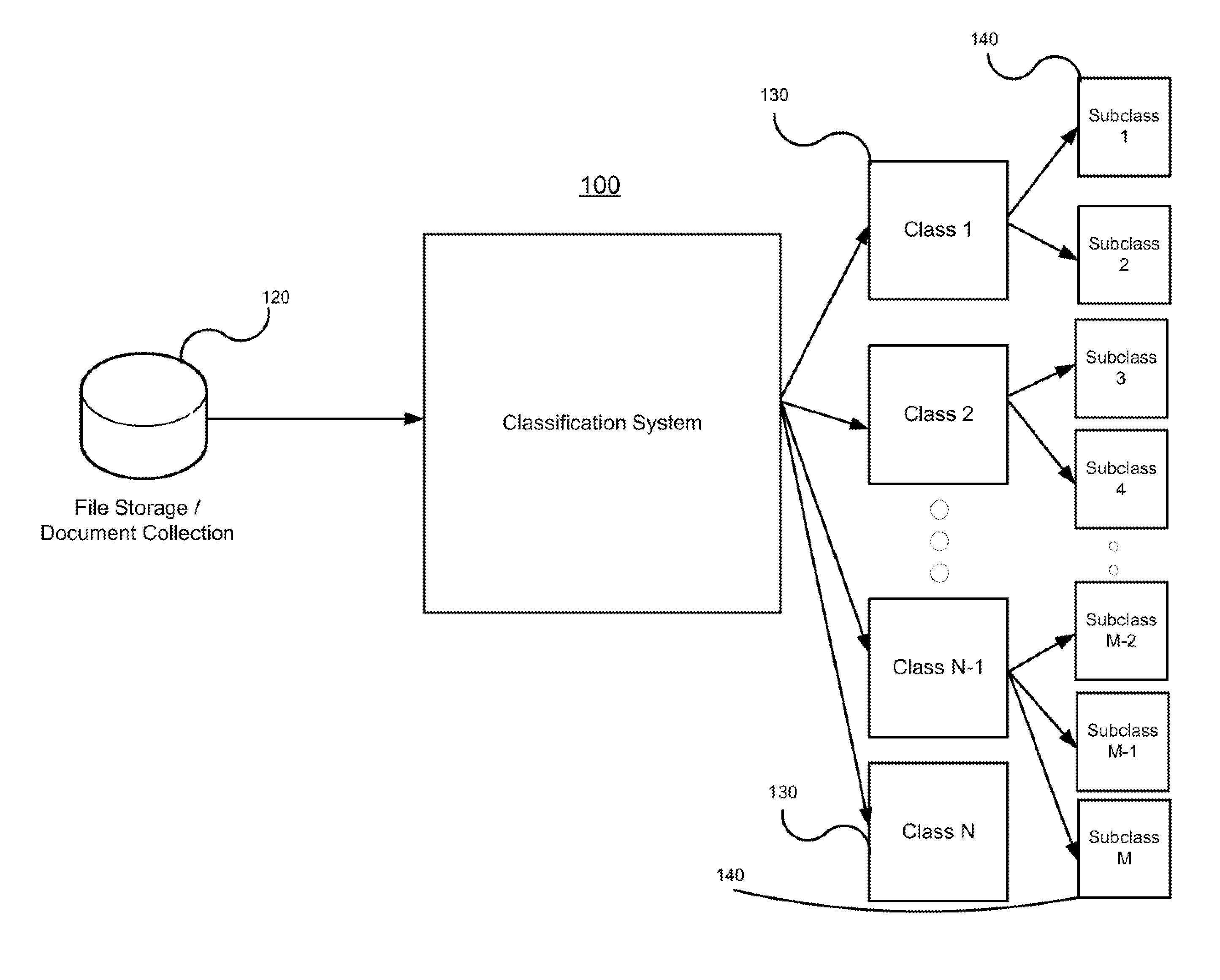

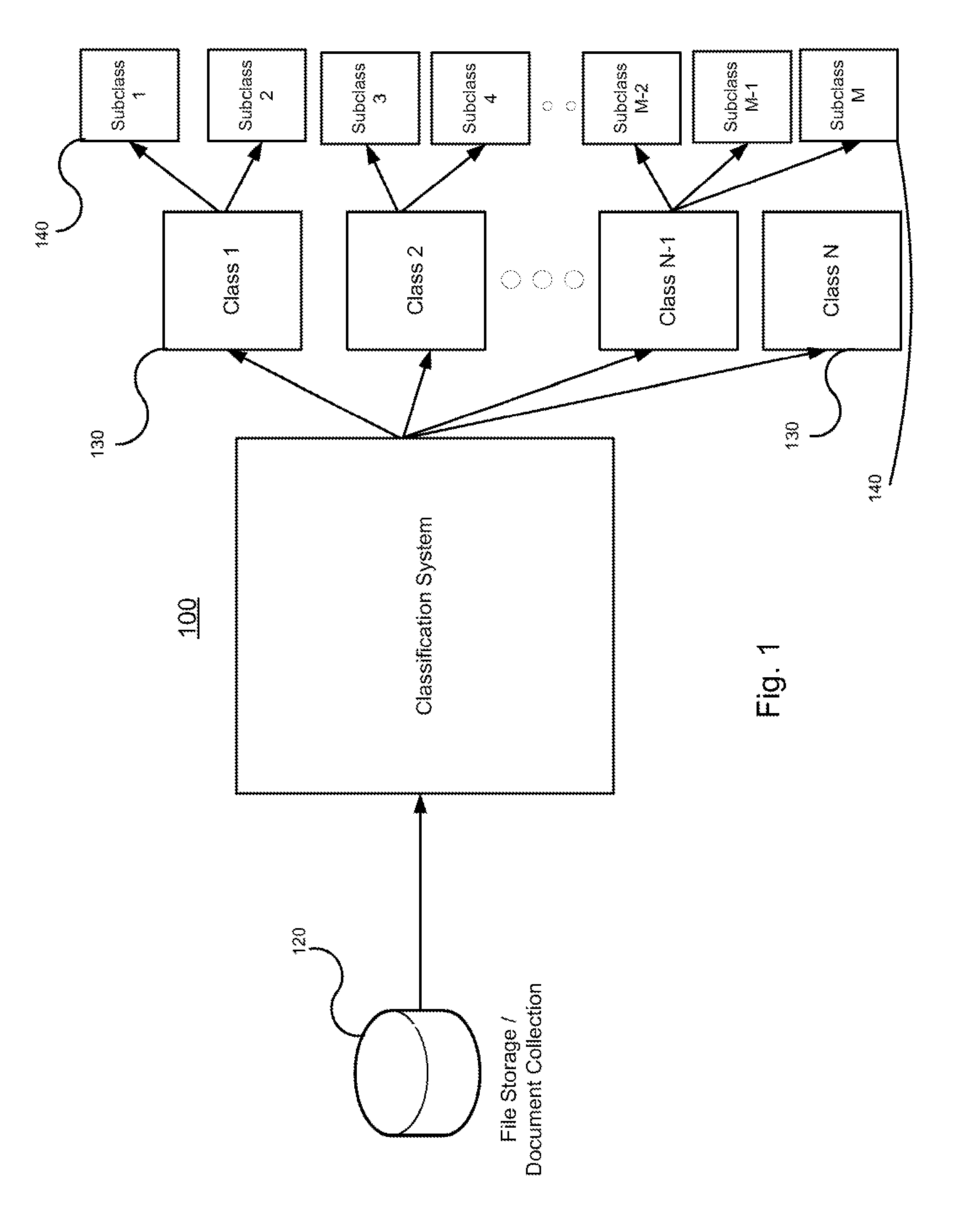

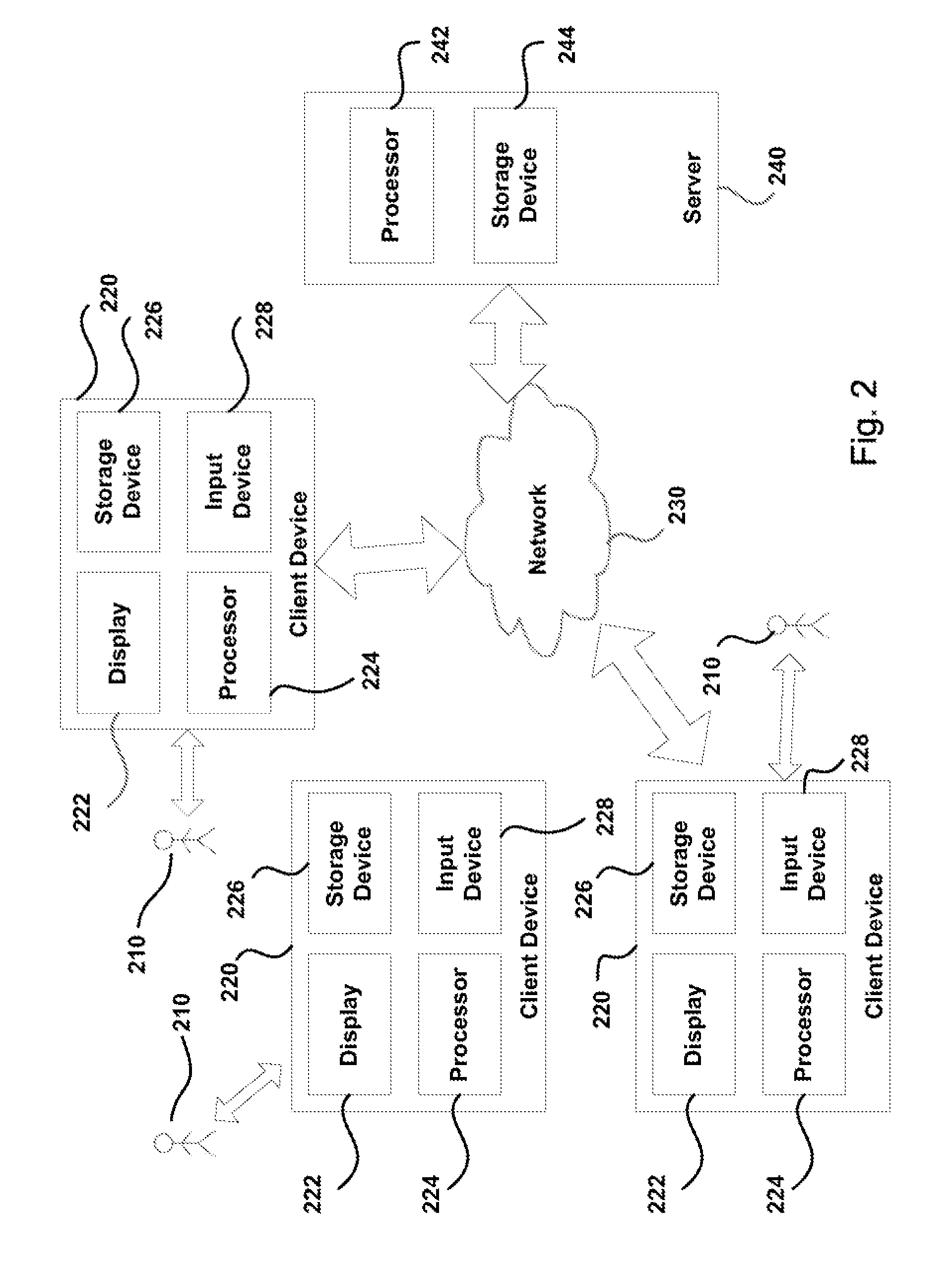

Systems and methods for classifying electronic information using advanced active learning techniques

ActiveUS8620842B1Easy to transportReduce complexityDigital computer detailsRelational databasesElectronic informationData mining

Systems and methods for classifying electronic information or documents into a number of classes and subclasses are provided through an active learning algorithm. In certain embodiments, the active learning algorithm forks a number of classification paths corresponding to predicted user coding decisions for a selected document. The active learning algorithm determines an order in which the documents of the collection may be processed and scored by the forked classification paths. Such document classification systems are easily scalable for large document collections, require less manpower and can be employed on a single computer, thus requiring fewer resources. Furthermore, the classification systems and methods described can be used for any pattern recognition or classification effort in a wide variety of fields.

Owner:CORMACK GORDON VILLY

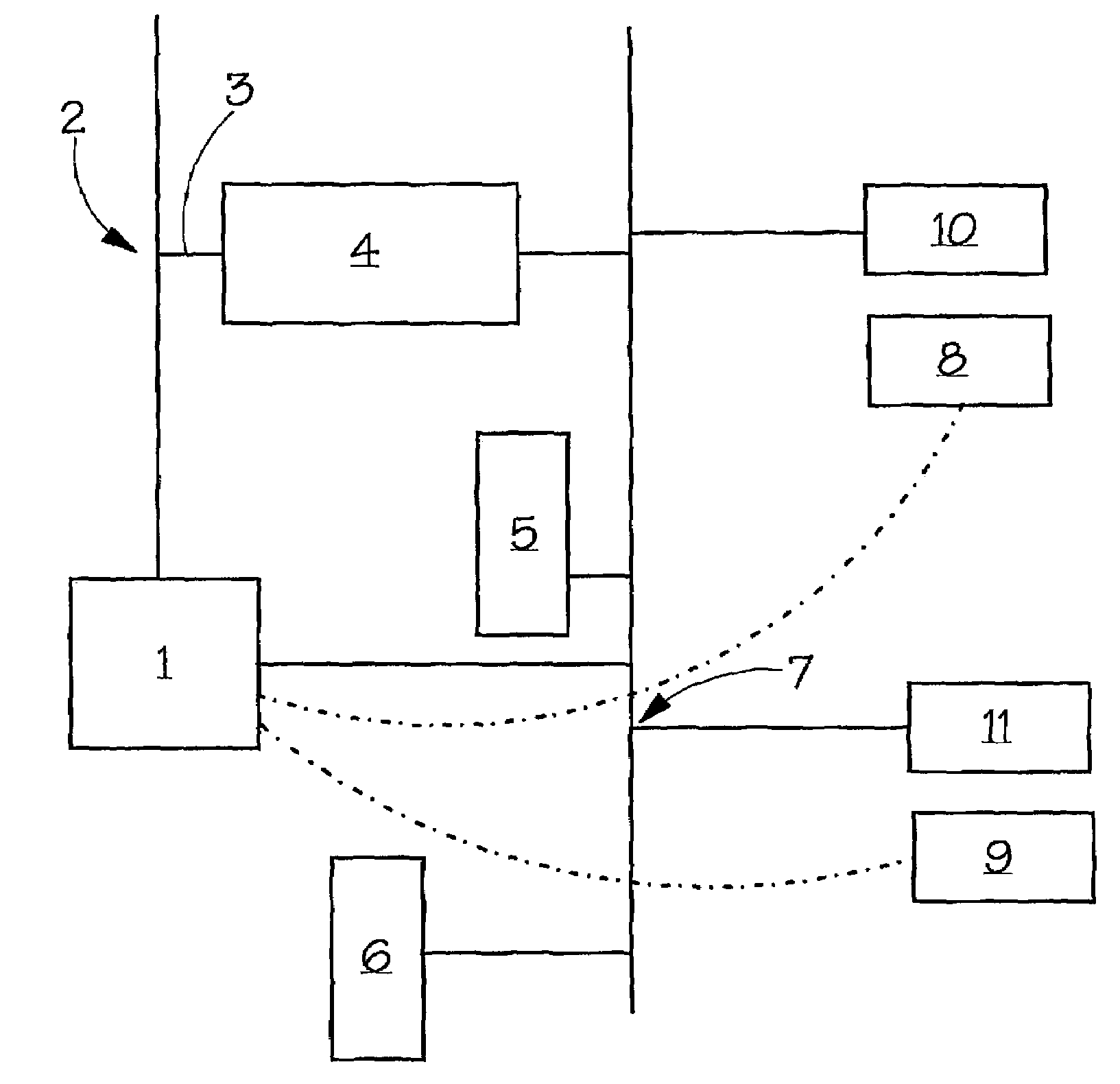

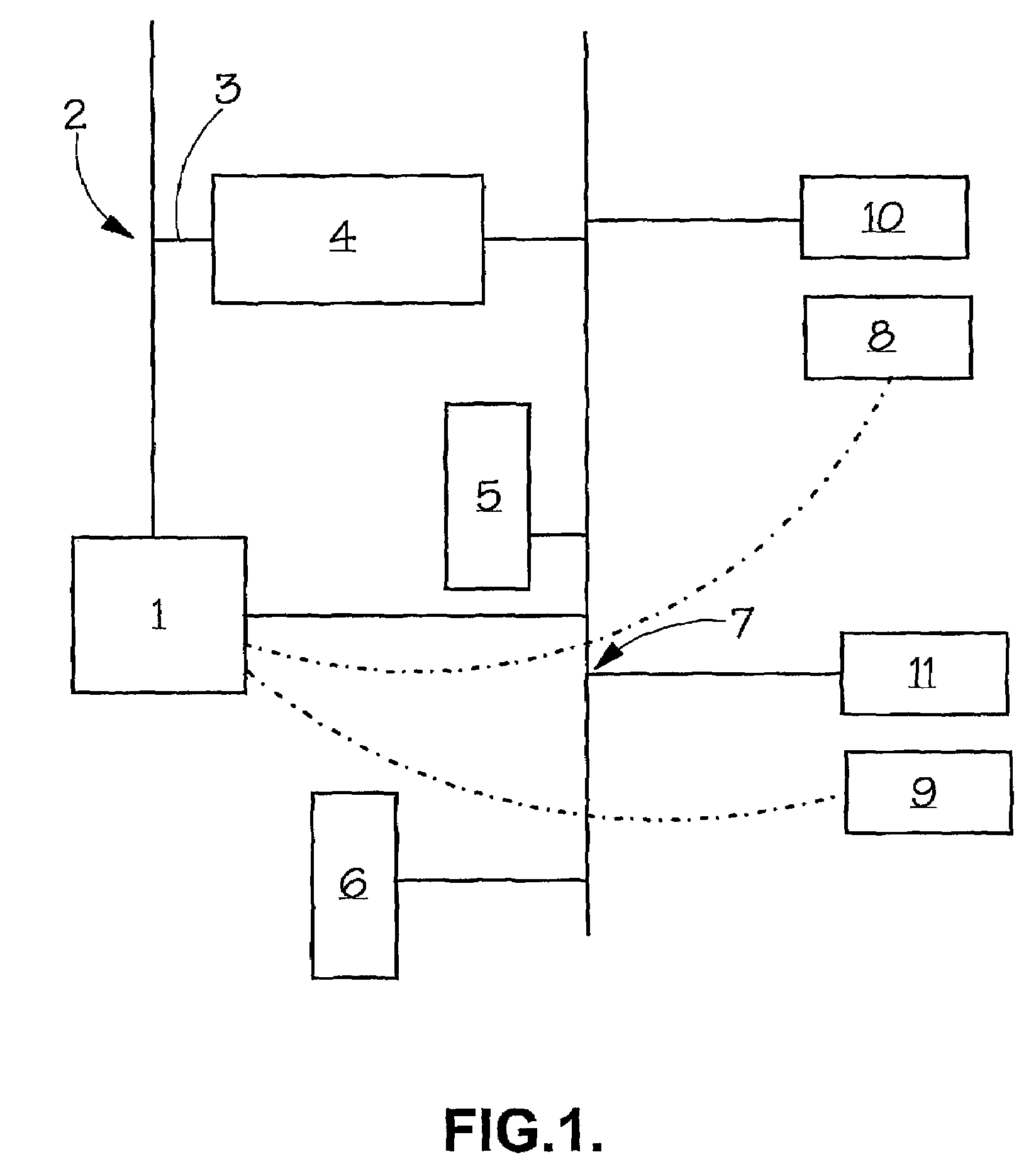

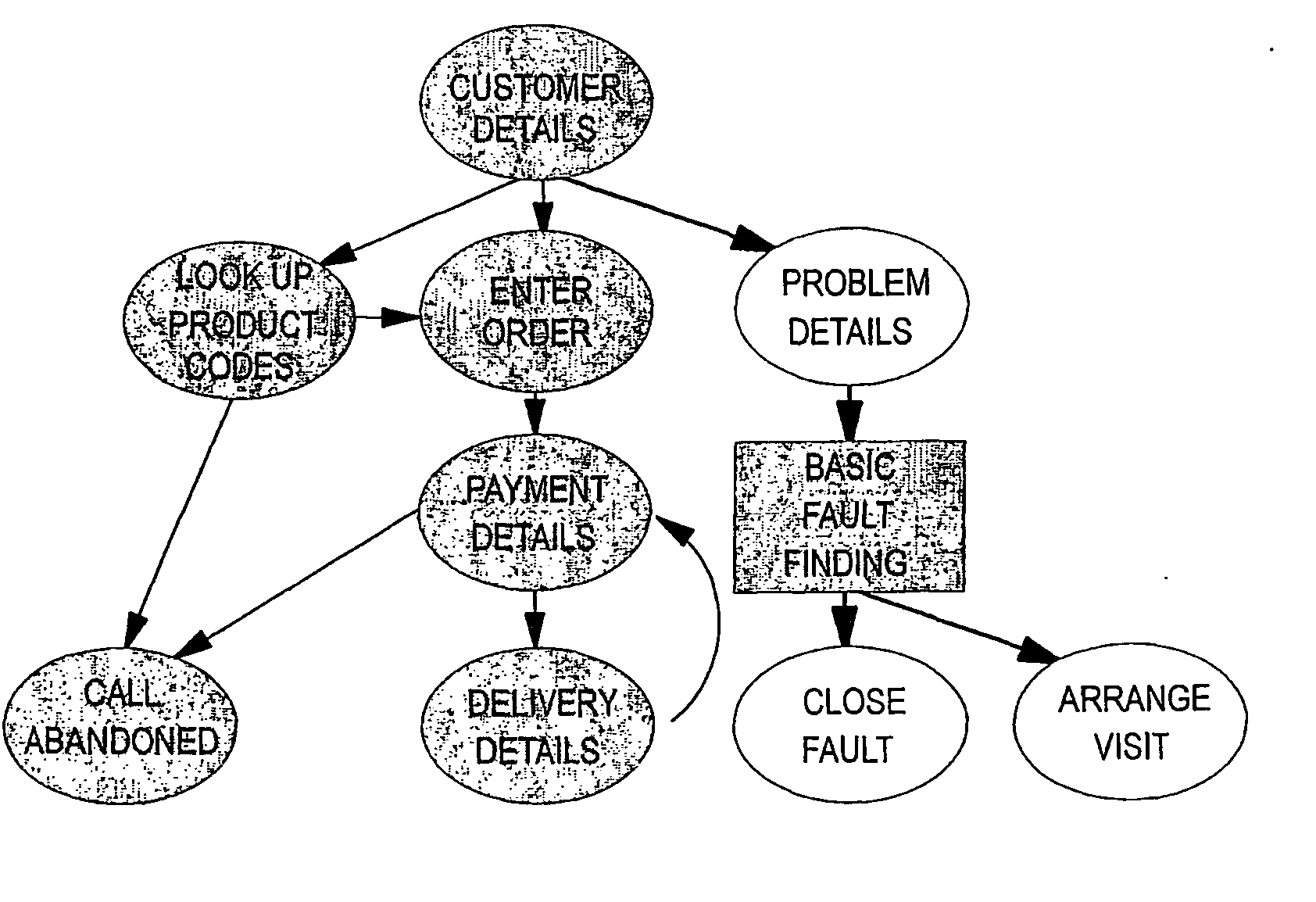

System and method for recording voice and the data entered by a call center agent and retrieval of these communication streams for analysis or correction

InactiveUS7203285B2Significant valueBetter statistical significanceSpeech analysisSpecial service for subscribersTraffic capacityTime information

The invention provides for a communications recording and analysis system including means for recording one or more communication streams, means for identifying the recorded stream, means for retrieving the content of said recordings by identifier tags, and wherein additional real-time information is inferred from analysis, in real-time or later, of keystrokes entered at a computer / terminal handling the interaction, and / or computer mouse actions, and / or internet traffic emanating from, or terminating at, any one or more of a number of computers / terminals handling the interaction, and / or the words and / or prosody spoken during the interaction is recorded. Furthermore graphical display means are provided such that the presentation of call flow recording is in the form of a direct graph showing the progress of the calls through the various states and transitions.

Owner:EYRETEL +1

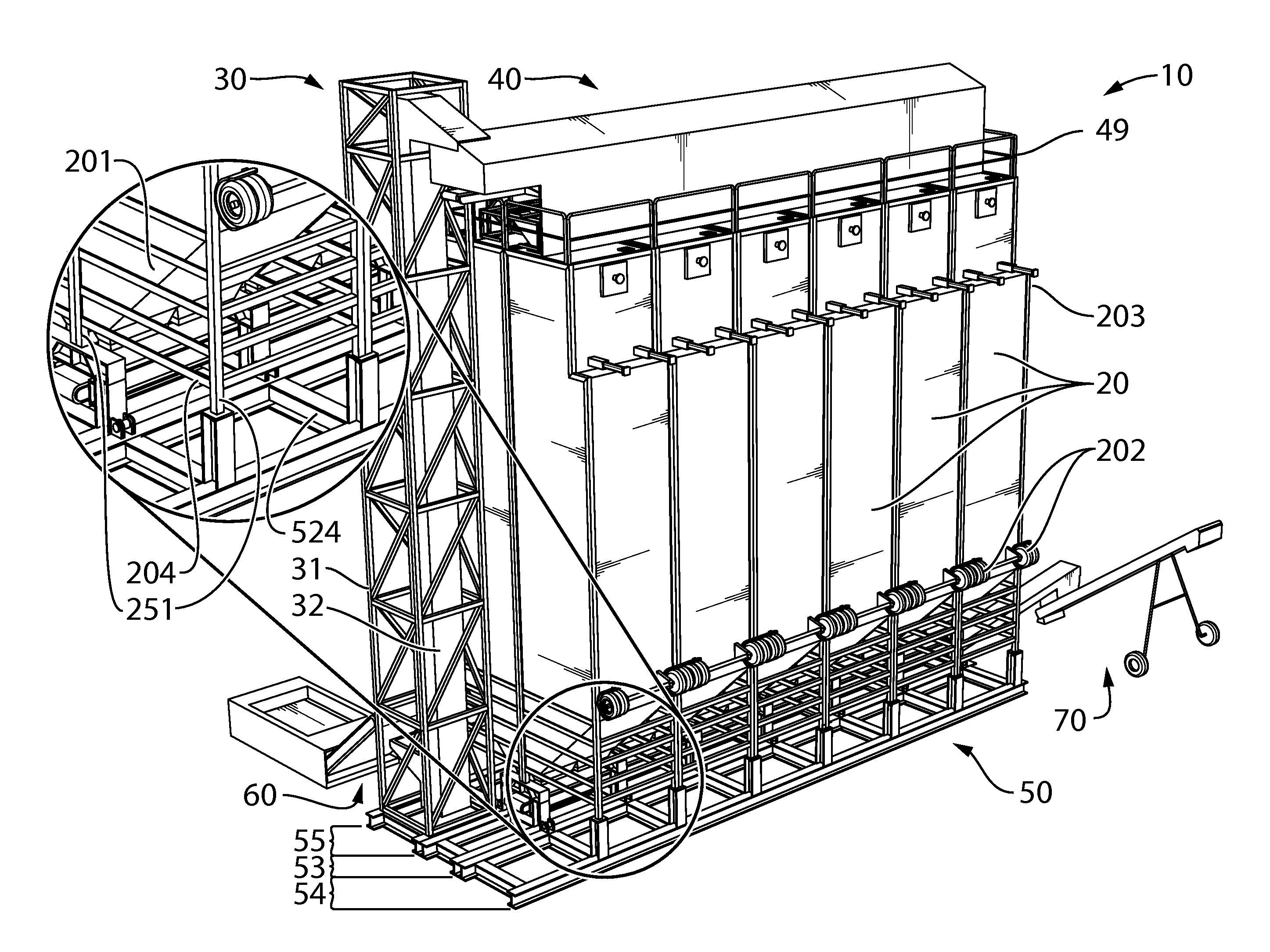

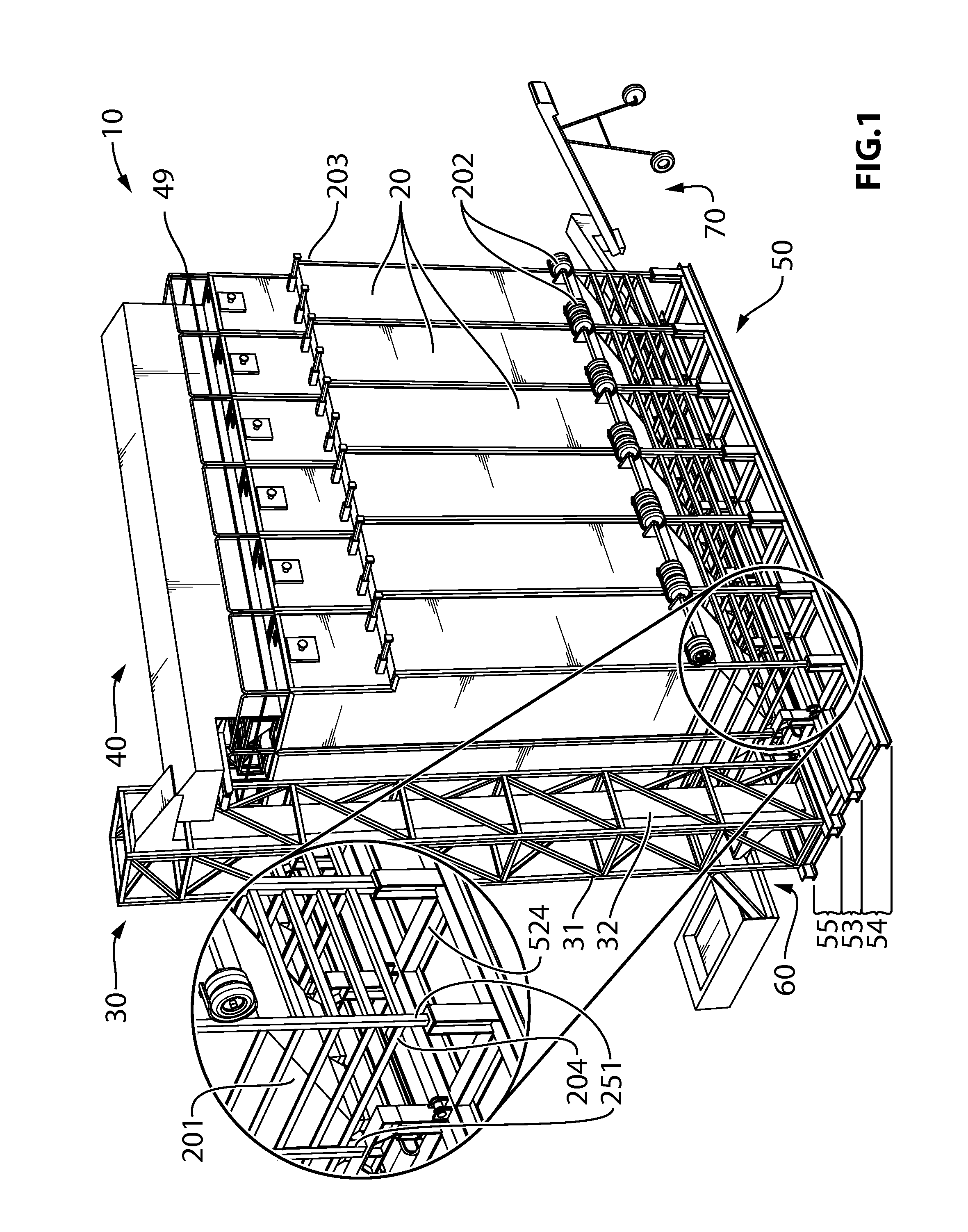

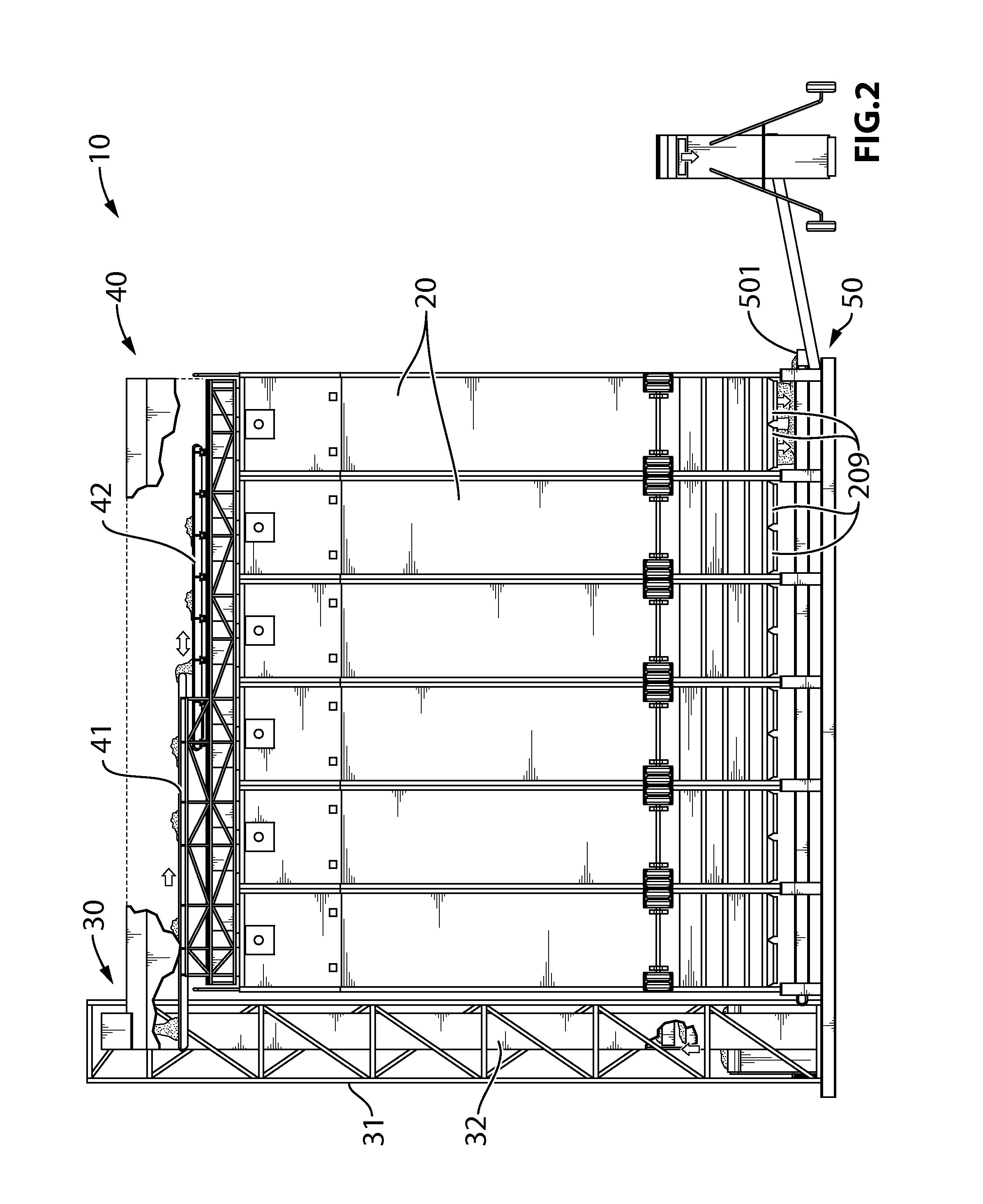

Mobile dry material storage

ActiveUS20140377042A1Avoid accidental damageIncrease volumeTractor-trailer combinationsKitchen equipmentWell drillingBucket elevator

A system that can be assembled at a well drilling or other site for storing bulk material such as sand includes a plurality of storage bins configured as trailers, a skid that includes a lower conveyor, a bucket elevator and a top conveyor system. At the site, the bins and the elevator are vertically oriented and stood on the skid, resulting in discharge outlets on the bins becoming positioned over the lower conveyor. The top conveyor is installed on top of the bins. In operation, the elevator lifts the material and discharges it onto the top conveyor system. The top conveyor system discharges the material into the bins for storage. The stored material is controllably discharged from the discharge outlets of the bins onto the lower conveyor from which the material is conveyed to one end of the skid for transport to a new location or directly into a blender.

Owner:SOURCE LOGISTICS LTD O A AMMOS FIELD SOLUTIONS +1

System and method for analysing communications streams

InactiveUS7574000B2Better statistical significanceLess manpowerSpecial service for subscribersManual exchangesGraphicsGraphical user interface

Owner:VERINT AMERICAS +1

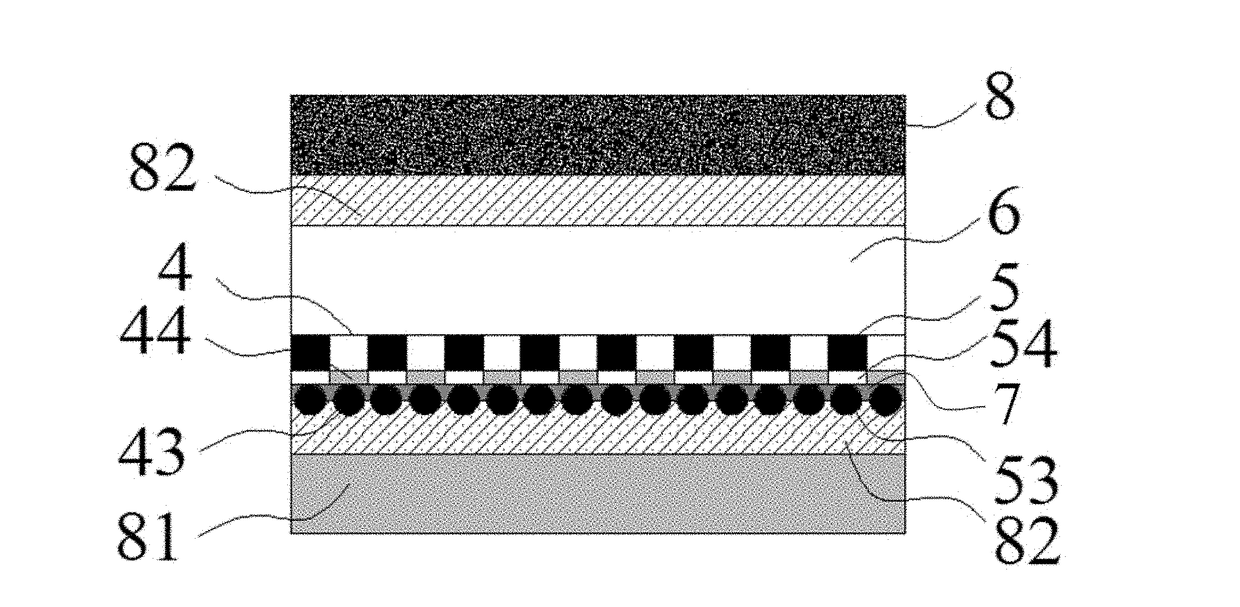

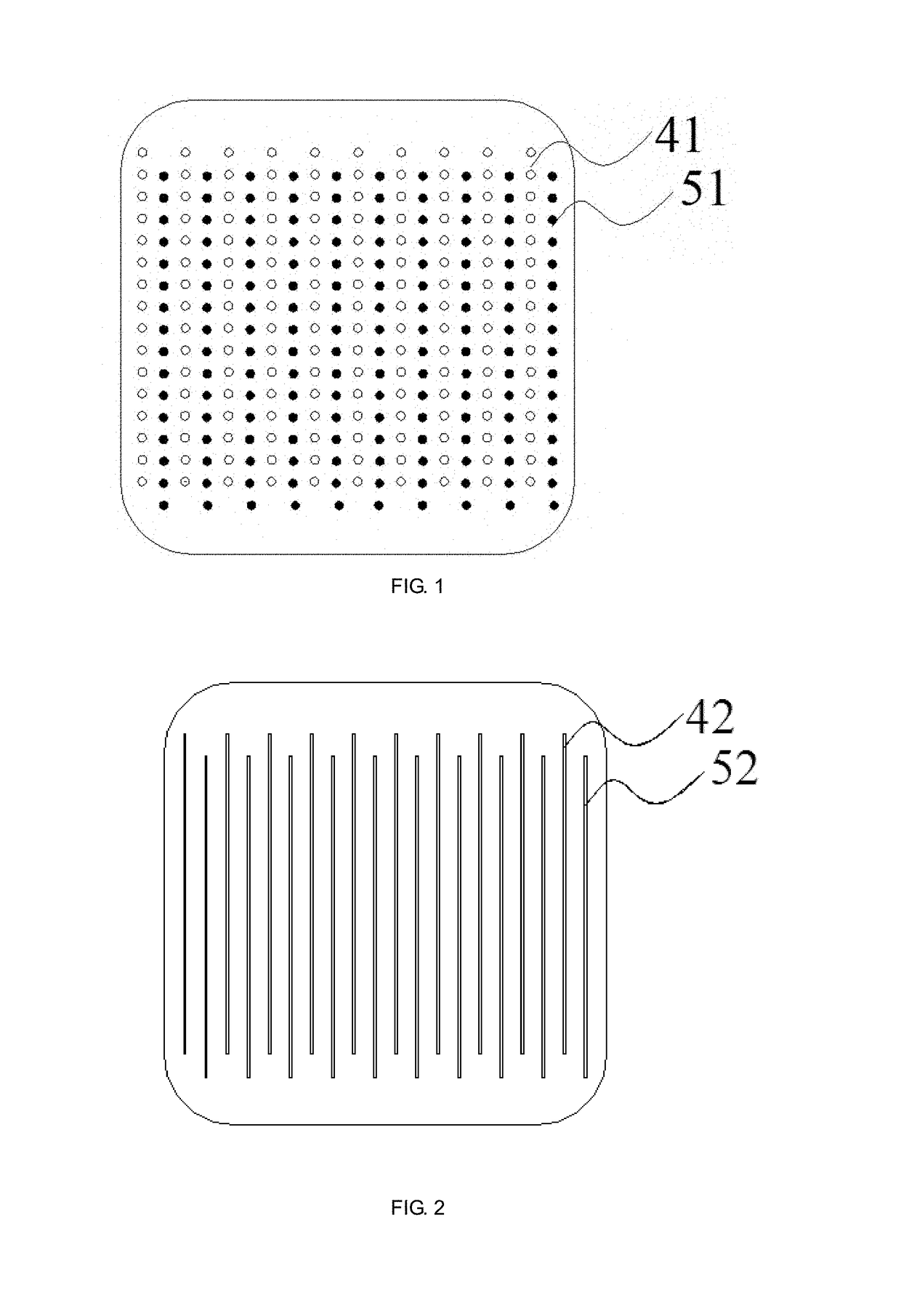

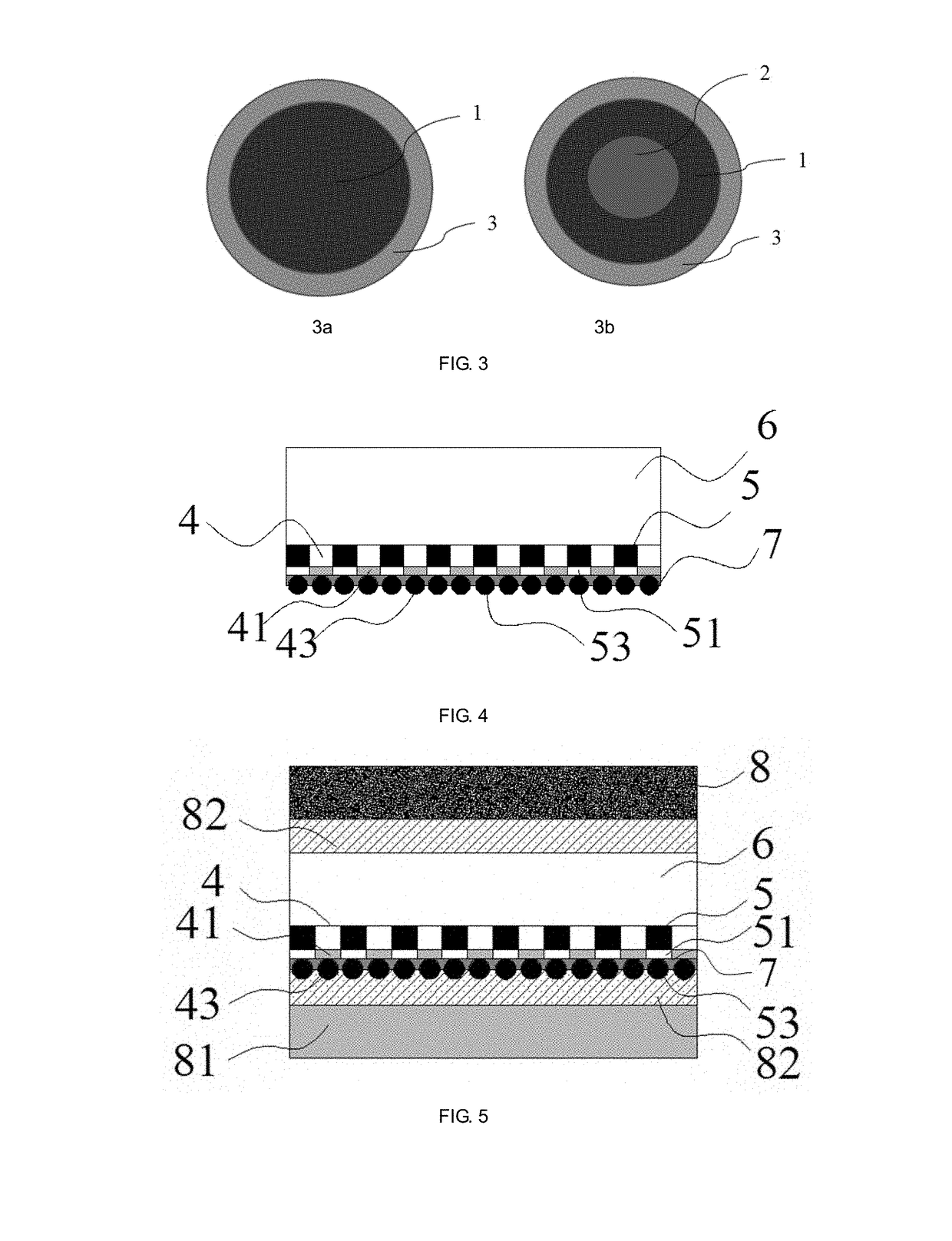

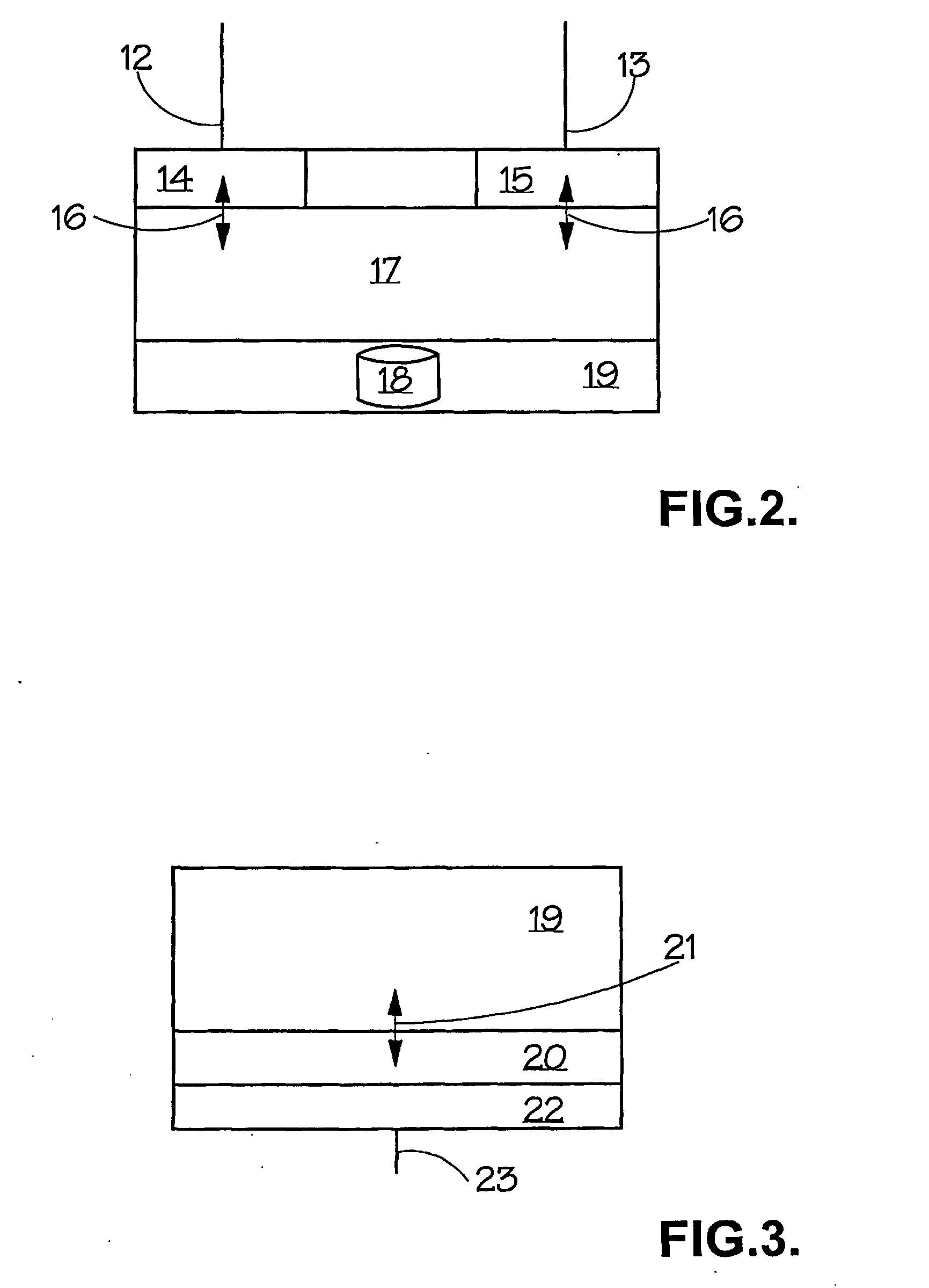

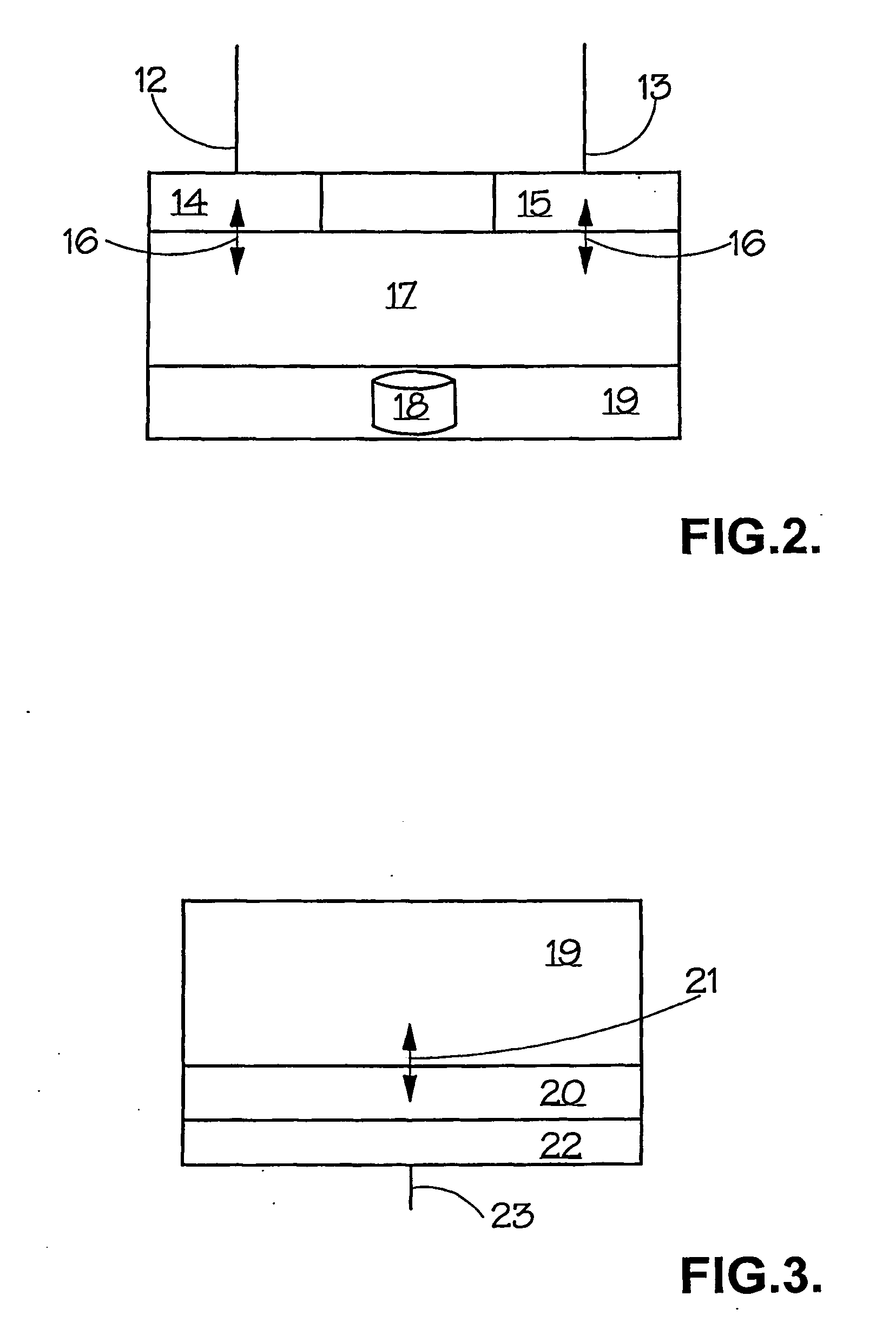

Main-gate-free and high-efficiency back-contact solar cell module, main-gate-free and high-efficiency back-contact solar cell assembly, and preparation process thereof

ActiveUS20170222082A1Reduces electron collection distanceReduced series resistanceFinal product manufacturePV power plantsElectricityCrack resistance

The present invention relates to the field of solar cells, and in particular to a main-gate-free and high-efficiency back-contact solar cell module, a main-gate-free and high-efficiency back-contact solar cell assembly, and a preparation process thereof. The solar cell module, comprising cells and an electrical connection layer, a backlight side of the cells having P-electrodes connected to a P-type doping layer and N-electrodes connected to a N-type doping layer, is characterized in that the electrical connection layer comprises a number of parallel leads each electrically connected to the P-electrodes or the N-electrodes. The present invention has the beneficial effect that a main-gate-free and high-efficiency back-contact solar cell module, a main-gate-free and high-efficiency back-contact solar cell assembly, and a preparation process thereof are provided, which can effectively the short-circuiting of the P-electrodes and the N-electrodes and has the advantages of low cost, high hidden-cracking resistance, high efficiency and high stability.

Owner:JOLYWOOD SUZHOU SUNWATT

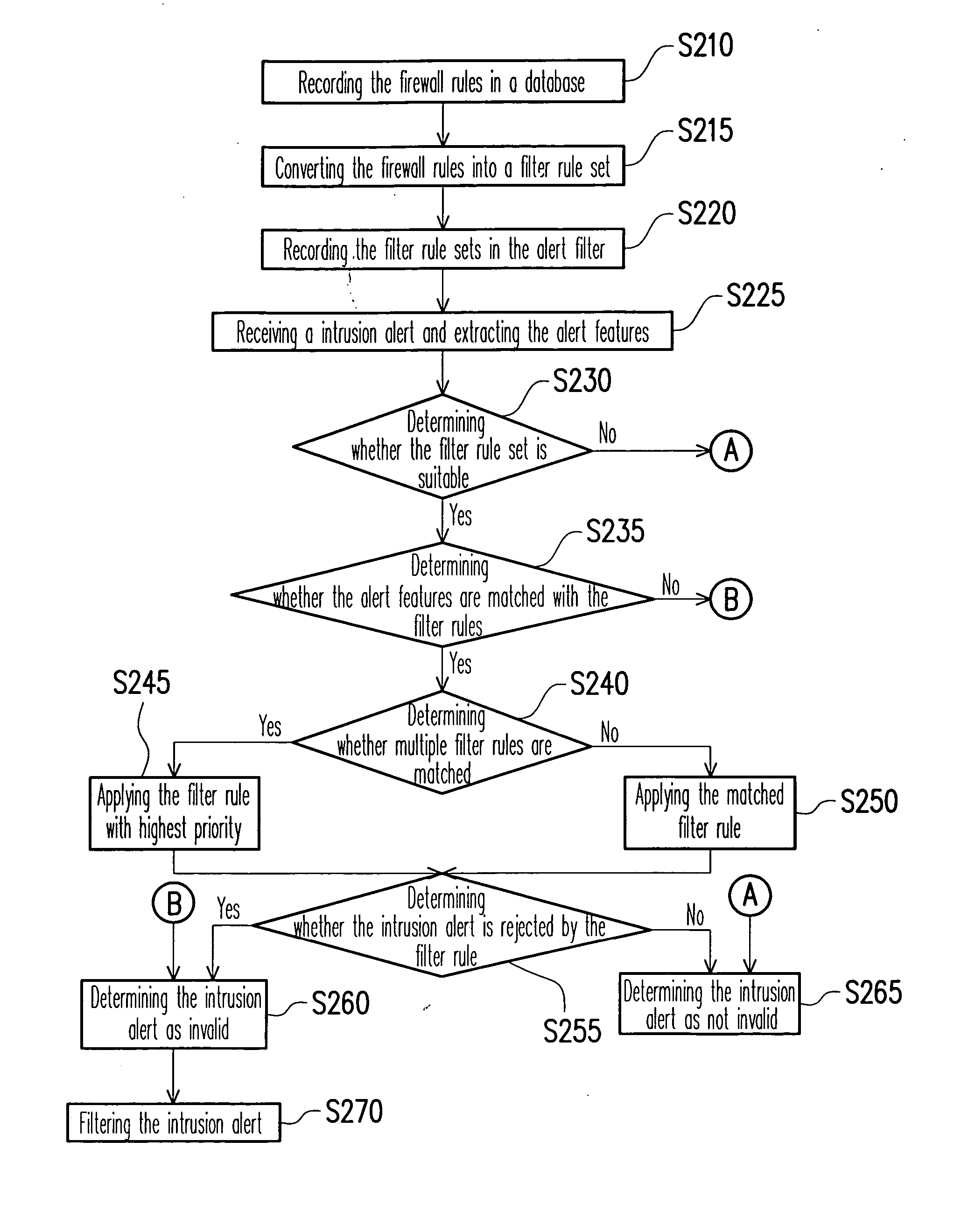

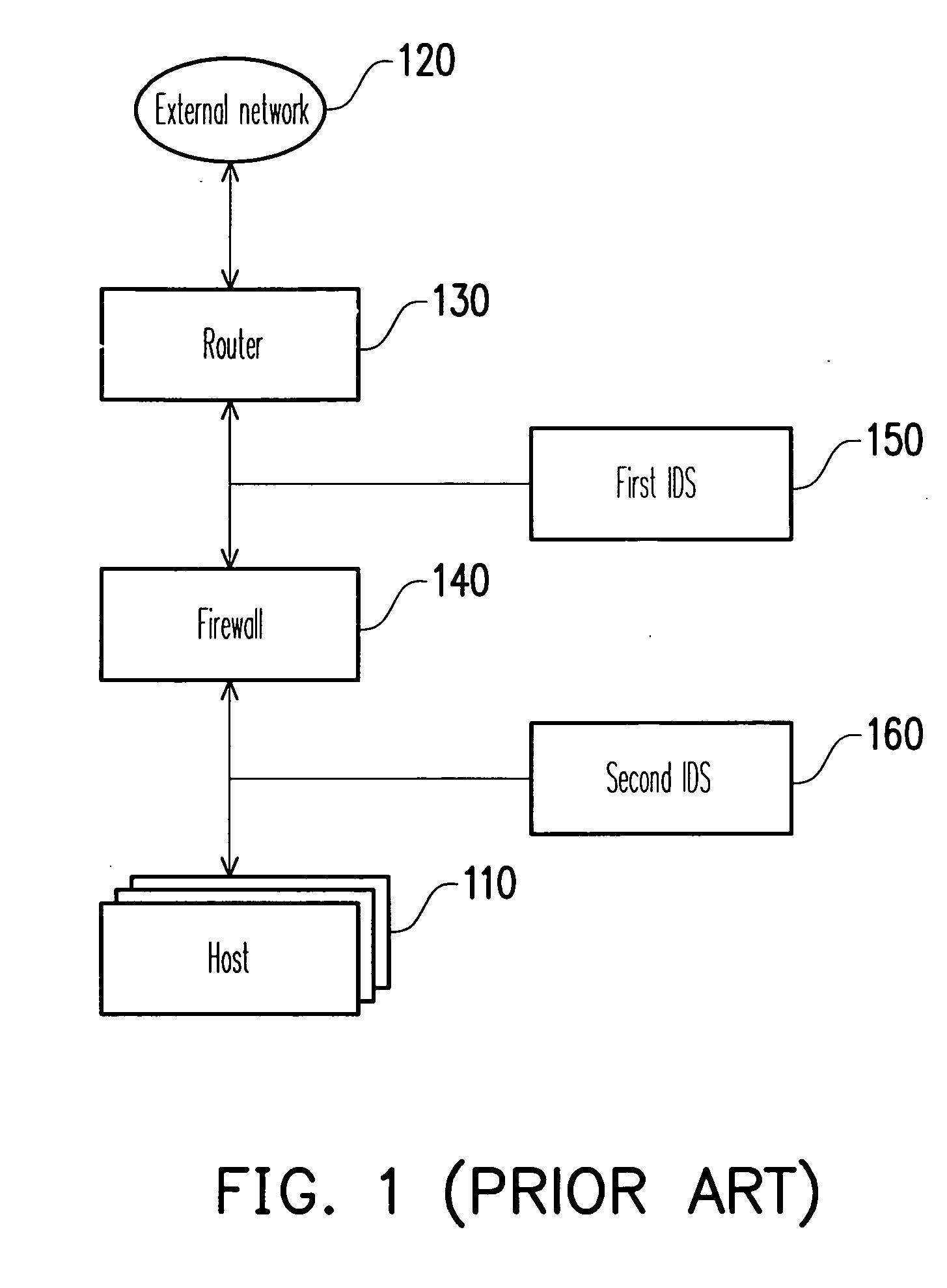

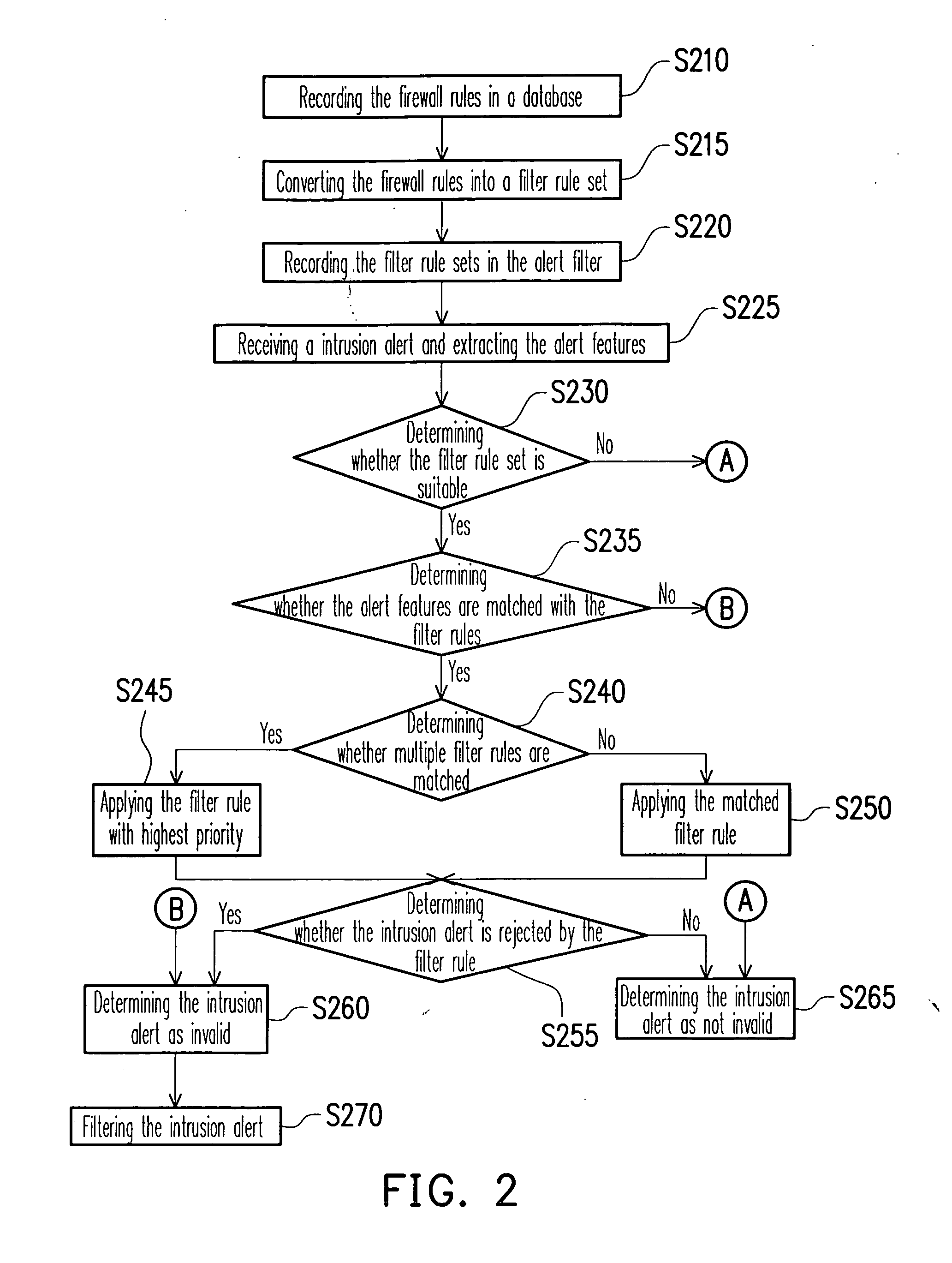

Method for eliminating invalid intrusion alerts

InactiveUS20070136813A1Avoid disadvantagesRapid deploymentMemory loss protectionError detection/correctionFiltering rulesComputer security

The method for eliminating invalid intrusion alerts operates according to a set of filter rules that are generated from given firewall rules. As a filter that implements this method receives an intrusion alert, it directly matches the features of the alert against its own rules, and then decides the validity of the alert. By coupling with the method, various filter-rule sets could be generated for numerous firewalls that may be not on the same specification, and an on-line deployment method could be applied to deploy filter-rule sets for filters. By applying the invention, it is reachable to eliminate invalid intrusion alerts precisely and efficiently, and to deploy quickly and with less manpower.

Owner:NAT CHUNG SHAN INST SCI & TECH

Systems and methods for classifying electronic information using advanced active learning techniques

ActiveUS8713023B1Review processEasy to transportDigital data processing detailsRelational databasesElectronic discoveryEngineering

Owner:CORMACK GORDON VILLY +1

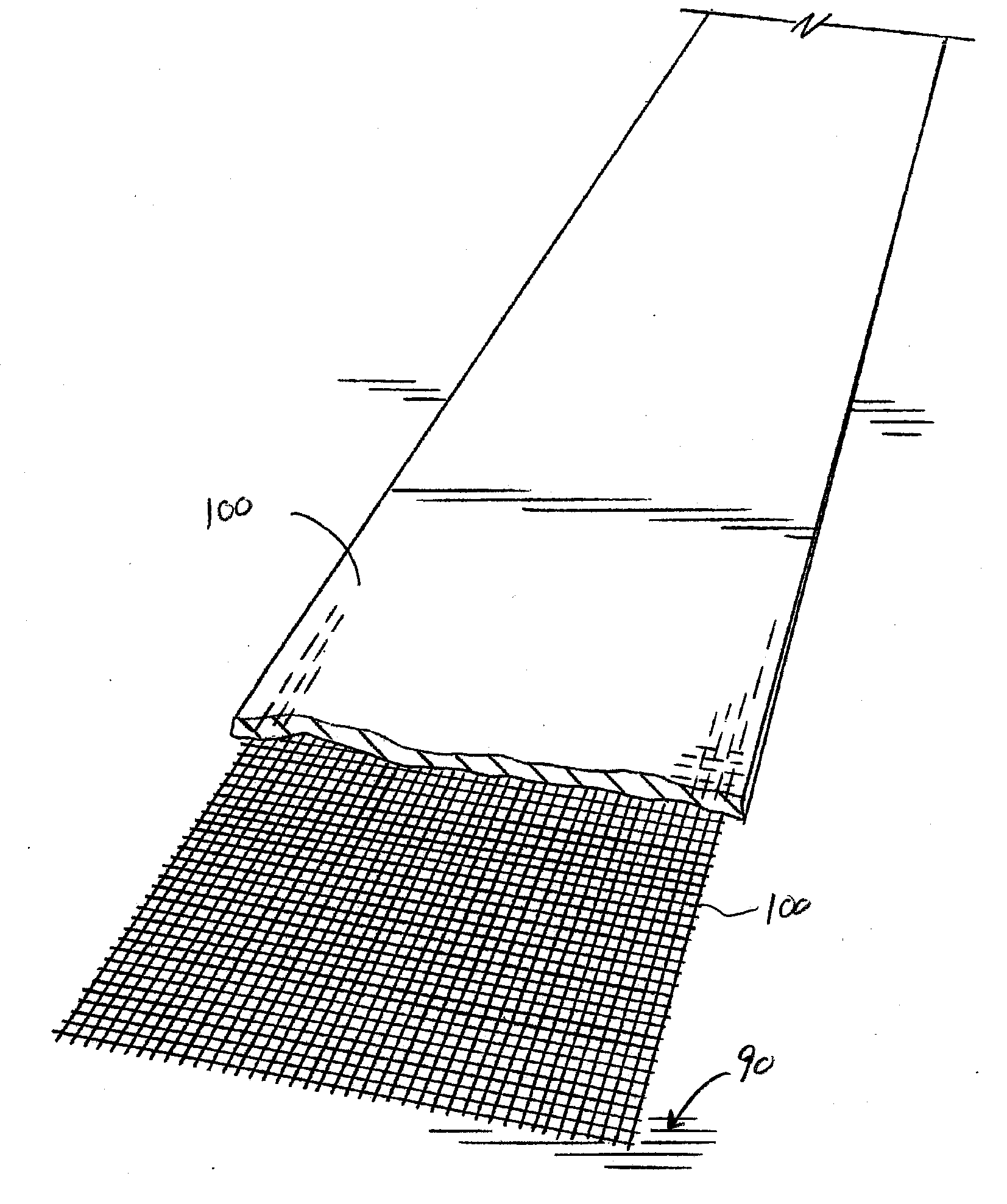

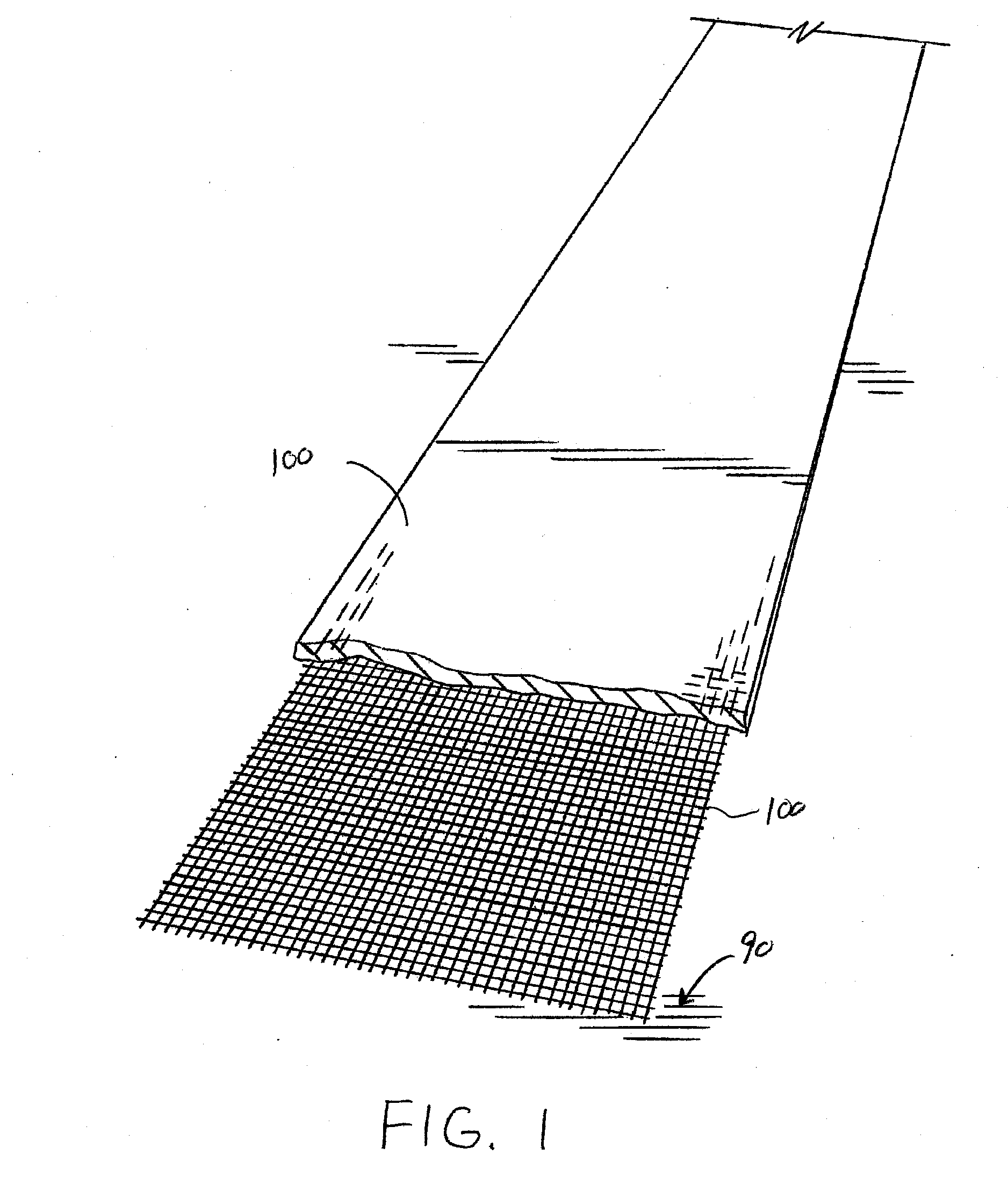

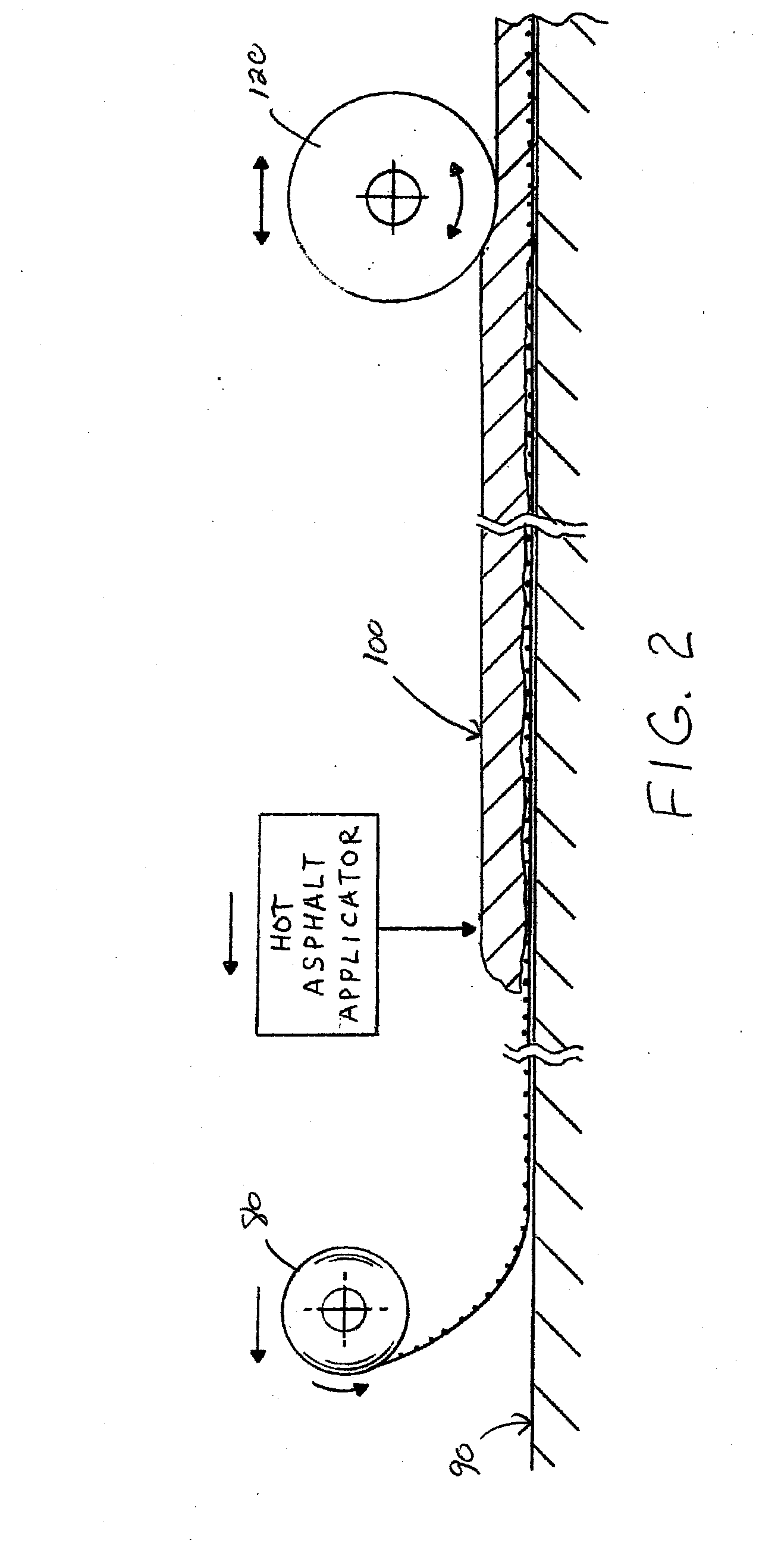

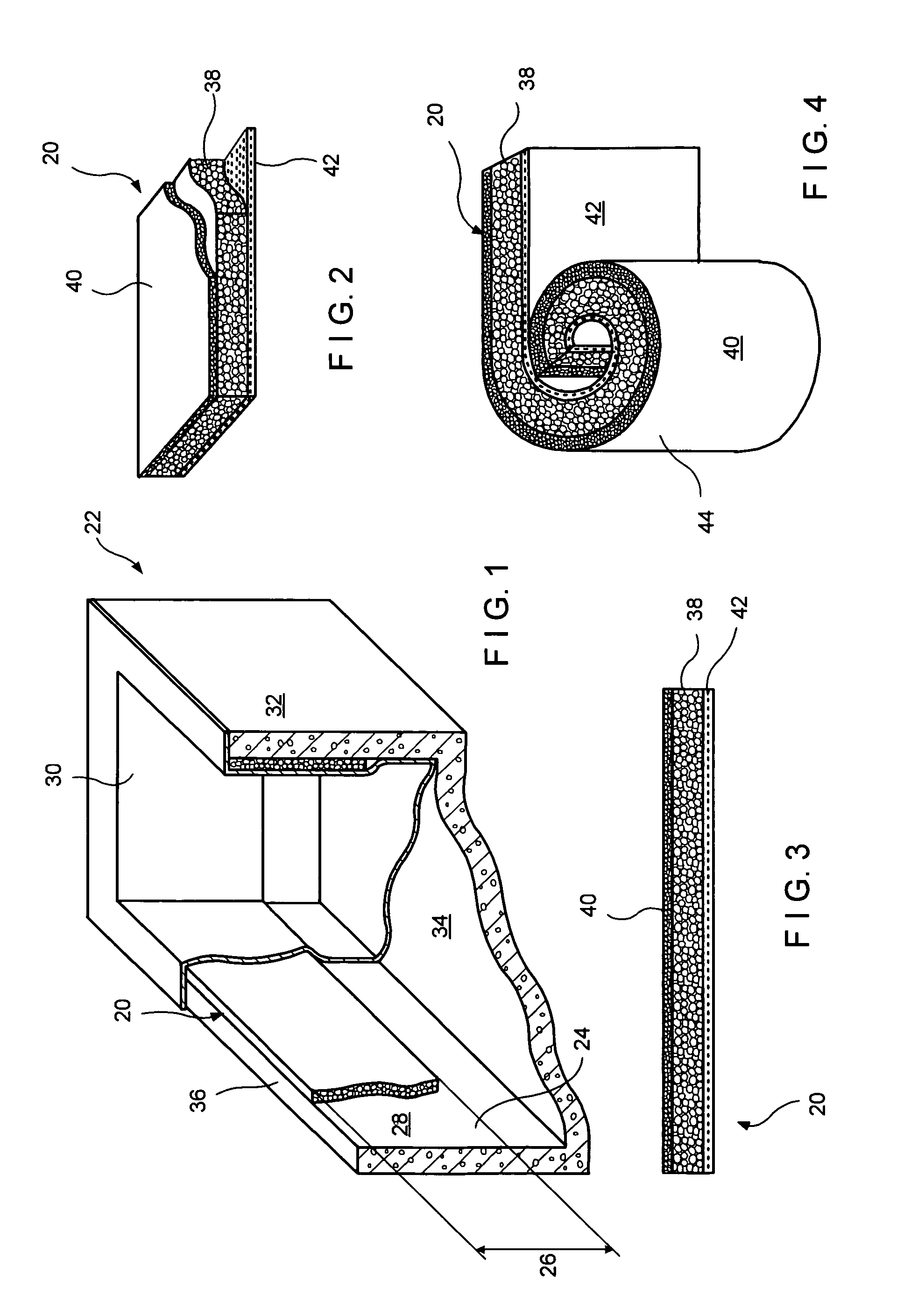

Reinforced fiber mats for use in paved surfaces

InactiveUS20130156501A1Easy to shapeGood for scrollingIn situ pavingsMedical patchesFiberEngineering

A reinforcement mat that can be used to improve the durability and life of an asphalt paved surface. The reinforcement mat is partially or fully coated with a resin. The resin generally has a cure temperature in excess of about 140° F.

Owner:HEMPHILL WILLIAM SCOTT

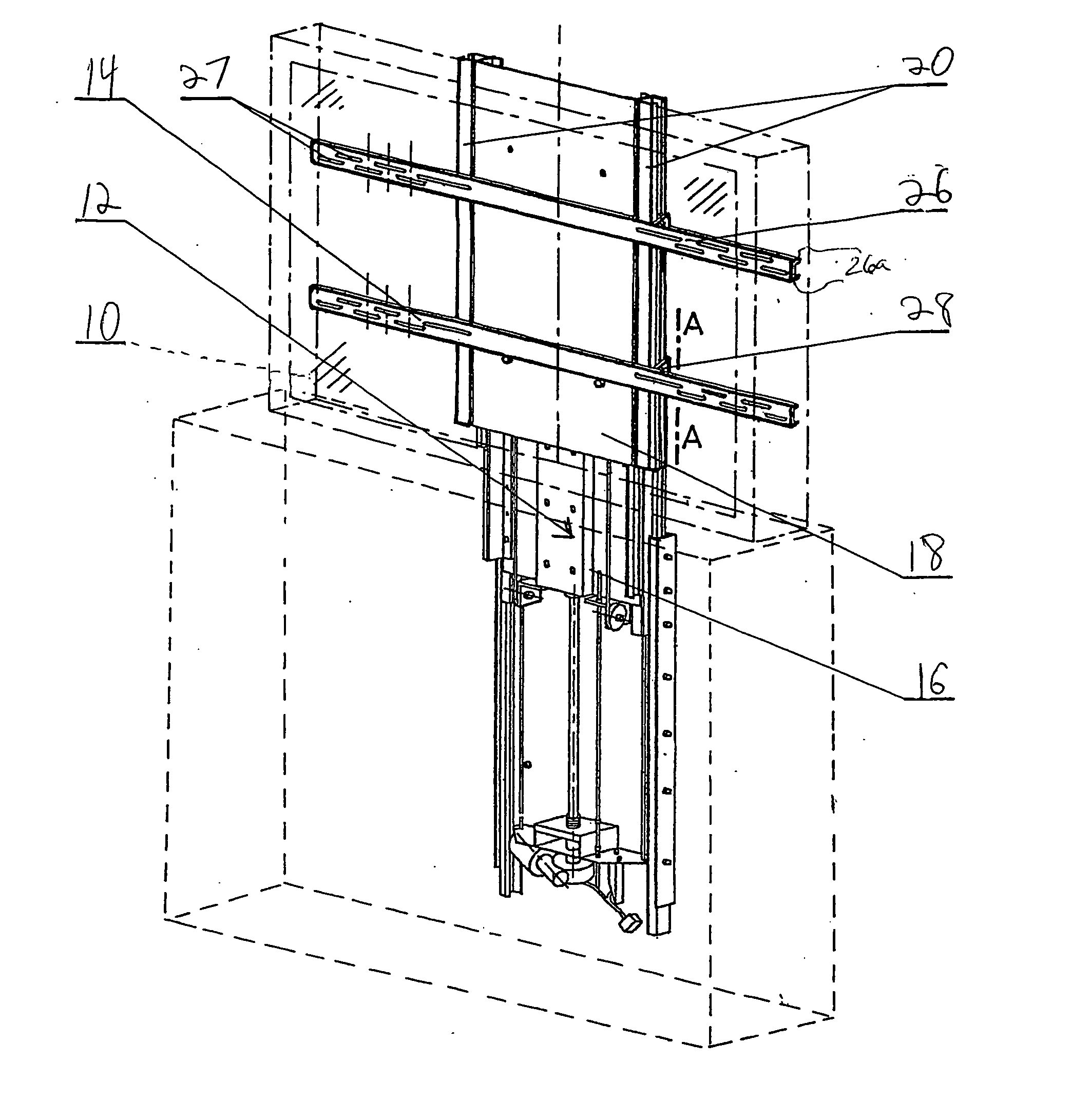

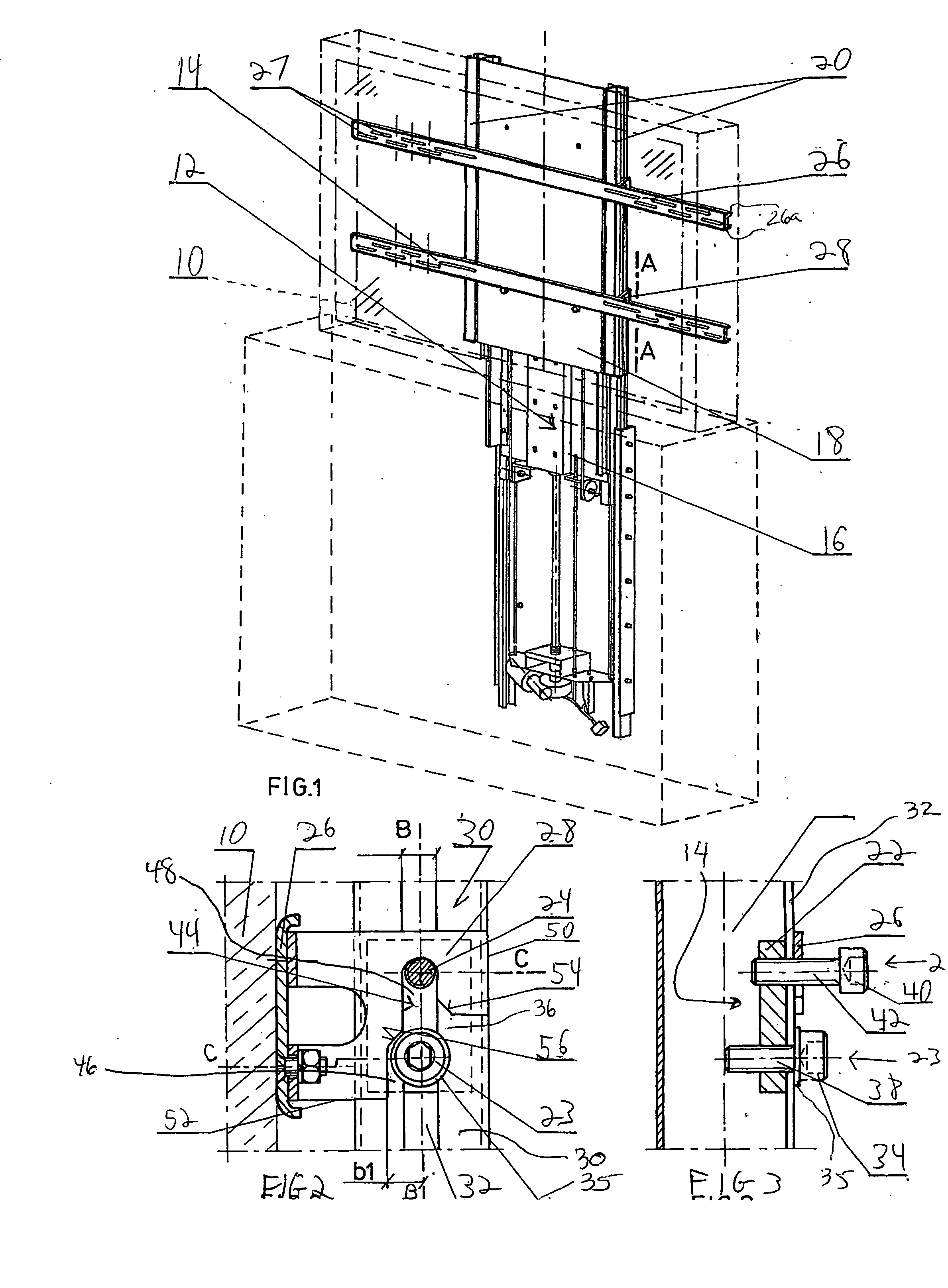

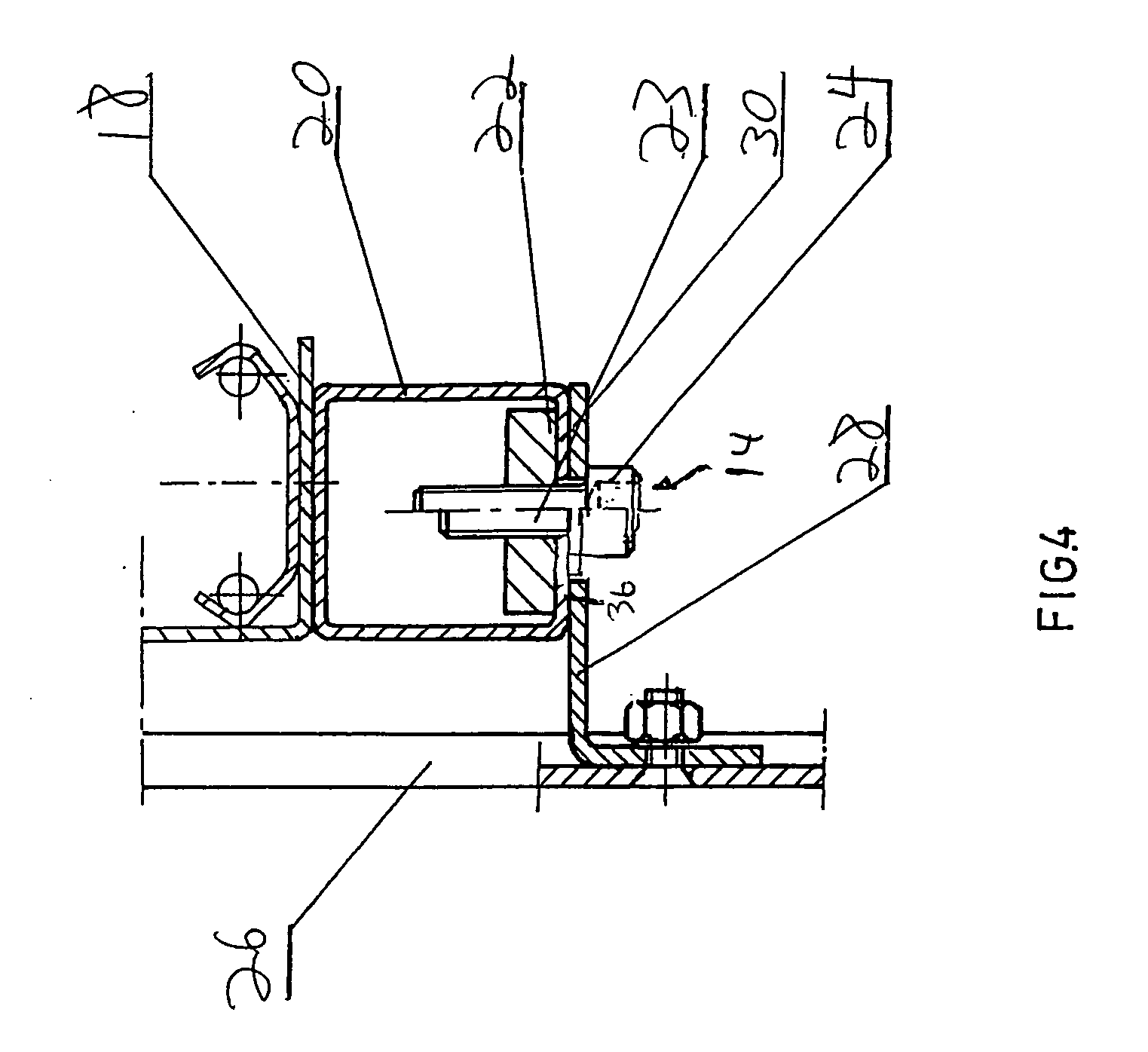

Apparatus for mounting a flat screen display device to a lift mechanism

InactiveUS20070152112A1Continuous adjustabilityEasy to installCabinetsStands/trestlesDisplay deviceEngineering

A mounting apparatus for affixing a flat screen display device to a vertical lift mechanism having vertical guide members situated at the lateral sides of a lift including at least one pair of mounting members, at least one pair of hanging members, at least one elongate support member, and at least one pair of bracket members. Each mounting member of the pair is affixed to a respective one of the pair of vertical tubular members at an adjustable position thereon in substantially horizontal alignment with the other mounting member of the pair. Each hanging member of the pair is affixed to a respective one of the mounting members. The at least one elongate support member is adapted for connection to mounting components at the rear of the flat screen display device and structured and arranged to extend substantially horizontally when the display device is mounted to the tubular members of the lift mechanism. The at least one pair of bracket members are affixed in spaced relationship to the at least one support member and each bracket member of a pair is structured and arranged to receive a respective one of the pair of hanging members.

Owner:BOBER WIESLAW

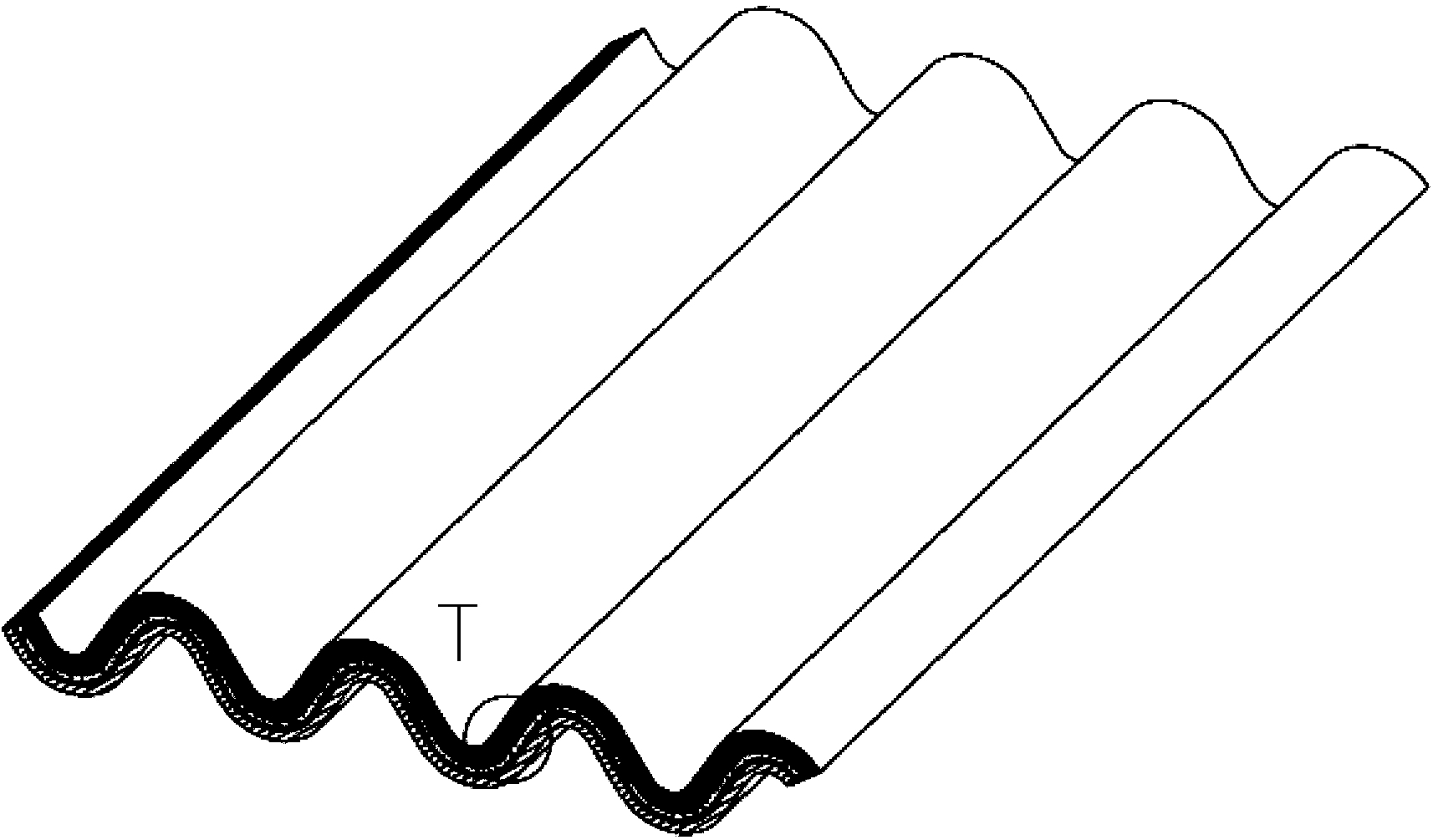

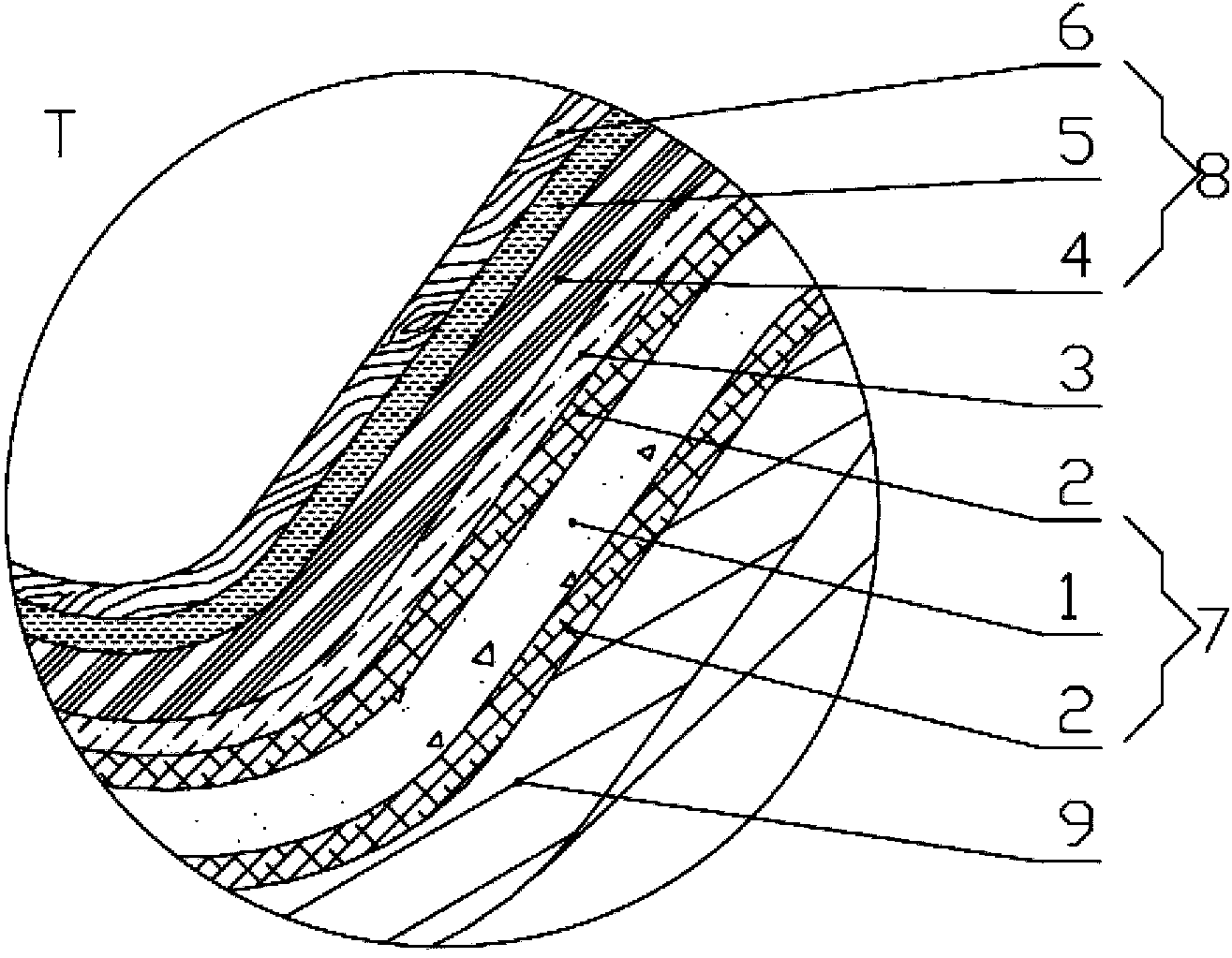

Thermal-insulation photovoltaic tile and producing method thereof

ActiveCN103410279AGood heat insulationReduce thicknessRoof covering using slabs/sheetsRoof covering using tiles/slatesRoof tileThermal insulation

The invention discloses a thermal-insulation photovoltaic tile. The thermal-insulation photovoltaic tile is characterized by being composed of a flexible thermal-insulation substrate and a flexible photovoltaic cell component which is bound on the flexible thermal-insulation substrate through an inflaming retardant polymer binder. The flexible thermal-insulation substrate is a nano silicon dioxide aerogel felt core material with two sides covered with flexible water-proof sheets. The flexible photovoltaic cell component comprises a flexible thin-film cell component, a film layer and a coating layer from the interior to the exterior successively. The flexible water-proof sheets are in layer structures, and each comprises a lower inflaming retardant polymer cement mortar layer, a high-tenacity glass fiber reinforced inflaming retardant non-woven fabric padding and an upper inflaming retardant polymer cement mortar layer from the bottom to the top successively, and the three layers of structures are integrally consolidated. According to the thermal-insulation photovoltaic tile, the flexible substrate which is water proof and impervious, fire proof and inflaming retardant, anti-crack and impact resistant, thermal insulating and light and thin is combined with the amorphous silicon flexible thin-film solar photovoltaic cell component to form the photovoltaic roof tile which can be fire proof and water proof and thermal insulation and can perform photovoltaic power generation.

Owner:金玛环保科技有限公司

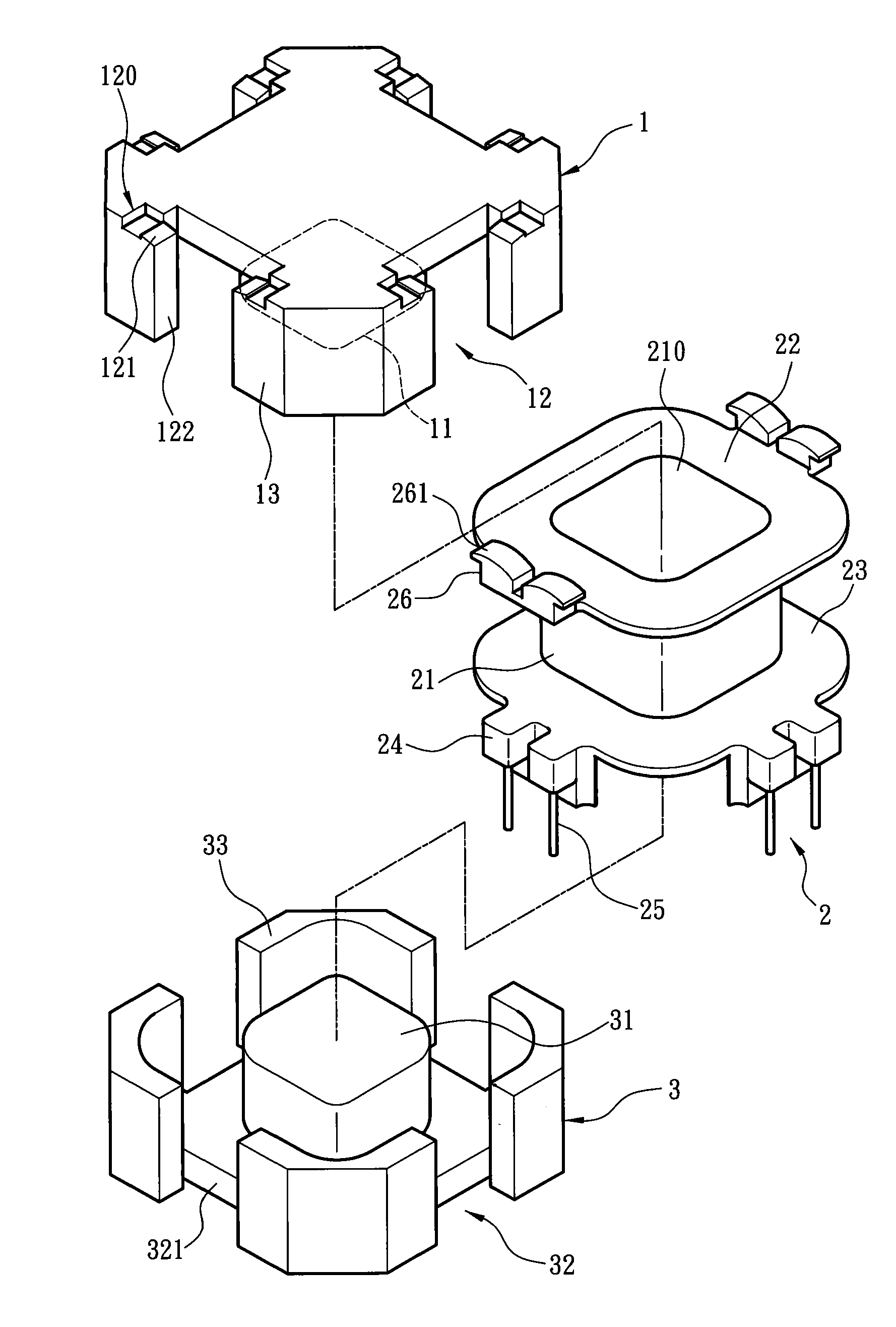

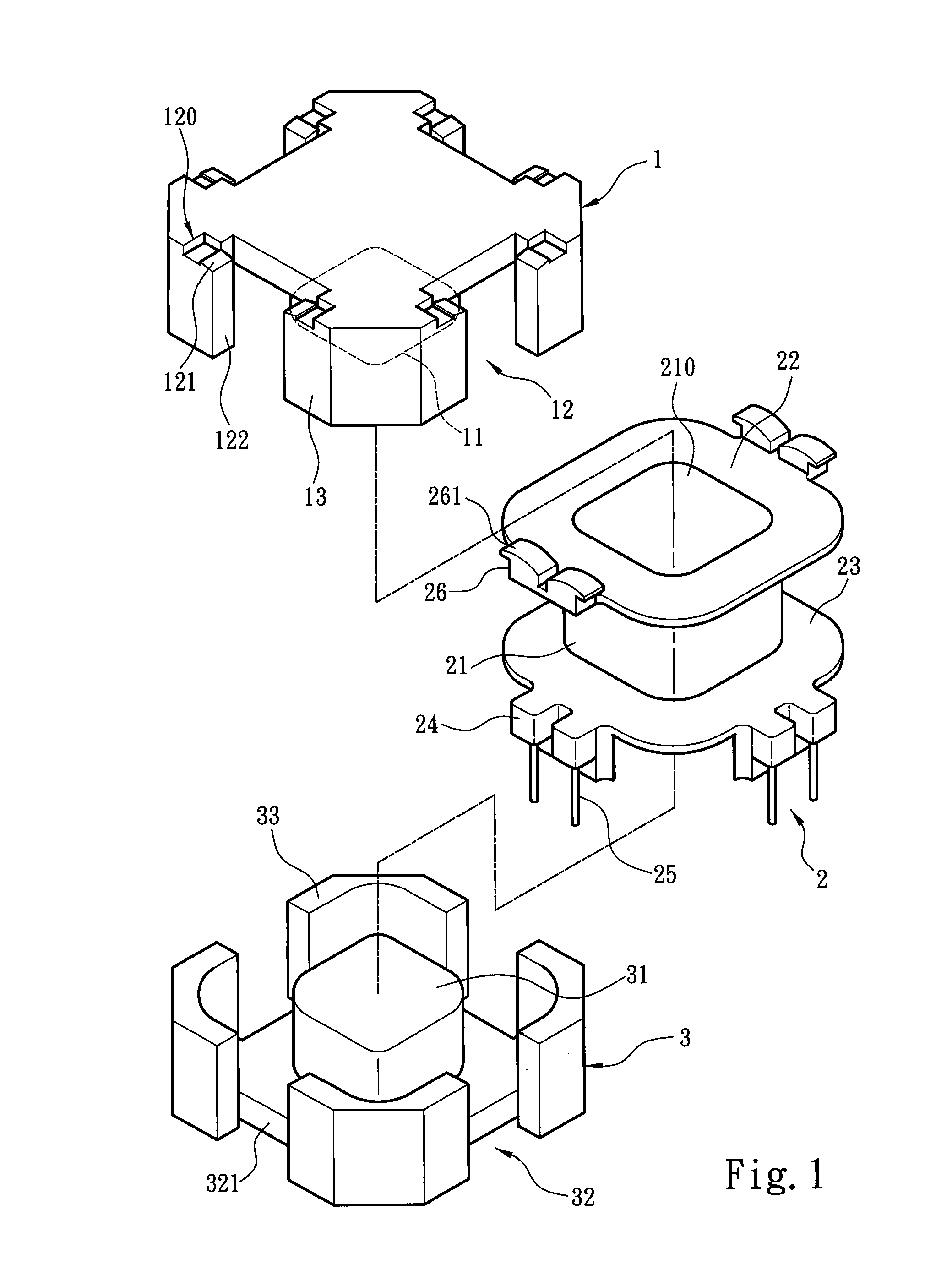

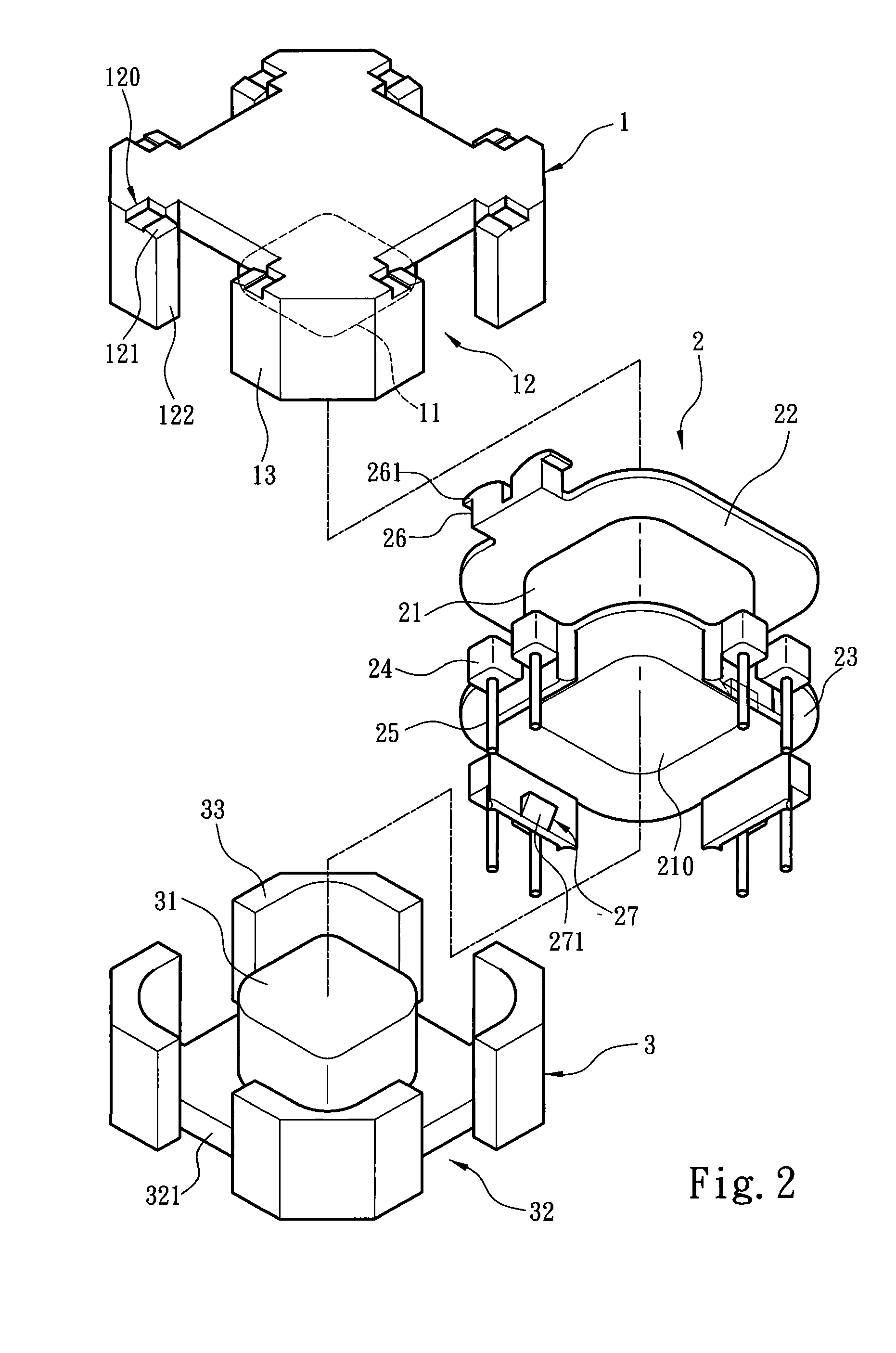

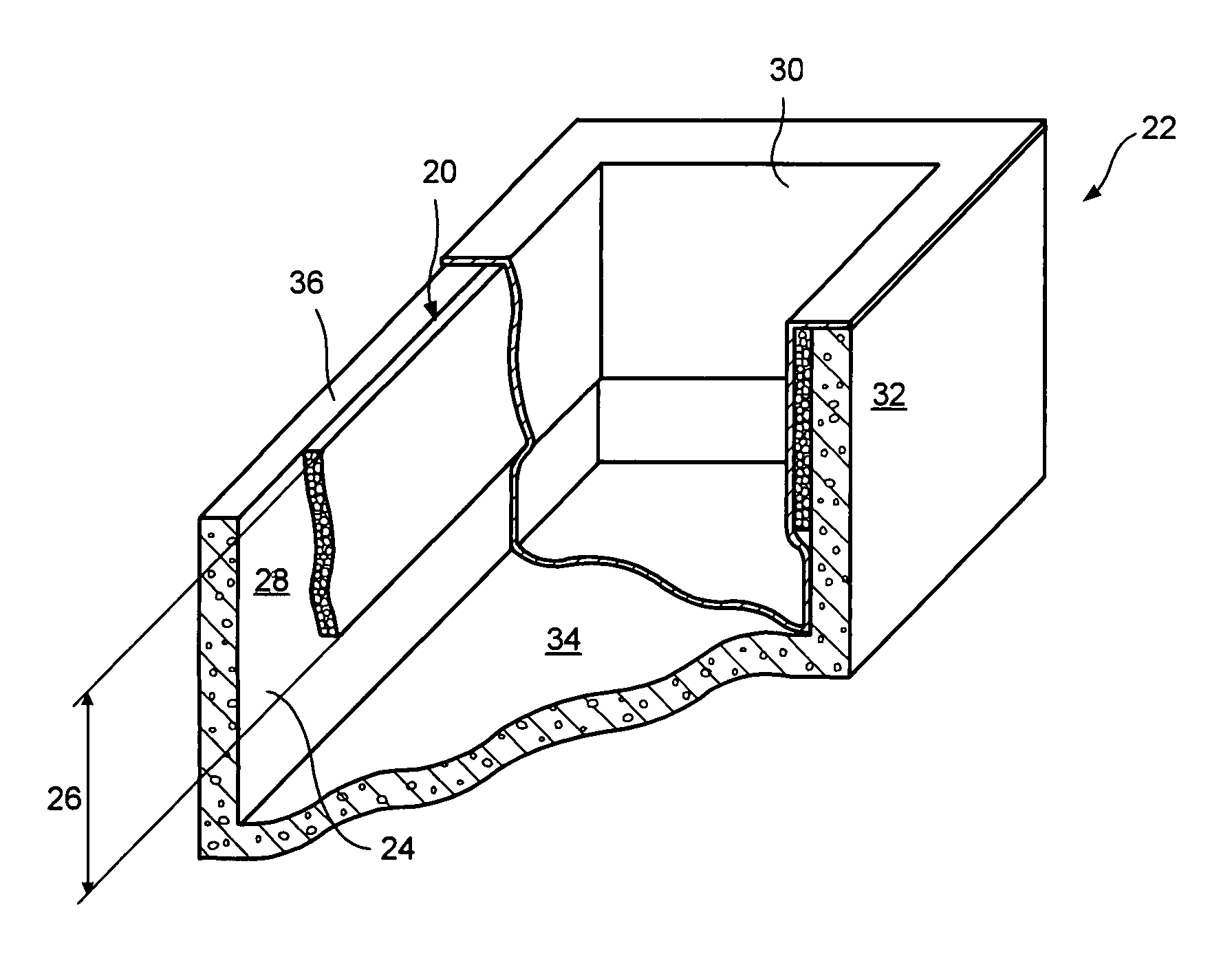

Tightly coupled iron core set and winding rack

InactiveUS20110241815A1Maintain standardEasy to assembleTransformers/inductances coils/windings/connectionsBobbinEngineering

A tightly coupled iron core set and winding rack structure includes a winding rack and an iron core set. The winding rack includes a hollow bobbin, a first partition board and a second partition board extended radially from openings at two ends of the bobbin, and a plurality of pin sections located on the second partition board. The first and second partition boards have respectively at least one latch portion. The iron core set includes a core running through the bobbin and a plurality of latch notches coupled with the latch portions to hold the iron core set on the winding rack. Thus the iron core set can be directly latched on the winding rack to form coupling without using extra bonding or latching tools.

Owner:INNOTRANS TECH

Foam interlining device for swimming pools

ActiveUS8028353B1Economical and easy to installEasy to packFilm/foil adhesivesBathsInterliningMarine engineering

A foam interlining device for swimming pools with pressure activated adhesive is shown. The device is disposed between the pool liner and the swimming pool backup wall. The interlining is also constructed with both a mounting adhesive and a self-sealing coating. The self-sealing coating seals minor punctures and tears of the pool liner. In one embodiment, the edge of the interlining also functions as an expansion joint between a deck and the swimming pool coping and as an underlayment or sill seal for the coping. The interlining device is also shown premounted on the backup-wall-side of the pool liner.

Owner:HOHMANN & BARNARD INC

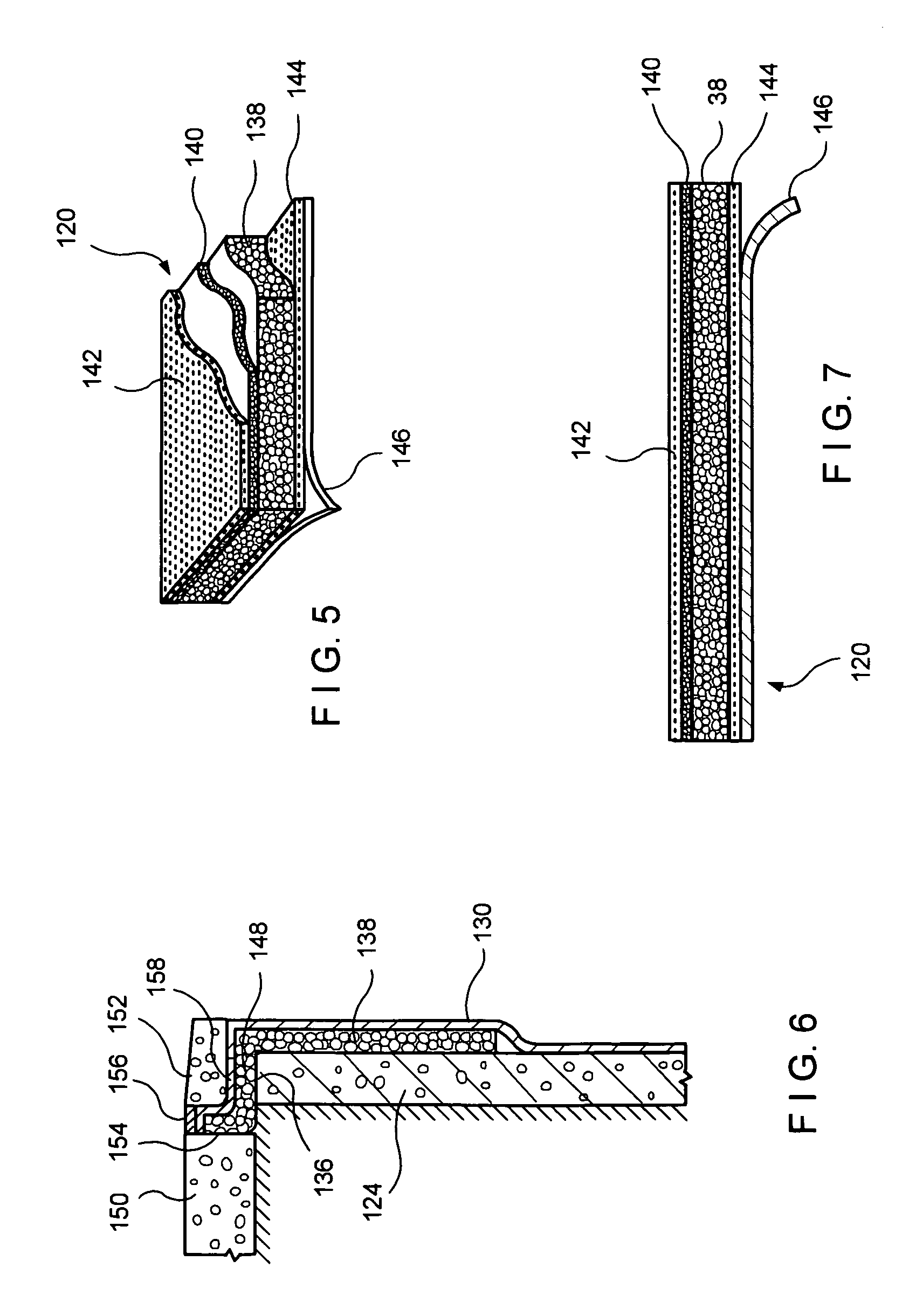

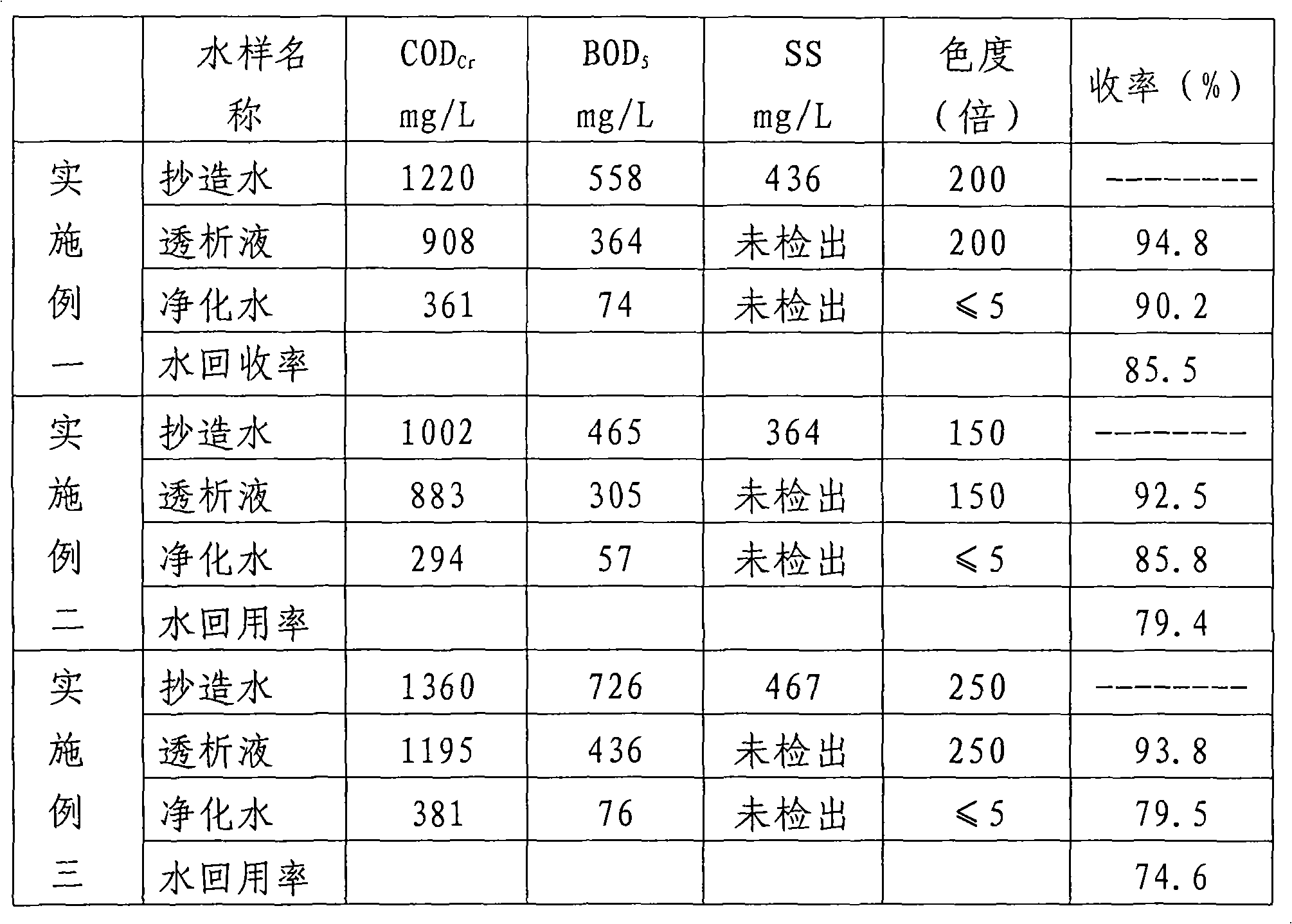

Treating method of paper-making water recycling use in the production process of reconstituted tobacco

ActiveCN101805077AIncreased protectionReduce consumptionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFiberUltrafiltration

The invention relates to a treating method of paper-making water recycling use in the production process of reconstituted tobacco, aiming at solving the problems that the massive discharge of treated water in the prior art causes pollution to the environment as well as low utilization ratio of water for production and large new-water consumption. The technical key points are characterized by carrying out fiber recovery on the paper-making water, then carrying out sedimentation, leading supernatant overflowing liquid after sedimentation into an ultrafiltration membrane separating system for separation, obtaining dislysate and concentrate, leading the dislysate into a reverse osmosis membrane system for separation again, obtaining purified water and concentrated water; the purified water is reused for water in the production process after treatment of removing off-odor, the recovered fiber is reused into the production process, the sediment is used as solid waste, the concentrate and the concentrated water are treated properly, the ultrafiltration membrane separating system adopts an ultrafiltration membrane with the bore diameter of 10-200nm, the pressure is 0.1-0.5MPa, the temperature of the feed liquid is 10-70 DEG C, the speed of the membrane surface is 2-8m / s, the pressure of the reverse osmosis membrane system is 1.0-10MPa, the temperature of the feed liquid is 20-45 DEG C, and the speed of the membrane surface is 2-7m / s.

Owner:GUANGDONG JINKE REFORGING TOBACCO LEAF CO LTD

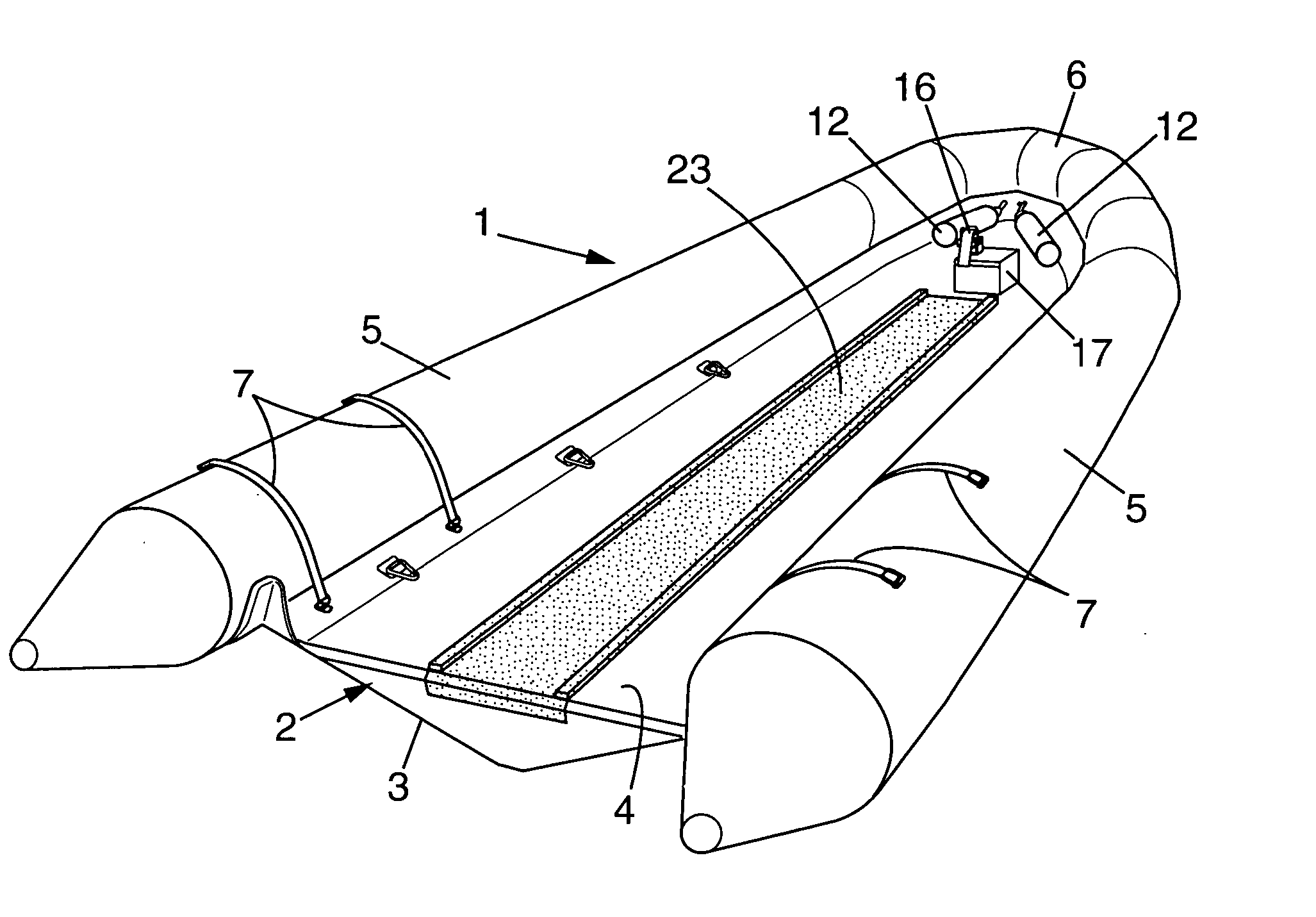

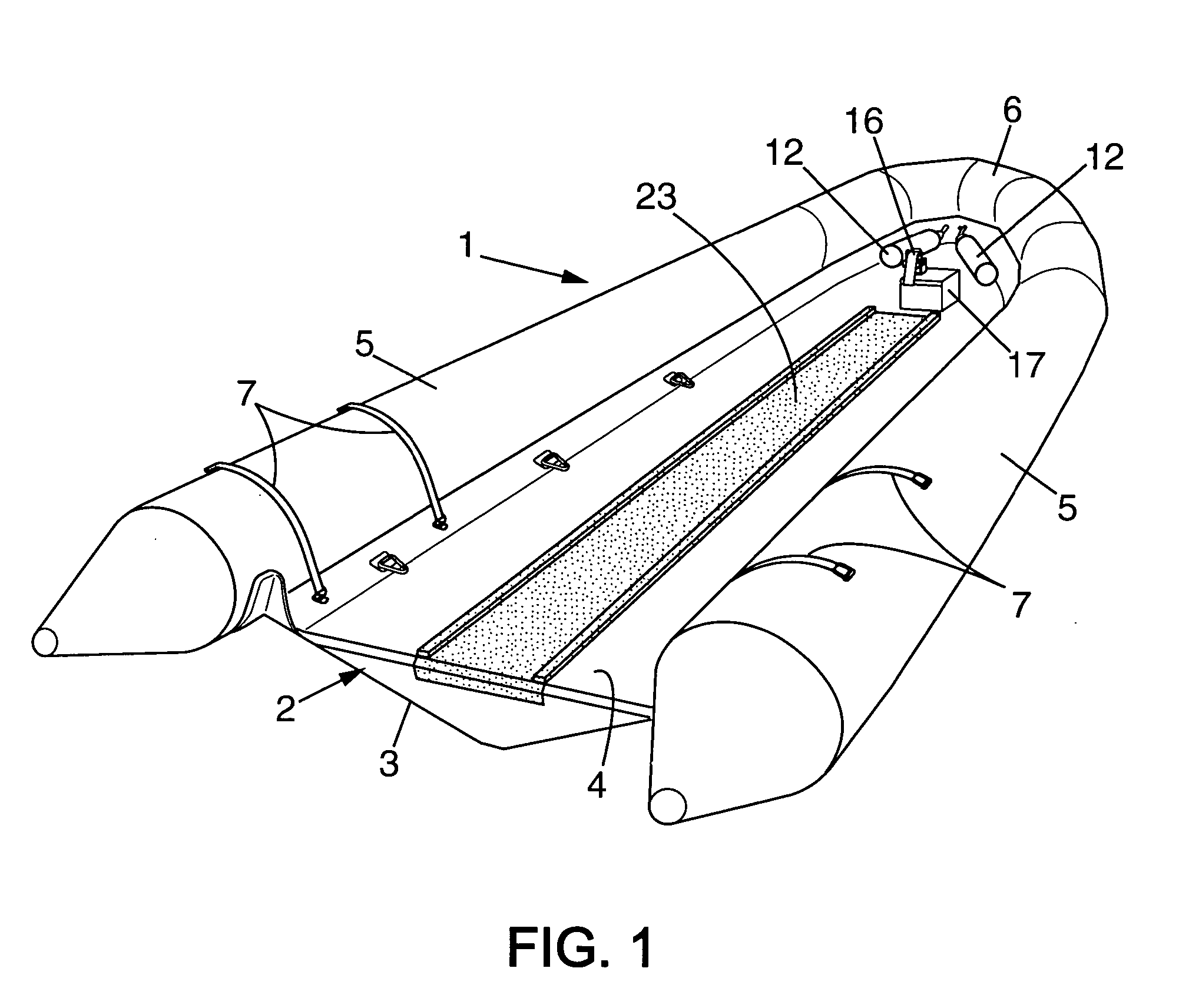

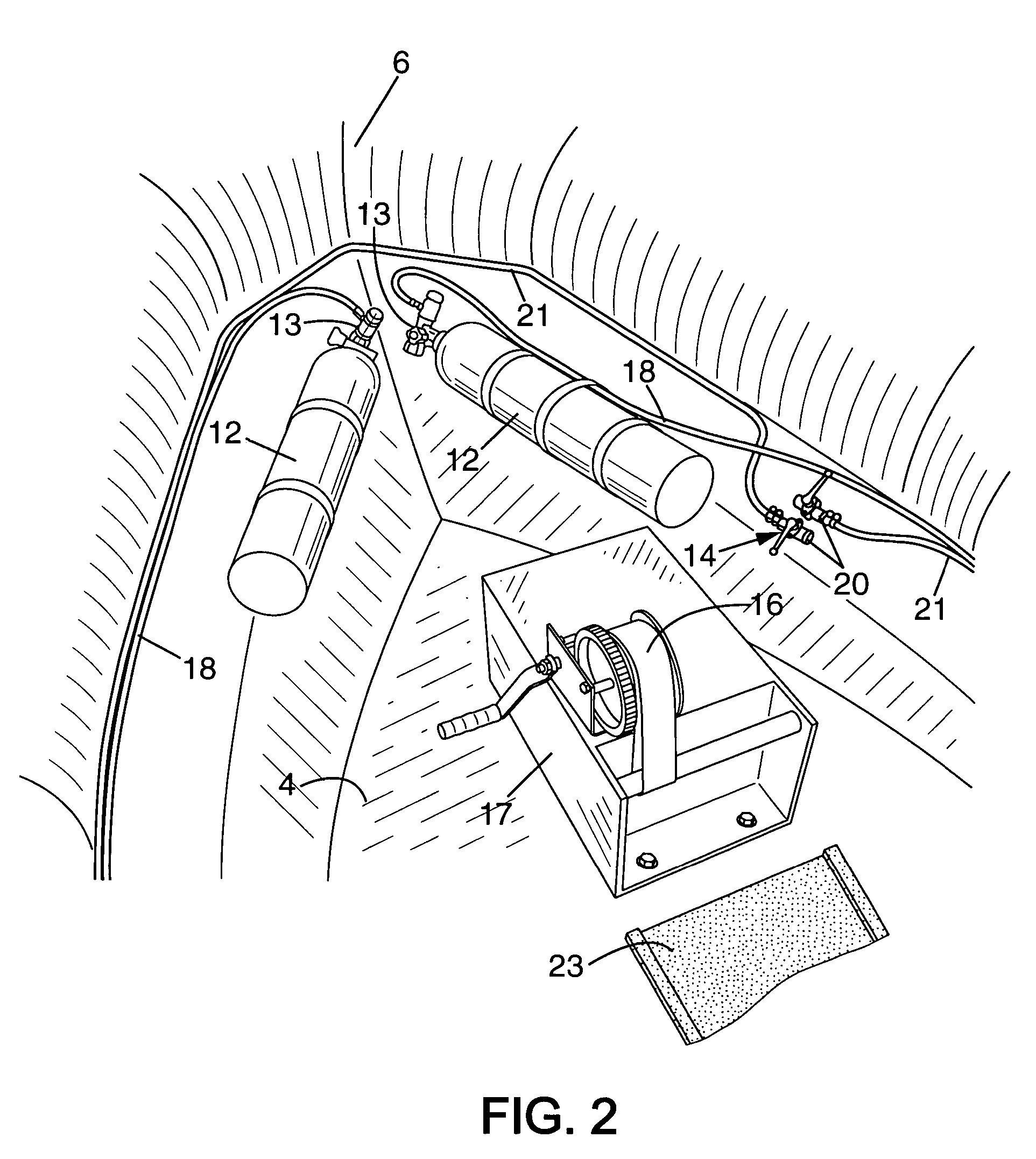

Pneumatic boat arranged for the loading/unloading and transportation of floating loads

ActiveUS20050126467A1Reduce manufacturing costLess manpowerCargo handling apparatusSelf-bailing equipments/scuppersMarine engineeringBallast

A semi-rigid pneumatic boat (1) comprising: a rigid hull (2) defined by a rigid underwater hull (3) closed on the top by a rigid floor (4) and bordered on two sides by two pneumatic floats (5); a ballast (8) arranged in the rear part of the rigid hull (2) and pumping means for filling it with water or emptying it thereof; two pneumatic chambers (10) defined in the respective rear parts of the two floats (5) and pneumatically isolated from the rest of the floats; means (12, 13) for inflating and means (14) for deflating the rear chambers; the boat having no rear board; thus, by filling the ballast (8) and by deflating the rear chambers (10) the boat is nosed up, with its rear part submerged and a load (25) may be brought closer, against the floor (4), and then by emptying the ballast and re-inflating the chambers (10) the boat is set afloat, supporting the load (25).

Owner:ZODIAC MILPRO INT

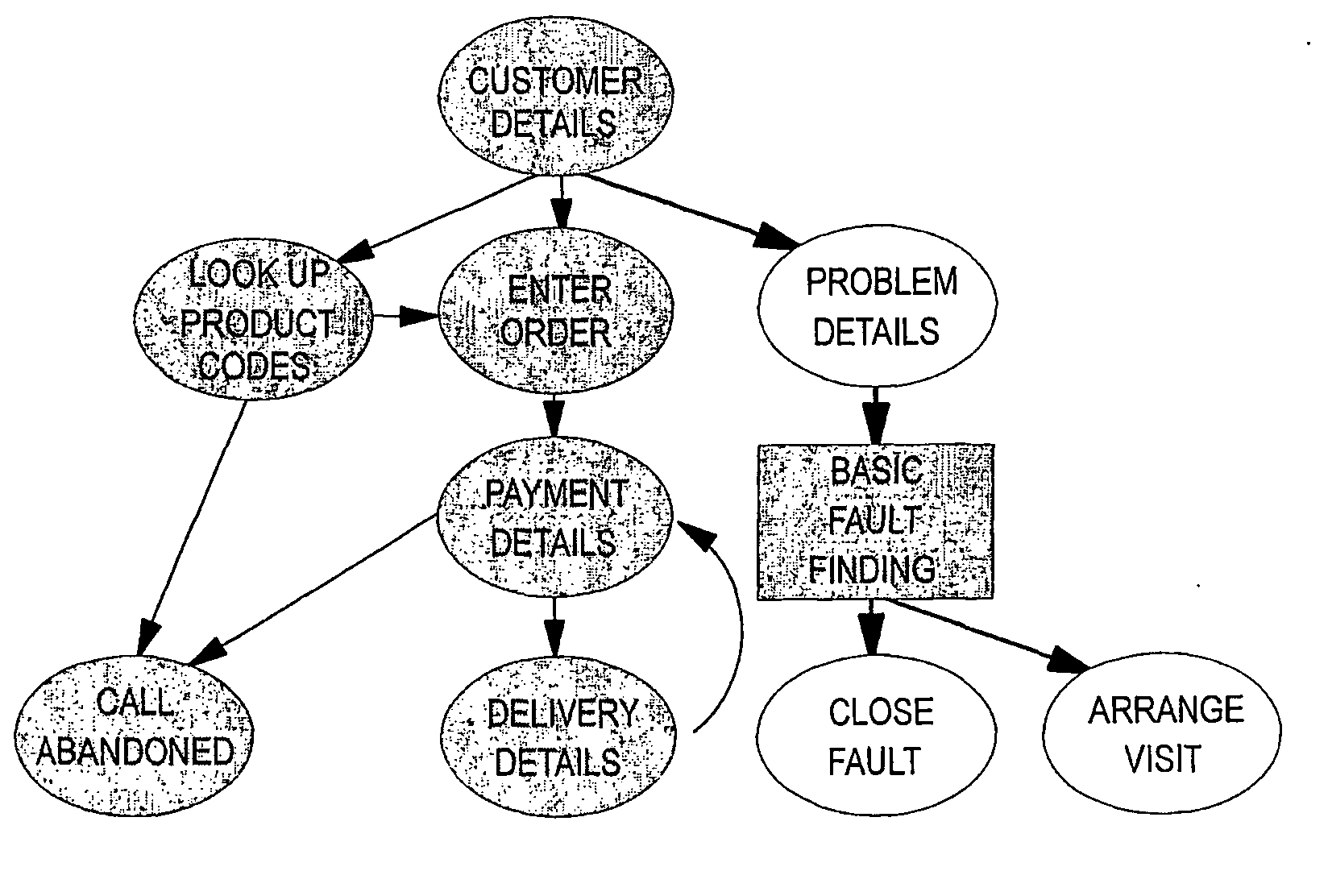

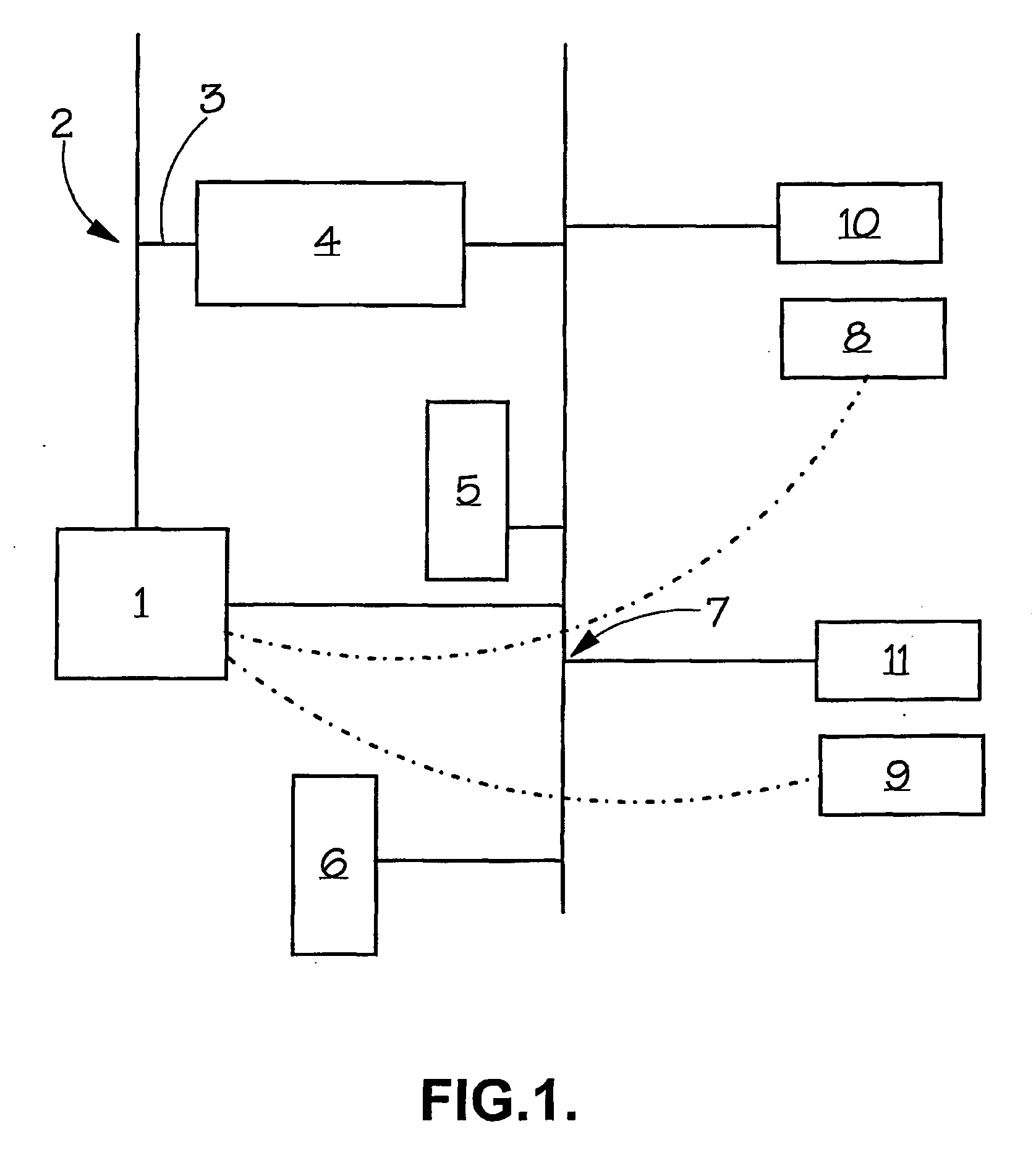

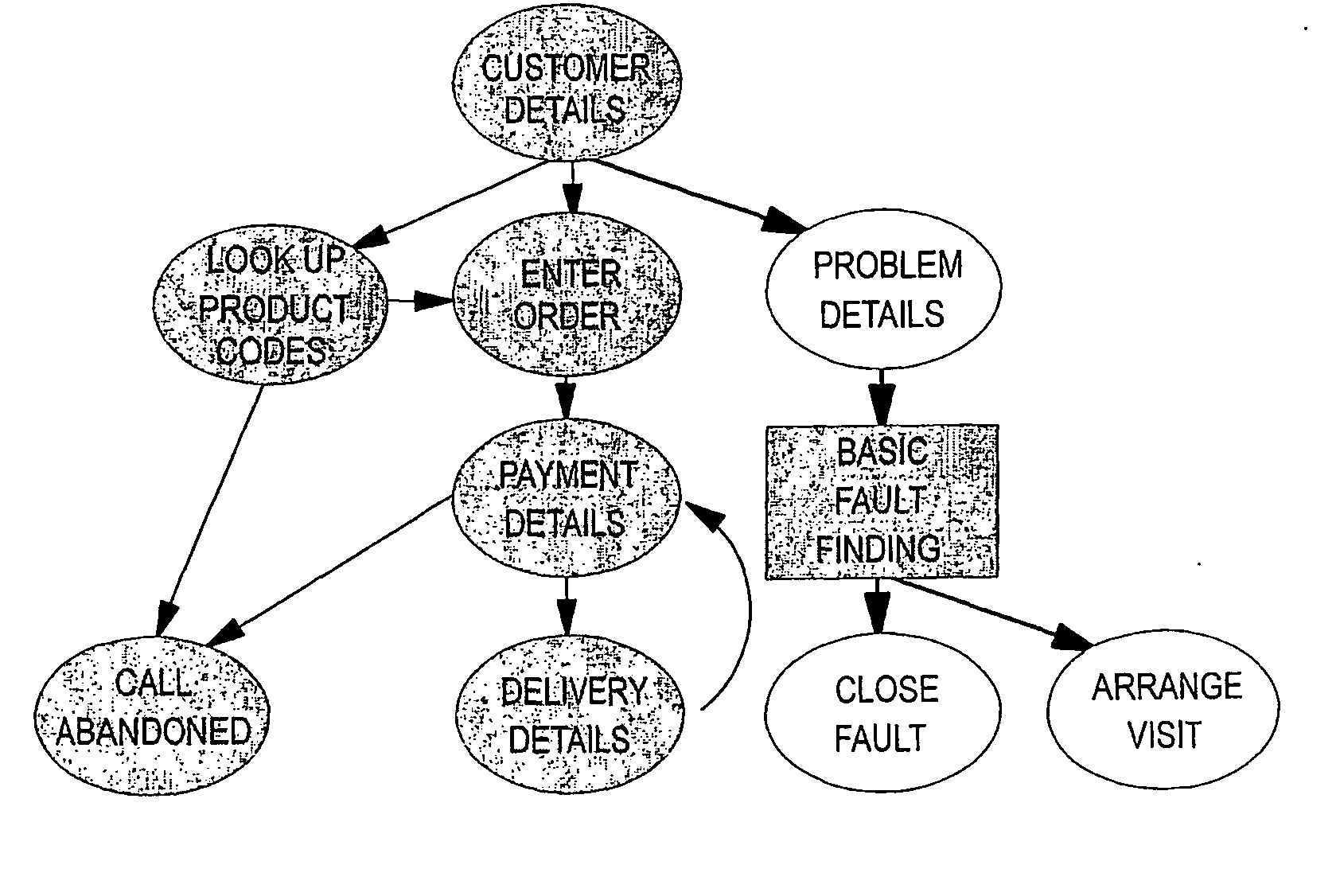

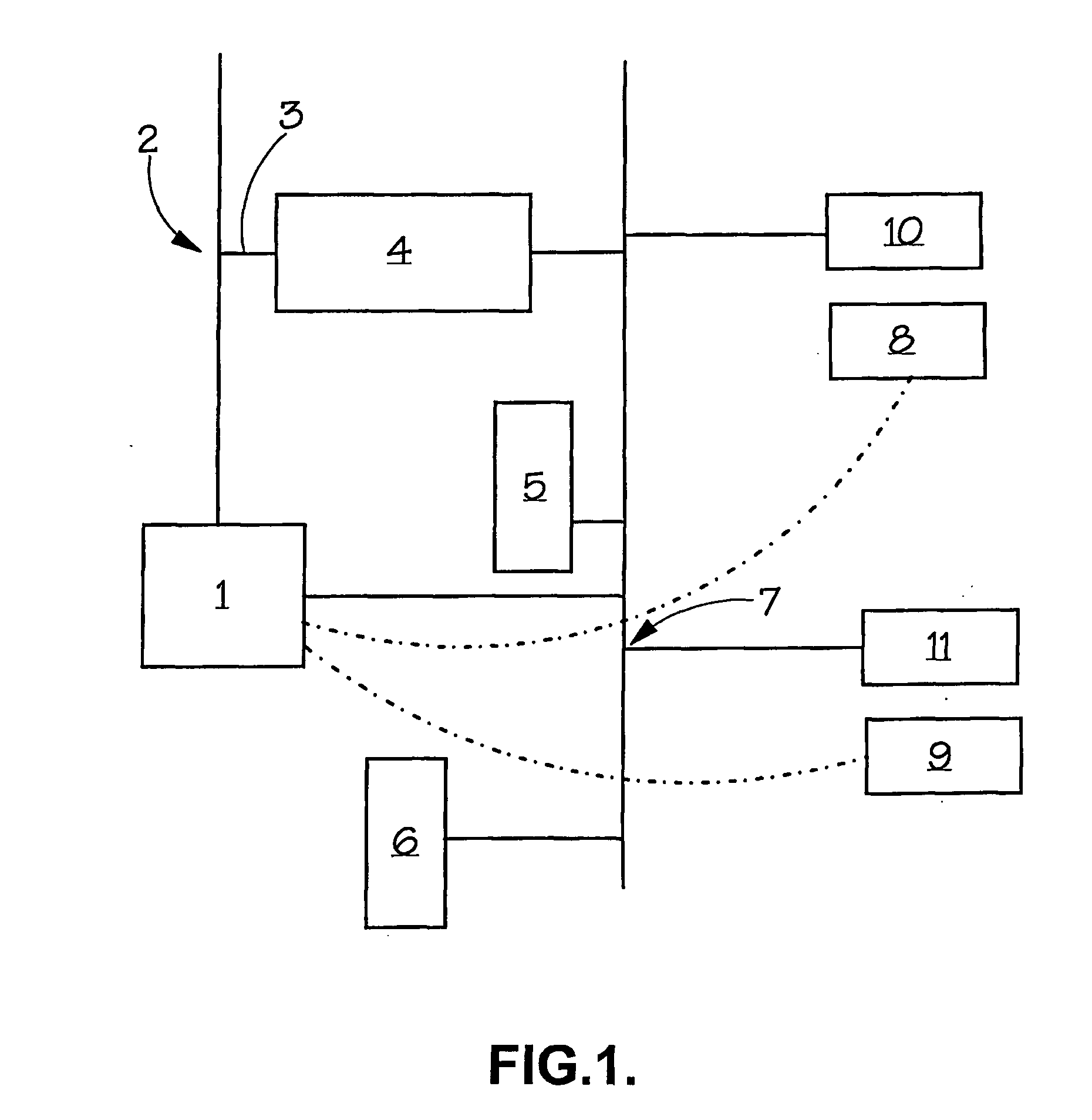

System and Method for Analysing Communication Streams

InactiveUS20070160189A1Better statistical significanceLess manpowerSpecial service for subscribersManual exchangesGraphicsCommunications system

Communications systems are provided, a representative one of which incorporates: a recorder operative to record information associated with a communication; and a first computer application operative to provide a graphical user interface, the graphical user interface being configured such that, responsive to a user input designating a portion of the communication via the graphical user interface, information corresponding to that portion of the communication and recorded by the recorder is presented to the user, the first computer application being further operative to construct an integrated data stream comprising at least some of the information recorded.

Owner:VERINT AMERICAS

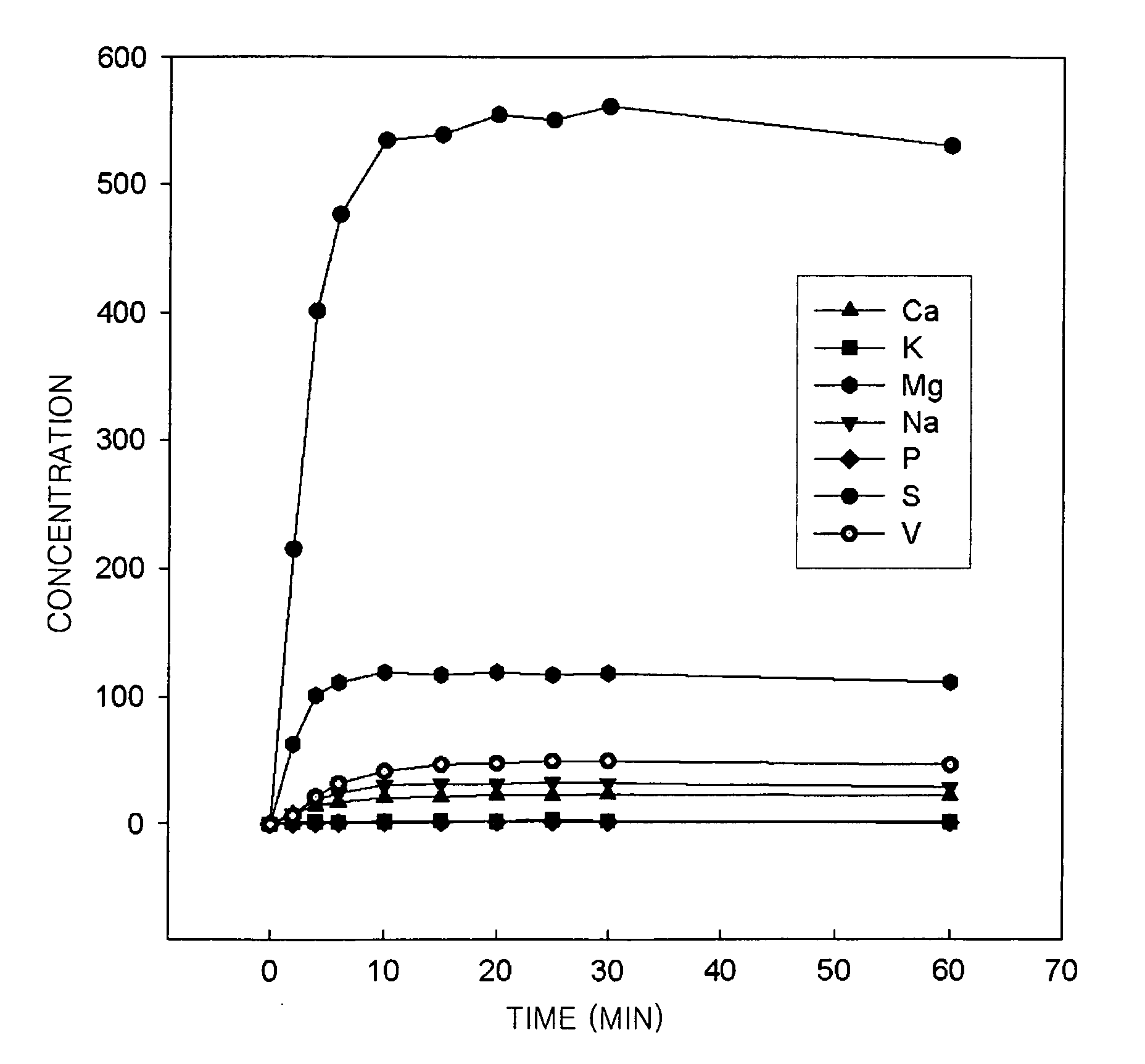

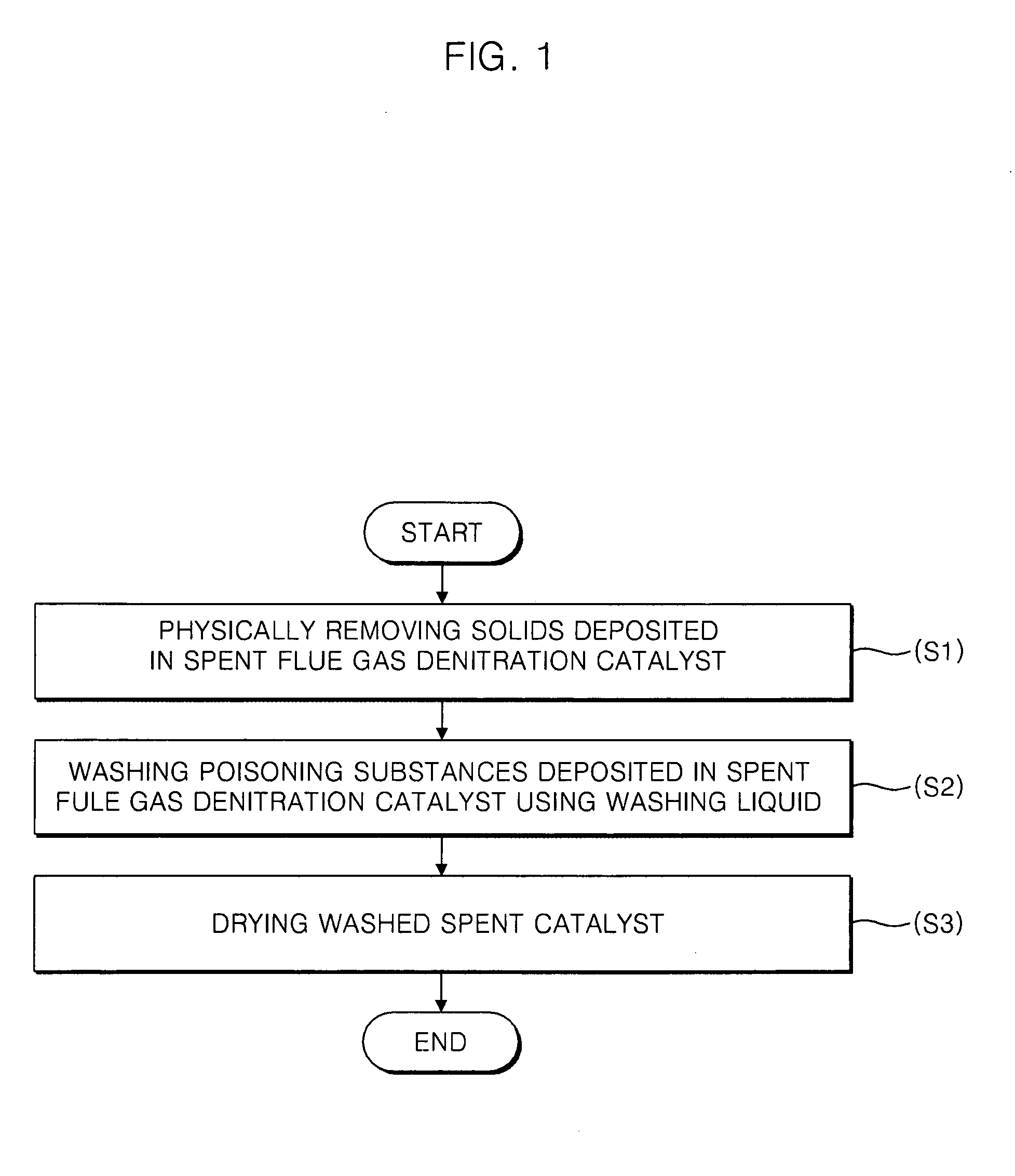

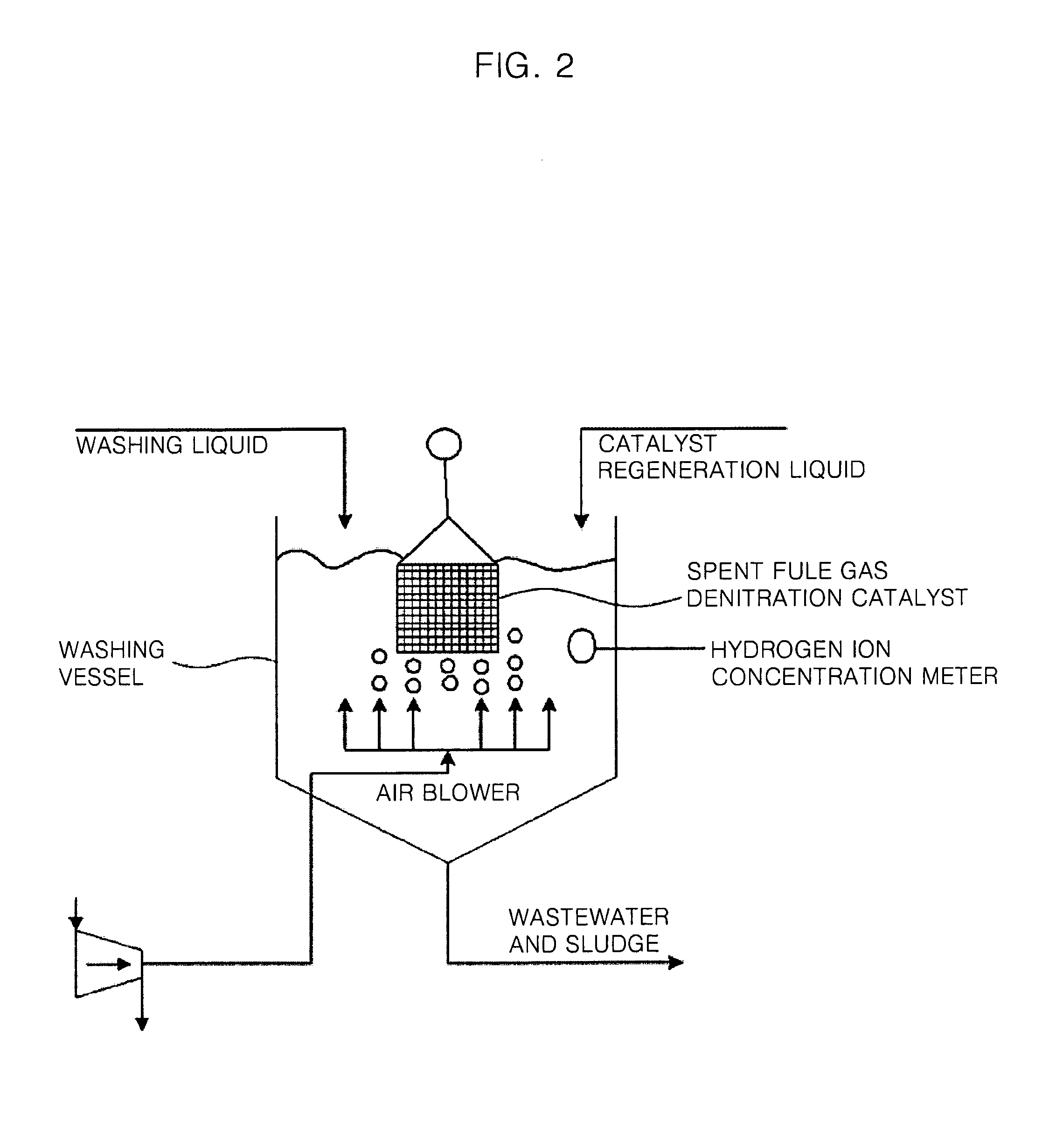

Method of recycling spent flue gas denitration catalyst and method of determining washing time of spent flue gas denitration catalyst

ActiveUS20090005235A1Less manpowerLow costInorganic chemistryOther chemical processesRecovery methodFlue gas

The present invention provides a method of recycling a spent flue gas denitration catalyst and a method of determining a washing time of the spent flue gas denitration catalyst. The method of recycling the spent flue gas denitration catalyst includes physically removing solids deposited in the spent flue gas denitration catalyst, removing poisoning substances deposited in the spent flue gas denitration catalyst by washing the spent flue gas denitration catalyst with a washing liquid for a washing time determined by measuring the hydrogen ion concentration of the washing liquid and drying the resulting spent flue gas denitration catalyst.

Owner:KOREA ELECTRIC POWER CORP +3

System and Method for Analysing Communications Streams

InactiveUS20070160191A1Efficient retrievalImprove efficiencySpecial service for subscribersAutomatic call-answering/message-recording/conversation-recordingGraphicsGraphical user interface

Systems and methods for analyzing communications of a contact center are provided. A representative system incorporates a graphical user interface operative to display information corresponding to a communication of the contact center, the graphical user interface being configured to display the information such that different portions of the communication are visually distinguished from each other.

Owner:VERINT AMERICAS

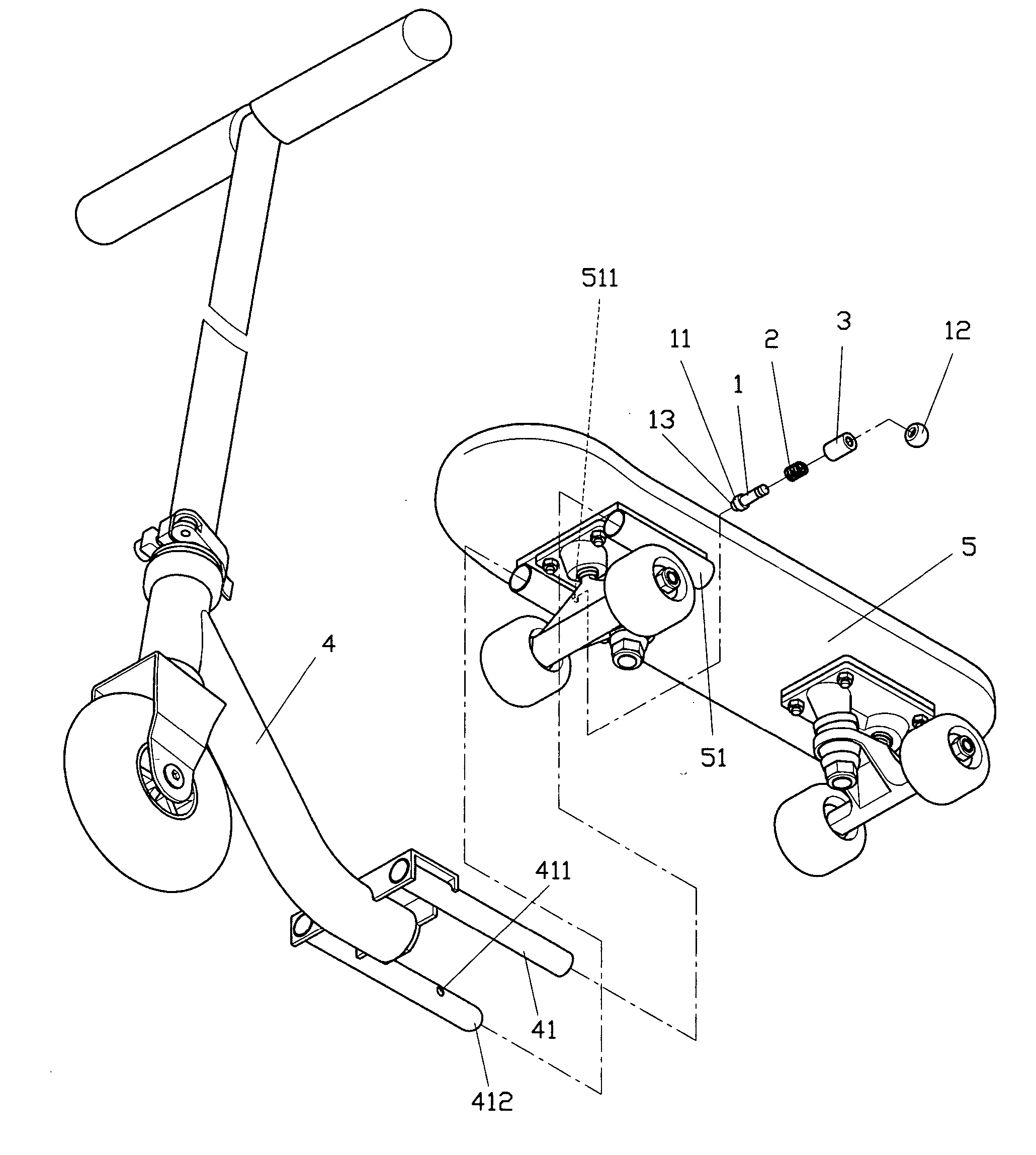

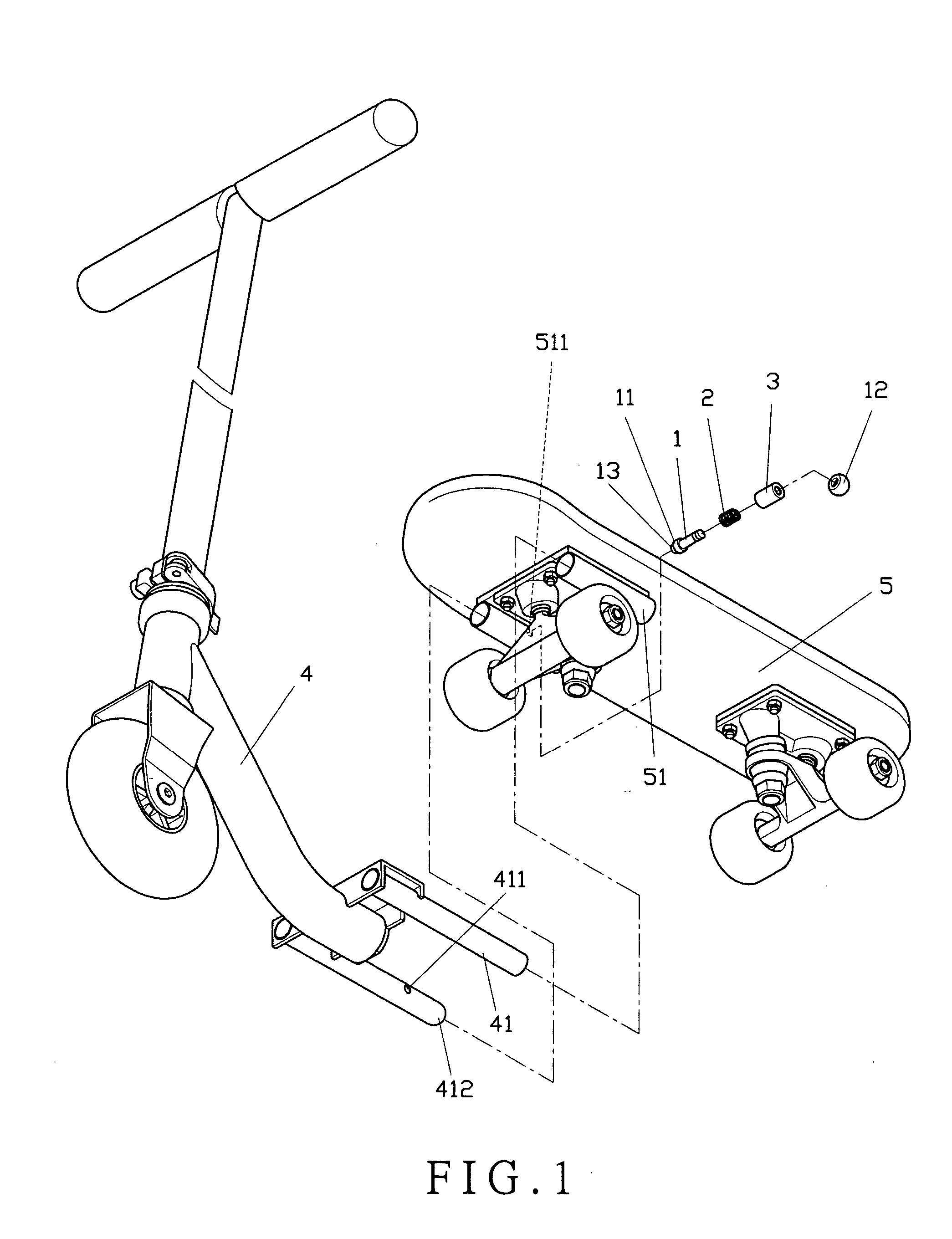

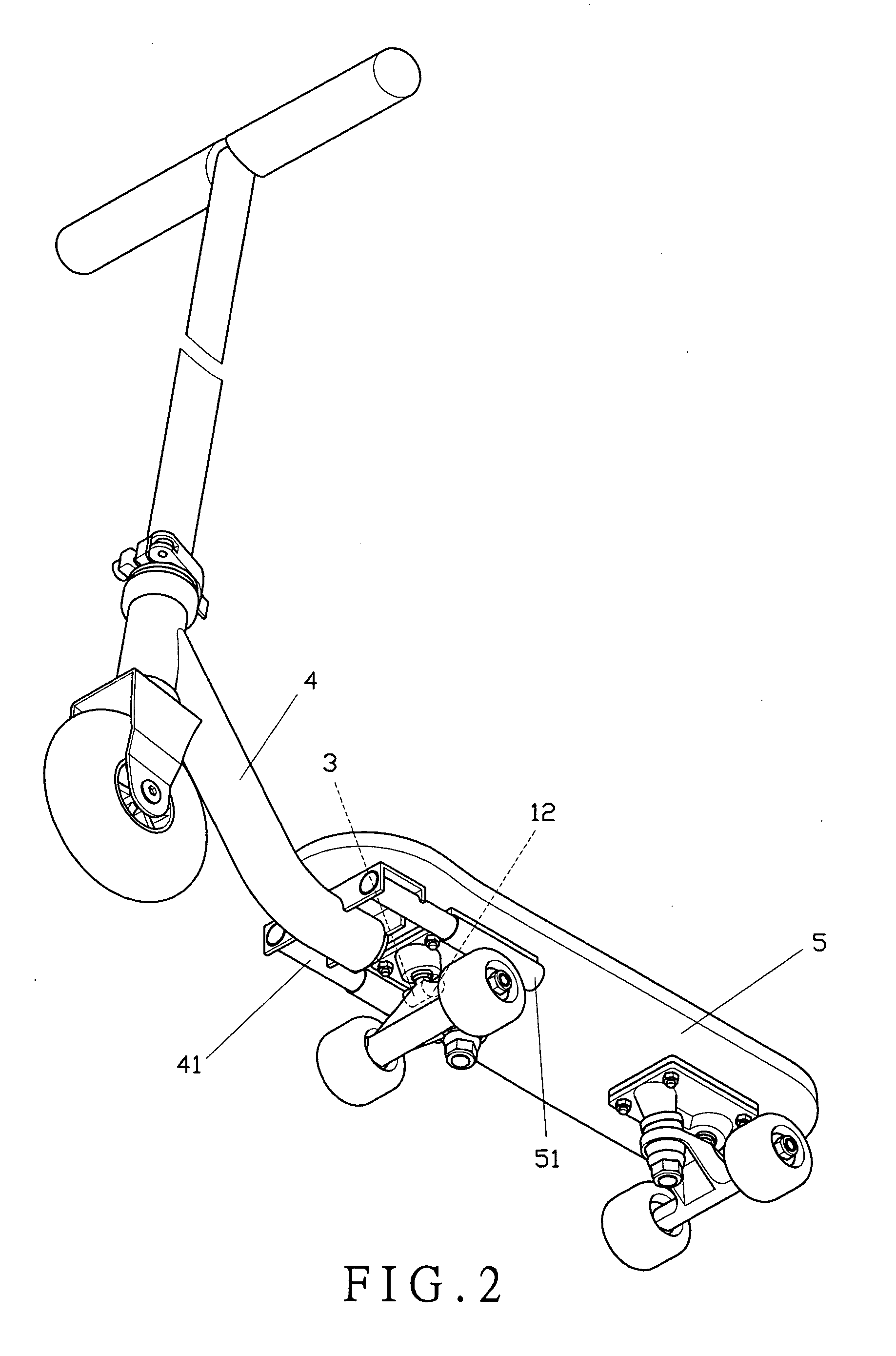

Fastening structure for a scooter

InactiveUS20050230929A1Easy to disassembleLess manpowerConvertible cyclesFoldable cyclesEngineeringMechanical engineering

A fastening structure for a scooter is coupled with a front strut and a board. The front strut comprises a pair of pipes for insertion into a pair of pipes of the board. Both the pipes of the front strut and the board comprise through holes corresponding to each other. The fastening structure includes a latch, an elastic element, and a barrel. The latch has a ring secured at the center portion thereof. The elastic element sleeves onto the latch which then inserts into the barrel with the ring sliding within the barrel. One end of the latch is formed with a knob while the other end is formed with a round corner. The elastic element has its two ends engaging with one end of the barrel and the ring, respectively. The latch inserts from one end into the barrel and protrudes a portion from another end of the barrel and into the holes of the pipes of the front fork and the board to secure the front strut and the board.

Owner:FAR GREAT PLASTICS INDAL

System and Method for Analysing Communications Streams

InactiveUS20070160190A1Better statistical significanceLess manpowerSpecial service for subscribersManual exchangesGraphicsGraphical user interface

Methods are provided, a representative one of which involves: recording information associated with a communication; providing a graphical user interface, the graphical user interface being configured such that, responsive to a user input designating a portion of the communication, information recorded and corresponding to that portion of the communication is presented to the user; and displaying, via the graphical user interface, graphical indications of events occurring during the communication

Owner:VERINT AMERICAS +1

Dry powder briquette adhesive, briquette including adhesive and preparation method of briquette

The invention relates to a dry powder briquette adhesive, which is made by mixing the following raw materials in parts by weight: 40 to 85 parts of bentonite, 10 to 50 parts of oxidized starch, 0.1 to 5 parts of sodium chlorides, 0.1 to 1 part of polyvinyl alcohol, 0.1 to 5 parts of sodium carbonate, 1 to 10 parts of calcium oxides and 0.5 to 10 parts of sodium carboxymethylcellulose. The invention also relates to a briquette including the adhesive and a preparation method thereof. By using the dry powder briquette adhesive, the briquette including the adhesive and the preparation method thereof, the disadvantages that a briquette adhesive has a large addition amount and a briquette is low in cold and hot strength and poor in heat stability, and the like in the prior art are solved.

Owner:河北东慈环保科技有限公司

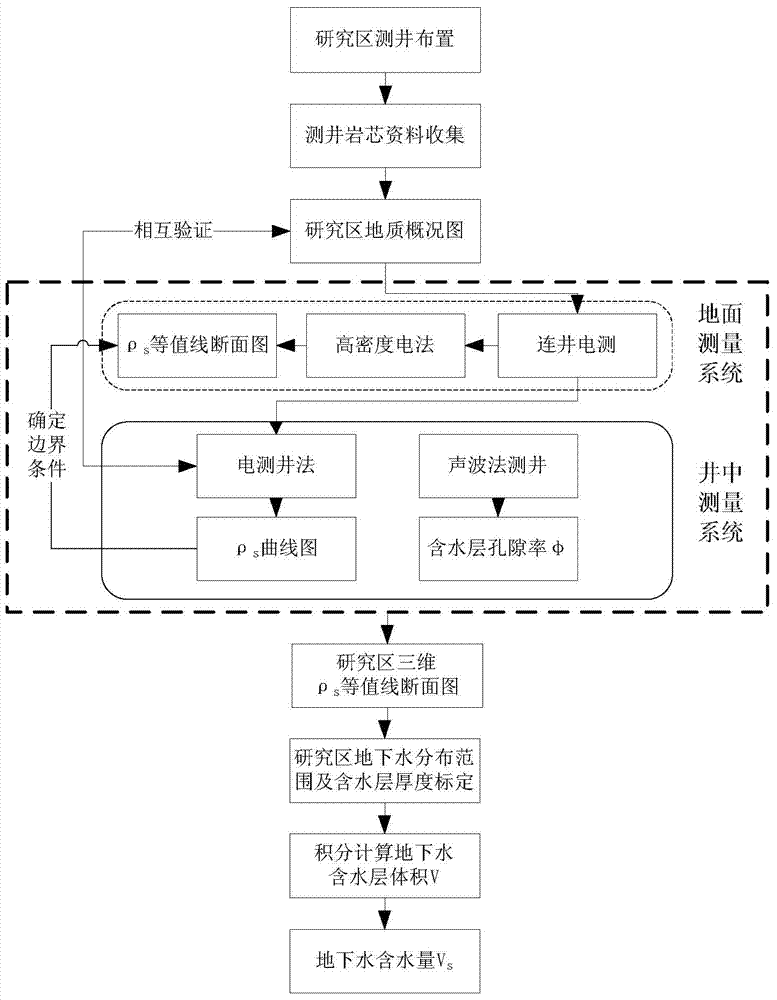

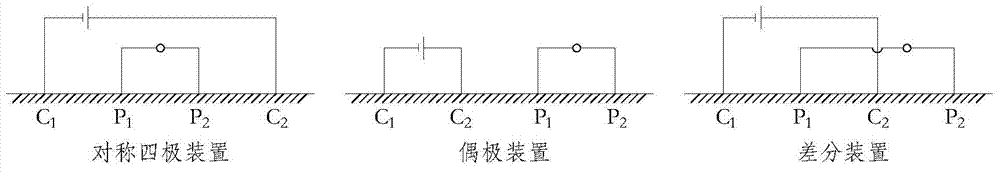

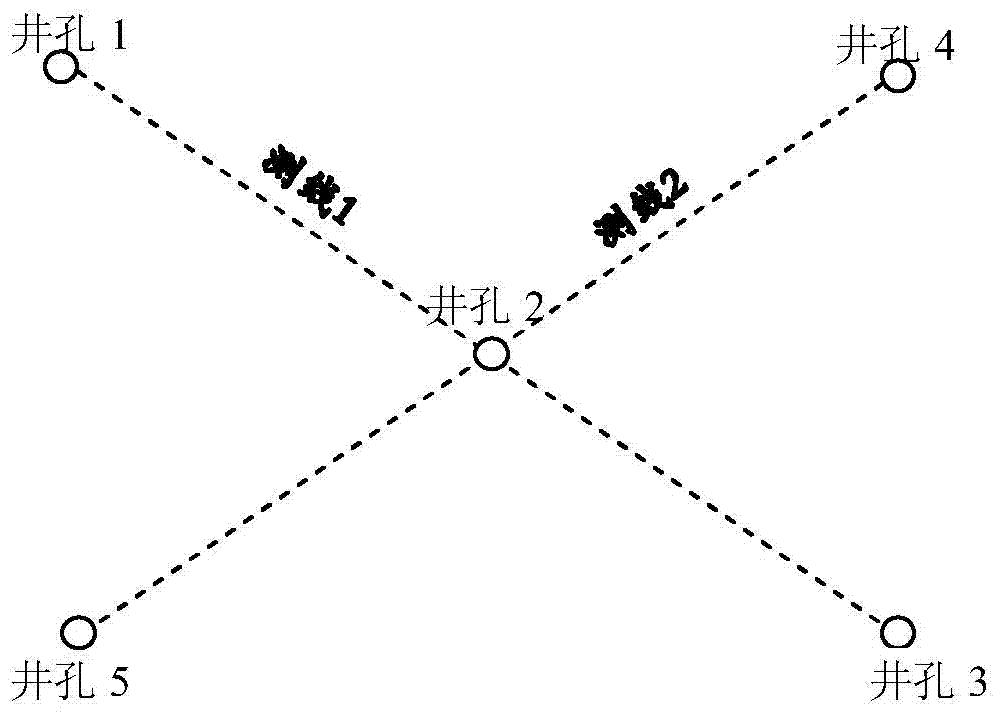

Underwater amount measuring method based on resistivity imaging technology

InactiveCN103487843AImprove accuracyEasy to measureWater resource assessmentGeological measurementsHigh densityWell logging

The invention discloses an underwater amount measuring method based on a resistivity imaging technology. A high density resistivity method is used, a connecting well electrical connecting test is conducted on measured wells which are in the same line, and a rho s contour line cross section diagram is drawn; meanwhile, measuring methods such as a geophysical well logging method and a sound wave method are used, according to the corresponding relation of a stratum and an electrical layer, a systematic observation method with ground measuring and well measuring combined is used, a research area three-dimensional resistivity imaging diagram is mapped, a splattering precise value in a traditional method is improved to a precision value of a connecting line profile, the underwater amount is calculated accordingly, and the accuracy of measuring of the underwater amount can be greatly improved.

Owner:HOHAI UNIV

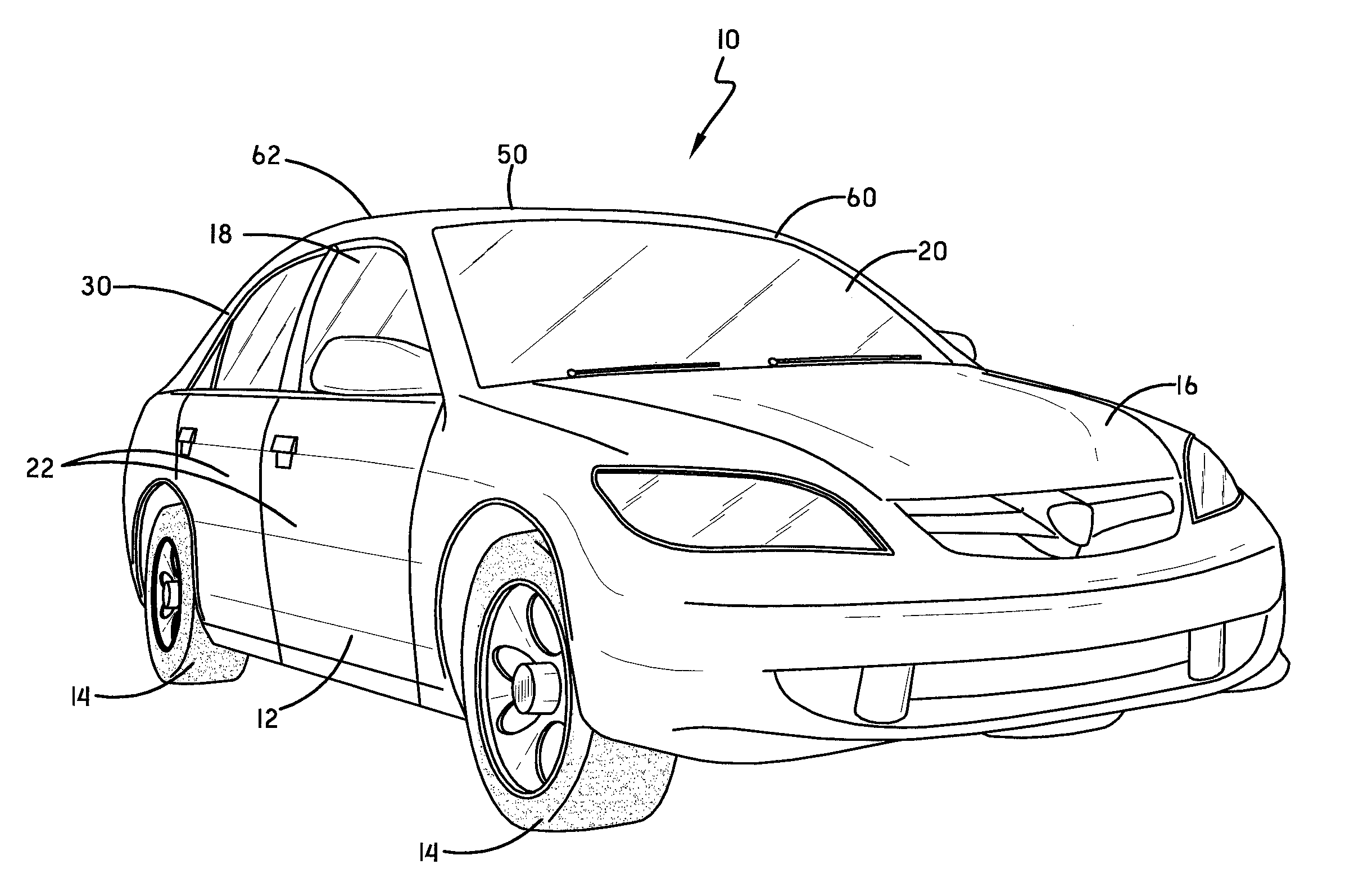

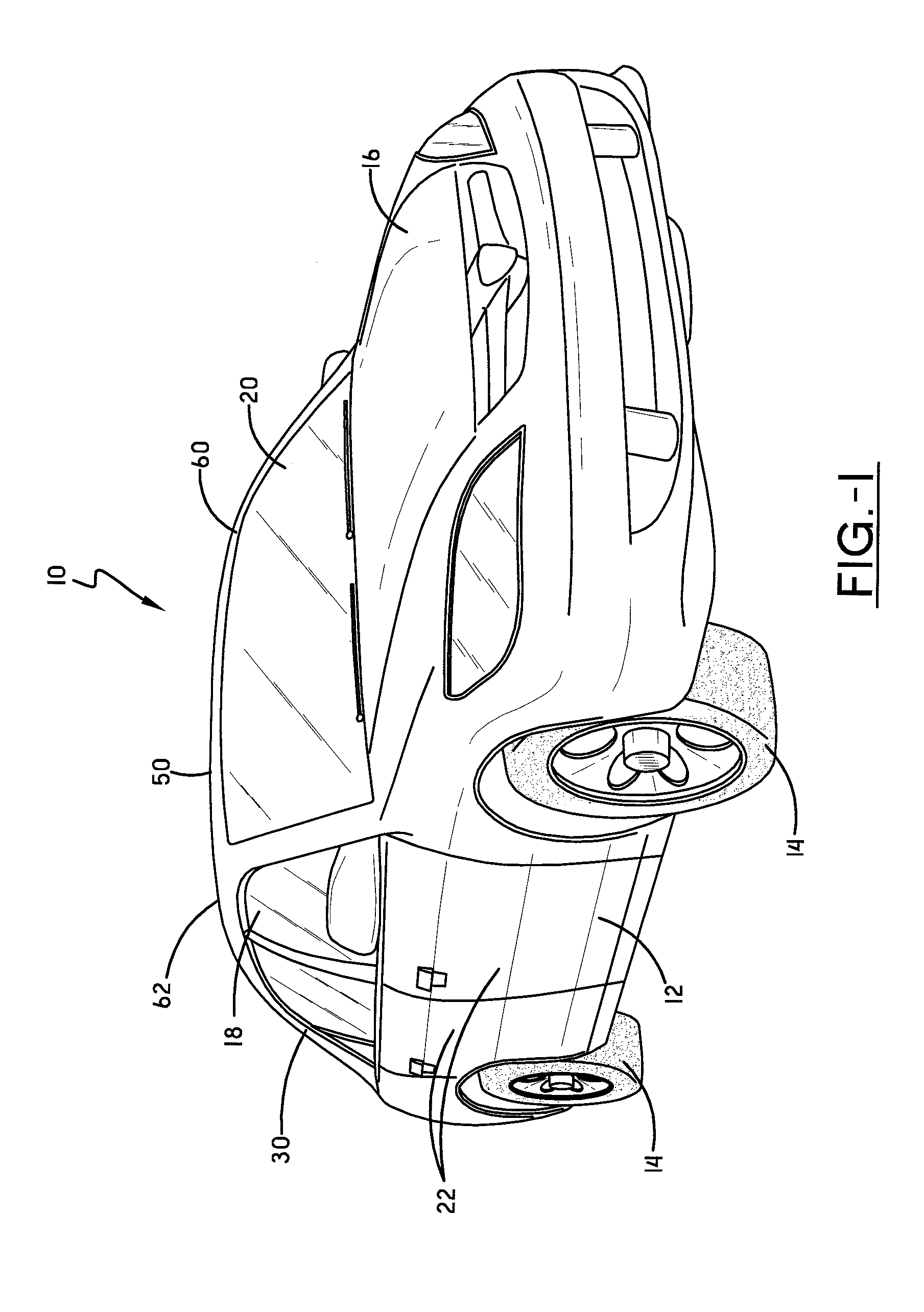

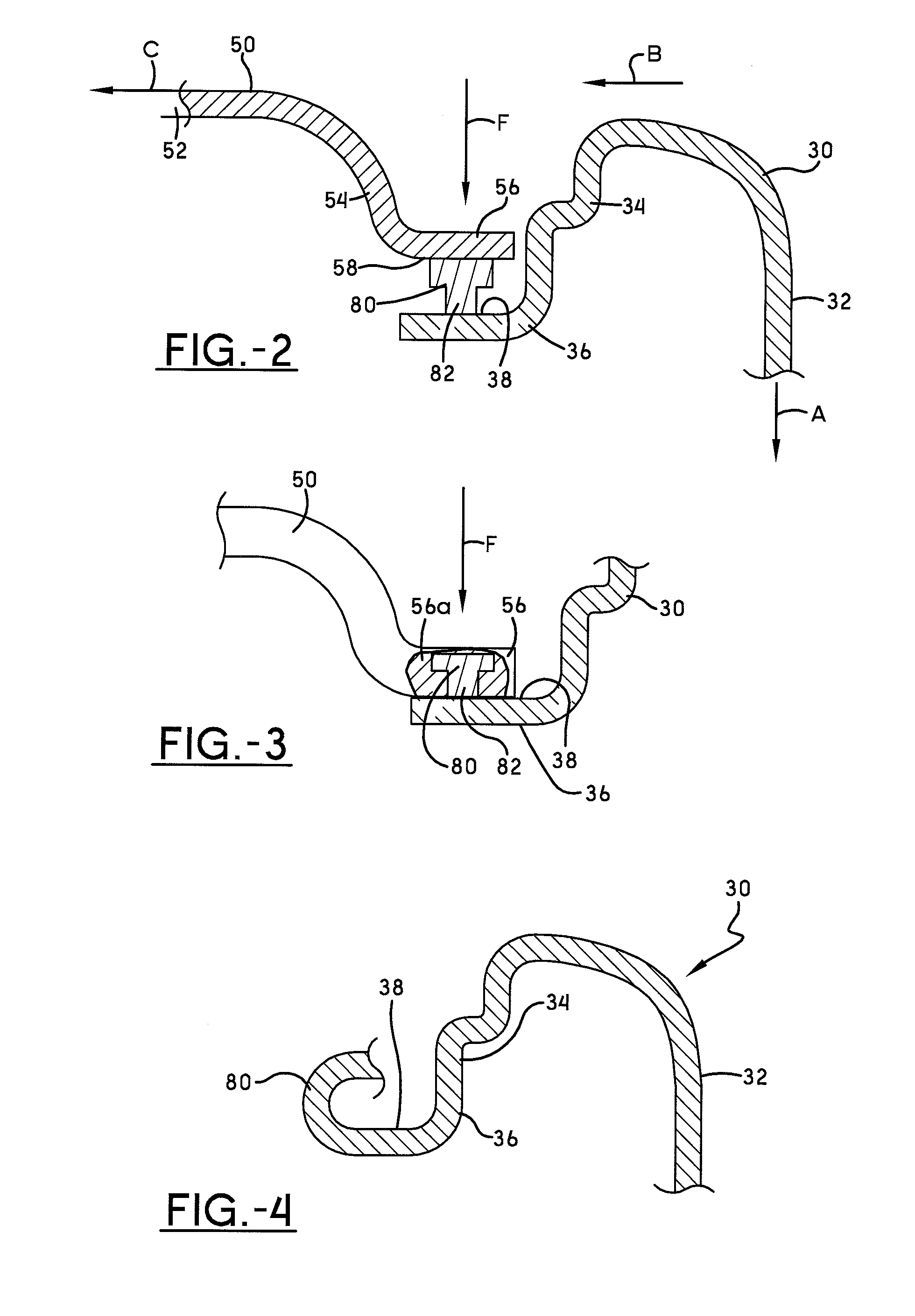

Connection between roof panel and side panel

InactiveUS20110080024A1Improve connection strengthInexpensive mannerVehicle seatsManual label dispensersRear quarterThermoplastic materials

A vehicle may include a roof panel having a segment that is formed of a thermoplastic material, a side panel having a segment that is formed of a metal, and a connection device. The roof panel may be connected to the side panel member by attaching the connection device to the side panel segment, heating the roof panel segment to melt at least a portion of it, enveloping the connection member within the melted portion of the roof panel segment; and, cooling the components.

Owner:HONDA MOTOR CO LTD

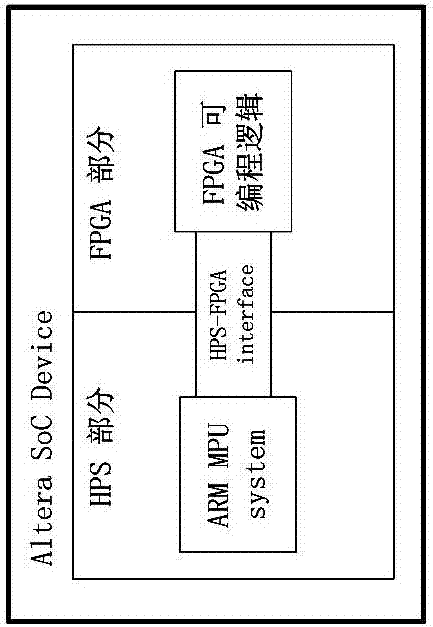

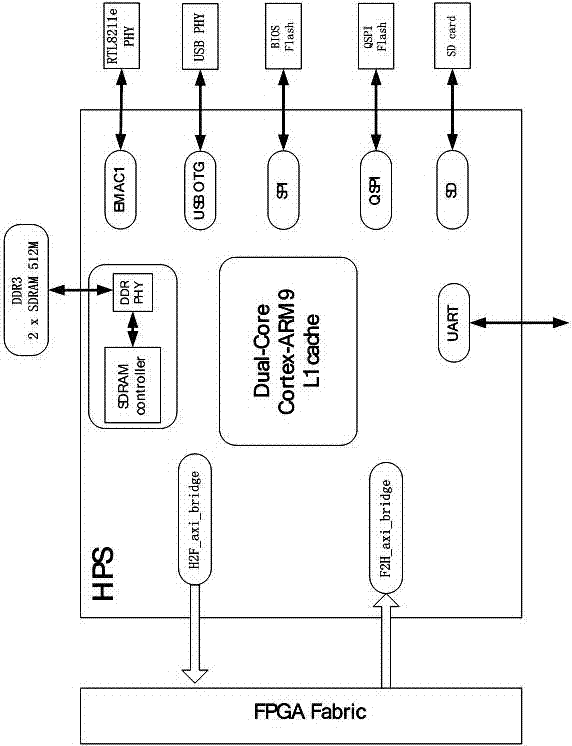

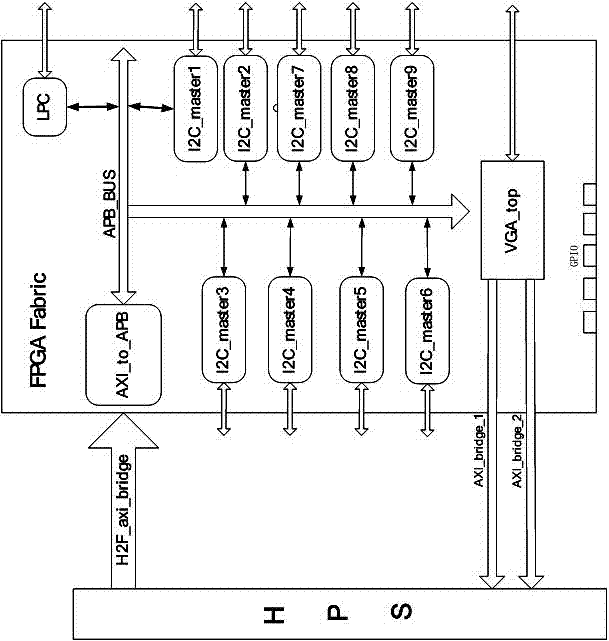

Implementation method for BMC (Baseboard Management Controller) system lower-layer interface based on SoC (System on a Chip) FPGA (Field Programmable Gate Array)

InactiveCN107506317AShort development cycleLess manpowerElectric digital data processingBaseboardLayer interface

The invention provides an implementation method for a BMC (Baseboard Management Controller) system lower-layer interface based on a SoC (System on a Chip) FPGA (Field Programmable Gate Array), and relates to the technical field of servers. The characteristic of high integration level of an Altera Cyclone V chip is used, and the own interface function of the chip is used and is cooperated with an independently researched and developed interface IP (Internet Protocol) module to quickly realize the integration of the lower-layer interface. The method mainly comprises the following steps of implementing on an HPS (Hard processor system) side and an FPGA side.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

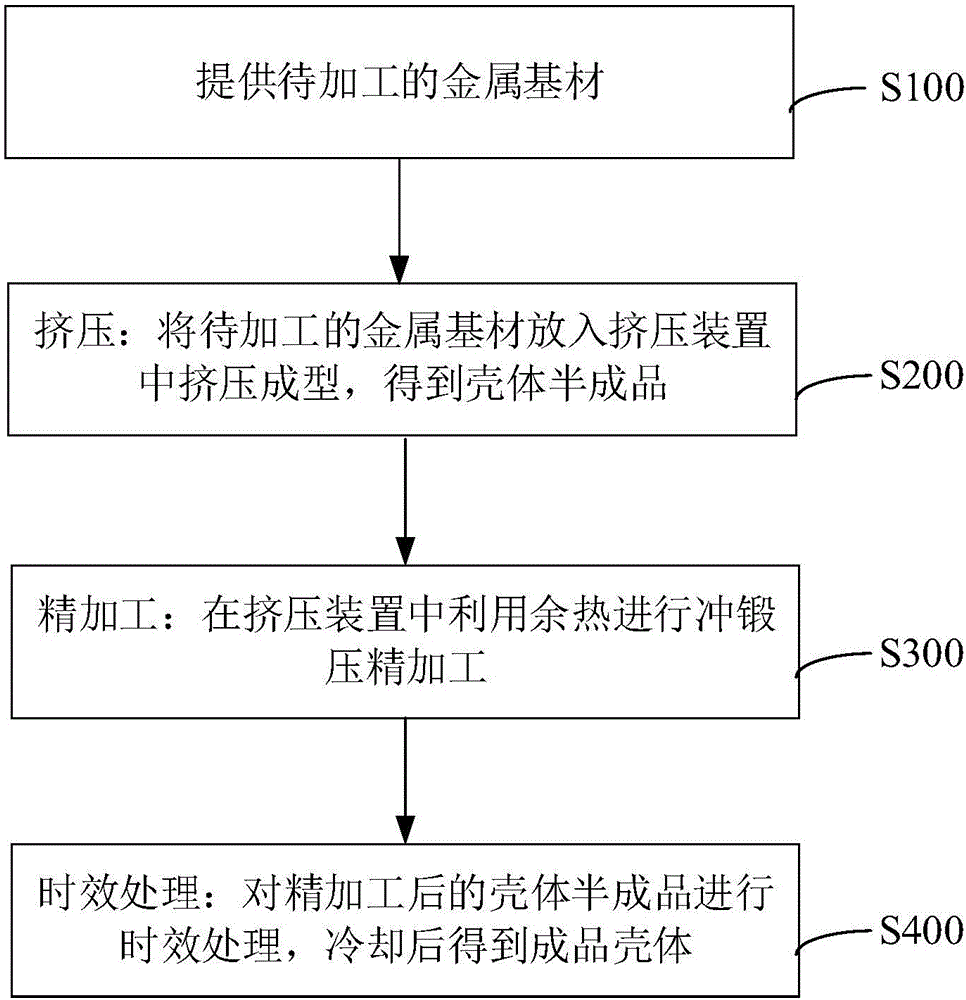

Mobile terminal shell and machining method thereof

The invention relates to a mobile terminal shell and a machining method thereof. The mobile terminal shell machining method includes the steps of providing a metal base material to be machined; putting the metal base material to be machined into an extrusion device for carrying out extrusion of rough machining and obtaining a semi-finished product of the shell; carrying out punching, forging and pressing of finish machining in the extrusion device; and carrying out aging treatment on the metal shell subjected to finish machining and obtaining a finished product after the aging treatment. According to the terminal shell machining method, because the extrusion forming method is adopted, no excess material is generated during extrusion, and a large amount of CNC machining is omitted; and because both the rough machining and the finish machining are carried out in the extrusion device, the waste heat in the extrusion device is utilized for carrying out the punching, forging and pressing of the finish machining, the energy is saved, the environment is protected, the production cost is low, and the manpower investment is small.

Owner:GUANGDONG EVERWIN PRECISION TECH

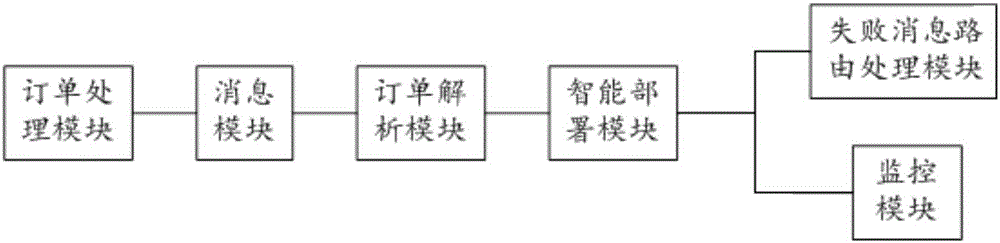

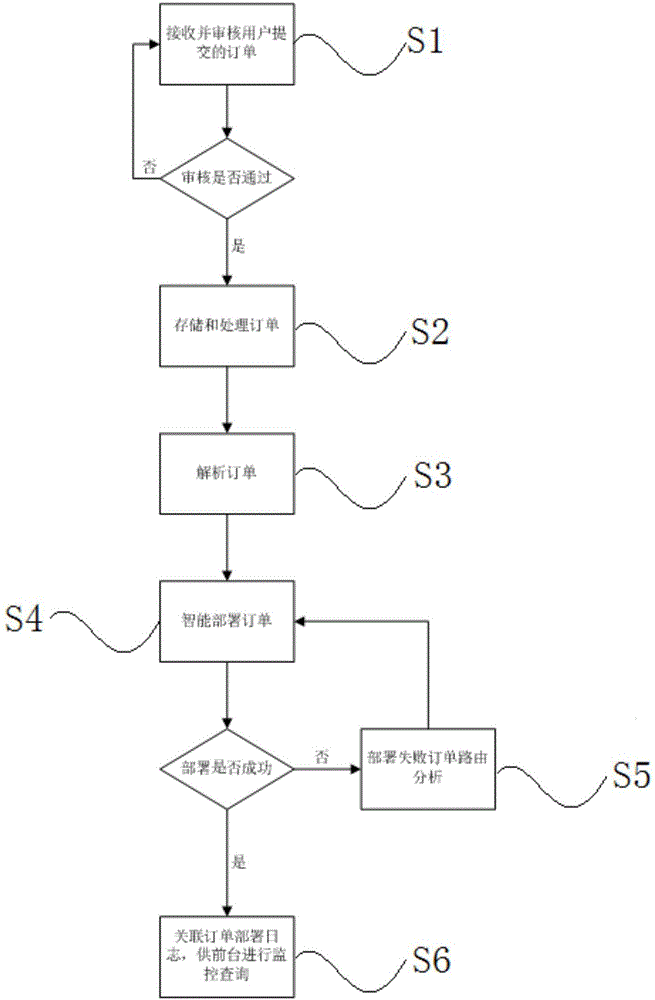

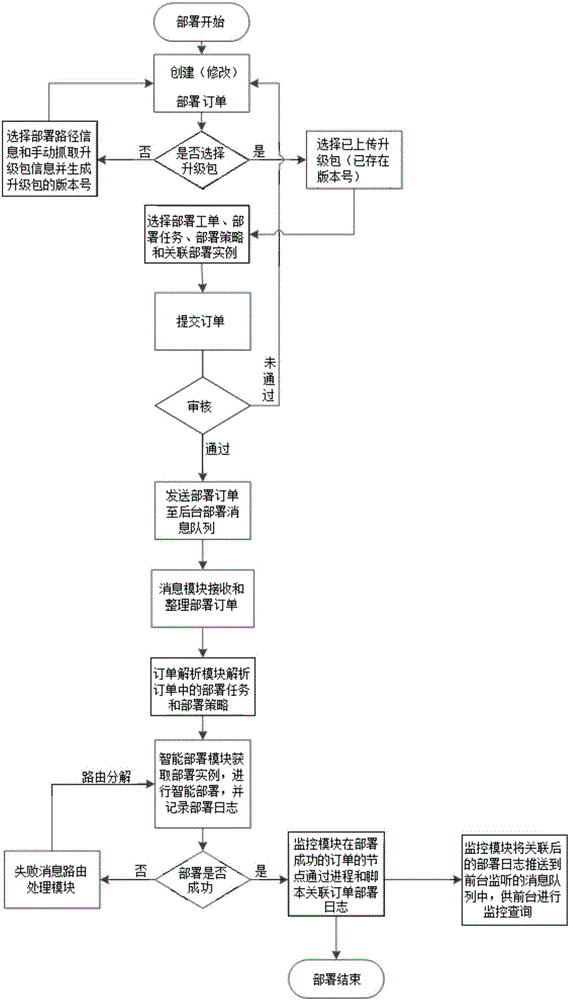

Intelligent disposition and process monitoring system and method based on cloud management platform

ActiveCN105791417ARealize one-click deploymentReduce investmentResourcesData switching networksProcess moduleOrder form

The present invention relates to an intelligent disposition and process monitoring system based on cloud management platform. The system comprises an order processing module, an information module, an order analysis module, an intelligent disposition module, a failure information route processing module and a monitoring module. The order processing module is configured to submit an order for users and perform ordering checking; the information module is configured to receive and process the order after the checking passes; the order analysis module is configured to analyze the order and obtain the disposition task and the disposition strategy in the order; the intelligent disposition module is configured to perform intelligent disposition; the failure information route processing module is configured to perform failure reason analysis and feed failure reason analysis back to the intelligent disposition module; and the monitoring module is configured to associate with the order disposition log in the order with successful disposition and monitor and inquire the order disposition log. The intelligent disposition and process monitoring system and method based on a cloud management platform are able to greatly reduce the manpower and material resources invested in the process of disposition, management and upgrading maintenance and decrease the operation cost.

Owner:北京思特奇信息技术股份有限公司

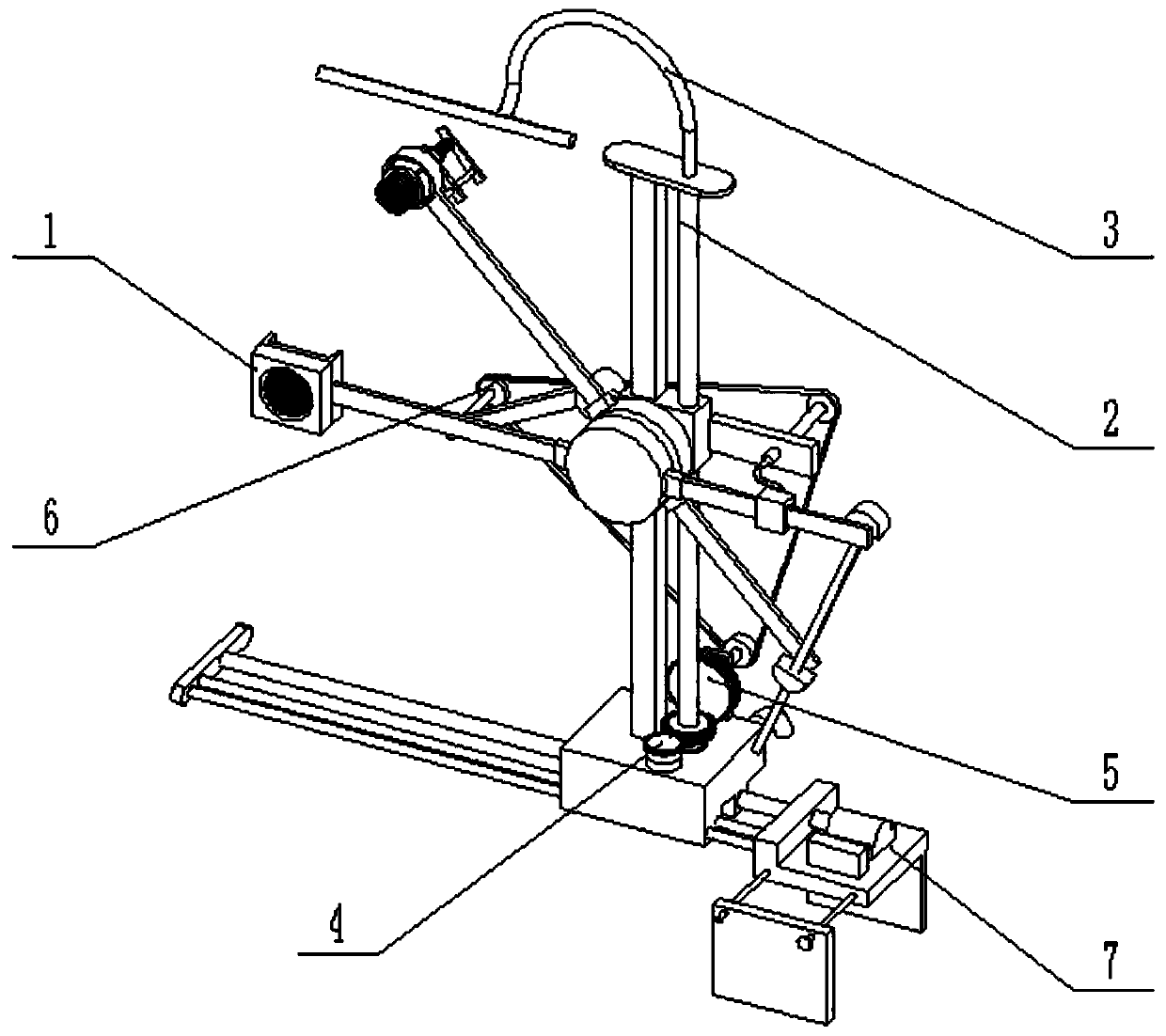

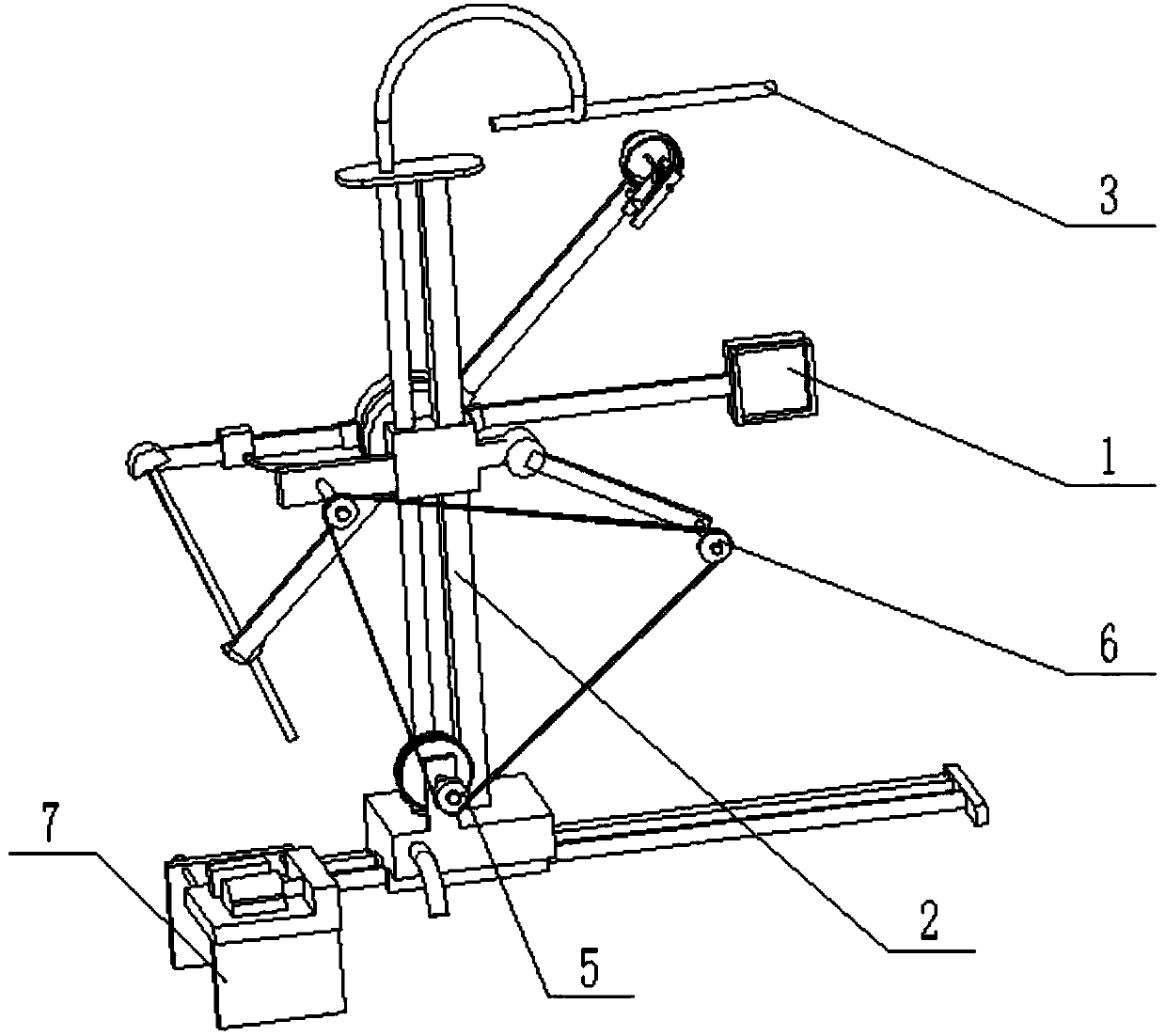

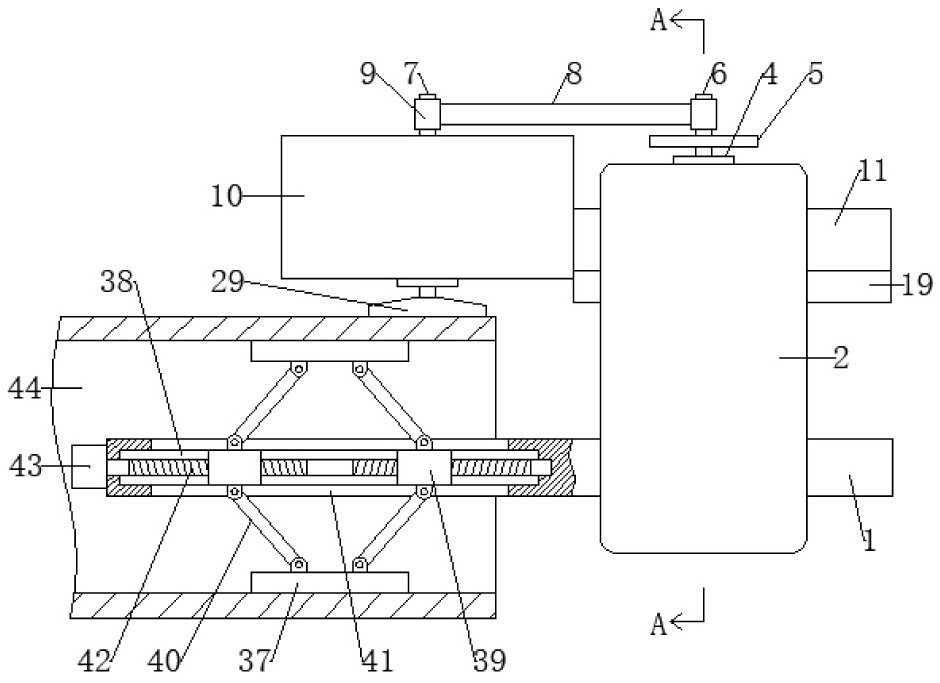

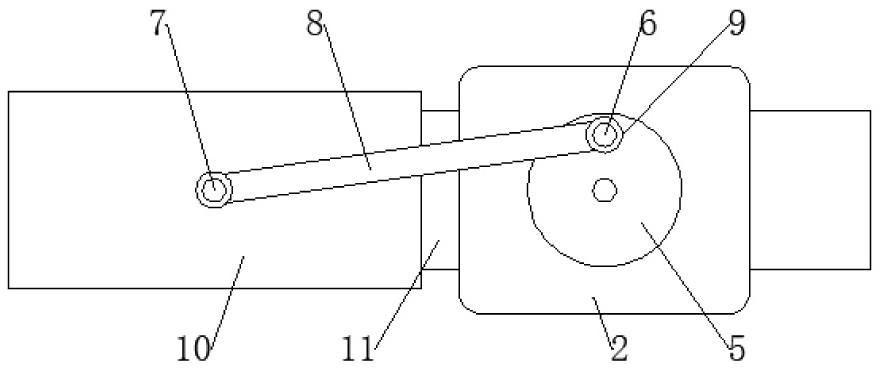

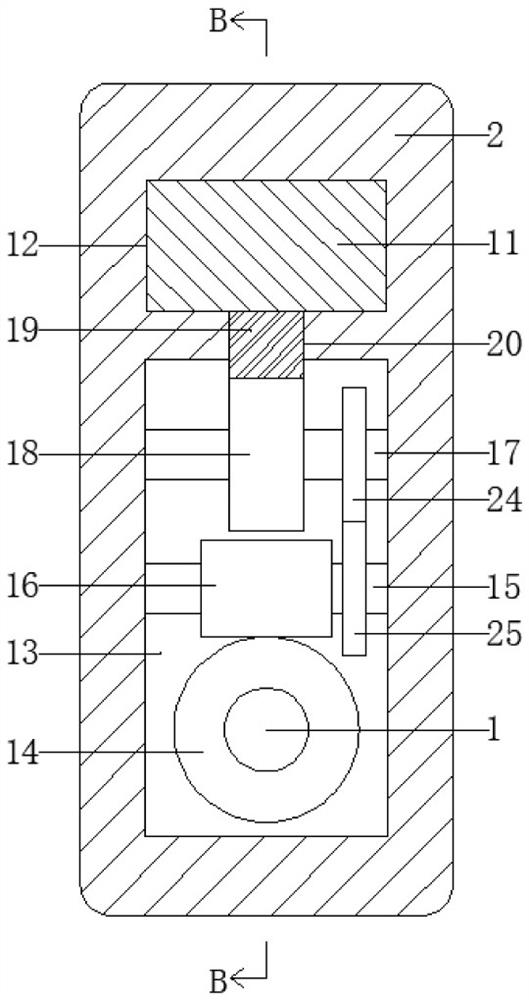

Automatic window cleaning device for high-rise buildings

The invention relates to a window cleaning device, in particular to an automatic window cleaning device for high-rise buildings. The automatic window cleaning device comprises a cleaning head assembly, a lifting frame assembly, a spraying pipe assembly, a drive assembly, a transmission wheel assembly, a tensioning wheel assembly and an installation base assembly, wherein the lifting frame assemblyis connected to the upper end of the installation base assembly; the spraying pipe assembly is connected with and installed on the lifting frame assembly; the drive assembly is fixedly installed on teththe front side of the top end of the lifting frame assembly; the transmission wheel assembly is connected with and installed at the rear side of the top end of the lifting frame assembly; the tensioning wheel assembly is connected with and installed at the rear side of the left end of the cleaning head assembly; the cleaning head assembly is connected with and installed on the lifting frame assembly. The automatic window cleaning device for the high-rise buildings does not need manpower, can be controlled by upper computers such as a mobile phone and a computer, and is high in cleaning efficiency and good in cleaning effect.

Owner:绍兴兴裕门窗有限公司

Nutrient multi-grain rice with easy digestion and absorption and preparation method thereof

InactiveCN101690563APromote digestion and absorptionQuick cookFood preparationDietary fiberJobs Tears

The invention relates to balanced nutrition multi-grain rice with easy digestion and absorption and a preparation method thereof. The preparation method comprises the steps of: performing extrusion treatment on a coarse food grain mixture, wherein the coarse food grain mixture comprises one or more of potatoes, yams, pumpkins, taroes, soybeans, chestnuts, horsebeans, peas, barley and the seed of Job's tears; and fully mixing the coarse food grain mixture after the extrusion treatment with rice, and packaging the mixture, wherein the coarse food grain mixture accounts for over 1 percent of the total weight of the coarse food grain mixture and the rice, namely is more than or equal to 1 percent. The balanced nutrition multi-grain rice with easy digestion and absorption does not need to be presoaked for certain time before the boiling, has the advantages that the rice can be quickly boiled, is easy to be digested and absorbed by human body, can achieve the effect of nutrition complementation of cereals, yams and beans, has balanced nutrition, gives consideration to the mouthfeel and the taste, and can simply, conveniently, scientifically and synchronously supplement various dietary fibers, vitamins, unsaturated fatty acids and proteins.

Owner:王雪

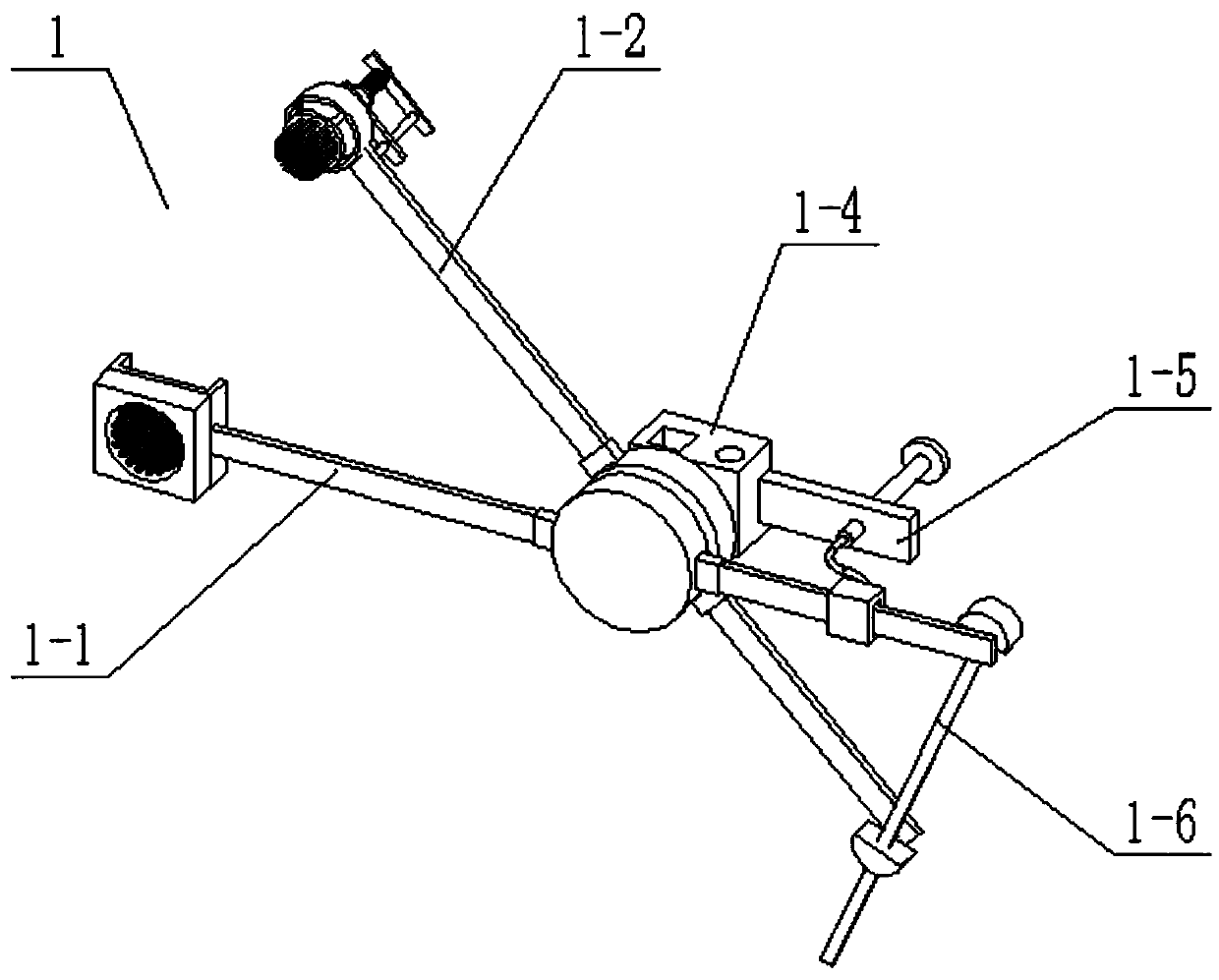

Novel pipeline polishing device

ActiveCN112059760AAffect the grinding areaLarge grinding areaGrinding carriagesRevolution surface grinding machinesRatchetGear wheel

The invention relates to the technical field of polishing devices, in particular to a novel pipeline polishing device. The novel pipeline polishing device is characterized in that a pipeline supporting mechanism is arranged at one end of a center shaft, a rotating seat is rotatably mounted at the other end of the center shaft, a supporting frame is slidably mounted on the rotating seat in the length direction of the center shaft, and a polishing mechanism is arranged on the supporting frame; a first small shaft is eccentrically and fixedly installed on a driving disc, a second small shaft parallel to the first small shaft is fixedly installed on the supporting frame, and a connecting rod is arranged between the first small shaft and the second small shaft. When the driving disc rotates, the connecting rod drives the polishing mechanism to reciprocate in the length direction of a pipeline so as to increase the polishing area of the polishing mechanism, when a driving gear rotates in thedirection opposite to the rotating direction of a ratchet wheel, the rotating seat is driven to rotate around the center shaft by a certain angle so as to increase the polishing process, and when thedriving gear rotates in the rotating direction of the ratchet wheel, the polishing area is increased. The rotating seat and the central shaft are kept in a relatively static state to prolong the contact time of the polishing mechanism and the same part of the pipeline.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

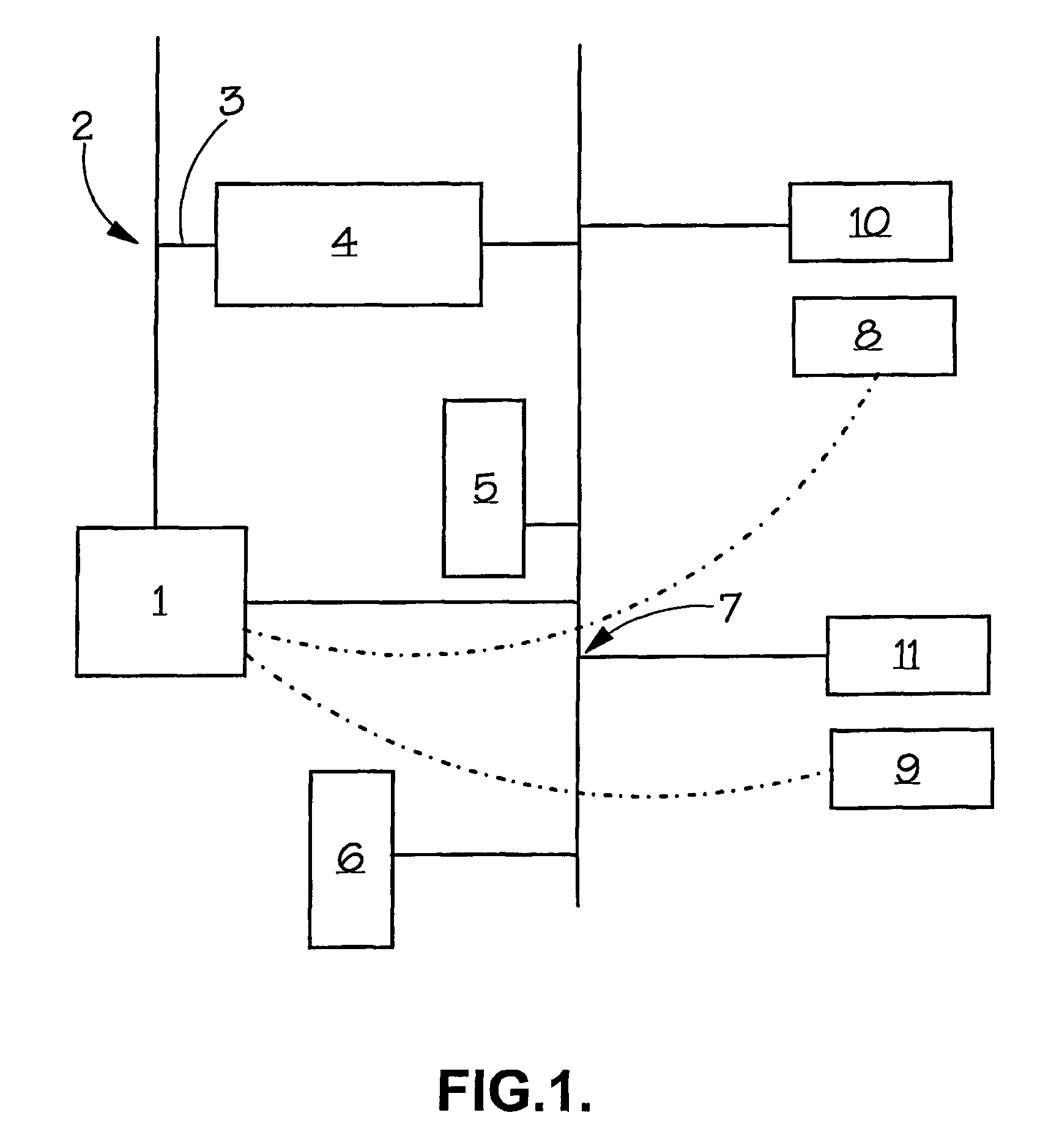

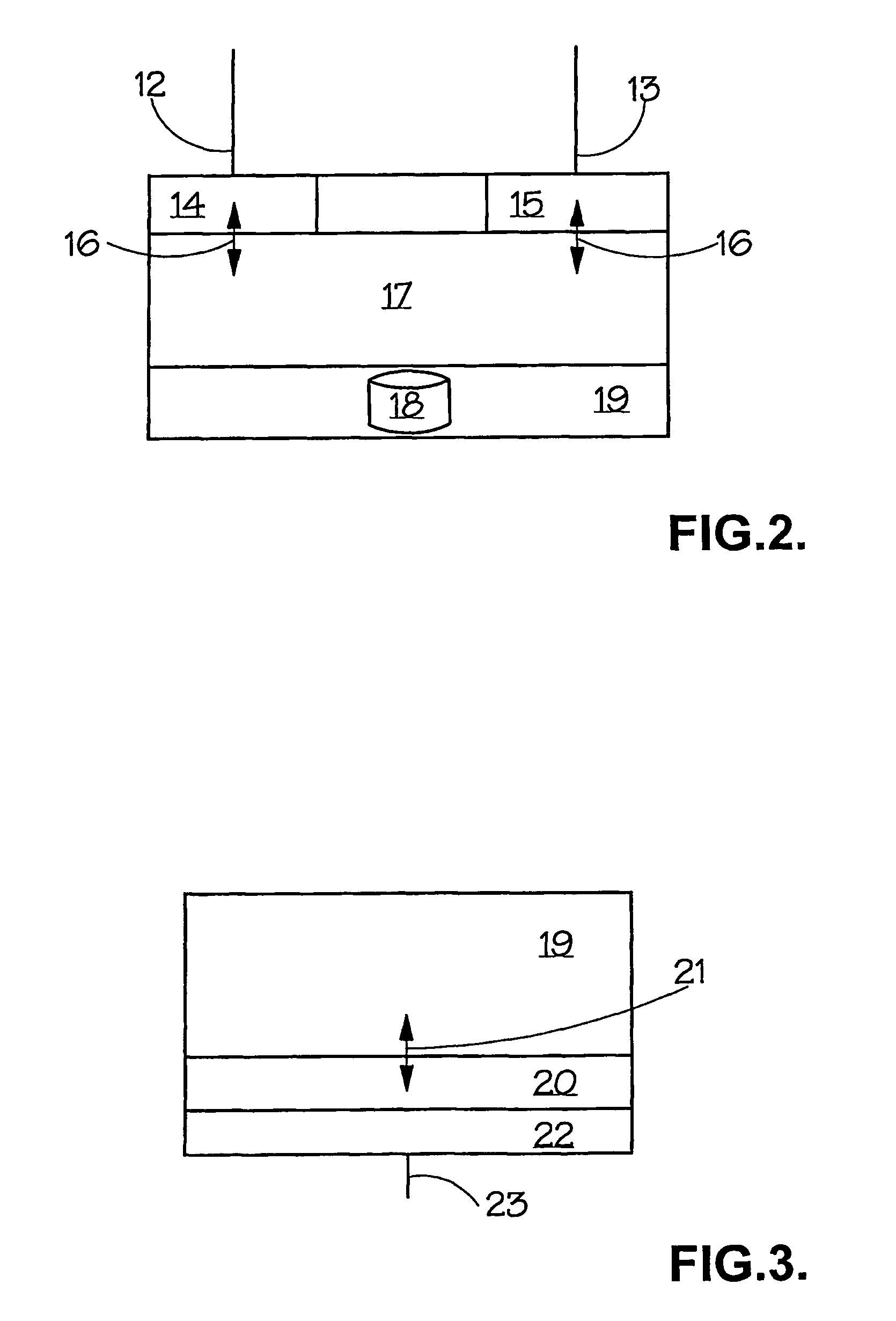

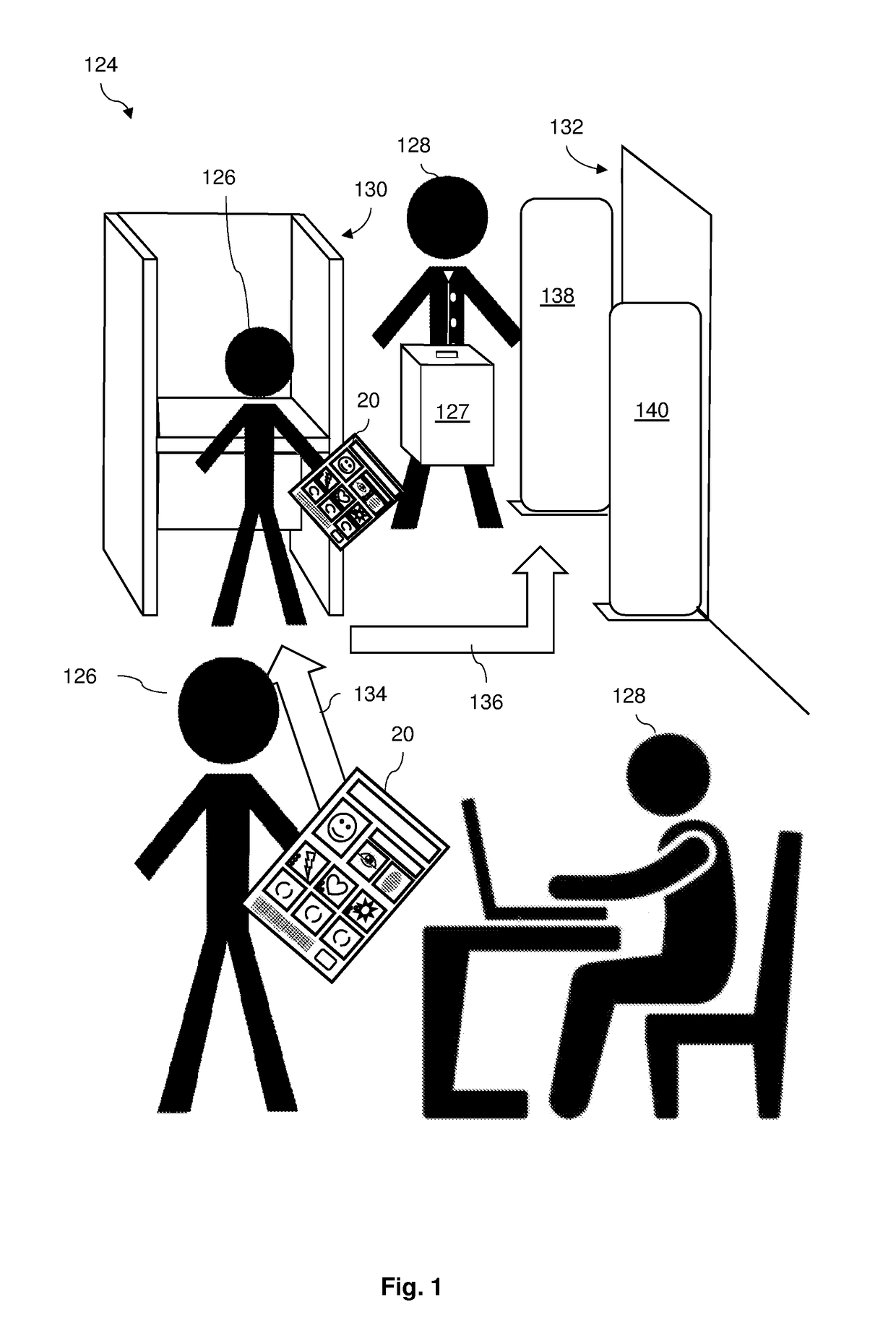

Tools and Methods for Ballot Counting

Owner:CHENG CHUAH JACK TEO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com