Patents

Literature

359results about "Textile parts treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for creating and sharing purchasing lists on a network

InactiveUS6925444B1Minimize network communicationImprove securityAdvertisementsPattern makingPurchasingWorld Wide Web

A system and method create and share purchasing lists in a network system. The system and method utilize a consumer user interface. The consumer user interface provides the consumer the ability to create a purchase list by receiving advertisement data on the consumer device, selecting an item desired for purchase, identifying the purchase list for the item to be saved, creating the purchase list if the purchase list identified does not exist, and saving the item to the identified purchase list. The consumer user interface further provides the consumer the ability to share a purchase list by identifying a purchase list to be shared, converting the purchase list to the appropriate format, identifying a recipient of the purchase list, and transmitting the purchase list to the recipient.

Owner:KNAPP INVESTMENT

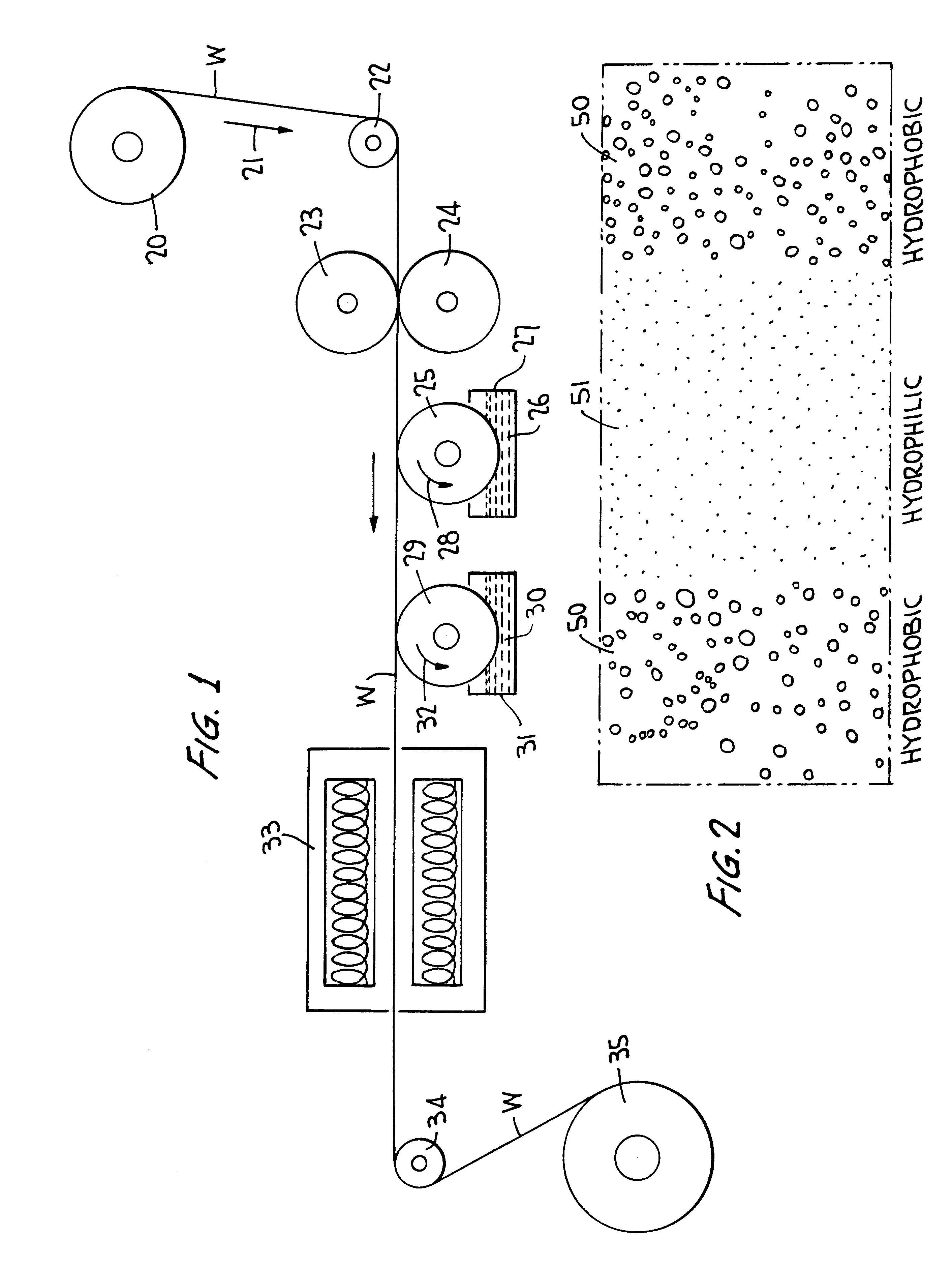

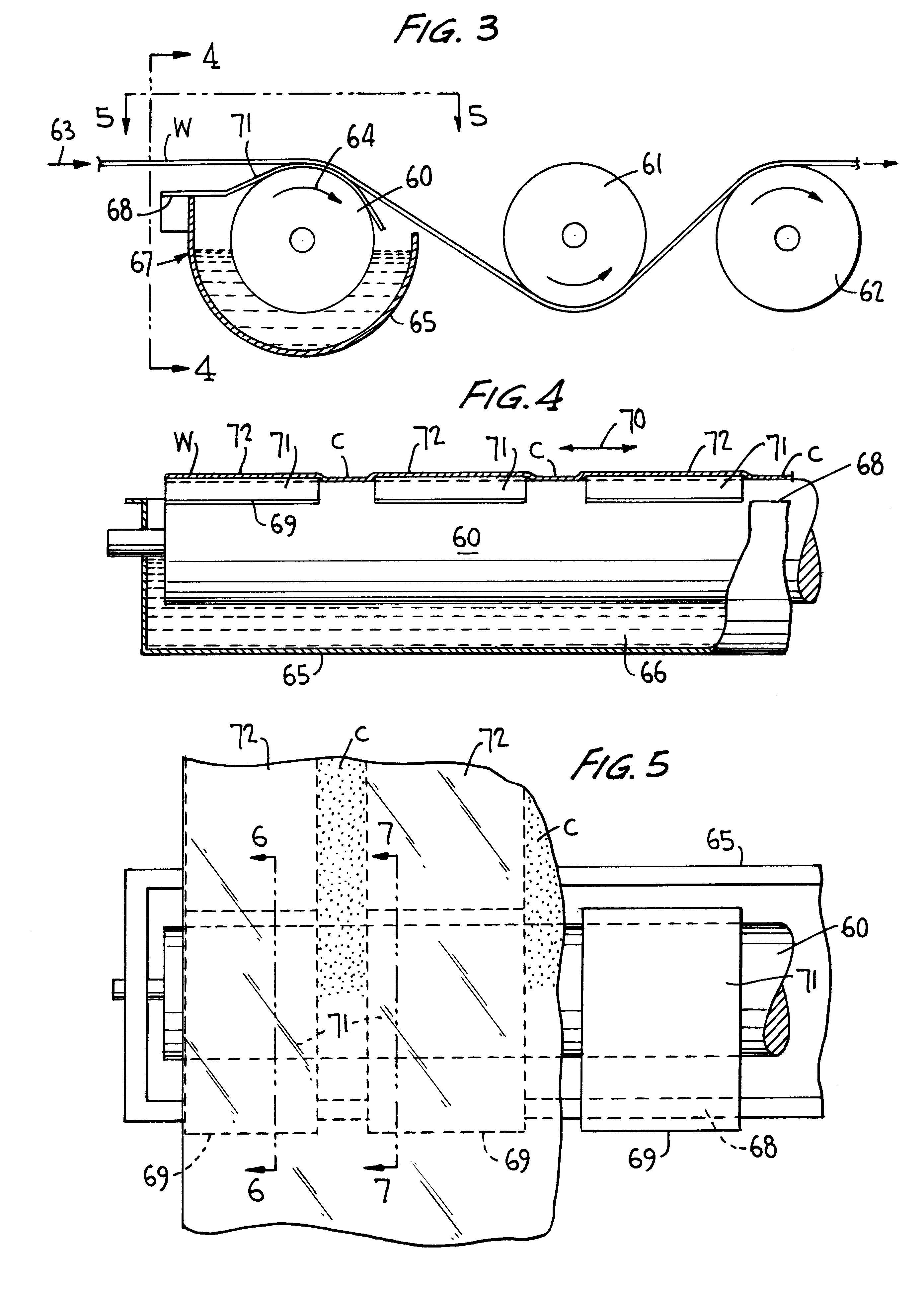

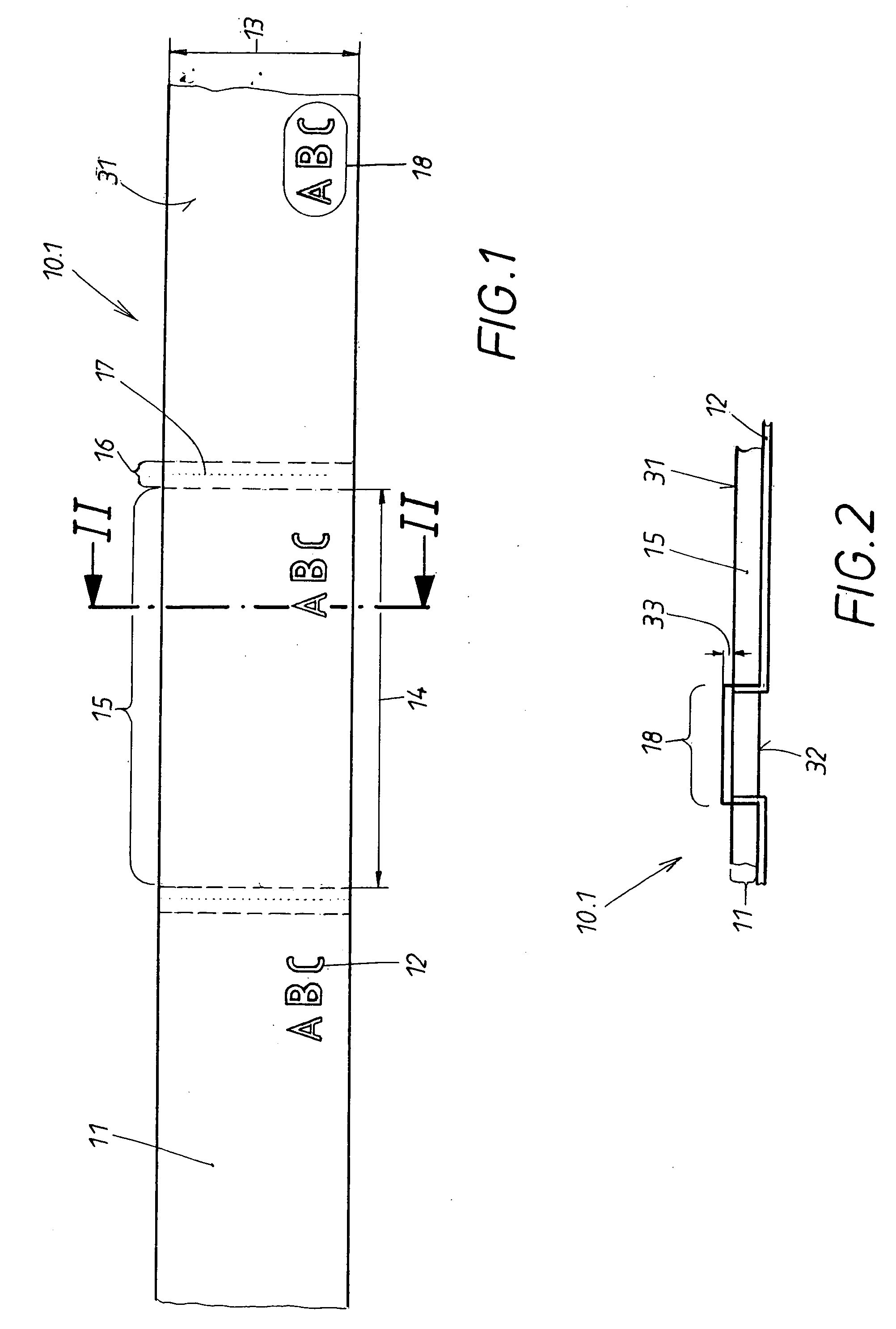

Coating selective zones of thin webs to change the pervious character thereof

InactiveUS6183847B1Easy to transportExcellent impregnationNon-adhesive dressingsDecorative surface effectsEngineeringPolypropylene

The process and apparatus of the present invention involves treating a well-integrated woven or non-woven web of hydrophobic fibers to make selected areas hydrophilic. It also can be used to make a web of hydrophilic fibers selectively hydrophobic. It uses a plurality of selectively adjustable covers on an applicator roll rotating in a bath of liquid to place the liquid material on selected areas of the web as the web moves over the roll. In a preferred embodiment the web is non-woven and the fibers are hydrophobic in nature, e.g., dry-laid or melt-blown polypropylene or polyethylene fibers or spun-bonded hydrophobic filaments. A woven web made of cotton or other hydrophilic fibers may also be used if the end result is to create partially hydrophobic areas on a hydrophilic web. The areas of liquid are positioned on the web only where desired so as to eliminate the excessive cost of unwanted and unnecessary coating material. If the web is hydrophobic, the liquid makes that area hydrophilic. If the web is hydrophilic, the liquid makes that area hydrophobic. Enhanced liquid containment and transport is obtained when at least one discontinuous fine fiber layer is utilized in the web and the fine fiber layer has a melt-blown content greater than zero but less than 1.5 gsm.

Owner:AVGOL NONWOVEN INDS

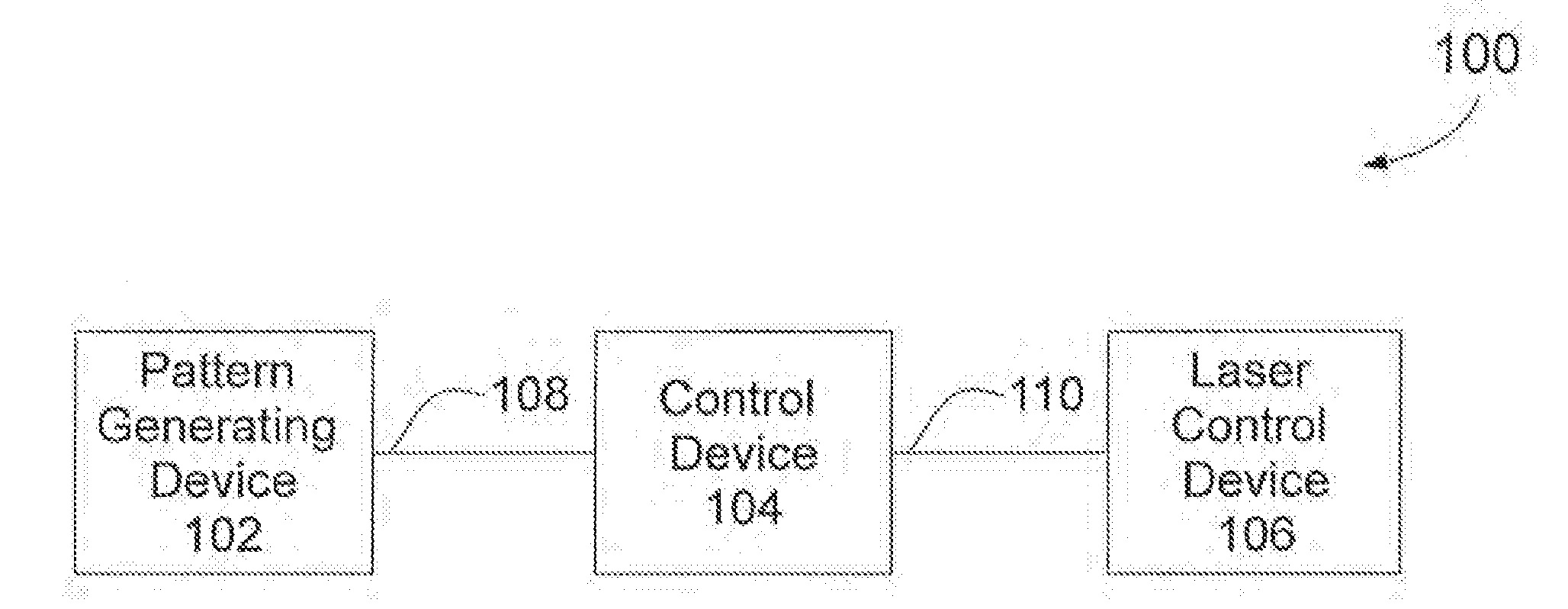

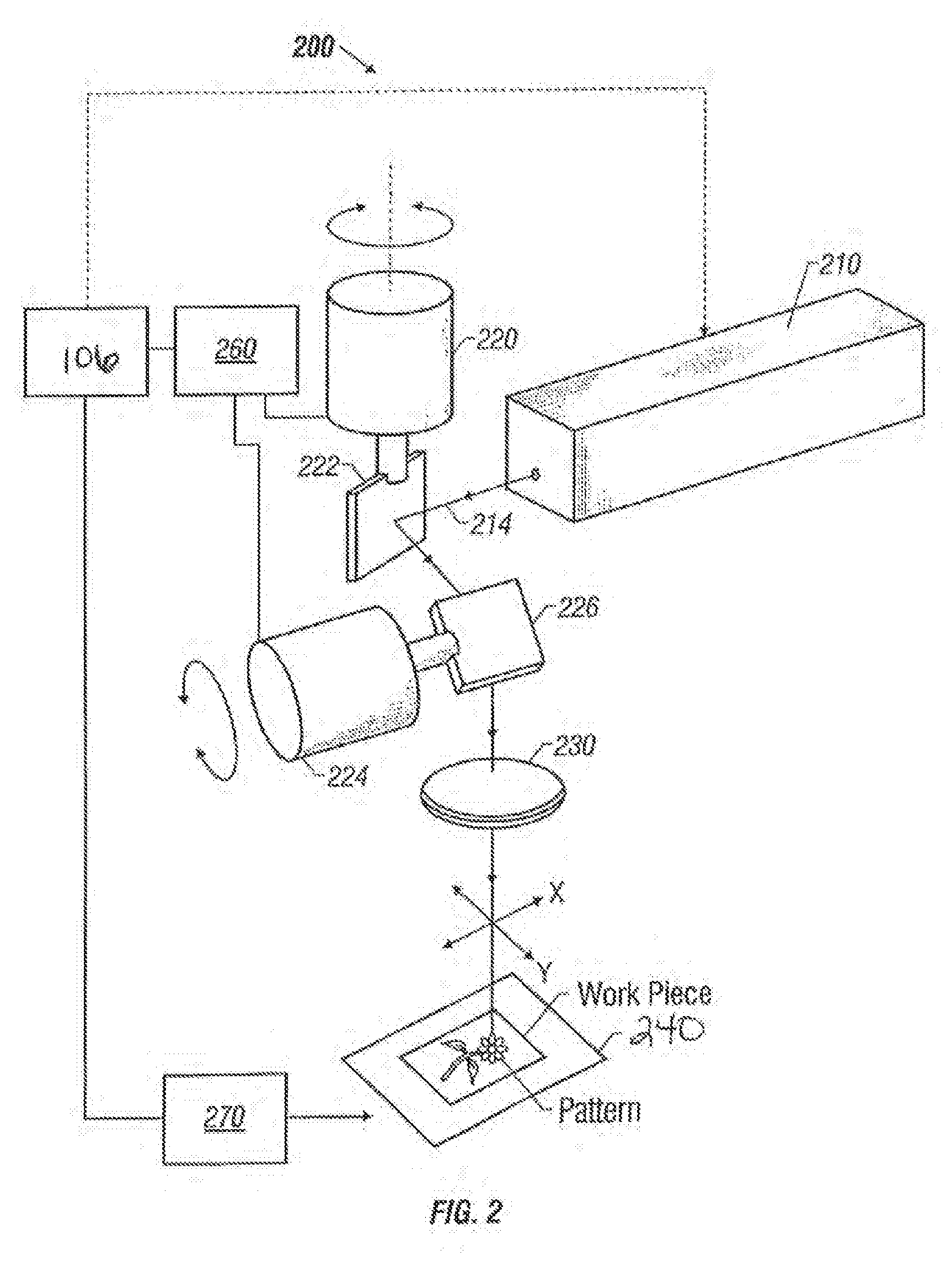

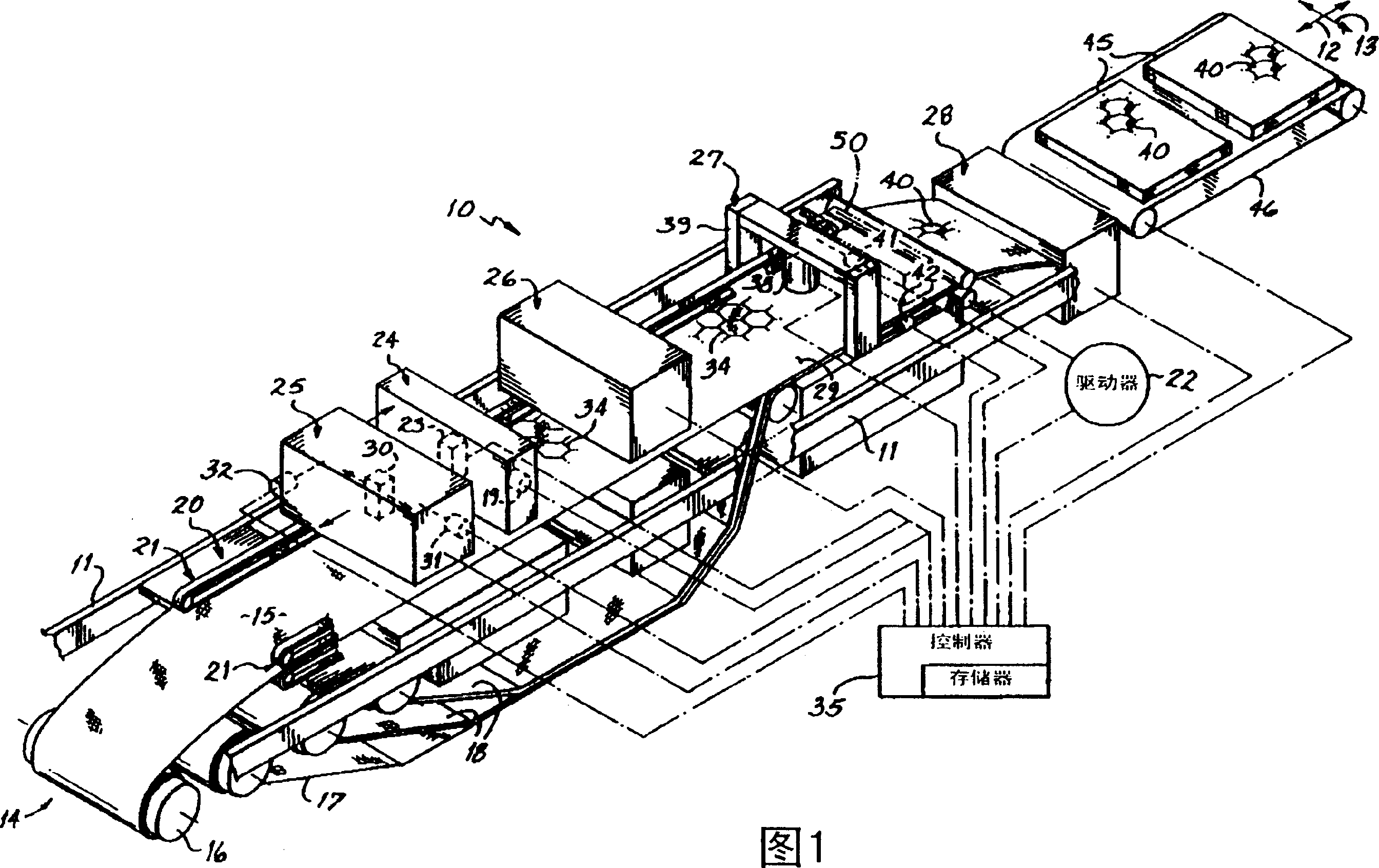

System and method of generating a pattern used to process a surface of a fabric through laser irradiation, and fabric created thereby

A method is provided of generating a pattern image used to form a pattern on a surface of a fabric using laser irradiation. A plurality of parameters associated with laser irradiation units are input into a user interface. The parameters include an area parameter, a laser irradiation unit density parameter, optionally a discontinuity parameter, and a dye removal parameter. A plurality of laser irradiation units arranged in a pattern area of a user interface based on computer processing of the inputted plurality of parameters is received for viewing at the user interface. The laser irradiation units collectively establish the pattern image for viewing by the user.

Owner:REVOLAZE LLC

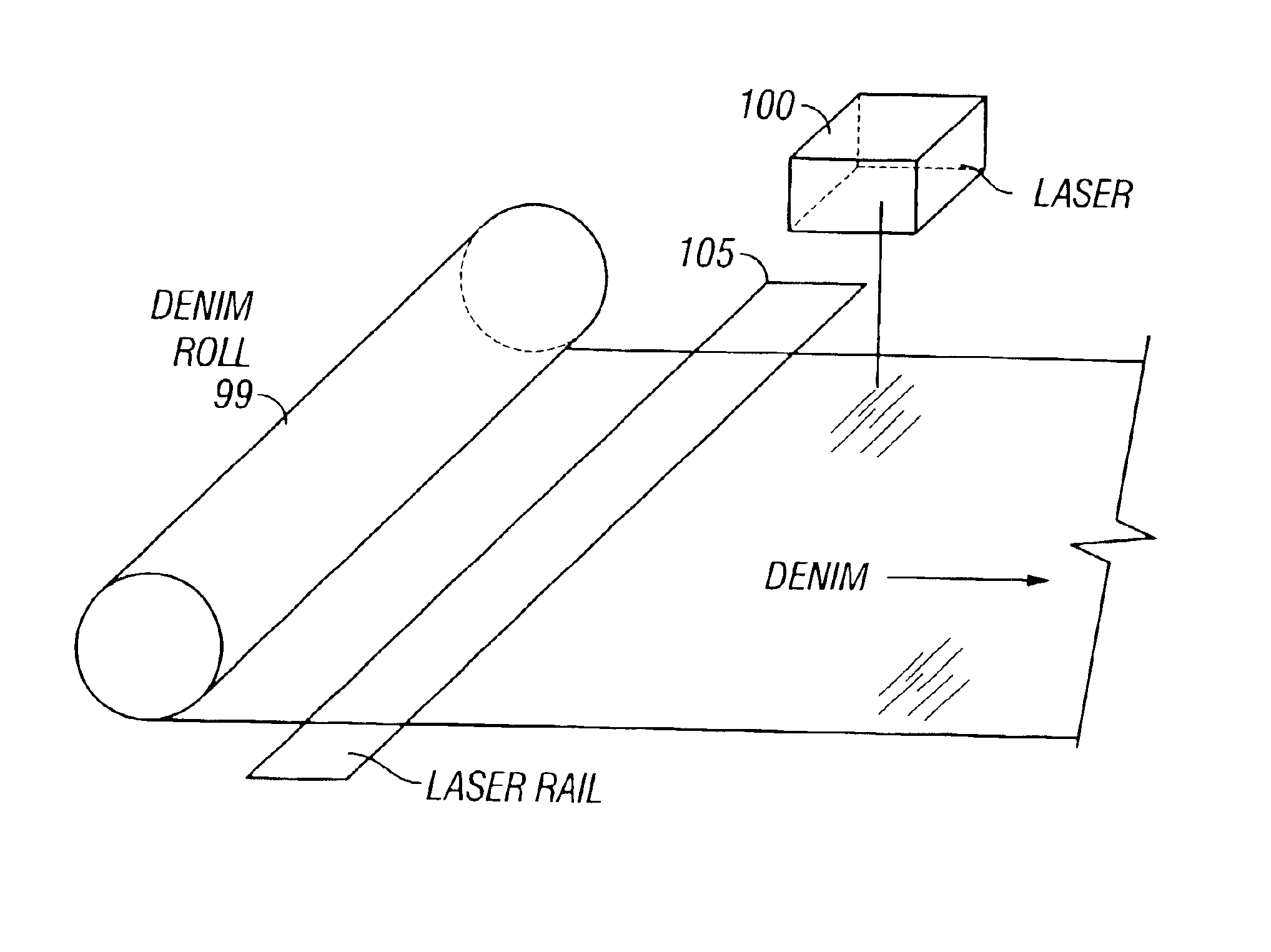

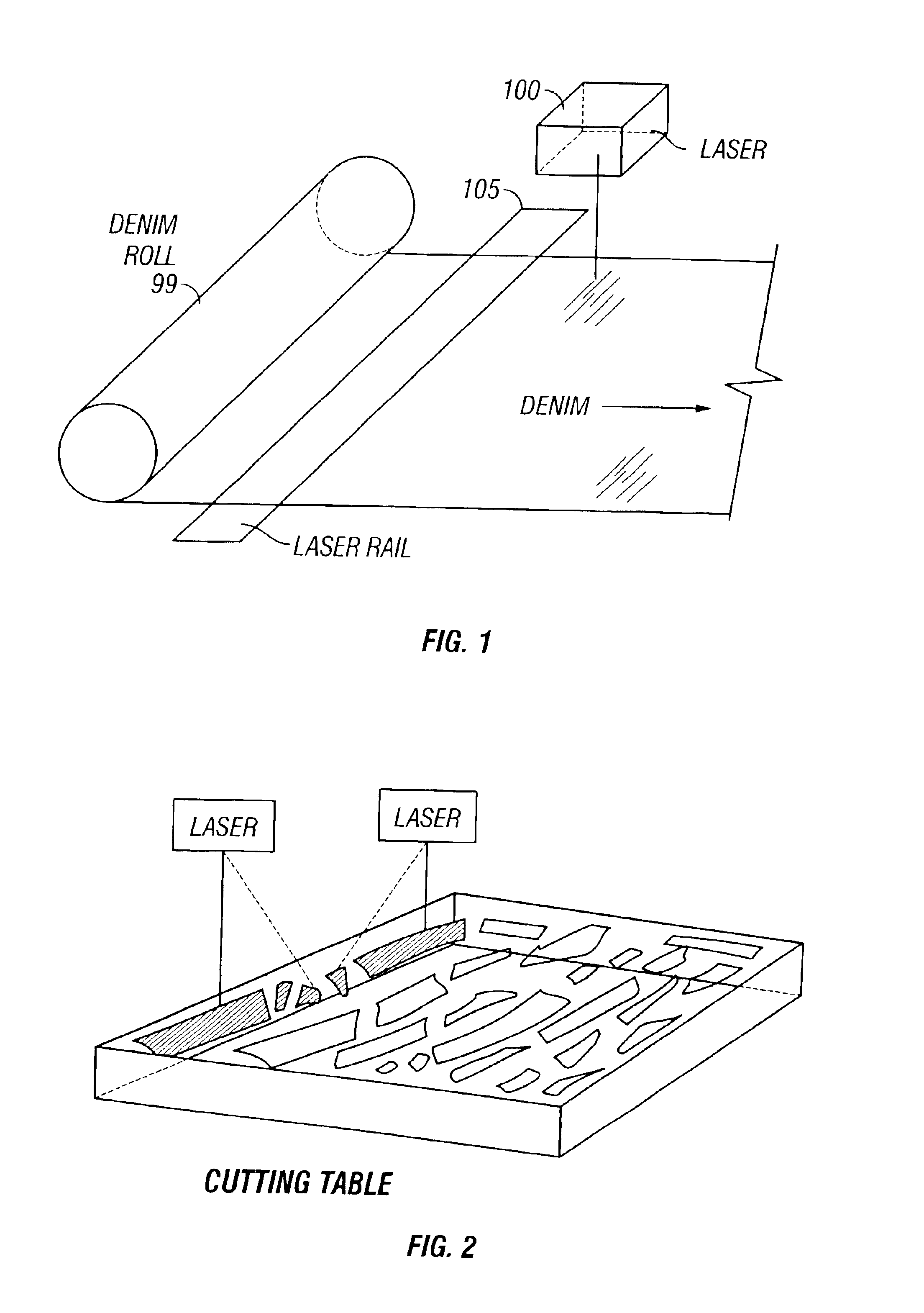

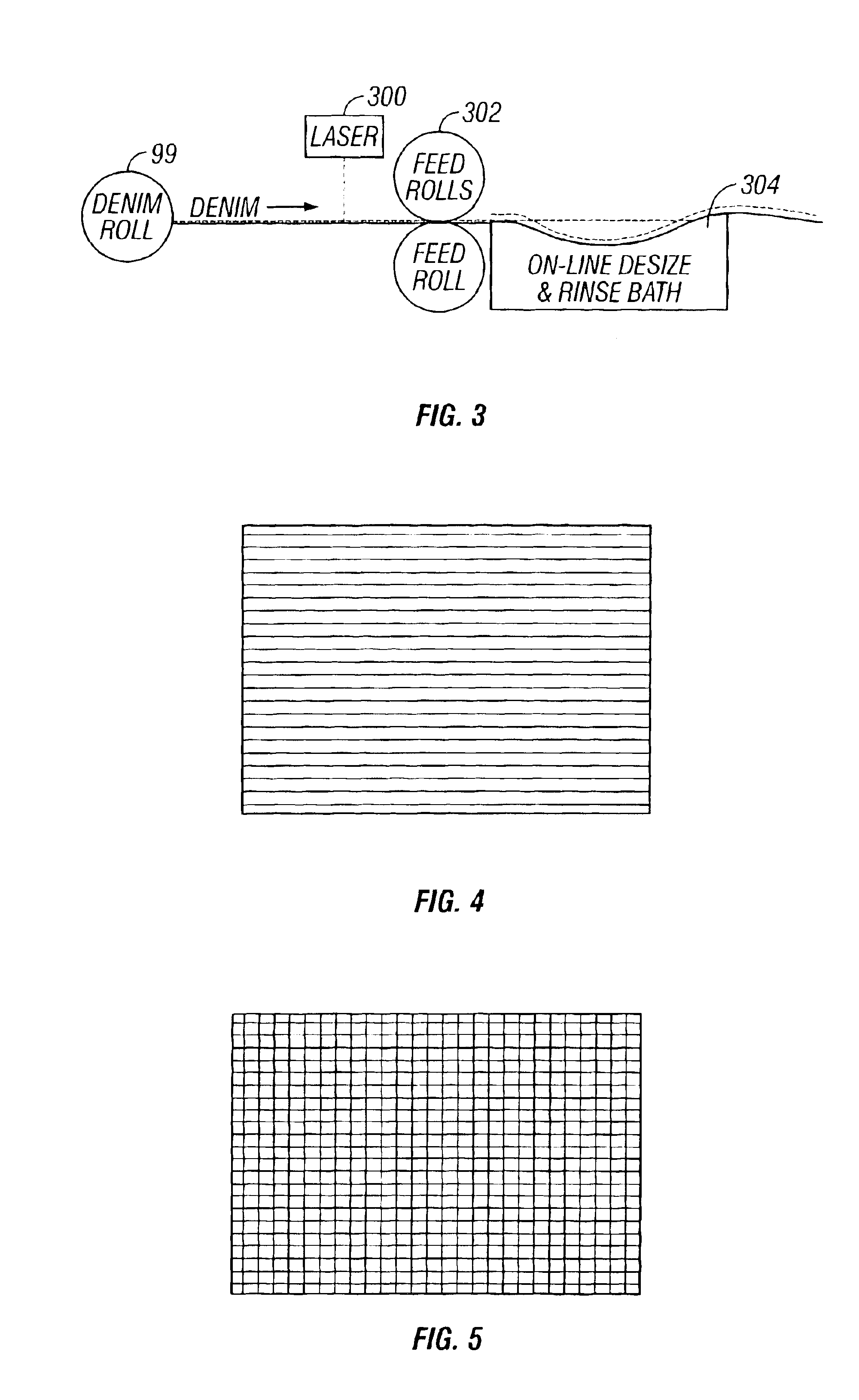

System and method of generating a pattern or image on fabric with linear laser irradiation, fabric made by said method, and products made with said fabric

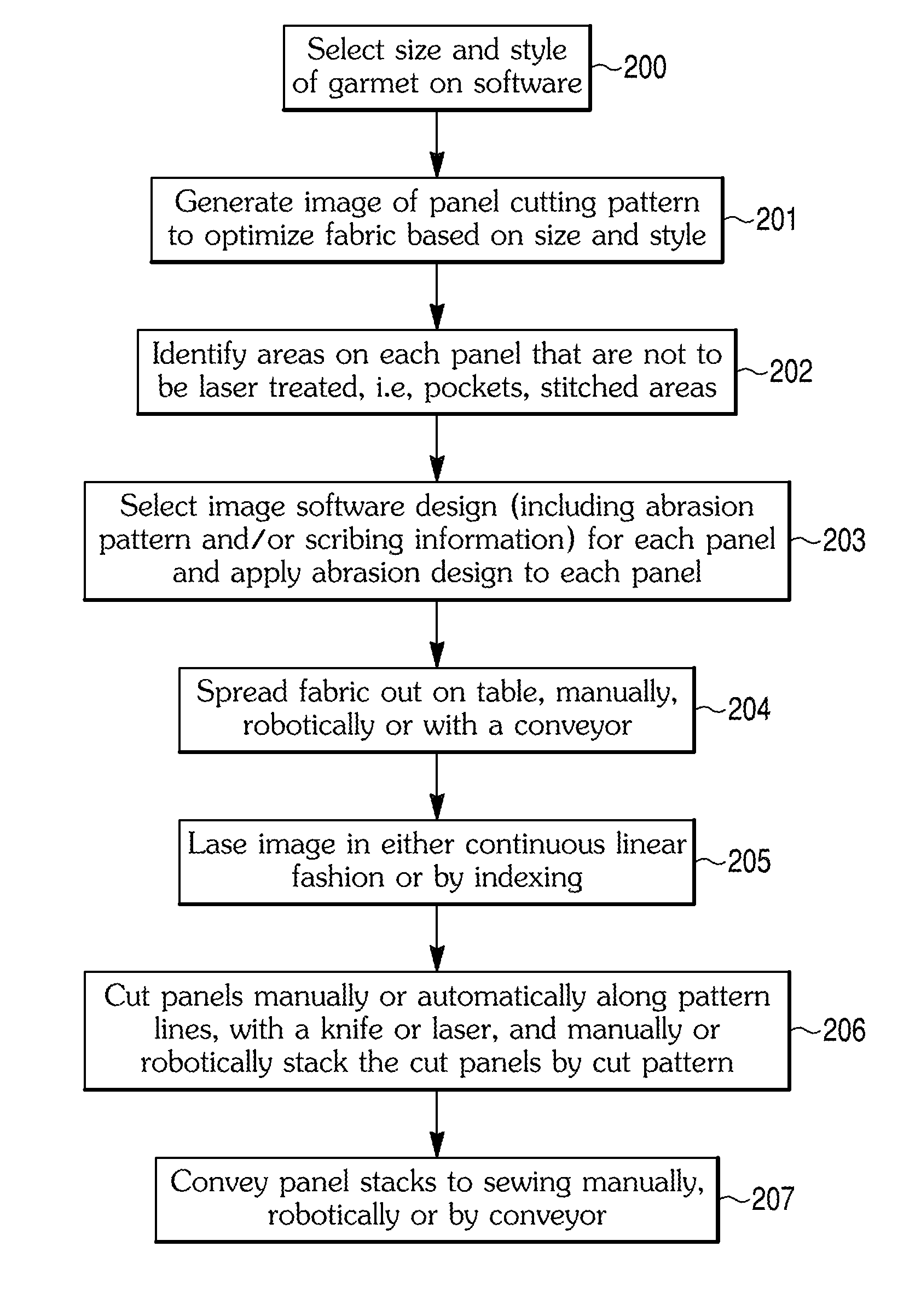

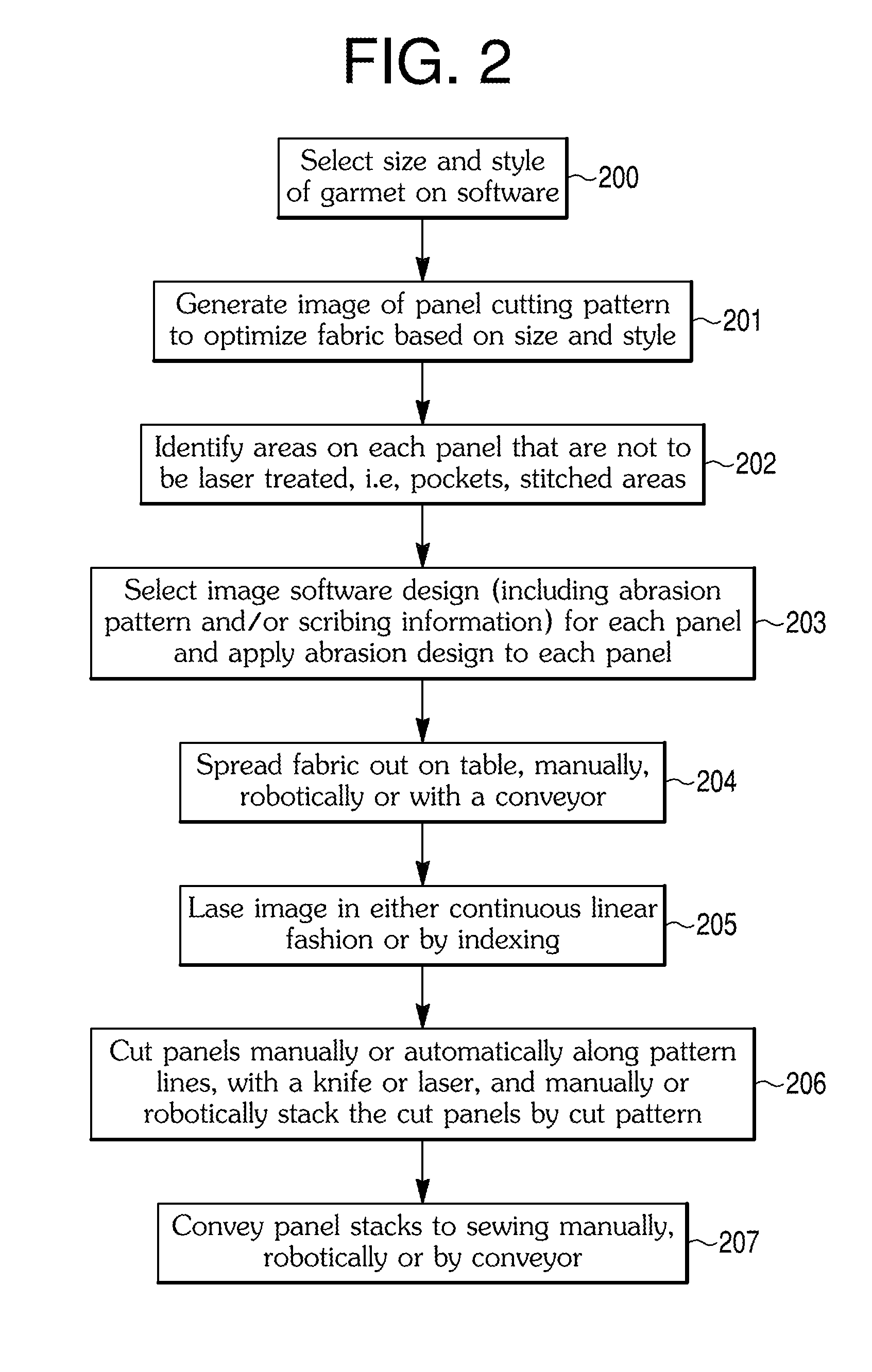

A method of scribing abrasion aesthetics, patterns, images, serial numbers, ply markings and / or other information, such as sizing or care information, on fabric such as denim, before or during the fabric cutting process is provided. The method comprises loading the panel abrasion software, pattern marker software, and fabric scribing software; placing the fabric on a flat surface under at least one laser; laser scribing ply numbers, serial labels, fabric markers, and panel abrasions on the fabric; cutting the fabric into fabric lengths; spreading the pre-abraded and pre-marked fabric lengths on top of each other to create multiple plies in precise alignment; cutting shaped panels along the lines of the pattern marker with a conventional knife, laser, or other appropriate cutting tool; and stacking the abraded, labeled and shaped panels robotically or manually for sewing.

Owner:REVOLAZE LLC

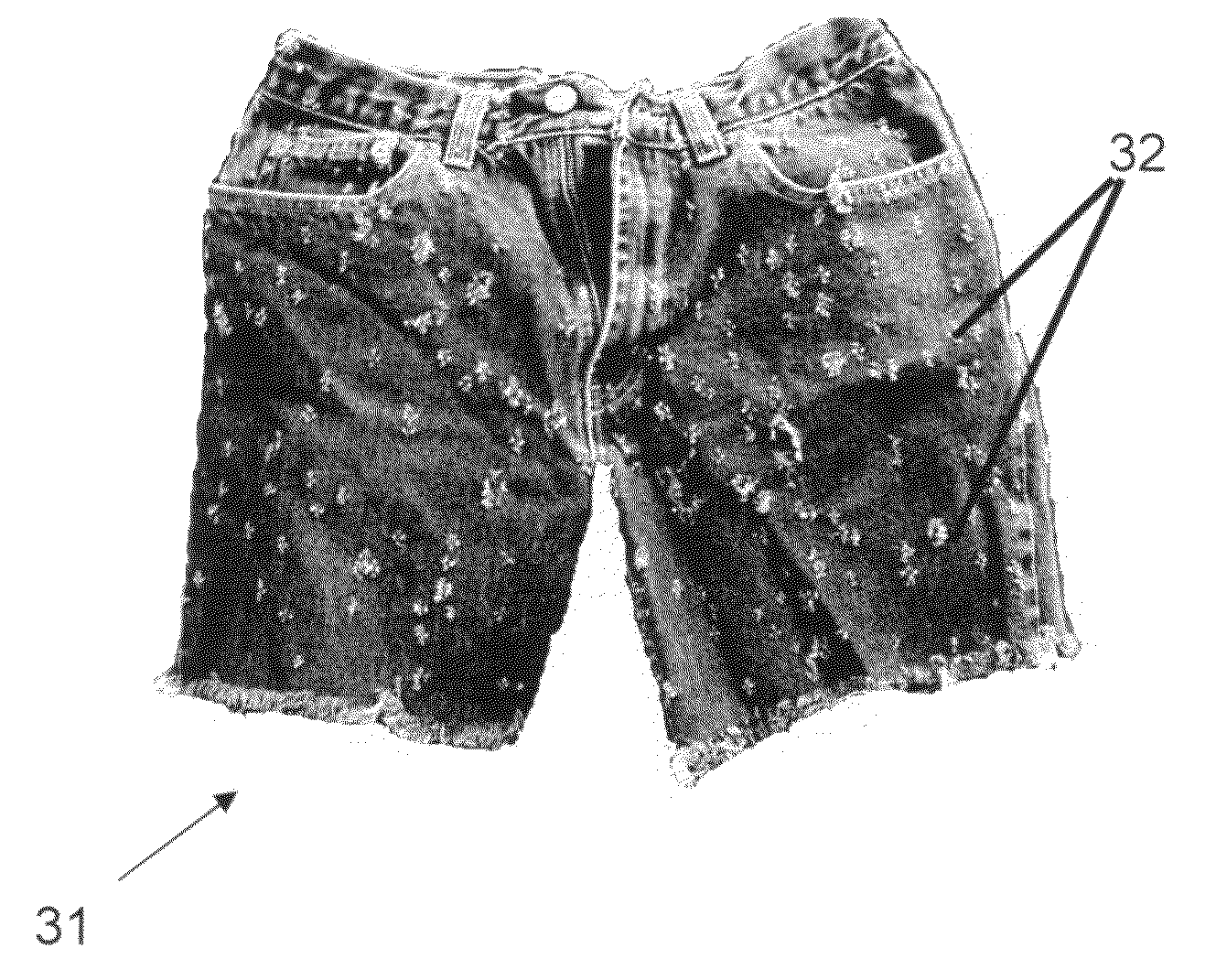

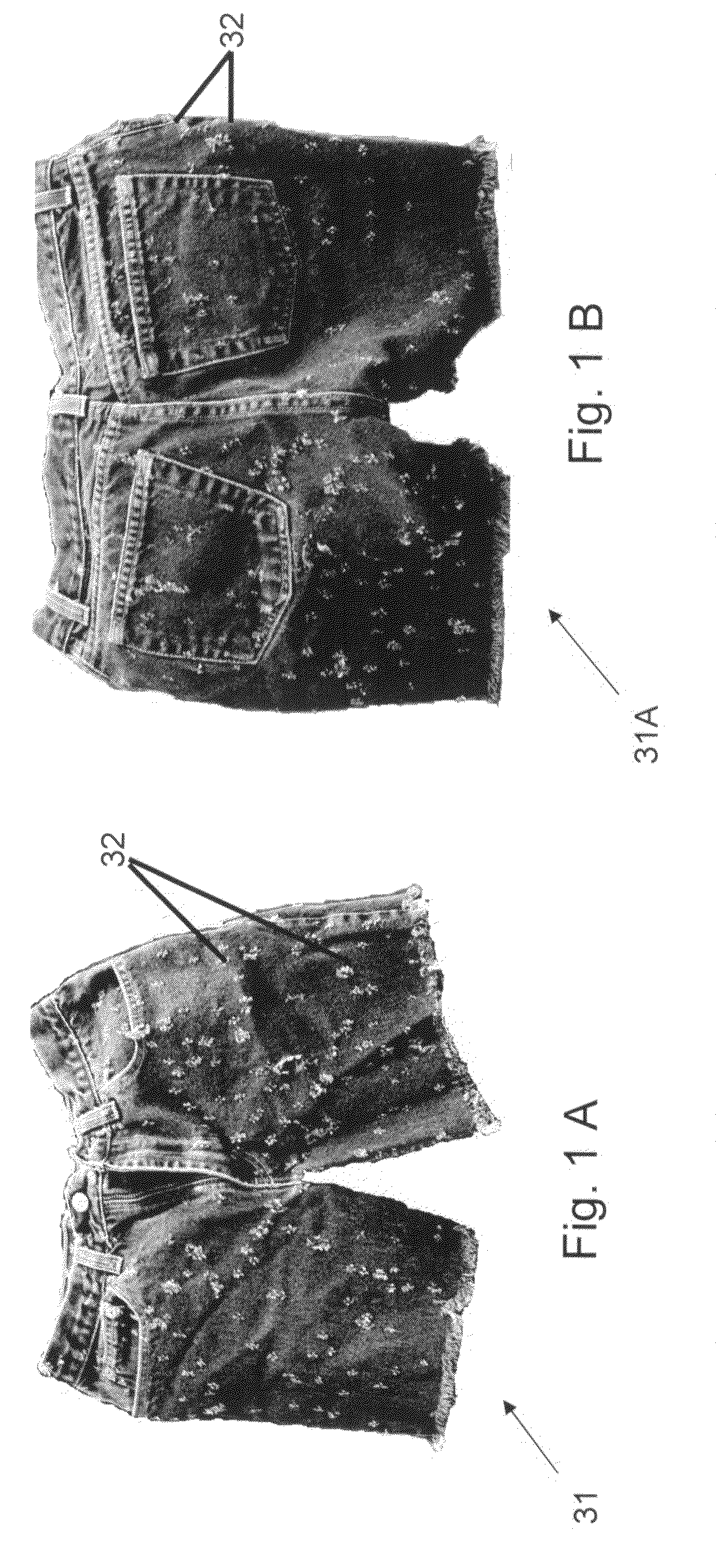

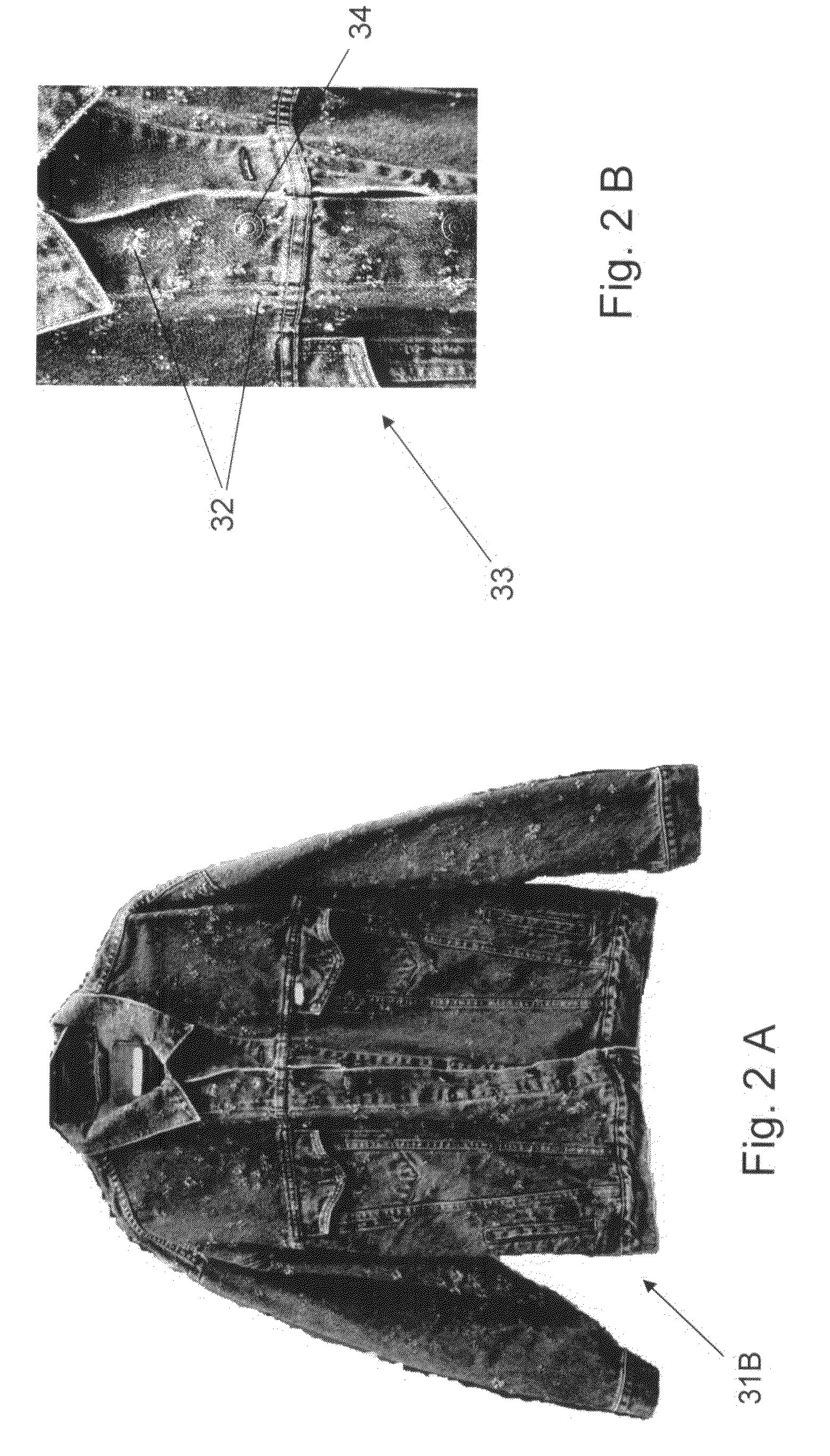

Buck shot blues specially processed denim product and the process methods to make the product

InactiveUS20070205541A1Efficiently provideIncrease heightPattern makingTextile parts treatmentDenimMetal

A process and the resulting uniquely configured product called “Buck Shot Blues”. The base product is a fabric such as denim that has been processed and altered to accomplish an appearance that the fabric has been “blasted” by buck shot or small metal pellets. The resultant fabric has a plurality of holes or apertures in a “blast pattern” that is either specific or random. The holes or apertures after processing are “frayed” from the penetration of the blast elements. The manner of production includes a number of methods, from a simple blast scheme to more complex production processes. An alternative computer controlled manufacturing process is also provided where the individual interacts with the process that produces his garment.

Owner:ALLEN DANN +1

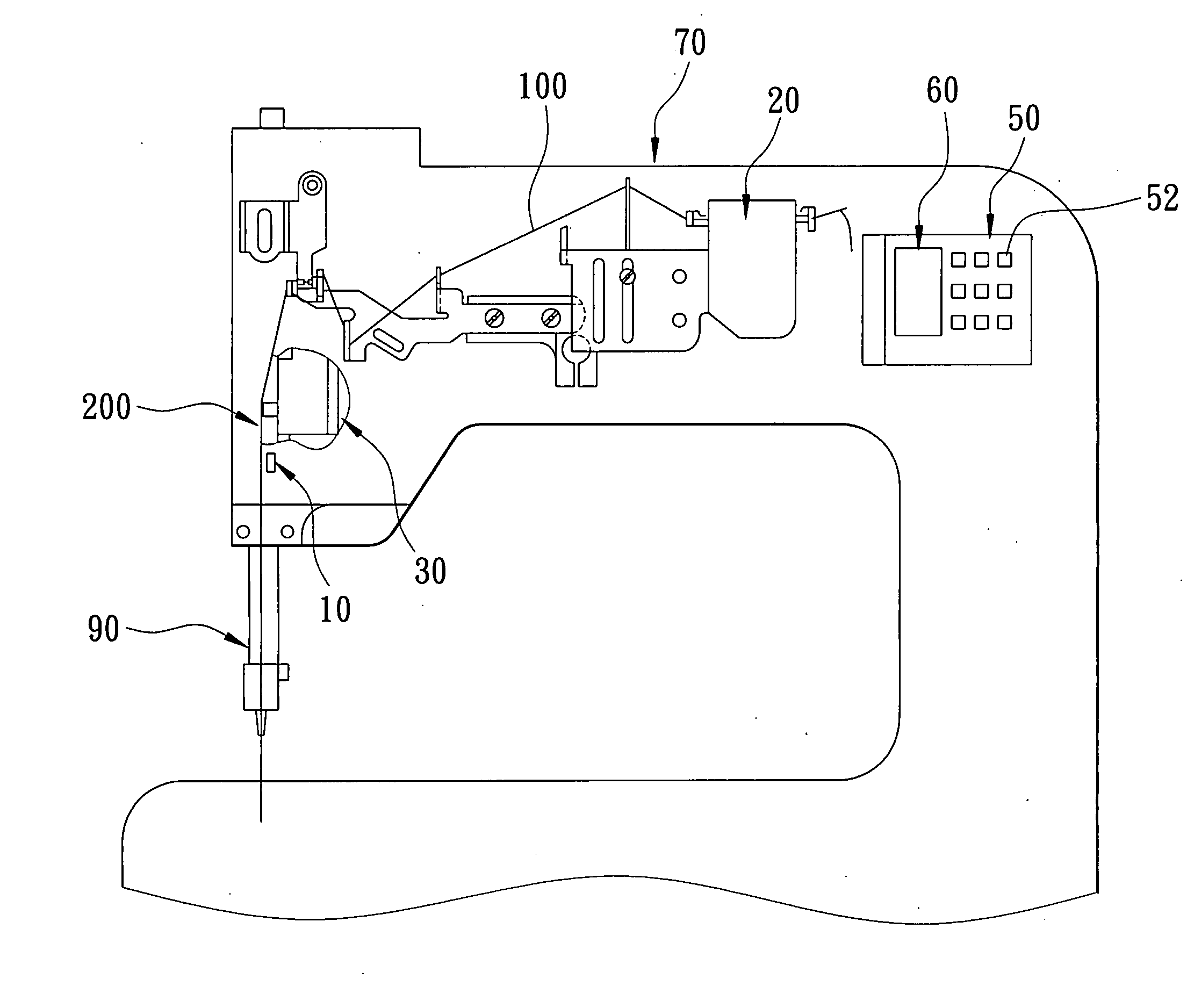

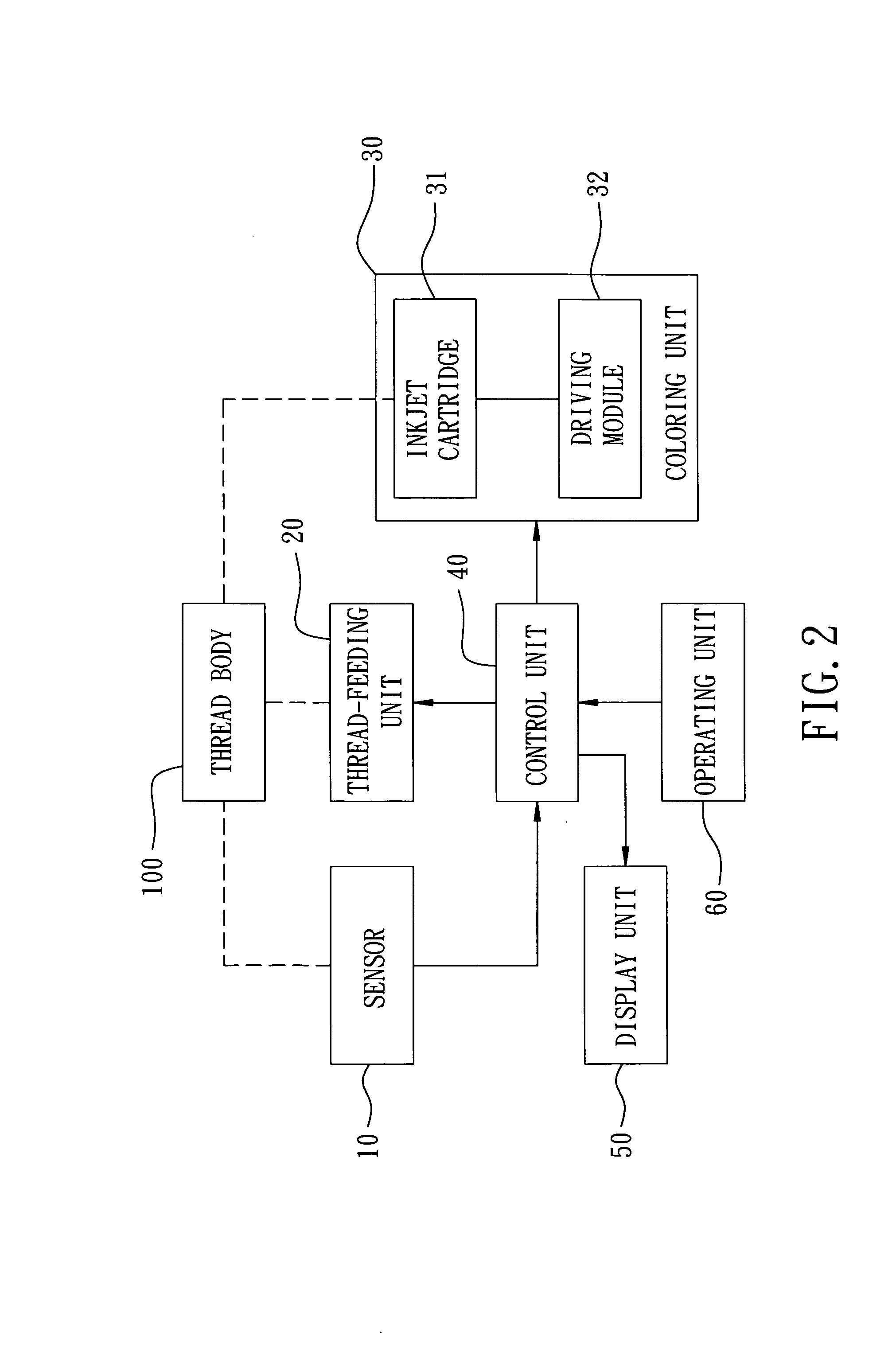

Device for coloring a thread body, and sewing machine having the same

InactiveUS20090241819A1Programme-controlled sewing machinesLiquid surface applicatorsEngineeringControl unit

A device for coloring a thread body includes a thread-feeding unit adapted for feeding the thread body at a predetermined speed such that the thread body is transported along a feeding path. A coloring unit is disposed fixedly adjacent to the feeding path, and is operable so as to spray a coloring material onto the thread body. A control unit is connected electrically to the coloring unit, and is operable so as to control the coloring unit to spray the coloring material, which has a desired one of a plurality of different colors.

Owner:ZENG HSING INDUSTRIAL CO LTD

Method for single-sided fabric finishing

ActiveCN101748575ALow costCloth speed upLiquid/gas/vapor removalTextile treatment by spraying/projectingEngineeringWater repellent

The invention provides a method for single-sided fabric finishing, which comprises the following steps: 1) pre-drying fabric; 2) applying finishing solution on a single side of the fabric by means of spraying; and 3) drying the fabric obtained in the second step, and obtaining the finished fabric product after drying. The method has a simple technical process, and can greatly improve the production efficiency in fabric finishing. After the single-sided finishing, such as the single-sided water-repellent and oil-repellent finishing, the fabric not only can meet the requirements for water repellence and oil repellence, but also can be worn more comfortably, thereby improving the product grade.

Owner:CHINESE TEXTILE ACAD

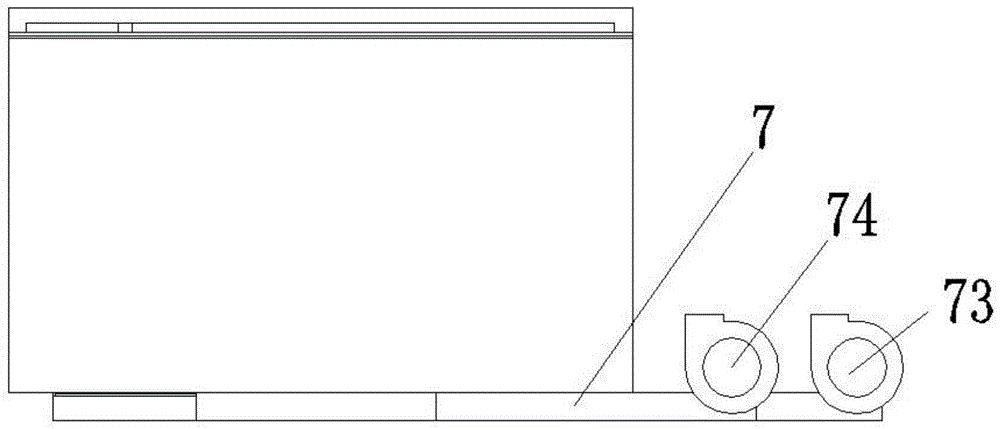

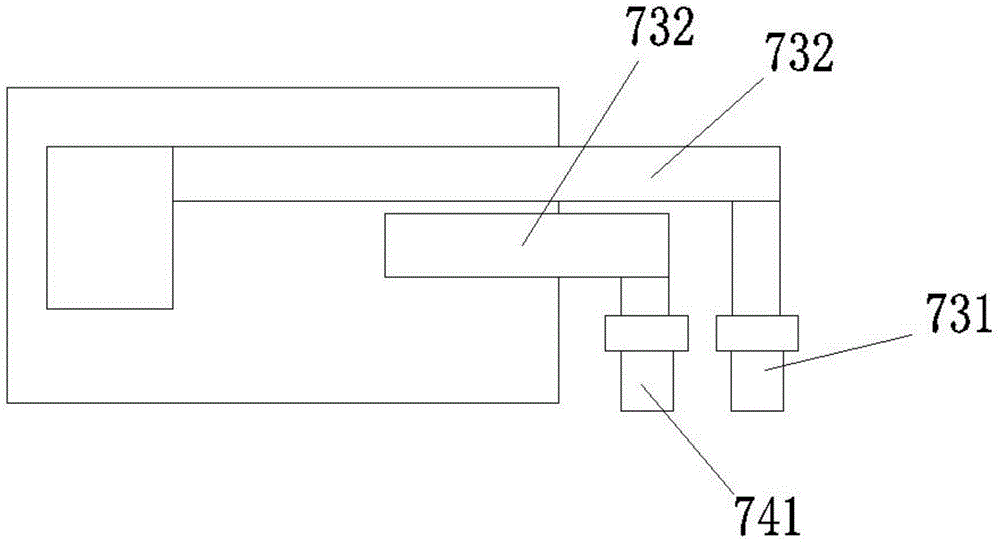

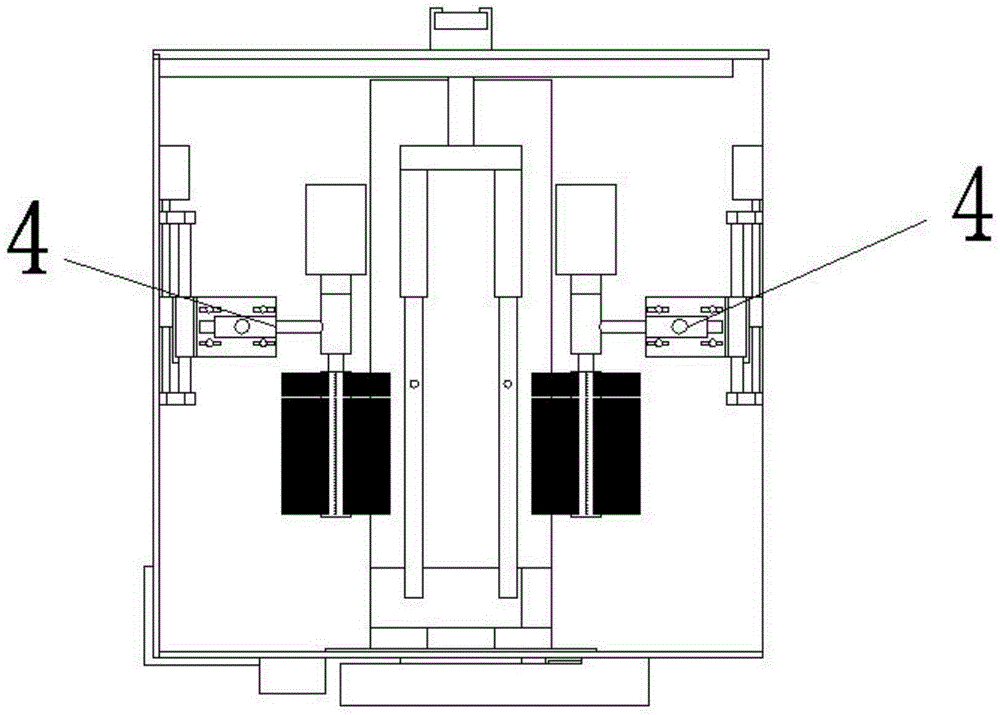

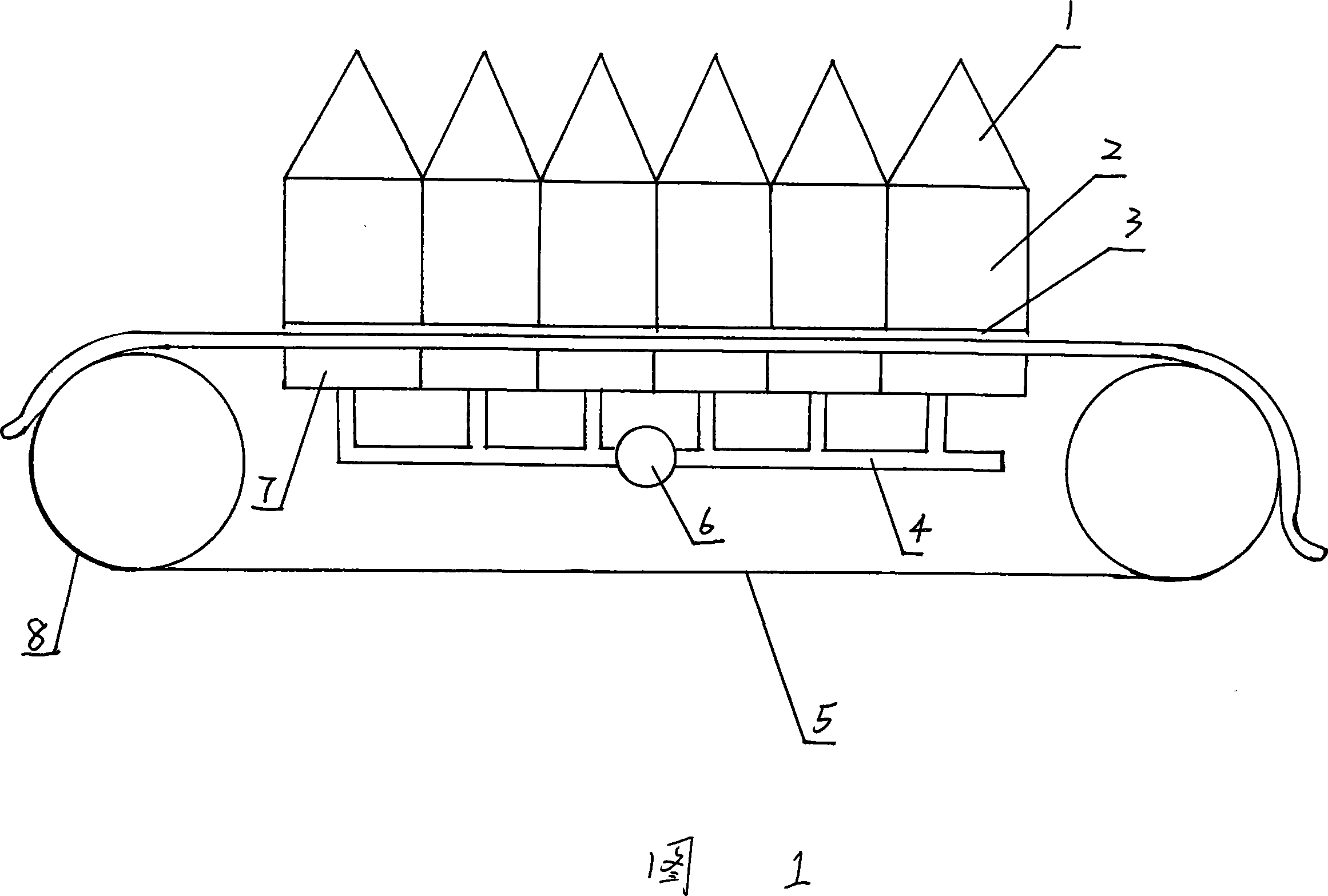

Automatic polishing and monkey washing device for jeans wear

ActiveCN105200694ASimple structureSmall footprintTextile treatment machine arrangementsTextile treatment carriersElectric machineryEngineering

The invention relates to an automatic polishing and monkey washing device for jeans wear. In the prior art, the working efficiency is relatively low since manual operation is carried out usually when jeans are polished. The automatic polishing and monkey washing device for jeans wear comprises a polishing room, a monkey washing room, jean fixing devices, polishing devices, monkey washing devices and a moving device and is characterized in that each polishing device comprises a fixing device, a brush, a control device and a driving motor; each control device comprises an adjusting plate and a driving device; each driving device comprises a lifting motor, a screw rod I and a sliding block connected with the adjusting plate; a connecting plate is arranged on each sliding block; an adjusting hole is formed in each of the connecting plate and the corresponding adjusting plate; a penetration hole corresponding to the adjusting hole is formed in the other one; each fixing device comprises a locking rod; each locking rod penetrates through the corresponding adjusting hole and the penetration hole sequentially. The automatic polishing and monkey washing device is simple in structure, reasonable in design, simple in operation and high in working efficiency.

Owner:嘉兴市金日不锈钢机械有限公司

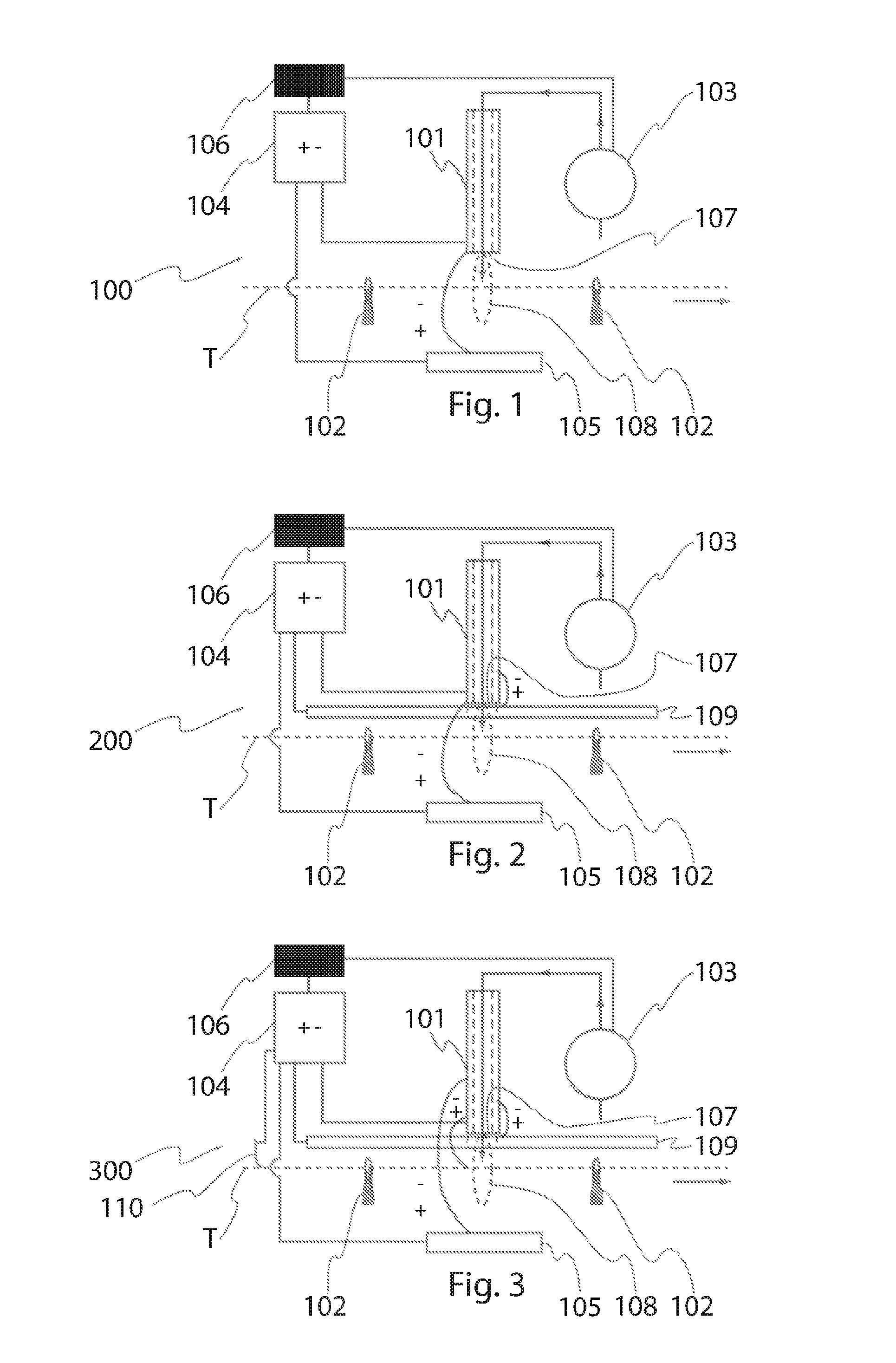

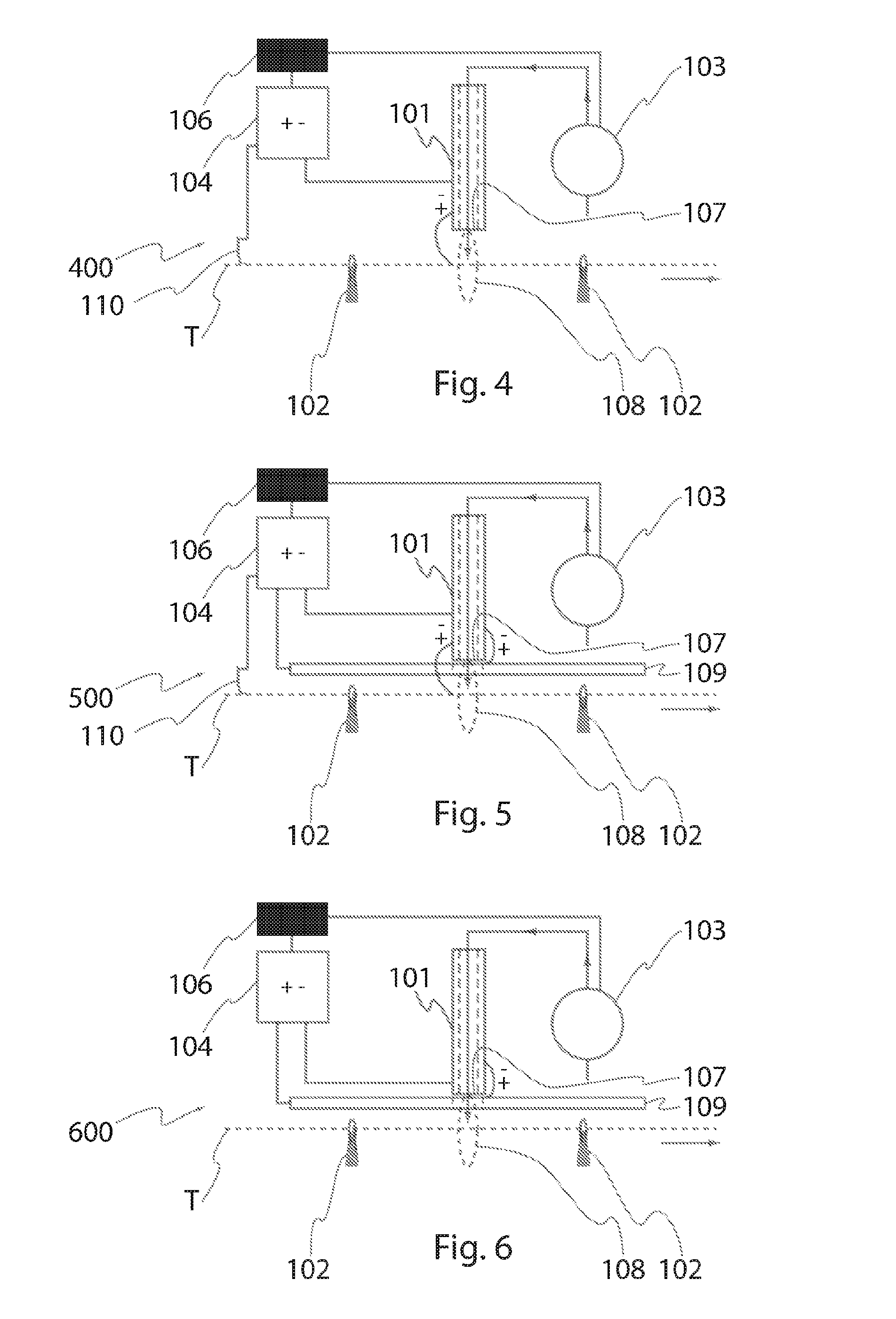

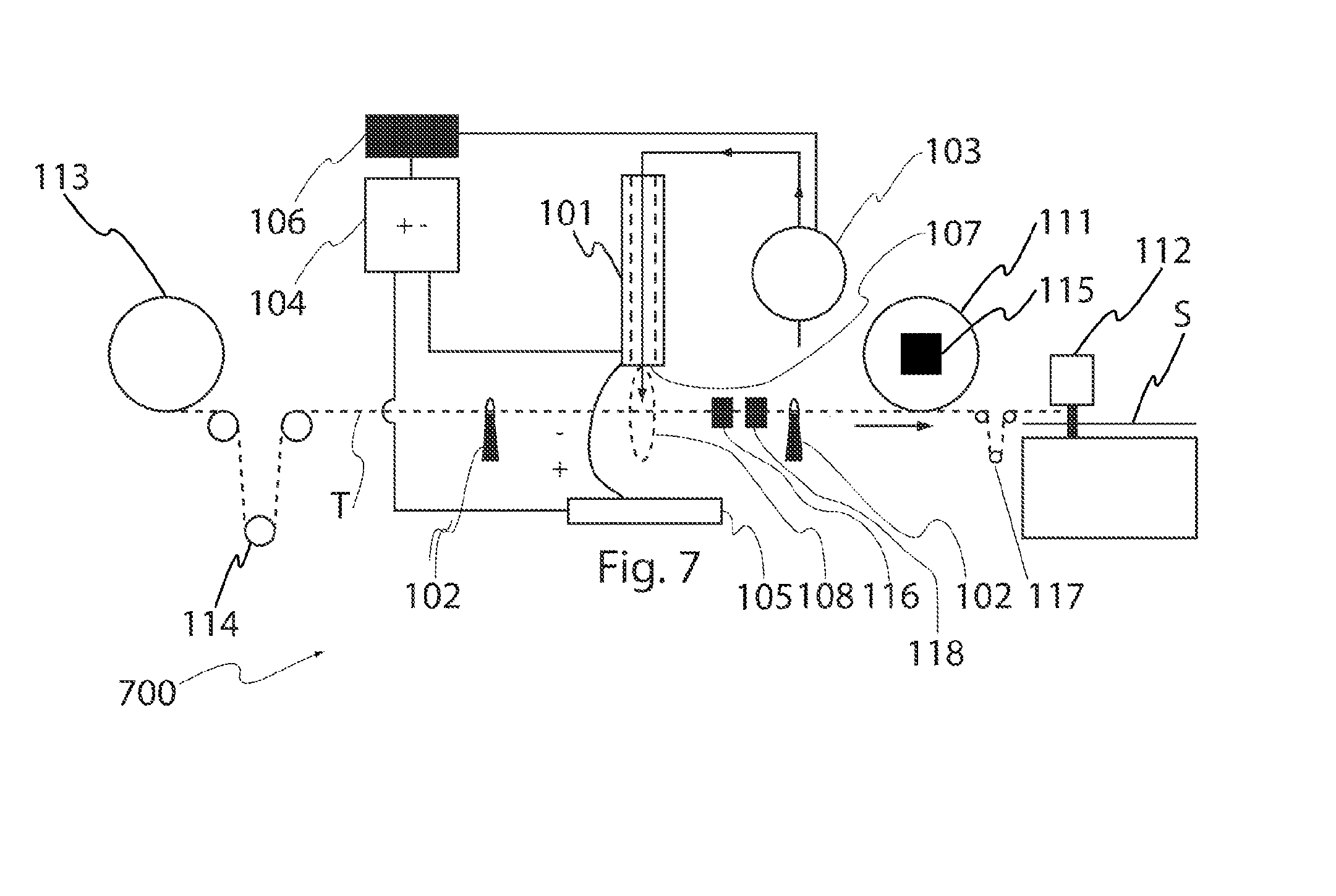

Coating Device for Coating an Elongated Substrate

InactiveUS20140349034A1Improve the lubrication effectImprove sewing effectLiquid spraying plantsLiquid surface applicatorsEngineering

A device and system for dynamically applying liquid to a single thread for a thread consuming device as said thread moves relative to the device along a path of movement. The device is configured to apply liquid to said thread by means of an electrospraying unit. A method for applying liquid to a single thread for a thread consuming device as said thread moves relative to the device along a path of movement is also provided.

Owner:COLOREEL GRP AB

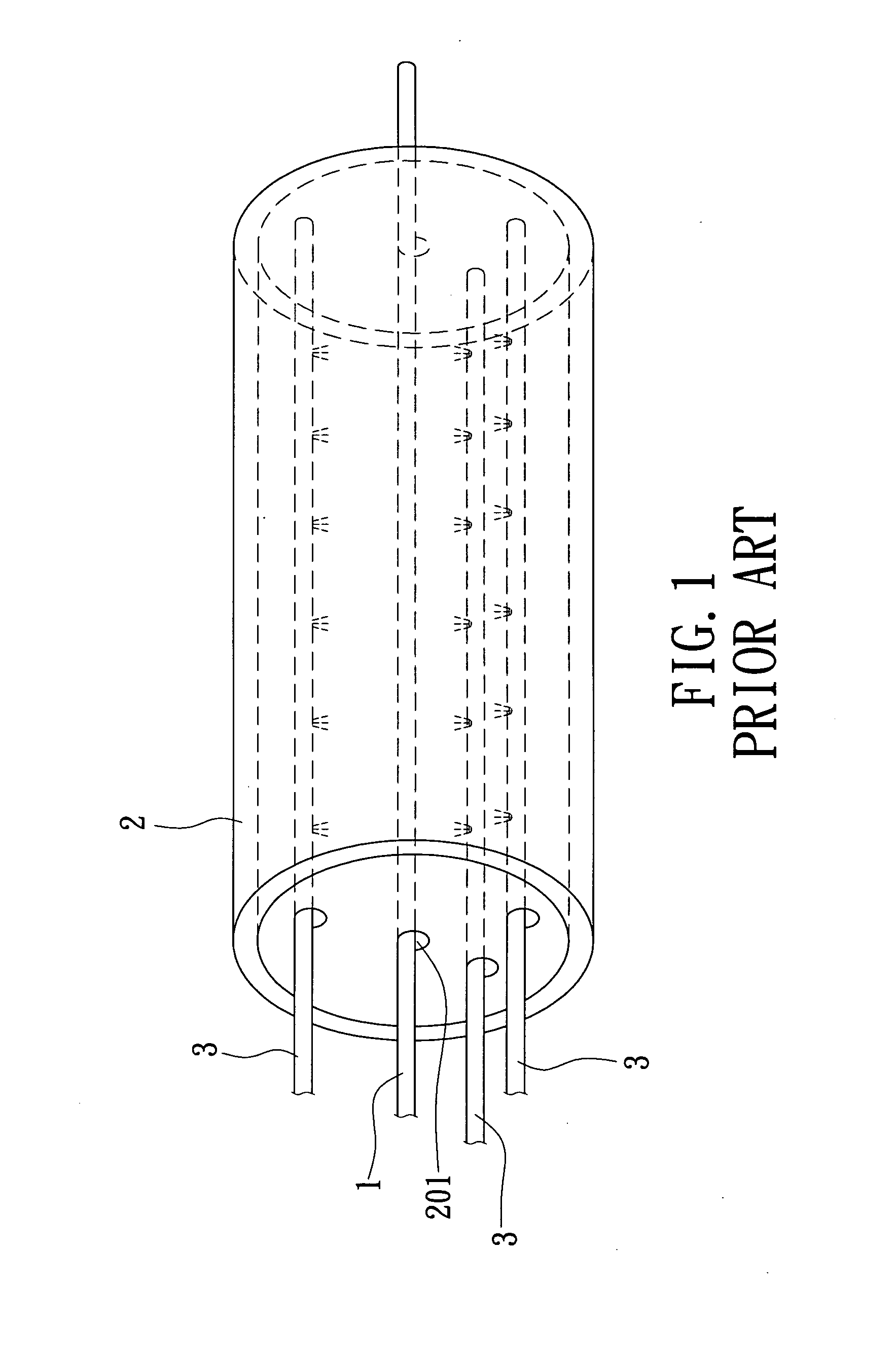

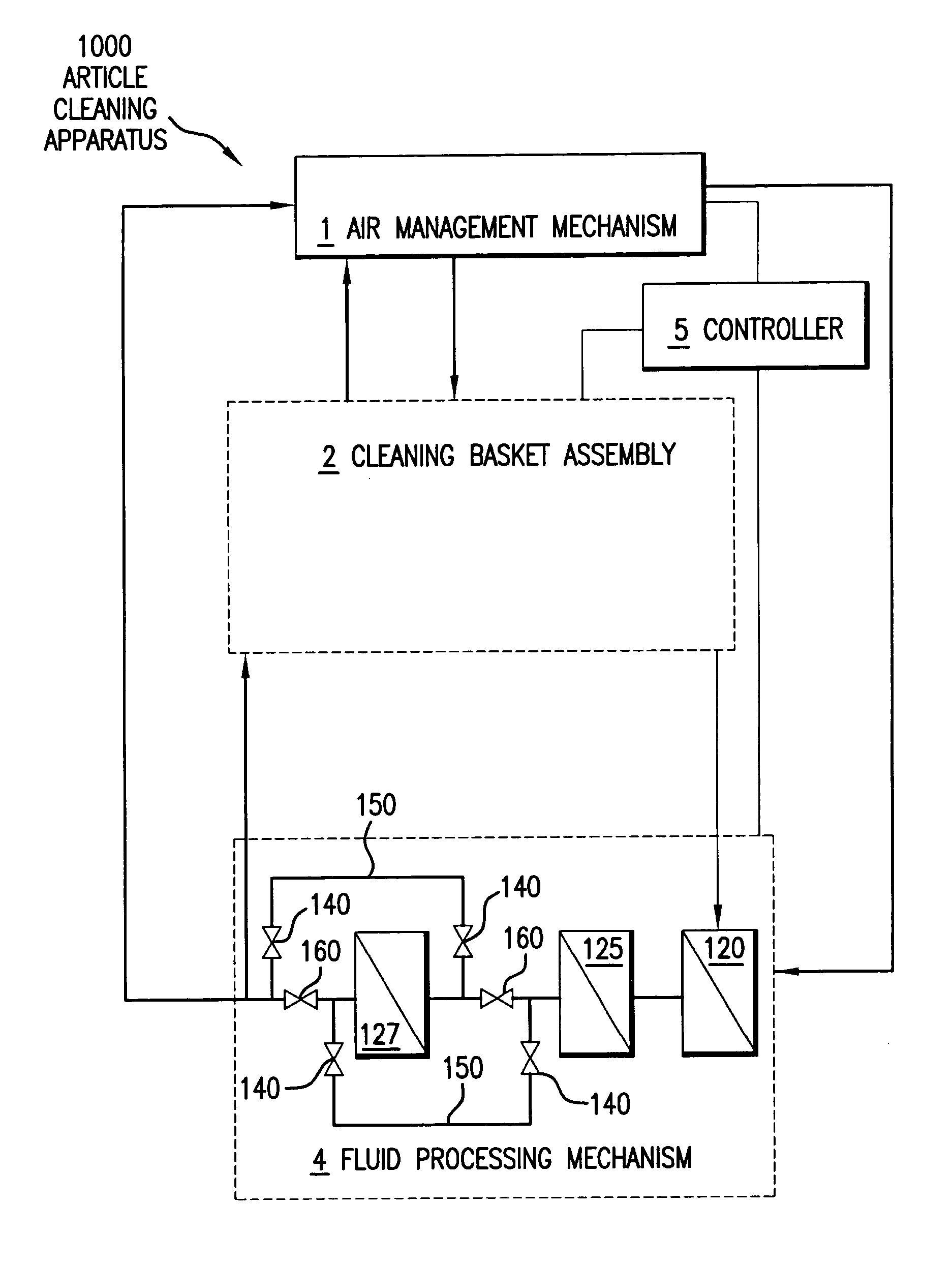

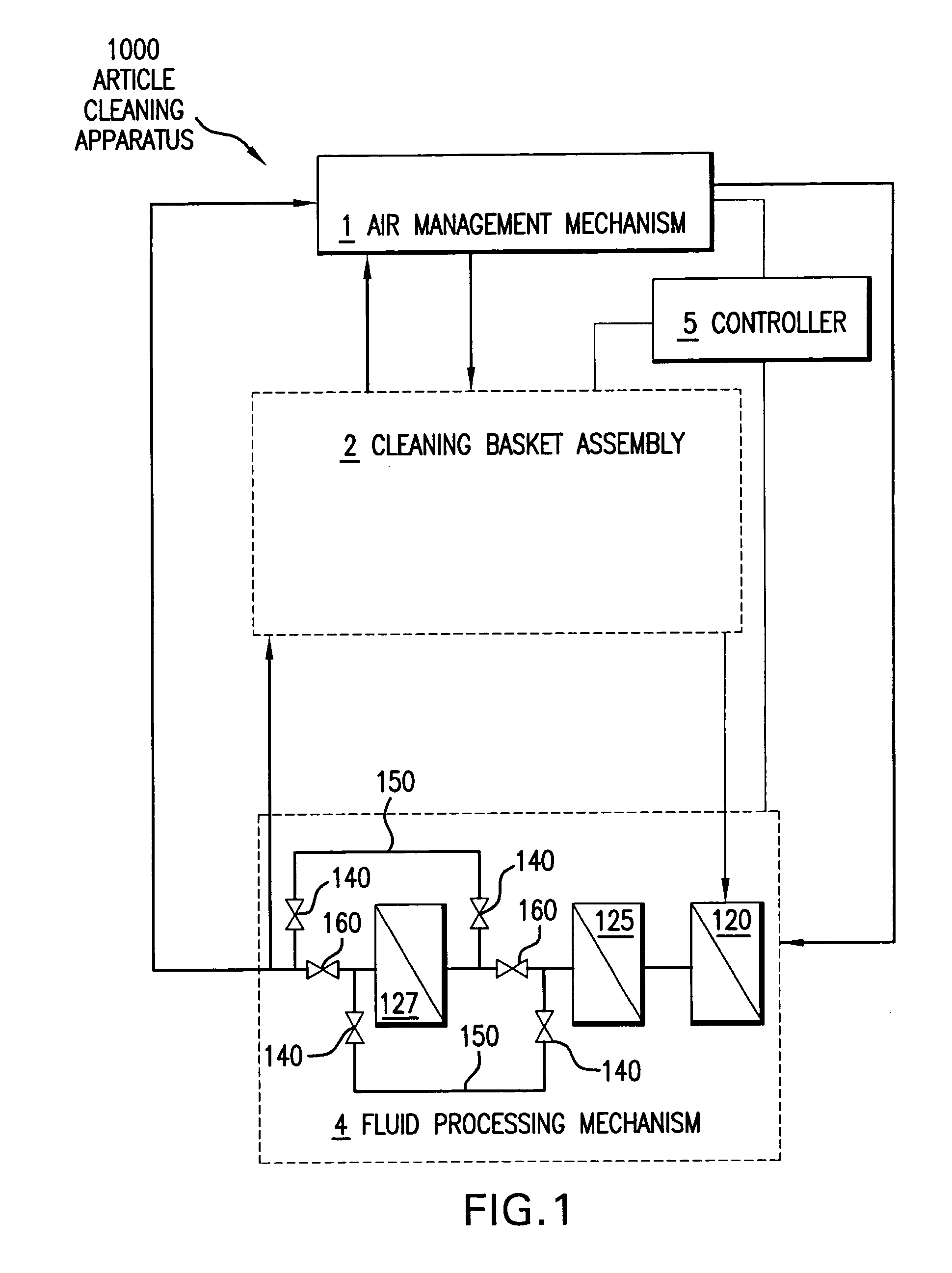

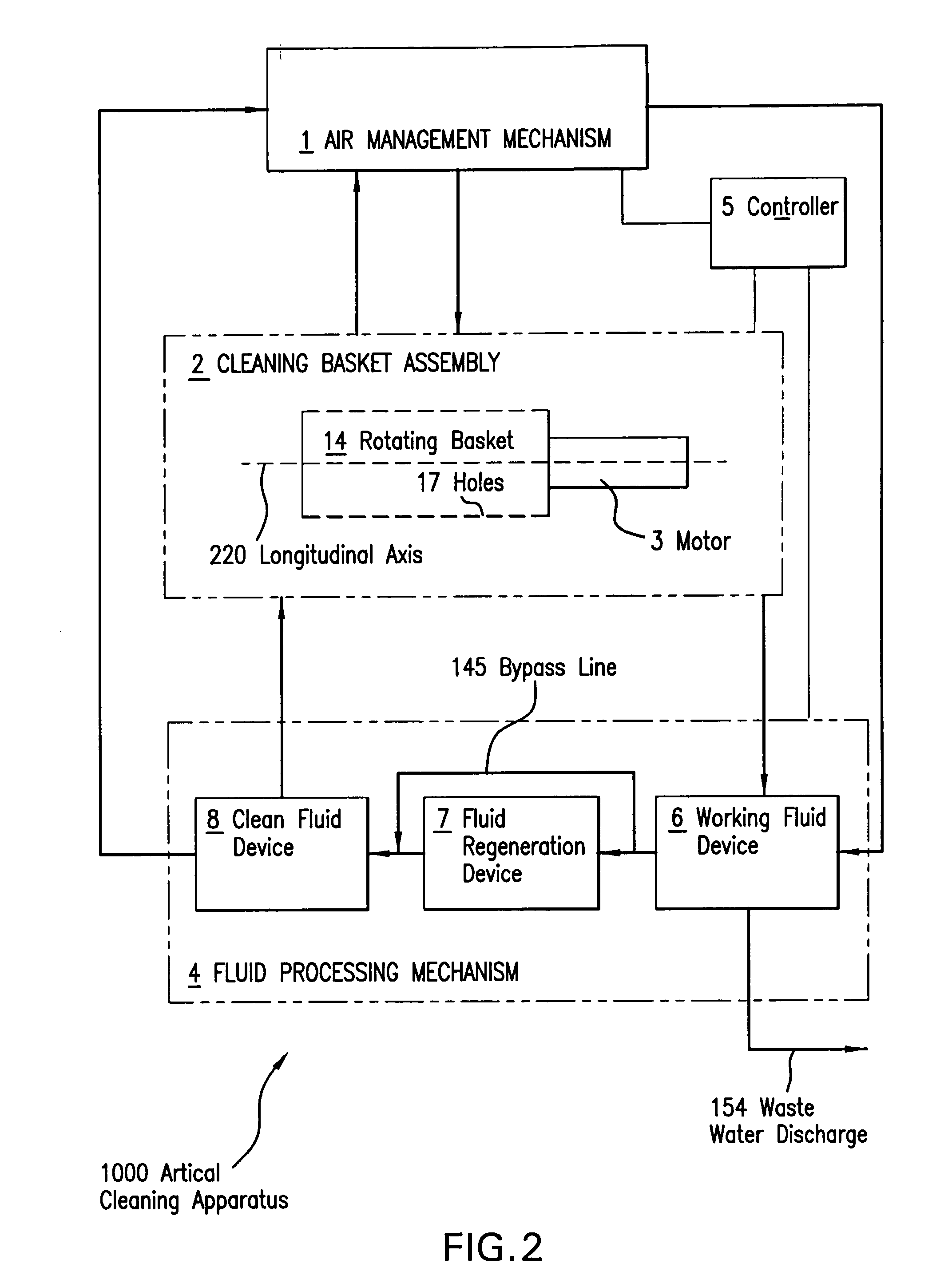

Apparatus and method for removing contaminants from dry cleaning solvent

The present invention relates to a method and apparatus for removing contaminants from a solvent based cleaning fluid. An article cleaning apparatus comprises an ultrafiltration filter having a pore size of about 0.01 microns to about 0.2 microns. A method for performing a solvent based cleaning process using an article cleaning apparatus comprises passing a solvent based cleaning fluid through an ultrafiltration filter having a having a pore size of about 0.01 microns to about 0.2 microns.

Owner:HAIER US APPLIANCE SOLUTIONS INC

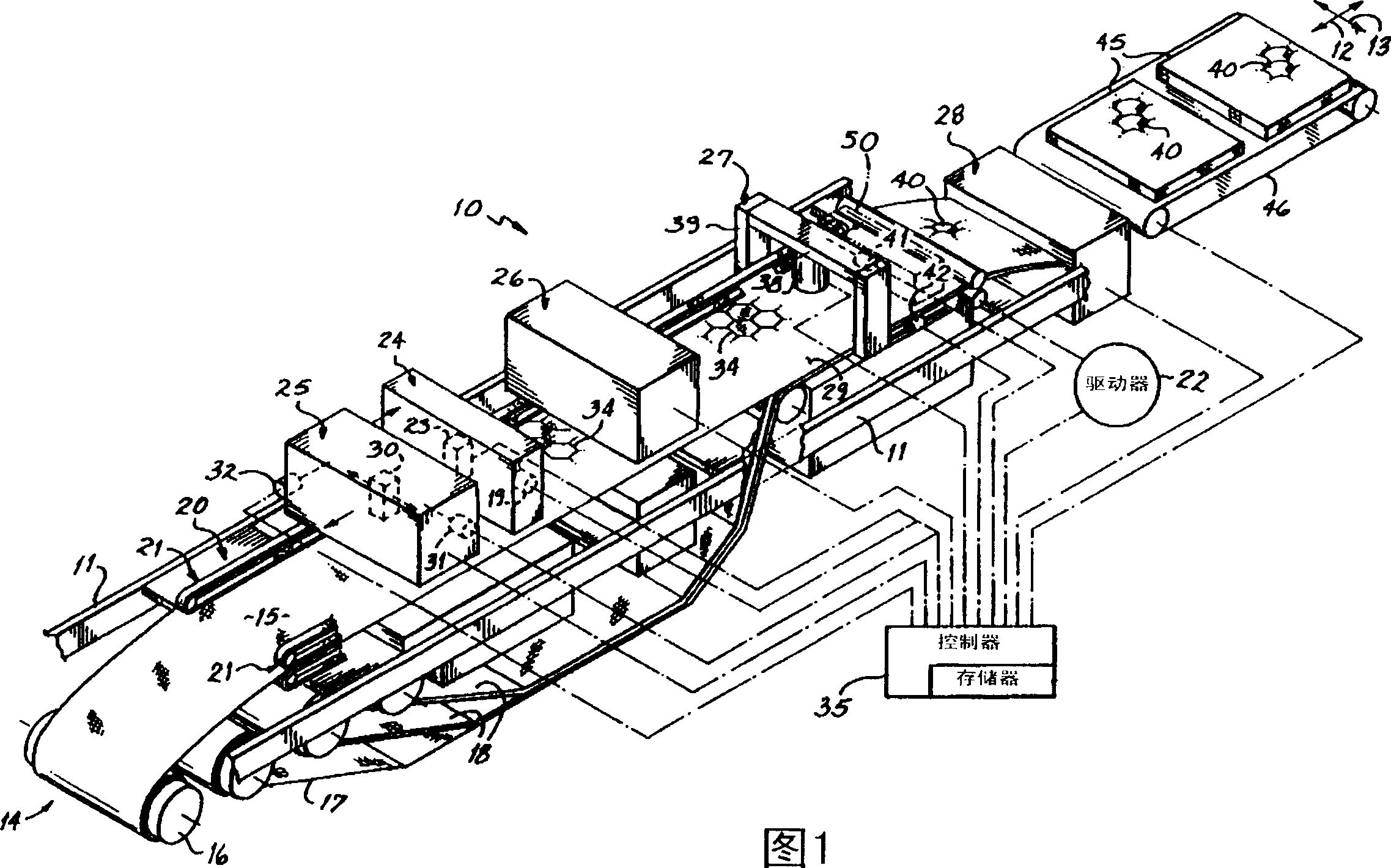

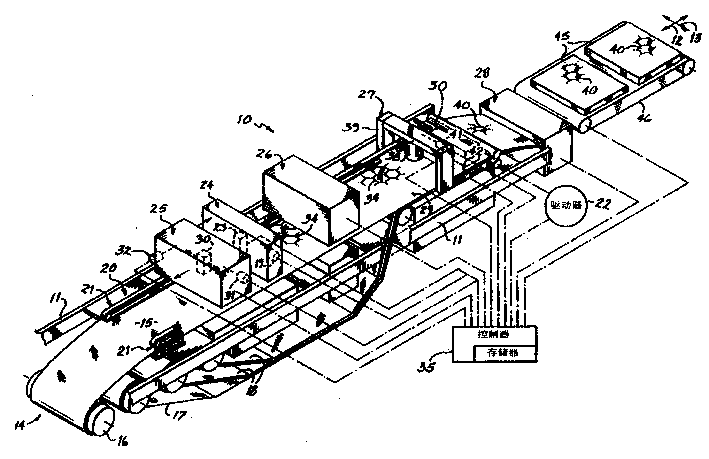

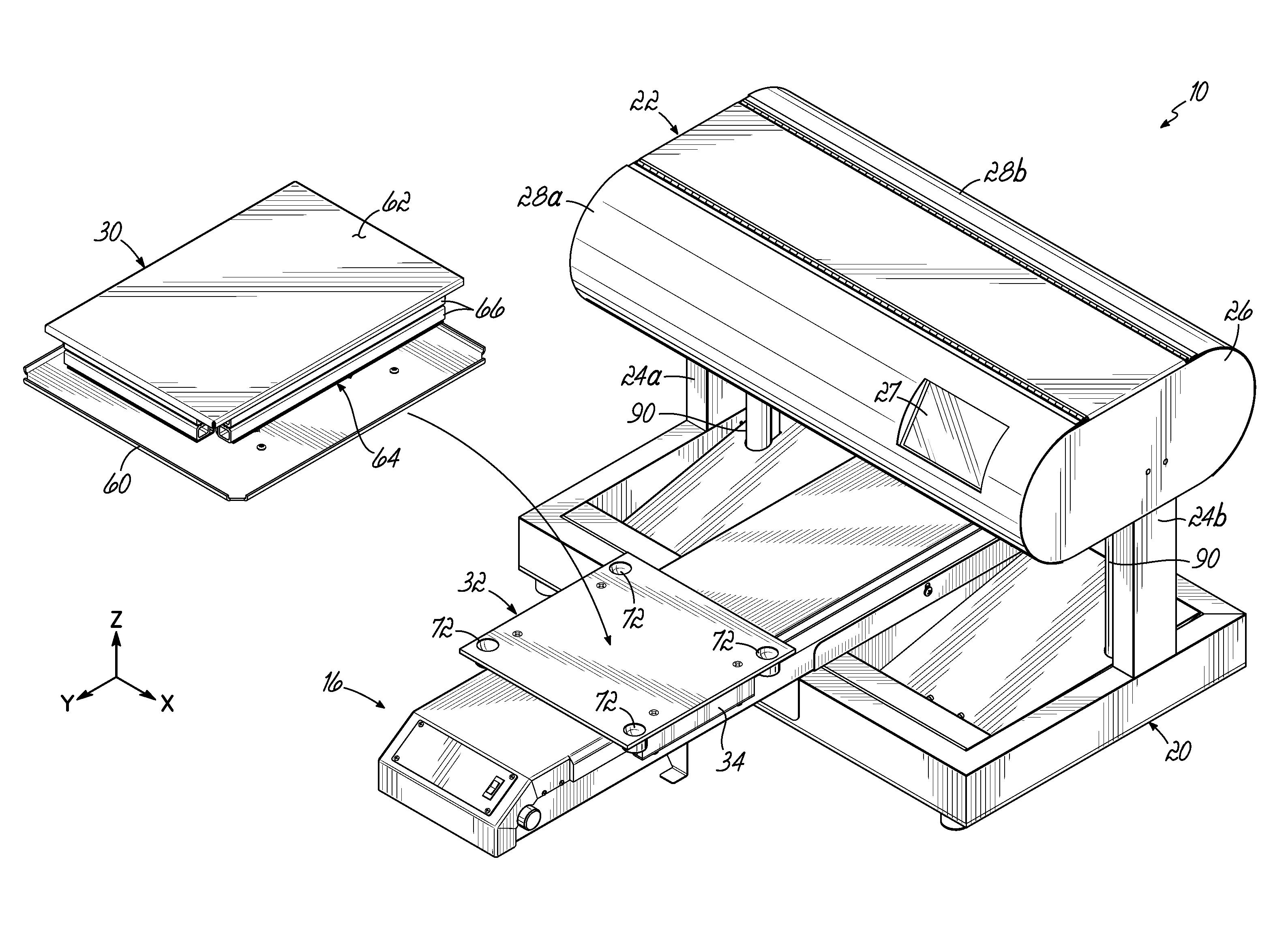

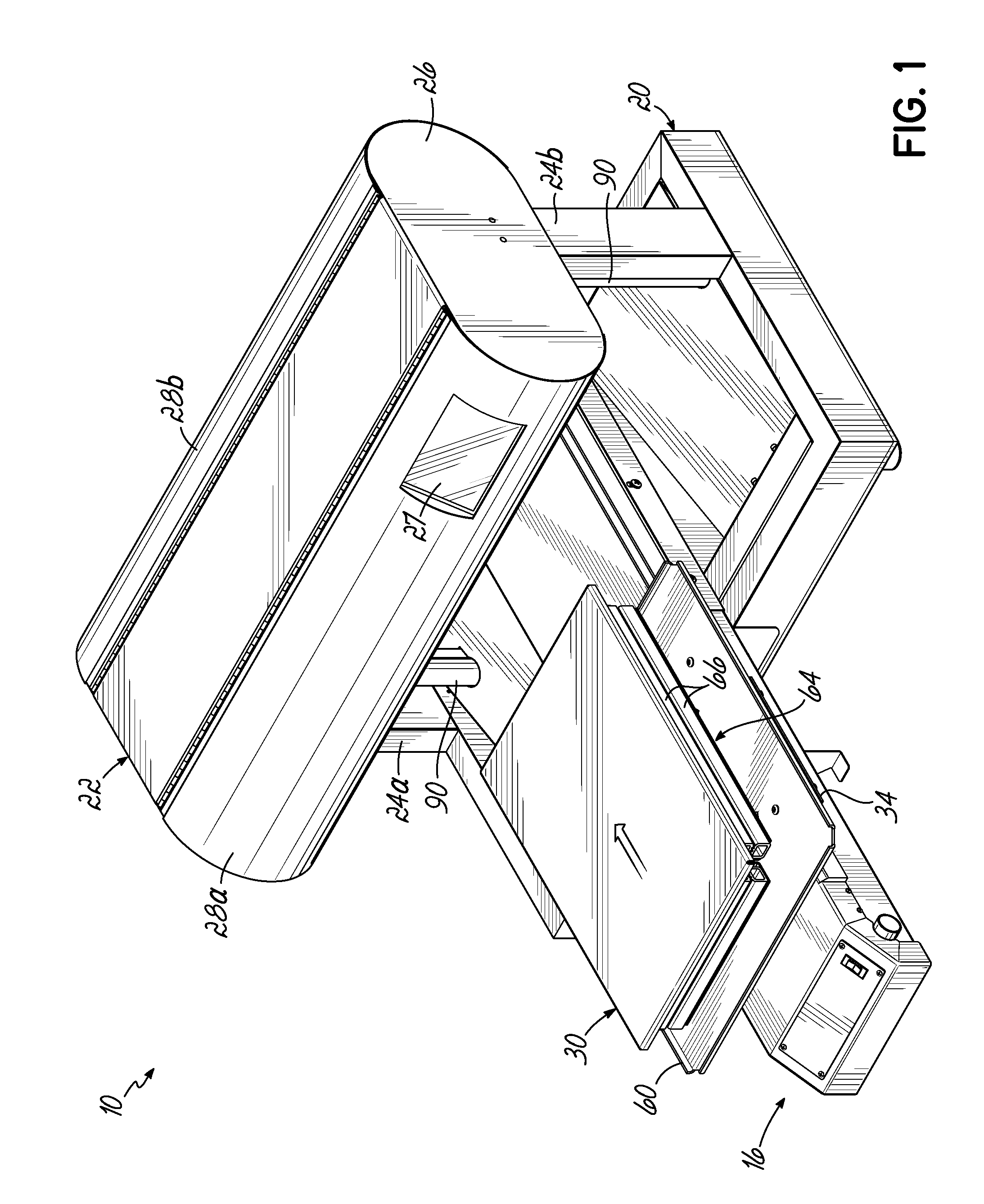

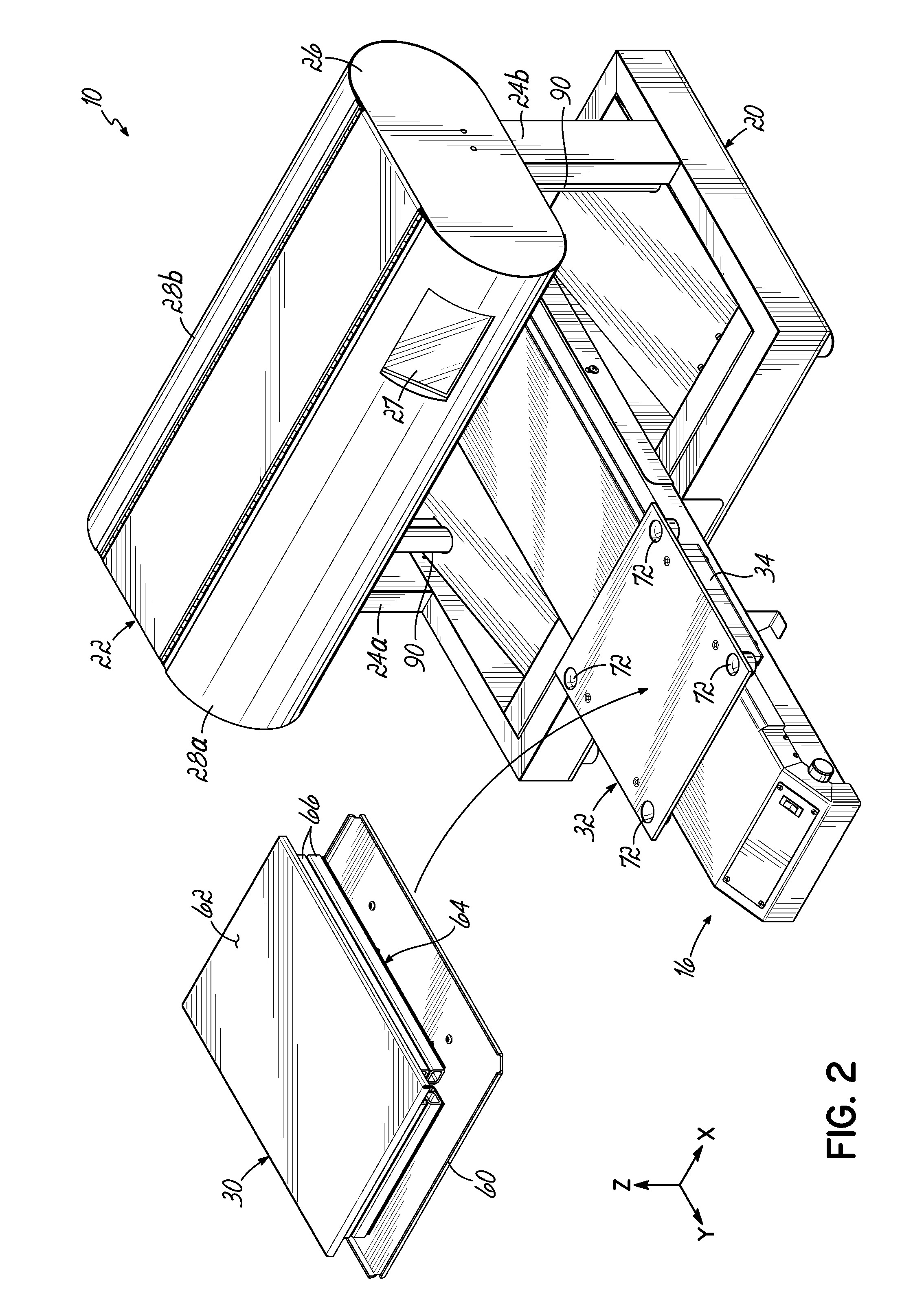

Method nad apparatus for UV ink jet printing on fabric and combination printing and quilting thereby

InactiveCN1377313AChanging the time of exposure to energyIncrease or decrease the time of energy exposureSewing-machine elementsLayered productsUV curingRadiant heater

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors across a bridge that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads, so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate.

Owner:L & P PROPERTY MANAGEMENT CO

Fabric dyeing method and apparatus therefor

InactiveCN101200860AEasy to operateGuaranteed operabilityDyeing processTextile parts treatmentWater resourcesEngineering

The present invention discloses a printing and dyeing method for fabrics, which applies the method of vacuum negative pressure to dye the atomized dye on fabrics by adsorption. The present invention also discloses the printing and dyeing equipment applied by the printing and dyeing method, which comprises a chassis, a power system and live rolls, wherein, a conveyer belt arranged on the live rolls is made of ventilating material or provided with air vents, and the upper and the lower sides of the conveyer belt are respectively provided with a vacuum adsorption system and a plurality of atomizing systems. The present invention utilizes the method of vacuum negative pressure adsorption to dye the atomized dye on fabrics, the technique is simple, the dyeing cost is low, the operability is strong, the dyeing efficiency is high, the dyeing effect is good, the colors of the dyed fabrics are uniform and beautiful, dyes and water resources can be saved, the rinsing process is not needed, so no pollution is generated. The printing and dyeing equipment disclosed by the present invention has the advantages of simple and reasonable structure and strong operability and can ensure the printing and dyeing effect of fabrics.

Owner:浙江宝通环保印染设备科技有限公司

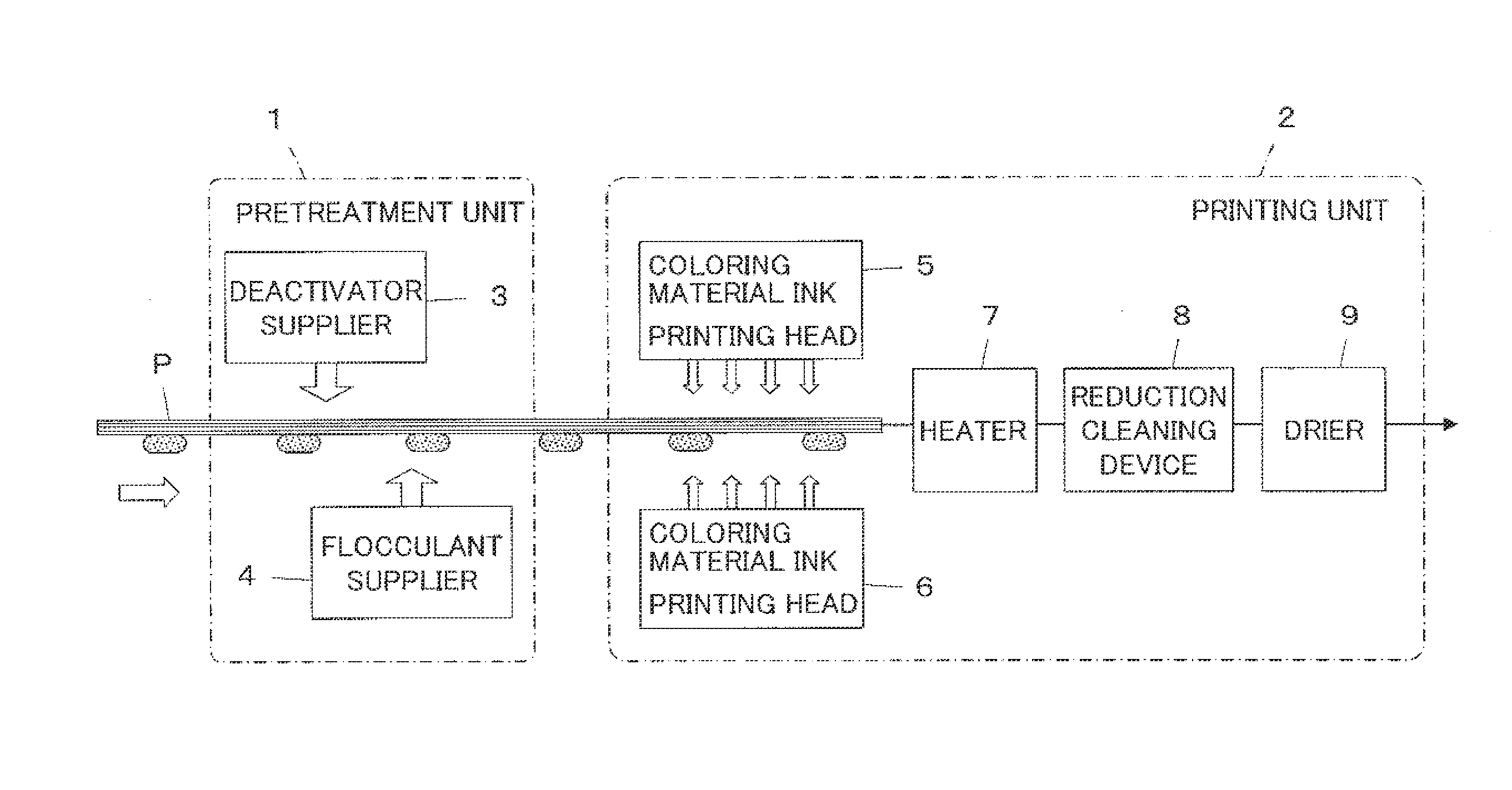

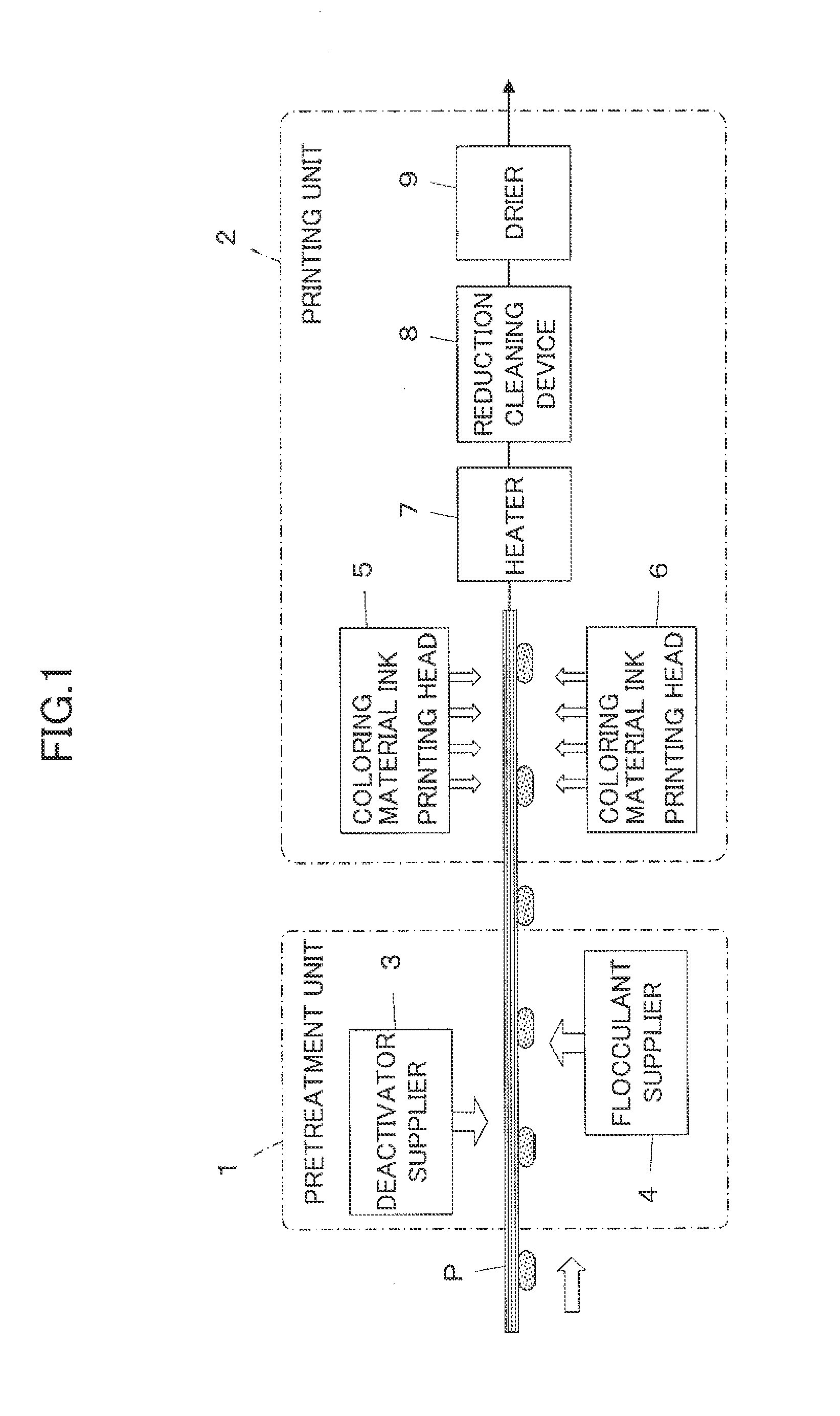

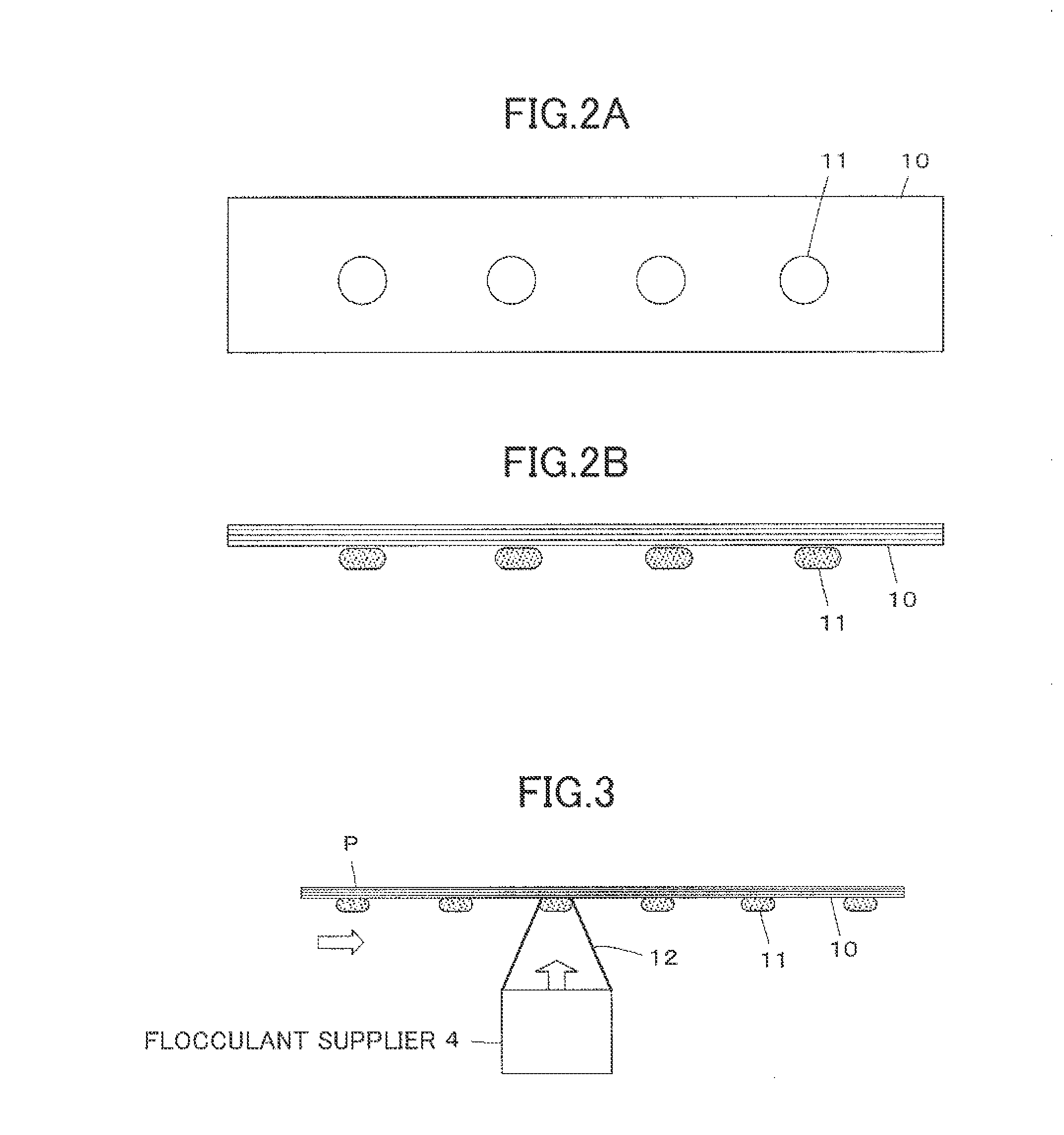

Printing method and printing device

InactiveUS20130155162A1Easy to dyePromoting aggregation reactionDuplicating/marking methodsInksEngineering

Owner:FUJIFILM CORP

Tie-dyeing method for cashmere textile

InactiveCN101003951ARich and varied texture graphicsNew Visual EnjoymentPattern makingDyeing processAcetic acidColour fastness

The present invention discloses a tie-dyeing method of cassimere. Said method includes the following steps: designing pattern of said cassimere and binding; adopting quick penetrating agent SP-2 and Peregal according to a certain mixing ratio to prepare solution, temperature is 40-70 deg.C, bath ratio is 1:15-20, making treatment for 15-20 min; adopting reactive dyes for wool as raw material, using sodium sulfate powder, glacial acetic acid, dye leveler Albatex B for wool and penetrating agent Albatex FFA for wool as adjuvant, after the temperature is risen to 98 deg.C from 70 deg.C, heat-insulating for 20-60 min, making sectional dyeing, then rinsing and cleaning; adopting 3-5% of cashmere bulking agent, 0.3-1% of glacial acetic acid and 0.2-1% of high-effective penetrating agent to make relaxing-bulking treatment, temperature is 40-50 deg.C and making treatment for 20-30 min to make cassimere be flabby, then making milling treatment.

Owner:HUAHENG TECH DEV JIANGSU

Method and apparatus for UV ink jet printing on fabric and combination printing and quilting thereby

InactiveCN1572492AChanging the time of exposure to energyIncrease or decrease the time of energy exposureSewing-machine elementsLayered productsPolymer scienceEngineering

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors across a bridge that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads, so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate.

Owner:L & P PROPERTY MANAGEMENT CO

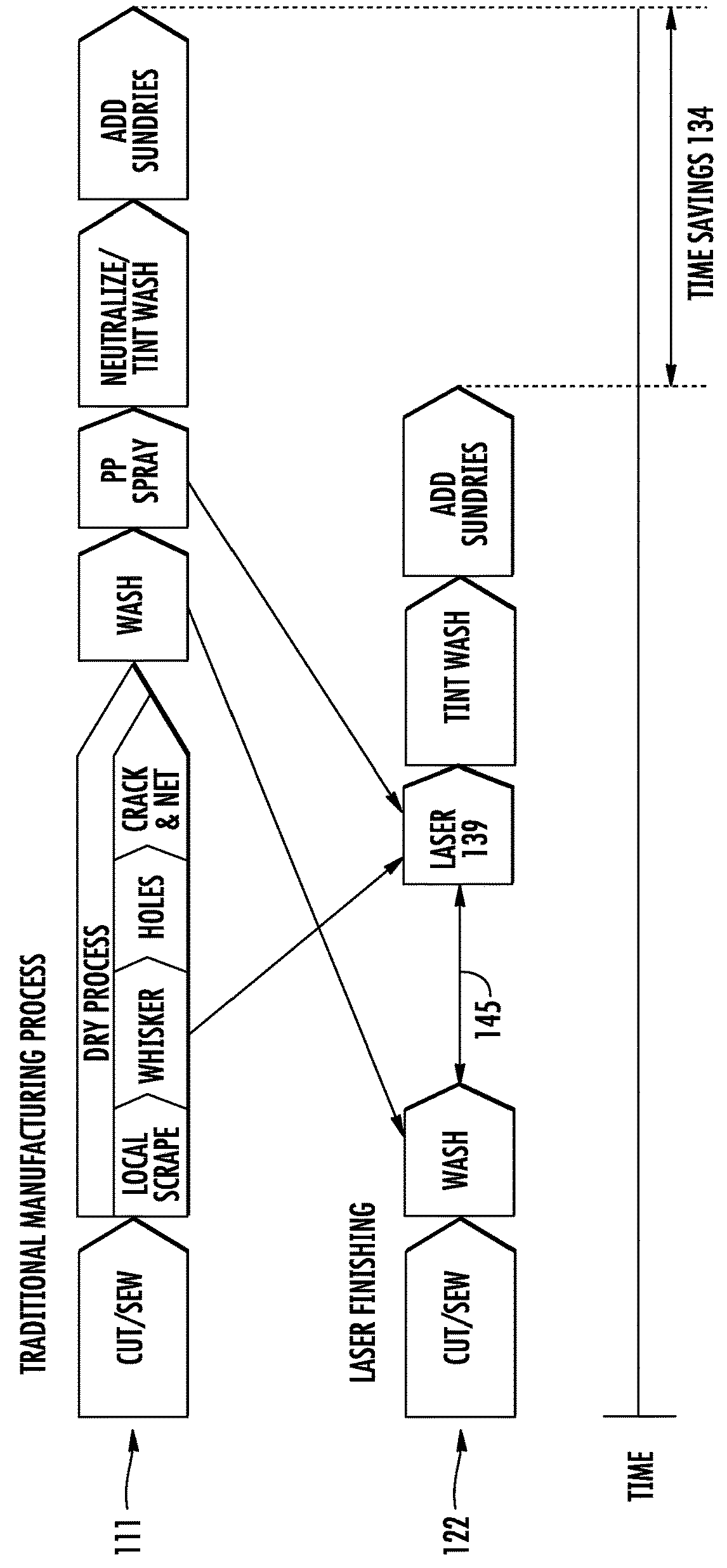

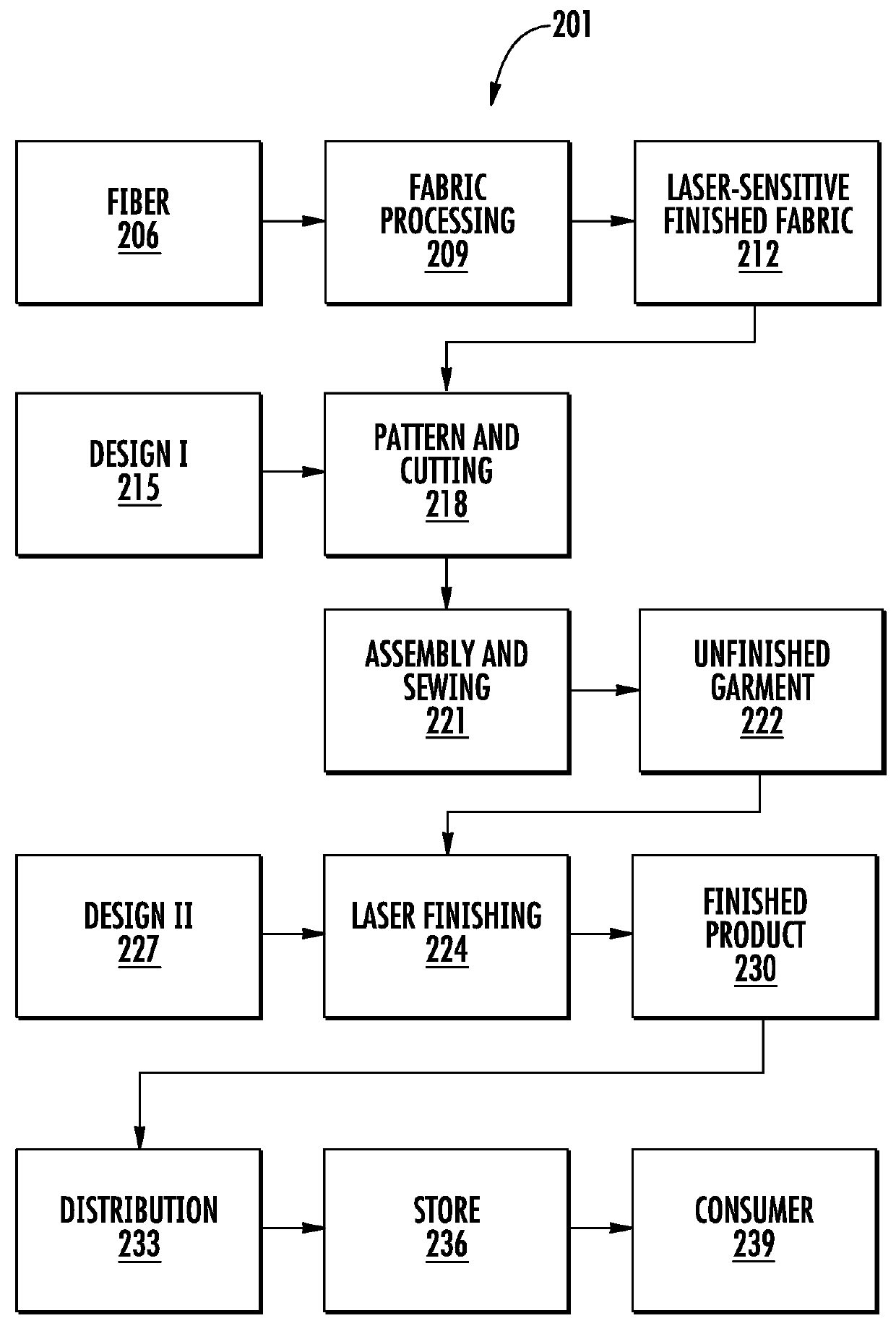

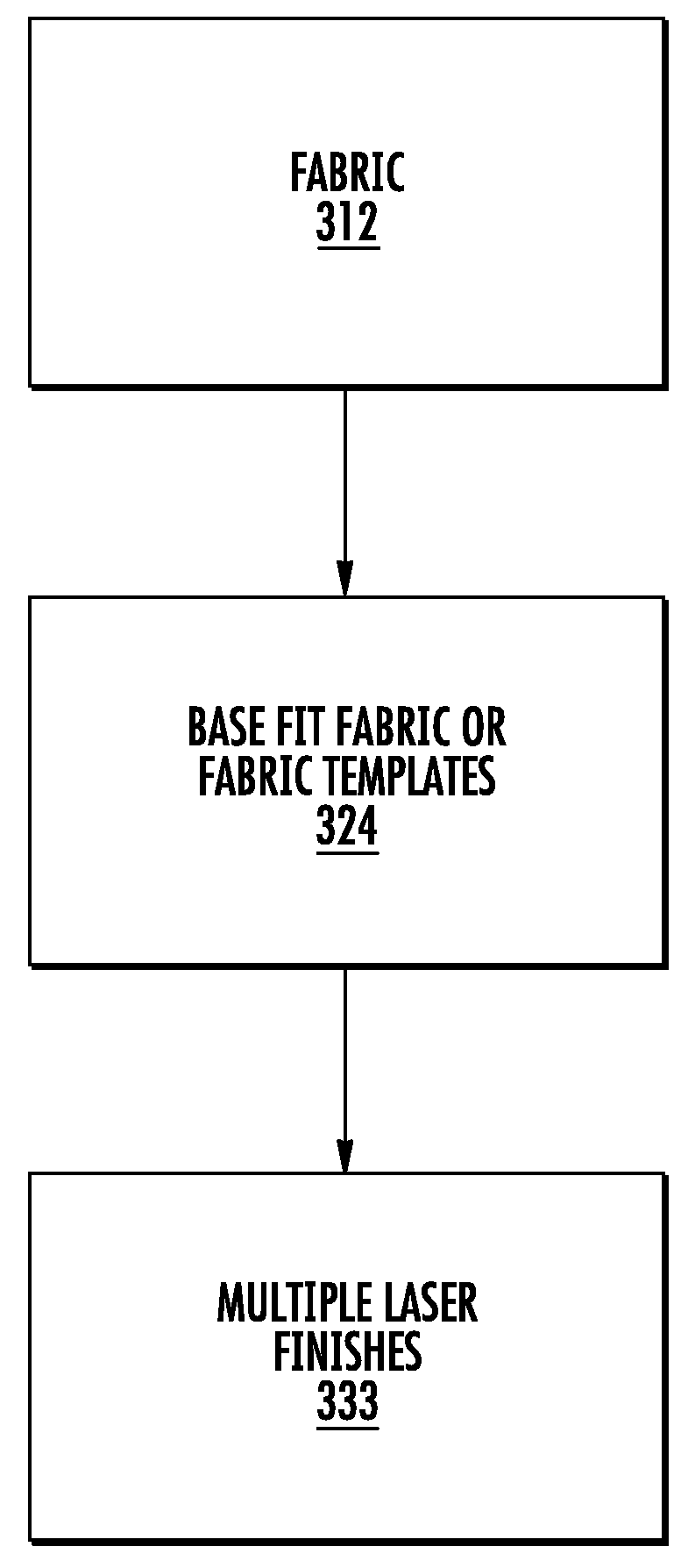

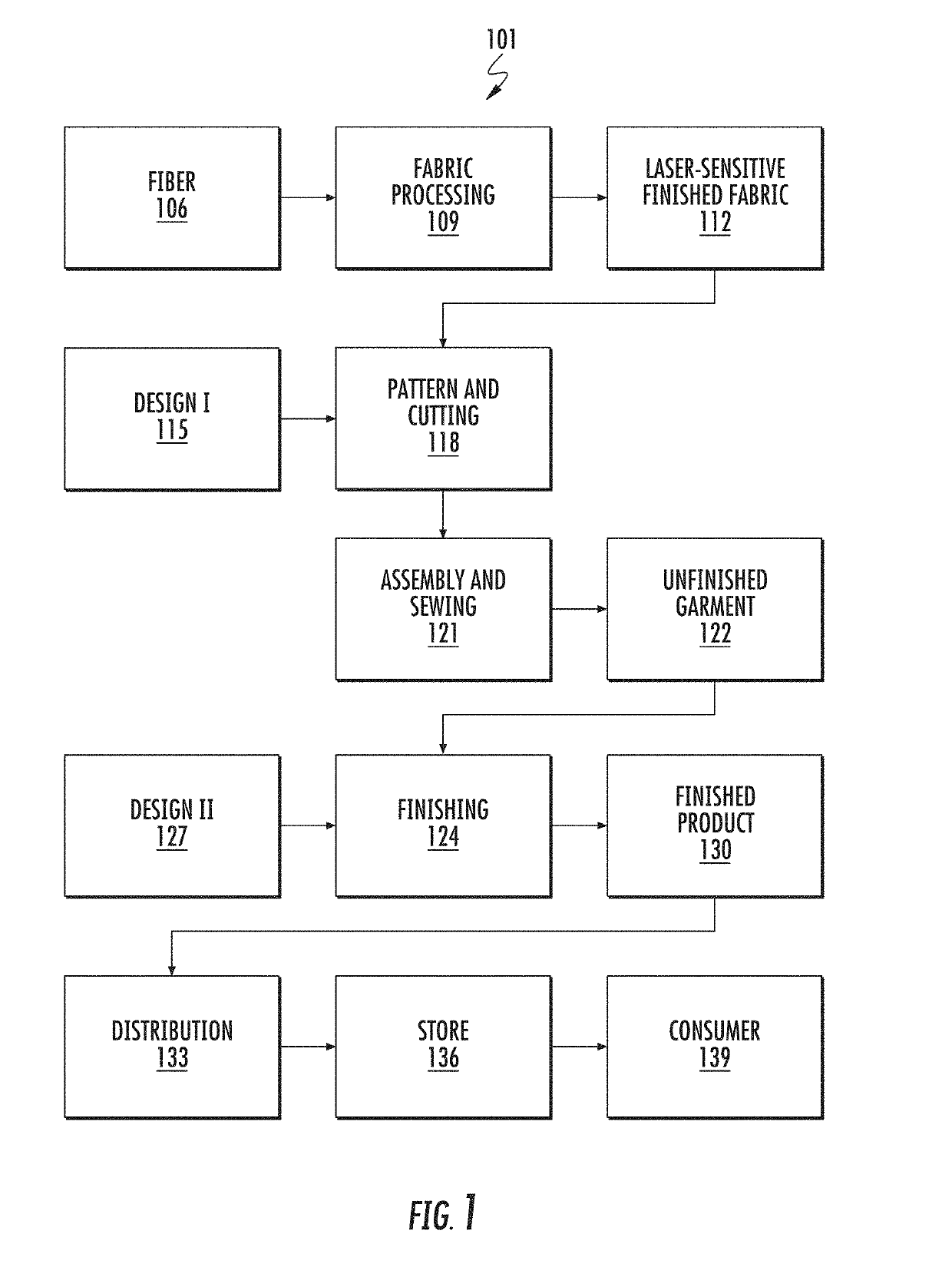

Using Fabric Templates to Obtain Multiple Finishes by Laser Finishing

ActiveUS20180165736A1Reduce finishing costsLow costPattern makingSewing apparatusLost salesTime to market

Laser finishing of apparel products allows an operating model that reduces finishing cost, lowers carrying costs, increases productivity, shortens time to market, be more reactive to trends, reduce product constraints, reduces lost sales and dilution, and more. Improved aspects include design, development, planning, merchandising, selling, making, and delivering. The model uses fabric templates, each of which can be used to produce a multitude of laser finishes. Operational efficiency is improved.

Owner:LEVI STRAUSS & CO

Treatment of textile material

ActiveUS20180291553A1Good lookingBrightness value increasedDyeing processTextile parts treatmentNitrate saltsColor changes

The present invention generally relates to a method for changing the color of a textile material to obtain a vintage and / or worn appearance comprising the steps of contacting the fabric textile material with a nitrate salt, activating the nitrate salt by the addition of an acid catalyst until the desired color change is achieved.

Owner:ACTICELL GMBH

Systems For Treating A Garment With Pre-Treatment Solution, And Related Methods

InactiveUS20140020189A1Hollow article cleaningOther washing machinesPre treatmentBiomedical engineering

A system for treating a garment with a pre-treatment solution includes a fluid application assembly configured to dispense pre-treatment solution onto pre-determined target areas of the garment. A fluid supply and delivery assembly is coupled with the fluid application assembly and configured to provide a supply of pre-treatment solution to the fluid application assembly for dispensing onto the garment at fluid pressures of between about 5 and about 30 psig. A garment movement assembly is configured to move the garment with respect to the fluid application assembly so that the target areas of the garment can receive the pre-treatment solution.

Owner:BELQUETTE

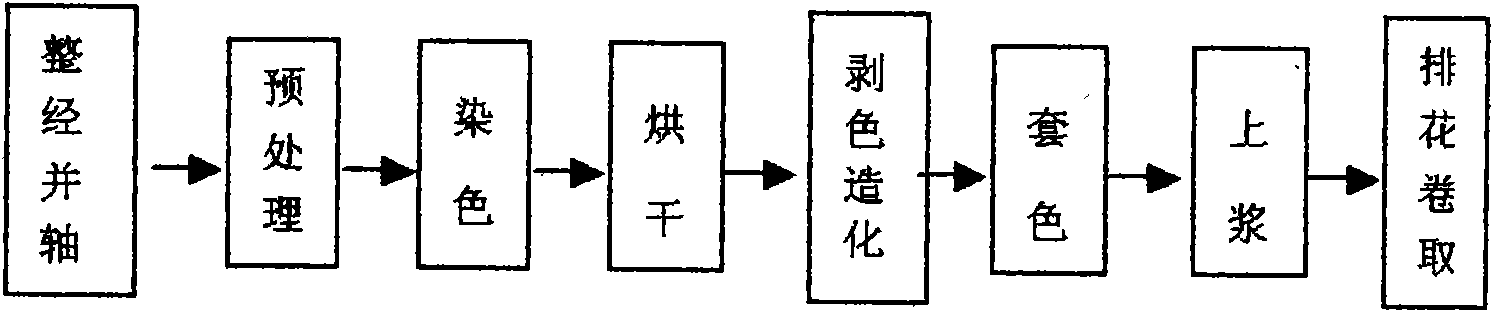

Camouflage color yarn production method

InactiveCN101619527AAdded staining stepsSucessive textile treatmentsTextile treatment by spraying/projectingYarnPulp and paper industry

The invention relates to a camouflage color yarn production method which comprises the following steps: raw yarn preparation, spray dying, decatizing and color fixing, soaping, drying and barrel inverting; the spay dying is characterized in that dyes are sprayed in a fog way; the yarns are flatly laid on a workbench of a continuous dying device in a yarn twisting way, a spray head leaves a distance from the yarns, and the dyes are sprayed onto the yarn surfaces. A dying step can be added between the raw yarn preparation step and the spray dying step. The invention adopts the spray dying technology, the spray head leaves a certain distance from the yarns to spray dyes, the dyes form a fog shape and are scattered onto the yarn surfaces, the yarn distribution is irregular, the color length is unequal, and the yarns are distributed in a mesh way, so the yarns can show a camouflage style. The invention adds the dying step between the raw yarn preparation step and the spray dying step, the yarns are dyed with bottom color, and the yarn is in a style of irregular camouflage characteristic.

Owner:WUXI NATURAL GREEN FIBER TECH

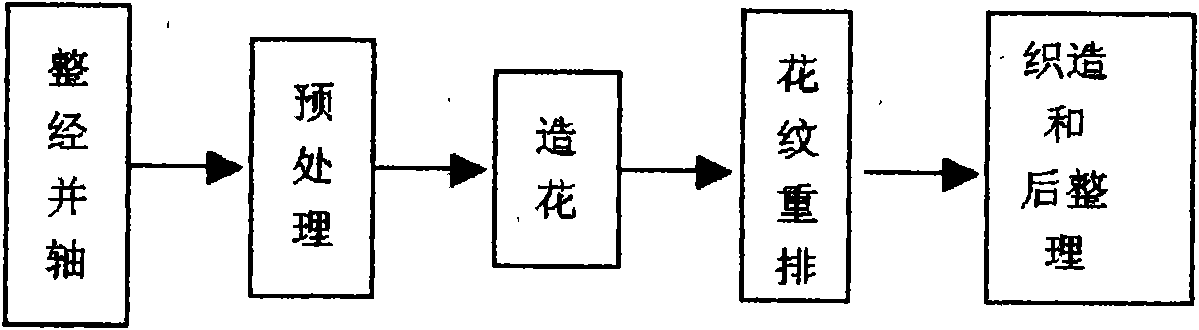

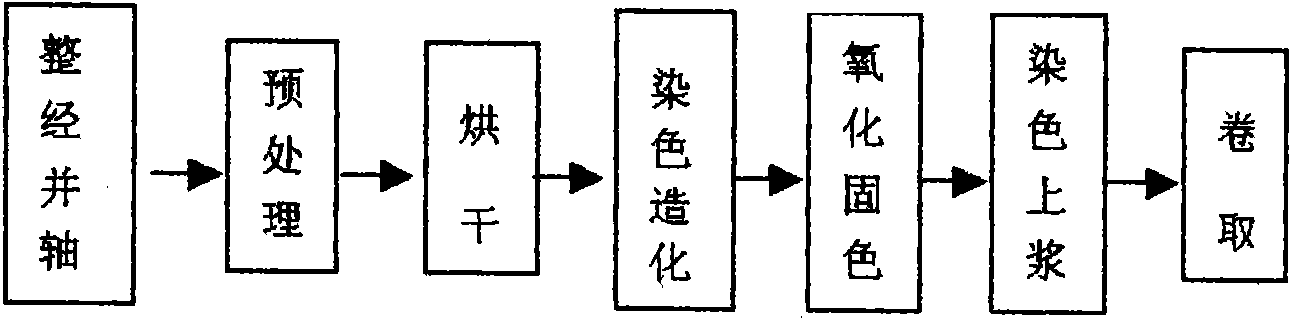

Production technology for watermark pattern cloth and production device thereof

InactiveCN101613965AClear and rich textureSoft colorOther manufacturing equipments/toolsDyeing processYarnTextile printer

The invention discloses production technology for watermark pattern cloth and a production device thereof, which belong to the technical field of textile printing and dyeing. A method thereof comprises the steps: arranging a pattern making device at the appropriate position of a sizing-dyeing combined machine; manufacturing a basic pattern with appropriate color and light and shade contrast on a cotton tape during the finishing of the dyeing and sizing of the cotton tape; using a pattern arrangement device for pattern rearrangement to reconstruct a needed fabric covering pattern; positioning various warp yarns, and coiling the warp yarns to a weaving cloth-roll; and finally obtaining finished watermark pattern cloth through registration, healding, reeding, weaving and appropriate afterfinish. The production device thereof comprises the pattern making device and the pattern arrangement device. The production technology can ensure that processes such as dyeing, pattern making and sizing are finished at one time, reduce repeated work, save a large quantity of energy sources, also has clear ridges as well as soft and natural color of the fabric covering pattern and exquisite fabric covering, but can also achieve the straightforward and unpretending style, and can also reduce the pollution and production cost.

Owner:刘林泉

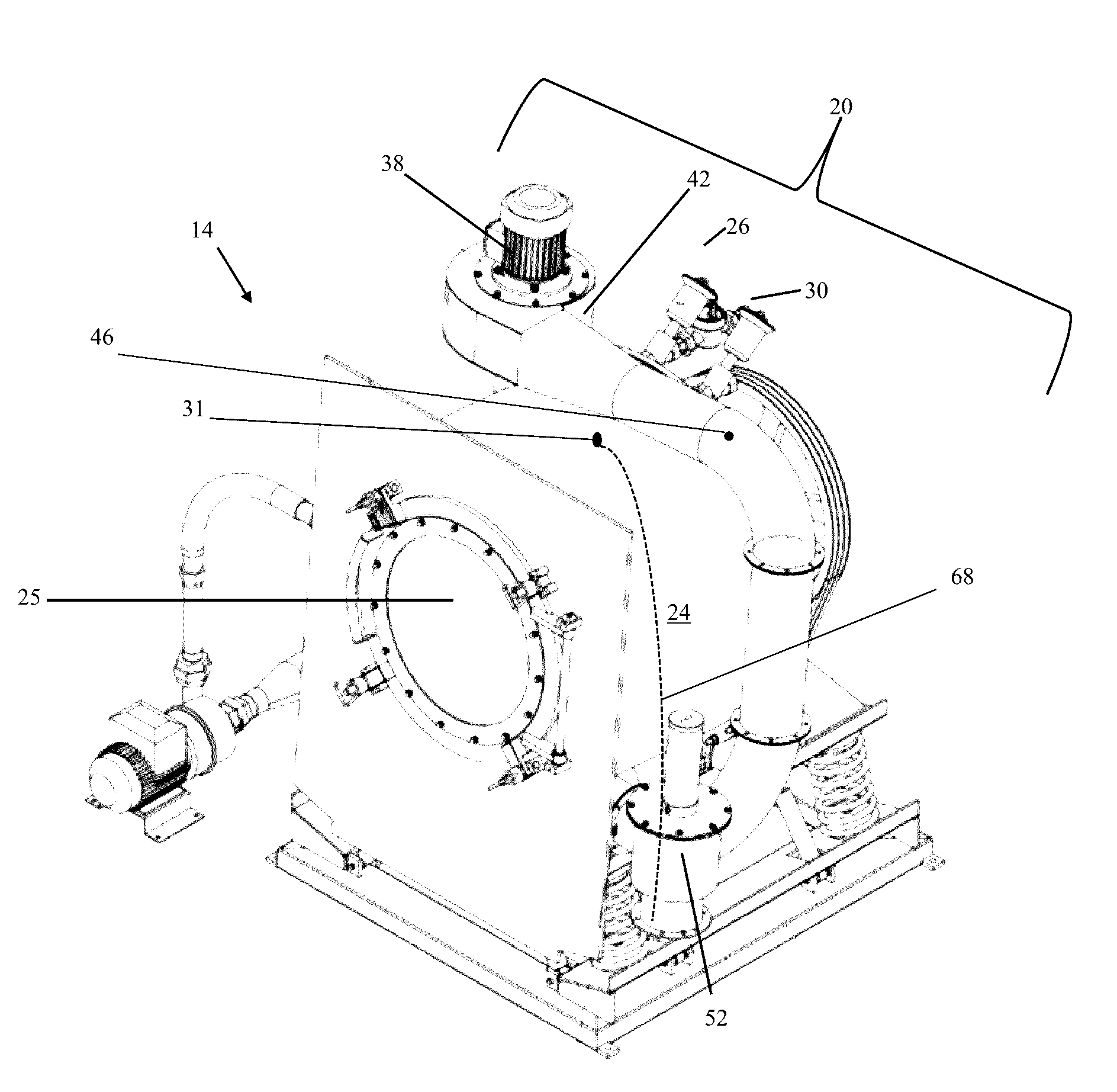

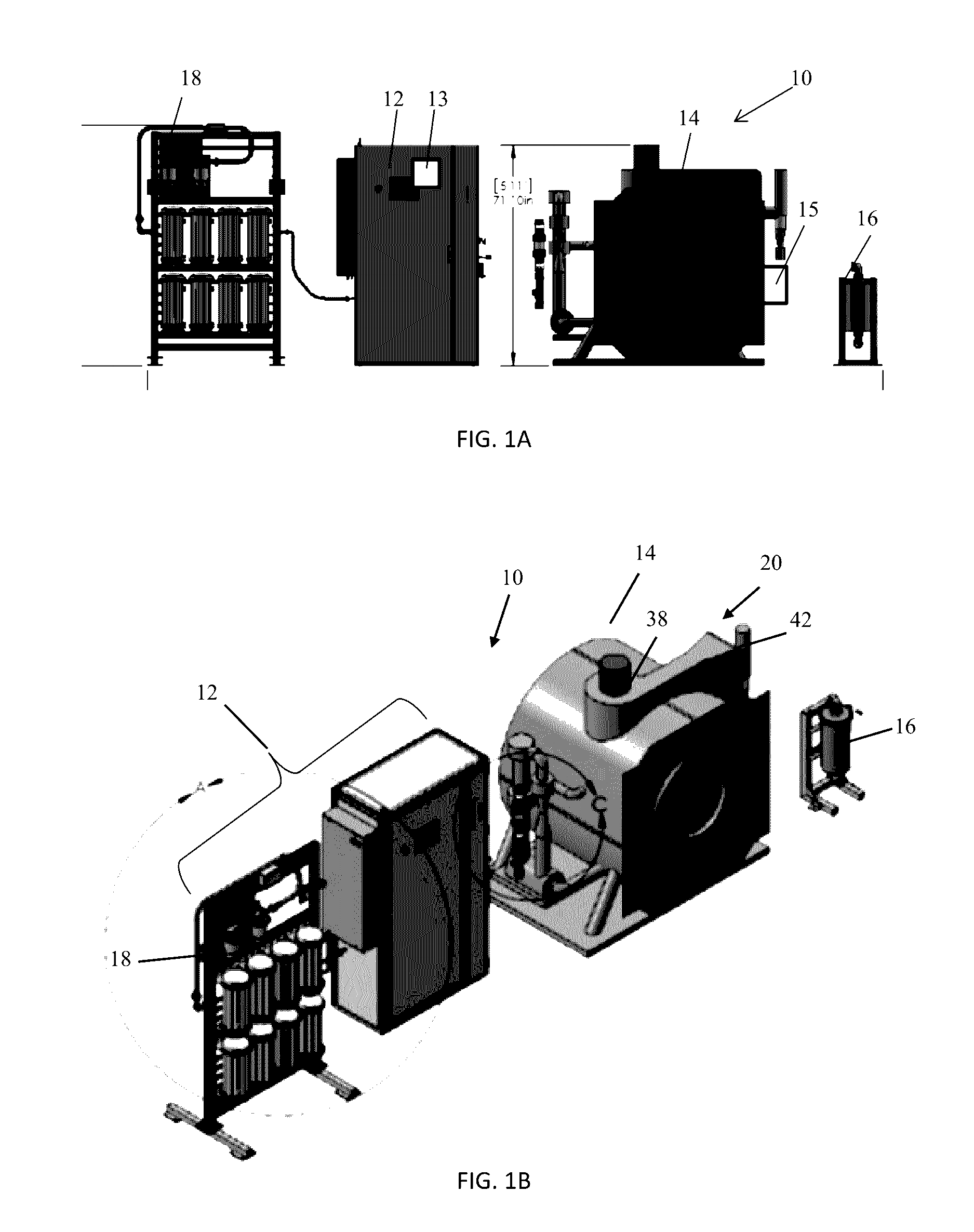

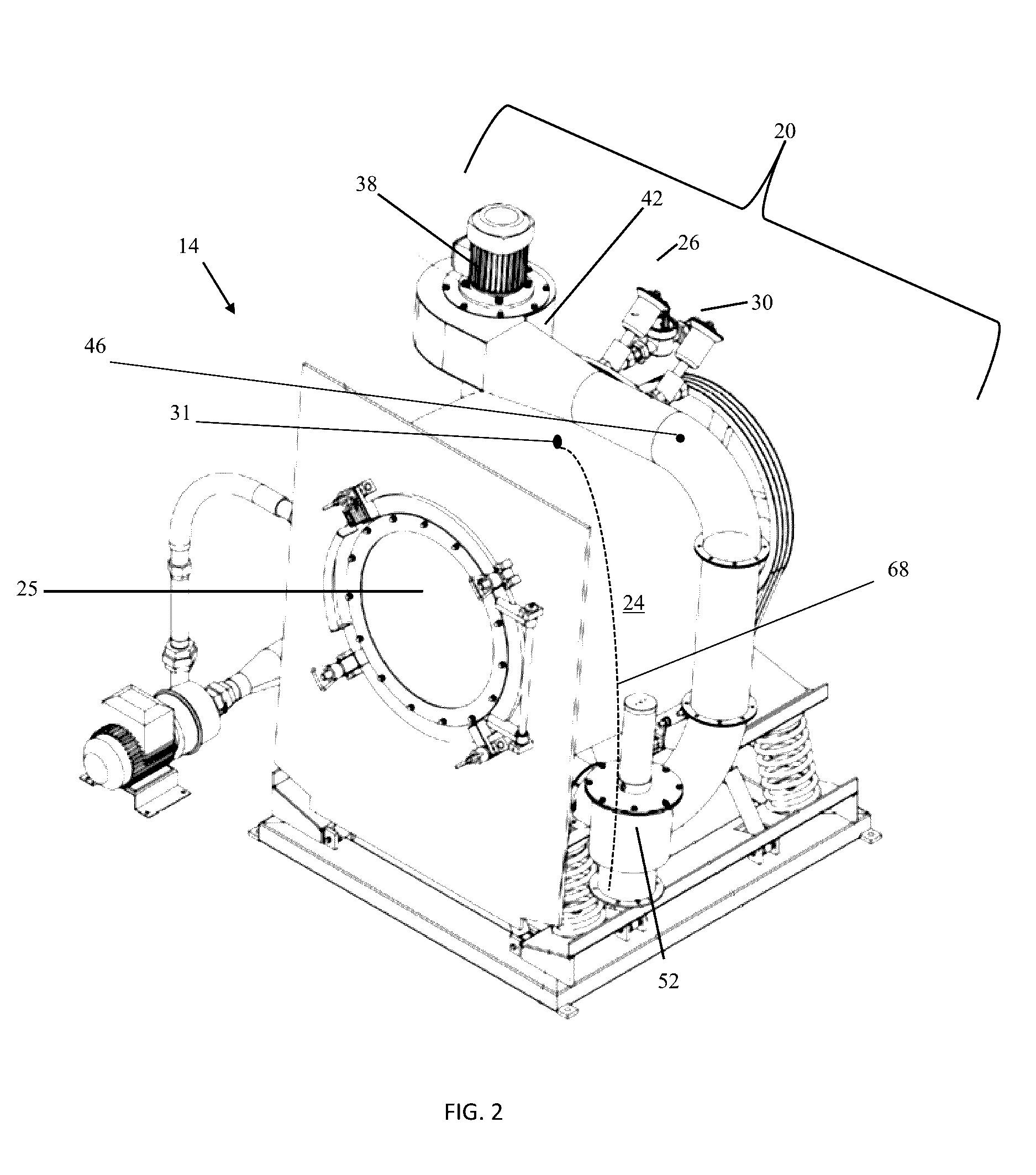

Ozone process for color removal

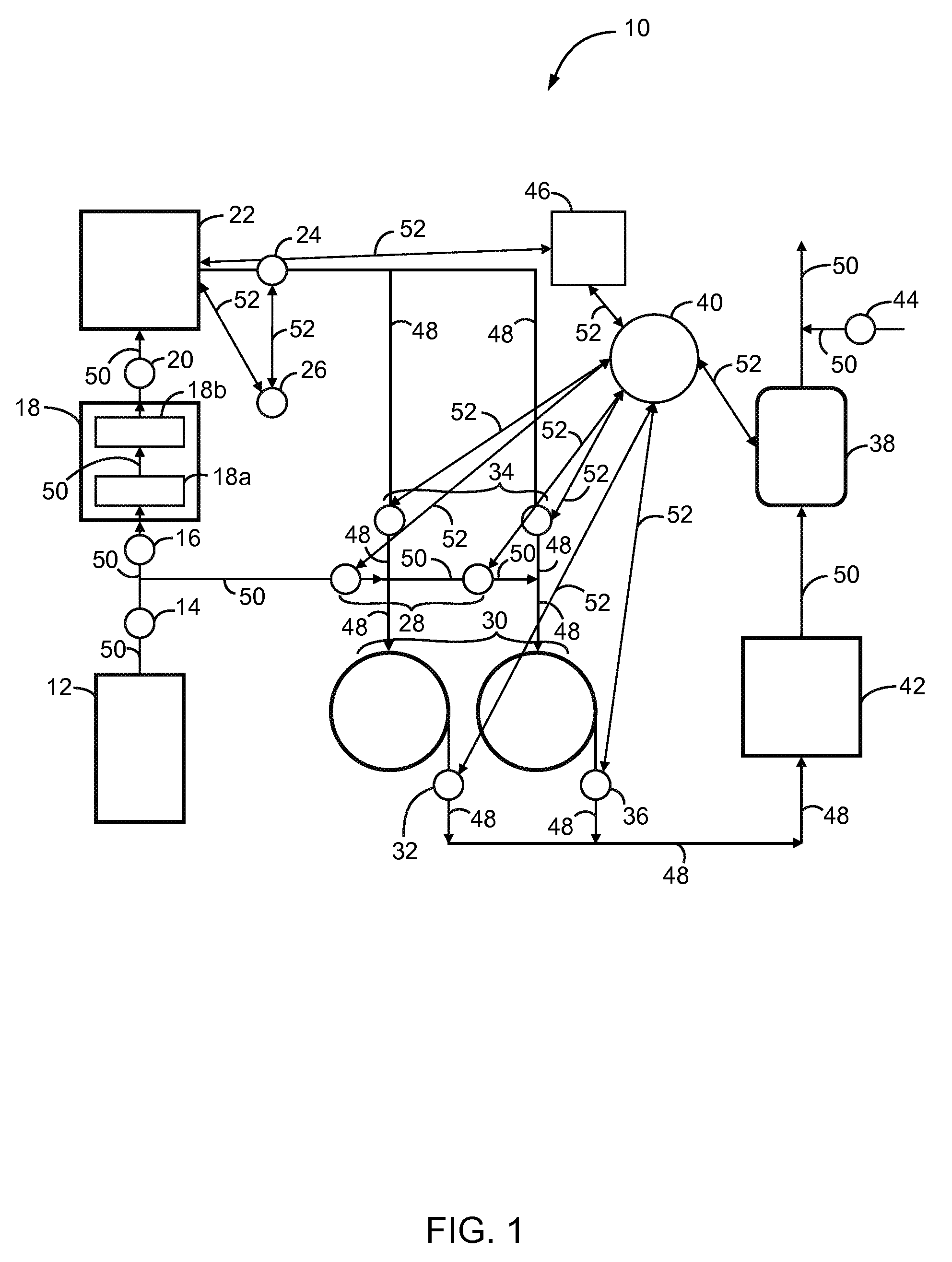

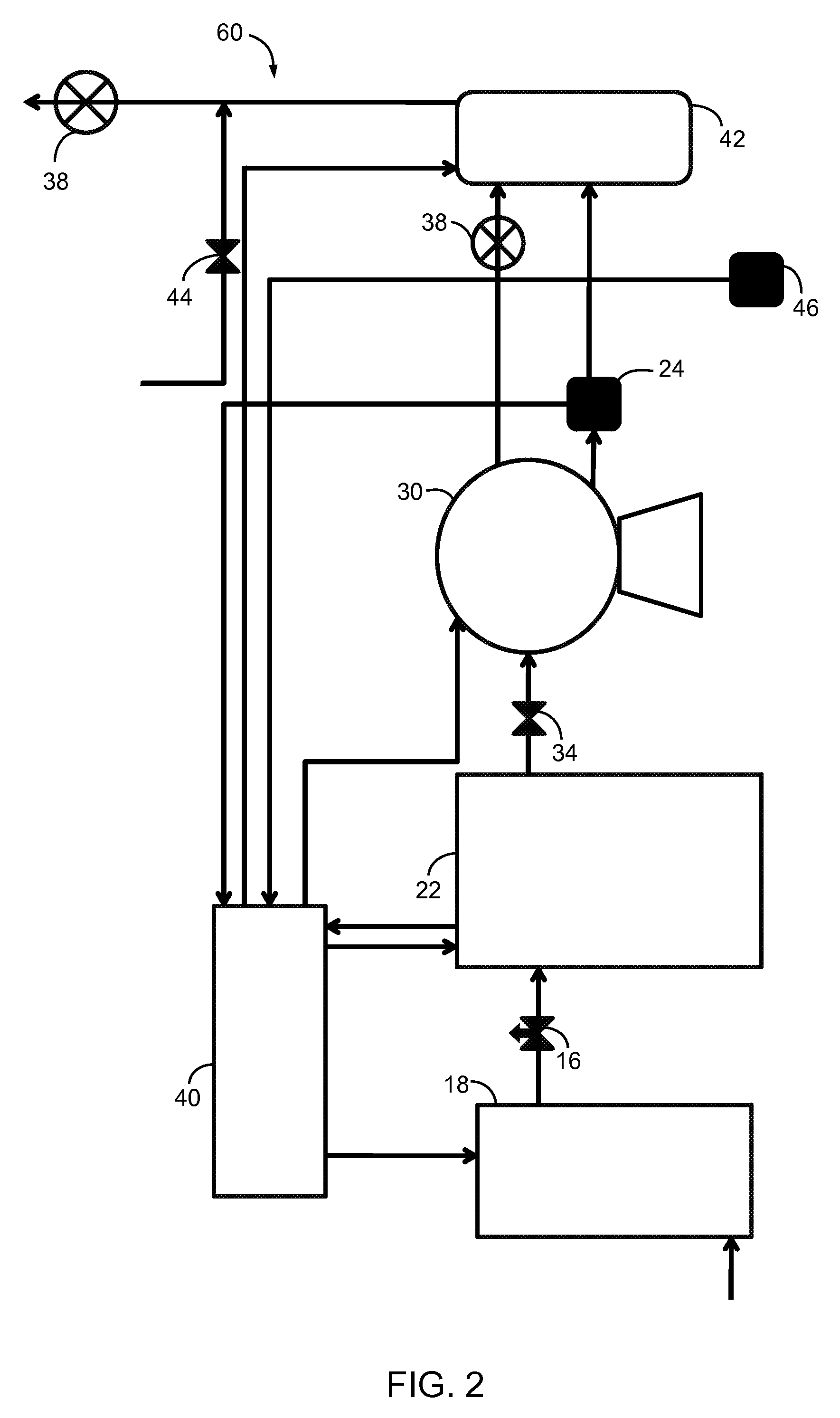

ActiveUS20170016175A1More reliable and reproducibleTextile treatment containersLiquid/gas/vapor article treatmentControl systemWastewater

Embodiments relate generally to methods and systems for bleaching textiles using ozone gas that incorporates a color removal step. In one example, there is provided a hybrid machine that incorporates certain features of a washer, but that also includes an integrated blower for gas distribution inside the machine. There is also provided an ozone dosing control system that allows for maintenance of a constant concentration of ozone in the machine. In one embodiment, the ozone output measured in grams / hour at this constant concentration in conjunction with the weight of product measured being treated may be referred to as the “bleaching factor.” There is further provided a wastewater dye removal step, in which ozone is used to clean the water and remove dyes and other colors that may be deposited via denim or other garments.

Owner:GUARDIAN MFG

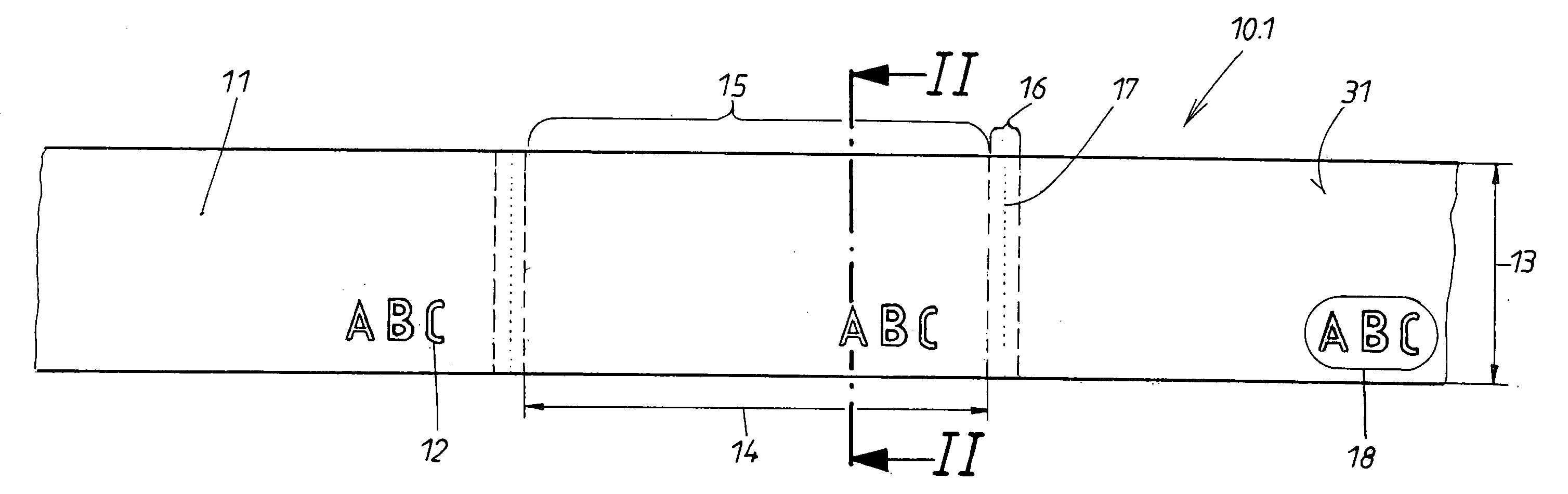

Method of manufacturing a printed textile ribbon

InactiveUS20050264642A1Inexpensive mannerMade preciselyStampsRecording apparatusEngineeringHeat treated

A method of manufacturing printed textile ribbons reliably and inexpensively, initially a web is produced which forms the later ribbon. The web is composed of two different materials, wherein a figure is applied on one side of the web. The web is subsequently subjected to a heat and pressure treatment with sublimation colors, such that the sublimation colors are absorbed by the first ribbon material and produce on one side a desired printed image. The figure is composed on this side of materials which do not absorb the sublimation colors. As a result, the color of the figure remains unchanged on this side of the ribbon, although the figure had contact with the sublimation colors.

Owner:AVERY DENNISON RINKE

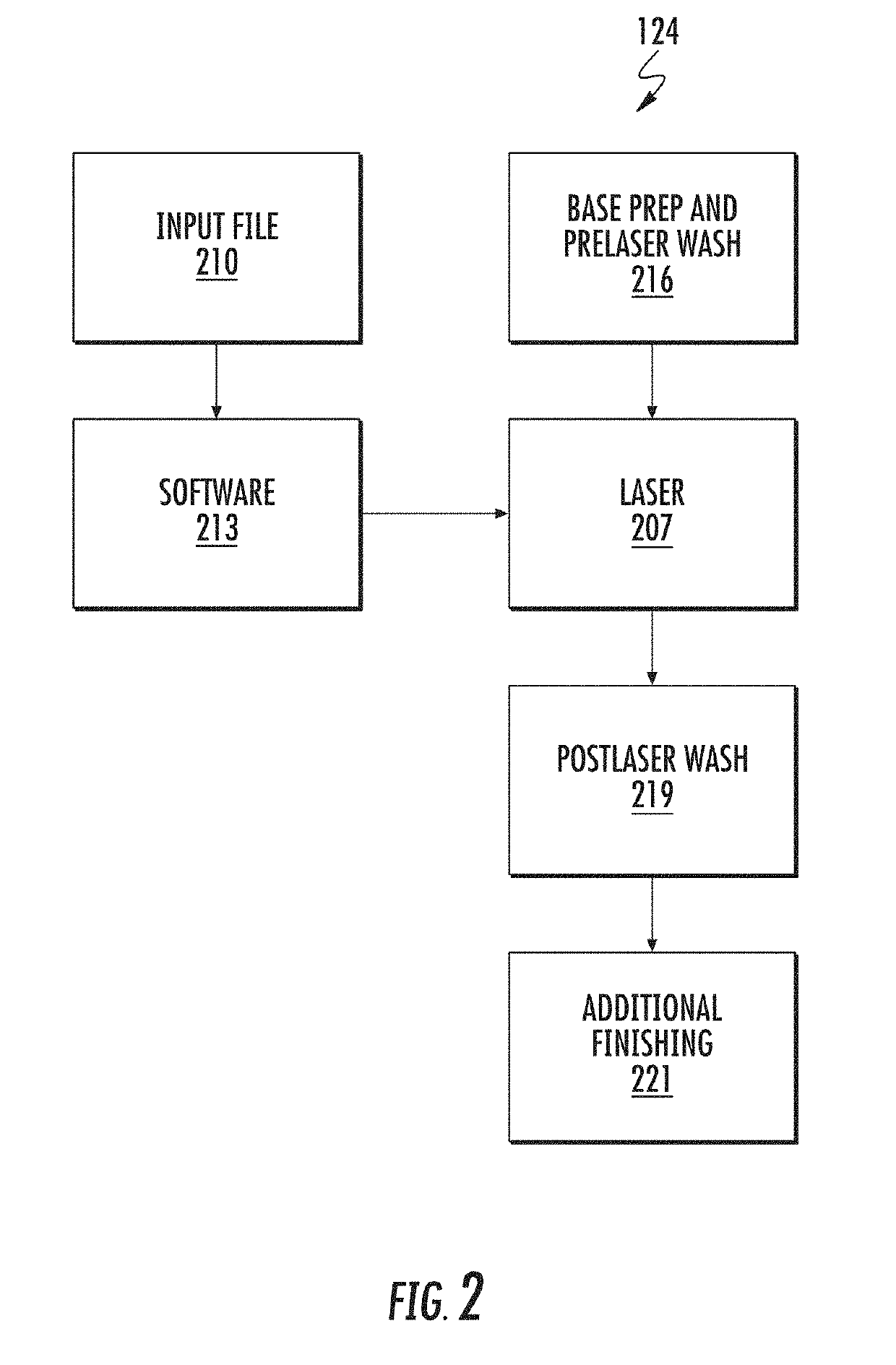

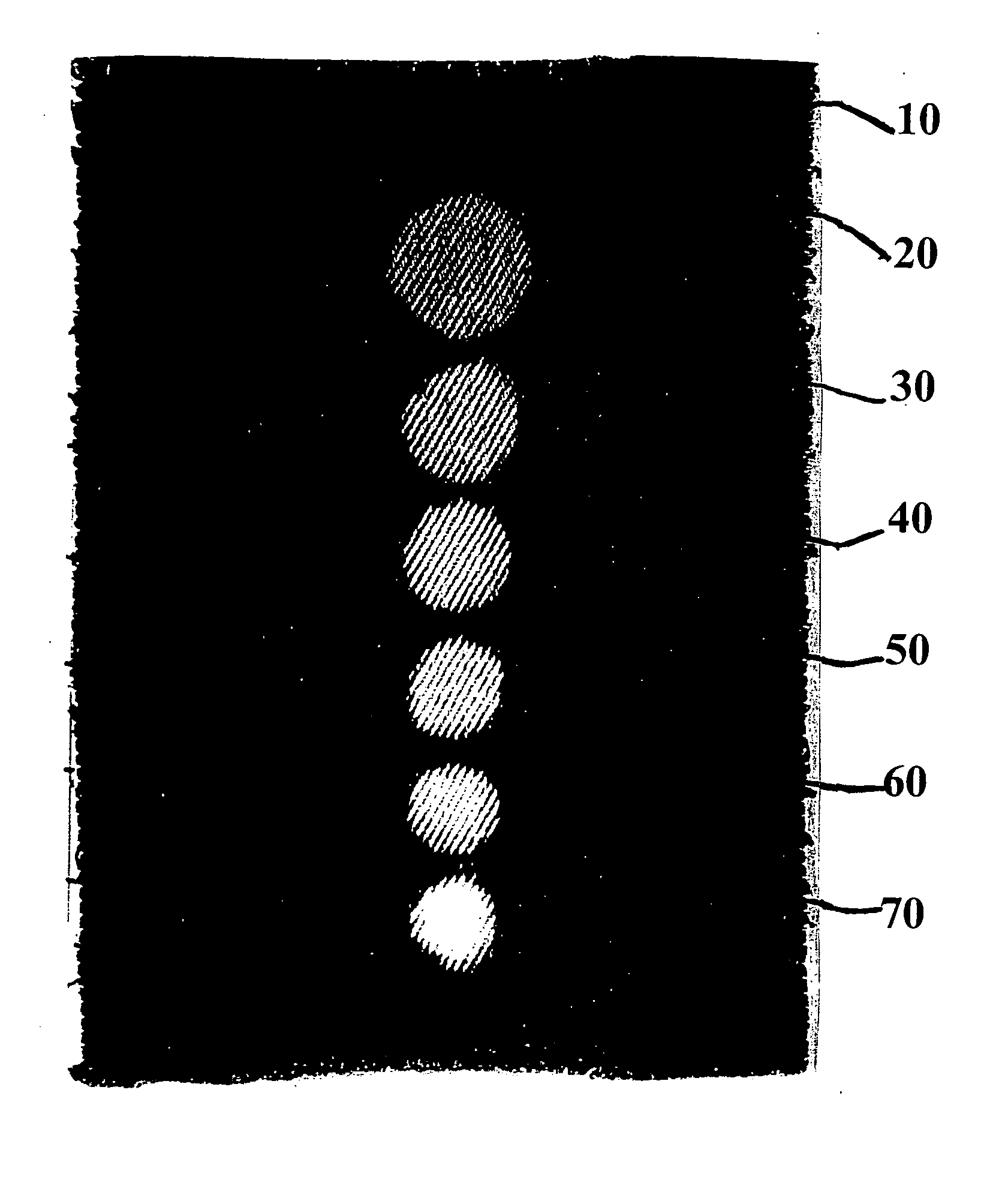

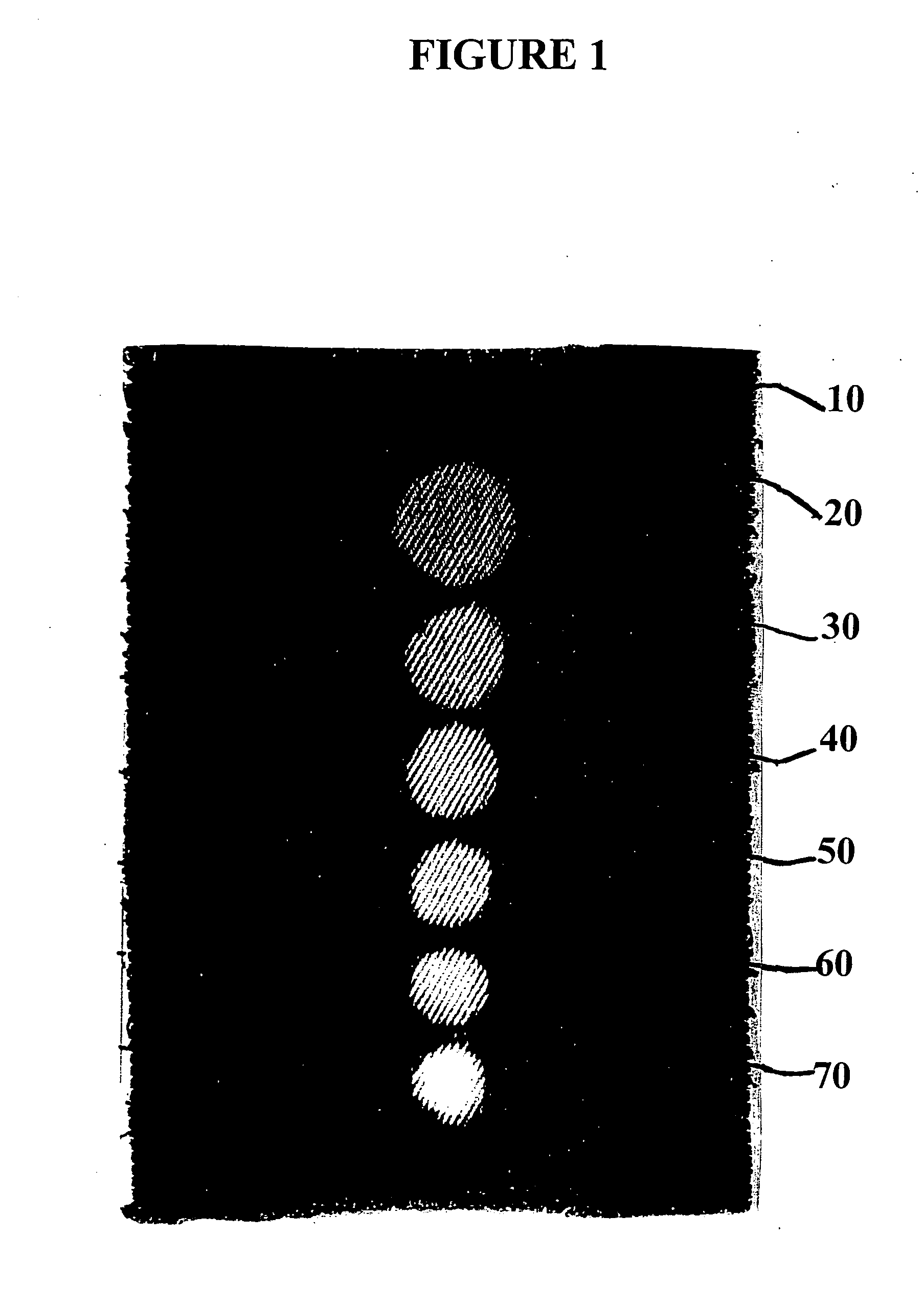

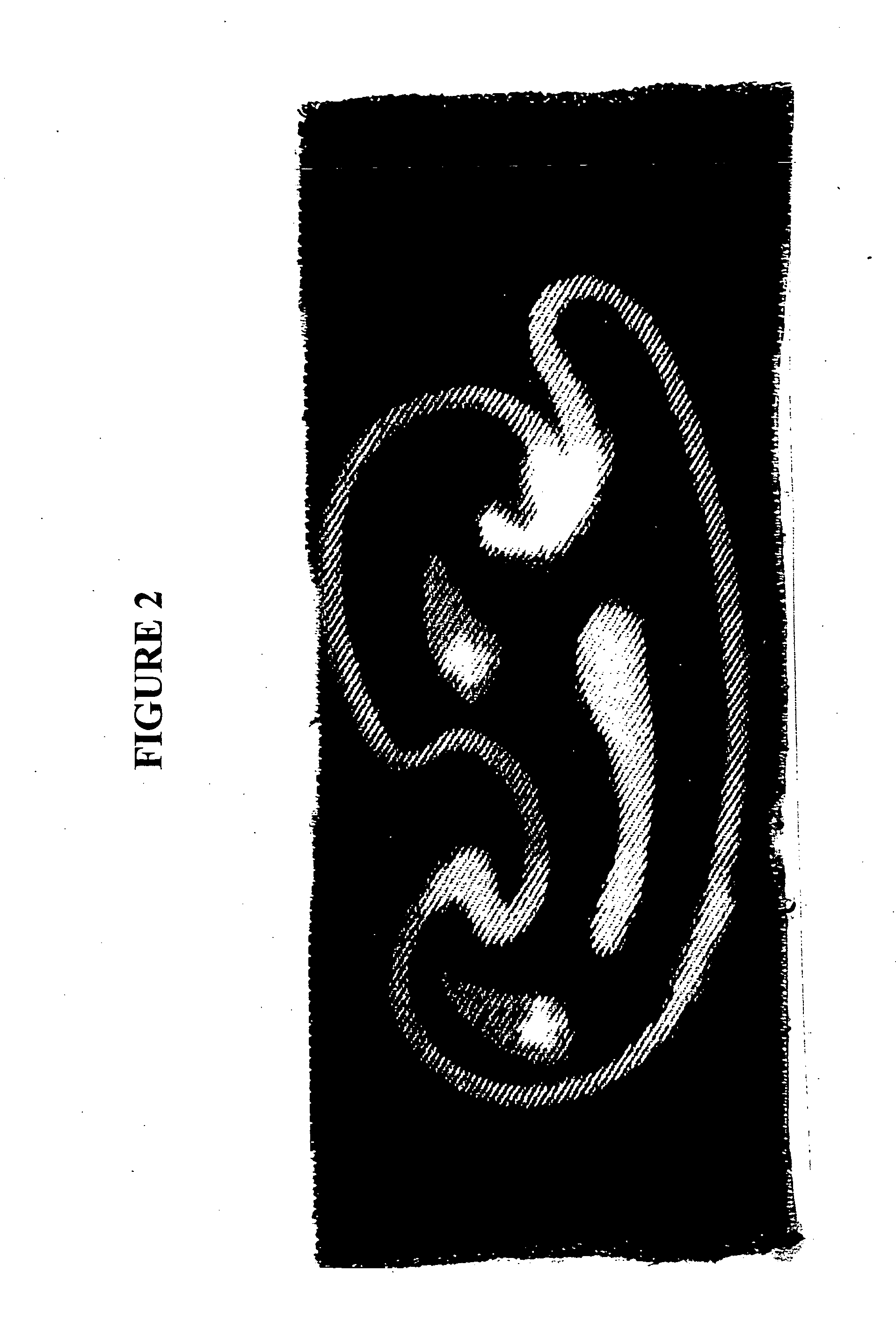

Laser Finishing Design Tool with Image Preview

ActiveUS20190129604A1Texturing/coloringLaser beam fibre treatmentWear patternUltimate tensile strength

A tool allows a user to create new designs for apparel and preview these designs before manufacture. Software and lasers are used in finishing apparel to produce a desired wear pattern or other design. Based on a laser input file with a pattern, a laser will burn the pattern onto apparel. With the tool, the user will be able to create, make changes, and view images of a design, in real time, before burning by a laser. Input to the tool includes fabric template images, laser input files, and damage input. The tool allows adding of tinting and adjusting of intensity and bright point. The user can also move, rotate, scale, and warp the image input.

Owner:LEVI STRAUSS & CO

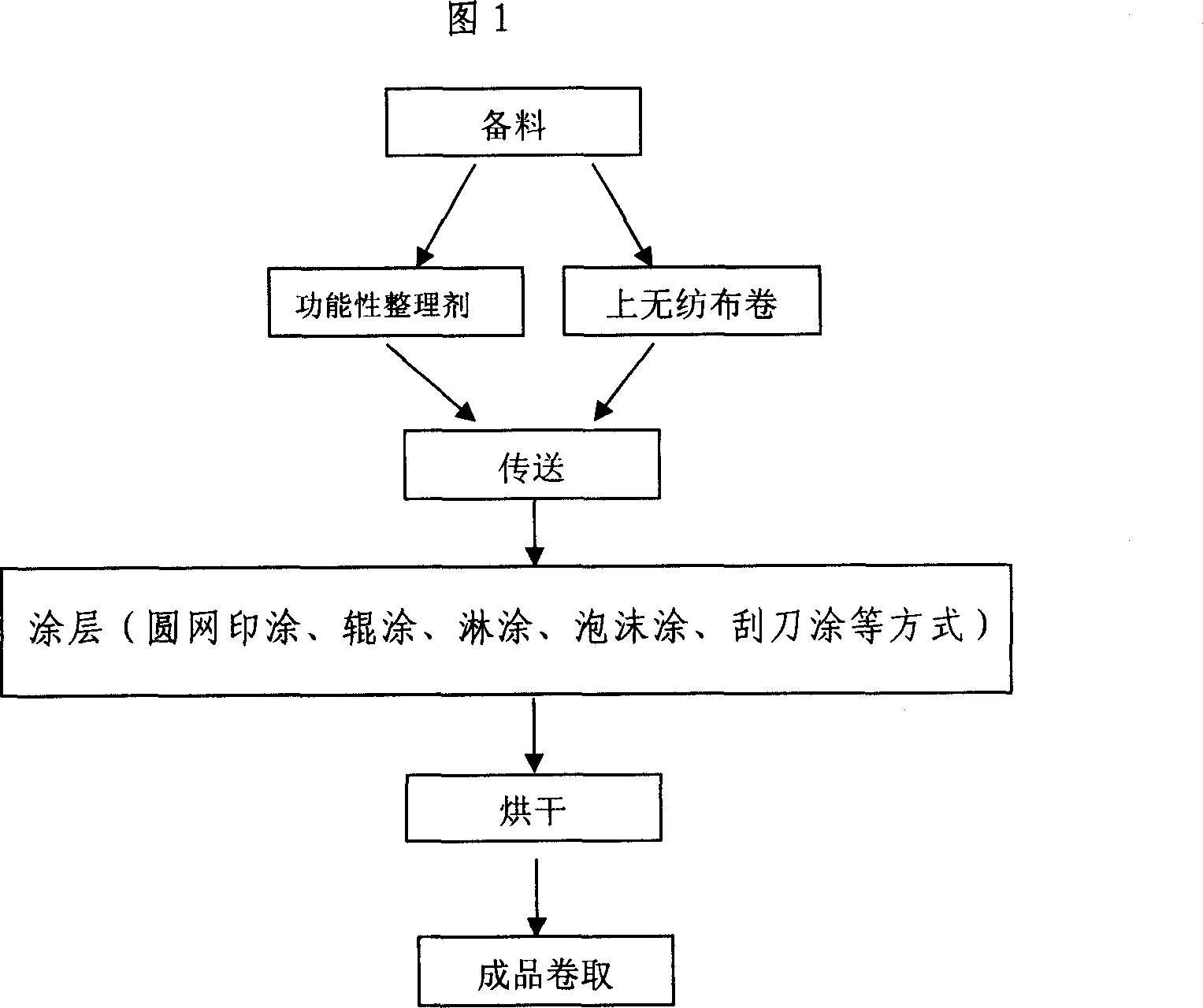

Production of non-woven cotton cloth with coating function finishing

This invention relates one functional finish non-wovens fabrics of coating staining in 100% cotton and its method. The process for this new cotton non-wovens fabrics is that attach uniformly the functional finishing agent in the form of solution, slurry and bubble to the surface of the non-wovens fabrics by coating staining (the treatment of rotary screen printed James, Roll James, leaching James, bubble James, scraper, transfer, and so on), fix to surface by the pine-drying and the reaction between finish agent and fiber. By the method one cotton non-wovens fabrics in which one side it has protective function (Exhibit 1) of 'Waterproof, anti-alcohol, anti-blood, anti-oil pollution, fire-retardant, anti-rays, anti-static' and in the other side it is with the cotton Fiber characteristics of 'Suction fluid, breathable, comfortable' Compared to the current stains rolling (ie, the entire stain soaked) methods, this invention has the advantages as follows: short time for processes, flexible technology, raw materials and energy saving, low cost, rich colors, forming without damaging non-woven fabrics, non-pilling, finish agent closely attached to the non-woven fabrics without losing.

Owner:WINNER MEDICAL CO LTD

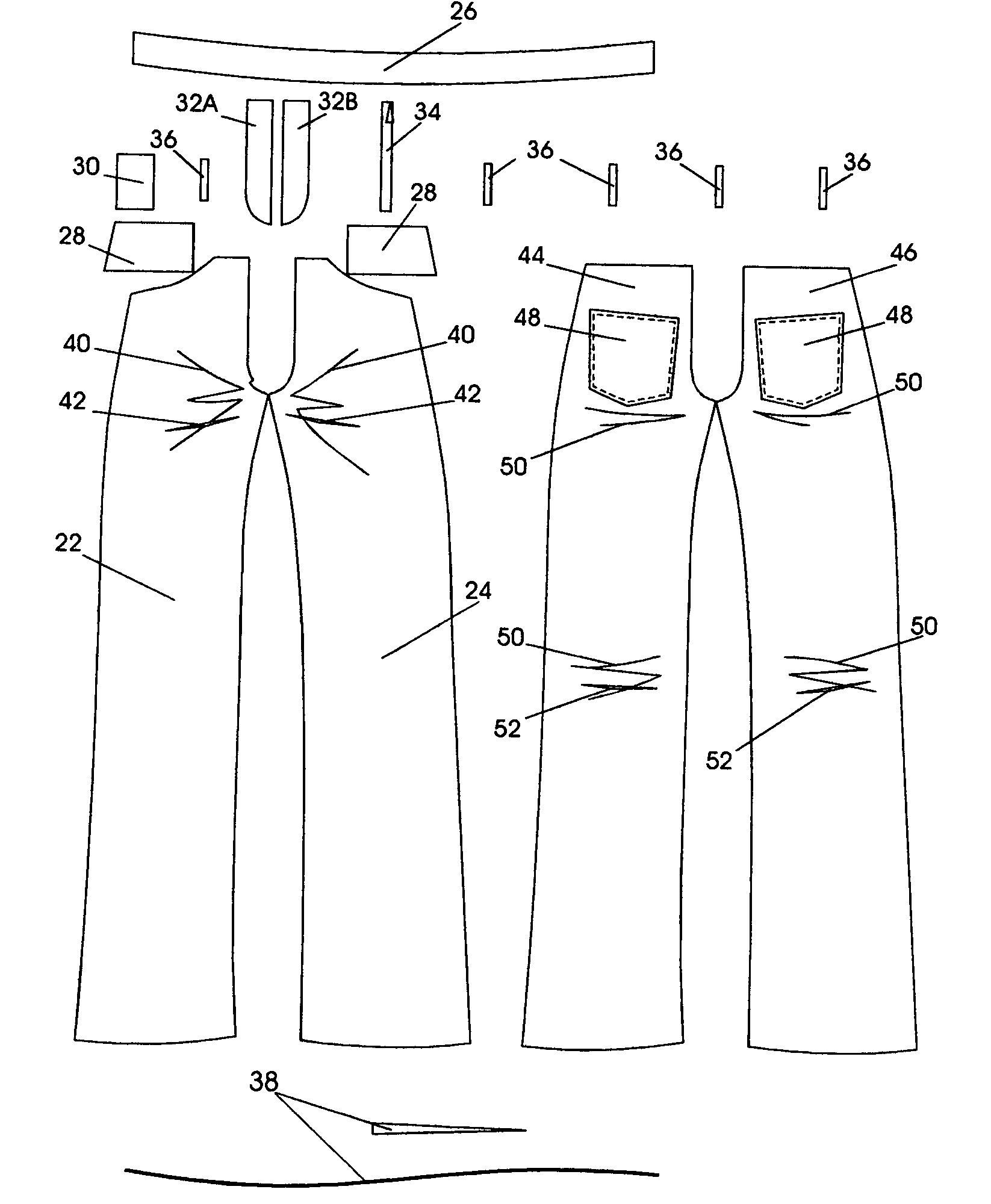

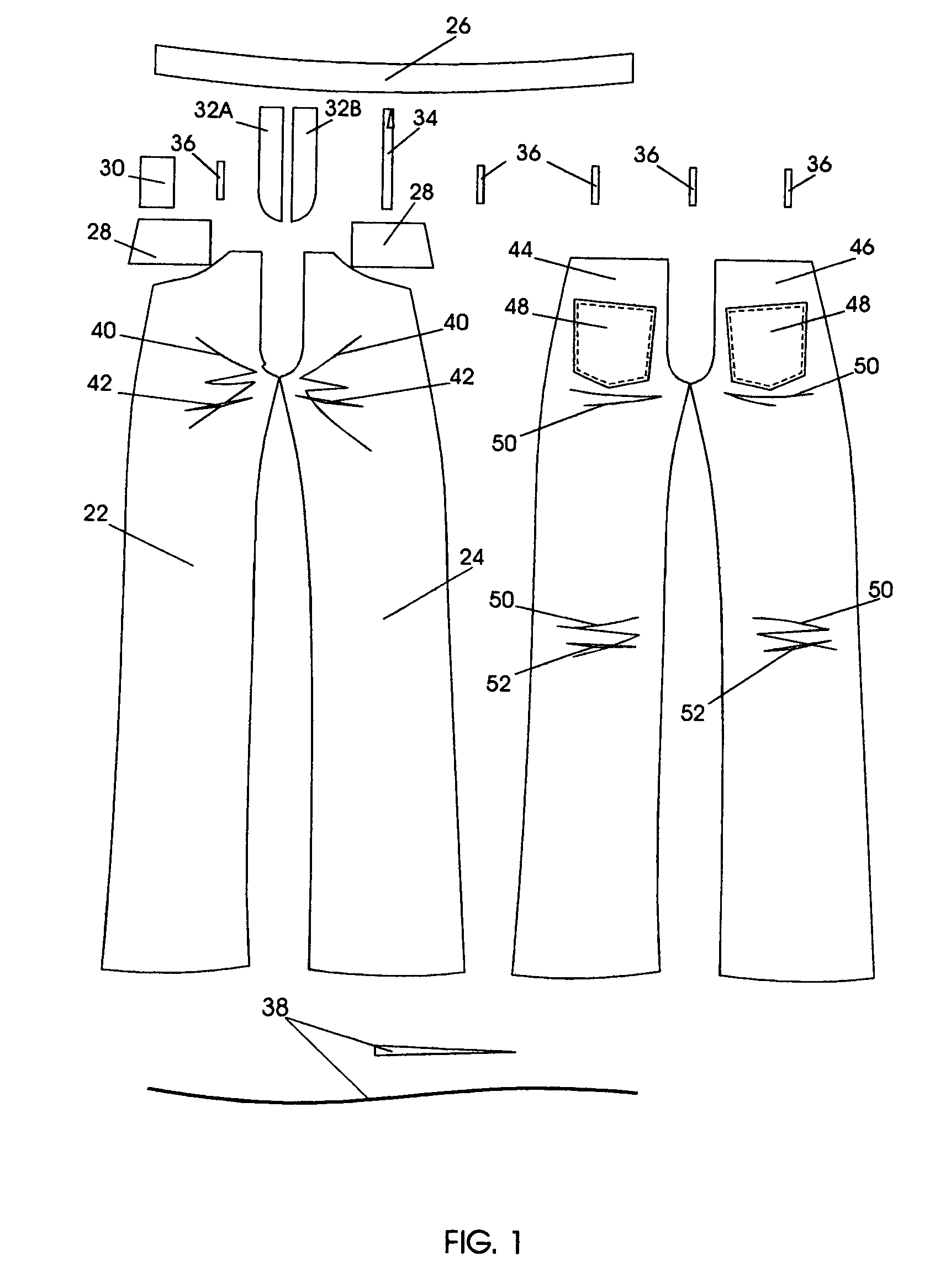

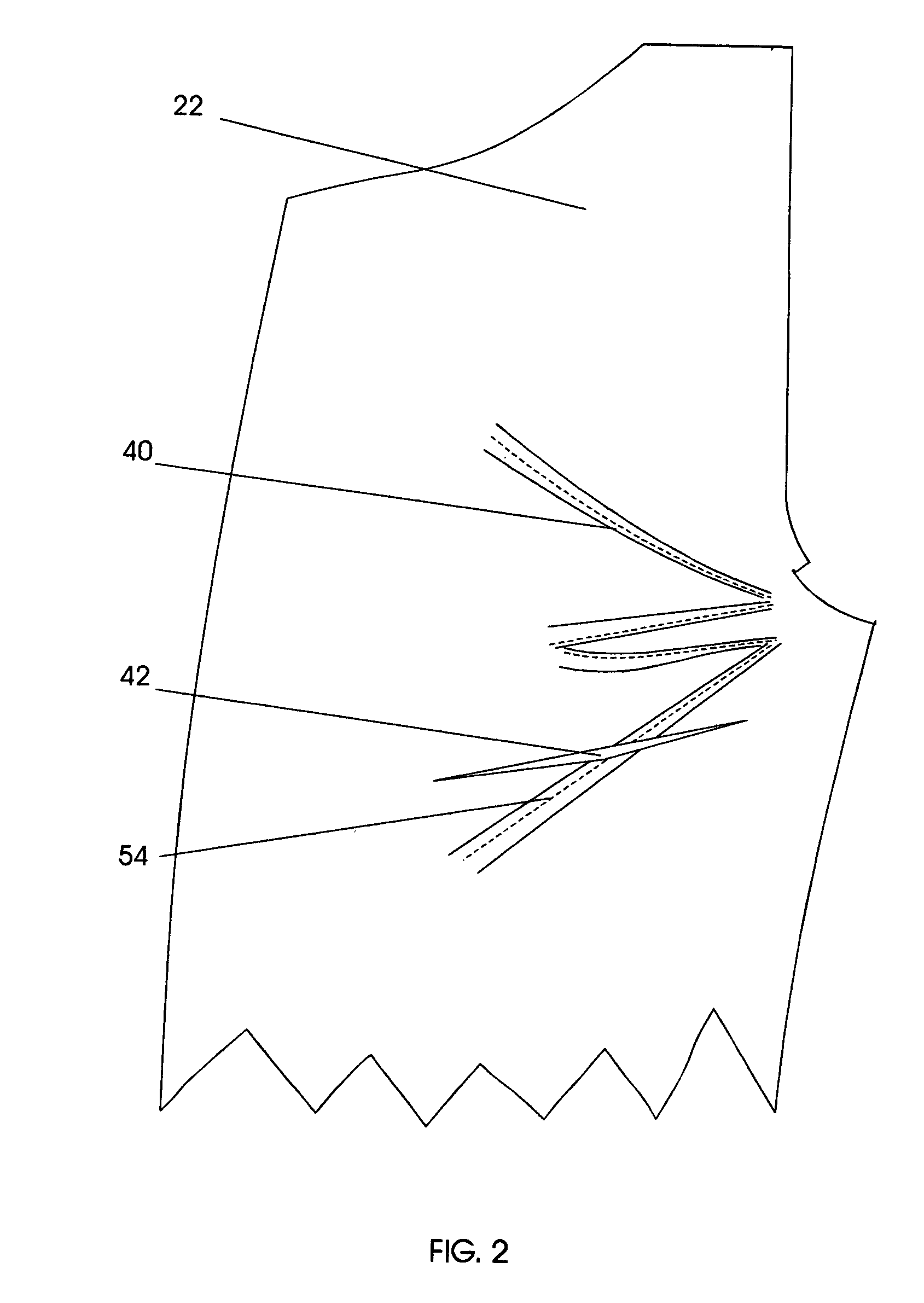

Formation of patterns of fades on fabrics

InactiveUS20060225224A1Minimize handlingEasy to produceFibre treatmentBleaching apparatusEngineering

This invention relates to a fabric having a pattern of fades and a methodology for their creation, both industrial and artistic. The fades are created by contacting at least one portion of the fabric with a hypochlorite salt-containing composition. The resulting fabric has a faded appearance either uniformly or non-uniformly. Methods, kits and a device for making a fabric having a pattern of fades are also disclosed.

Owner:LHTAYLOR ASSOC

Ozone process for denim

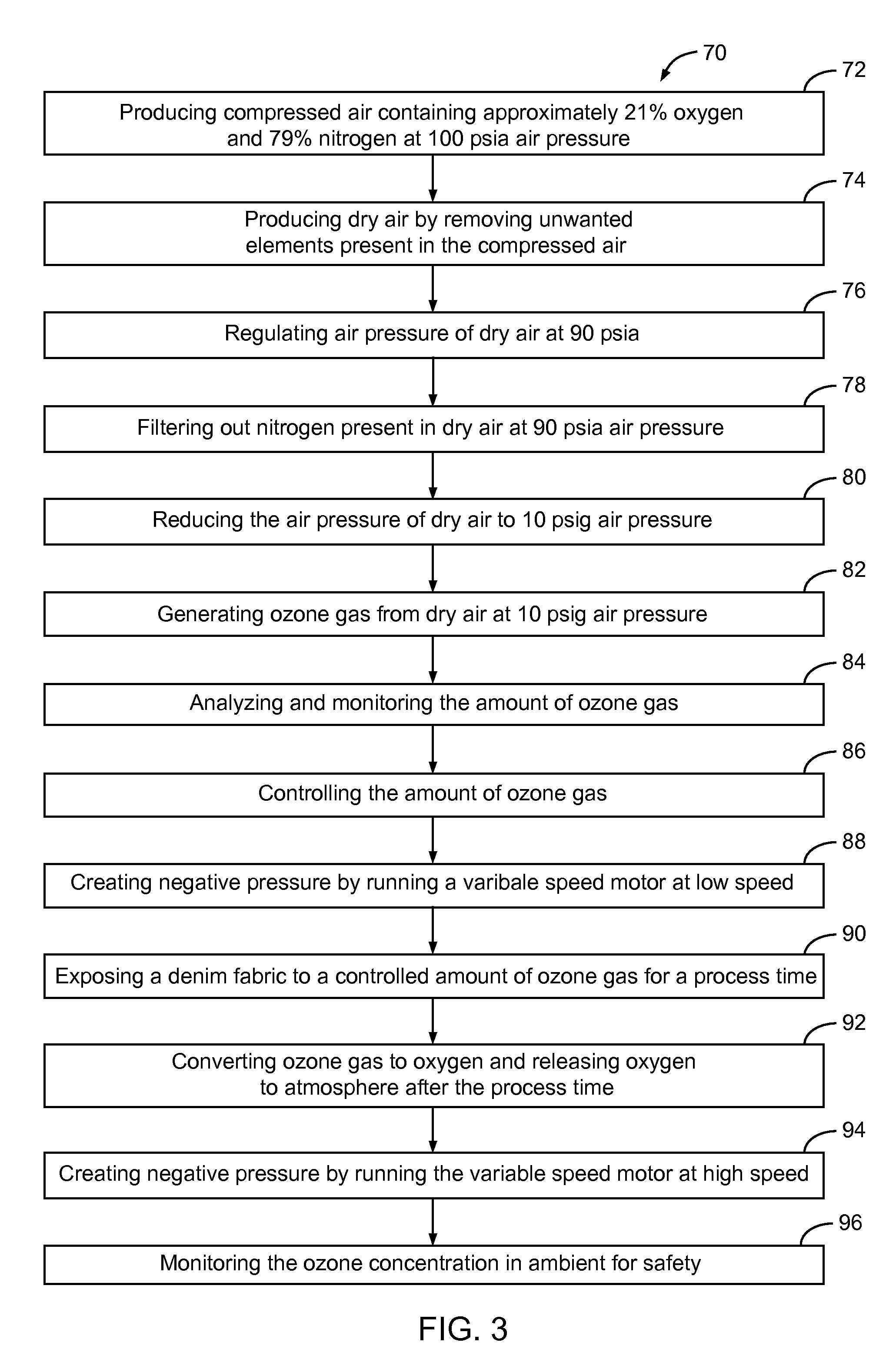

InactiveUS20110083282A1Low costUnfriendly to environmentOther washing machinesBleaching apparatusEnvironmental engineeringOxygen

An apparatus and a method for decolorizing a denim fabric with an oxidizing gas is disclosed. The process is initiated by producing compressed air which is processed to generate dry air. The air pressure of dry air is reduced to maintain at 10 psig and thereby generates ozone gas. A negative pressure is maintained to ensure no ozone leak out to ambient from a washer. The denim fabric may be exposed to a controlled amount of ozone gas for a predetermined time such as a process time. Whenever the process time expires, the amount of ozone gas is converted back to oxygen by running a variable speed motor at high speed to create a negative pressure within the processing unit and released to atmosphere. The method also incorporates a means for monitoring the level of ozone concentration in ambient for the safety of operators.

Owner:MYUNG JASON +2

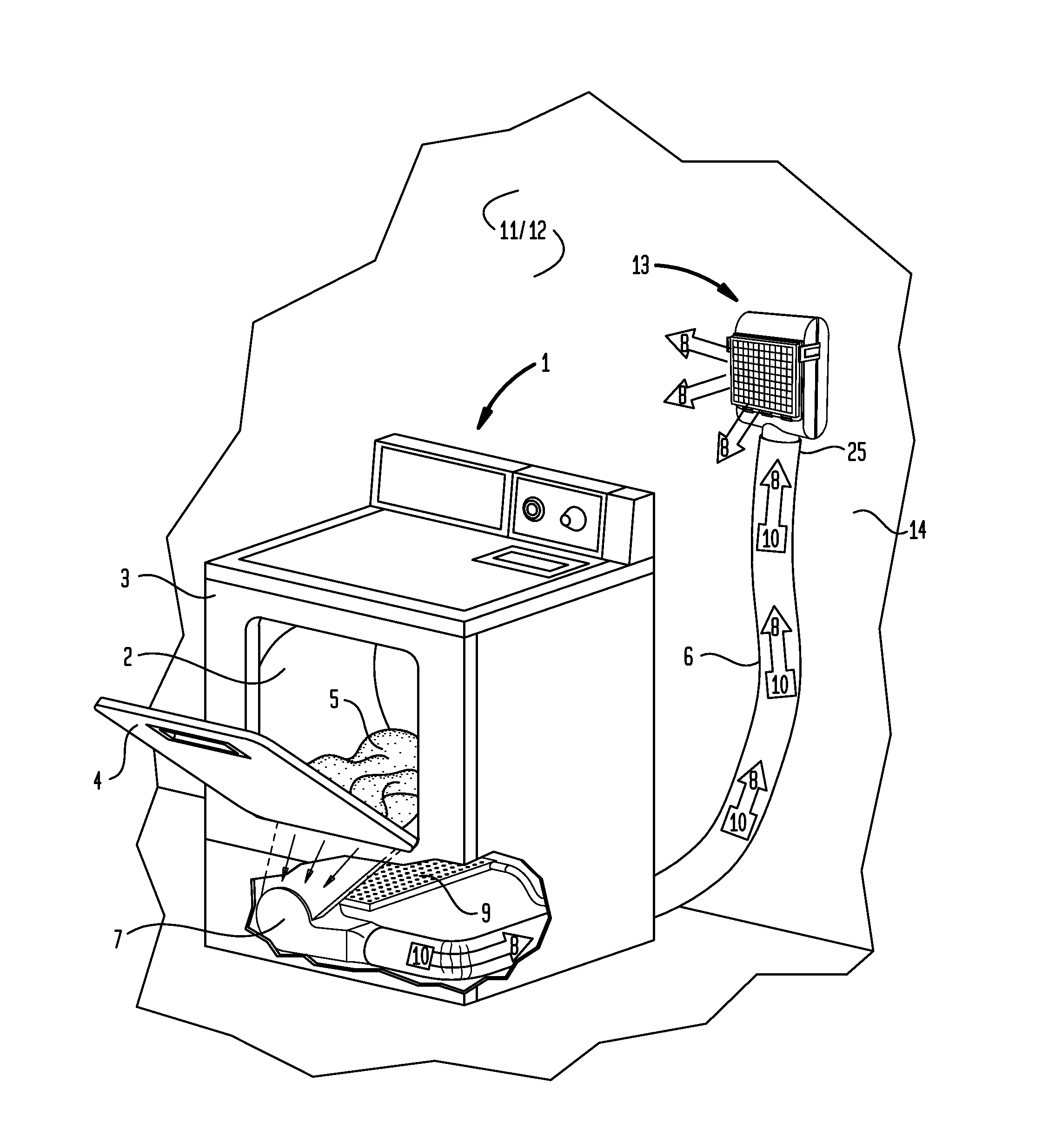

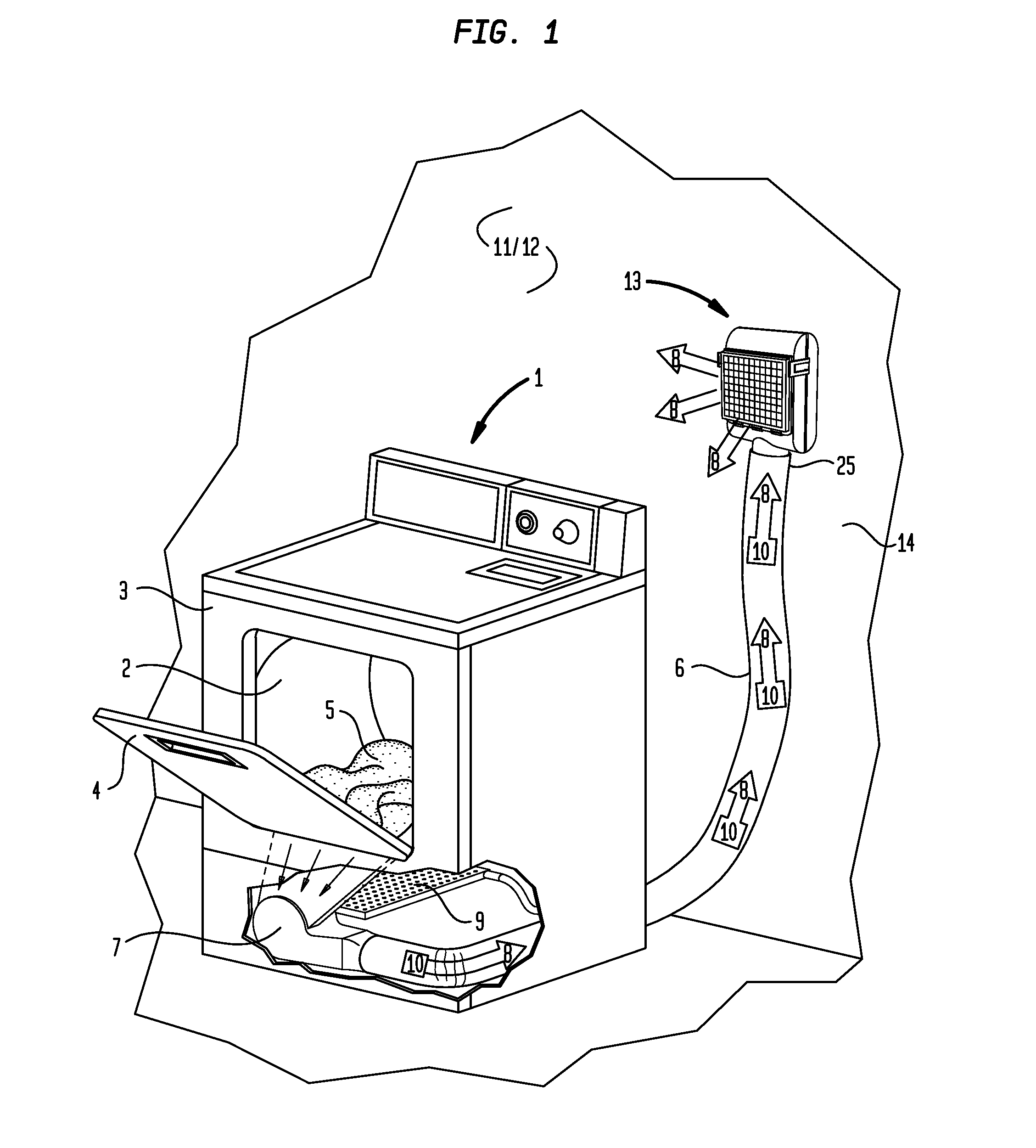

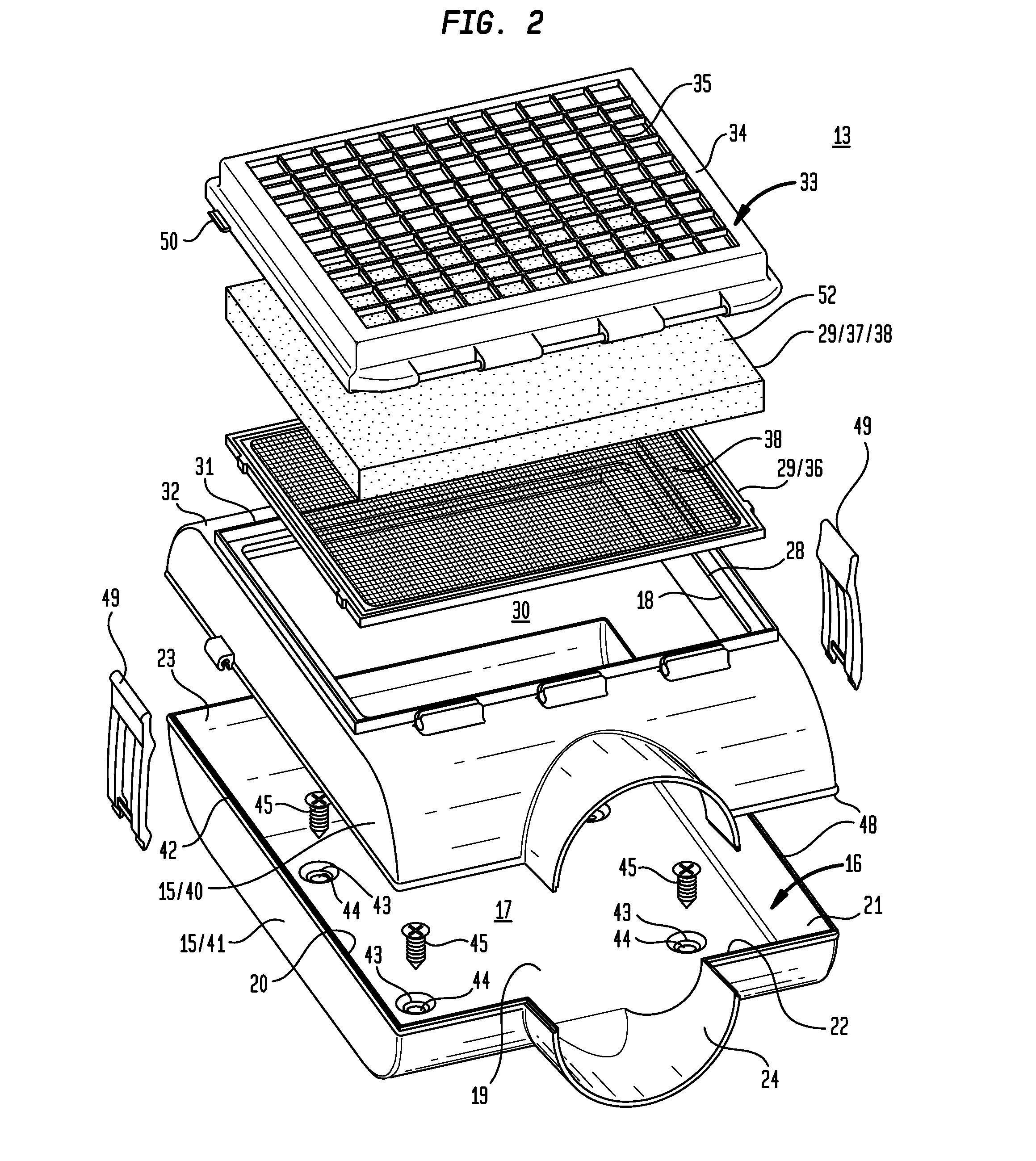

Lint catching system

ActiveUS8893399B2Increase depositionIncrease exhaust flowDrying using combination processesDrying solid materials with heatWaste management

Owner:ADR PROD

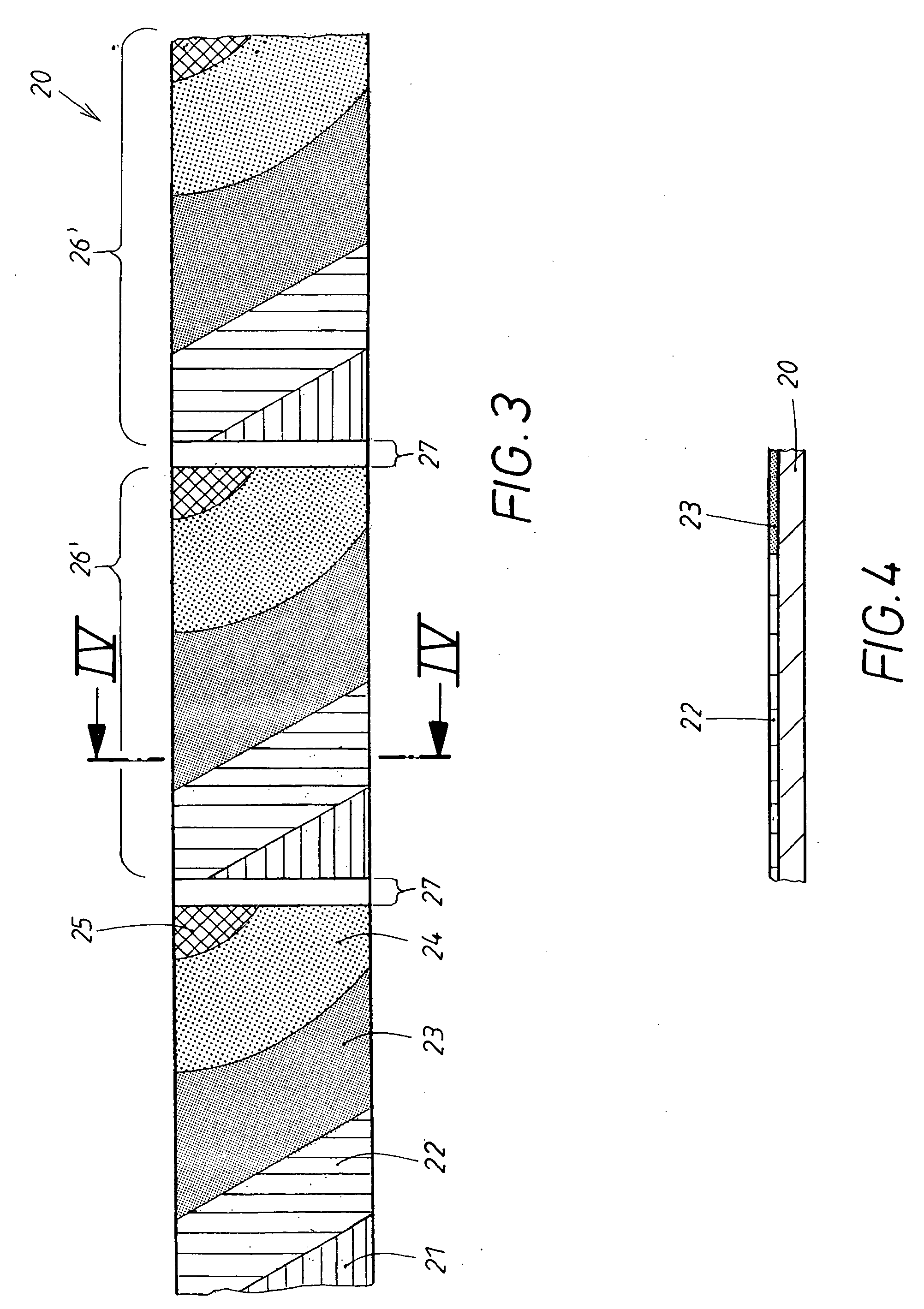

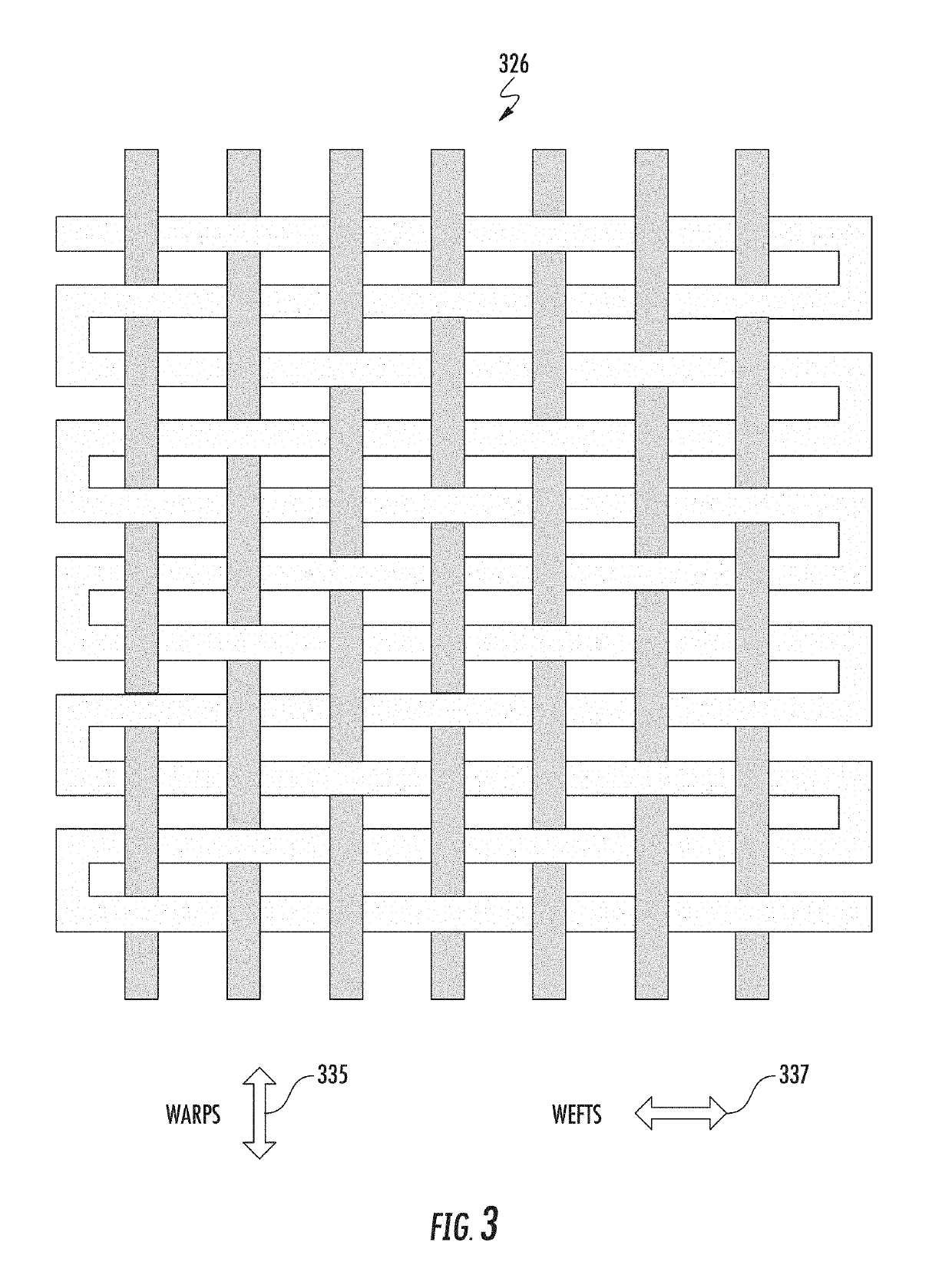

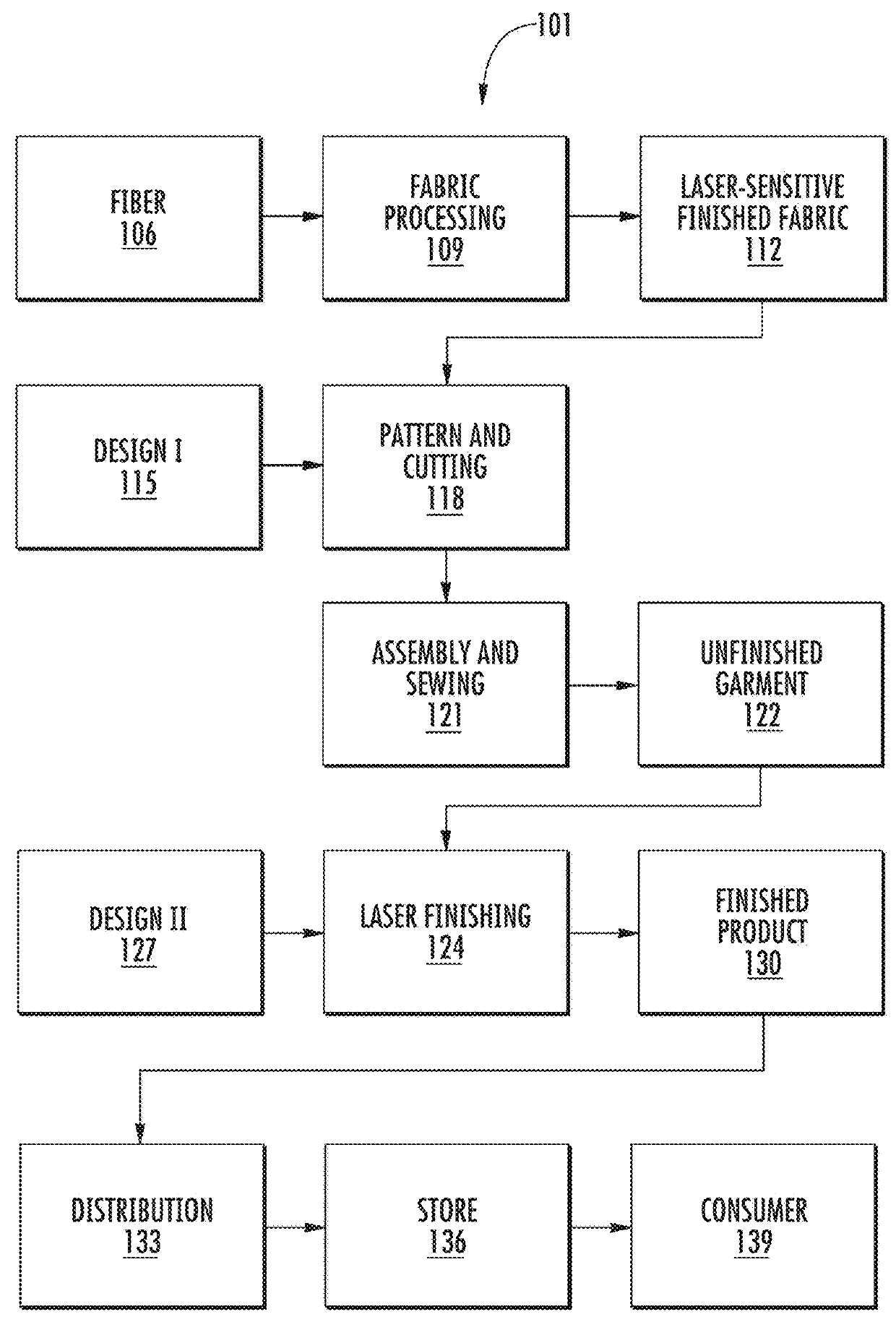

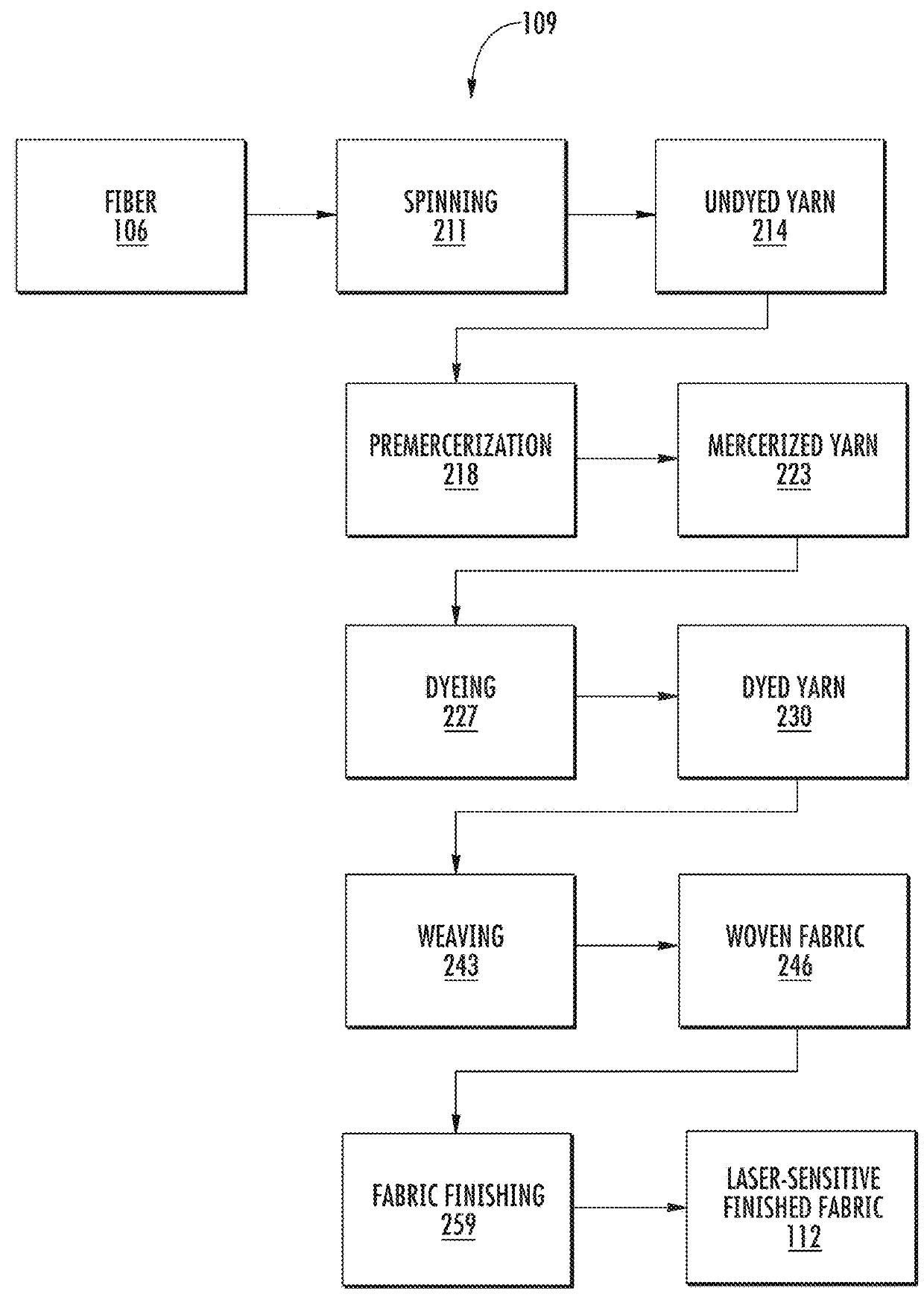

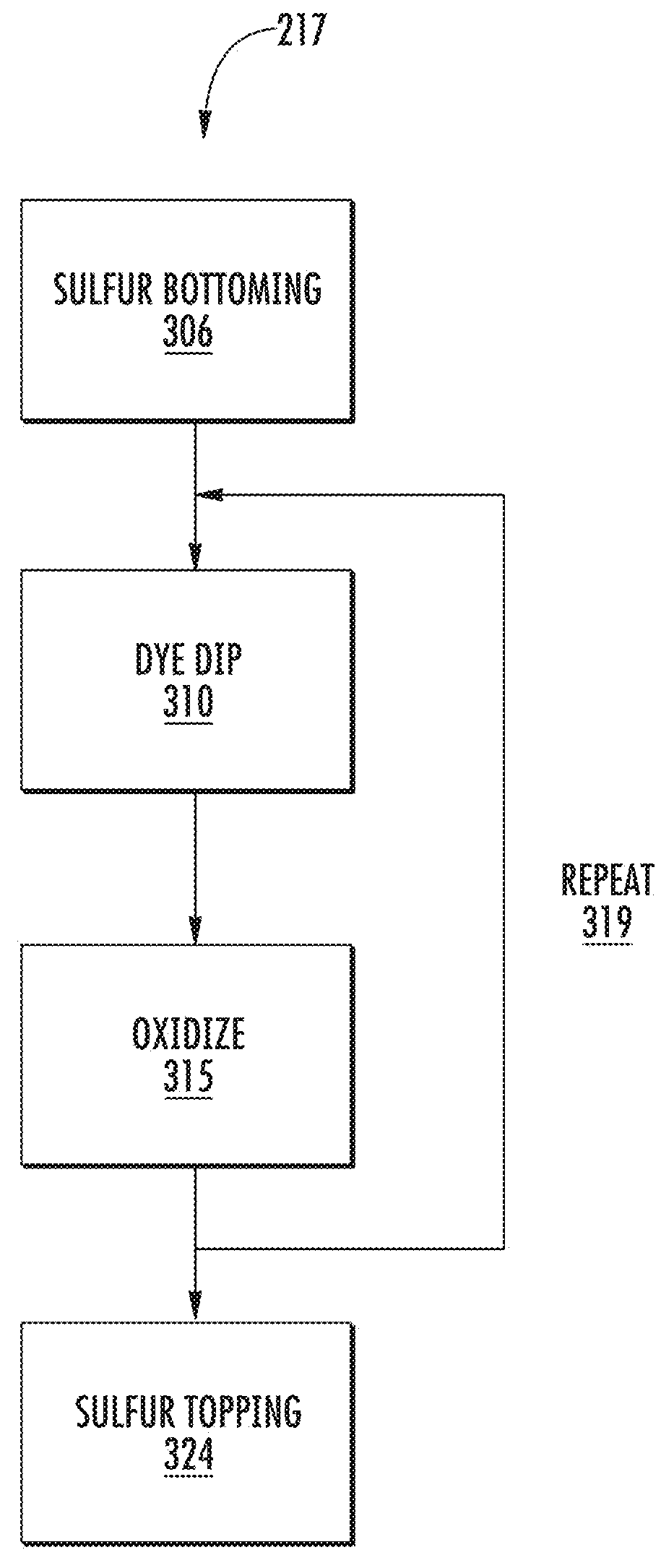

Fabric with Enhanced Response Characteristics for Laser Finishing

ActiveUS20180160756A1Improve responsivenessChange color quicklyPattern makingFibre treatmentYarnEngineering

A fabric has enhanced response characteristics for laser finishing. The fabric can be denim for denim apparel such as jeans. Software and lasers are used to finish apparel made of the fabric to produce a desired wear or distressing pattern or other design. The fabric allows for relatively fast color change in response to the laser, color changes in hue from indigo blue to white, many grayscale levels, and maintains strength and stretch properties. A method used to make the fabric includes spinning, dyeing, and weaving yarns in such a way to obtain the desired enhanced response characteristics for laser finishing.

Owner:LEVI STRAUSS & CO

Vintage fading method for jeans

Owner:MEI DAVID +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com