Micro-wire annealing tin plating machine production line

A technology of tinning machine and production line, which is applied in the direction of hot-dip plating process, coating, furnace type, etc. It can solve the problems of unreachable process and no production capacity, etc., and achieve the effects of saving time, beautiful effect and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

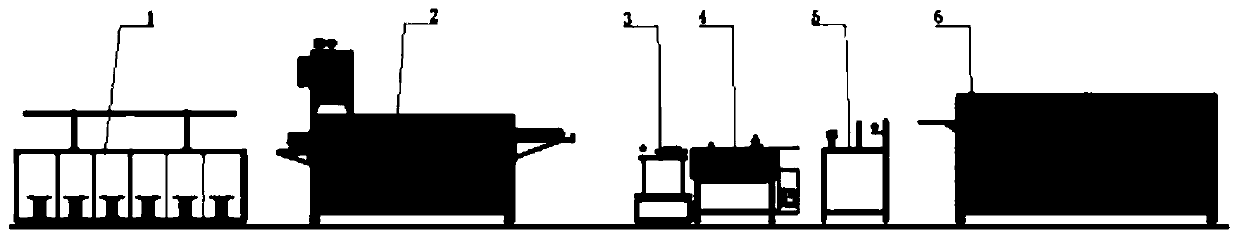

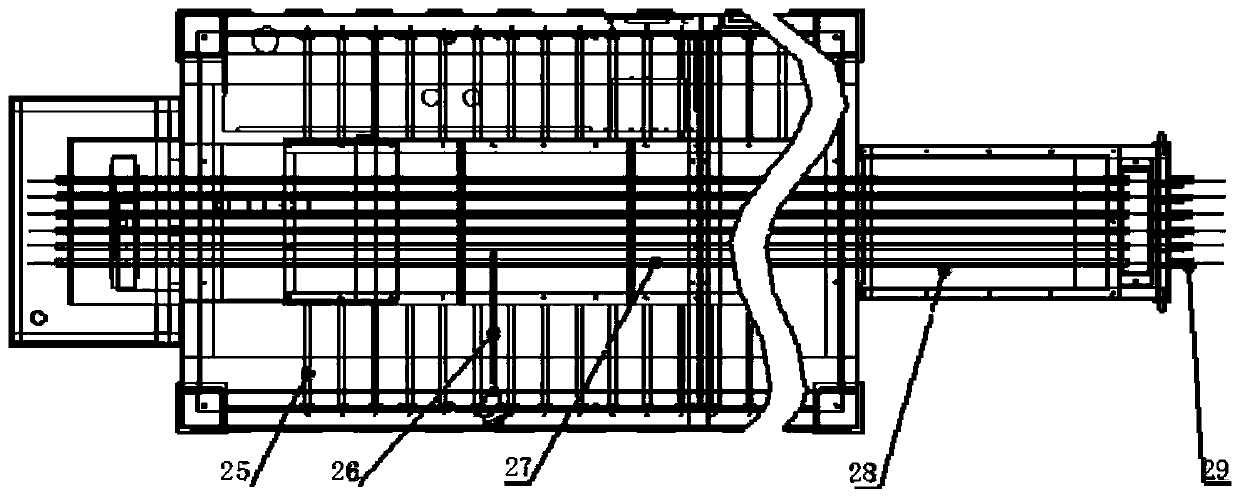

[0039] see Figure 1-10 , a micro-wire annealing and tinning machine production line, including a pay-off frame 1, please refer to Figure 1-7 , the lower end of the pay-off frame 1 is provided with a base, and the upper end of the base is respectively fixedly connected with an annealing furnace 2, a pickling tank 3, a tin furnace 4, a wire guide wheel group 5 and a wire take-up machine 6;

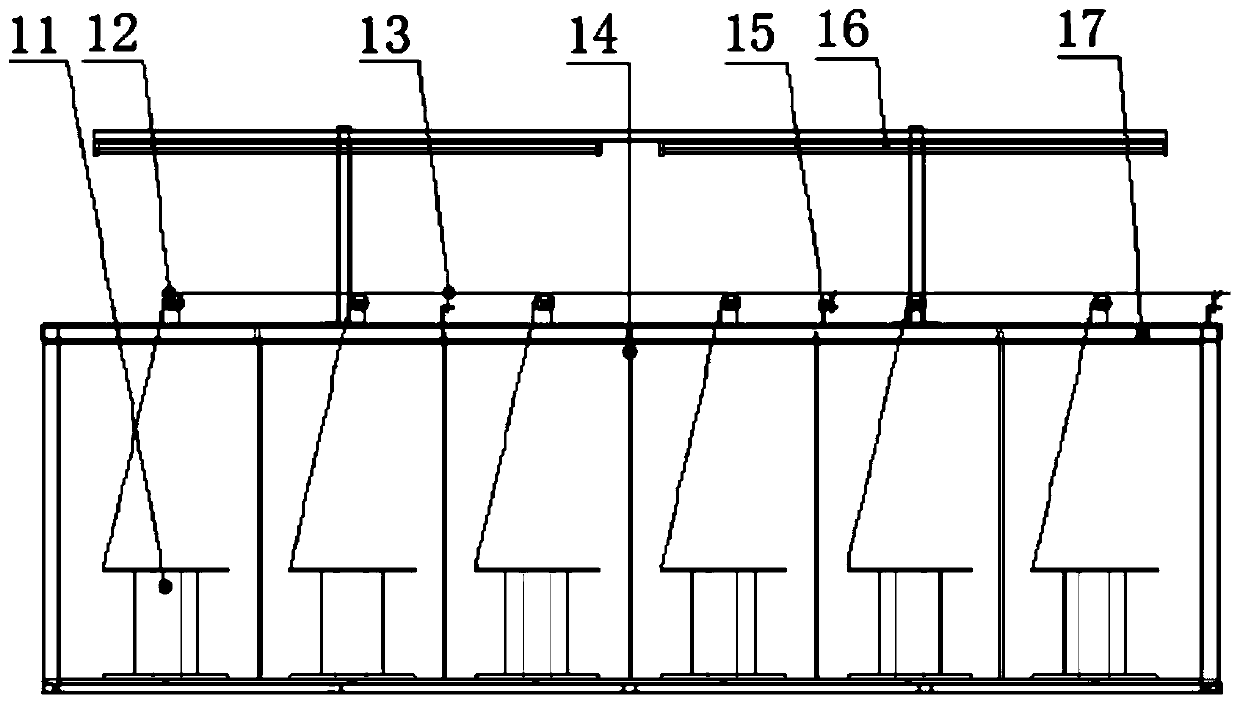

[0040] The pay-off rack 1 is provided with a spool 11, the surface of the pay-off rack 1 is provided with a first wire passing guide wheel 12, the surface of the pay-off rack 1 is provided with a pig tail fixing plate 15, and the pig tail wire passing plate 15 is provided with a passing Wire pig tail 13, the anti-breakage partition 14 is provided with in the pay-off rack 1, and the lighting lamp 16 is arranged on the pay-off rack 1, and the traditional pay-off rack generally is according to the number of heads of the equipment, and each of the two sides of the pay-off rack Half of the spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com