Treating method of paper-making water recycling use in the production process of reconstituted tobacco

A technology for reconstituted tobacco leaves and production process, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Environmental pollution and other problems, to achieve the effect of easy automatic operation, less manpower investment, and simple operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

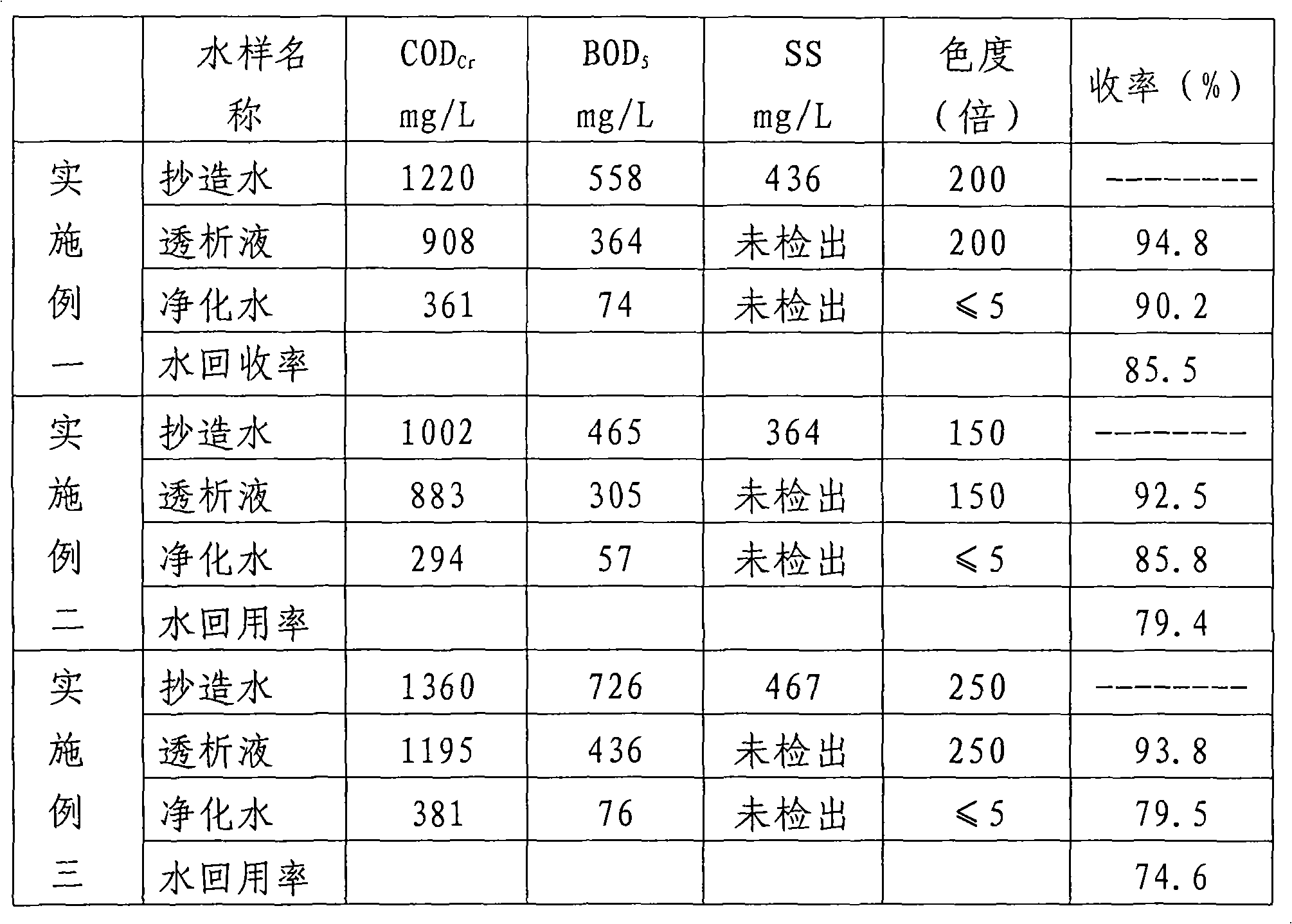

Embodiment 1

[0019] The processing method for recycling water in the reconstituted tobacco leaf production process is characterized in that the method steps are:

[0020] ①. Filtrate and recycle the fiber from the papermaking water produced in the papermaking process of reconstituted tobacco leaf production, and then import it into a sedimentation tank or a sedimentator for sedimentation treatment, and take 54.0Kg of the supernatant overflow liquid after the sedimentation treatment;

[0021] ②. The supernatant overflow liquid is introduced into the ultrafiltration membrane separation system for separation. The membrane element of the ultrafiltration membrane separation system adopts an ultrafiltration membrane with a separation pore size of 10-200nm. The operating pressure of the ultrafiltration membrane separation system is controlled at 0.3MPa. The feed liquid temperature is controlled at 23-35°C, the membrane surface velocity is controlled at 5m / s, and 51.2Kg of dialysate and 2.8Kg of co...

Embodiment 2

[0026] The processing method for recycling water in the reconstituted tobacco leaf production process is characterized in that the method steps are:

[0027] ①. Filtrate and recycle the fiber from the papermaking water produced in the papermaking process of reconstituted tobacco leaf production, and then import it into a sedimentation tank or a sedimentator for sedimentation treatment, and take 600Kg of the supernatant overflow liquid after the sedimentation treatment;

[0028] ②. The supernatant overflow liquid is introduced into the ultrafiltration membrane separation system for separation. The membrane element of the ultrafiltration membrane separation system adopts an ultrafiltration membrane with a separation pore size of 10-200nm. The operating pressure of the ultrafiltration membrane separation system is controlled at 0.3MPa. The feed liquid temperature is controlled at 23-58°C, the membrane surface velocity is controlled at 4m / s, and 554.7Kg of dialysate and 45.3Kg of c...

Embodiment 3

[0033] The processing method for recycling water in the reconstituted tobacco leaf production process is characterized in that the method steps are:

[0034] ①. Filtrate and recycle the fiber from the papermaking water produced in the papermaking process of reconstituted tobacco leaf production, and then import it into a sedimentation tank or a sedimentator for sedimentation treatment, and take 900Kg of the supernatant overflow liquid after the sedimentation treatment;

[0035] ②. The supernatant overflow liquid is introduced into the ultrafiltration membrane separation system for separation. The membrane element of the ultrafiltration membrane separation system adopts an ultrafiltration membrane with a separation pore size of 10-200nm. The operating pressure of the ultrafiltration membrane separation system is controlled at 0.3MPa. The feed liquid temperature is controlled at 28-60°C, and the membrane surface velocity is controlled at 5m / s to obtain 844Kg of dialysate and 56Kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com