Production technology for watermark pattern cloth and production device thereof

A production process and production device technology, which are applied to the production process and device field of watermark pattern cloth, can solve the problems of difficult control of arrangement and combination rules, easy blockage of small-aperture nozzles, blurred pattern patterns, etc. Reduced duplication of effort, moderate color and contrast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

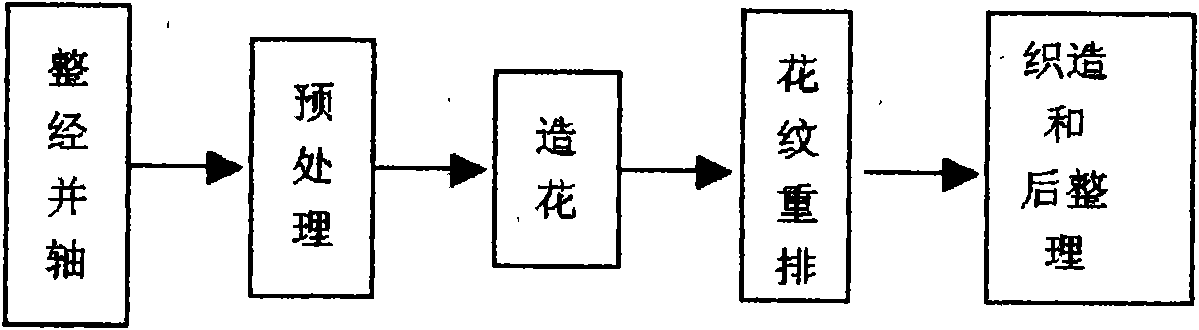

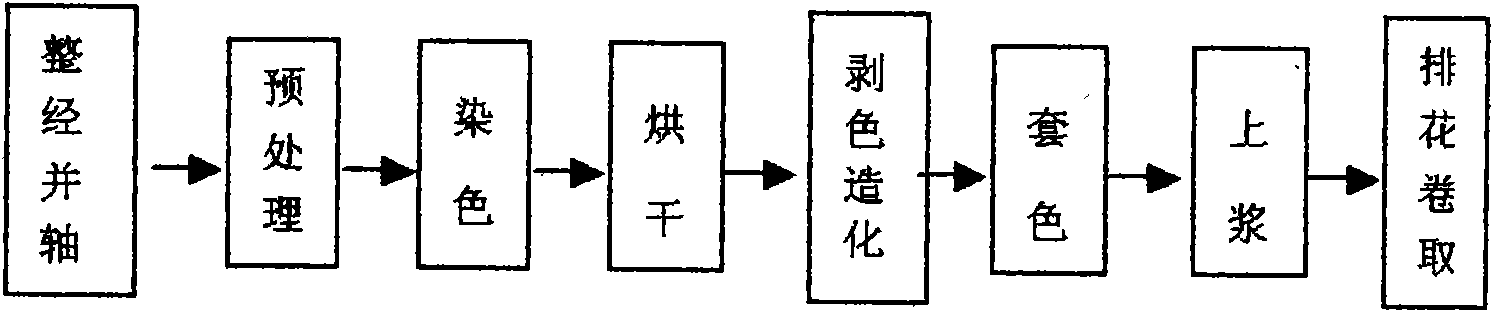

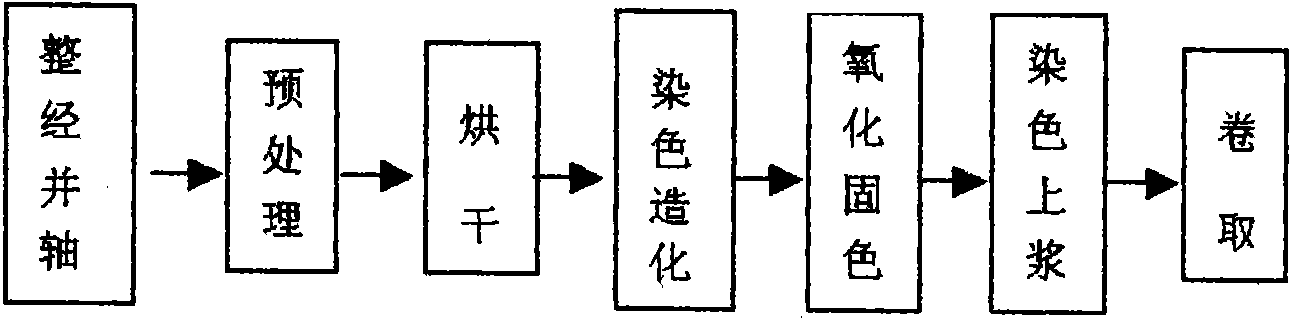

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: Using the watermark pattern cloth production process of the present invention, a set of flower-making device is installed between the 7th and 8th dyeing vats of the sizing-dyeing machine, and the stripping and flower-making process is used to dye the indigo blue sheet as a whole. White horizontal stripes are produced at intervals on the yarn tape, and then the piece of yarn tape is passed through a dark blue-green vulcanization dyeing vat, so that dark blue-green stripes are produced on the dark blue piece of yarn tape as the basic pattern, and repeated with a flower arrangement device. A piece of yarn tape with evenly distributed dark blue-green line segments is constructed to produce a watermark pattern cloth with the effect of dark blue-green colored slub yarn.

[0071] According to the technical scheme of the present invention, the above-mentioned watermark pattern cloth whose main color is dark blue and has the effect of dark blue-green colored slub ya...

Embodiment 2

[0084] Embodiment 2: Using the watermark pattern cloth production process of the present invention, a set of flower making device is installed between the 9th and 10th dyeing vats of the sizing and dyeing machine, and a flower making process is adopted to separate the dark blue piece yarn belt. The white horizontal stripes are produced in a precise manner, and then the piece of yarn is divided into two layers. The first layer passes through a green vulcanization dye vat, and the second layer passes through a red vulcanization dye vat, and then the two layers of gauze tape are combined Go through several ultra-dark blue dyeing vats together to create dark blue-green and dark blue-purple horizontal stripes on the dark blue yarn tape as the basic pattern, and use the flower arrangement device to reconstruct dark blue-green and dark blue-purple line segments Uniformly distributed strips of yarn create a watermark patterned cloth with dark blue-green and dark blue-purple colored spa...

Embodiment 3

[0092] Embodiment 3: Using the watermark pattern cloth production process of the present invention, two sets of flower making devices are installed before the dyeing vat of the sizing-dyeing machine, and white, light yellow and light red strips are produced on the white yarn tape. The basic pattern pattern, and the light yellow and light red basic pattern patterns are evenly distributed through the flower arrangement device, and then dyed for several times to make bright blue as the main base color, and have blue-green and blue-purple uniform patterns. Yarn pieces, and weave a vivid blue mixed color denim with a watermark pattern.

[0093] According to the technical scheme of the present invention, the above-mentioned bright blue mixed-color denim fabric with blue-green and blue-violet watermark patterns is manufactured according to the following production technology:

[0094] ① Yarn matching and warping: according to the pattern density and color requirements of the watermar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com