Patents

Literature

164results about How to "High speed production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

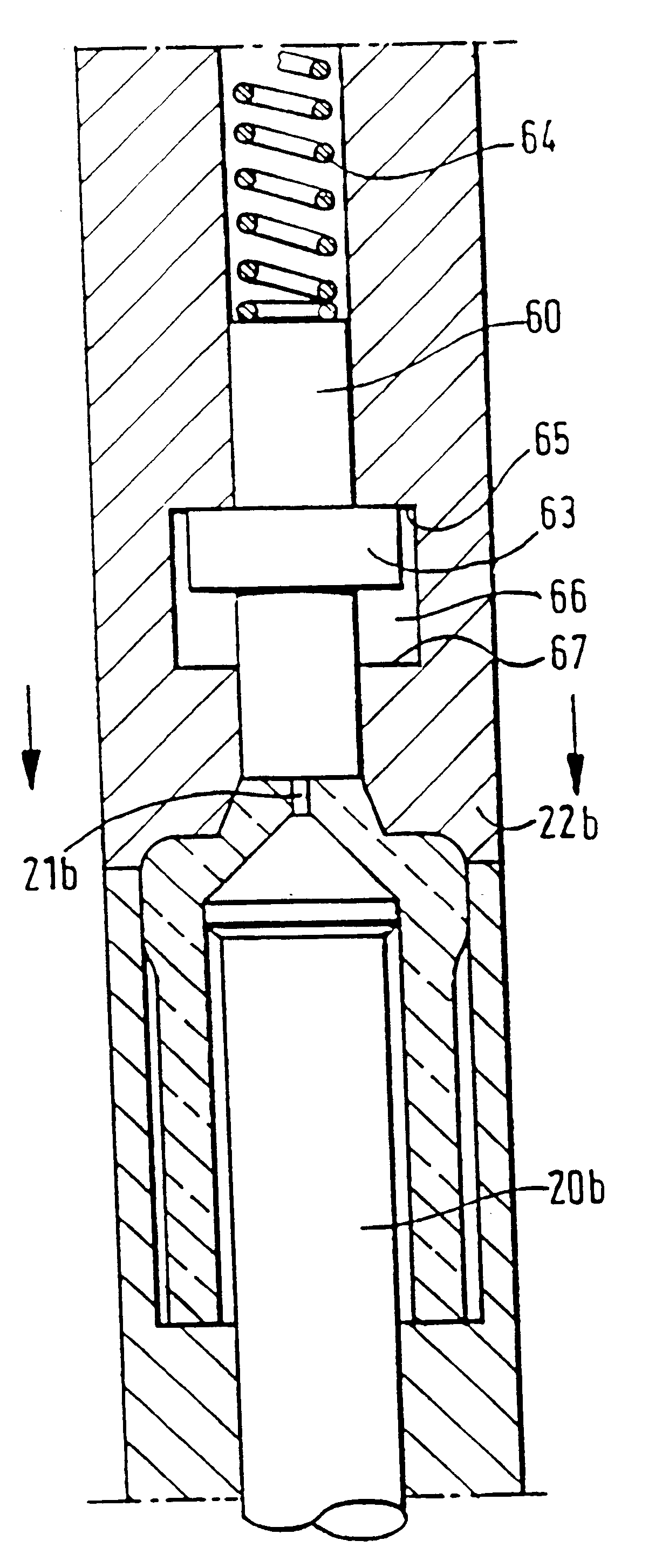

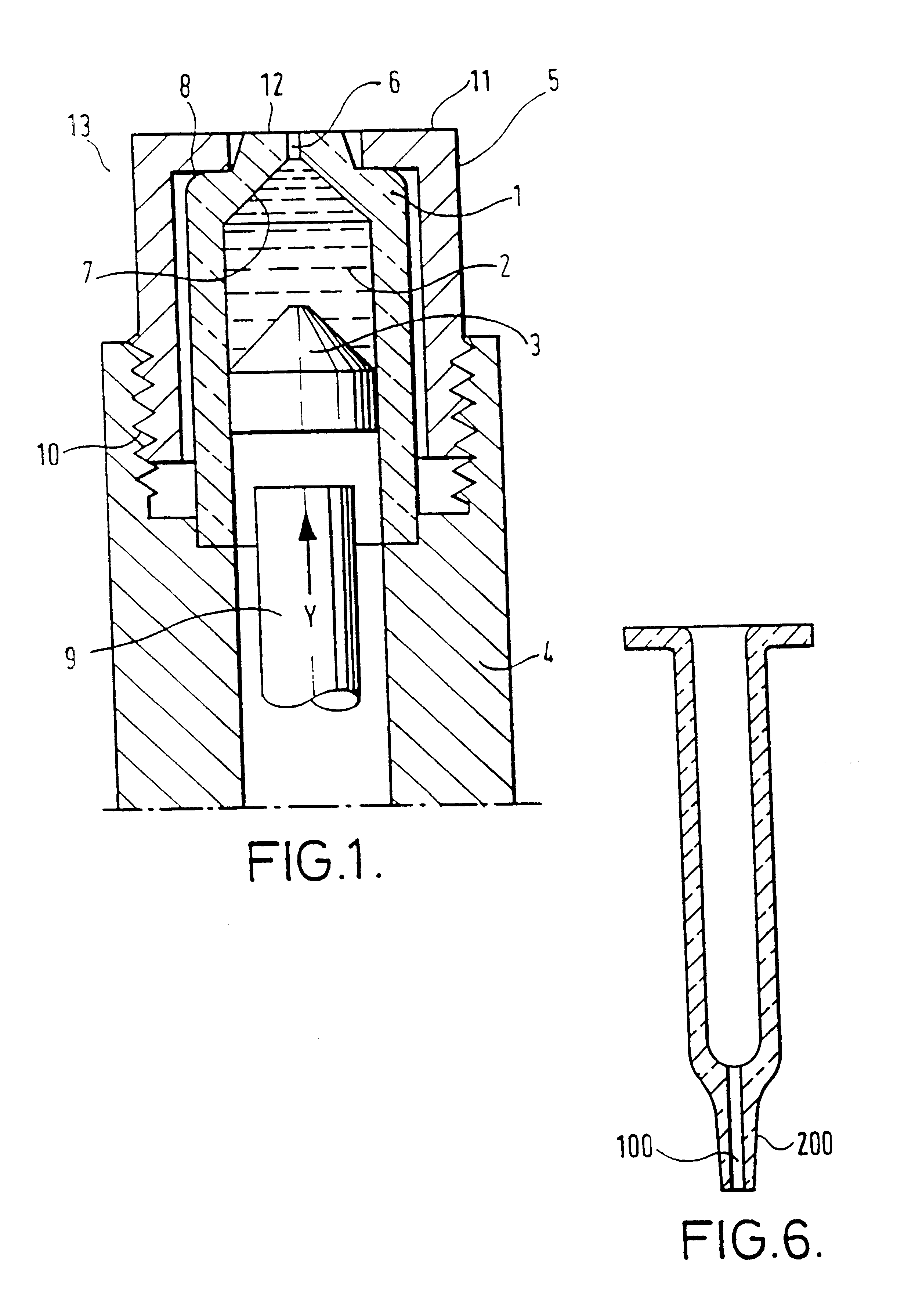

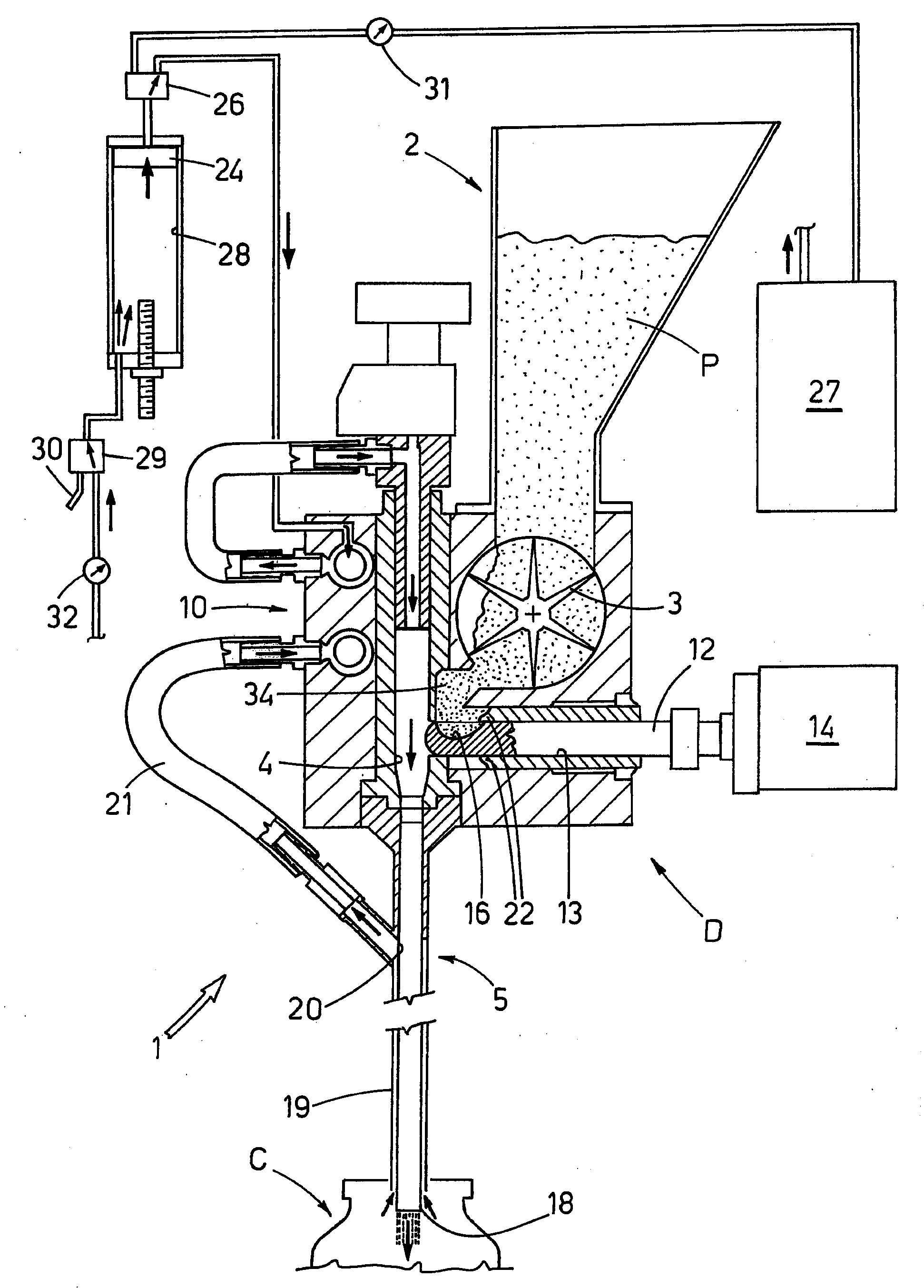

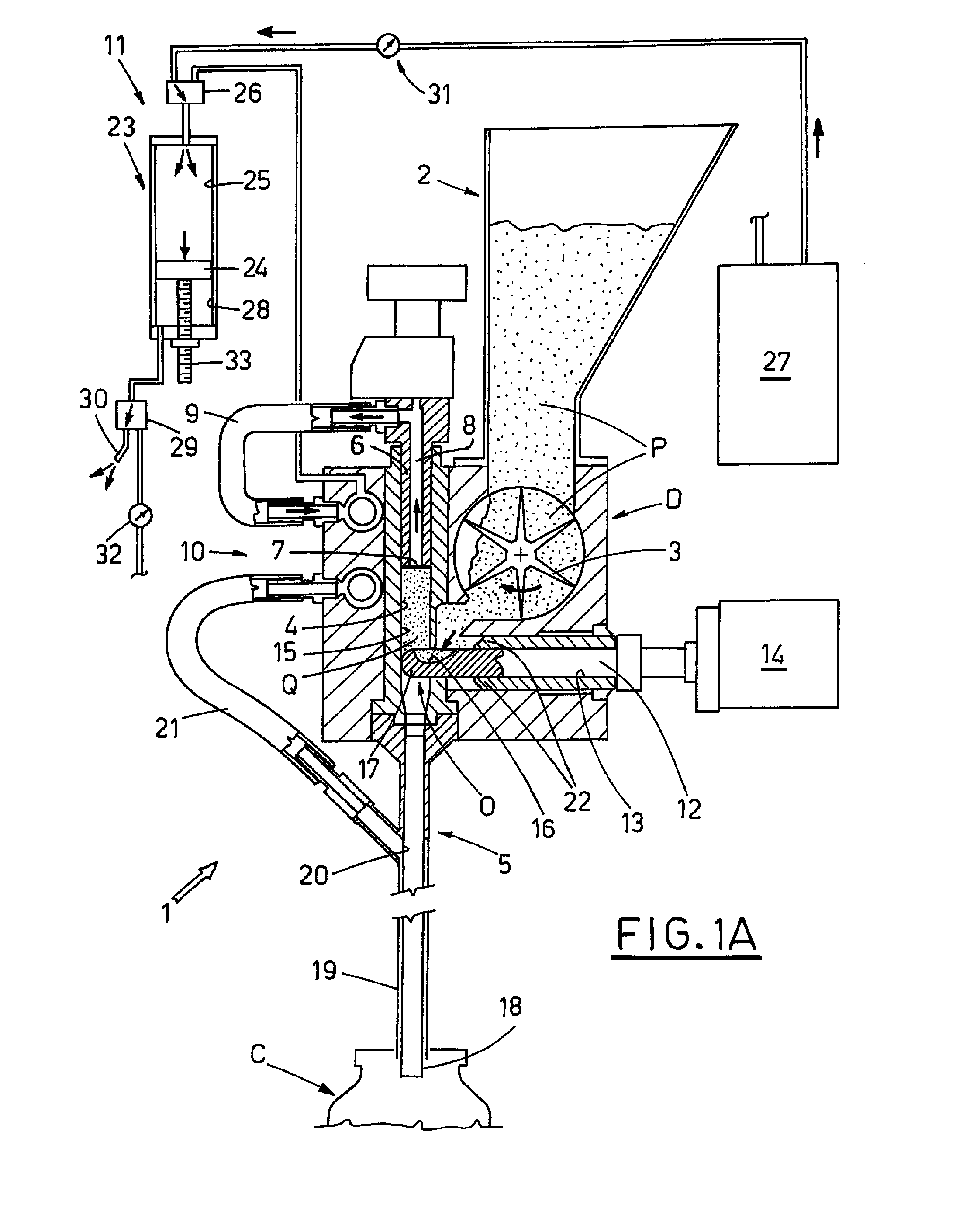

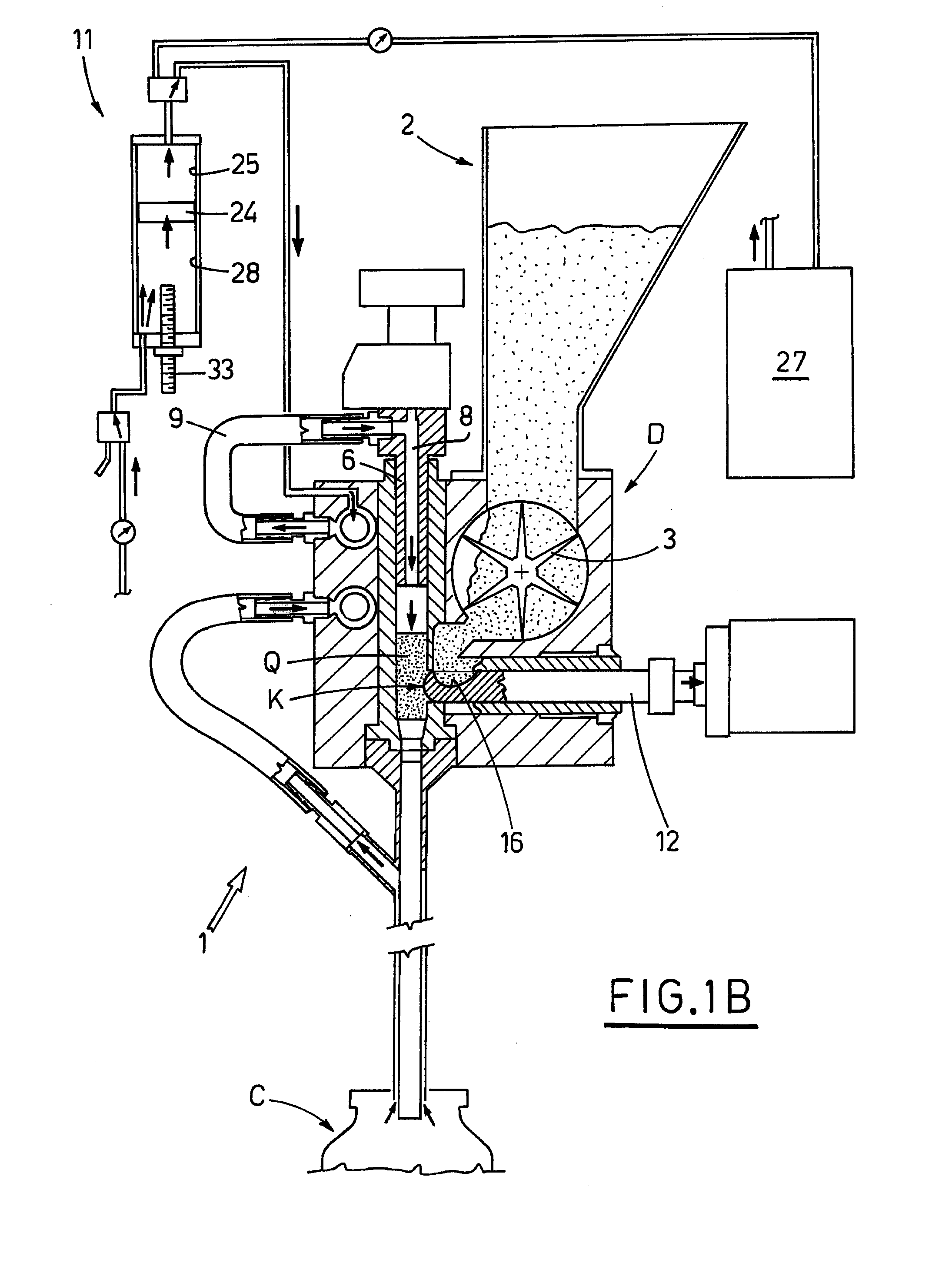

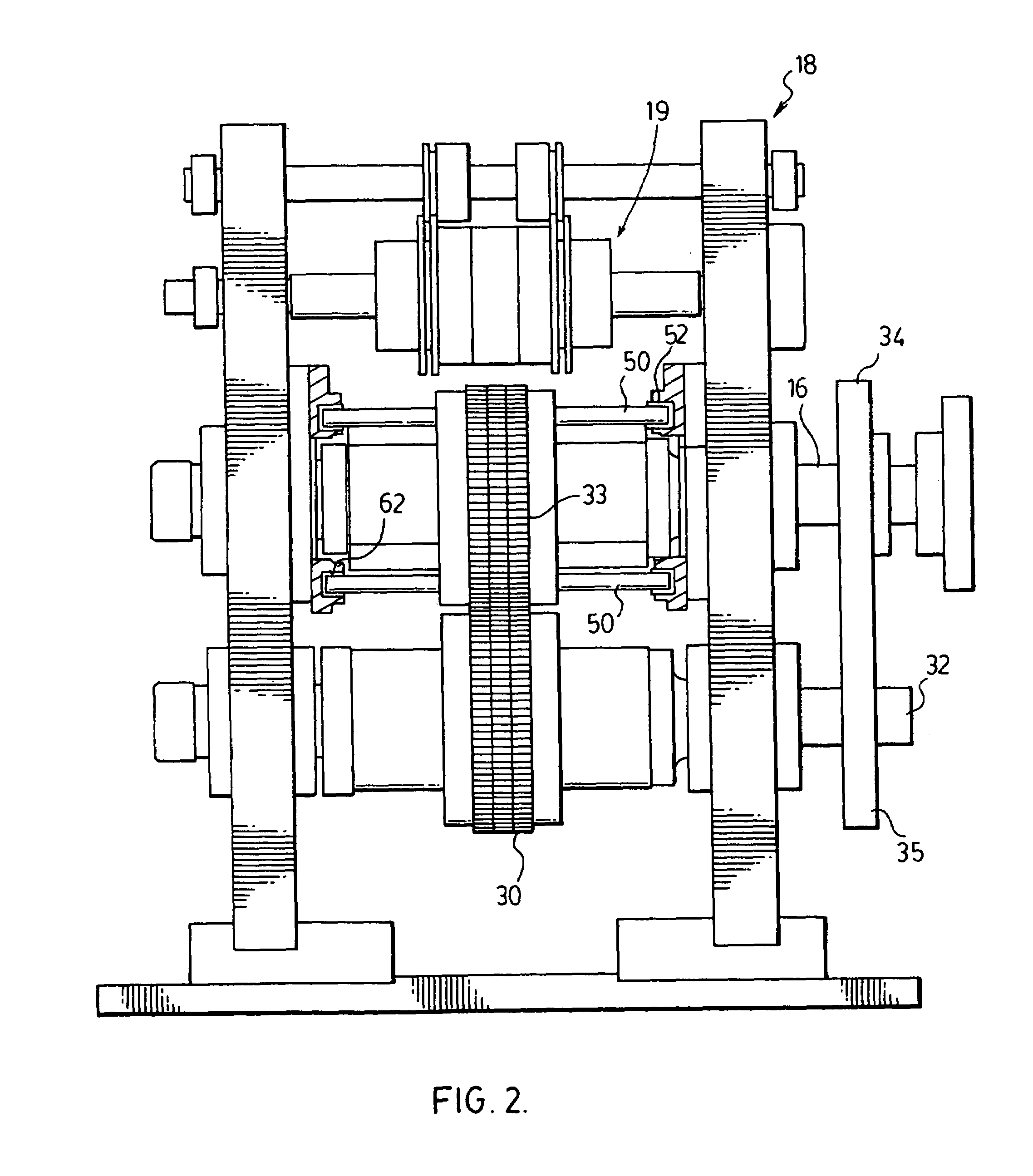

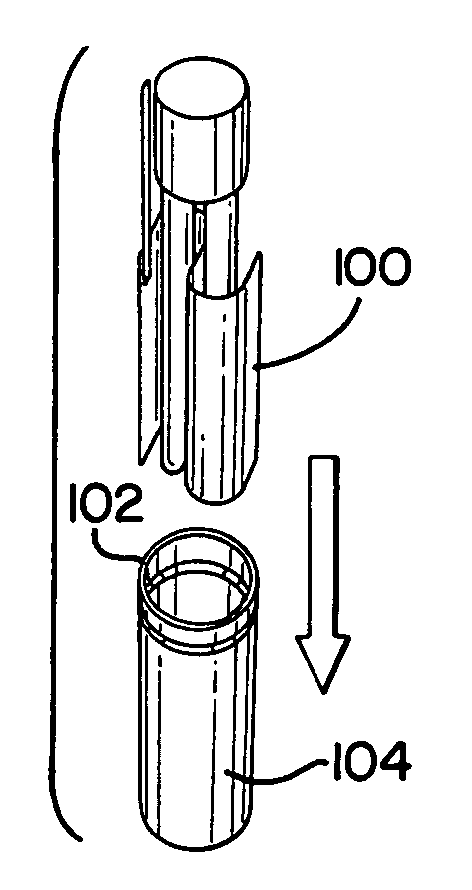

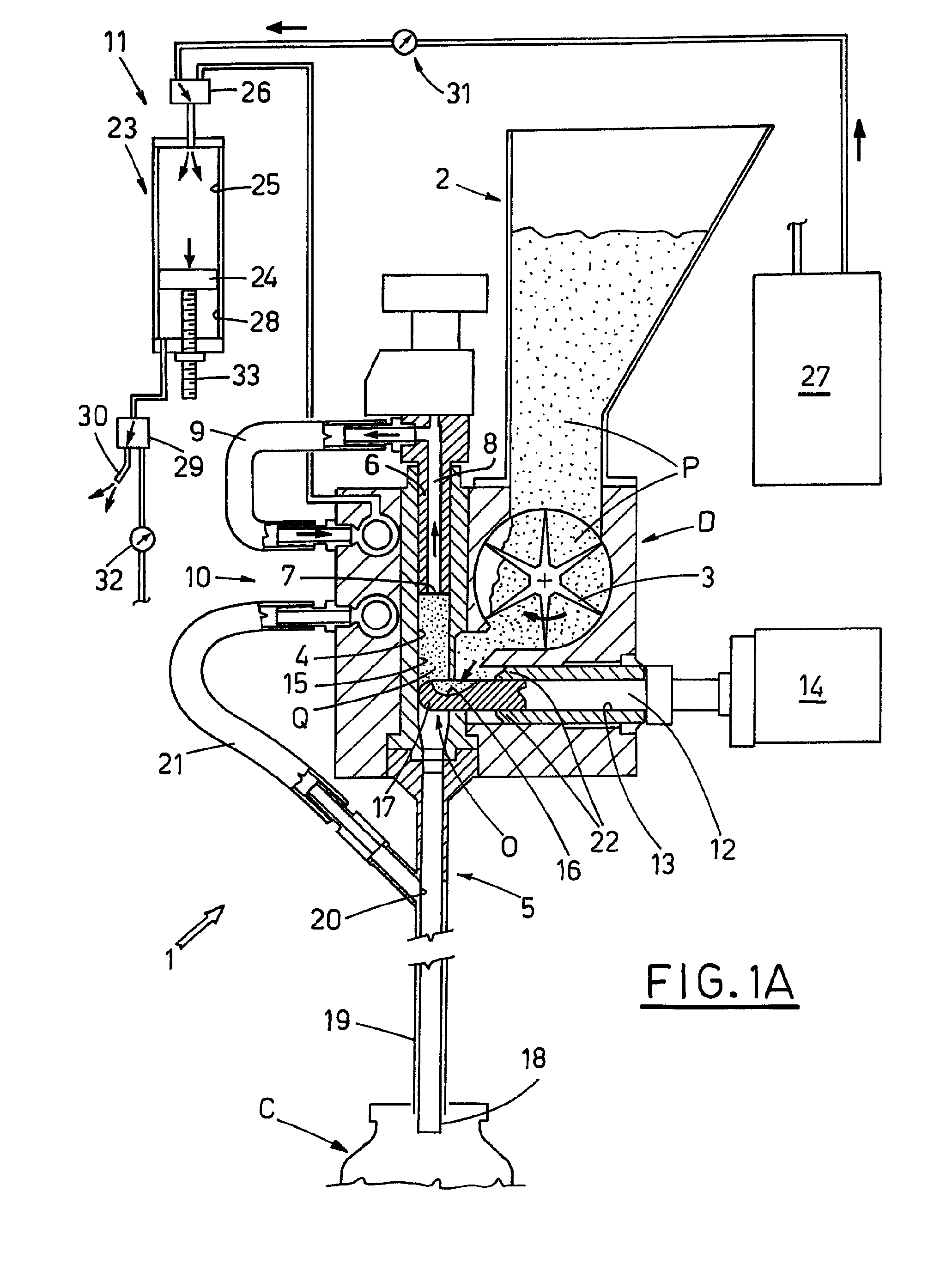

Method and apparatus for making an article from a formable material

InactiveUS6415631B1Good repeatabilityHigh speed productionButtonsAmpoule syringesEngineeringInjector

A method and apparatus are described for making an article such as the body of a needleless injector capsule, from a formable material, such as glass, the article having a cavity communicating with the exterior via an orifice. A blank having an open end is mounted on a first forming tool, and the open end is engaged by a second forming tool while an end region of the blank adjacent the open end is in a condition to permit it to be formed. One of the tools has a pin extending therefrom, and when the tools are brought together to form the end region into the desired shape the pin defines the orifice.

Owner:ZOGENIX INC

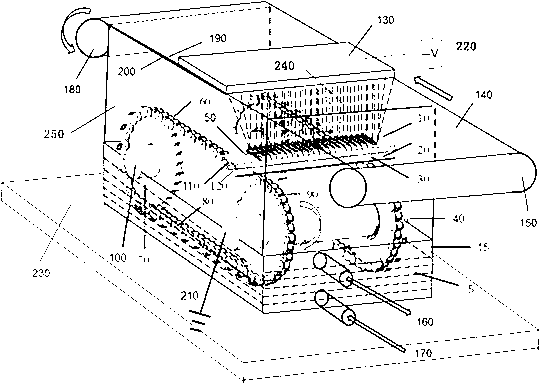

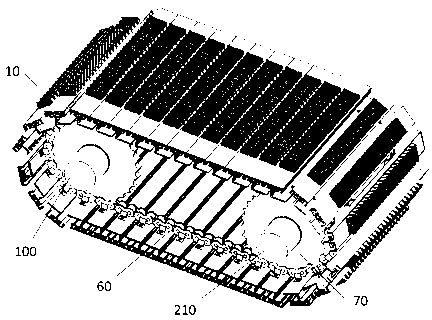

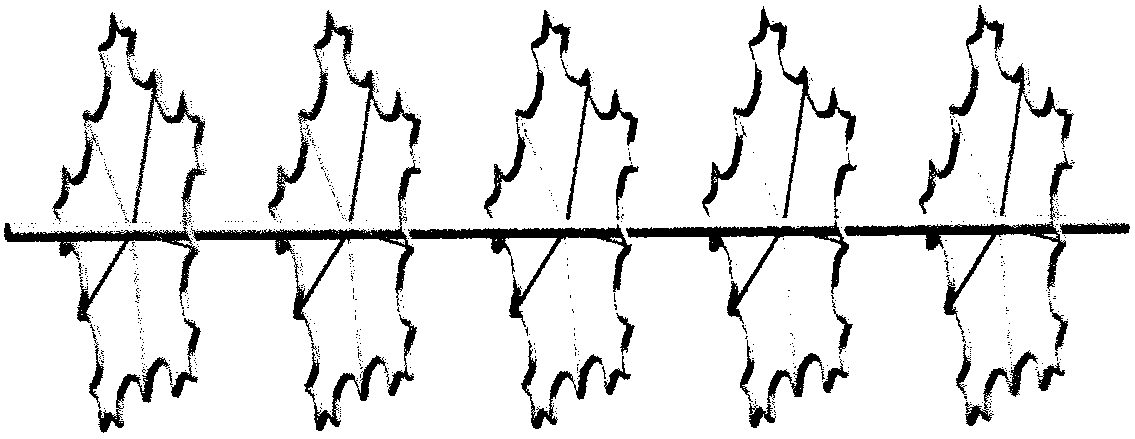

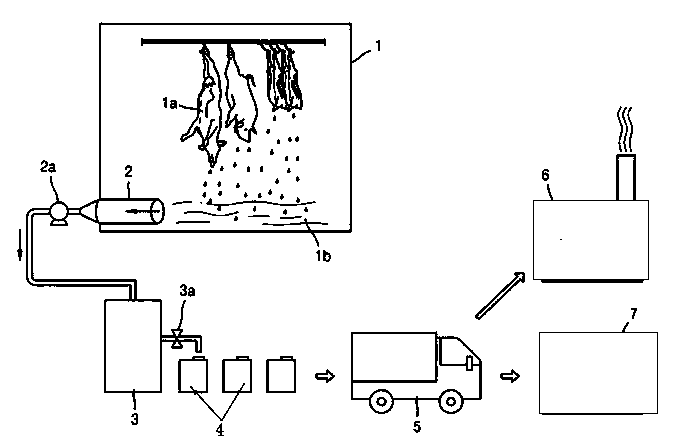

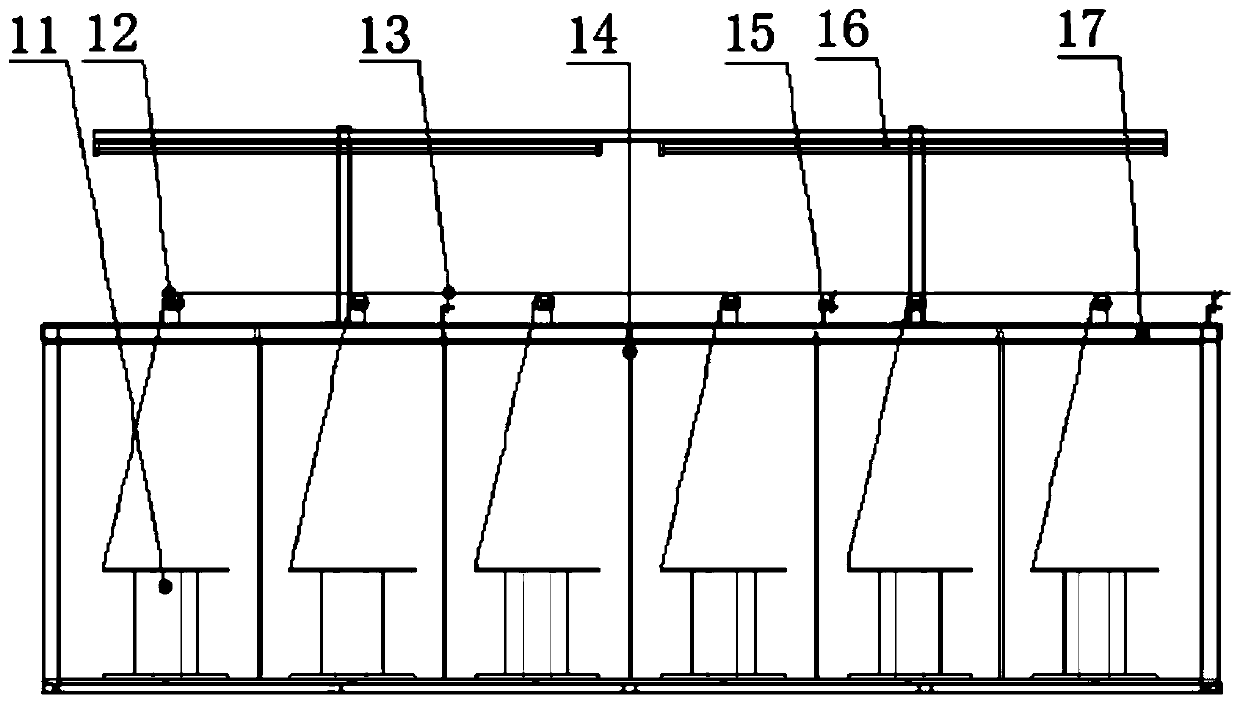

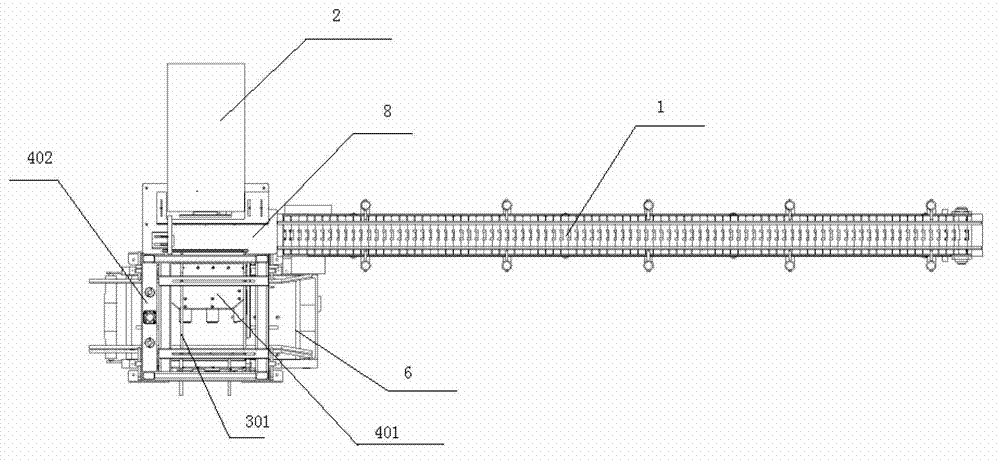

Tip-end type needle-free electrostatic spinning equipment

ActiveCN103255485AImprove uniformityTake advantage ofFilament/thread formingSpinningHigh-voltage direct current

The invention discloses tip-end type needle-free electrostatic spinning equipment which comprises a spinning solution storage box, base cloth, a spinning device and a negative-high-voltage direct-current power source, wherein the spinning device comprises a spinning box body, a needle plate, a chain, a negative electrode and a connecting device. The spinning box body is fixedly connected at the top end of the spinning solution storage box, and the chain is connected on the inner wall of the spinning box body. The connecting device is connected with a transmission device to achieve rotation of the chain, a lowermost link of the chain is submerged in spinning solution of the spinning solution storage box, and the needle plate is fixedly connected on the chain. The base cloth covers the top end of the spinning box body. The spinning solution storage box, the spinning box body and the base cloth form an enclosed spinning space. The negative electrode is attached to the top surface of the base cloth. The spinning device is earthed, the negative electrode is connected with the negative-high-voltage direct-current power source, and a high-voltage electrostatic field is formed between the negative electrode and metal card clothing. The tip-end type needle-free electrostatic spinning equipment can improve the yield and the uniformity of nanofiber products, the fineness of nanofiber manufactured through the tip-end type needle-free electrostatic spinning equipment is small, and the variation of the fineness is less.

Owner:JIANGSU FILTERTEX FILTER MATERIAL +1

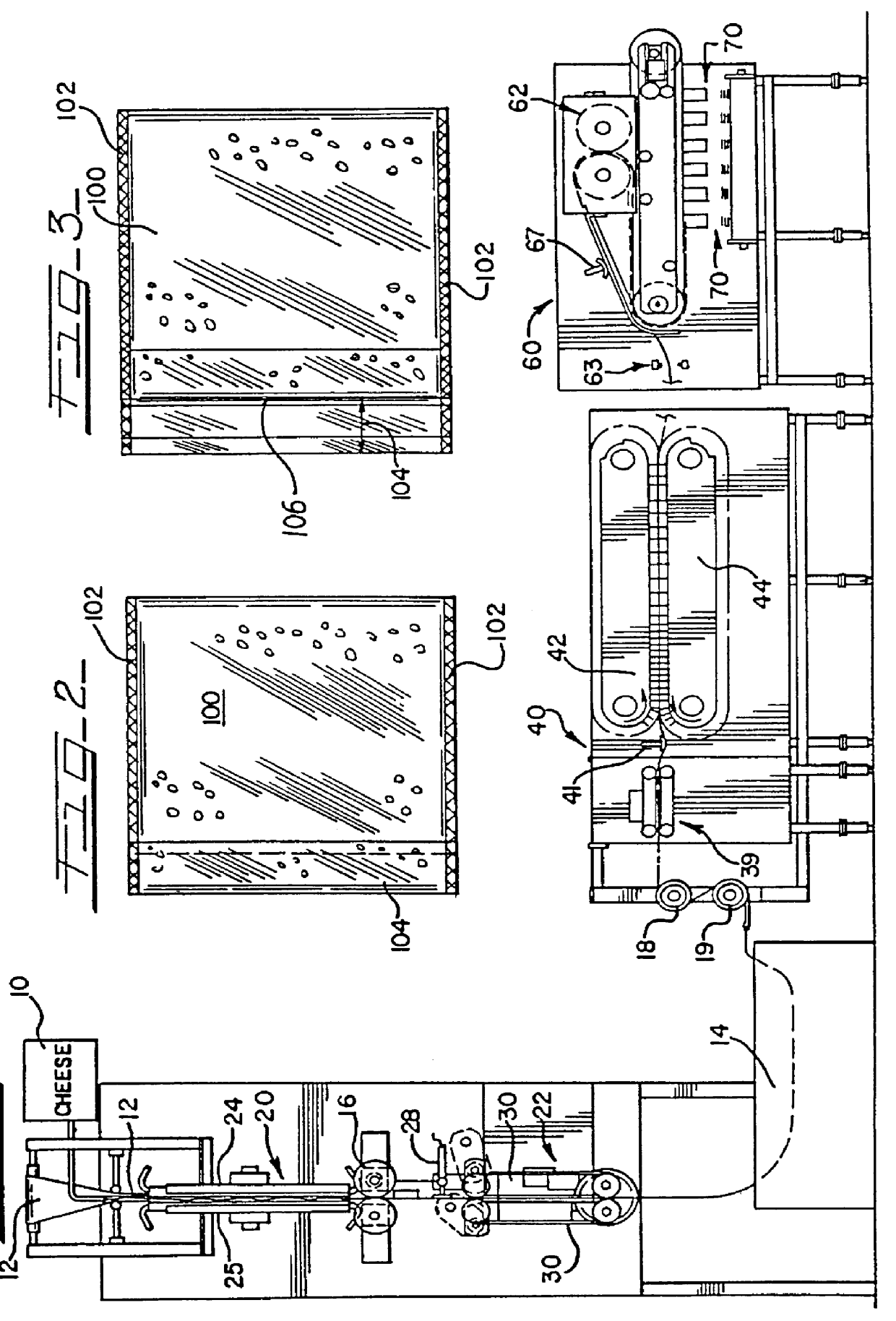

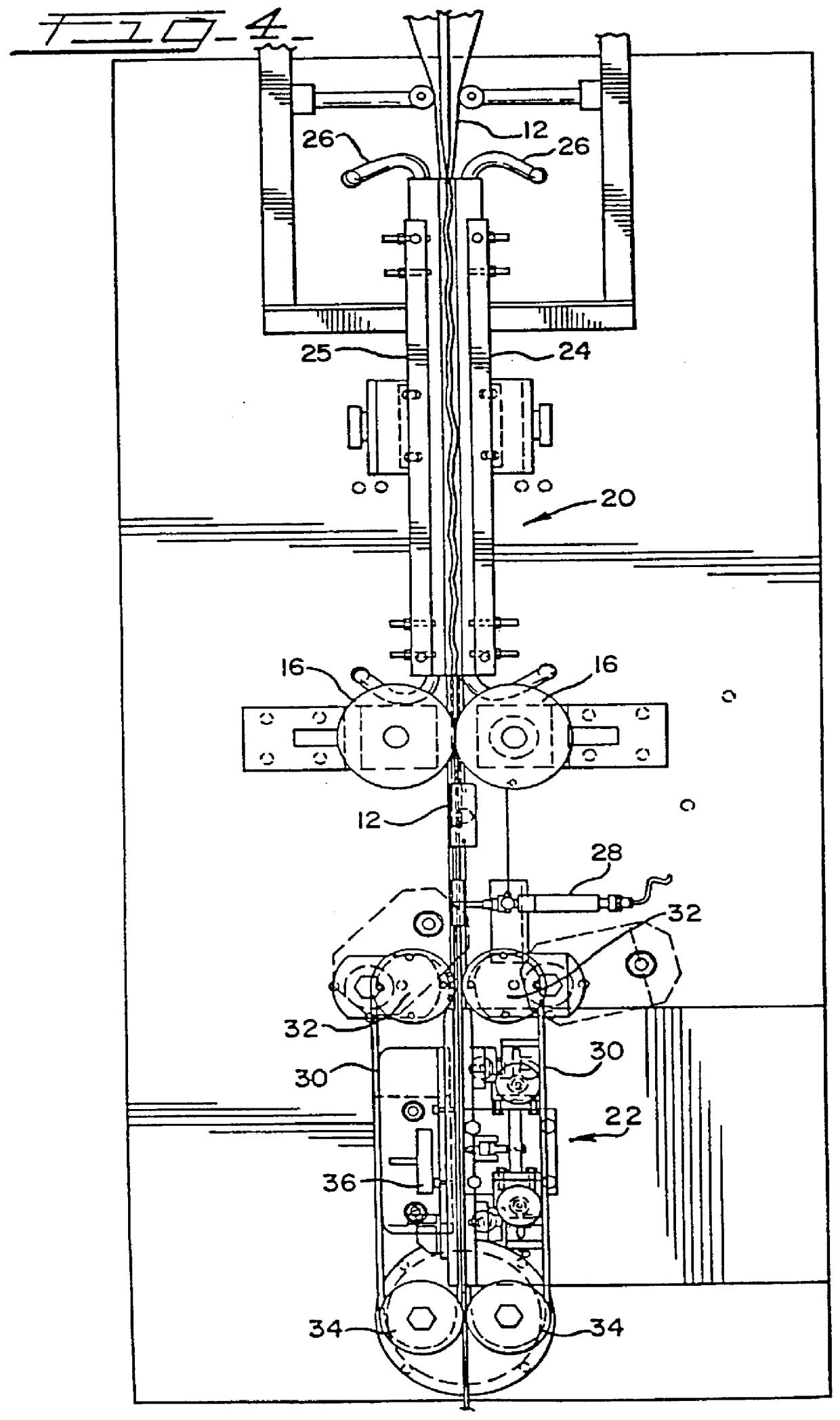

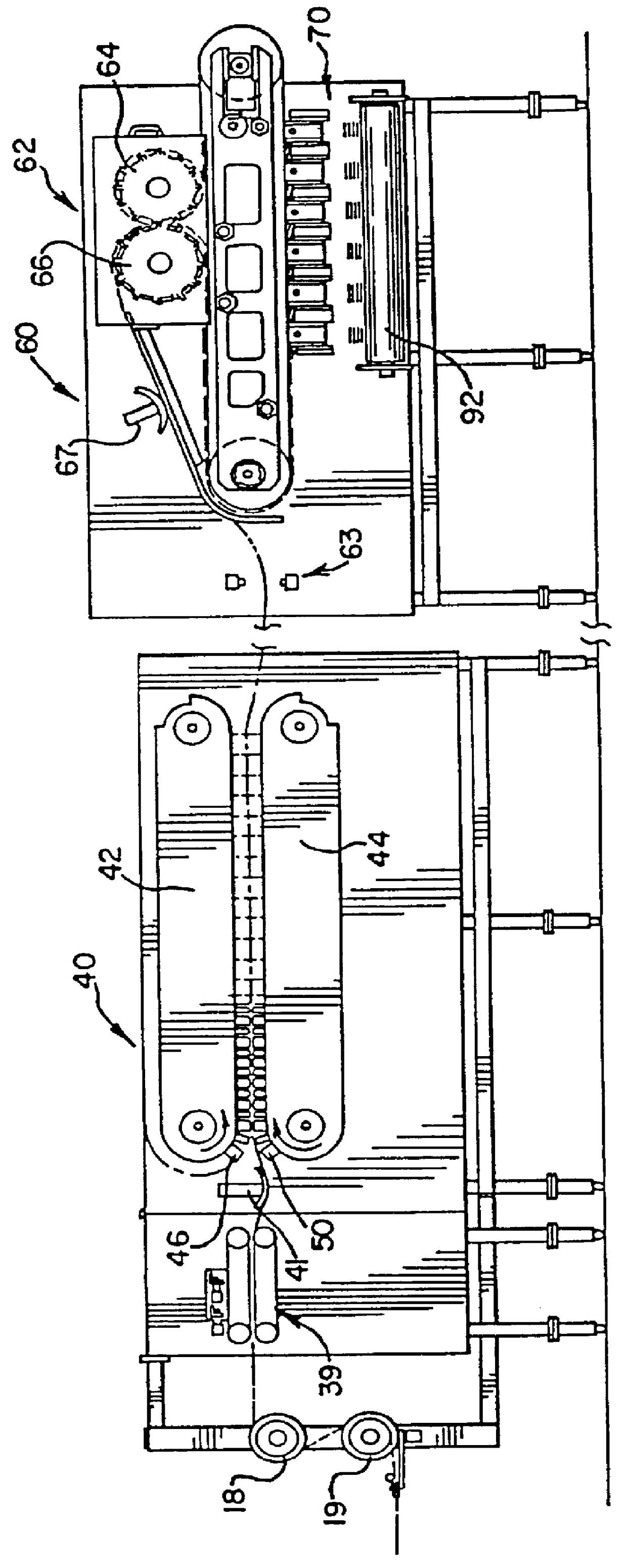

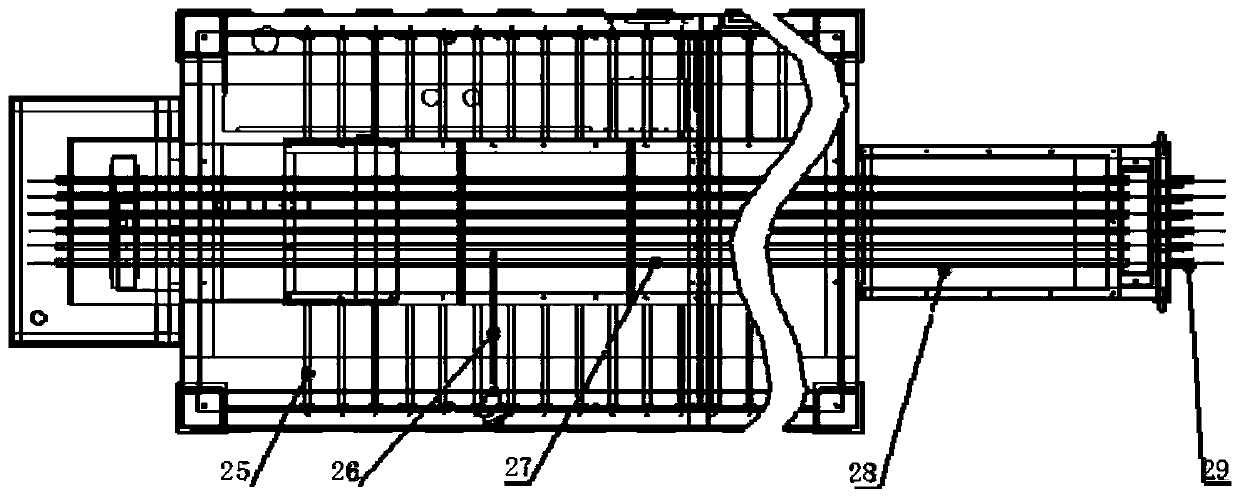

Method and apparatus for forming and hermetically sealing slices of food items

InactiveUS6058680AEfficient and rapid production rateExtended shelf lifePackaging cheeseReady-for-oven doughsHermetic sealThin membrane

An apparatus and method are provided for forming a hermetically sealed package for a slice of a food item. A web of thermoplastic material is first formed into a tubular arrangement with a hermetic longitudinal seal. To form the tubular arrangement, means are provided for folding a continuous web of thermoplastic material into V-folded condition and for continuously forming a hermetic seal along the open longitudinal edge of the V-folded web. The hermetic seal is formed between the inner surfaces of the front and rear faces of the web to define a tubular web member. The food item which has been formed into a soft mass, is then inserted into the tubular member and the tubular member is flattened to form a thin film tube. Means are provided for forming a hermetically sealed cross-seal which are disposed substantially transverse to the longitudinal forward moving direction of the web.

Owner:SCHREIBER FOODS

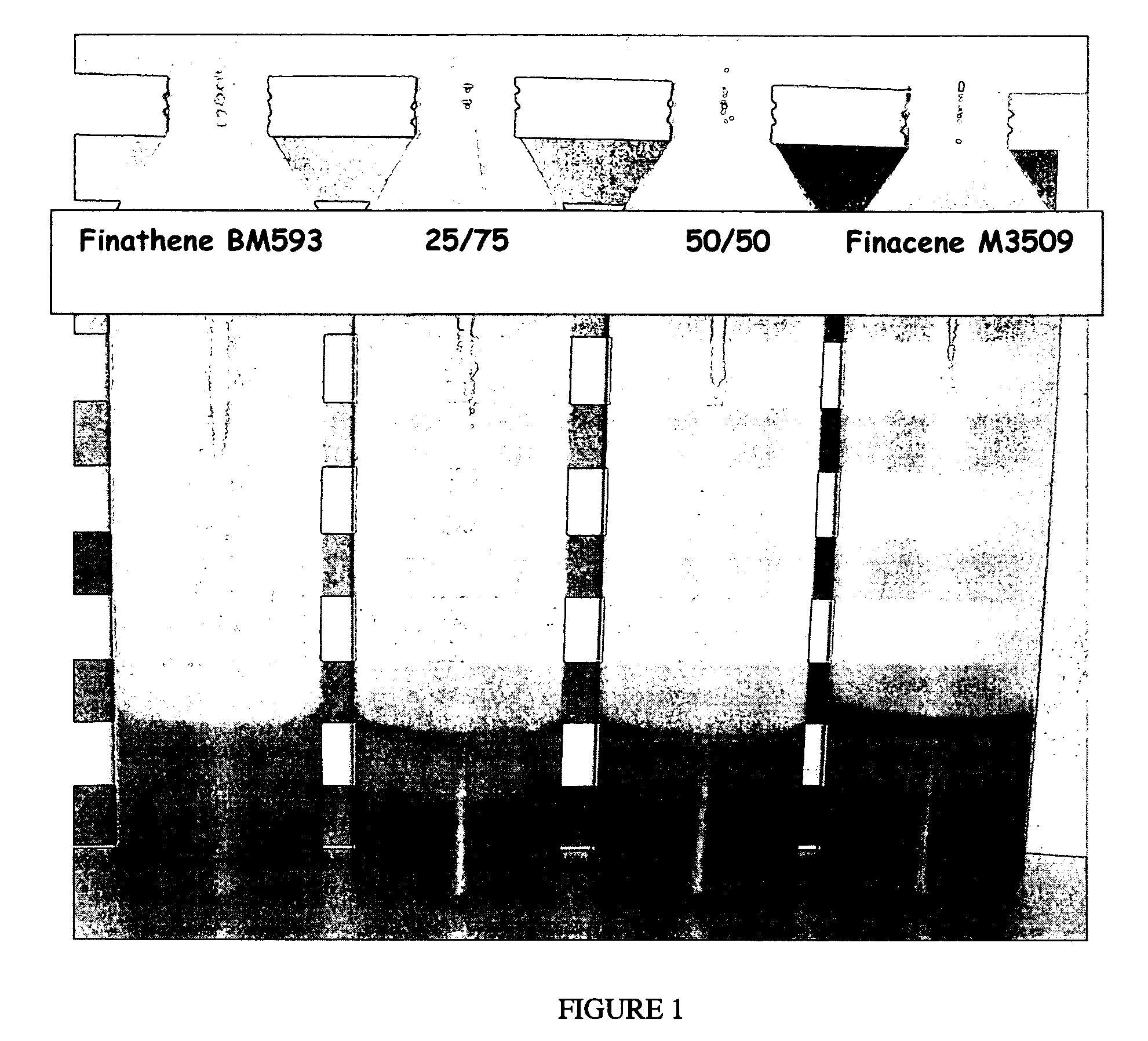

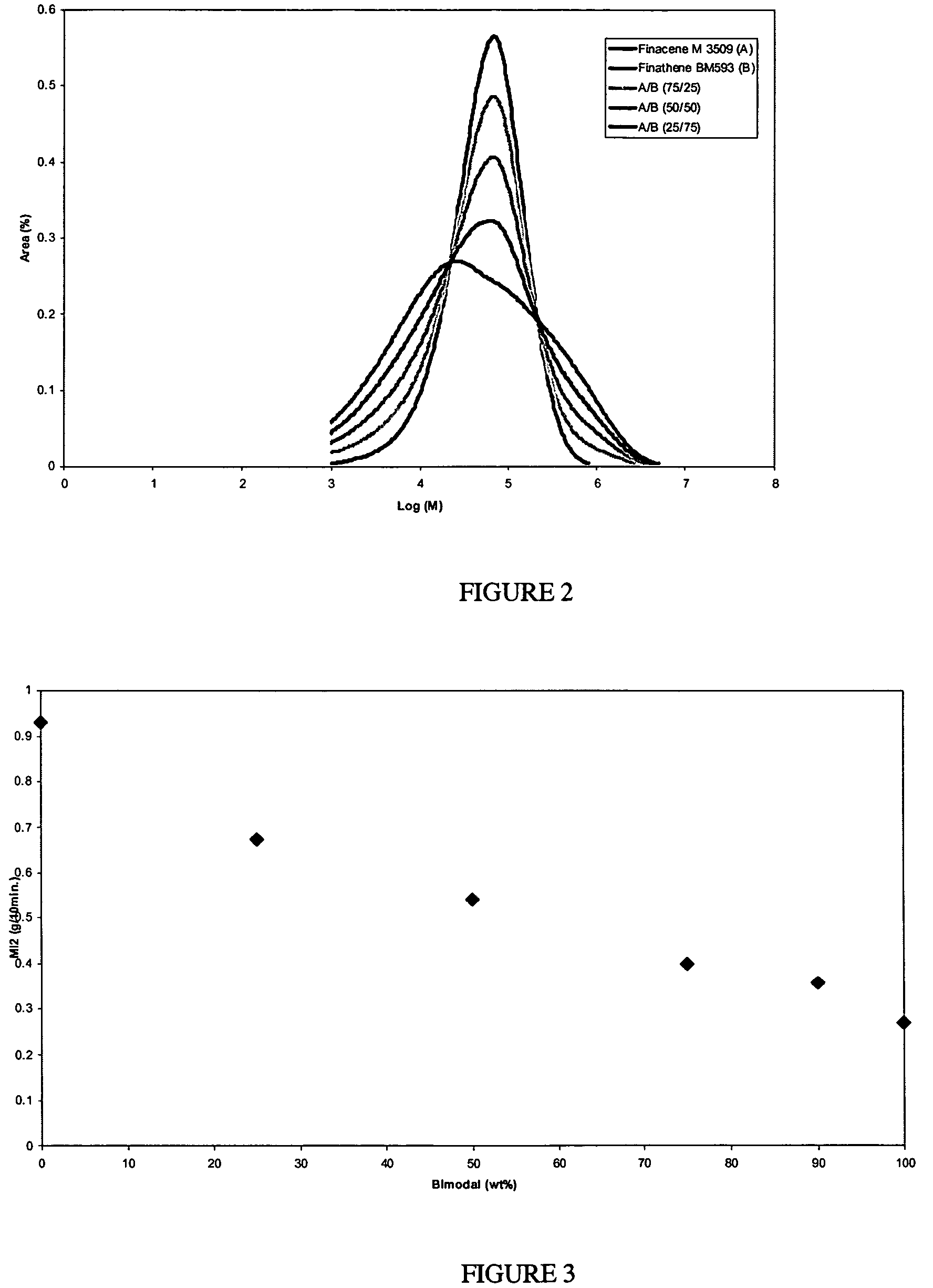

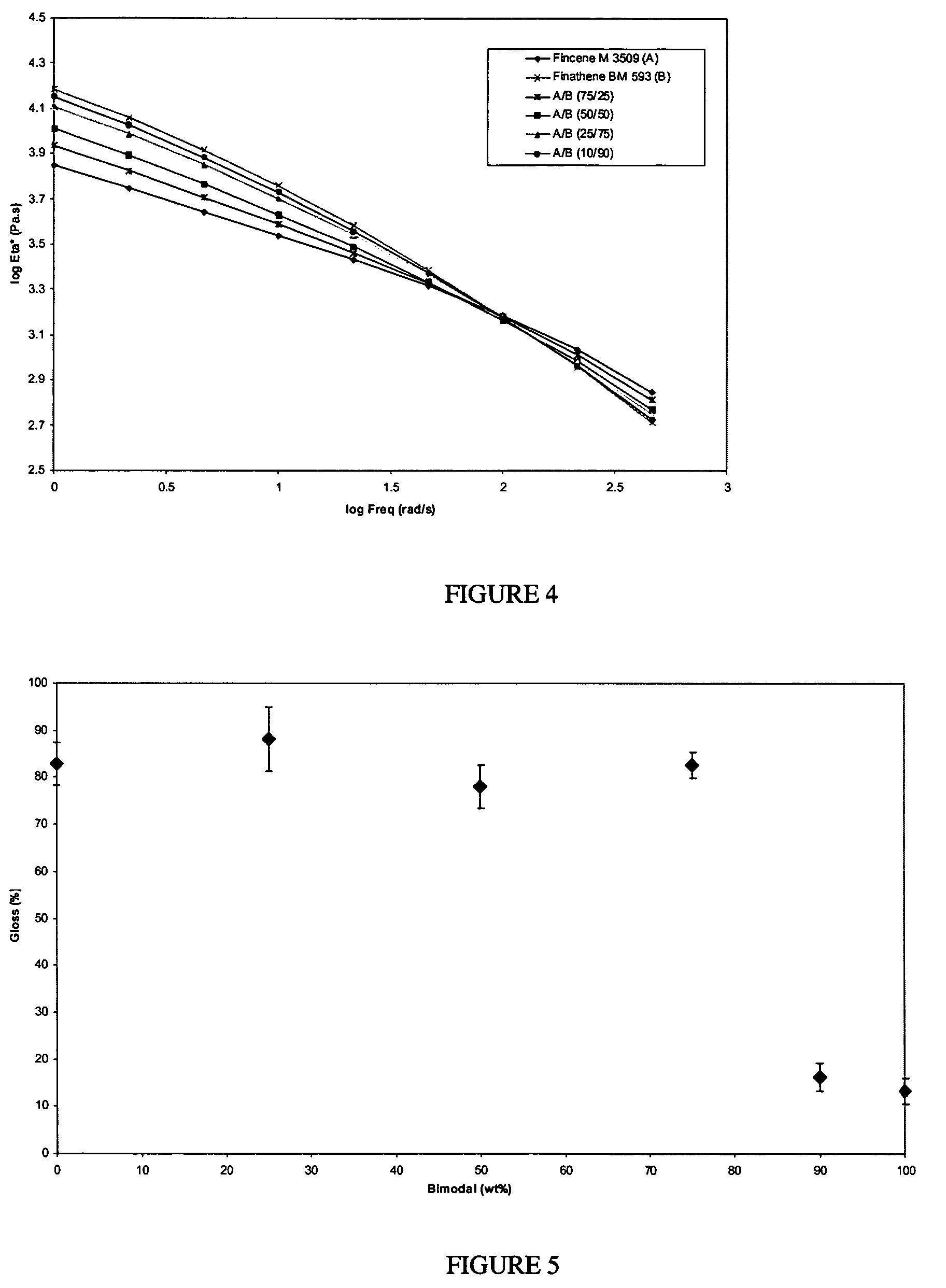

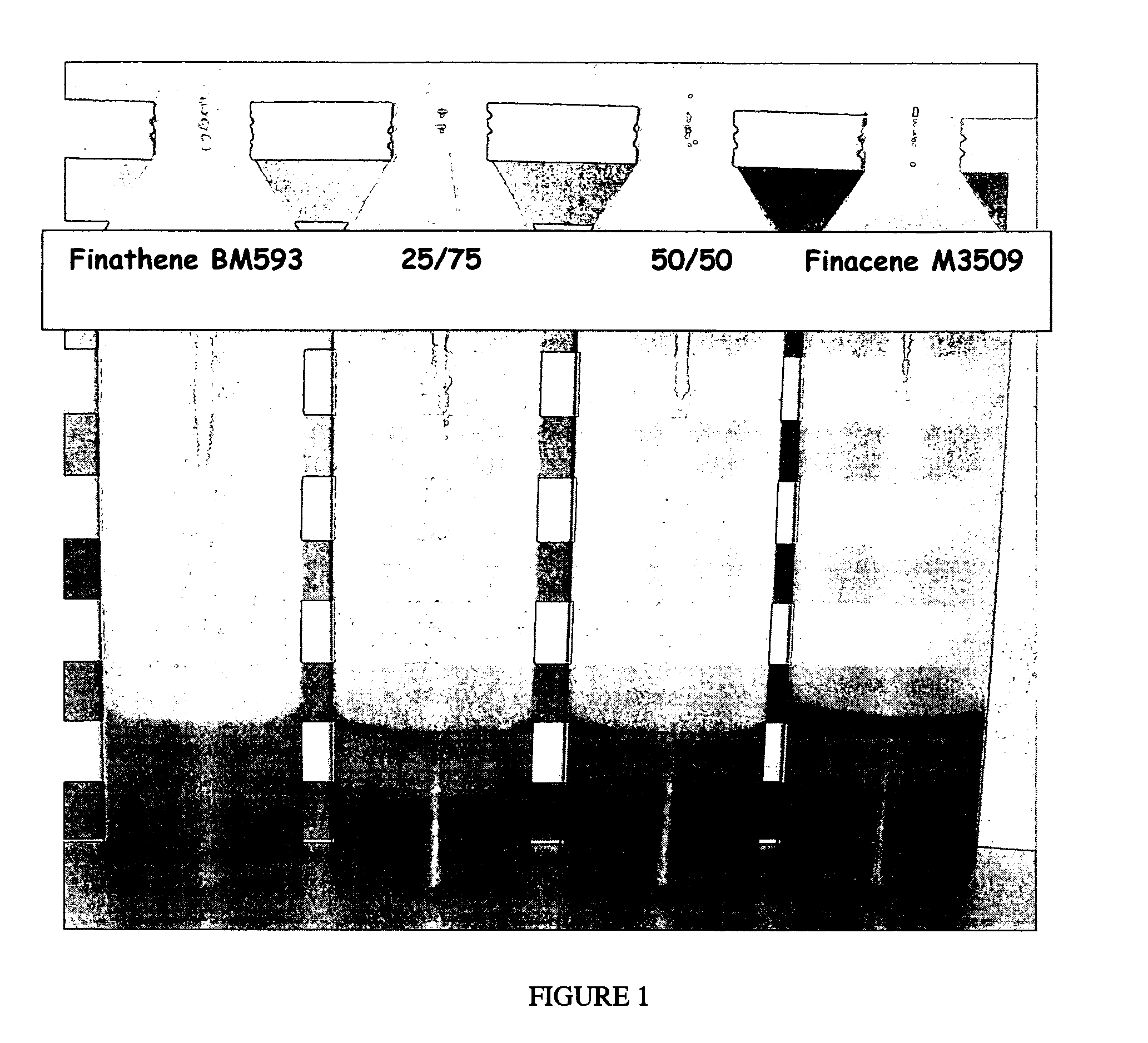

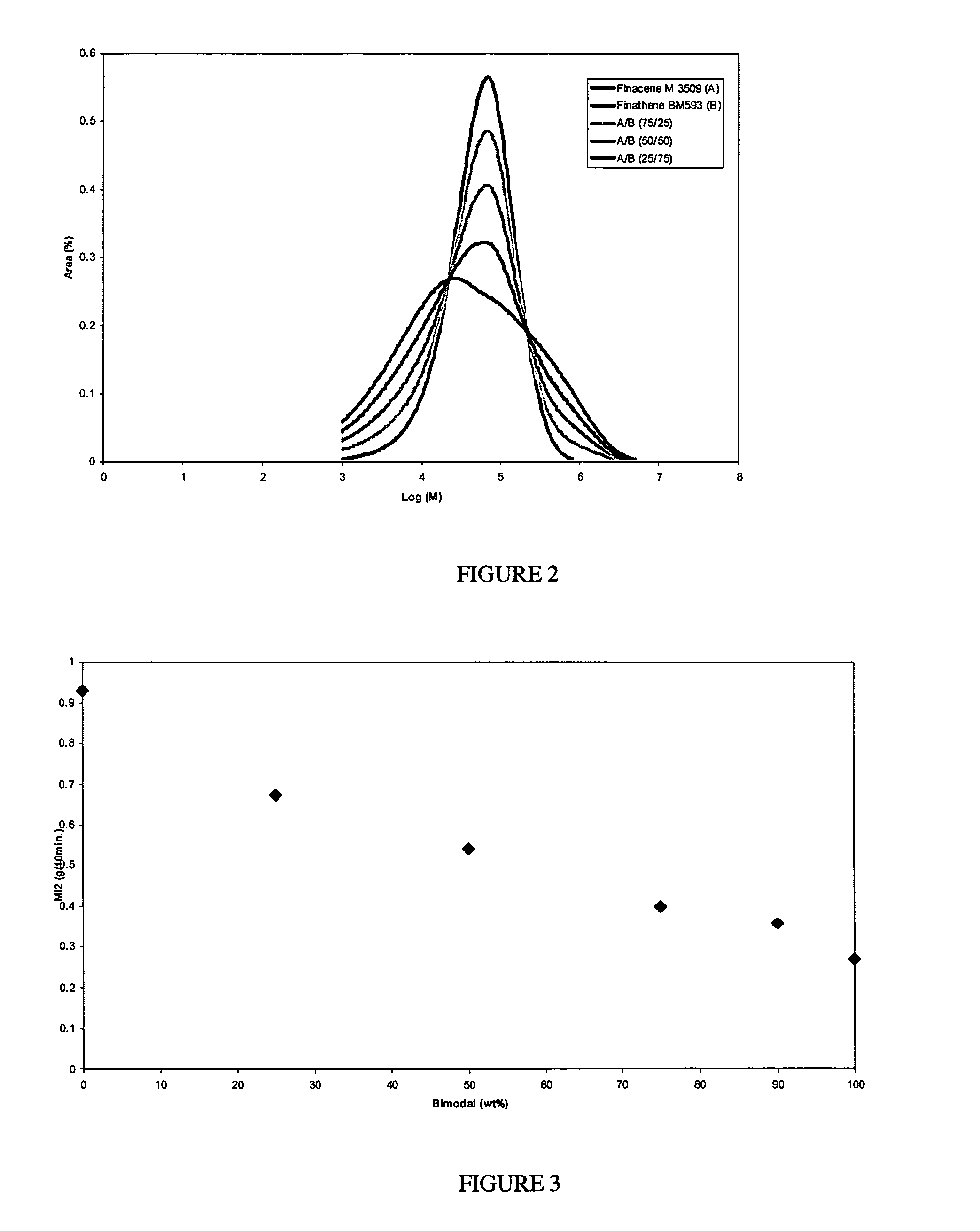

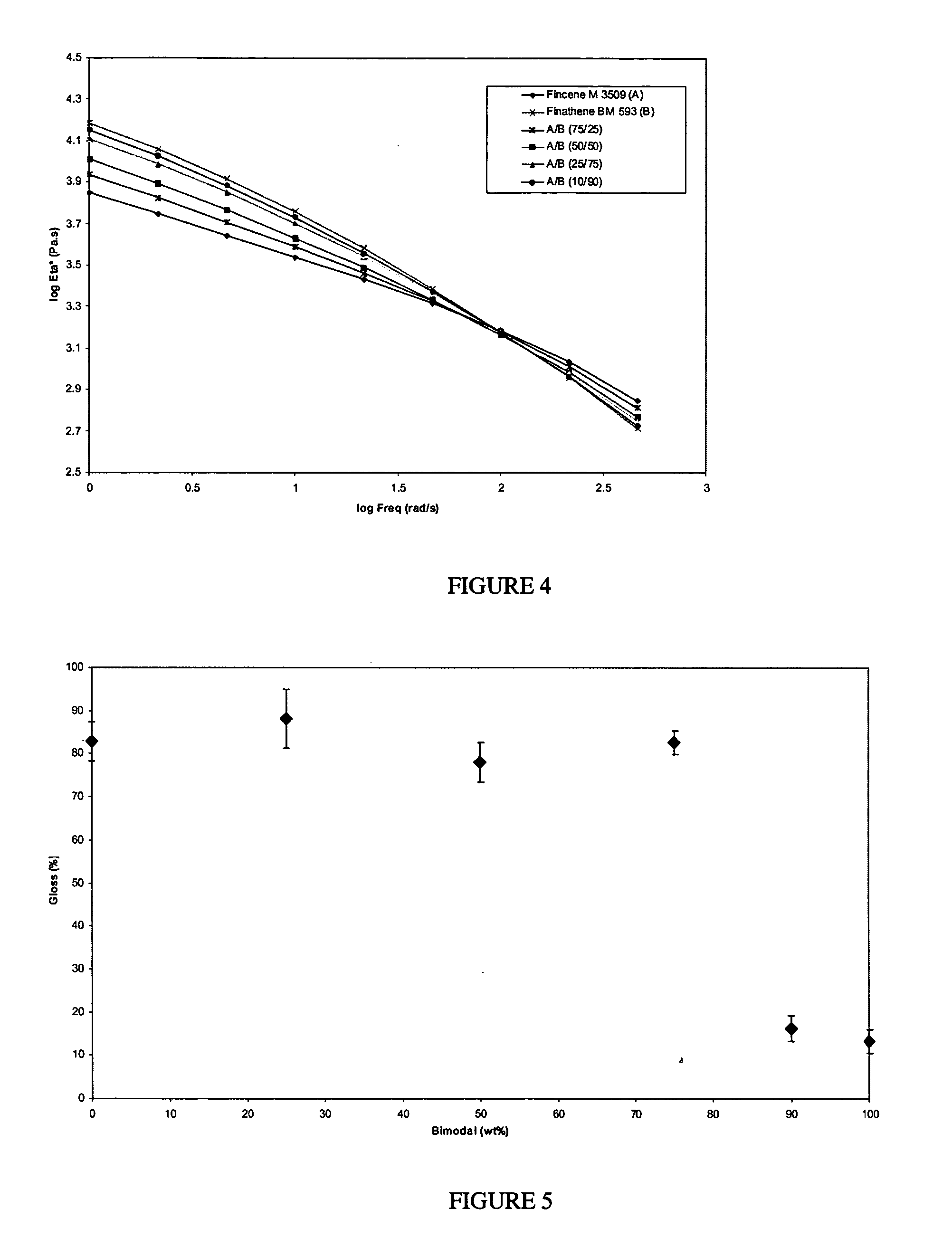

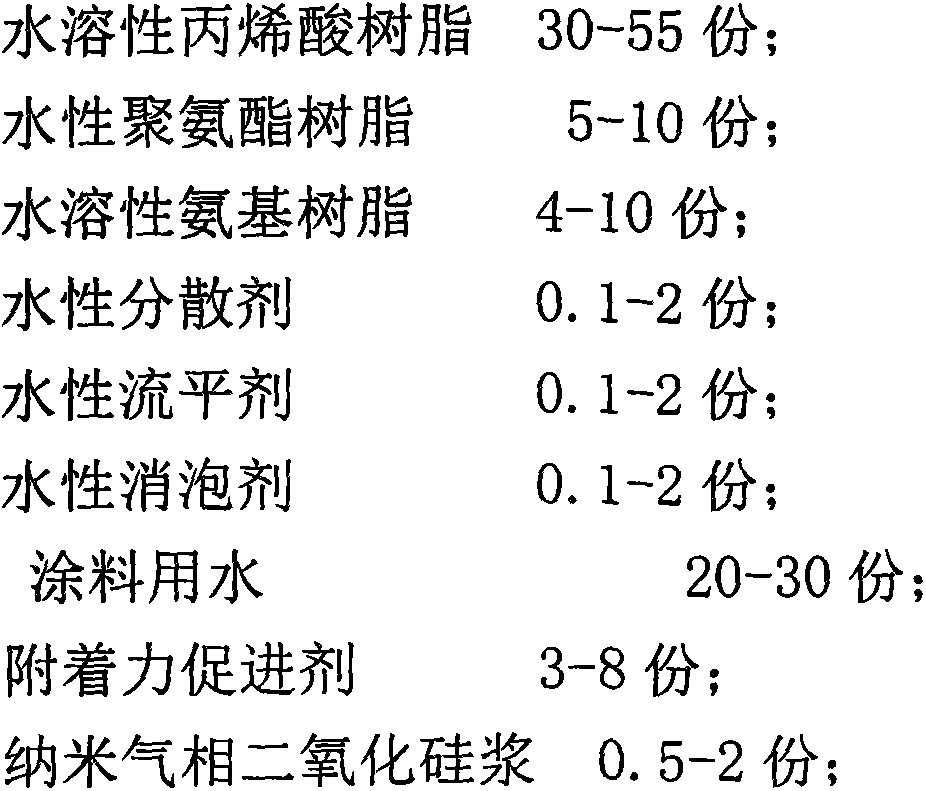

Polyethylene blends with good contact transparency

InactiveUS7514504B2Good contact transparency and glossHigh environmental stress crack resistanceLow-density polyethyleneLinear low-density polyethylene

This invention discloses the production and use of a polyethylene composition comprising a metallocene-produced linear low density polyethylene and a multi modal high density polyethylene prepared from either a Ziegler-Natta or a metallocene catalyst system. The resulting polyethylene composition is suitable for preparing articles having improved environmental stress crack resistance, rigidity, contact transparency, gloss as well as good processing capabilities.

Owner:TOTAL RES & TECH FELUY

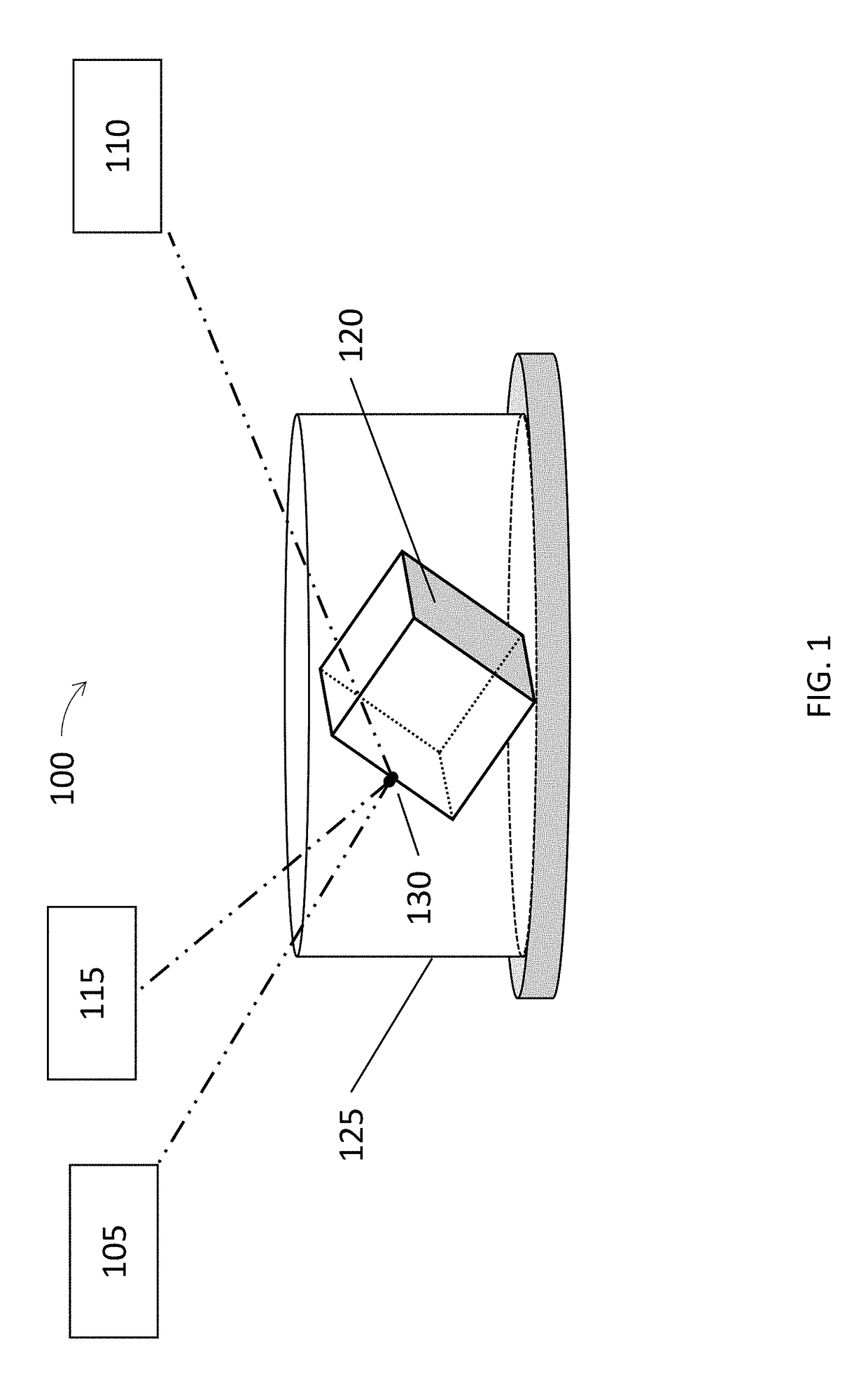

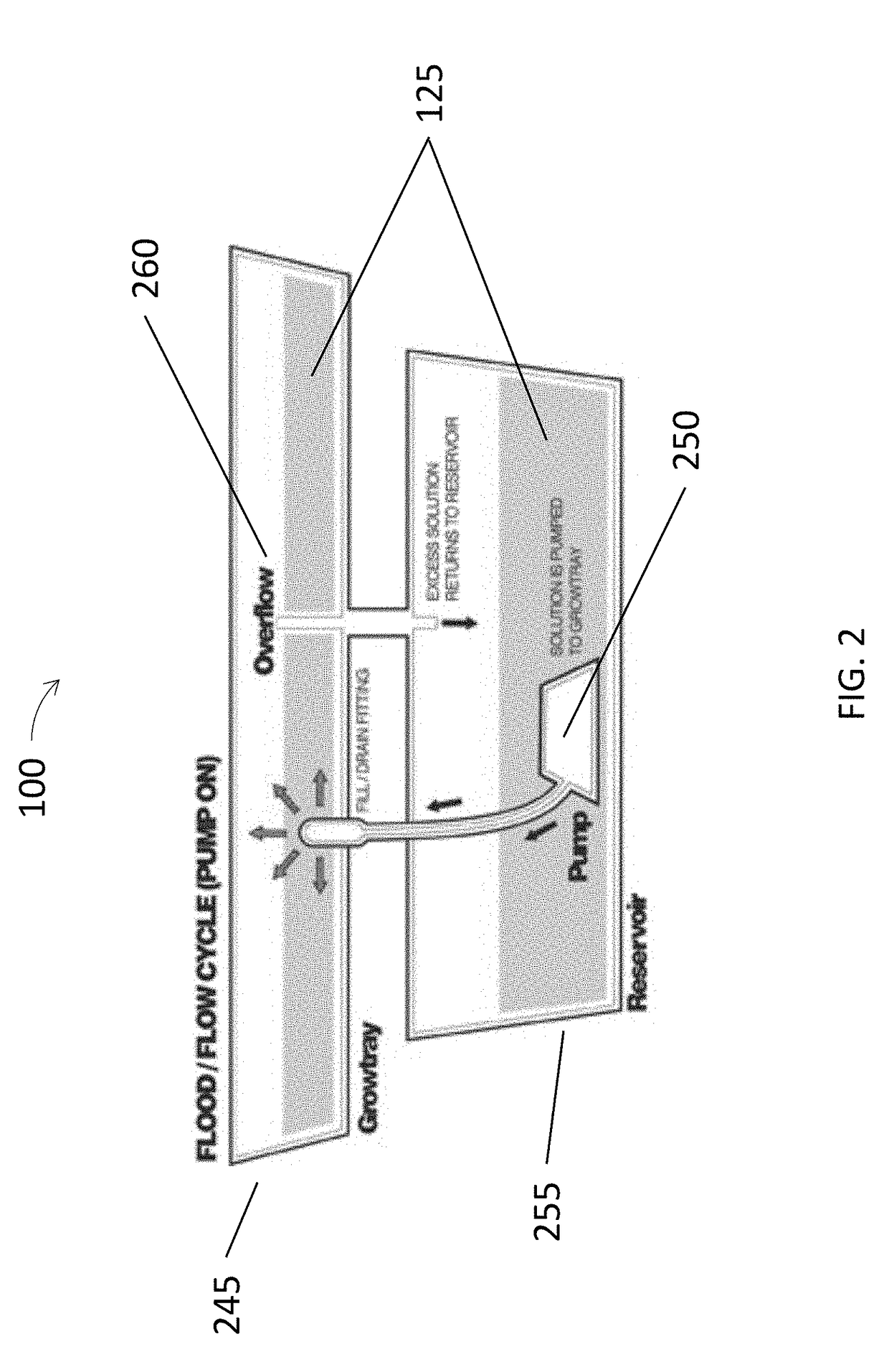

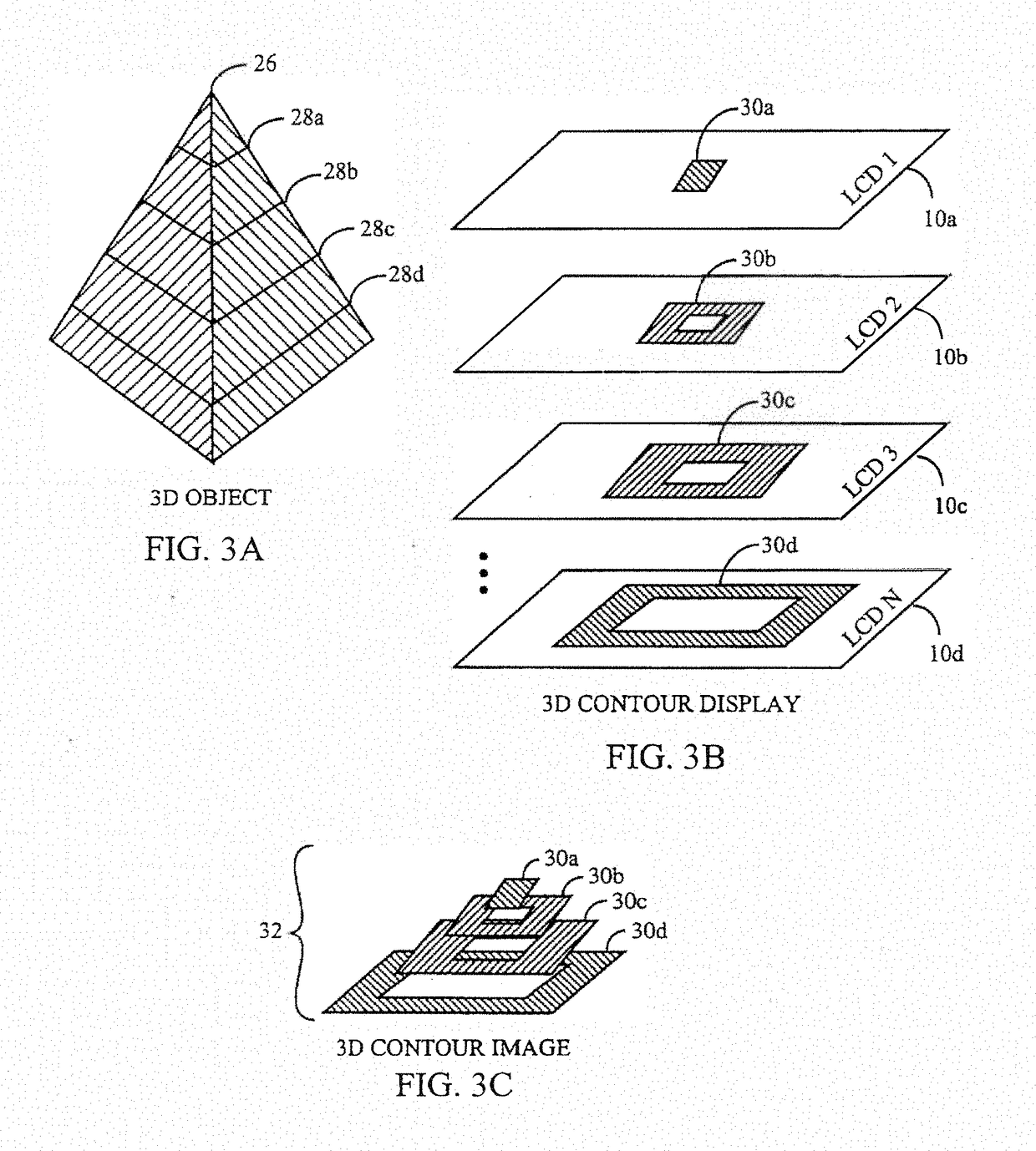

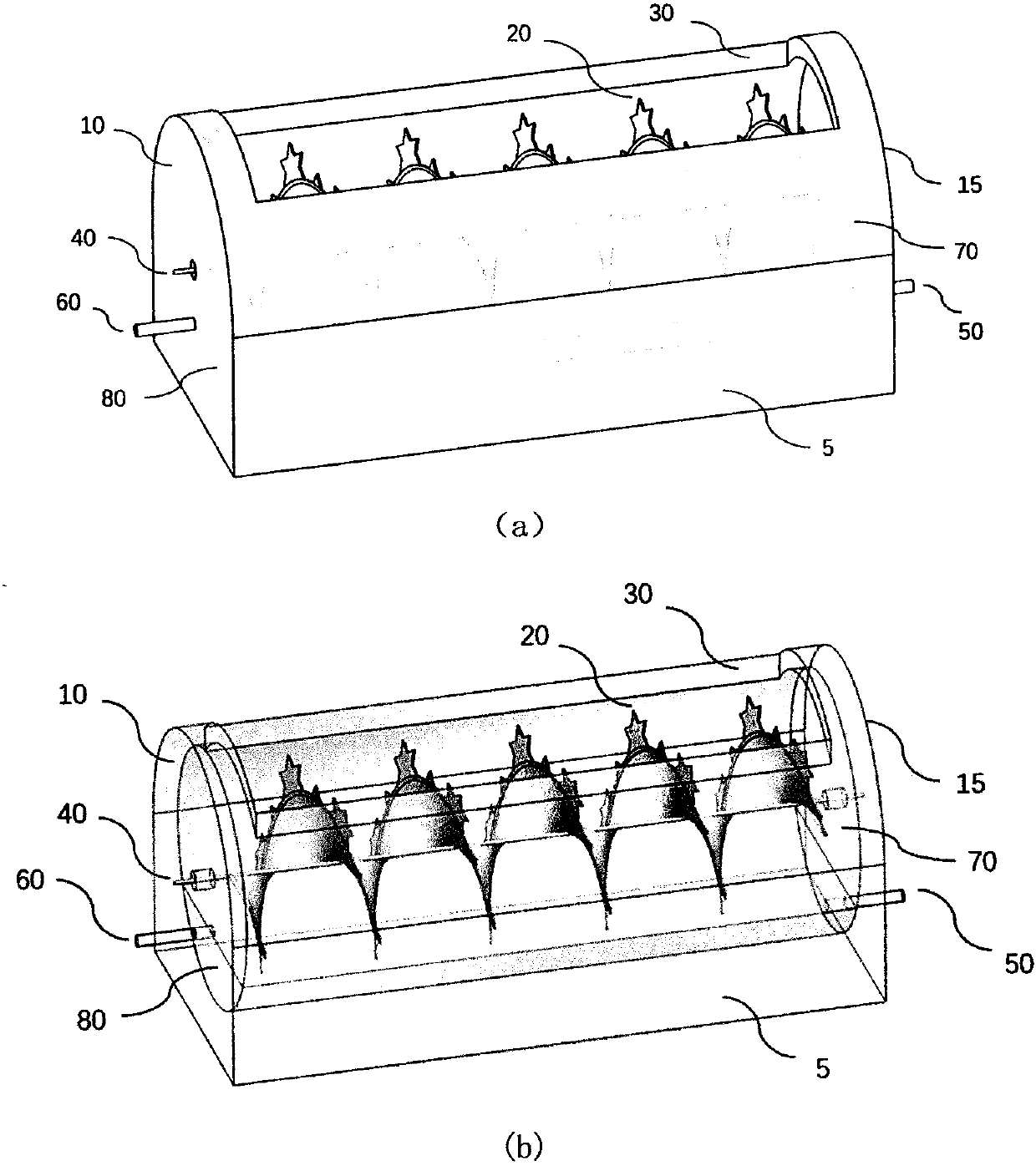

5d part growing machine with volumetric display technology

ActiveUS20190016052A1Rapid productionHigh speed productionManufacturing enclosuresManufacturing recyclingAdditive layer manufacturingVolumetric display

Methods and systems of and for using volumetric display technology including volumetric display technology to create three-dimensional objects for various industries, including, but not limited to solar, automotive and / or other technological areas that use 3D printing or additive manufacturing.

Owner:CLARK DANIEL S

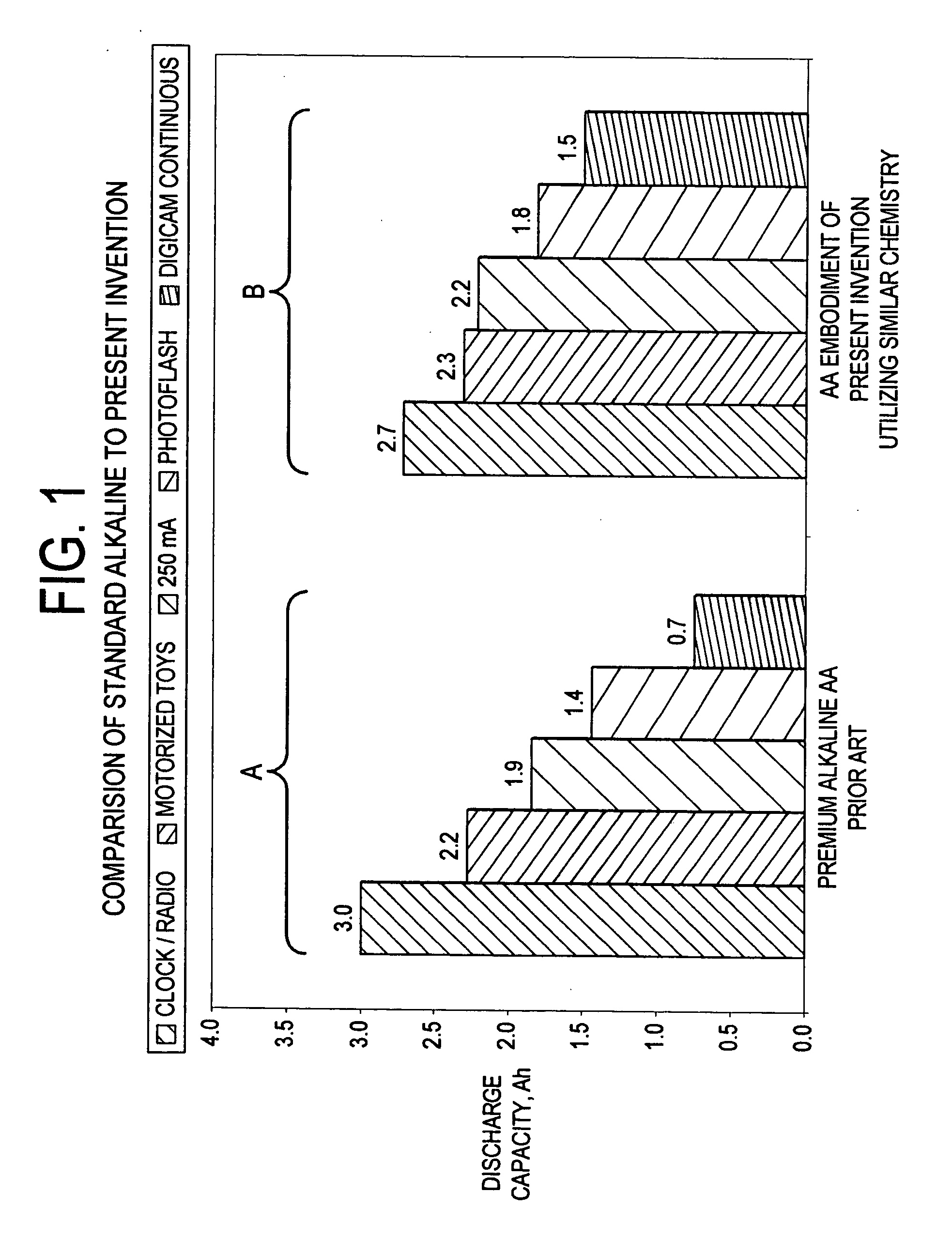

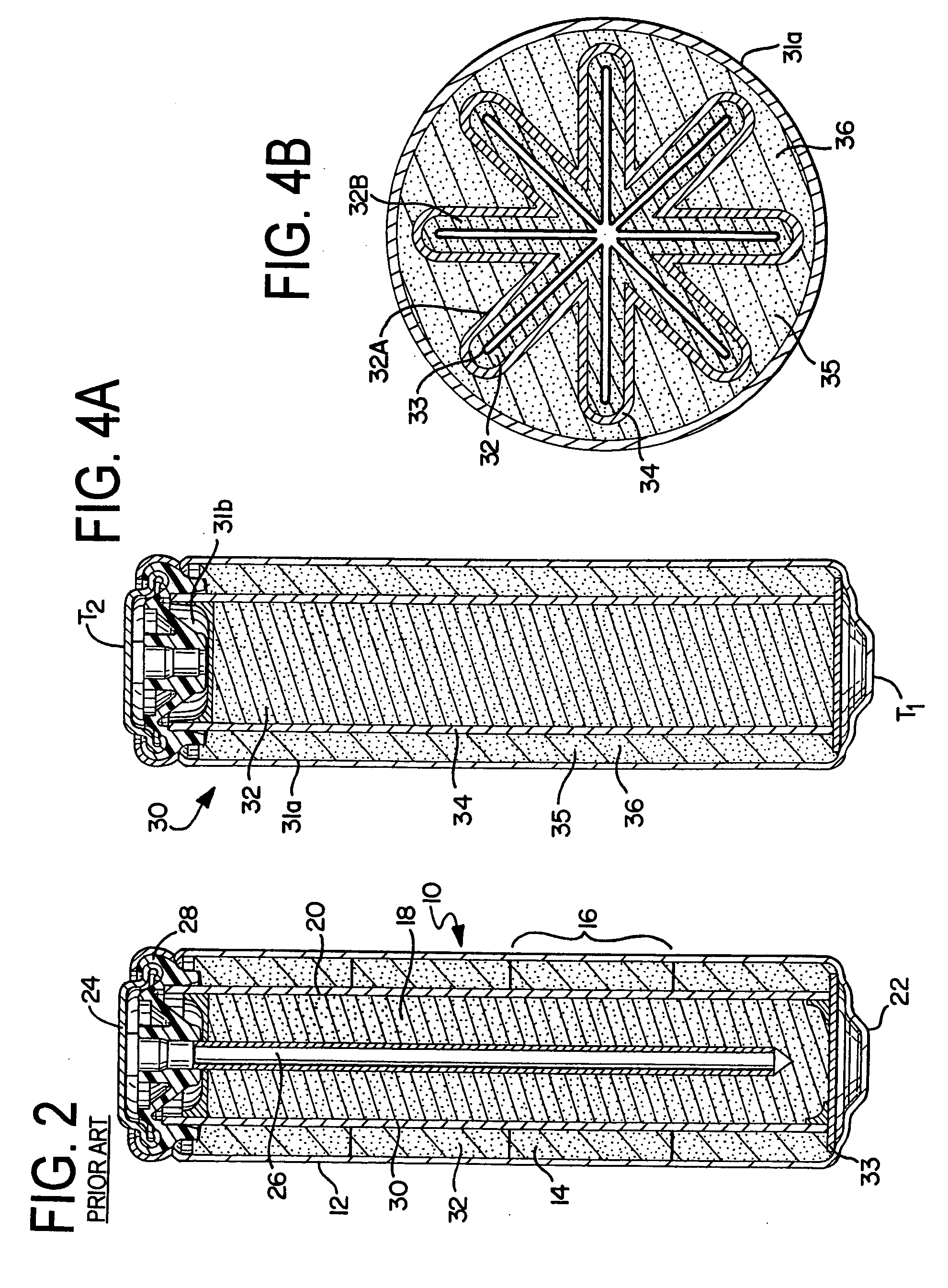

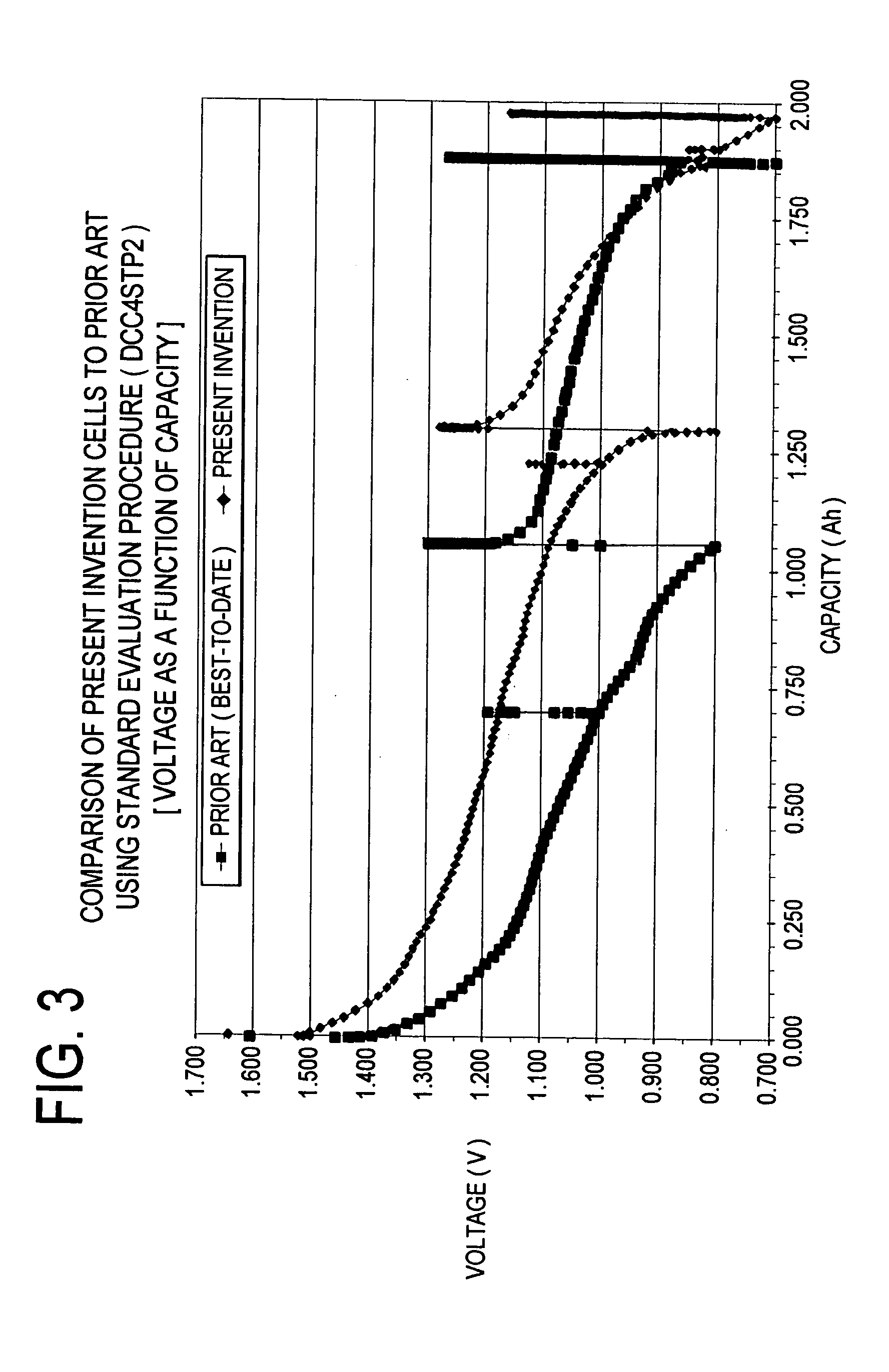

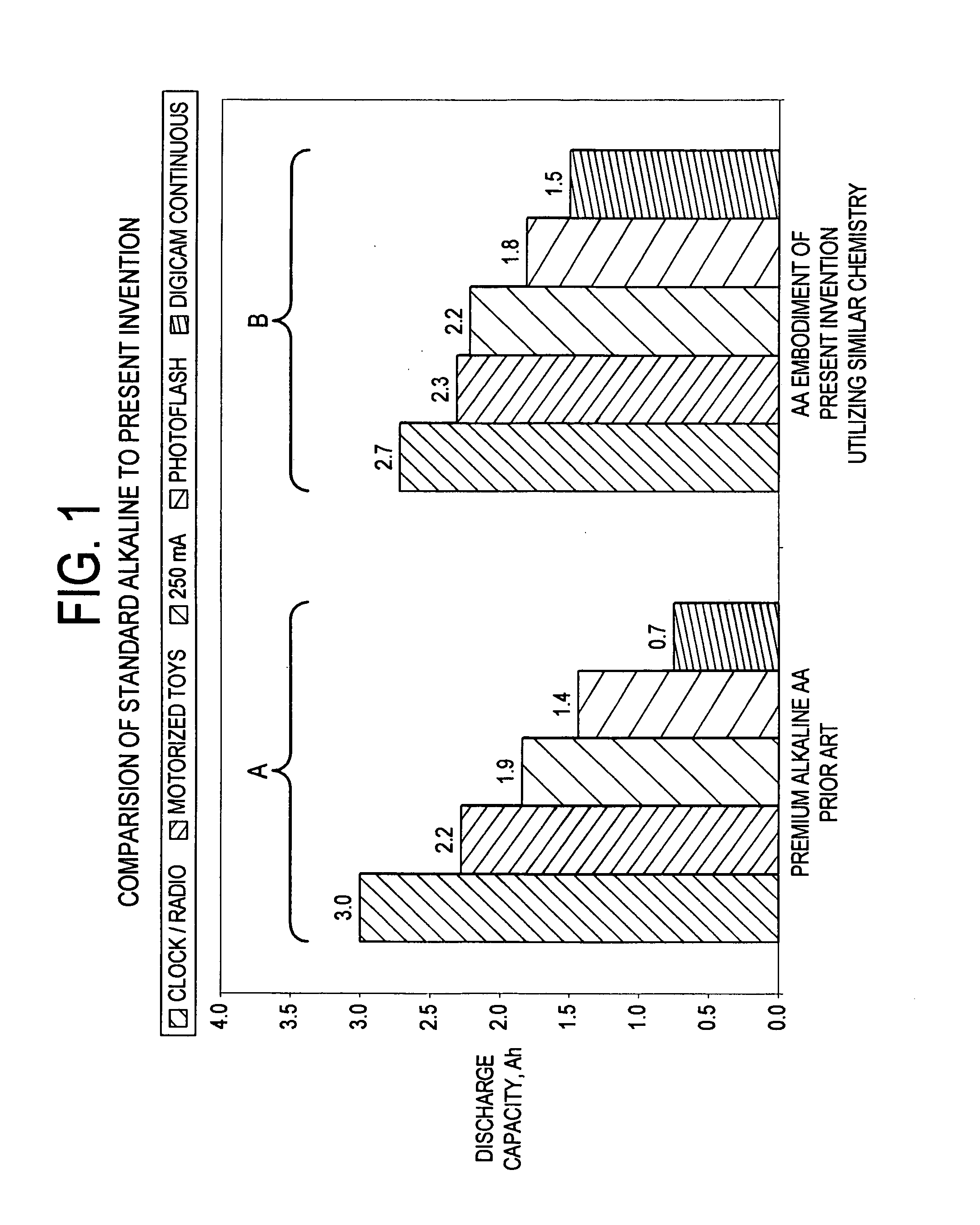

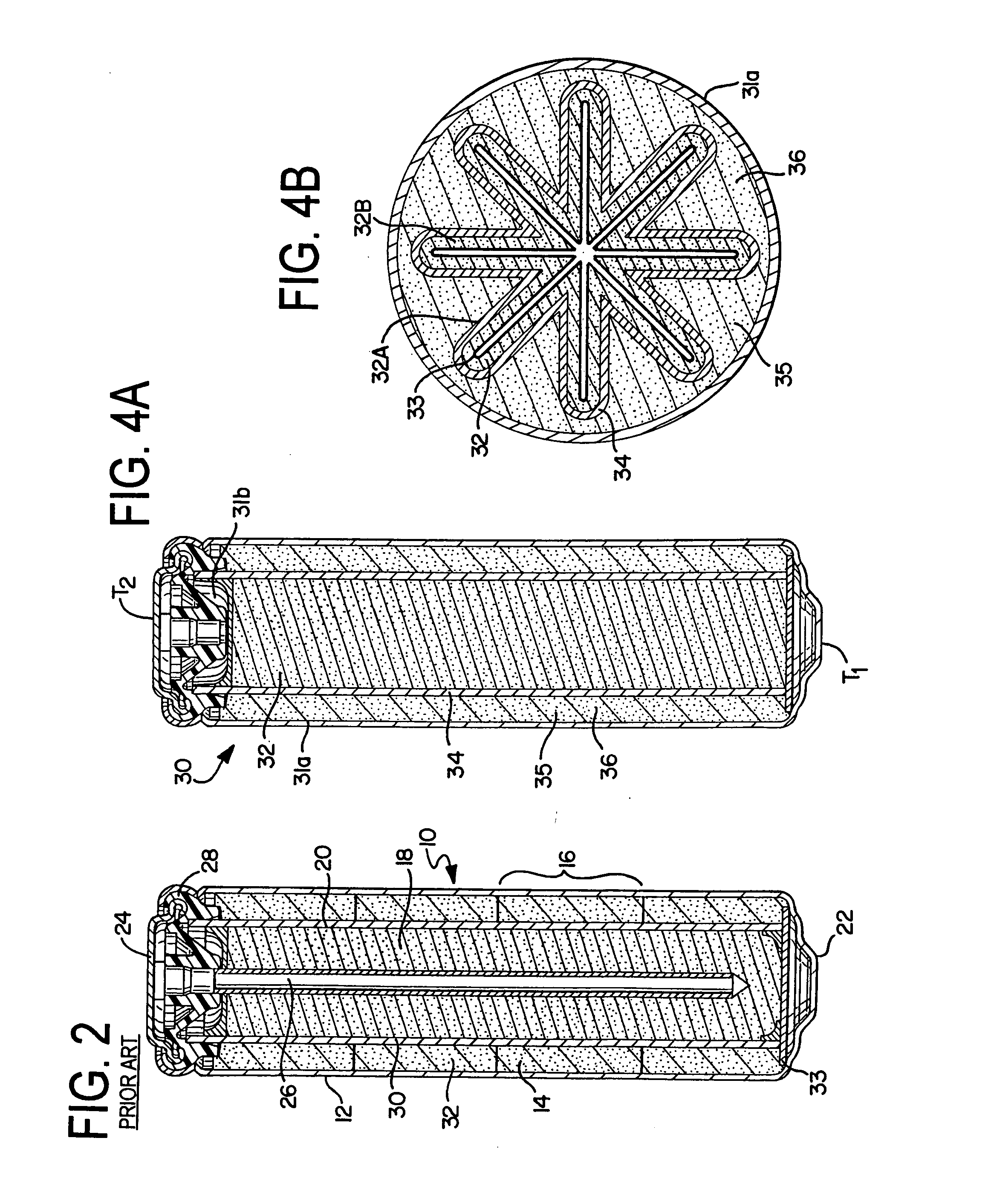

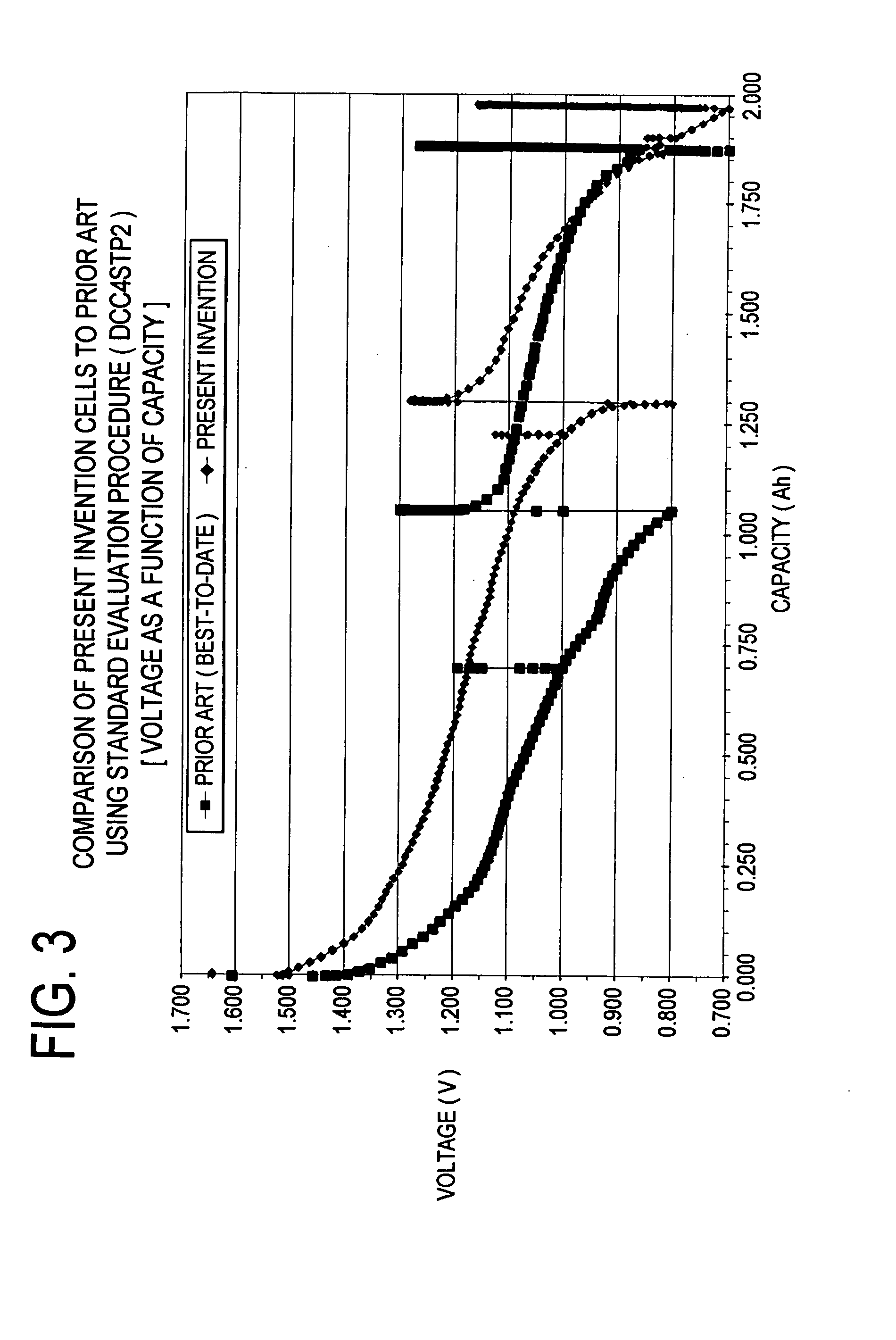

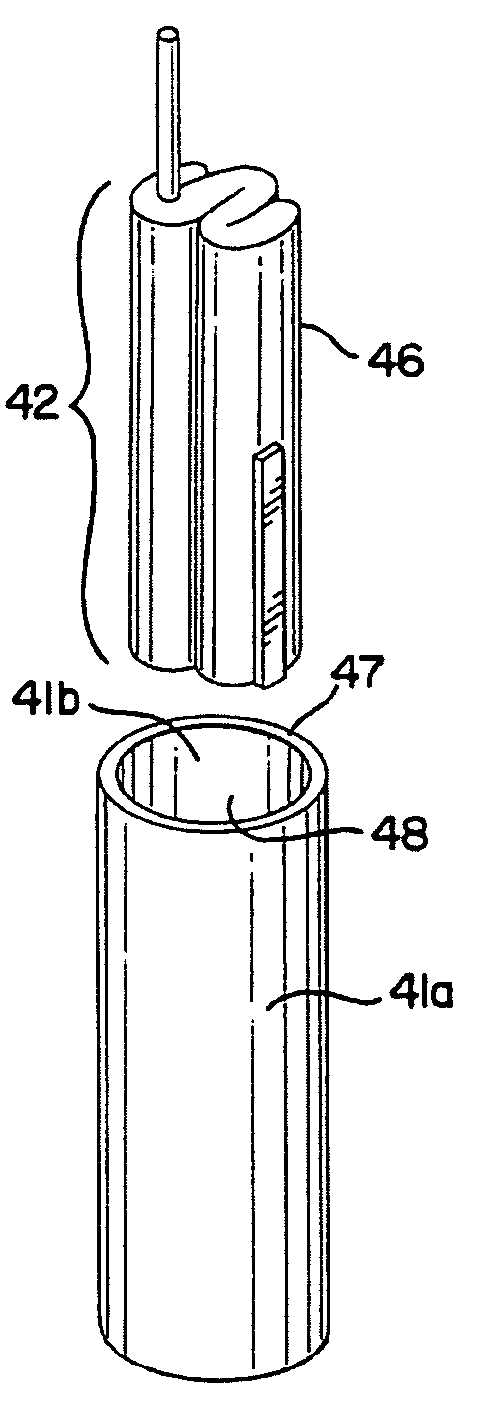

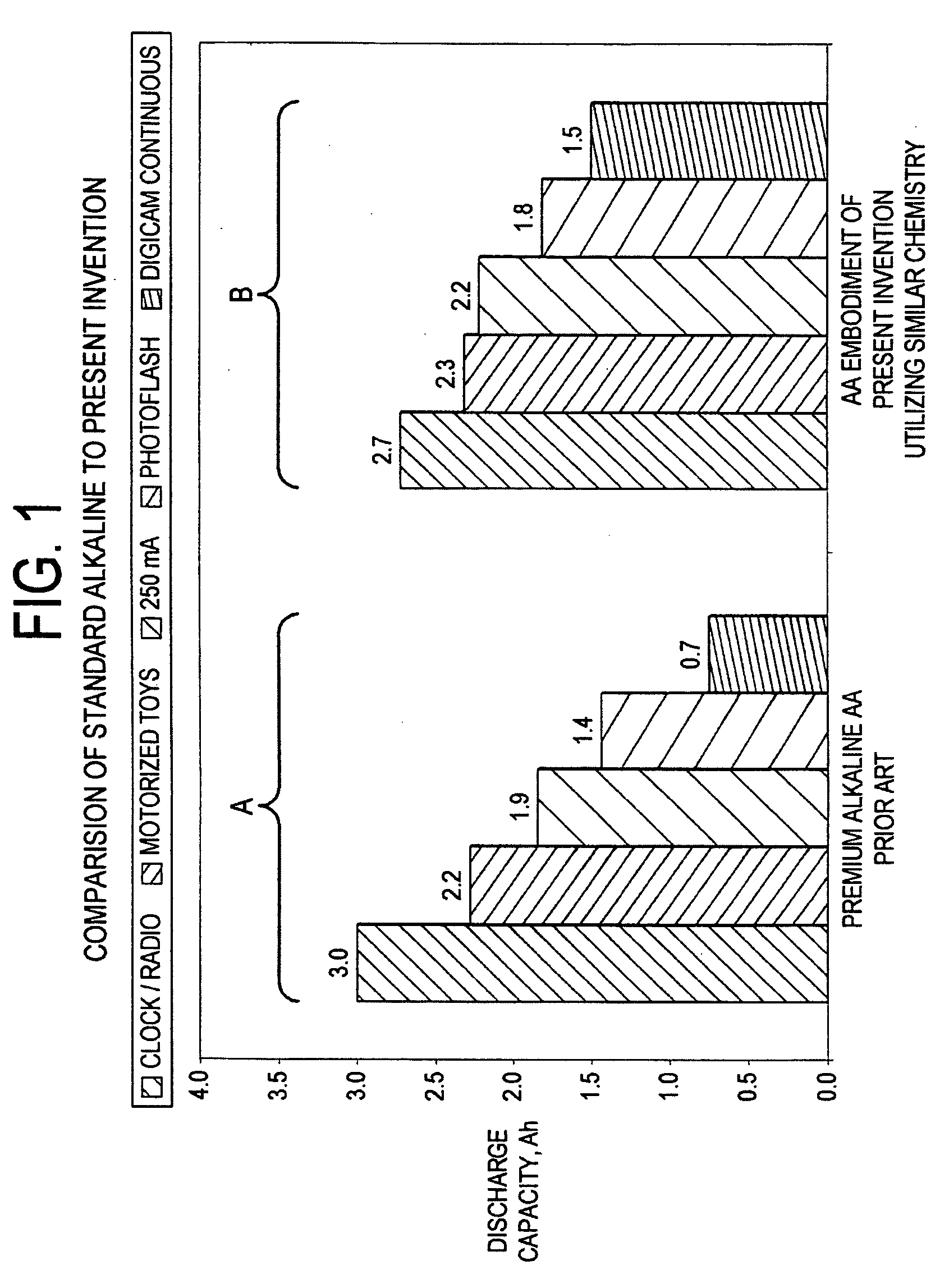

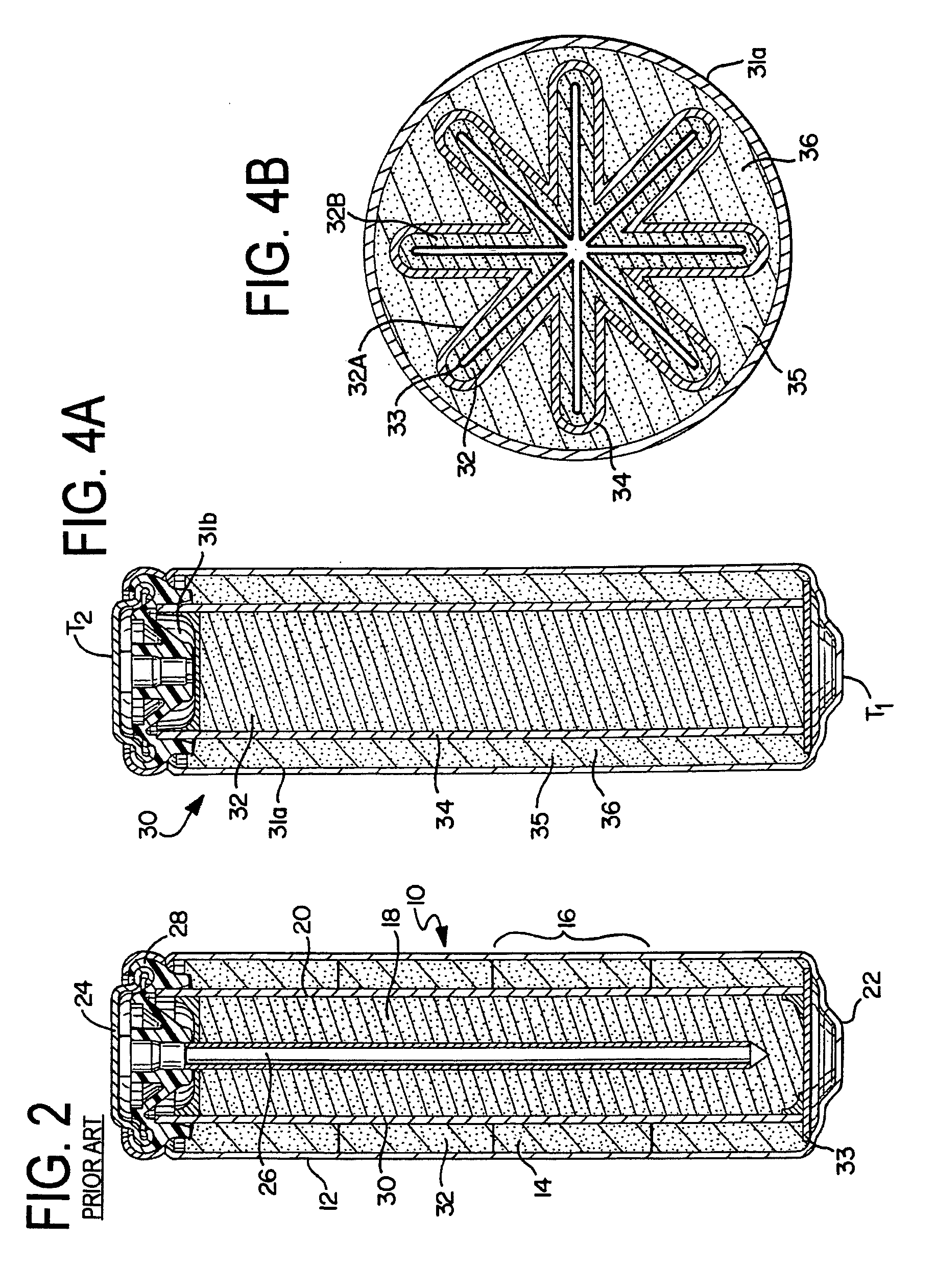

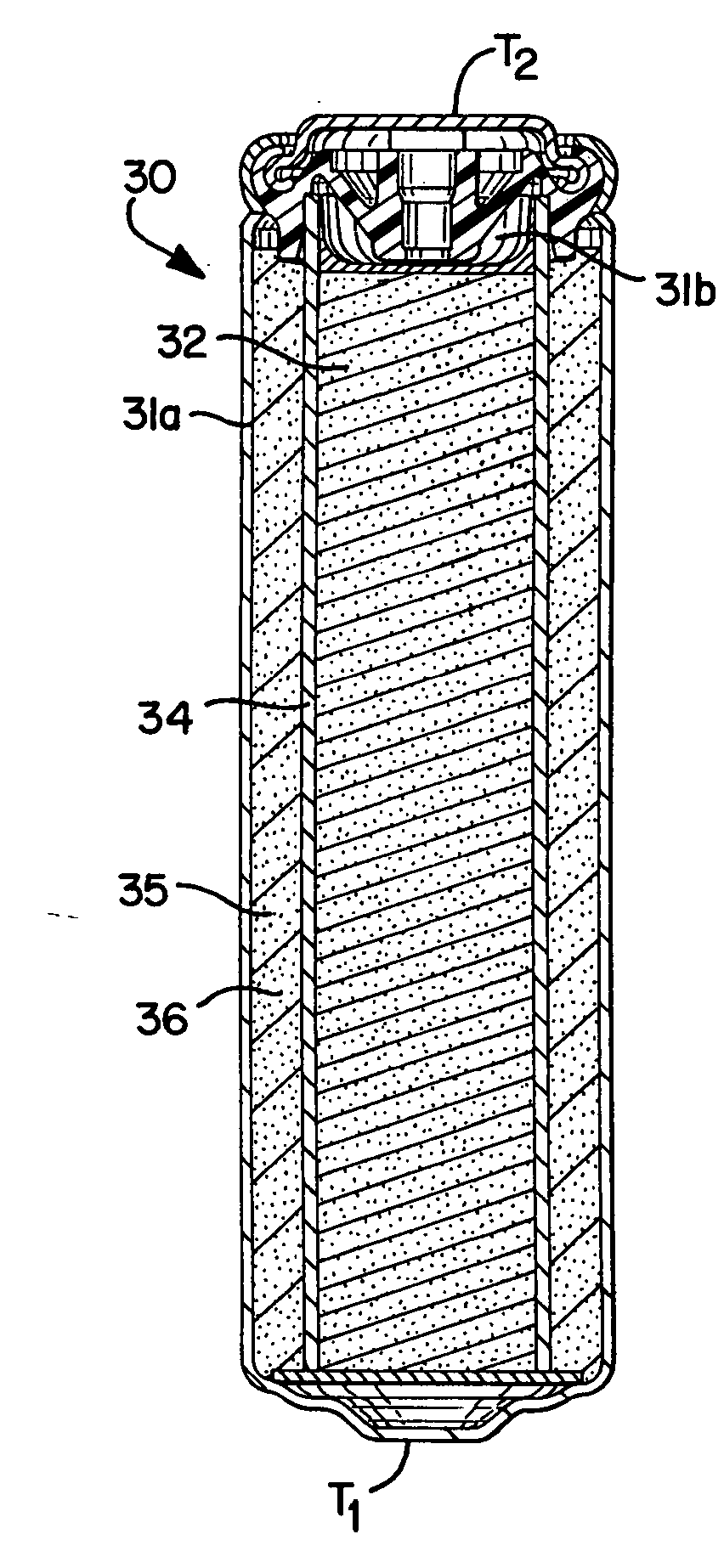

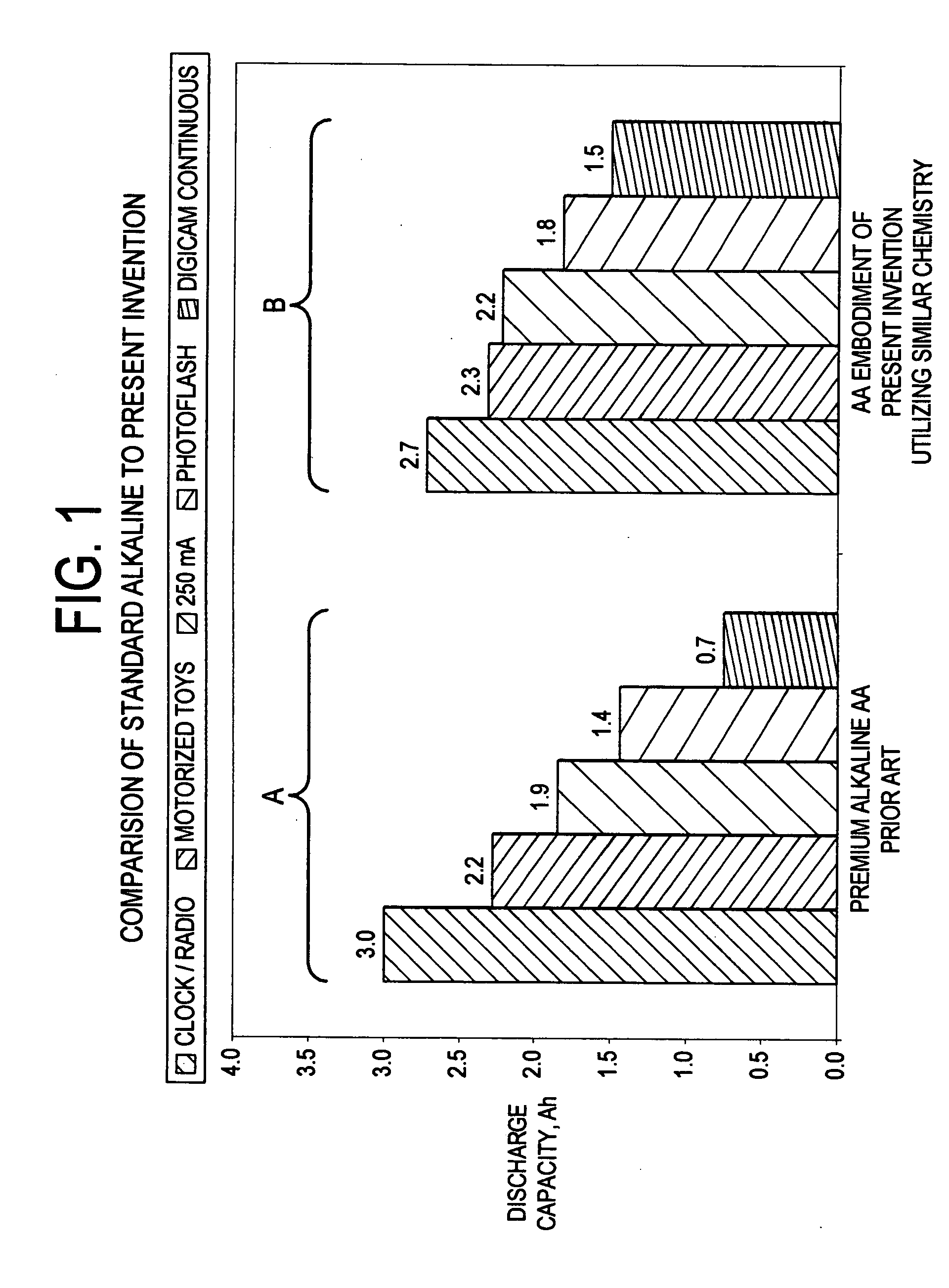

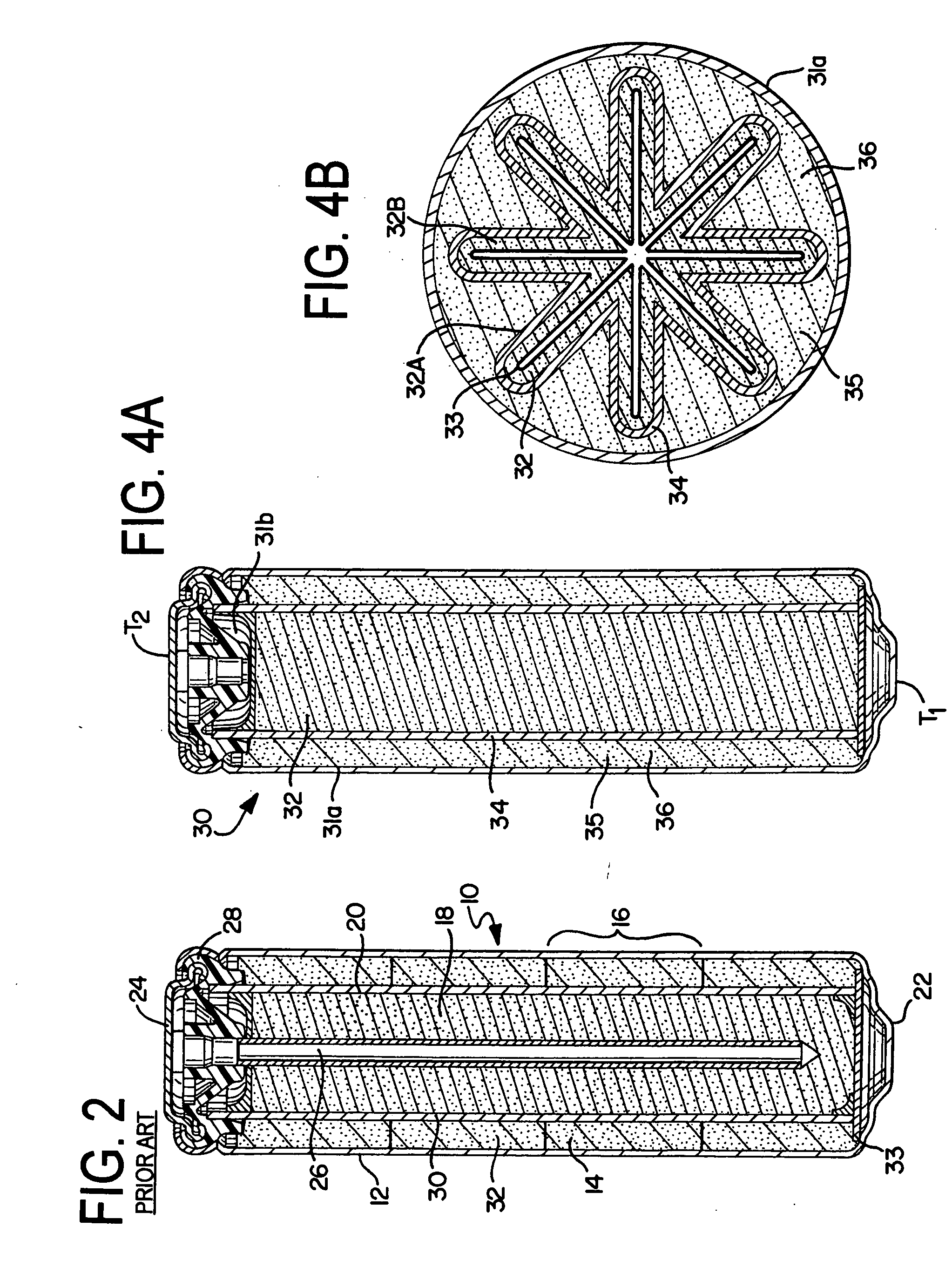

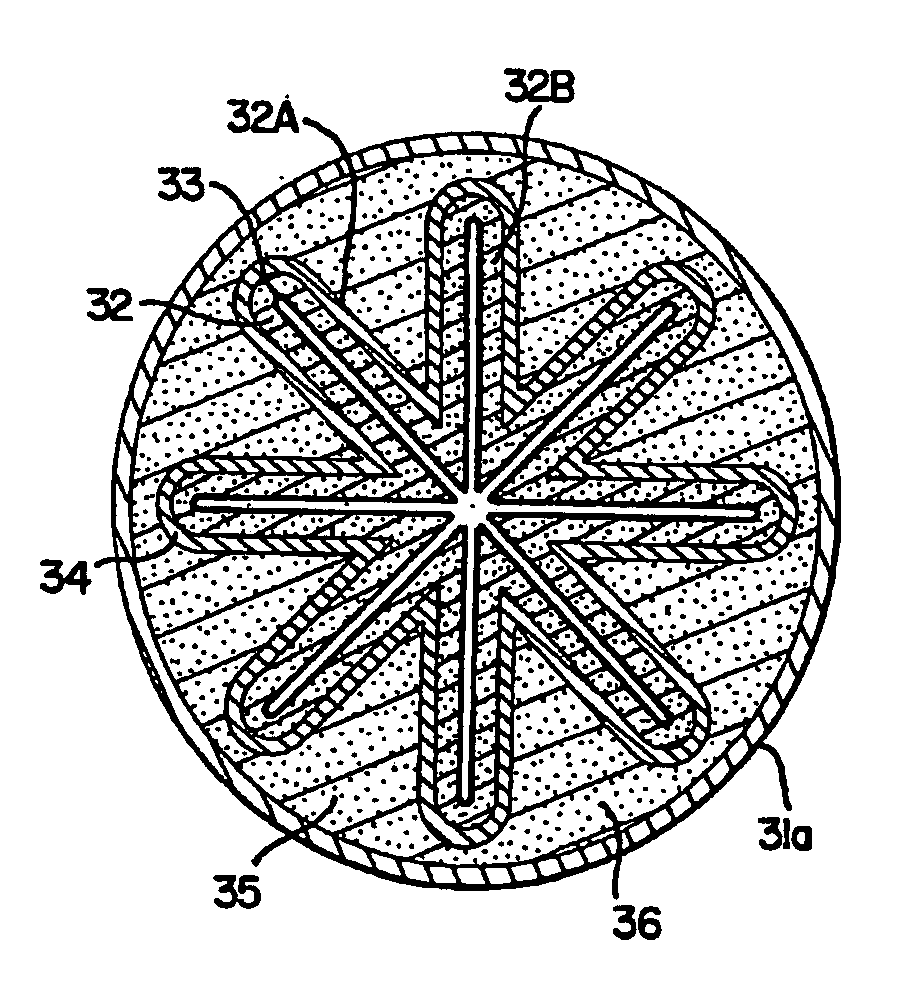

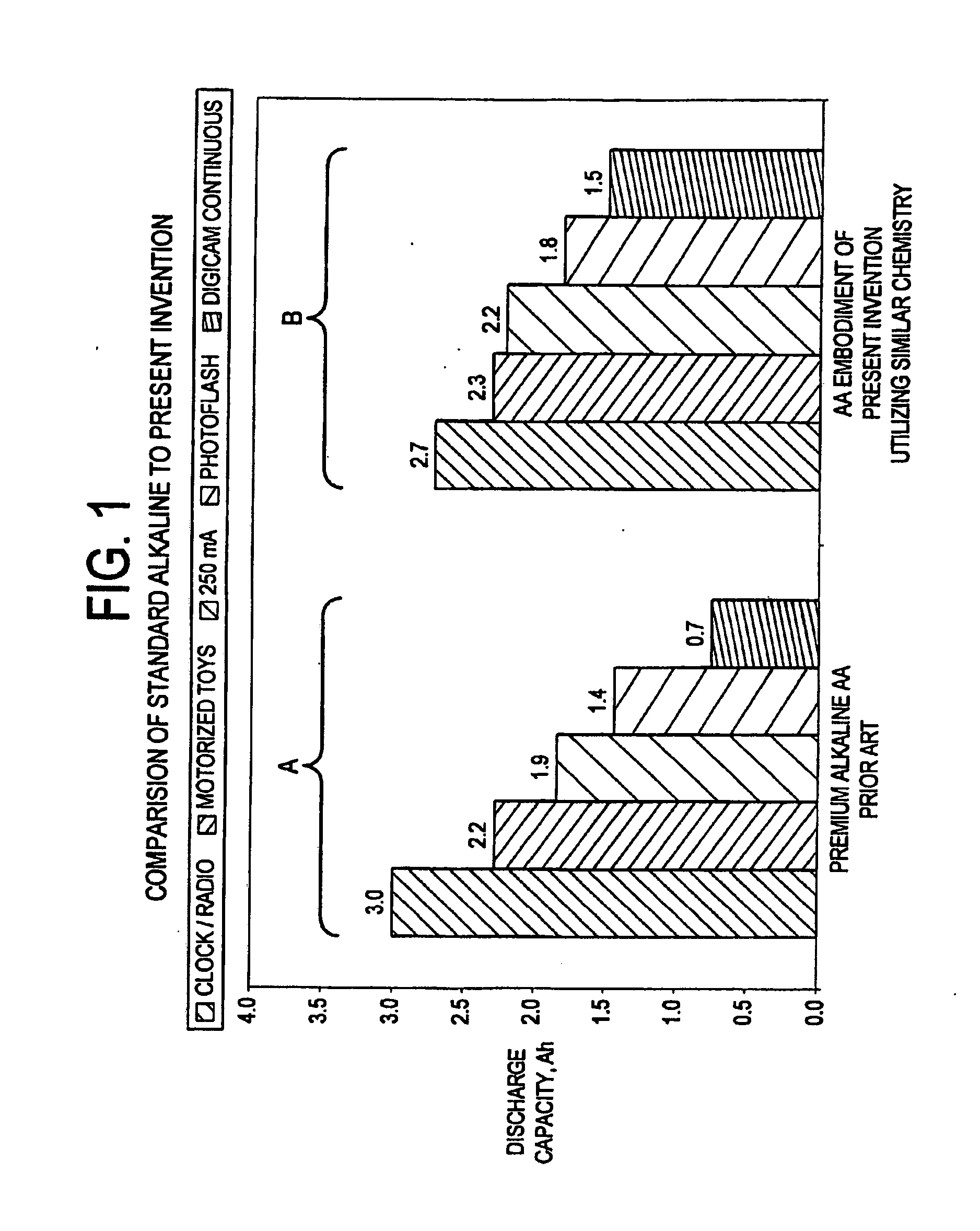

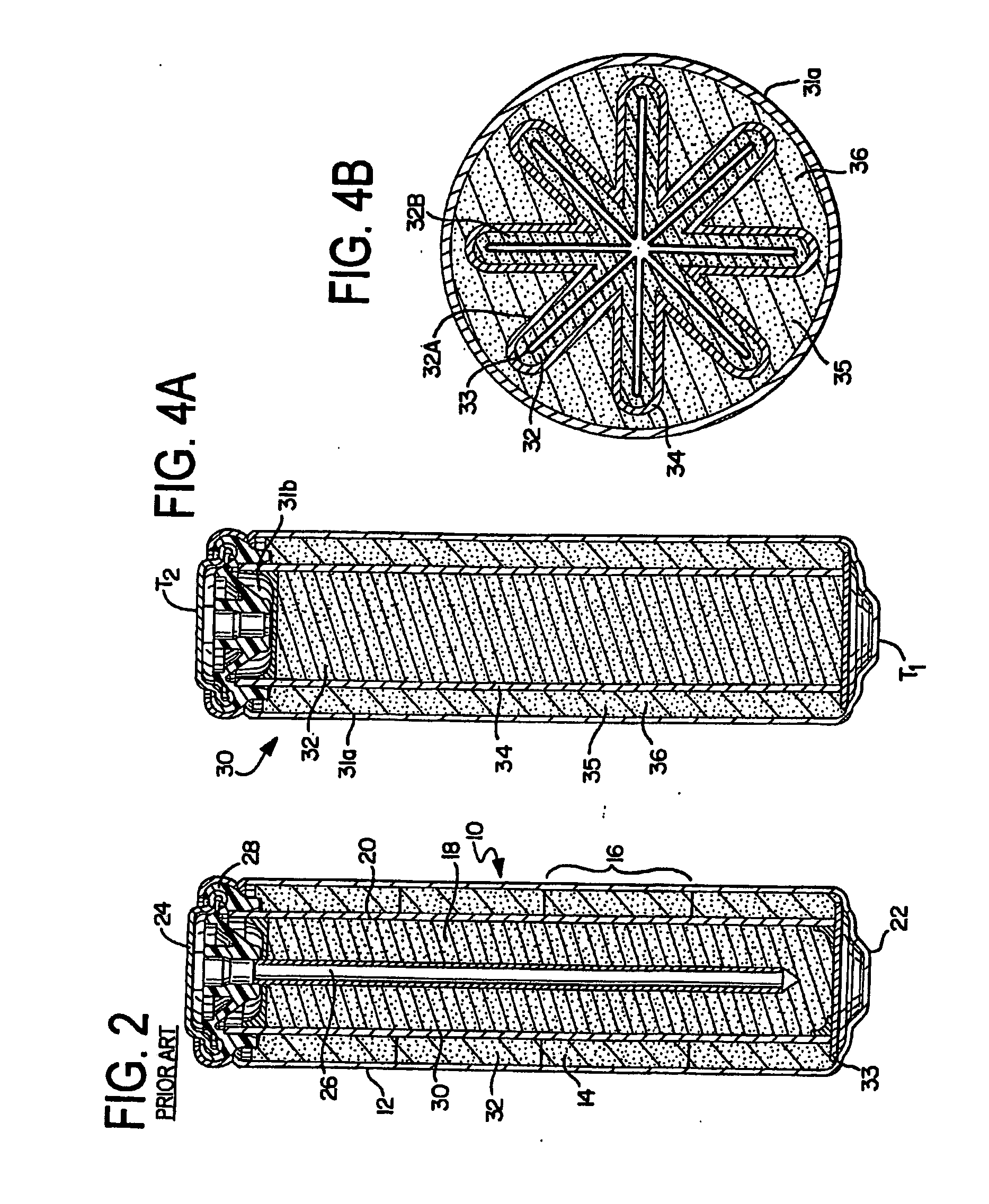

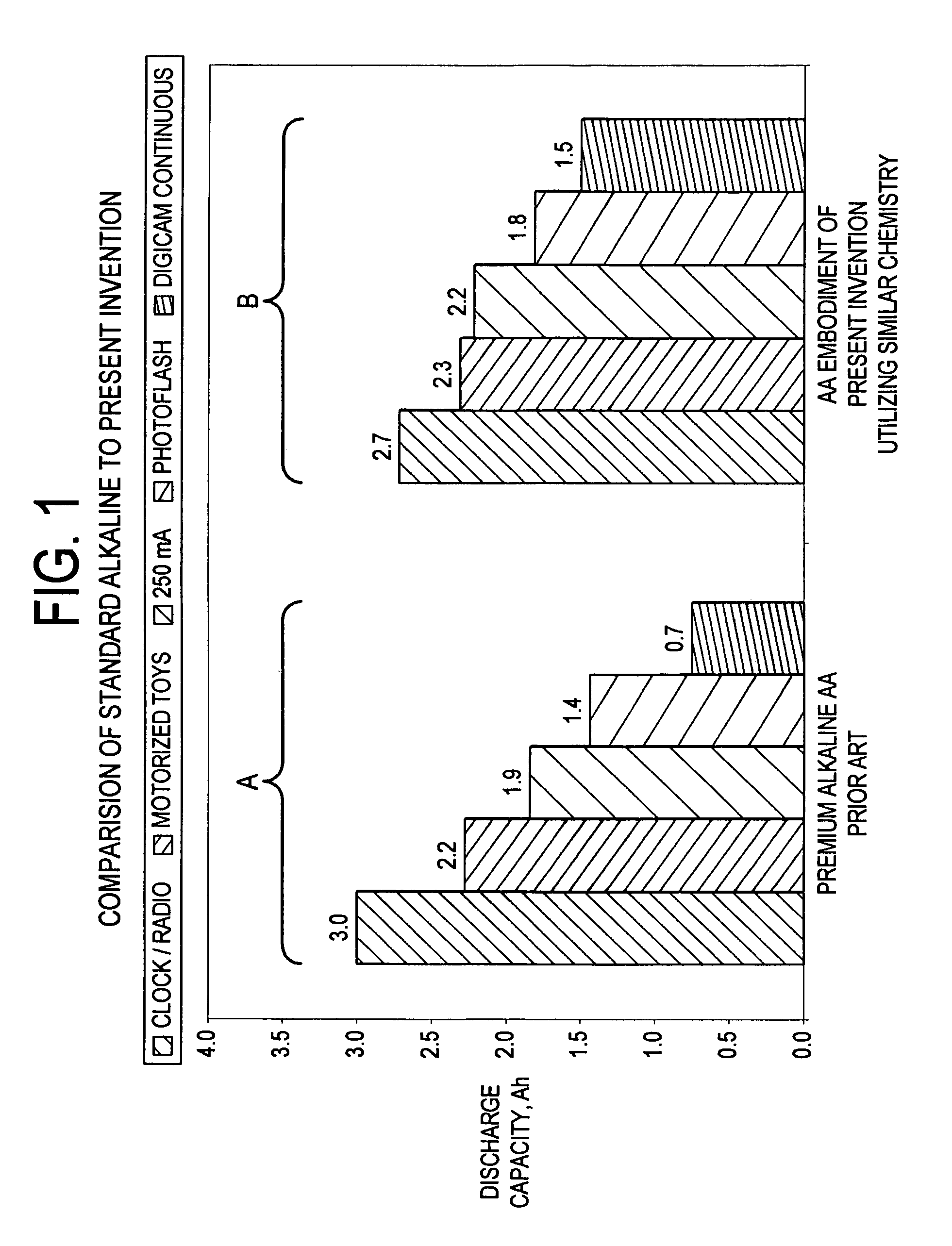

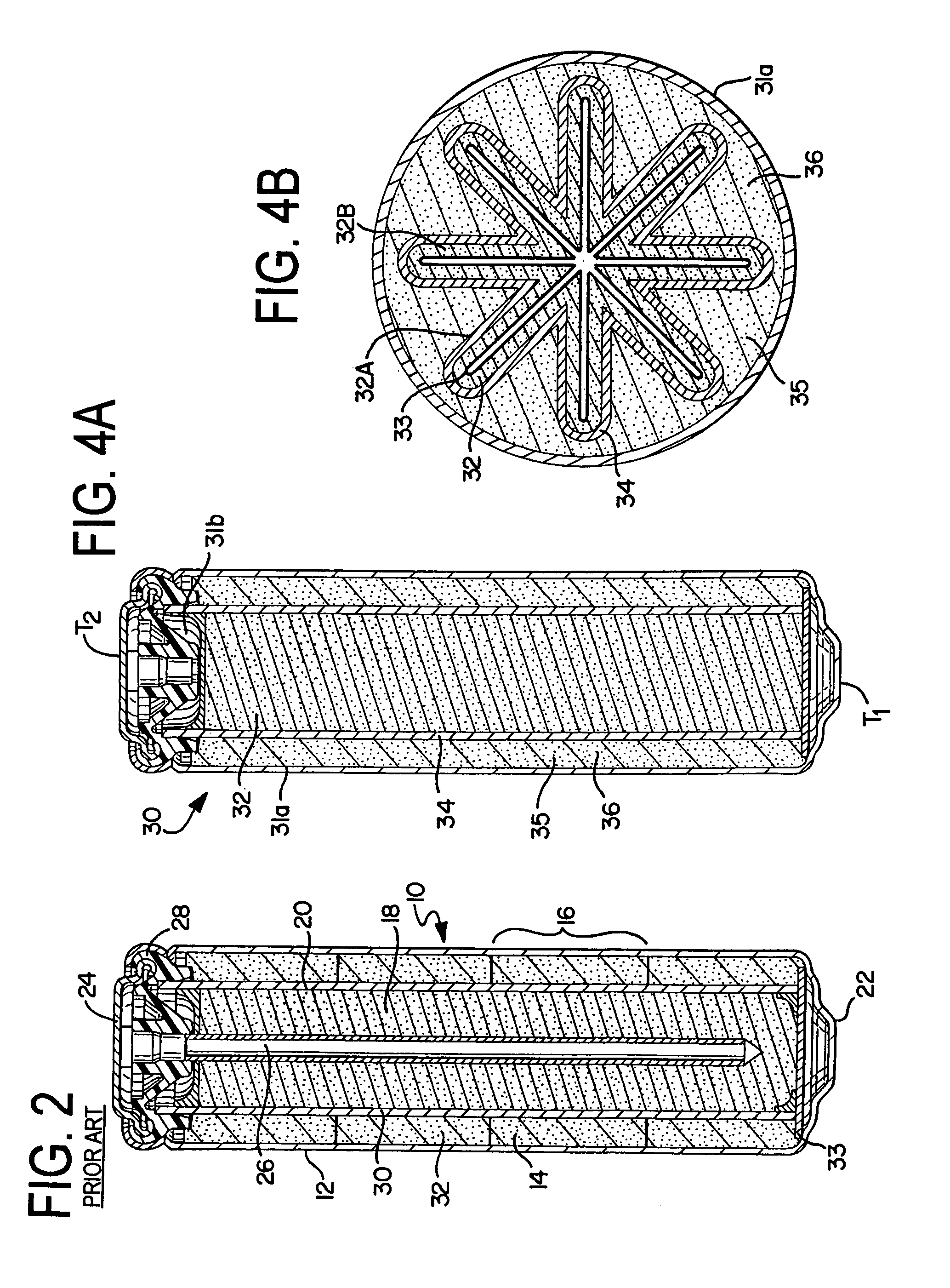

Cylindrical battery cell having improved power characteristics and methods of manufacturing same

InactiveUS20050048364A1Equivalent throughput ratesHigh speed productionCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesInterior spaceElectricity

A battery cell, such as a cylindrical alkaline cell, is disclosed having significantly improved capacity utilization at high discharge rates while maintaining much of the energy content and other feature advantages of typical cylindrical alkaline cells, by implementing a novel cell construction that produces increased surface area between the anode and cathode. One particular characterization of the cell construction of the present invention comprises an electrochemical battery cell comprising a cell housing defining an interior space having an interior surface, a first terminal and a second terminal. The cell further comprises an inner electrode encapsulated by a separator and disposed within the interior space of the housing. The inner electrode has a thin cross section in a folded configuration and is formed such that an outer extent of the inner electrode is generally conforming to a contour defined by the interior surface of the cell housing. The inner electrode is in electrical communication with the second terminal of the housing. An outer electrode is disposed within the interior space of the housing such that it is in ionic communication with the inner electrode and in electrical communication with the first terminal of the cell housing.

Owner:RECHARGEABLE BATTERY CORP

Polyethylene blends with good contact transparency

InactiveUS20050222338A1Good transparencyHigh stress crack resistanceHigh-density polyethylenePolymer blend

This invention discloses the production and use of a polyethylene composition comprising a metallocene-produced linear low density polyethylene and a multi modal high density polyethylene prepared from either a Ziegler-Natta or a metallocene catalyst system. The resulting polyethylene composition is suitable for preparing articles having improved environmental stress crack resistance, rigidity, contact transparency, gloss as well as good processing capabilities.

Owner:TOTAL RES & TECH FELUY

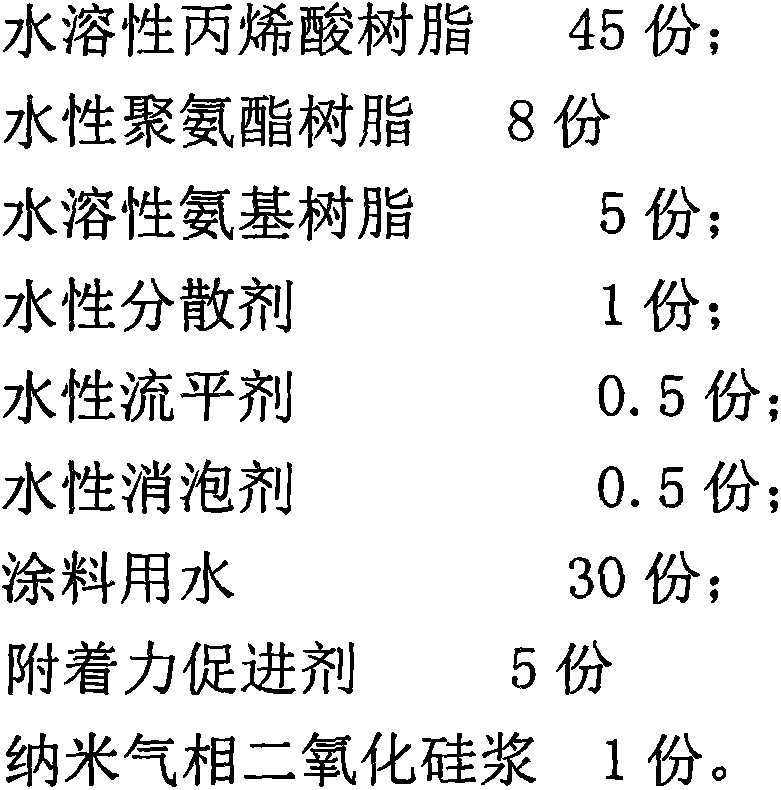

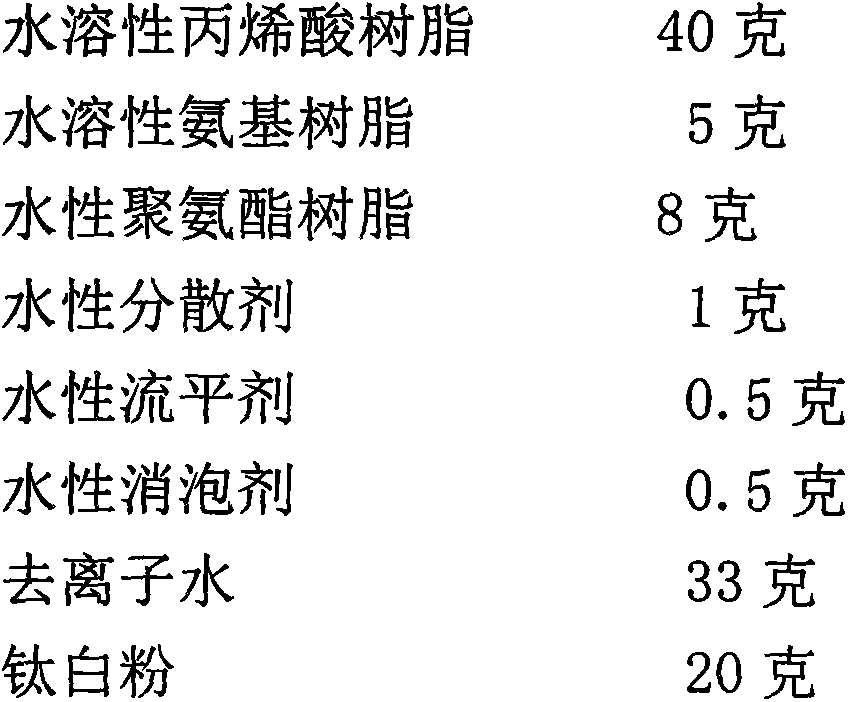

Water-based paint applied in aluminum-plastic plates and color steel coiled material

ActiveCN103602188AFast dryingHigh speed productionPolyurea/polyurethane coatingsSolventDefoaming Agents

The invention provides a water-based paint applied in aluminum-plastic plates and a color steel coiled material. The water-based paint comprises the following components by weight: 30-55 parts of water soluble acrylic resin, 5-10 parts of water-based polyurethane resin, 4-10 parts of water soluble amino resin, 0.1-2 parts of a water-based dispersion agent, 0.1-2 parts of a water-based leveling agent, 0.1-2 parts of a water-based defoaming agent, 20-30 parts of water for the paint, 3-8 parts of an adhesion promoter, and 0.5-2 parts of a nano fumed silica slurry. The water-based paint has the main volatile which is water, thereby having no harm to the environment and operators. The water-based paint has the product quality which is equal to or slightly higher than the coating effect of an oily product. Moreover, the water-based paint has fast drying speed, can satisfy continuous and high-speed production in aluminum-plastic plate industry, and does not affect the production efficiency. Compared with an oily acrylic amino stoving varnish, the water-based paint has excellent solvent resistance, and has quite good market popularizing value.

Owner:天津梓明涂料制造有限公司

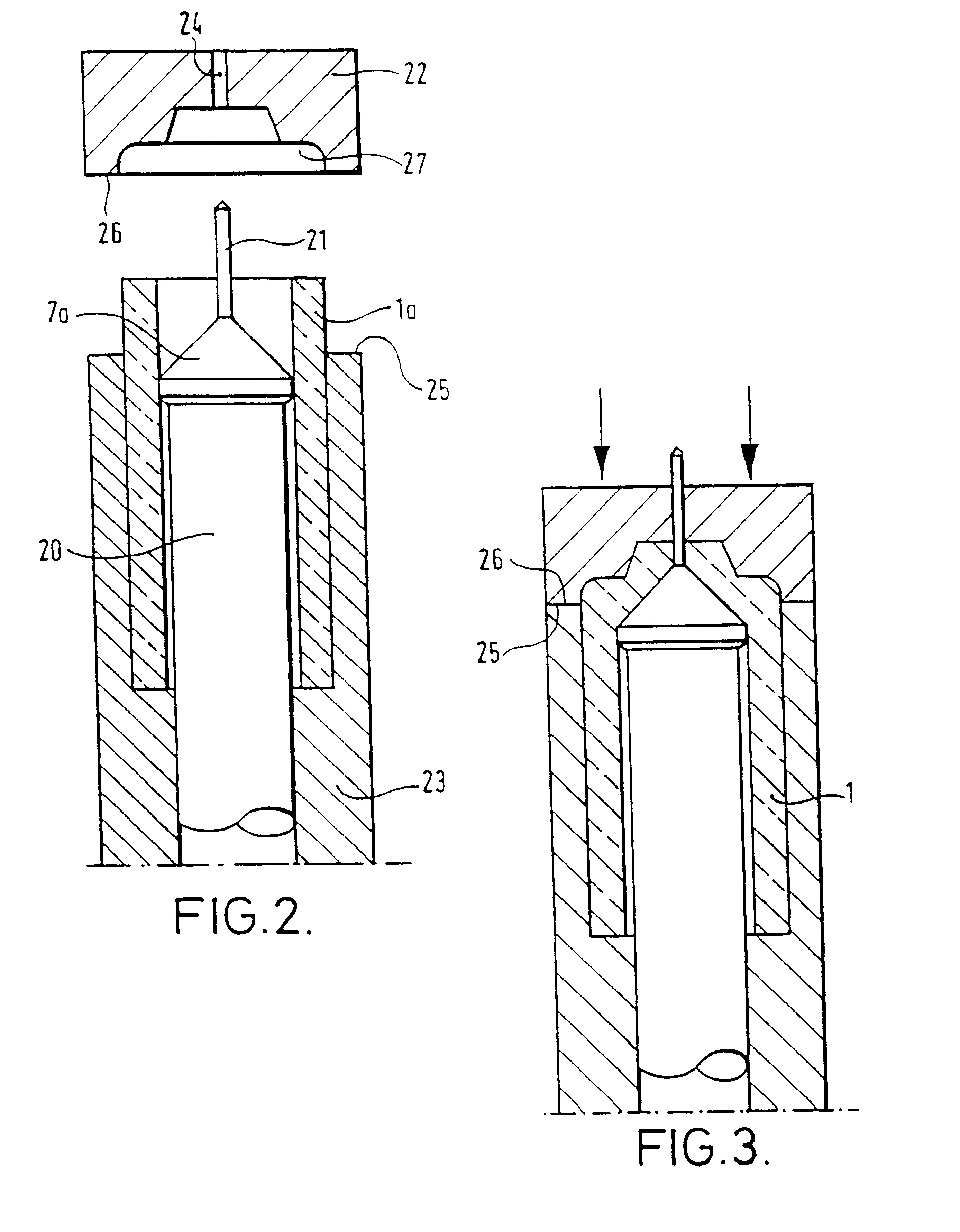

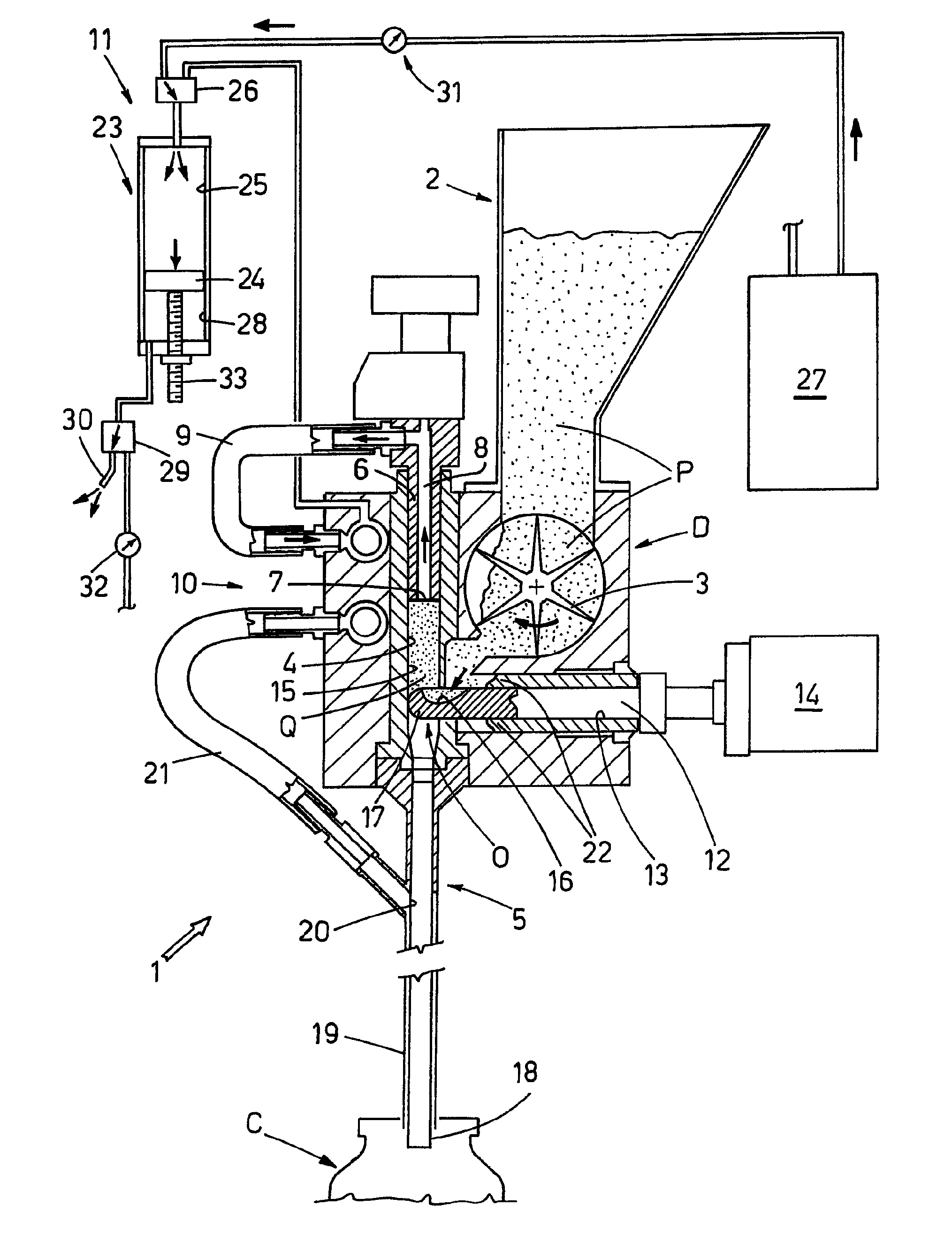

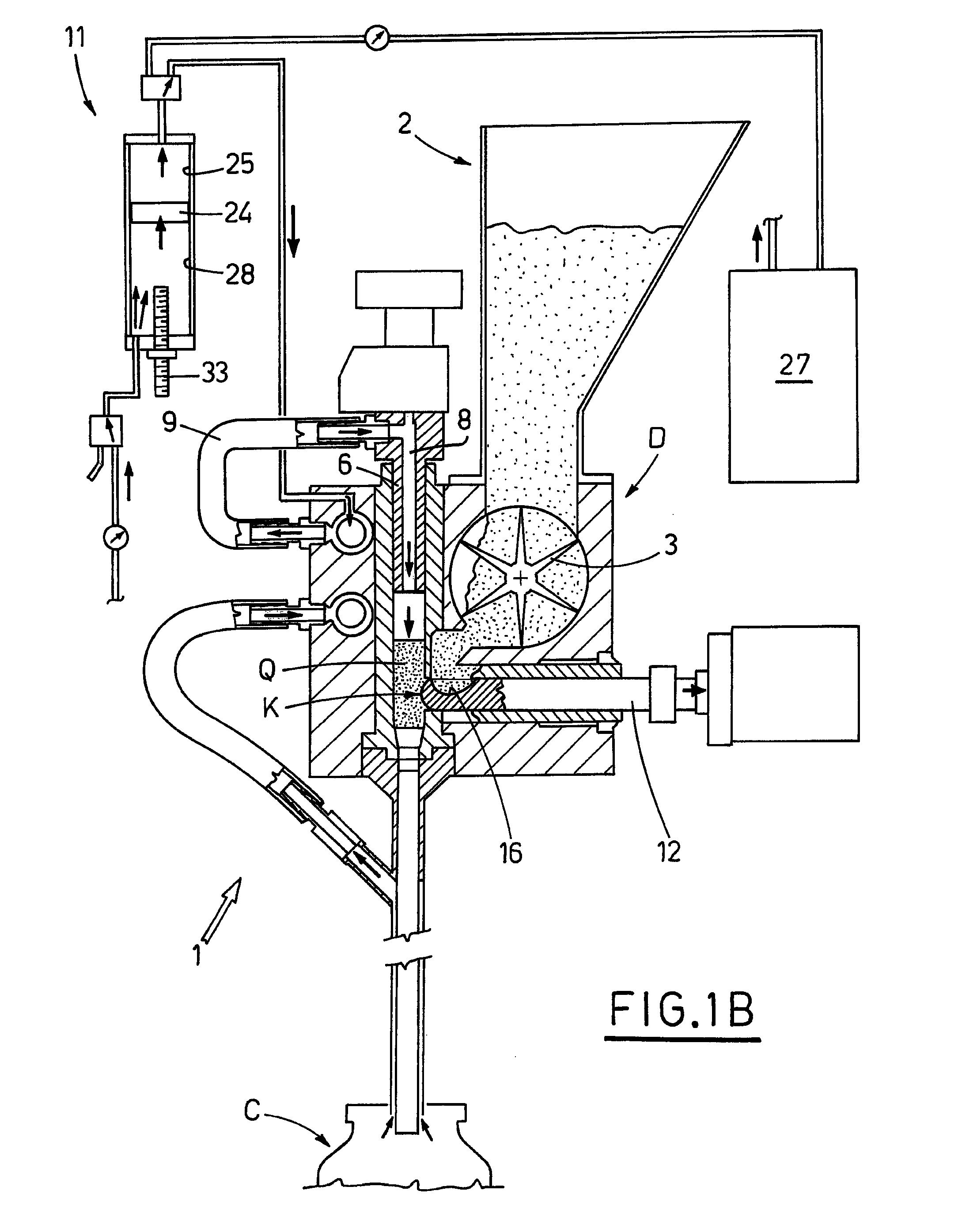

Method for batching powder and/or granular products internally of container elements and apparatus for actuating the method

ActiveUS20080236701A1Reduced toleranceHigh speed productionLiquid fillingSolid materialEngineeringMechanical engineering

An apparatus for batching powder and / or granular products, comprising: a hopper; at least a passage, delimited at one side thereof by a gas-permeable element which alternatively communicates with a first depressed source and with a first pressurized source, and at opposite side thereof communicating with a discharge region; an obturator acting in the passage between an occluding position, in which a batching chamber is defined, and an enabling position. The obturator element is conformed such as to place the hopper in communication with the batching chamber when it is in the occluding position; the first depression source, the first pressurized source and the obturator element being activated in phase relation with one another for loading a batched quantity of powder and / or granular products internally of the batching chamber and for projecting the batched quantity internally of a container element.

Owner:MARCHESINI GROUP SPA

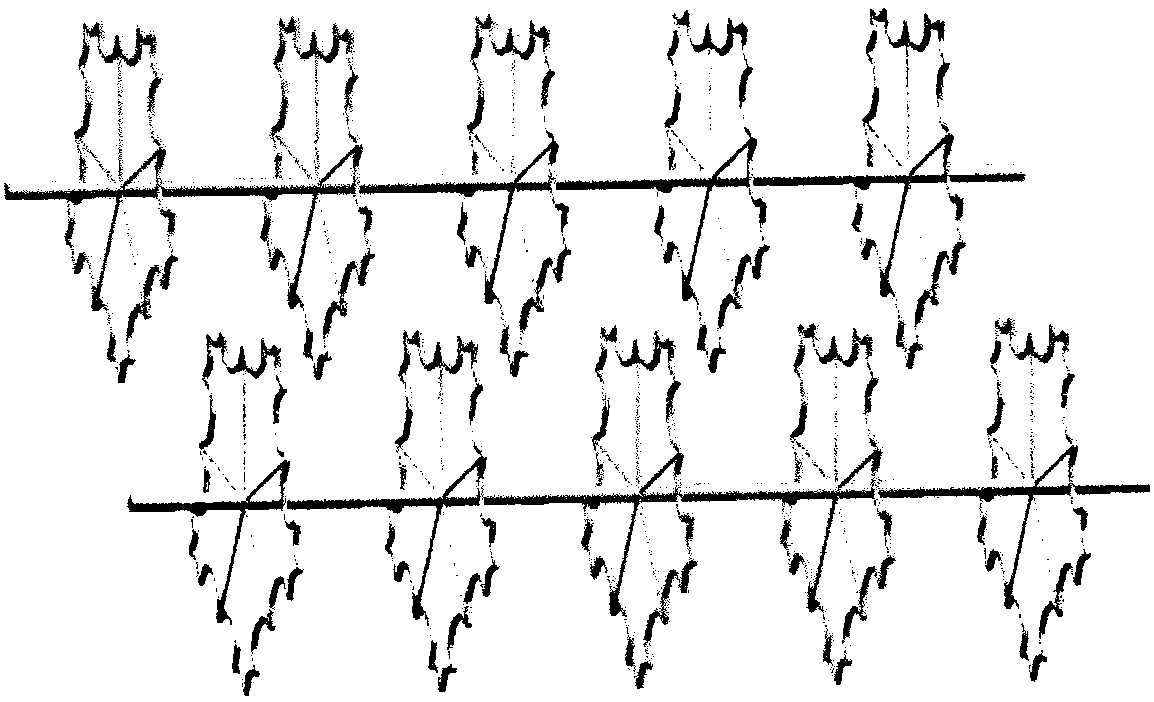

Embeedded electrode conformations for balanced energy, power, and cost in an alkaline cell

InactiveUS20050153197A1Easy translationImprove capacity utilizationElectrode manufacturing processesElectrode carriers/collectorsEngineeringBattery cell

A battery cell, such as a cylindrical or prismatic alkaline cell, is disclosed having significantly improved capacity utilization at mid-range power levels of discharge by implementing a curvilinear-like inner electrode configuration that provides moderated surface area between the inner and outer electrodes as compared to high-power discharge applications utilizing a densely corrugated geometry for the inner electrode.

Owner:RECHARGEABLE BATTERY CORP

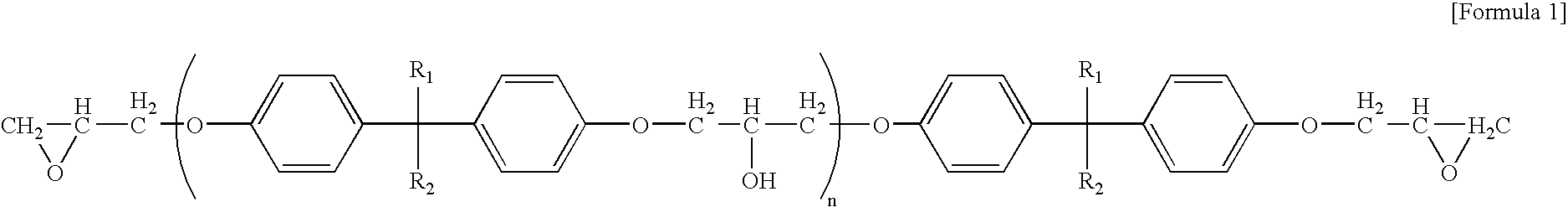

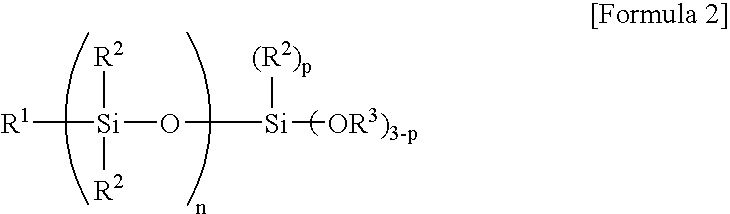

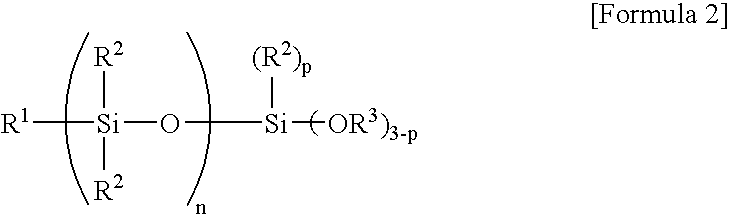

Sealant composition for liquid crystal and process for producing liquid-crystal display panel with the same

ActiveUS20060006362A1High speed productionImprove adhesionLiquid crystal compositionsOther chemical processesSolventBoiling point

The present invention provides a liquid crystal sealing composition and a liquid crystal display panel excellent in adhesion, moisture permeation resistance and heat resistance and superior for use in a sheet press heating bonding system. The liquid crystal sealing composition comprises (1) an alkoxysilyl group-containing modified epoxy resin obtained by de-alcohol condensation reaction of (a) an epoxy resin having at least one hydroxyl group in one molecule and (b) analkoxysilyl group-containing compound, (2) a heat latent epoxy curing agent, (3) a filler having an average particle diameter of 0.1 to 10 μm, and if necessary (4) an epoxy resin having at least 1.2 epoxy groups on average in one molecule, (5) an aprotic solvent having a boiling point in the range of 140 to 220° C., compatible with epoxy resin and inert to an epoxy group, and (6) other additives.

Owner:MITSUI CHEM INC

Continuous squeezing method and device for directly cooling squeeze wheel race and material stop block surfaces

InactiveCN101623712AIncrease production speedImprove equipment productivityExtrusion control devicesRams/plungersEngineeringSurface layer

The invention relates to the field of metal plastic shaping. The invention discloses a continuous squeezing method of directly cooling squeeze wheel race and material stop block surfaces. A squeeze wheel or a material stop block is cooled with the method that liquid cooling medium directly cools the surface of squeezed metal covered by a squeeze wheel groove or the outer surface of the material stop block; before the squeezed metal covered by the squeeze wheel groove rotates to a compaction wheel and the cooling medium contacts the squeezed metal rod material, no cooling medium is left on the surface of the squeezed metal covered by the surface layer of the squeeze wheel. The continuous squeezing method of the invention more effectively lowers the temperature of the squeeze wheel and the material stop block, improves the production rotation speed of the squeeze wheel, improves the production efficiency of the device and improves the utilization ratio of the material and the service life of the squeeze wheel.

Owner:大连康丰科技有限公司

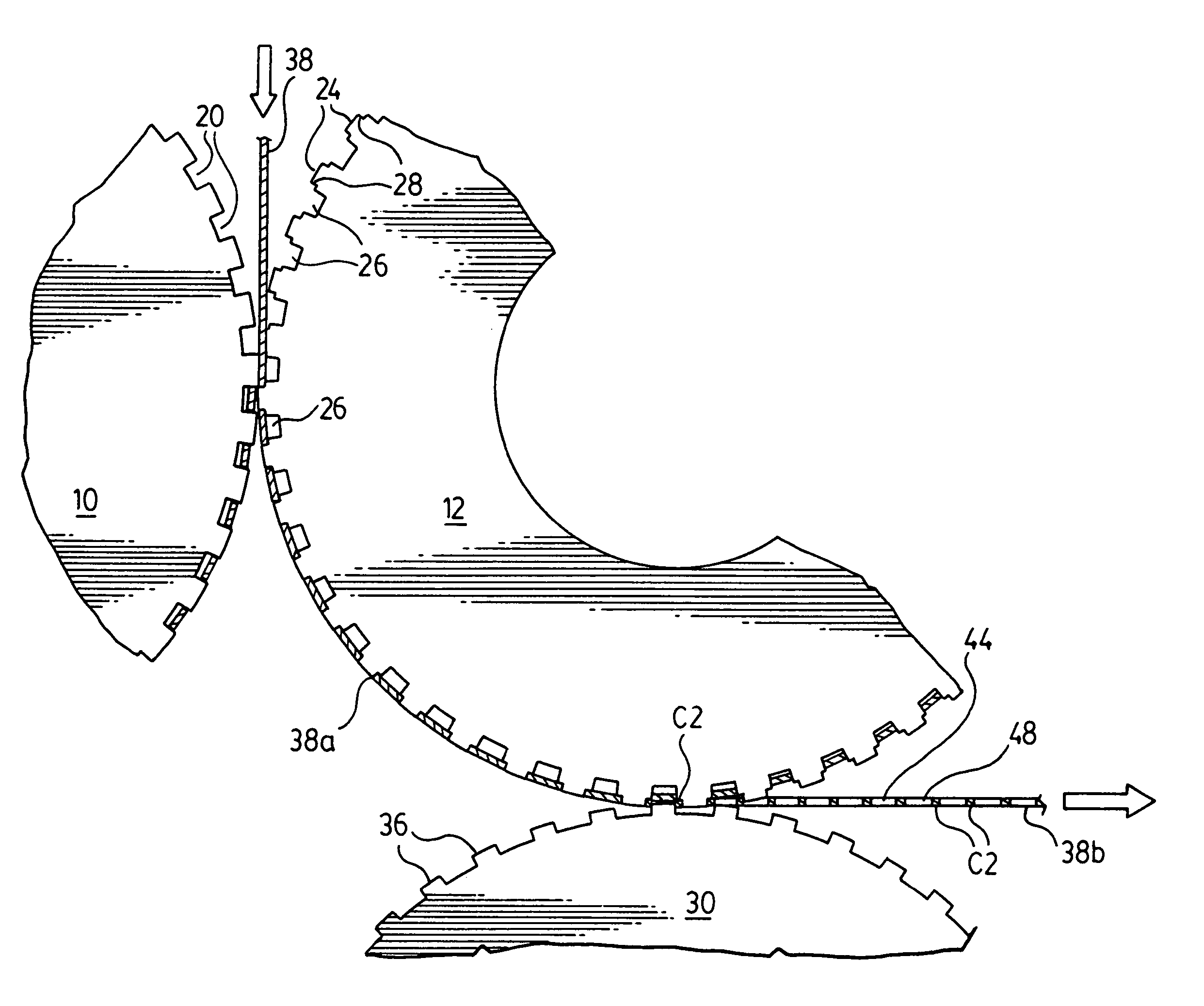

Battery cells having improved power characteristics and methods of manufacturing same

InactiveUS20050048363A1Improve capacity utilizationIncrease surface areaCell seperators/membranes/diaphragms/spacersLarge-sized flat cells/batteriesElectricityInterior space

A battery cell, such as a cylindrical or prismatic alkaline cell, is disclosed having significantly improved capacity utilization at high discharge rates while maintaining much of the energy content and other feature advantages of typical cylindrical or prismatic alkaline cells, by implementing a novel cell construction that produces increased surface area between the anode and cathode. One particular characterization of the cell construction of the present invention comprises an electrochemical battery cell comprising a cell housing defining an interior space having an interior surface, a first terminal and a second terminal. The cell further comprises an inner electrode encapsulated by a separator and disposed within the interior space of the housing. The inner electrode comprises a substantially flat material in a folded configuration and formed such that an outer extent of the inner electrode is generally conforming to a contour defined by the interior surface of the cell housing. The inner electrode is in electrical communication with the second terminal of the housing. An outer electrode is disposed within the interior space of the housing such that it is in ionic communication with the inner electrode and in electrical communication with the first terminal of the cell housing. Other aspects of the present invention are also disclosed, including various other embodiments and methods of manufacturing.

Owner:RECHARGEABLE BATTERY CORP

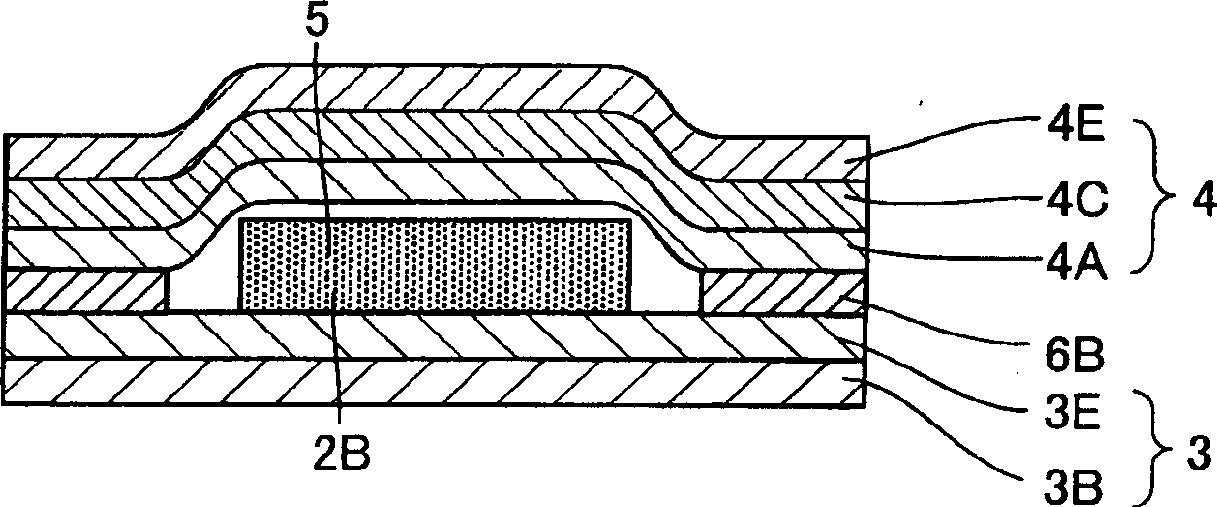

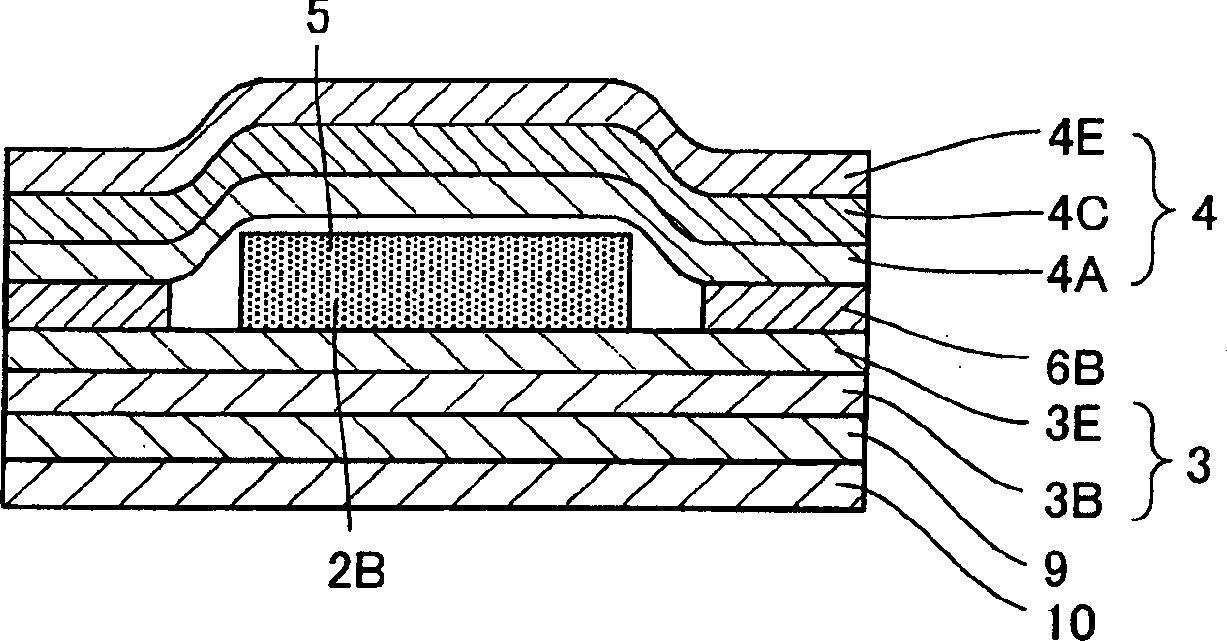

Polarizing plate, manufacturing method therefor, optical film and image display

ActiveUS20090086318A1High-speed productionIncrease durabilityLamination ancillary operationsLayered product treatmentPolarizerChemistry

A polarizing plate of the present invention comprises: a polarizer; a transparent protective film placed on at least one side of the polarizer; and an adhesive layer and an adhesion facilitating layer interposed in this order from the polarizer side between the polarizer and the transparent protective film, wherein the adhesive layer is formed with an active energy ray-curable adhesive that contains a hydroxyl group-containing N-substituted amide monomer as a curable component, and the adhesion facilitating layer is formed with a polymer resin composition that contains 100 parts by weight of a polymer resin and 3 to 30 parts by weight of an organosilane compound having at least one functional group selected from an acryloyl group, a methacryloyl group, a vinyl group, and a mercapto group. The polarizing plate has good adhesion.

Owner:NITTO DENKO CORP

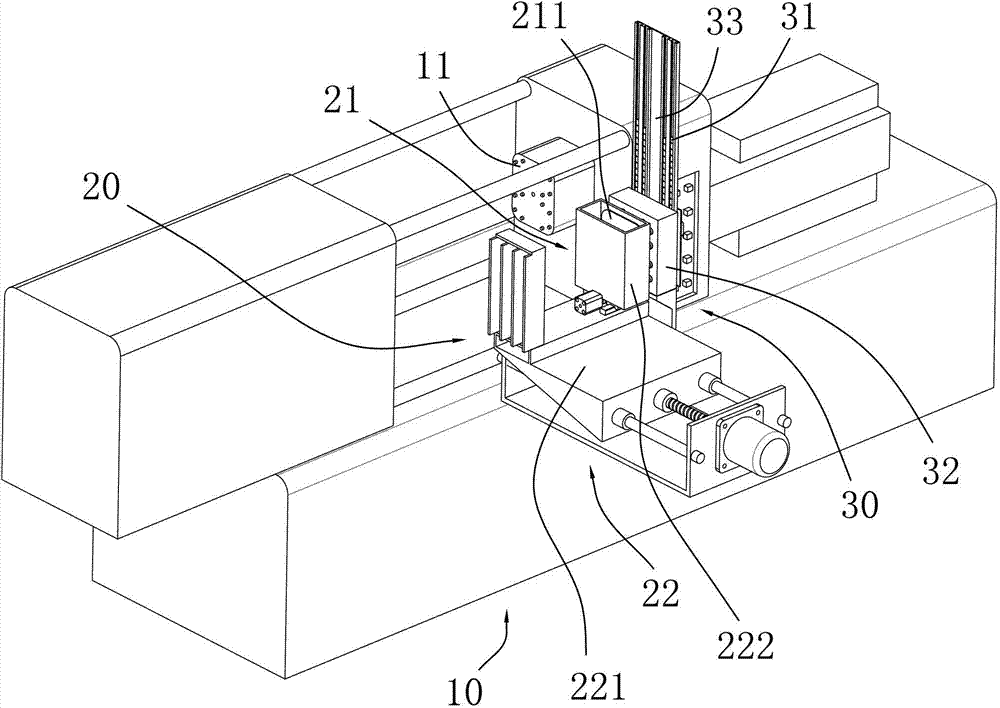

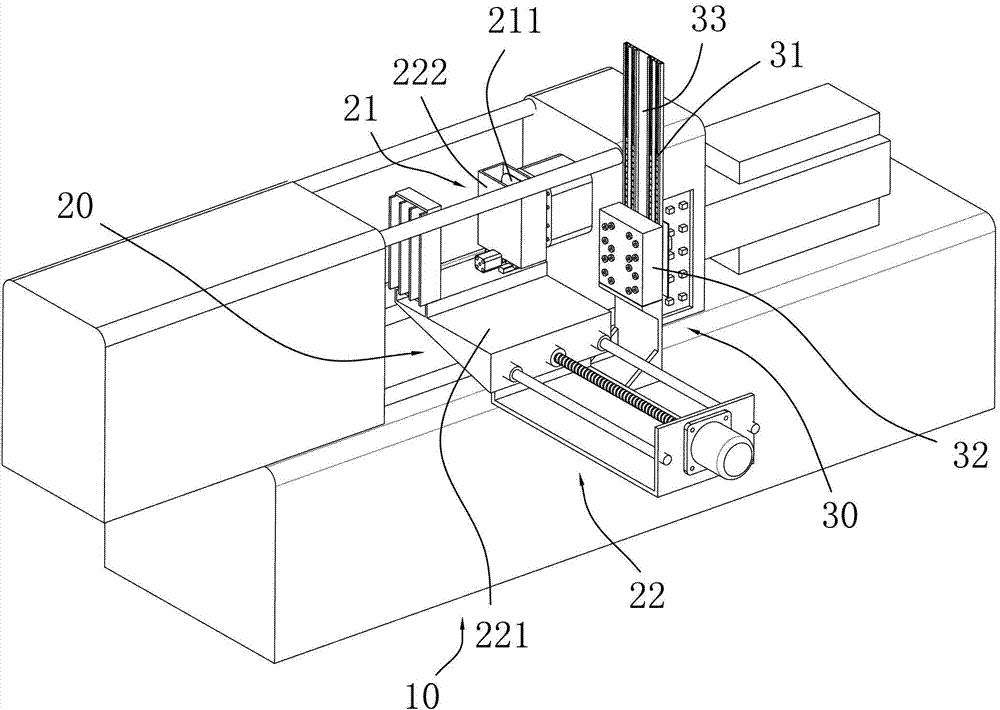

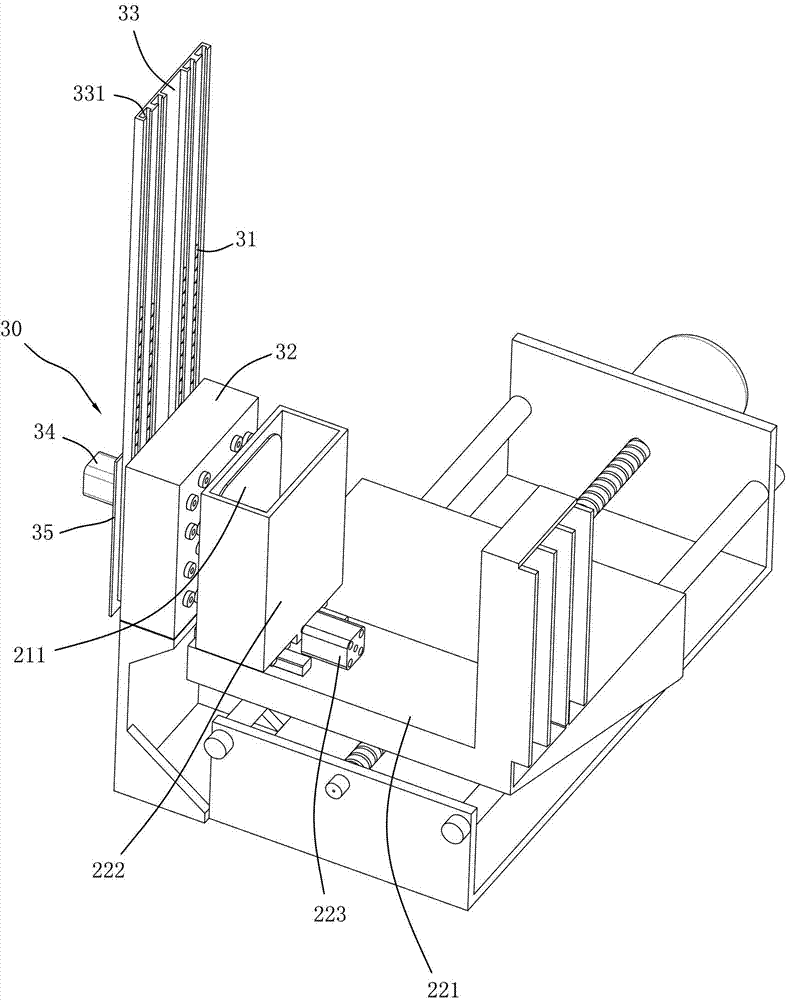

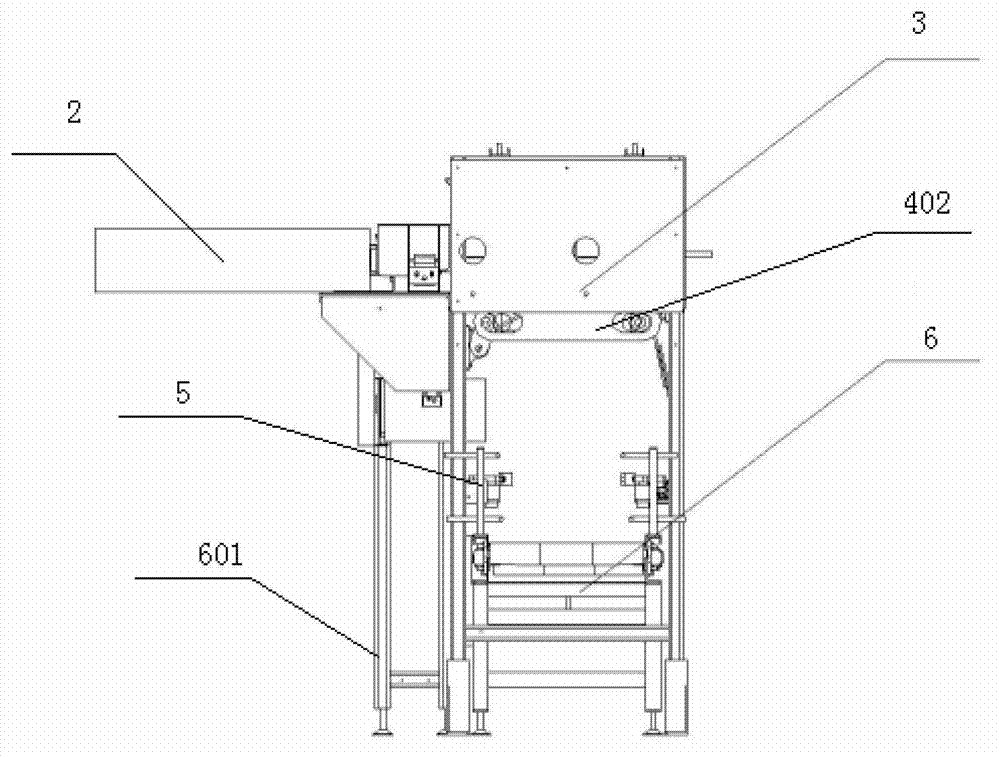

Metal insert positioning and loading device in injection moulding process

InactiveCN103481444AReduce labor intensityReduce the risk of defective partsCoatingsEngineeringInjection moulding

The invention discloses a metal insert positioning and loading device in an injection moulding process. The metal insert positioning and loading device is used for filling and positioning a metal insert into a mould cavity of an injection mould, and comprises an insert feeding part and an insert positioning mechanism, wherein the insert positioning mechanism comprises a magnetic adsorption device and a driving device; the magnetic adsorption device is used for adsorbing the metal insert in the insert feeding part; the driving device is used for driving the magnetic adsorption device to move to the injection mould to fill and position the metal insert into the mould cavity after the magnetic adsorption device adsorbs the metal insert. The magnetic adsorption device of the insert positioning mechanism automatically fills and positions the metal insert into the mould cavity through the driving device after adsorbing the metal insert in a magnetic adsorption manner, the traditional manual metal insert filling mode is abandoned, and manual work is replaced by a machine, so the production efficiency is greatly improved, the labor intensity of workers is reduced, the risk of defective parts caused by misoperation of the workers is reduced, and high-efficiency, high-speed and high-quality production is guaranteed. The metal insert positioning and loading device is applied to the technical field of injection moulds.

Owner:GUANGDONG TECHN COLLEGE OF WATER RESOURCES & ELECTRIC ENG

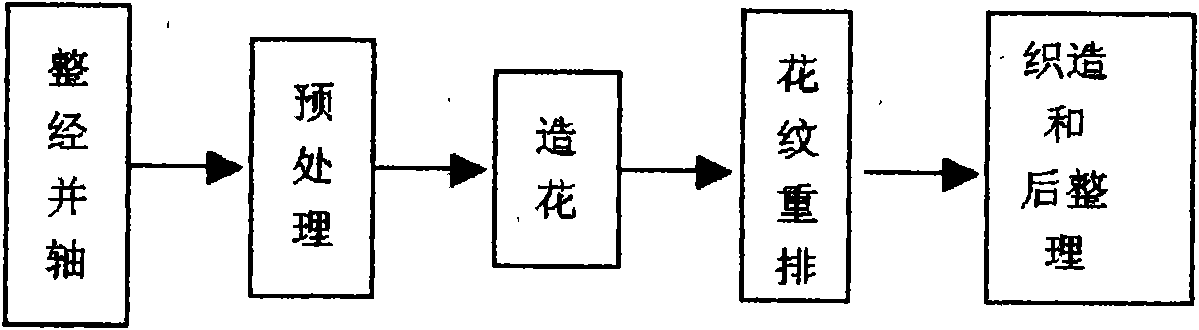

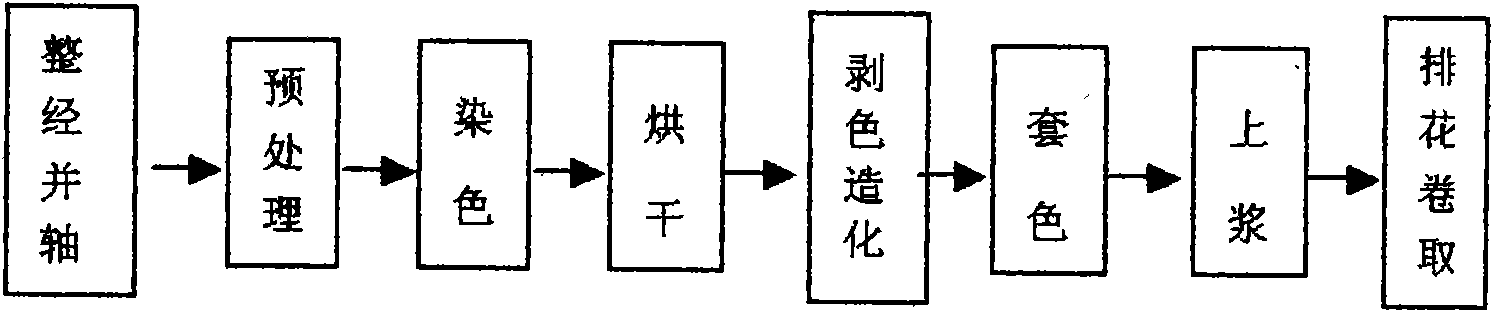

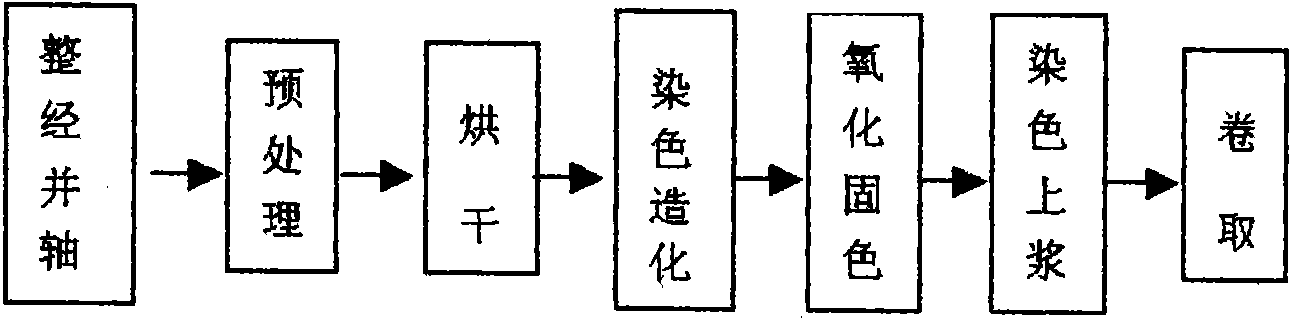

Production technology for watermark pattern cloth and production device thereof

InactiveCN101613965AClear and rich textureSoft colorOther manufacturing equipments/toolsDyeing processYarnTextile printer

The invention discloses production technology for watermark pattern cloth and a production device thereof, which belong to the technical field of textile printing and dyeing. A method thereof comprises the steps: arranging a pattern making device at the appropriate position of a sizing-dyeing combined machine; manufacturing a basic pattern with appropriate color and light and shade contrast on a cotton tape during the finishing of the dyeing and sizing of the cotton tape; using a pattern arrangement device for pattern rearrangement to reconstruct a needed fabric covering pattern; positioning various warp yarns, and coiling the warp yarns to a weaving cloth-roll; and finally obtaining finished watermark pattern cloth through registration, healding, reeding, weaving and appropriate afterfinish. The production device thereof comprises the pattern making device and the pattern arrangement device. The production technology can ensure that processes such as dyeing, pattern making and sizing are finished at one time, reduce repeated work, save a large quantity of energy sources, also has clear ridges as well as soft and natural color of the fabric covering pattern and exquisite fabric covering, but can also achieve the straightforward and unpretending style, and can also reduce the pollution and production cost.

Owner:刘林泉

Battery cells having improved power characteristics and methods of manufacturing same

InactiveUS20050048362A1Improve capacity utilizationIncrease surface areaPrimary cell to battery groupingCell seperators/membranes/diaphragms/spacersInterior spaceDischarge rate

A battery cell, such as a cylindrical or prismatic alkaline cell, is disclosed having significantly improved capacity utilization at high discharge rates while maintaining much of the energy content and other feature advantages of typical cylindrical or prismatic alkaline cells, by implementing a novel cell construction that produces increased surface area between the anode and cathode. One particular characterization of the cell construction of the present invention comprises an electrochemical battery cell comprising a cell housing defining an interior space having an interior surface, a first terminal and a second terminal. The cell further comprises an inner electrode encapsulated by a separator and disposed within the interior space of the housing. The inner electrode comprises a substantially flat material in a folded configuration and formed such that an outer extent of the inner electrode is generally conforming to a contour defined by the interior surface of the cell housing. The inner electrode is in electrical communication with the second terminal of the housing. An outer electrode is disposed within the interior space of the housing such that it is in ionic communication with the inner electrode and in electrical communication with the first terminal of the cell housing. Other aspects of the present invention are also disclosed.

Owner:RECHARGEABLE BATTERY CORP

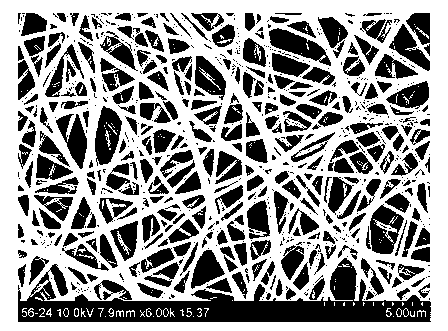

Needle-free electrostatic spinning assembly based on fractal structures

InactiveCN107620127AIncrease field strengthLow fineness variationFilament/thread formingNeedle freeElectrospinning

The invention discloses a needle-free electrostatic spinning assembly based on fractal structures and provides an electrostatic spinning technology which can effectively improve the fineness, uniformity and yield of nanometer fibers. The needle-free electrostatic spinning assembly is characterized in that electrostatic spinning heads are formed by using fractal structure units, and the electrostatic spinning heads of different types are obtained through the fractal structures of different forms; different-scale continuous production of the nanometer fibers can be achieved by adjusting the specification and number of the spinning heads of the fractal structures and the working width and length of the spinning heads. The needle-free electrostatic spinning assembly has the advantages that thespecially designed spinning heads of the fractal structures can improve the field intensity and the distribution uniformity, improve the fineness, uniformity and yield of the nanometer fibers, the phenomena that in an existing needle-free electrostatic spinning device, the field intensity is low, the energy consumption is high and the field intensity is nonuniform are avoided, the spinning voltage can be effectively reduced, the cost can be reduced, the energy utilization rate can be improved, and industrialized application and popularization are facilitated.

Owner:WUHAN TEXTILE UNIV

Embedded electrode conformations for balanced energy, power, and cost in an alkaline cell

InactiveUS20070092794A1Equivalent throughputratesHigh speed productionFinal product manufactureElectrode carriers/collectorsHypochloriteEngineering

A battery cell, such as a cylindrical or prismatic alkaline cell, is disclosed having significantly improved capacity utilization at mid-range power levels of discharge by implementing a curvilinear-like inner electrode configuration that provides moderated surface area between the inner and outer electrodes as compared to high-power discharge applications utilizing a densely corrugated geometry for the inner electrode. A battery cell, such as a cylindrical or prismatic alkaline cell, having a curvilinear-like inner electrode configuration that provides moderated surface area between the inner and an NiOOH outer electrodes. The NiOOH material made from a nickel hydroxide reacted with a hypochlorite in the absence of an alkaline hydroxide

Owner:RECHARGEABLE BATTERY CORP

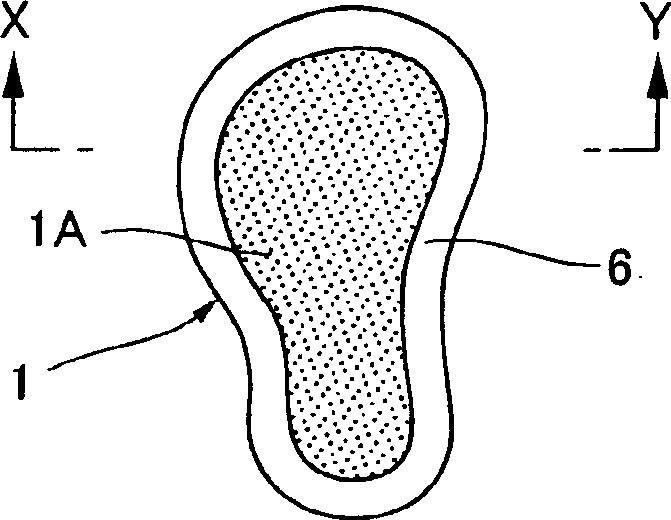

Foot warming heating element and method of manufacturing foot warming heating element

InactiveCN1518435AHeating comfortBroaden your optionsHeat-exchange elementsHeating element shapesSOCKSEngineering

A foot warming heating element capable of preventing a heating composition from moving by fixing a part or all of the composition in a packaging materi al by using the shape maintainable heating composition and capable being suitably fitted to the shape of a foot at the time of installation to efficiently war m the specified portions of the foot for a long time irrespective of an air pressure in a storage bag when the heating element is used by sticking on th e foot, footware, and socks, characterized in that a heating formed product causing heating reaction under the presence of air and having a shape maintaining degree of 70 or higher is sealed in the storage bag formed of a substrate material and a cover material, and at least a part of the storage bag is a permeable.

Owner:MYCOAL

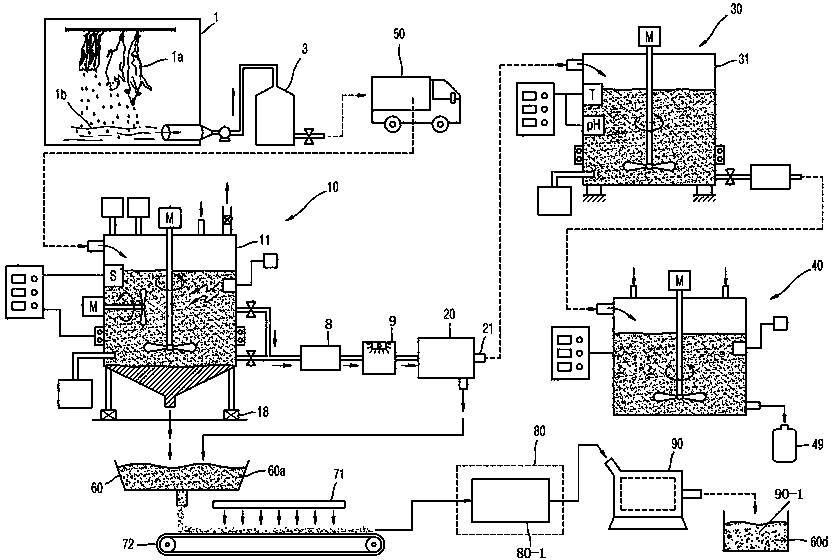

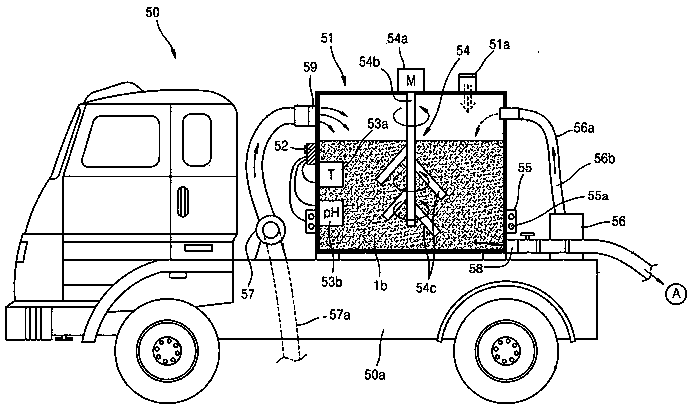

Method and system for producing natural amino acid, fertilizer and feed by using slaughtering blood

ActiveCN103451248AGood decomposition performanceHigh speed productionAnimal feeding stuffFermentationFertilizerChemistry

The invention relates to a method and a system for producing a natural amino acid, a fertilizer and a feed by using slaughtering blood. The method is characterized by comprising the following steps: adding a natural ferment agent into the slaughtering animal blood collected by slaughtering equipment and carrying out a decomposition and reaction processes; separating the slaughtering blood subjected to the decomposition treatment into a liquid substance and a solid matter by a liquid and solid matter separation device part; receiving a separated amino acid liquid substance and storing in the low-temperature state of 0-7 DEG C; preparing the amino acid into the fertilizer and the feed. Therefore, the effects of saving the equipment cost and the production cost can be realized.

Owner:蔡晖

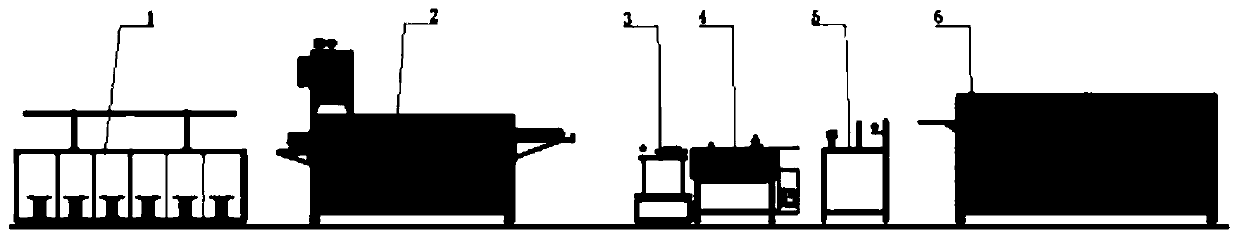

Micro-wire annealing tin plating machine production line

PendingCN109929971AProduction standardizationHigh speed productionHot-dipping/immersion processesFurnace typesFine lineProduction line

The invention discloses a micro-wire annealing tin plating machine production line and belongs to the field of cable machining. The micro-wire annealing tin plating machine production line comprises apay-off frame. A base is arranged at the lower end of the pay-off frame. An annealing furnace, a pickling bath, a tin furnace, a wire passing guide wheel set and a take-up machine. The pay-off frameis provided with a wire shaft. A first wire passing guide wheel is arranged on the surface of the pay-off frame. According to the production line, the special pay-off frame, the annealing furnace, thepickling bath, the tin furnace and the wire passing guide wheel set are arranged to be combined with the take-up machine, thus production of microwires is not troublesome any more, a user only needsto thread wires into the whole production line one by one like that of a traditional machine mode, the equipment can carry out the annealing technology and the tin plated technology automatically, allthe machined wires can be rolled and wound attractively with the standard and at a high speed, the defect that in the current wire industry, the microwires cannot be manufactured in batches is overcome, and the microwires can be produced with the standard and at a high speed.

Owner:鹰潭毅鹏智能科技有限公司

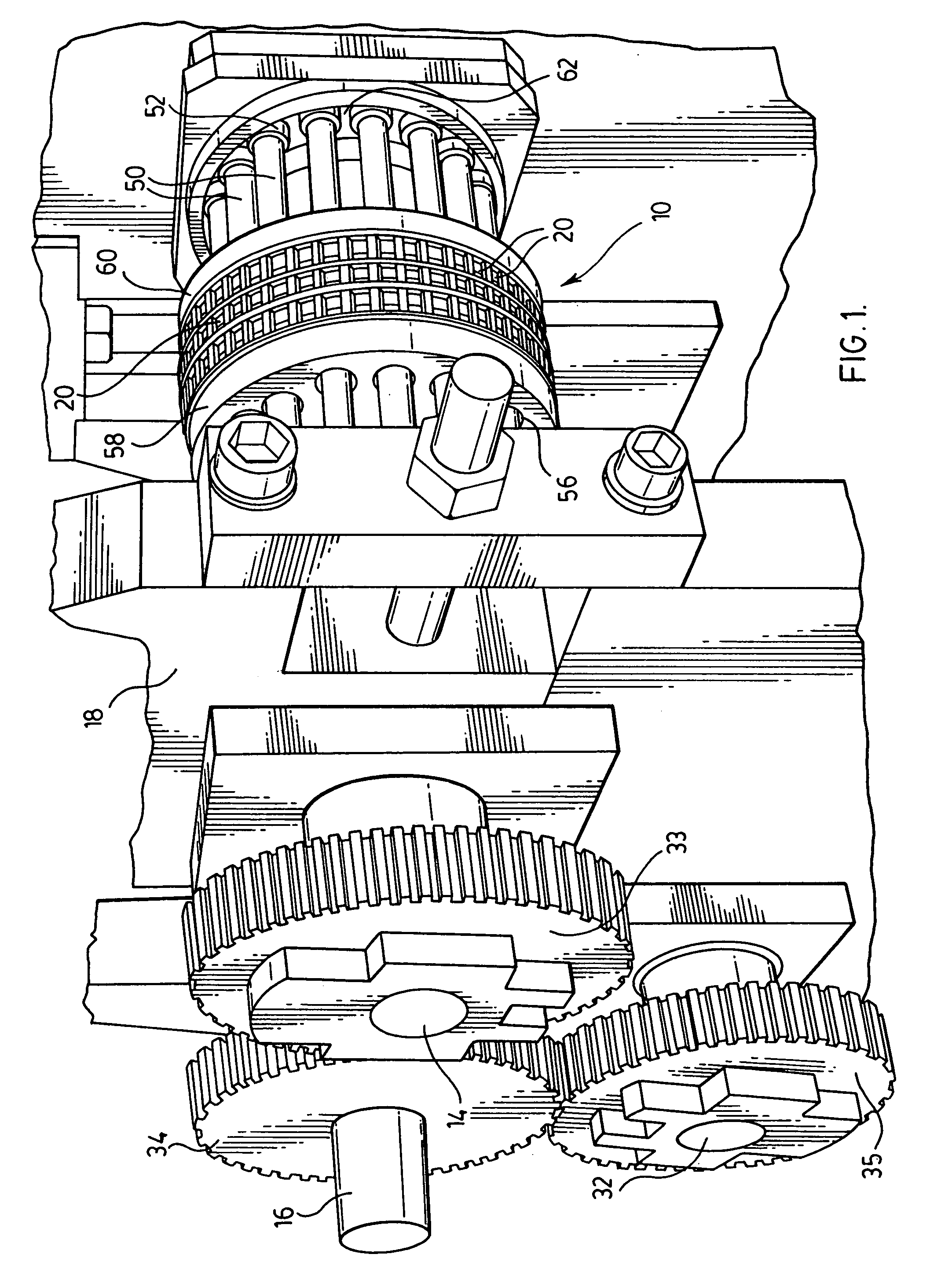

Continuous rotary hole punching method and apparatus

ActiveUS7066066B2Positive ejection of waste materialHigh speed productionBox making operationsPaper-makingPunchingStamping process

A method and apparatus for continuous, high-speed production of punched strip having an array of high-tolerance closely-spaced holes with positive ejection of waste punch-out material. A first pair of opposed rotary dies, one a female die and the other a male / female die, punches a first set of holes in a strip fed continuously between the dies, and a second pair of opposed rotary dies, one the male / female die and the other a male die, punches a second set of holes in the strip between the first set of holes, the strip being wrapped about the common male / female die during punching of the first and second sets of holes to continuously index the strip with the two opposed pairs of rotary dies to ensure production of the high-tolerance closely-spaced holes. A plurality of angular segments mounted in an annulus formed in proximity to the perimeter of the dies adapted for controlled radial travel of the angular segments during rotation of the dies, each angular segment having at least one ejector pin for radial reciprocal travel in a die recess, ejects punch-out material from the recess.

Owner:TBS USA INC

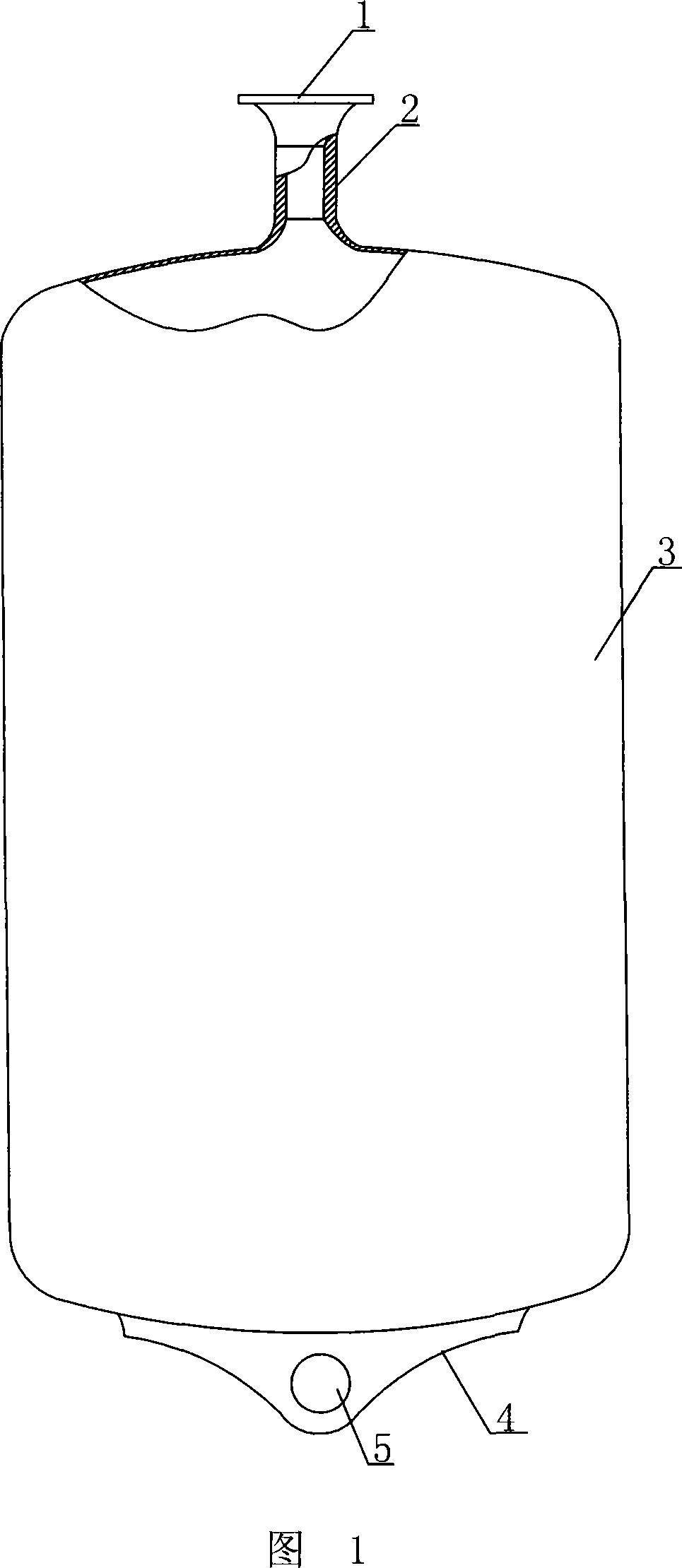

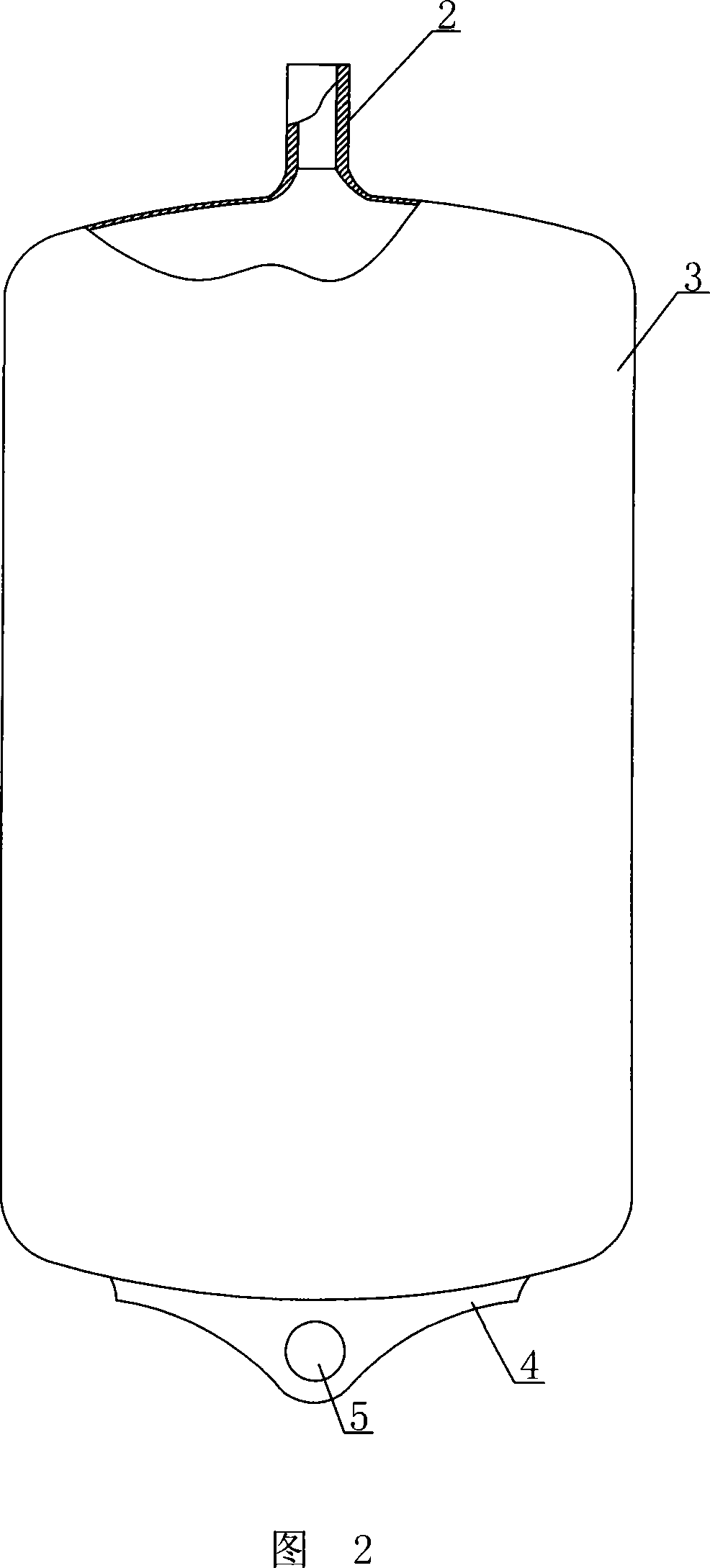

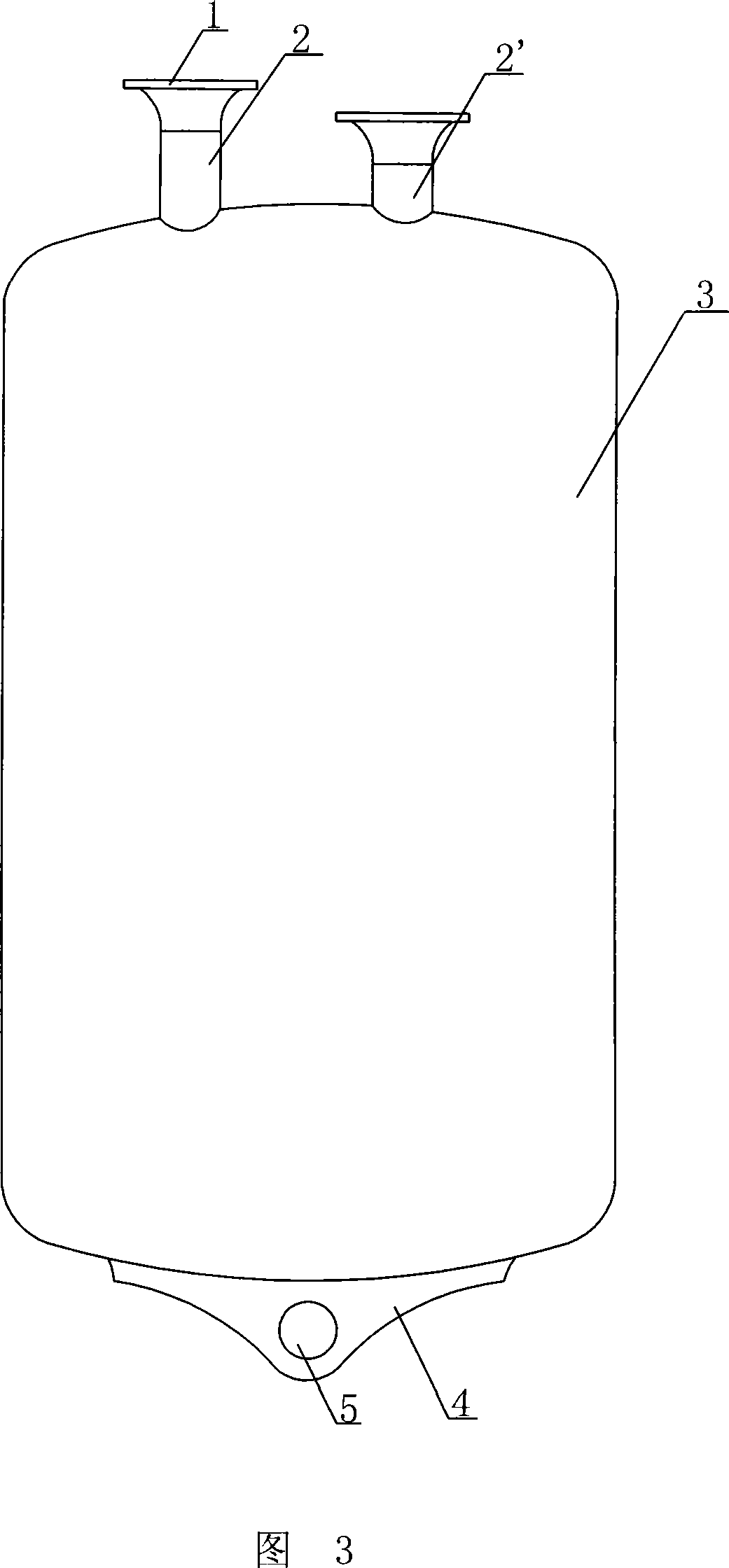

Blow molding medical bag and preparing method thereof

InactiveCN101229097APrevent leakageAvoid pollutionPharmaceutical containersMedical packagingBlow moldingBottle

The invention relates to a blow molding medical bag and a preparation method thereof. The blow molding medical bag includes a bag body. One end of the bag body is provided with a convex filling opening and the other end is provided with a lifting ring. The bag body, the filling opening and the lifting ring form an integral structure. The preparation method includes: taking medical polythene, medical polypropylene or medical modified-polypropylene as the raw materials and adopting a hollow blow molding method and a hollow blowing device to carry out one-time blow molding on the medical polythene, the medical polypropylene or the medical modified-polypropylene to acquire the blow molding medical bag. The blow molding medical bag has the advantages of reasonable structure, being convenient for mechanized filling and packaging, effectively preventing a loaded liquid from leaking and divulging. The invention can not only ensure the pollution free property during the filling and packaging processes, but also realize high speed manufacture with low cost, thus solving a plurality of defects existed in the existing perfusion bag of non PVC materials and polypropylene perfusion bottle. The preparation method can realize industrialized and mechanized manufacture and automatic filling and has the advantages of low cost and high output.

Owner:辽宁九洲龙跃药业有限公司

Embedded electrode conformations for balanced energy, power, and cost in an alkaline cell

InactiveUS7407724B2Improve capacity utilizationHigh rateElectrode manufacturing processesElectrode carriers/collectorsEngineeringBattery cell

A battery cell, such as a cylindrical or prismatic alkaline cell, is disclosed having significantly improved capacity utilization at mid-range power levels of discharge by implementing a curvilinear-like inner electrode configuration that provides moderated surface area between the inner and outer electrodes as compared to high-power discharge applications utilizing a densely corrugated geometry for the inner electrode.

Owner:RECHARGEABLE BATTERY CORP

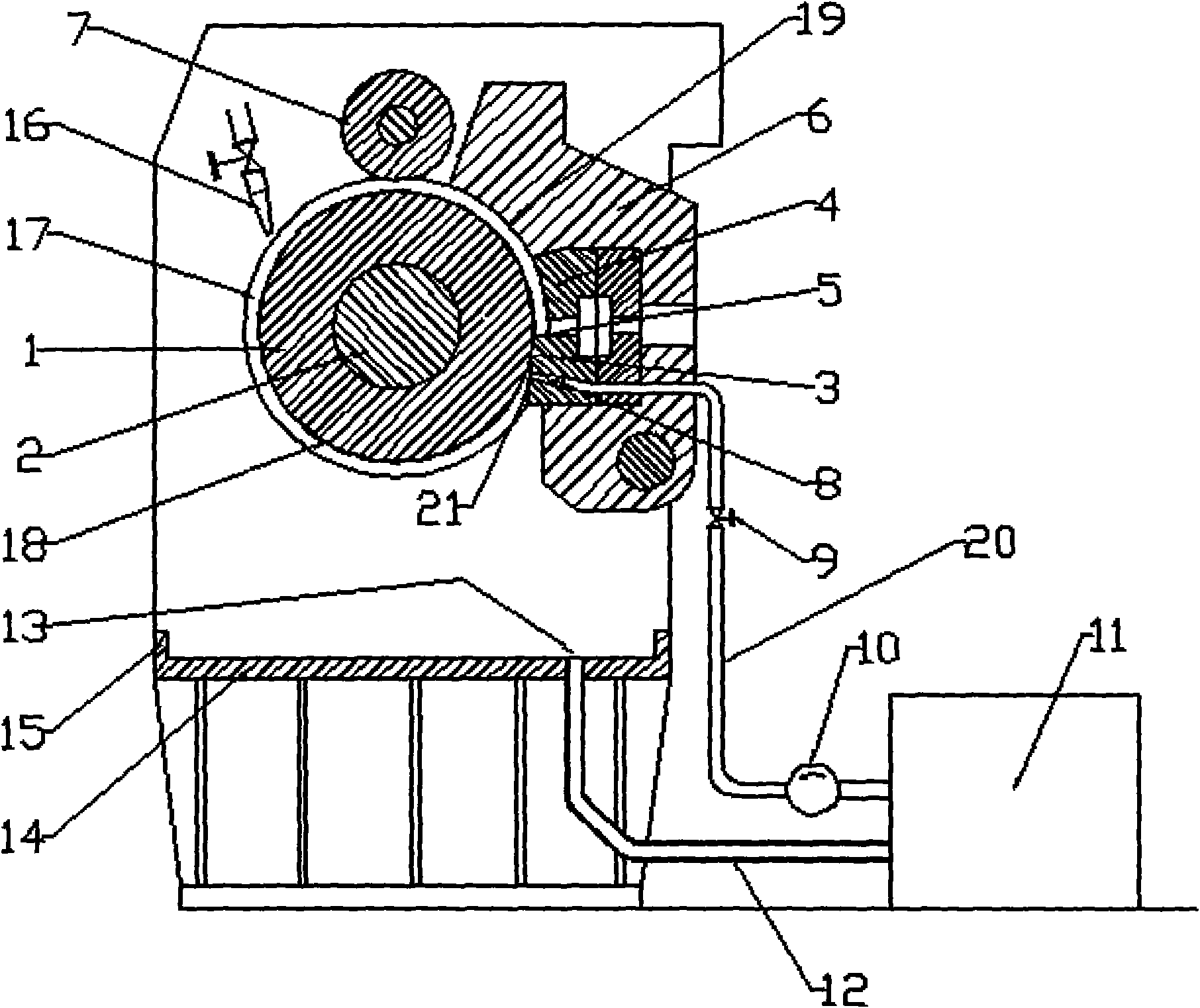

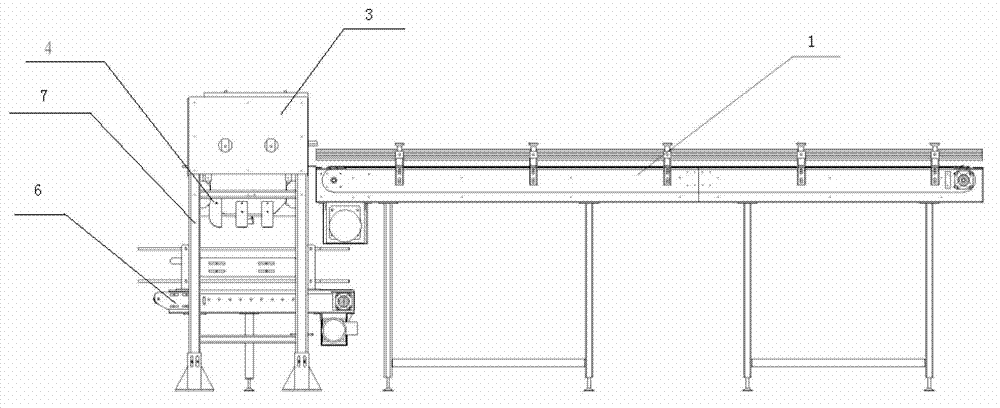

Falling type packaging machine system

The invention relates to a falling type packaging machine system which comprises a rack (7), wherein a first positioning device (3) is arranged at the upper end of the rack (7); one side of the first positioning device (3) is connected with a push device through an arranging device (8); one end of the arranging device (8) is connected with a conveyer (1); and a support device (4), a second positioning device (5) and a belt conveying device (6) are arranged at the lower end of the first positioning device (3) in sequence. With the adoption of the system provided by the invention, the steps of pushing bottles, separating the bottles, positioning cartons, putting the bottles into the cartons and the like are continuously carried out, rapid packaging is realized, the production efficiency is improved, and the high speed continuous production is realized.

Owner:上海宗义自动化设备制造有限公司

Method for batching powder and/or granular products internally of container elements and apparatus for actuating the method

ActiveUS8201591B2Reduced toleranceHigh speed productionLiquid fillingSolid materialEngineeringProduct gas

An apparatus for batching powder and / or granular products, comprising: a hopper; at least a passage, delimited at one side thereof by a gas-permeable element which alternatively communicates with a first depressed source and with a first pressurized source, and at opposite side thereof communicating with a discharge region; an obturator acting in the passage between an occluding position, in which a batching chamber is defined, and an enabling position. The obturator element is conformed such as to place the hopper in communication with the batching chamber when it is in the occluding position; the first depression source, the first pressurized source and the obturator element being activated in phase relation with one another for loading a batched quantity of powder and / or granular products internally of the batching chamber and for projecting the batched quantity internally of a container element.

Owner:MARCHESINI GROUP SPA

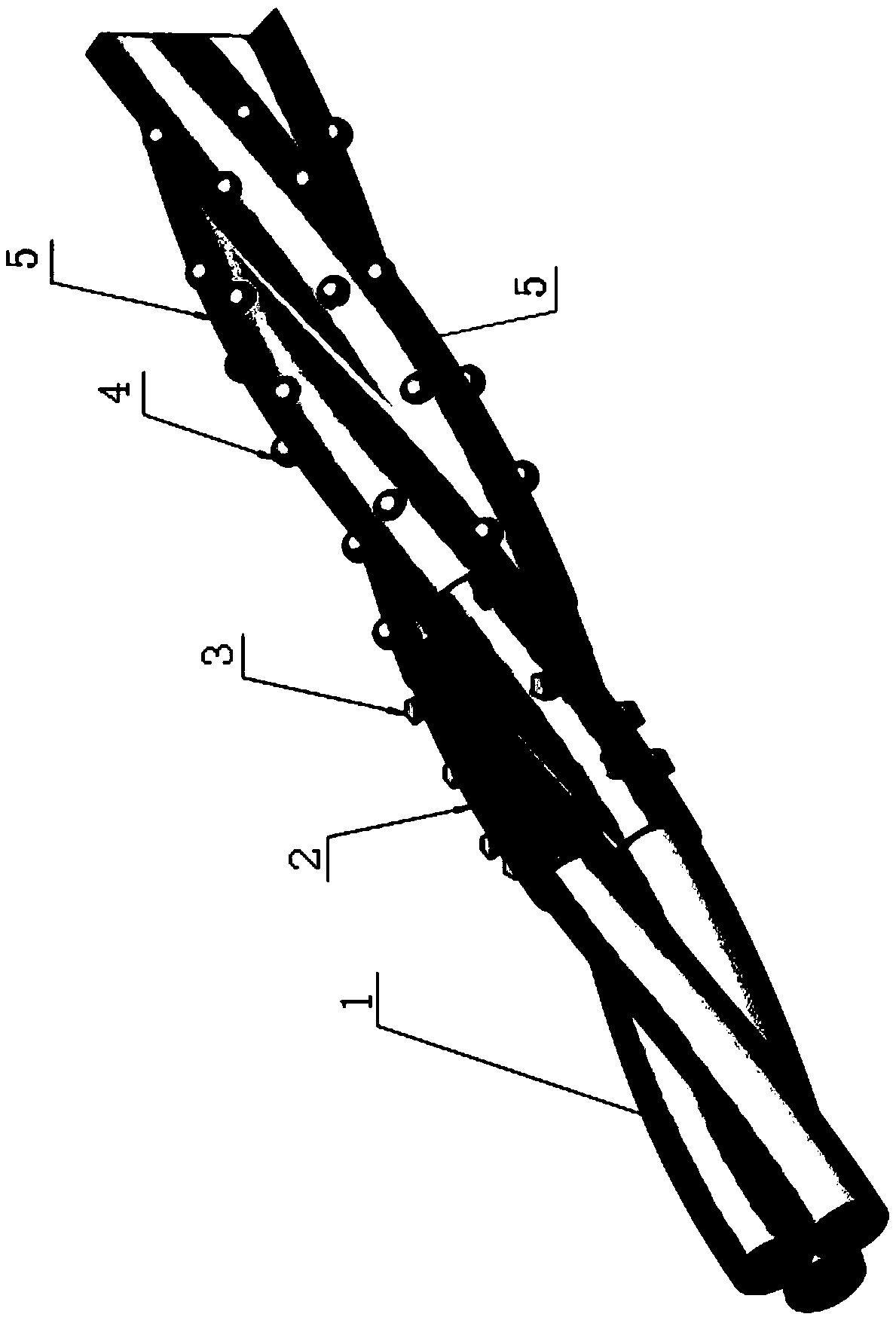

Resin consolidated abrasive diamond wire and production process thereof

InactiveCN105507047AAvoid corrosionReduce stiffnessFine working devicesCoatingsResin coatingPre treatment

The invention relates to the technical field of diamond wires, in particular to a resin consolidated abrasive diamond wire. The resin consolidated abrasive diamond wire comprises a core wire formed by twisting a plurality of steel wire strands, a brass bottom plated layer is plated on the outer side of the core wire, a consolidated resin layer is cured at the outer side of the brass bottom plated layer, and diamond micro-powder granules are distributed in the consolidated resin layer. The invention also discloses a resin consolidated abrasive diamond wire production process. The production process comprises the following steps: manufacture of the core wire; surface pretreatment; plating of the core wire bottom plated layer; resin paste coating; and resin diamond wire curing. Compared with an electroplated diamond wire, the resin diamond wire produced by the process has the advantages that corrosion caused by a solution accumulated in the space of a wire core part can be avoided due to no contact with a water-phase electrolyte solution during production of the resin combined diamond wire. Compared with a metal combination layer of the electroplated wire, the resin layer is low in rigidity, so that the thickness of an effected layer of a cut surface of a processed workpiece is lower than that of the electroplated wire, and the stress of a section is small. Resin coating and curing can be finished in two stages, thereby realizing high-speed production and reducing production cost greatly.

Owner:盛利维尔(常州)金属材料有限公司

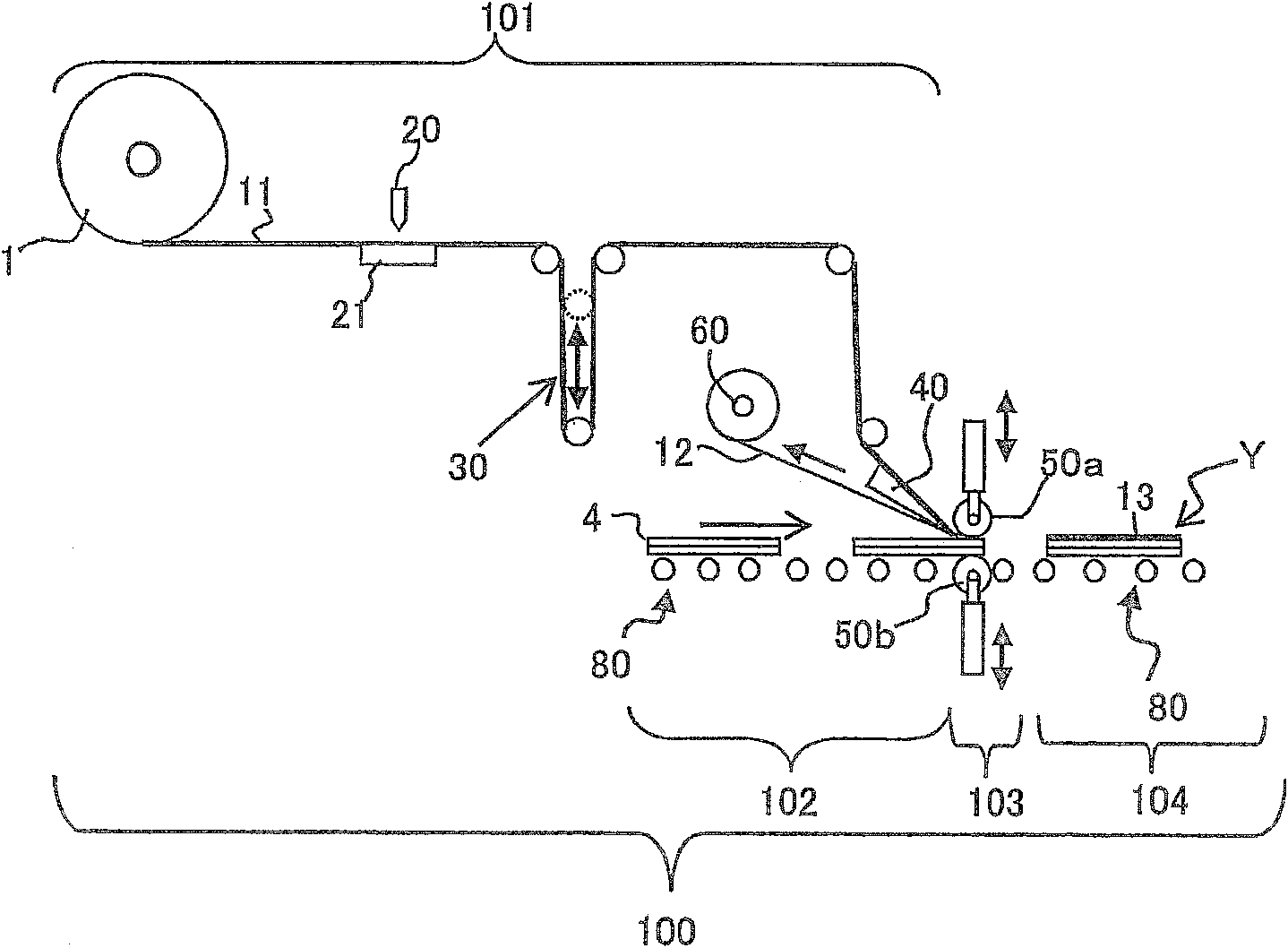

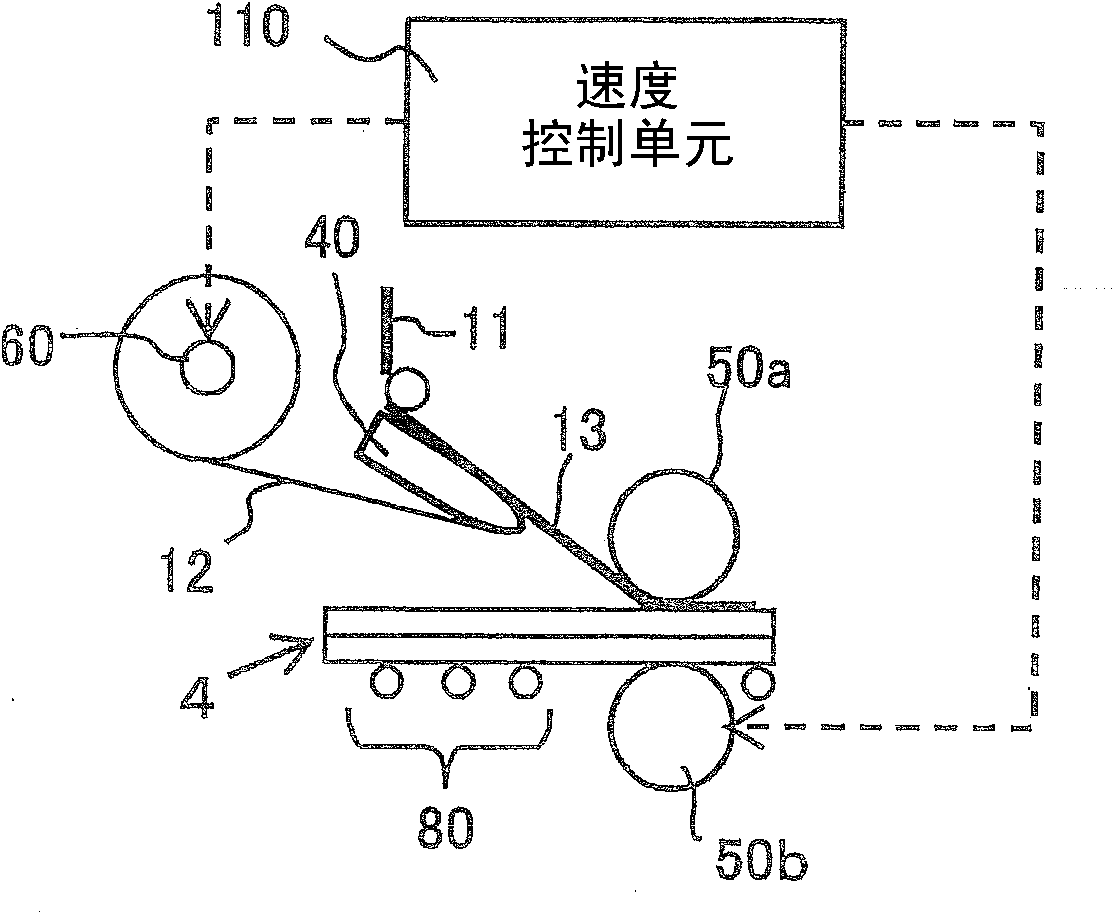

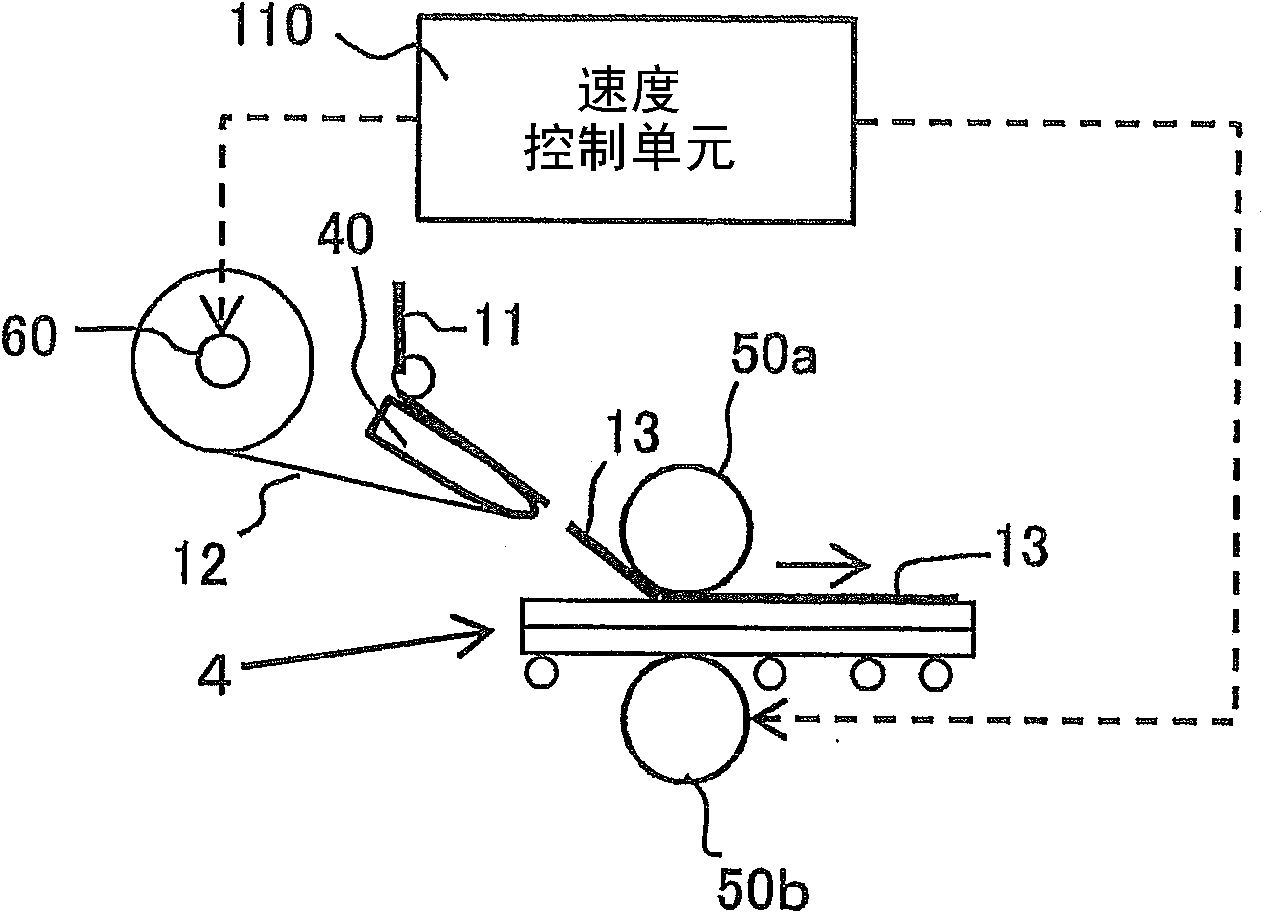

Continuous manufacturing system and continuous manufacturing method of liquid crystal display element

ActiveCN102419490AHigh speed productionImprove stopping accuracyLayered product treatmentControlling laminationLiquid-crystal displayAdhesive

The invention relates to a continuous manufacturing system of a liquid crystal display element. The continuous manufacturing system is provided with a peeling unit which is used to peel a film sheet from a carrier film, a reeling unit which is used to reel the carrier film, a pasting unit which is used to paste the film sheet to a liquid crystal panel via an adhesive to form a liquid crystal display element, a speed control unit which is used to control the reeling unit and the pasting unit. In the process that the film sheet is pasted on the liquid crystal panel, during the period from the film sheet is pasted on the liquid crystal panel to the film sheet is peeled from the carrier film via the front end of the peeling unit, the carrier film reeling speed of the reeling unit V1 and the pasting speed of the pasting unit V2 satisfy the equation: V1 is equal to V2. The moment before the film sheet is peeled from the carrier film via the front end of the peeling unit to be pasted on the liquid crystal panel and after the film sheet is pasted on the liquid crystal panel, the V1 is smaller than V2. The continuous manufacturing system can prevent the adhesive dropping and adhesive residual when the polarized film is pasted on the liquid crystal panel.

Owner:NITTO DENKO CORP

Production method of heat-sealing self-adhesive medical dialyzing paper

ActiveCN110939009AImprove surface bond strengthHigh bonding strengthWater-repelling agents additionPulp beating methodsProcess engineeringSizing

The invention discloses a production method of heat-sealing self-adhesive medical dialyzing paper. The production method comprises the following steps: pulping a pulp; pulping; preparing materials; forming on a net; squeezing and dehydrating; drying and surface sizing; drying, transferring and coating; calendaring and coiling; rewinding and packaging to obtain a finished product. According to themedical dialyzing paper prepared by the method, the indexes of air permeability and bonding strength can meet the use requirements of the medical industry, the production of base paper and an adhesivelayer is completed in a papermaking machine in one time, the medical dialyzing paper is directly used for manufacturing medical packaging paper plastic bags, the equipment, labor and transportation cost can be saved, and the efficiency is greatly improved.

Owner:安徽华邦古楼新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com