Metal insert positioning and loading device in injection moulding process

An injection molding process and metal insert technology, applied in coating and other directions, can solve the problems of high labor intensity, high labor intensity and slow feeding speed of workers, so as to reduce the risk of defective parts, reduce labor intensity, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

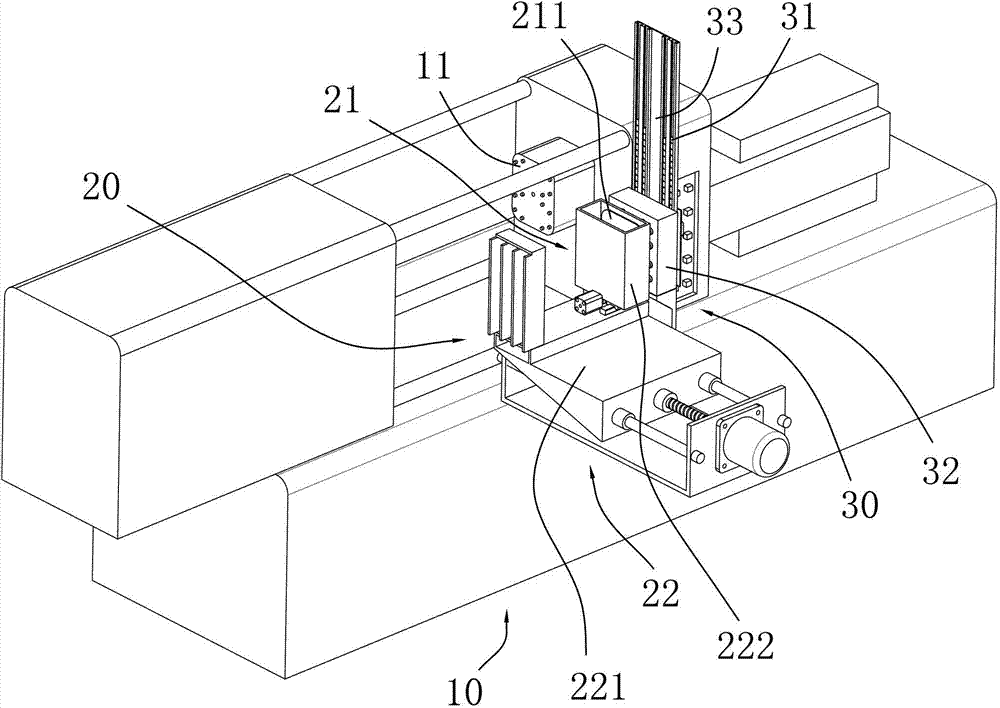

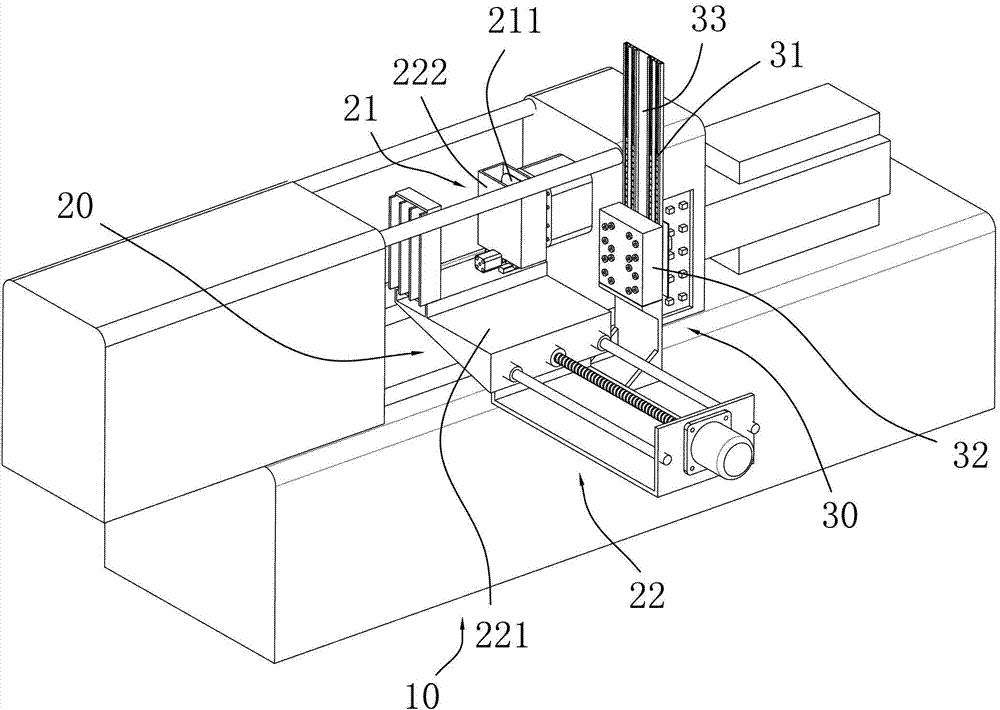

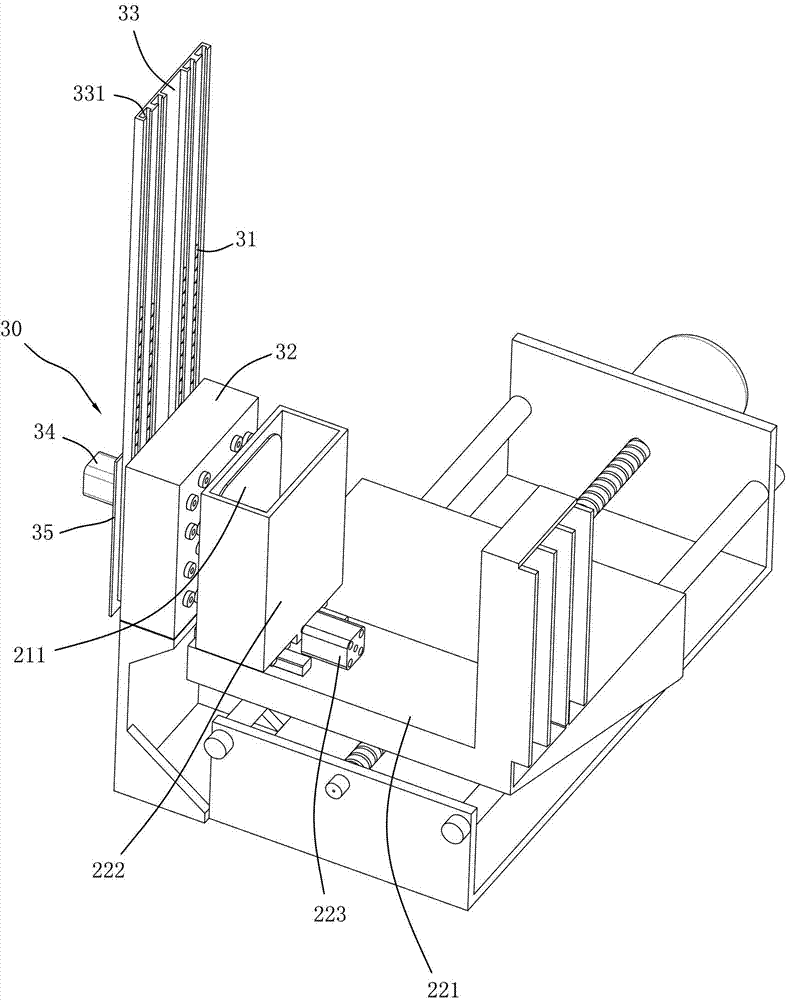

[0028] refer to Figure 1 to Figure 11 , a metal insert positioning and feeding device in the injection molding process, which is used to fill and position the metal insert into the cavity of the injection mold, including an insert feeding part 30 on which a metal insert 31 is stored on the body 10 And the insert positioning mechanism 20, the insert positioning mechanism 20 includes a magnetic adsorption device 21 that can absorb the metal insert 31 in the insert supply part 30 and drives the magnetic adsorption device after the magnetic adsorption device 21 absorbs the metal insert 31 21 moves to the injection mold to load the metal insert 31 into the driving device 22 positioned in the mold cavity 11 .

[0029] In this embodiment, the metal insert 31 is an annular metal insert, and a plurality of metal inserts 31 arranged in a fixed shape are loaded and positioned into the mold cavity 11 through the positioning and feeding device.

[0030] The insert feeding part 30 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com