Patents

Literature

99results about How to "Production standardization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

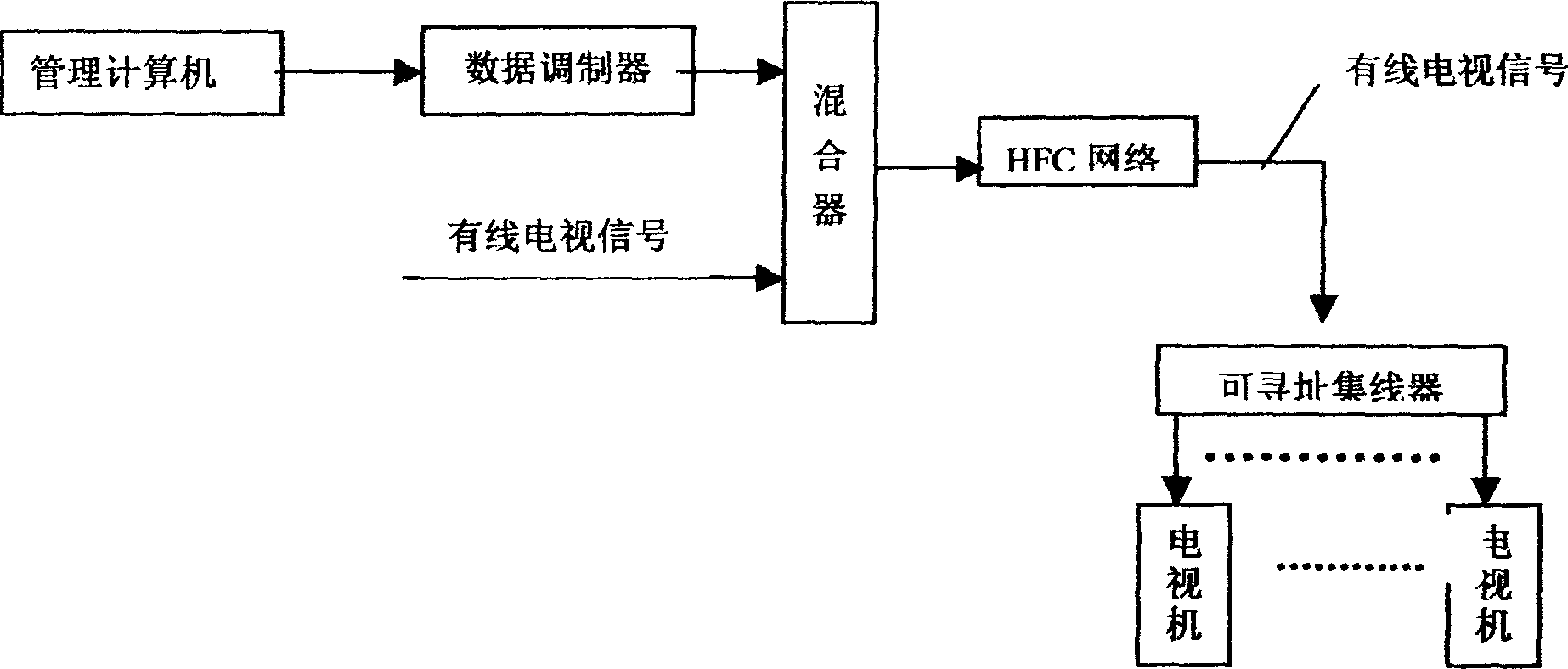

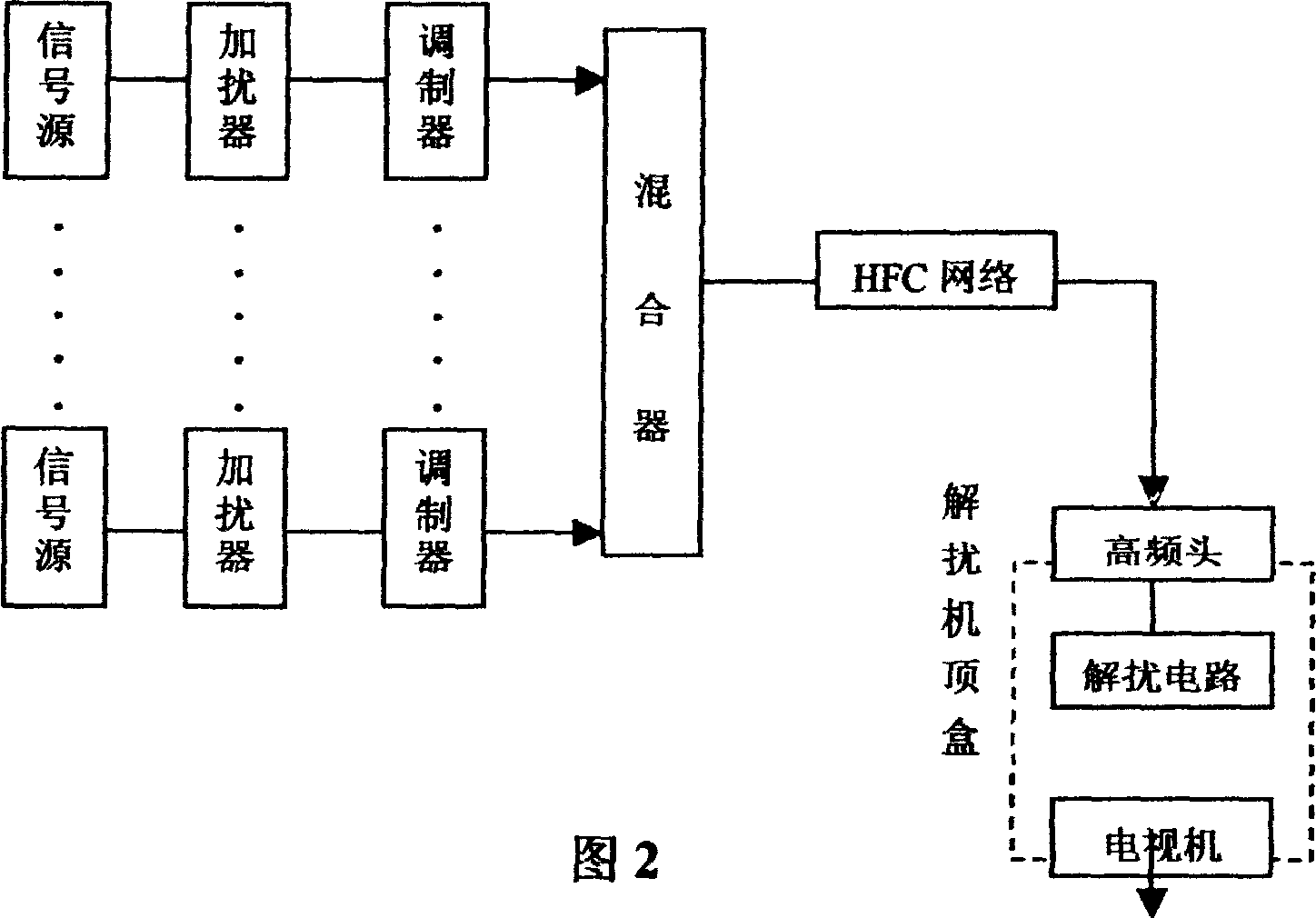

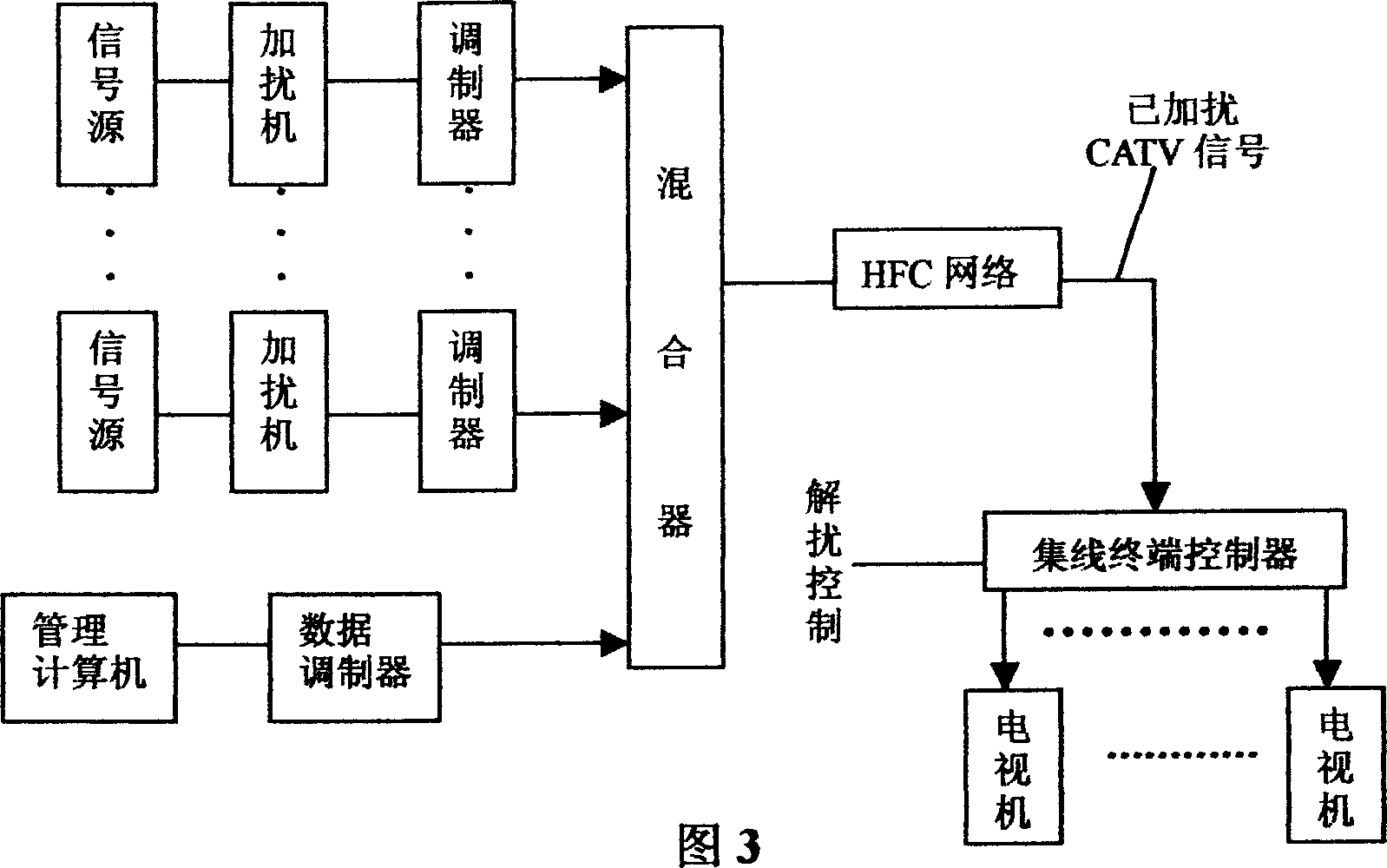

Remote controlled single channel outputting method for concentrating controller in digital analog Tv-set

InactiveCN1615017ARealize the mouthpiece functionAdapting to the choice of autonomyElectrical cable transmission adaptationRemote controlTerminal equipment

The invention consists of: TV station signal output device; HFC transmission network; hub and descramble controller; user terminal device. The remote control for single channel output at the mode of signal processing combining channel processing can make scramble / descramble of digital cable TV more efficiency, safety.

Owner:梁光海

Continuous carbon fiber reinforced composite material for bone repair

The continuous carbon fiber reinforced composite material for bone repair is prepared with continuous carbon fiber, continuous carbon fiber felt or continuous carbon fiber, cloth through soaking in methyl methacrylate monomer or pre-polymer and subsequent extruding or bulk molding. The composite material of the present invention includes methyl methacrylate and carbon fiber, and the carbon fiber content is 20-80 wt%. The composite material may be used as the external fracture fixing material, internal fracture fixing material and bone repairing material. The composite material has the features of light weight, no interference on NMR examination and excellent biocompatibility. It may be implanted inside life body without negative effect on tissue, blood, etc.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Production of polyaniline micro/nanometer fibre

Production of polyphenyl micro / nanometer fiber is carried out by polymerizing by oil / water two-phase interface in proportion of oxidant concentration: monomer concentration>=2:4, reactive medium in water phase can be organic acid or organic benzenesulfonic acid and reactive medium concentration is >=0.5mol / L. It has standard production and more yield.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

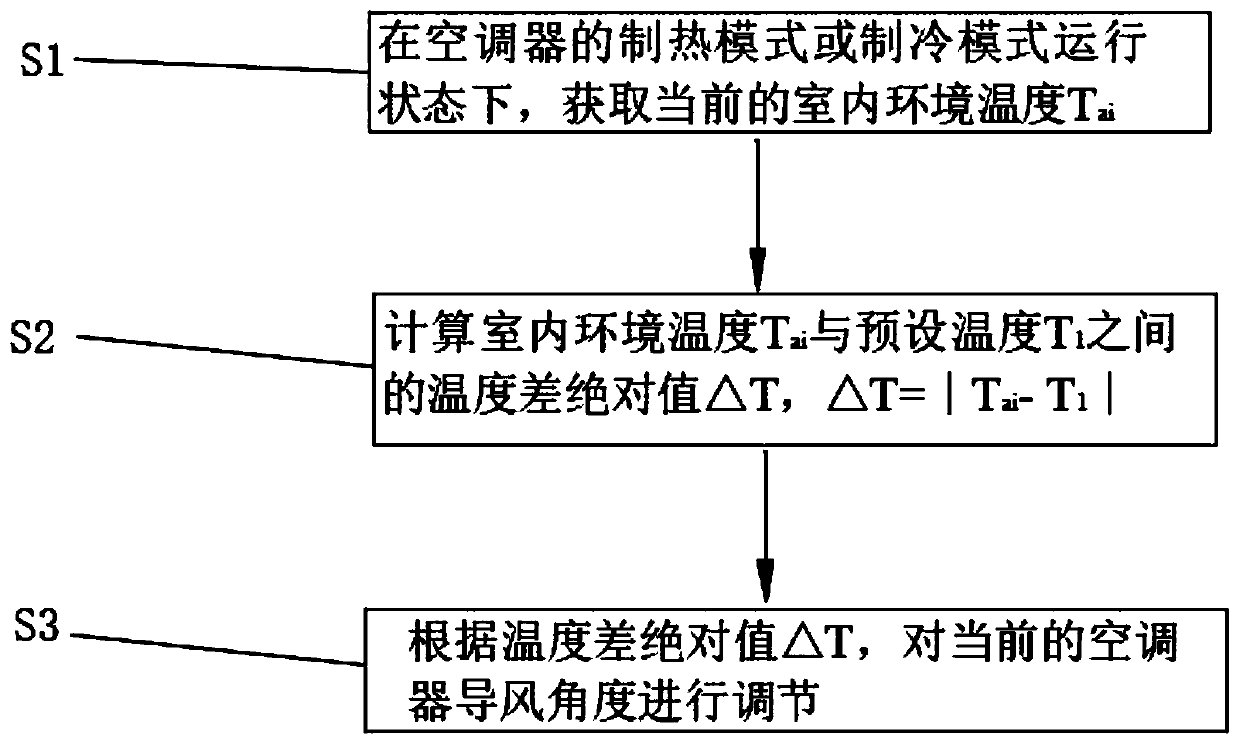

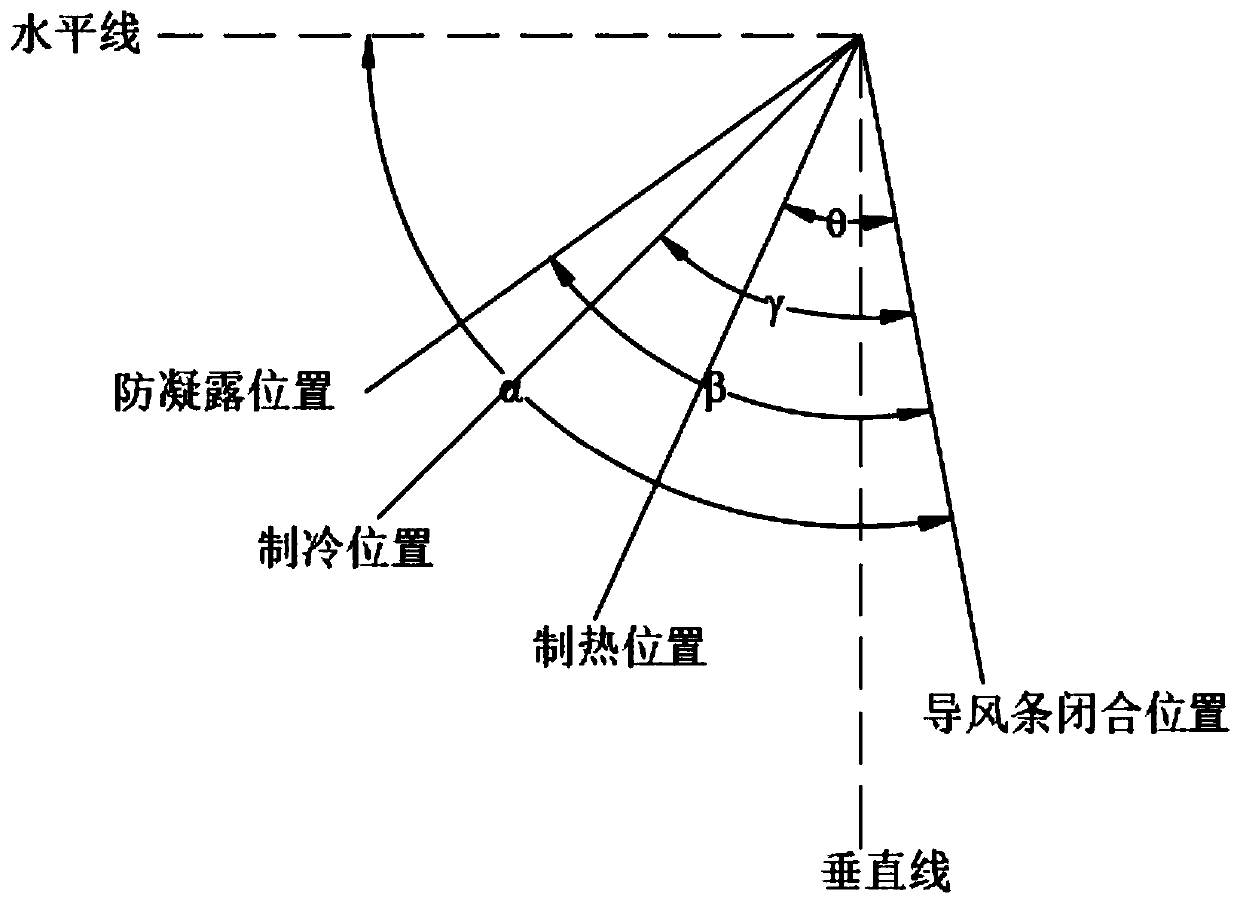

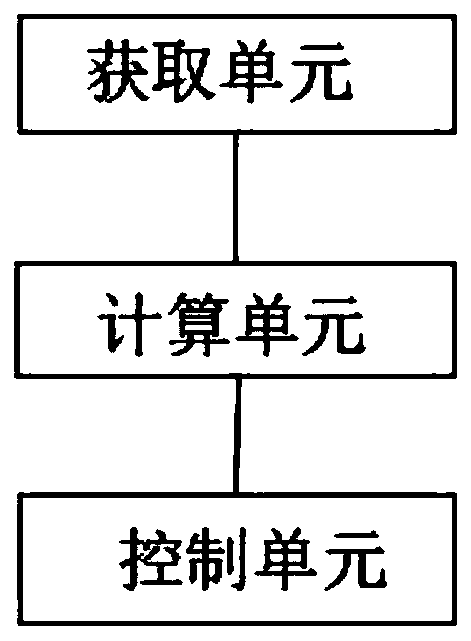

Wind guide angle control method and device and air conditioner

ActiveCN110195922AReasonable judgmentProduction standardizationMechanical apparatusCondensate preventionTemperature differenceEngineering

The invention provides a wind guide angle control method and system and an air conditioner. The window guide angle control method includes the steps that the current indoor environment temperature Taiis obtained under the operation state of a heating mode or a refrigerating mode of the air conditioner; the temperature difference absolute value deltaT between the indoor environment temperature Taiand a preset temperature T1 is calculated, wherein deltaT equals to the absolute value of Tai-T1; and according to the temperature difference absolute value deltaT, the current wind guide angle of the air conditioner is adjusted. The wind guide angle control method and system and the air conditioner have the beneficial effects that by comparing the indoor environment temperature Tai with the preset temperature T1, the wind guide angle of the air conditioner is adjusted in time according to comparison conditions, so that the wind guide angle is more flexible to adjust, and the use satisfactiondegree of a user is better.

Owner:NINGBO AUX ELECTRIC

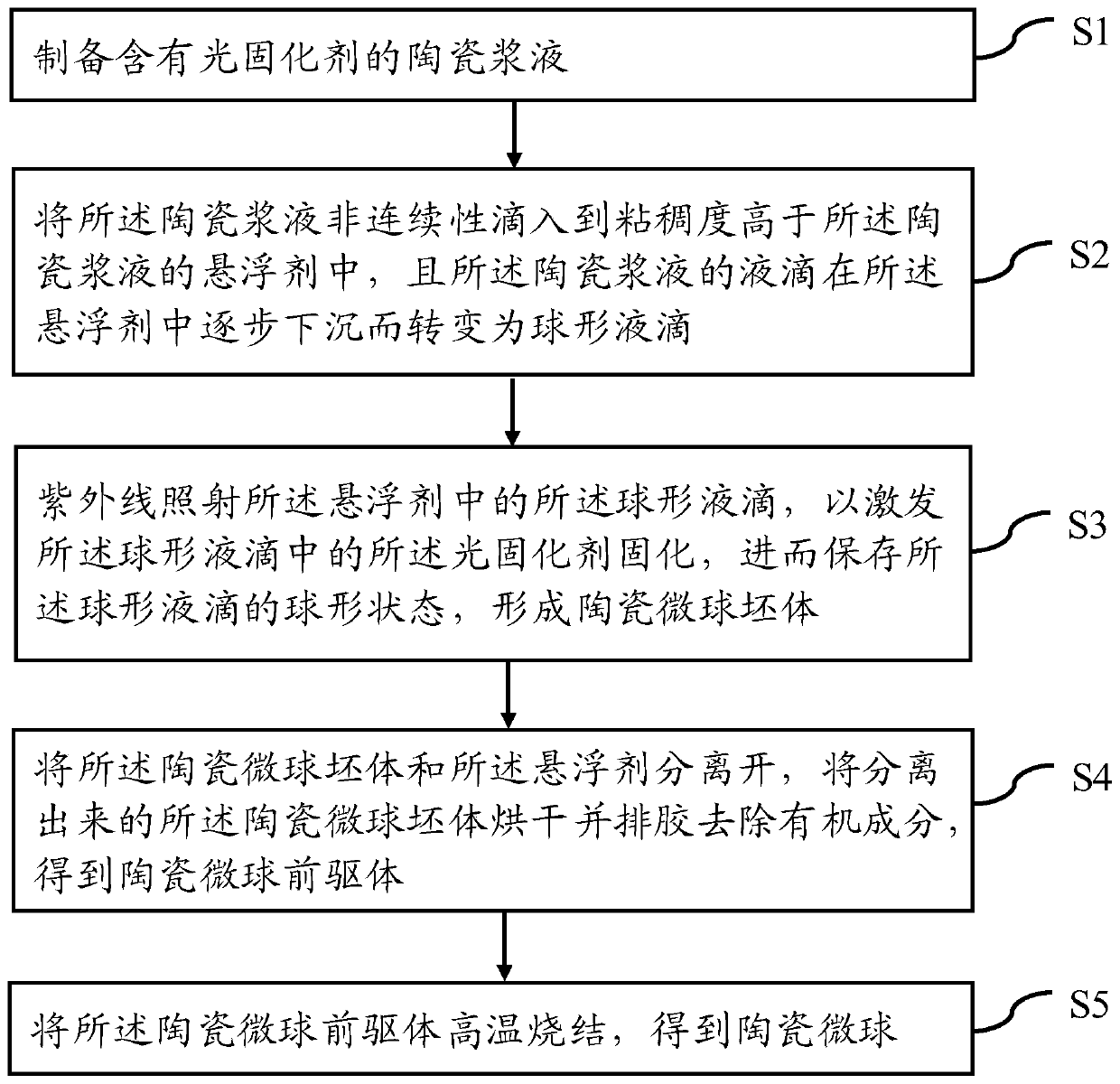

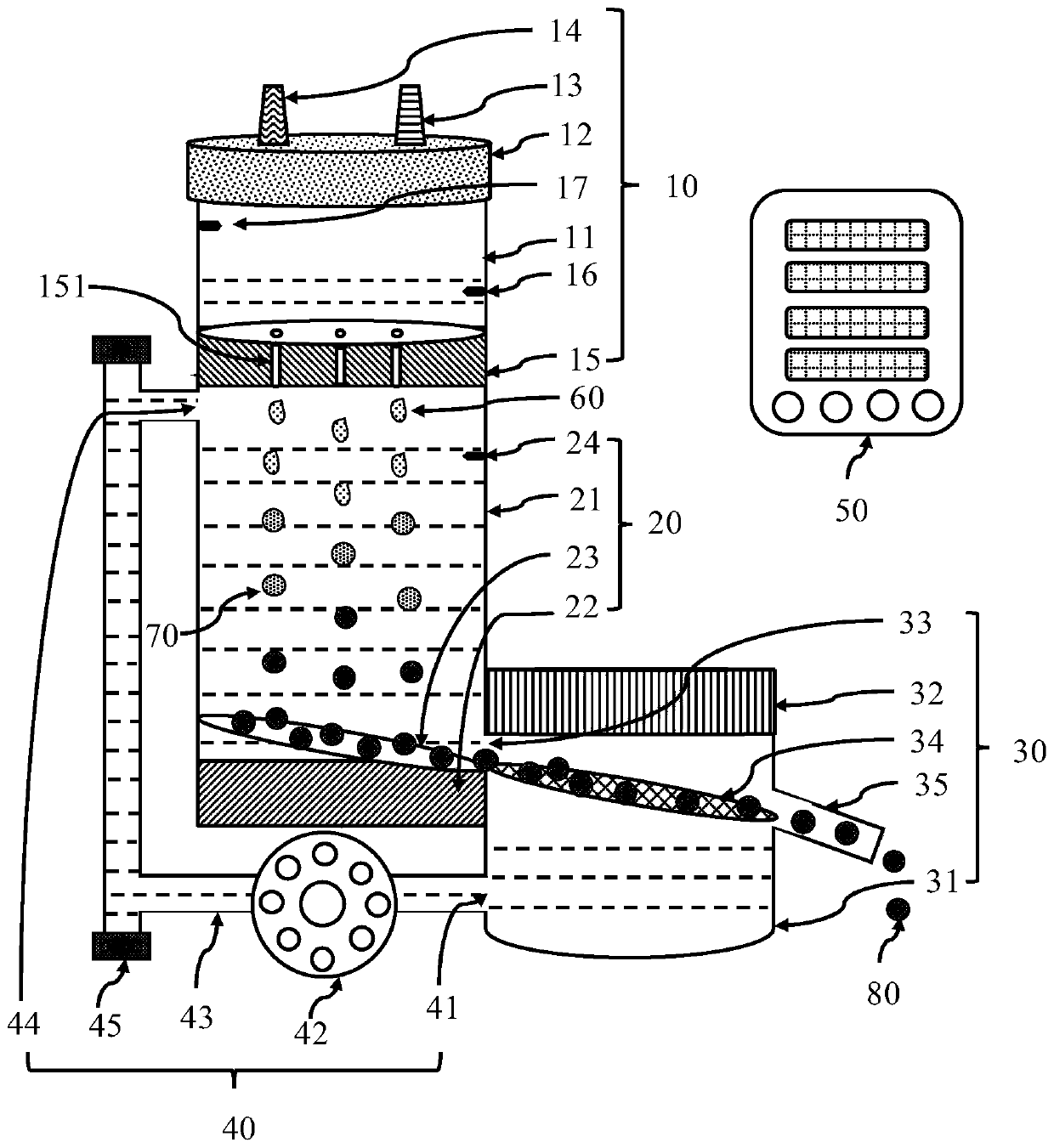

Ceramic microsphere as well as method and device for preparing ceramic microsphere by using suspension photo-curing method

ActiveCN110154201AChemically stableReduced Chances of ContaminationGranulation by liquid drop formationCeramic shaping apparatusMicron scaleMicrosphere

The invention provides a ceramic microsphere as well as a method and a device for preparing the ceramic microsphere by using a suspension photo-curing method. The method for preparing the ceramic microsphere by the suspension photo-curing method comprises the following steps that ceramic slurry containing a photo-curing agent is dropped in a suspending agent in a non-continuity mode, and liquid drops of the ceramic slurry are gradually sunken in the suspending agent to be converted into spherical liquid drops; the spherical liquid drops are irradiated by ultraviolet rays so as to excite the photo-curing agent in the spherical liquid drops to be solidified, and then a ceramic microsphere green body is formed; the separated ceramic microsphere green body is dried and discharged glue so as toremove organic components, and a ceramic microsphere precursor is obtained; and the ceramic microsphere precursor is sintered at high temperature to obtain the ceramic microsphere. According to the technical scheme of the method and device, the morphology, the size and the internal structure of the prepared ceramic microsphere are more controllable, so that the preparation of the ceramic microsphere is standardized, systematized, automatic and large-scale, and the ceramic microsphere with the micron-scale particle size can be prepared.

Owner:SHANGHAI BIO LU BIOMATERIALS

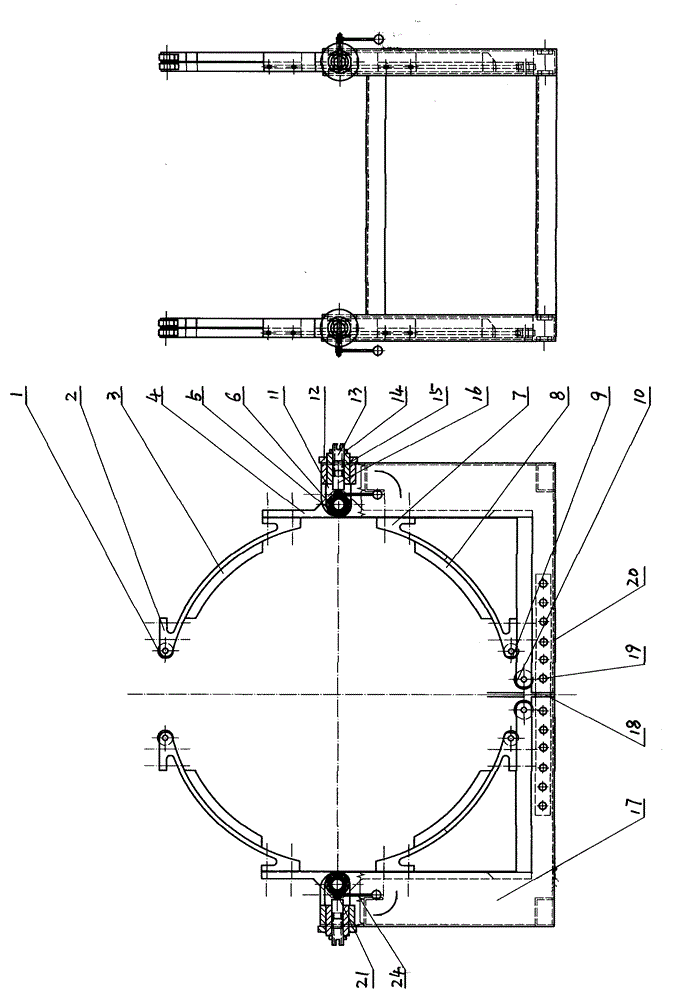

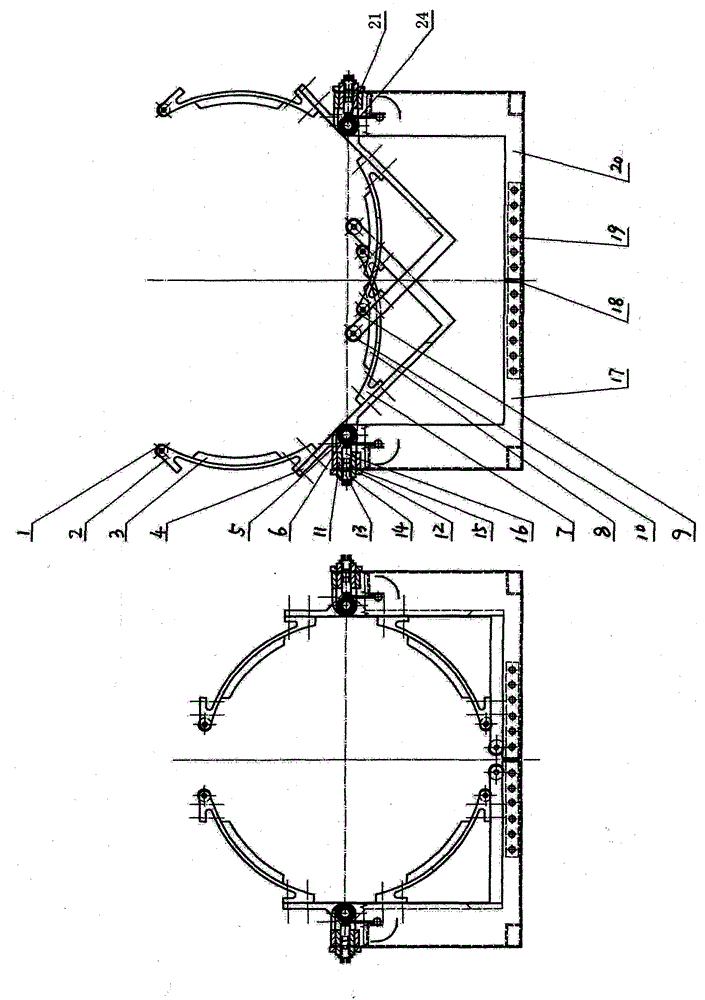

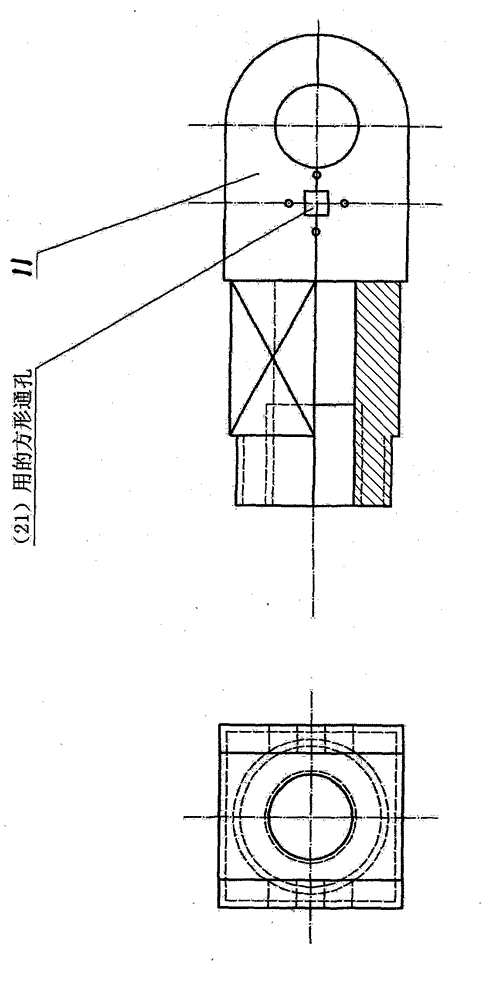

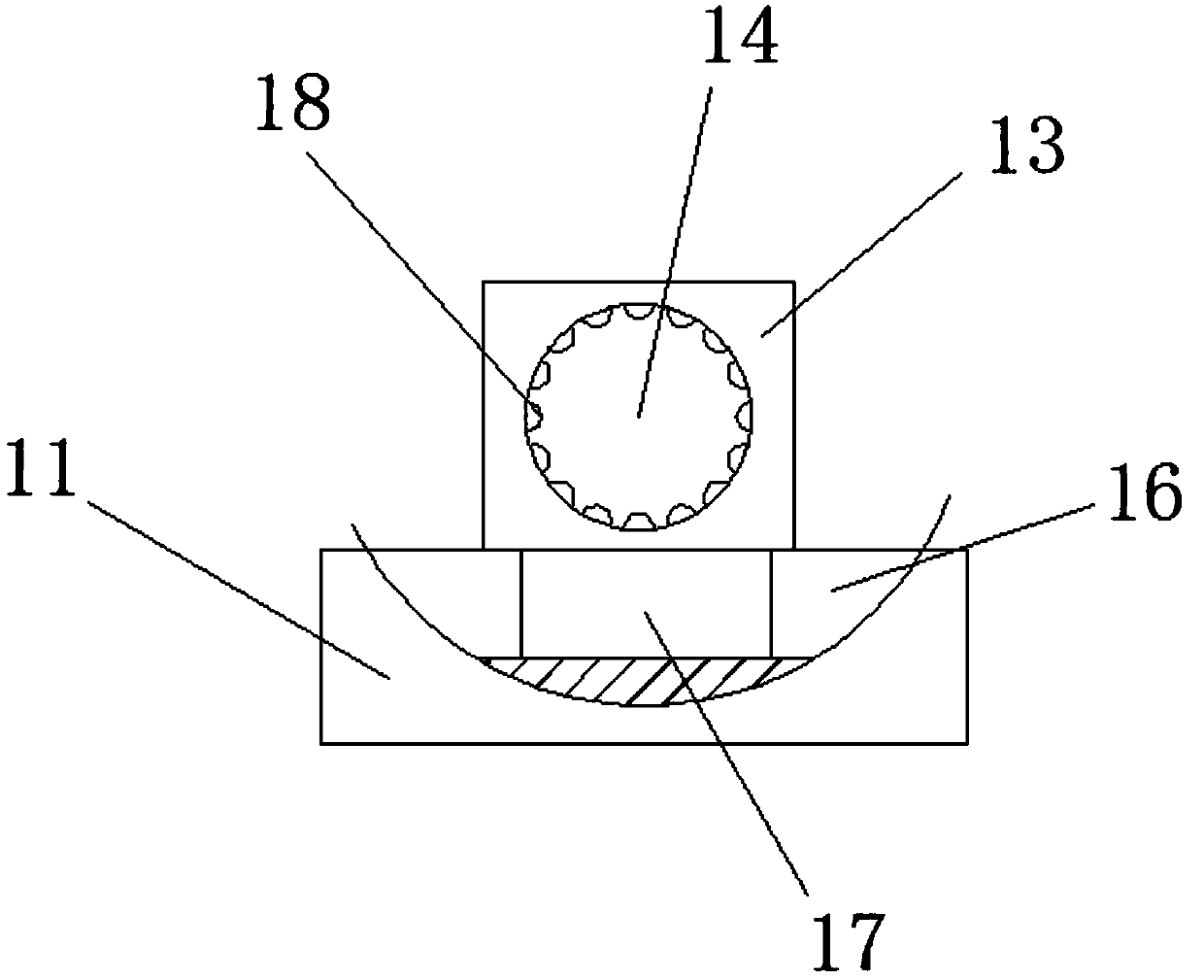

Automatic gravity gripper

ActiveCN104058182AStrong interchangeabilityFast loading and unloadingExternal framesEngineeringMechanical engineering

The invention relates to a gripper for transportation and storage. The gripper consists of a gripper seat assembly, a square shaft assembly, groove-shaped movable gripping head assemblies and a spine lock assembly, wherein the gripper seat assembly looks like a square with a half capable of being separated and combined, and the gripper seat assembly is fastened integrally through screws and adjusting connecting plates; the square shaft assembly is fastened on square holes for square shafts of the gripper seat assembly through fastening nuts; each groove-shaped movable gripping head assembly looks like a bow, the left and right groove-shaped movable gripping head assemblies can be matched to form a sleeved ring which can be opened and closed, and the groove-shaped movable gripping head assemblies are mounted in hinge pin holes in front ends of the square shafts through hinge pins and can be freely opened at 45 degrees-135 degrees; the spine lock assembly penetrates through round spine lock assembly through holes above the front side of the gripper seat assembly and is fastened on the square shafts through screws. The automatic gravity gripper is generally applicable to transportation and storage, and parts are high in interchangeability and can be produced in batches in a standard manner (the automatic gravity gripper can also be assembled on a liftable trolley and is quick, convenient and safe in object transportation, loading and unloading).

Owner:江苏北华微电子科技有限公司

Modernization production method of traditional Feng goose

InactiveCN1341386AReduce fishy smellQuality assuranceFood preparationBiotechnologyChinese traditional

The industrial production method of Chinese traditional air-dried goose includes the following steps: mechanically-killing live goose, eviscerating, poaching, dewatering, curing in specially-made pickle to make salt component and natural spice infiltrate into goose body, and mechanically air-drying and controlling air-drying temp., relative humidity and air-speed in the required range so as to obtain the invented air-dried raw goose with high protein, low-fat and unique flavour. Said invention raises its production efficiency, stabilizes product quality and can implement large-scale production.

Owner:扬州馋神食品有限公司

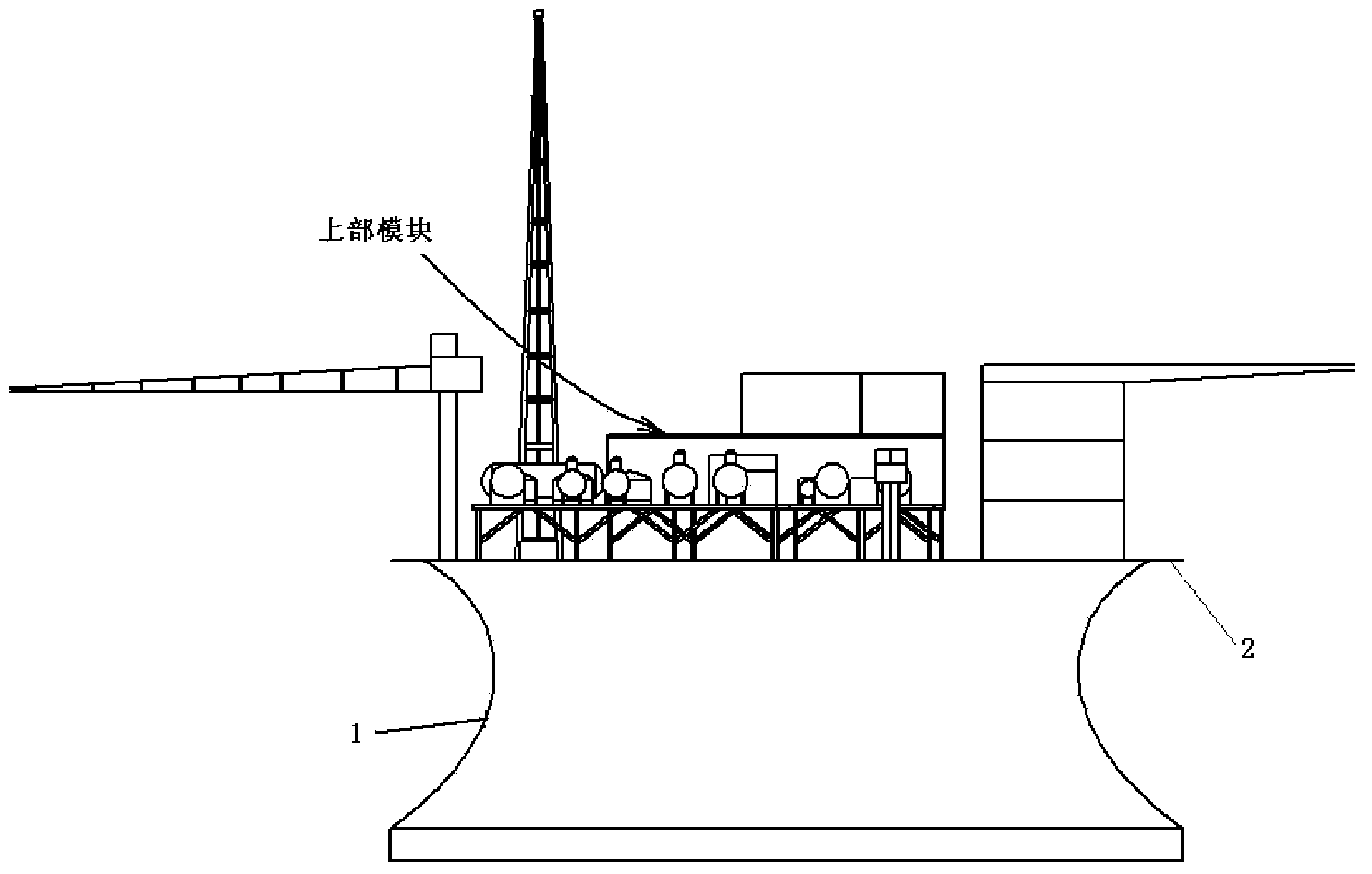

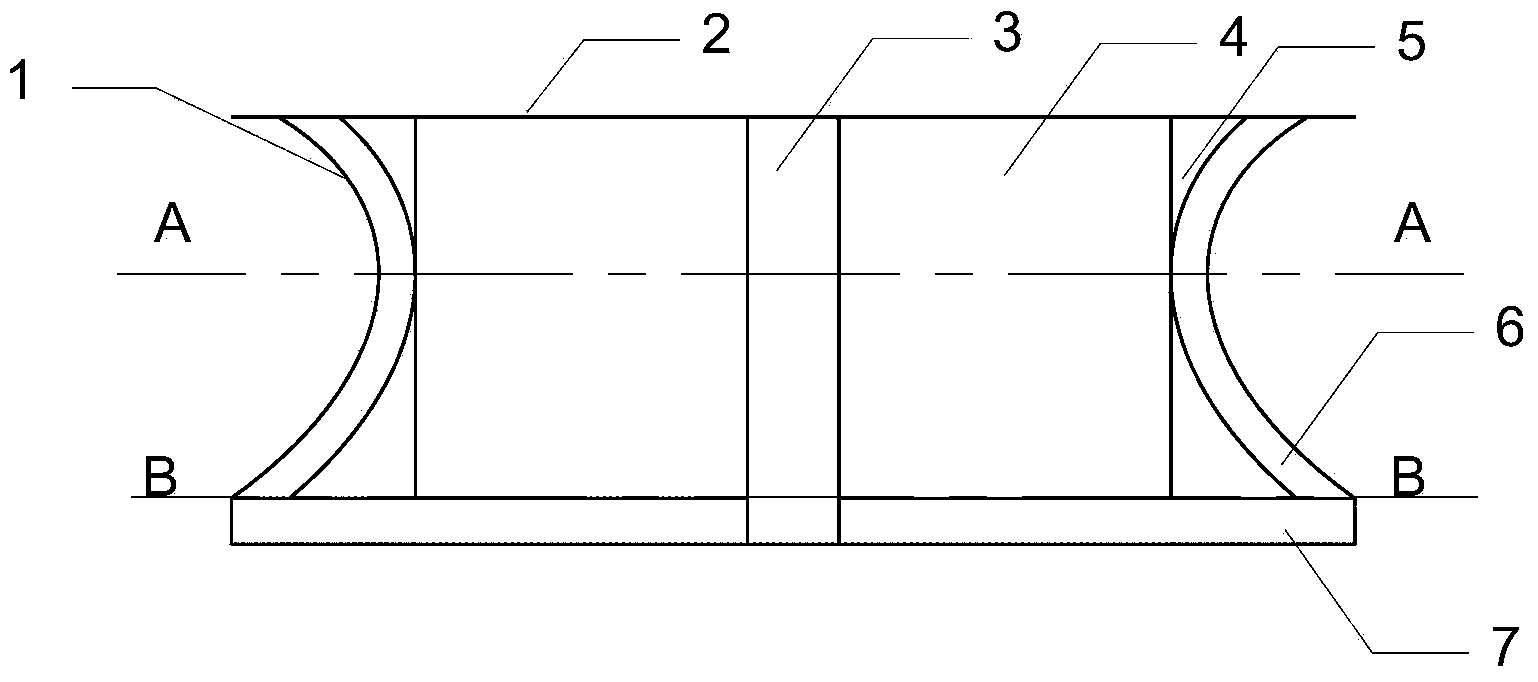

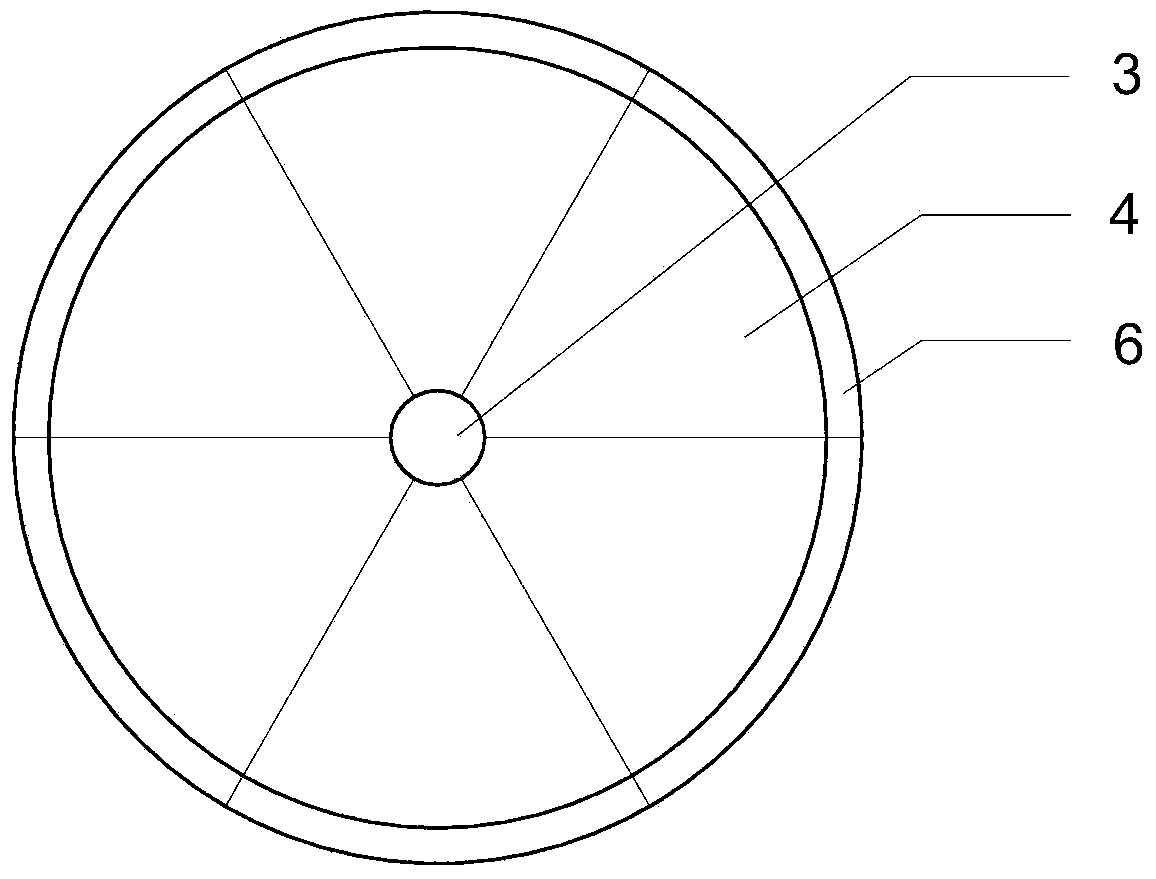

Double-curved-surface floating type production oil storage platform

InactiveCN103895828AImprove stabilityIncrease the usable areaFloating buildingsHyperboloidMarine engineering

The invention discloses a double-curved-surface floating type production oil storage platform. The platform comprises a floating body and a production deck. The vertical section of the floating body is of a uniparted hyperboloid shape or a rotary uniparted hyperboloid shape. A cylindrical central cabin is disposed in the middle of the floating body and along the axial direction of the floating body. An annular oil storage canine is disposed along the outer wall of the central cabin. The production deck is disposed on the upper end face of the floating body and provided with an oil-gas processing module, a water injection module, a water processing module, a power supply and distribution module, an auxiliary production module and a living building module. The platform has the advantages that the inherent defects of ship FPSO are overcome, the advantages of convenient moving and repeated using of traditional FPSO are inherited, stability and hydrodynamic performance of the platform are further improved, oil storage efficiency and bearing capacity are increased, building difficulty and cost are lowered, and a novel device is provided for efficient development of offshore oil fields.

Owner:SINOPEC PETROLEUM ENG DESIGN

Production of polyaniline micro/nanometer fibre

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

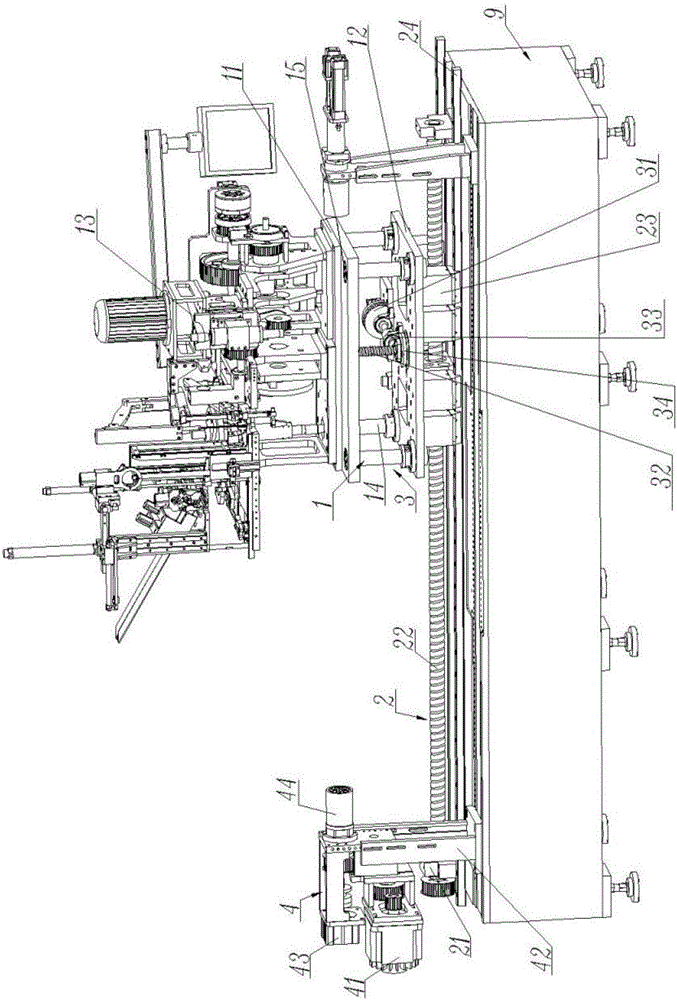

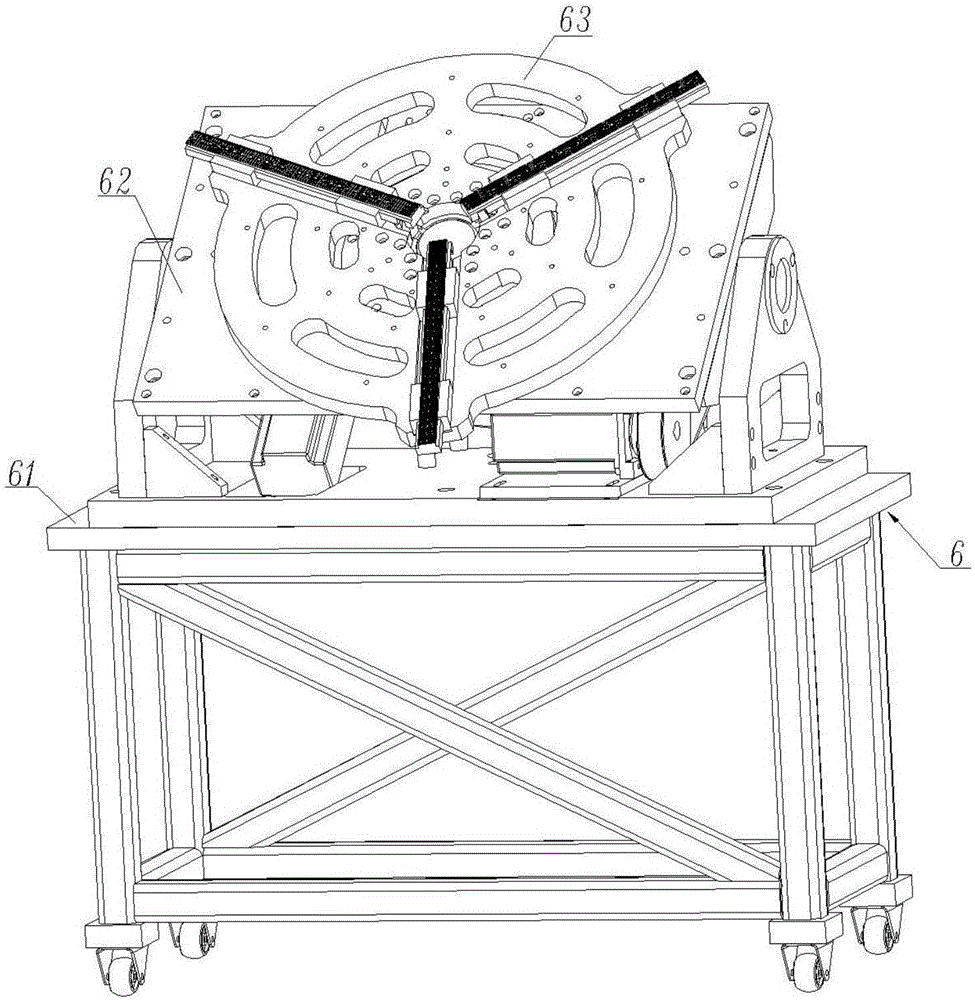

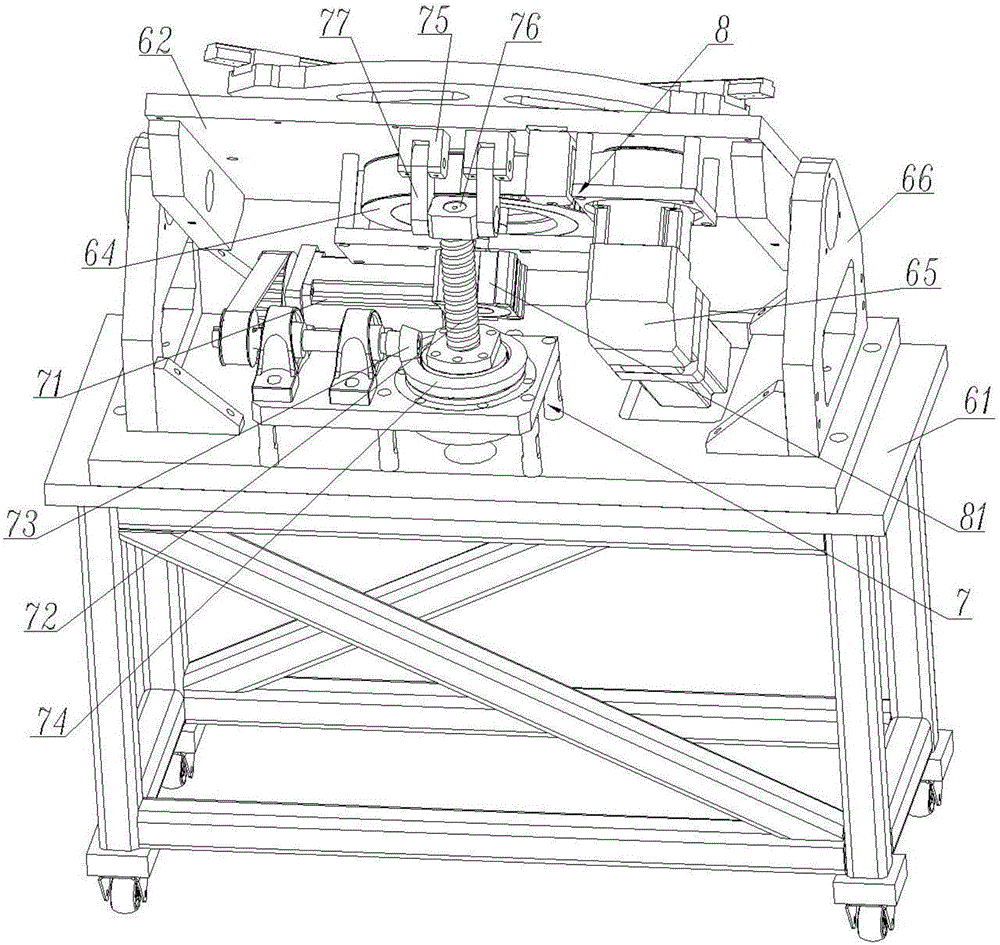

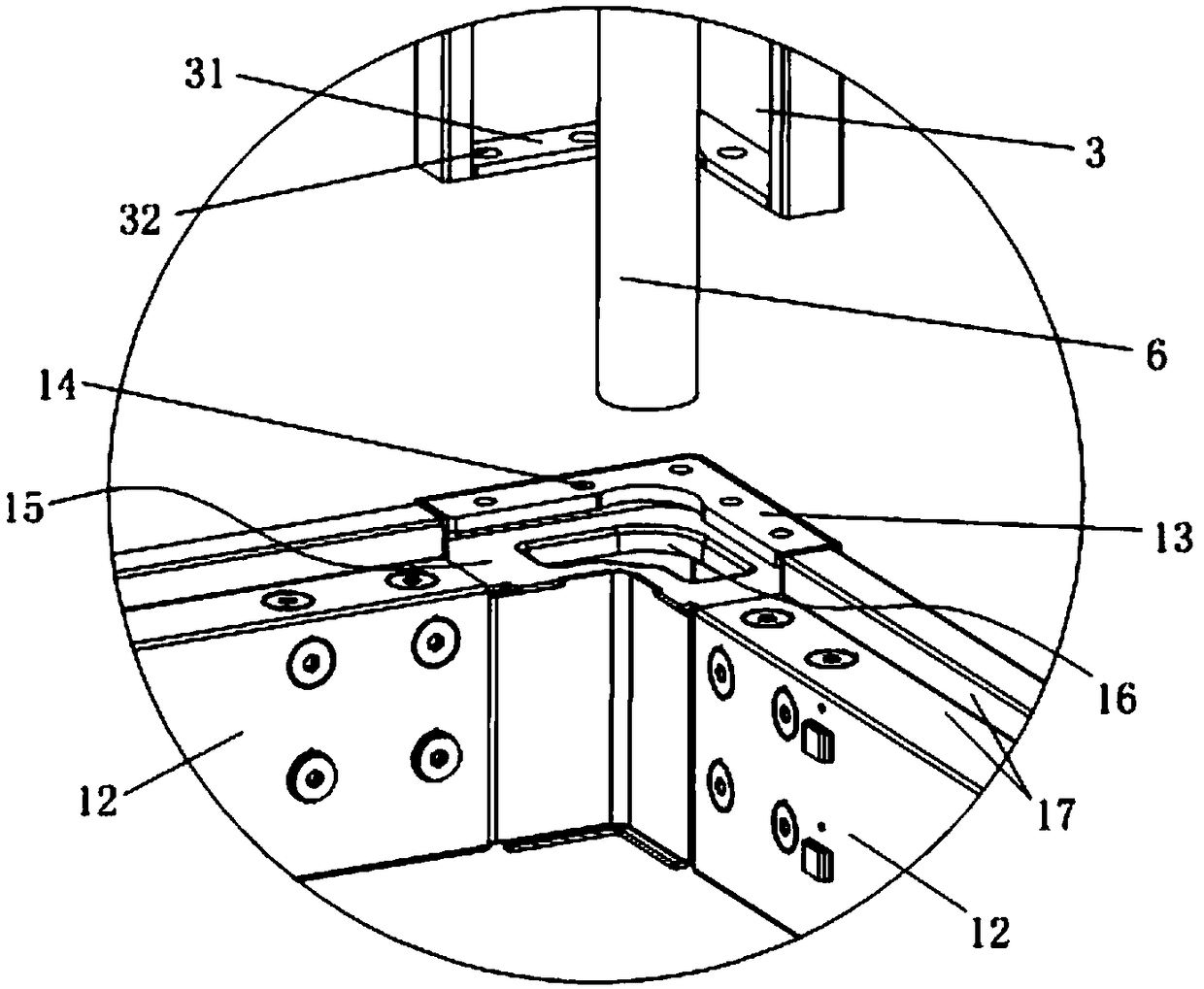

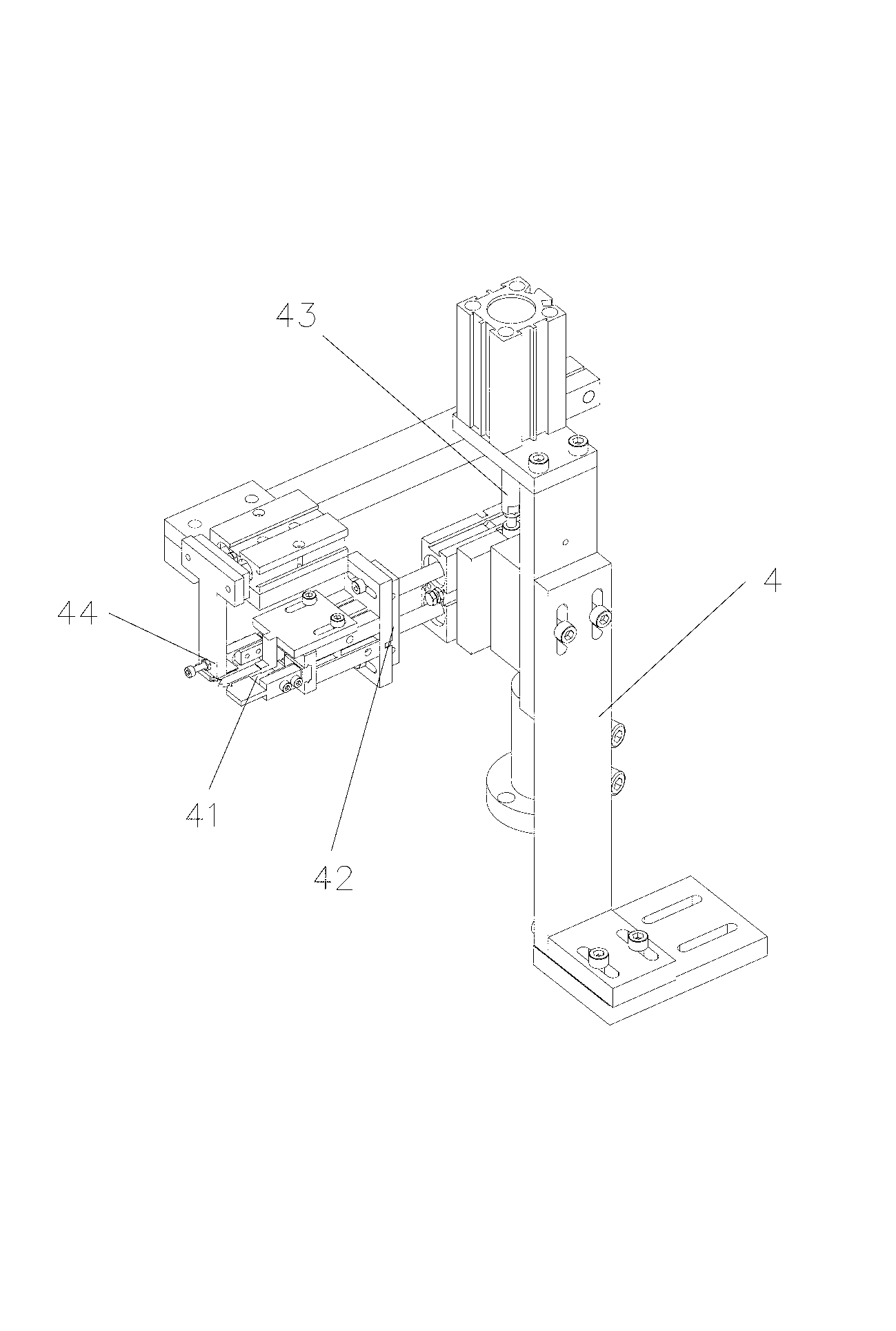

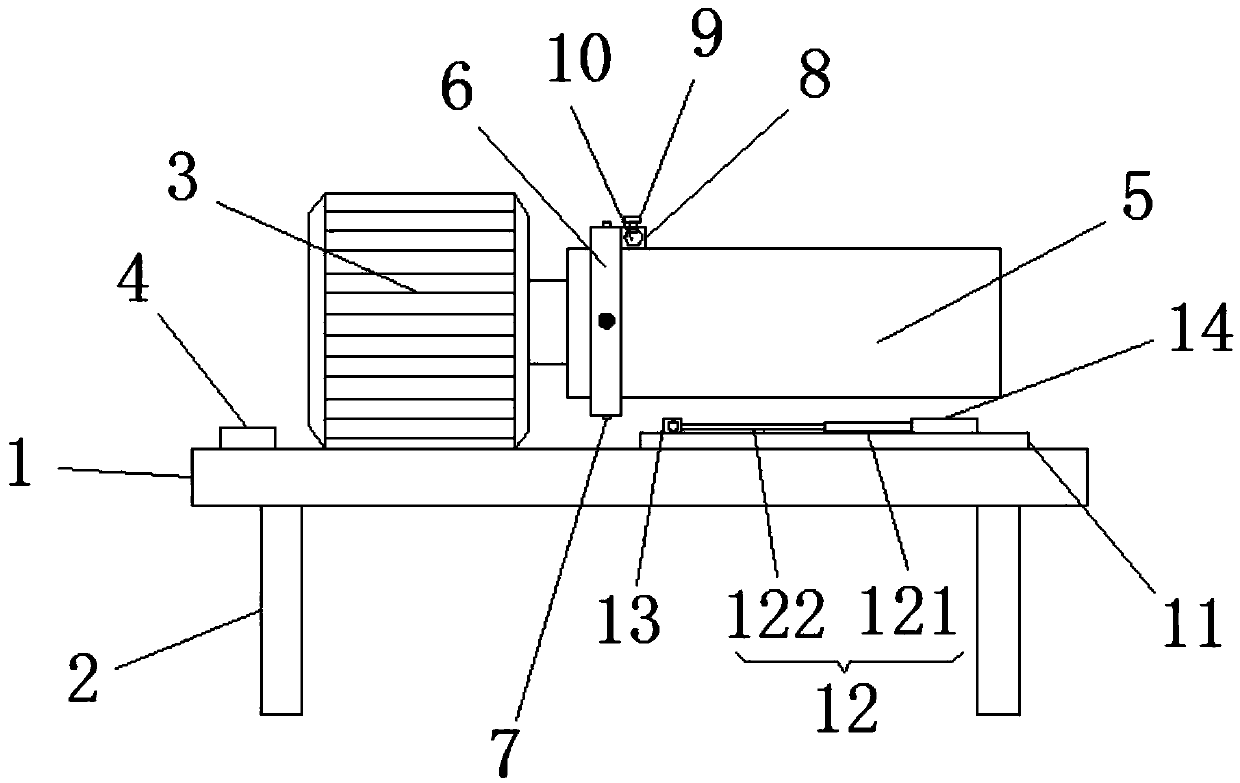

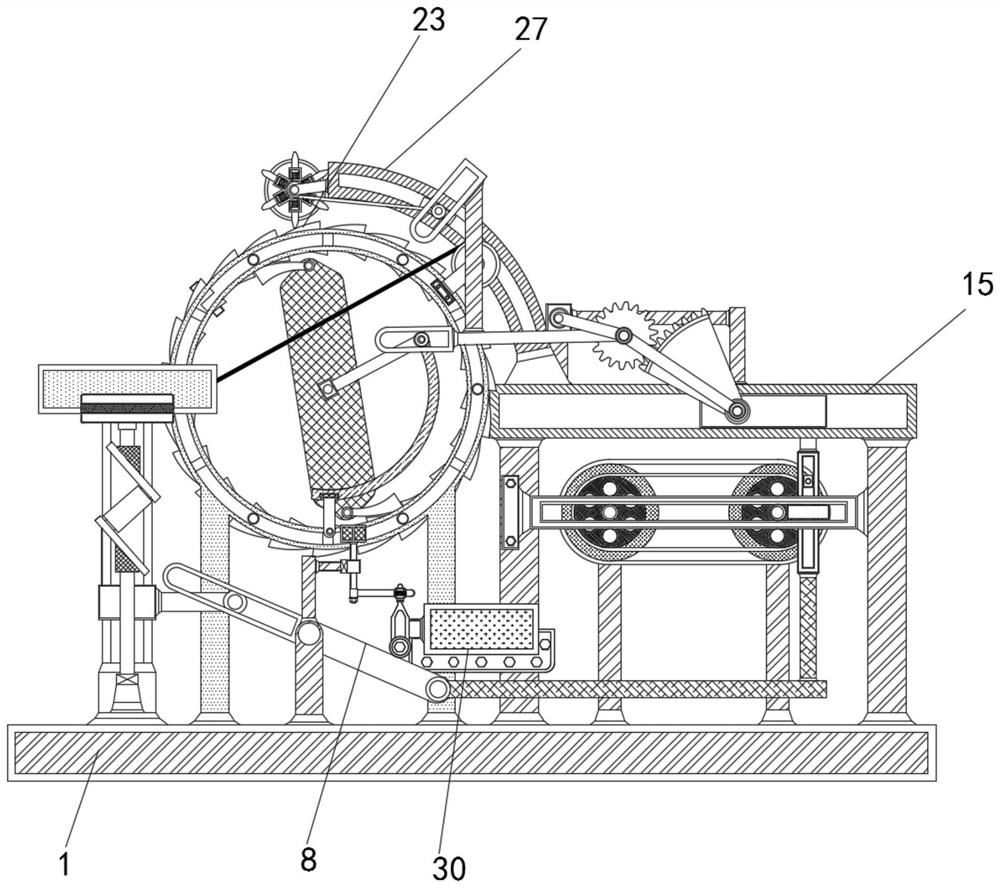

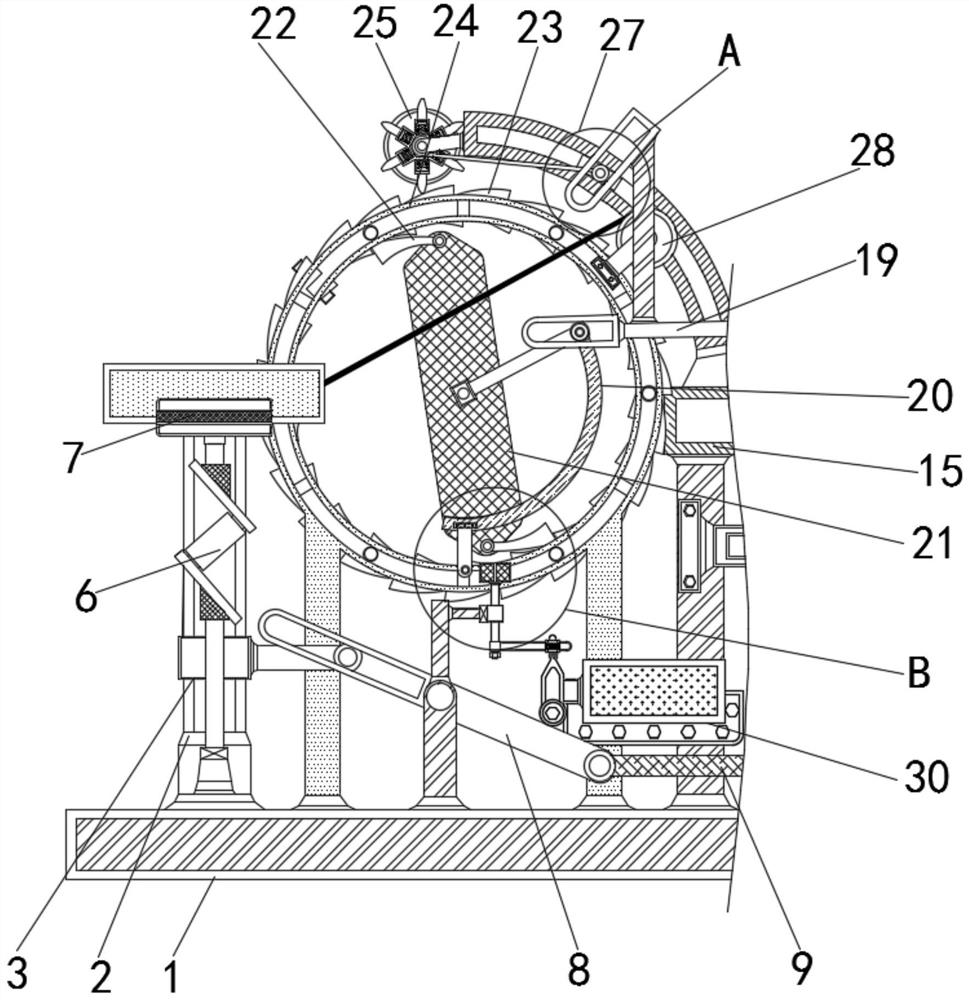

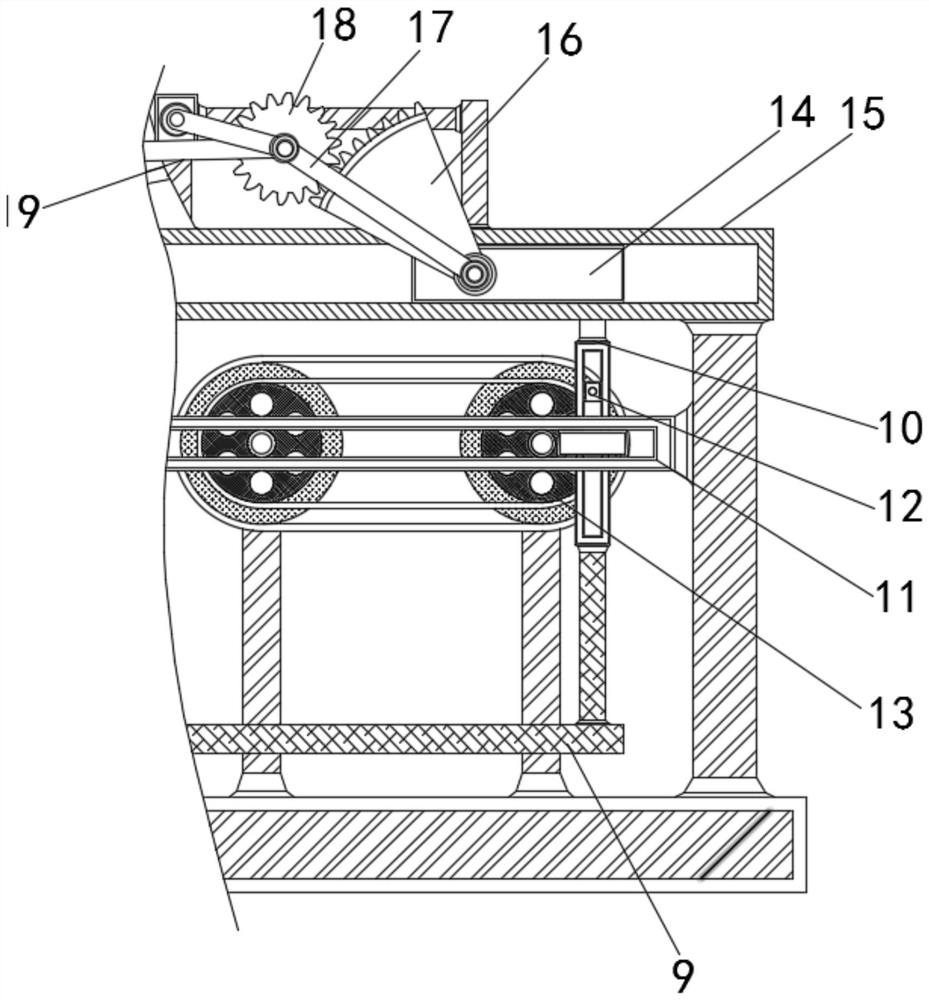

Three-in-one drilling and flocking machine with large disk, flat plate and rod brush

ActiveCN107173984AProduction standardizationImplement standardized productionBrush bodiesCircular discEngineering

The invention discloses a three-in-one drilling and flocking machine with a large disk, a flat plate and a rod brush and relates to a structure of a drilling and flocking machine. The three-in-one drilling and flocking machine comprises a machine body workbench, a handpiece placement table, a handpiece left and right movement mechanism, a handpiece up-and-down movement mechanism, a rod brush clamp, a disk clamp and a flat plate clamp, wherein the handpiece placement table, the handpiece left and right movement mechanism, the handpiece up-and-down movement mechanism and the rod brush clamp all are arranged on the machine body workbench; and at most one of the disk clamp and the flat plate clamp is arranged in the middle of the machine body workbench. The three-in-one drilling and flocking machine can meet the modern production requirements of high efficiency, high quality and high grade, and is stable in product performance, powerful in function and simple in operation, and standardized production of parts is implemented.

Owner:HUBEI C P NC MACHINERY

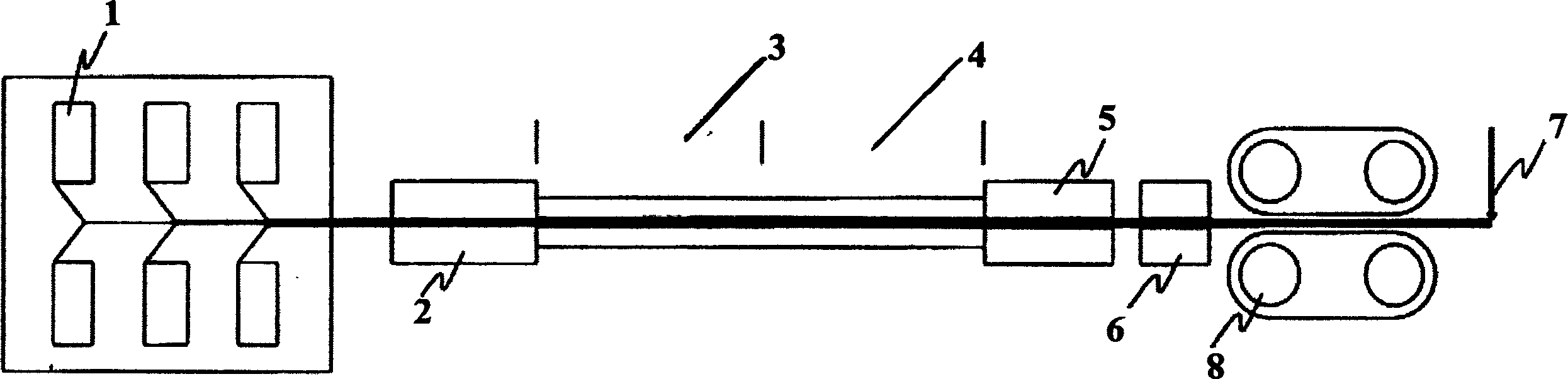

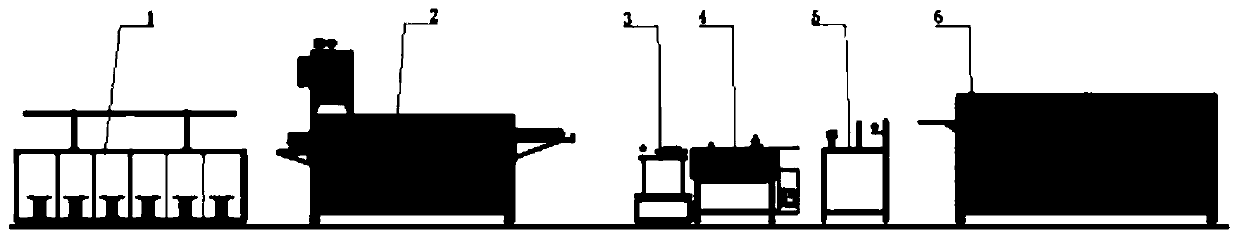

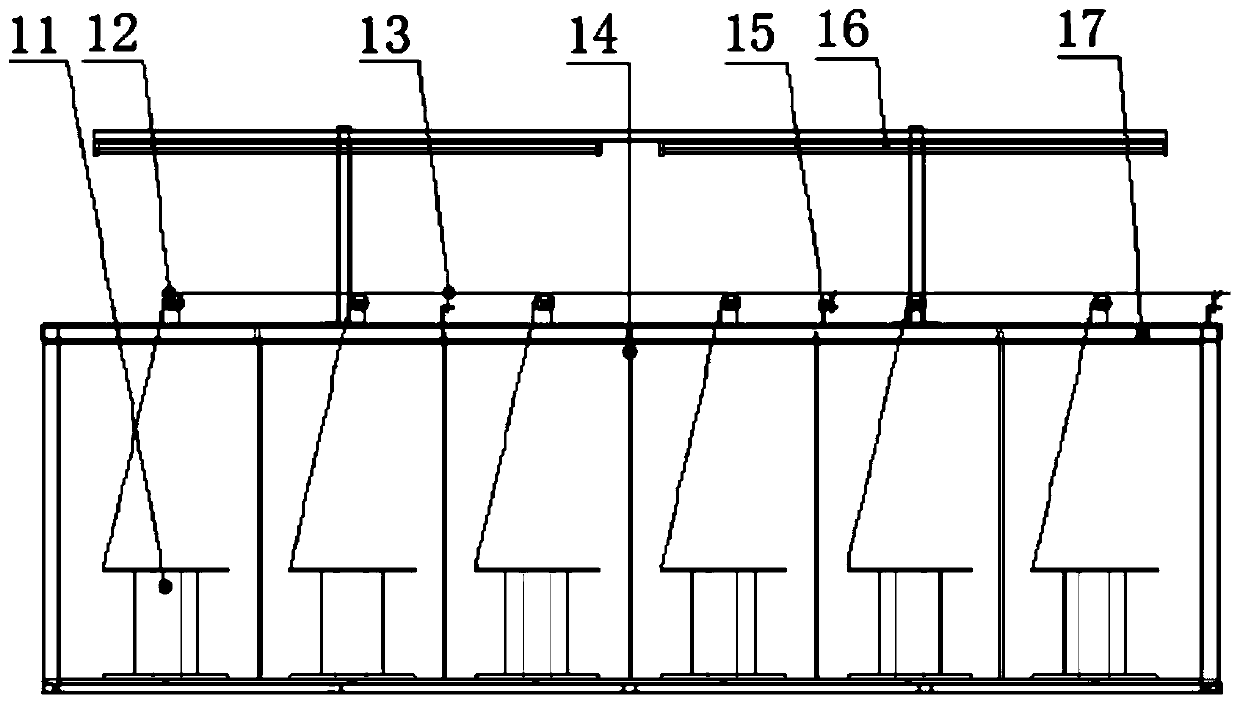

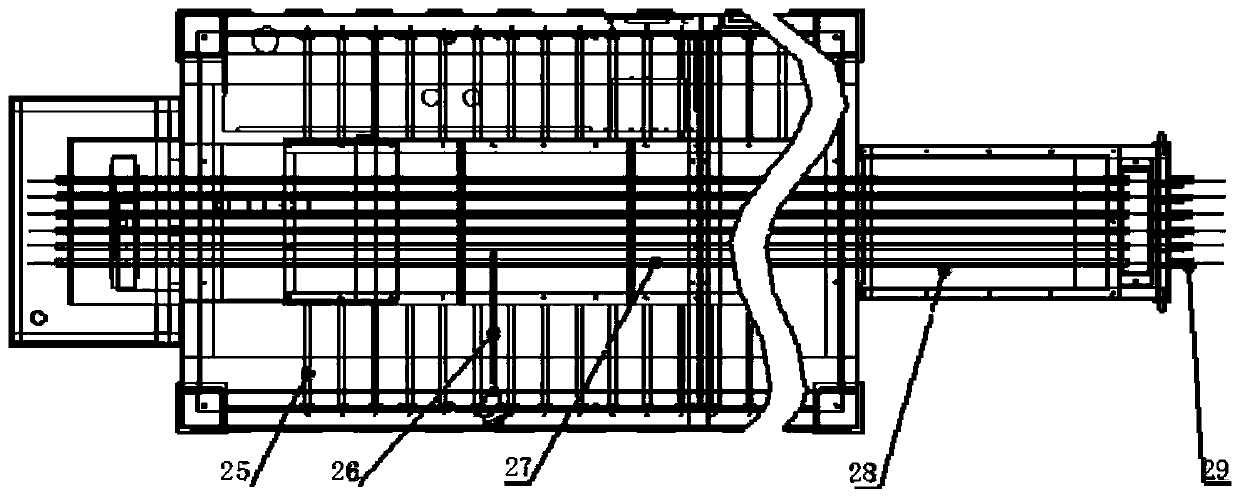

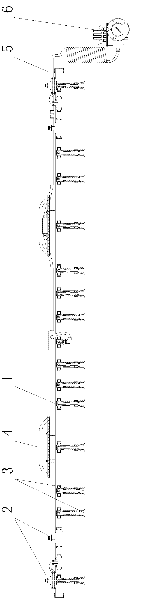

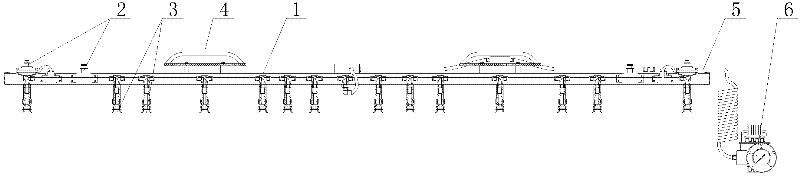

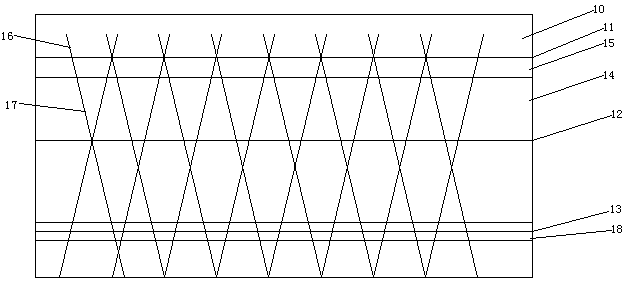

Micro-wire annealing tin plating machine production line

PendingCN109929971AProduction standardizationHigh speed productionHot-dipping/immersion processesFurnace typesFine lineProduction line

The invention discloses a micro-wire annealing tin plating machine production line and belongs to the field of cable machining. The micro-wire annealing tin plating machine production line comprises apay-off frame. A base is arranged at the lower end of the pay-off frame. An annealing furnace, a pickling bath, a tin furnace, a wire passing guide wheel set and a take-up machine. The pay-off frameis provided with a wire shaft. A first wire passing guide wheel is arranged on the surface of the pay-off frame. According to the production line, the special pay-off frame, the annealing furnace, thepickling bath, the tin furnace and the wire passing guide wheel set are arranged to be combined with the take-up machine, thus production of microwires is not troublesome any more, a user only needsto thread wires into the whole production line one by one like that of a traditional machine mode, the equipment can carry out the annealing technology and the tin plated technology automatically, allthe machined wires can be rolled and wound attractively with the standard and at a high speed, the defect that in the current wire industry, the microwires cannot be manufactured in batches is overcome, and the microwires can be produced with the standard and at a high speed.

Owner:鹰潭毅鹏智能科技有限公司

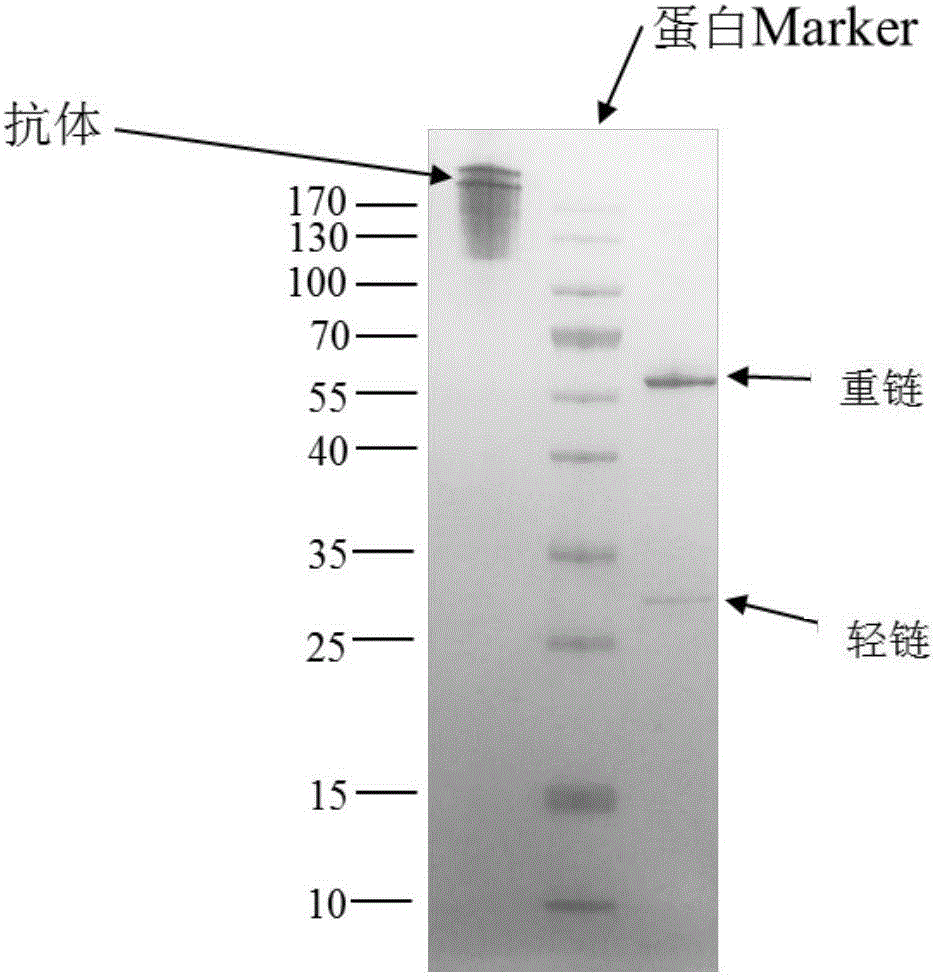

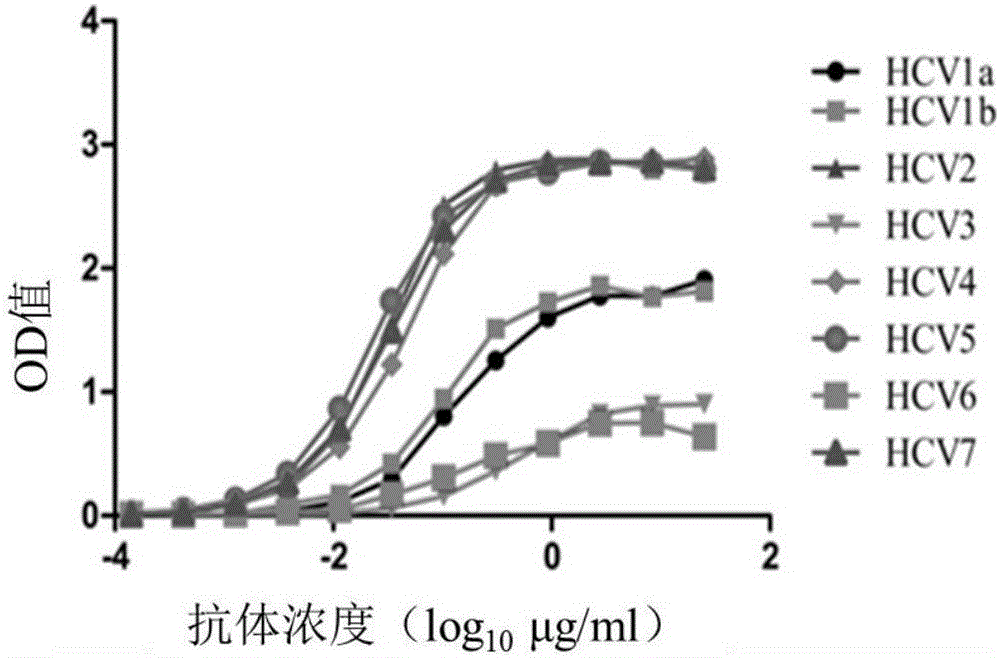

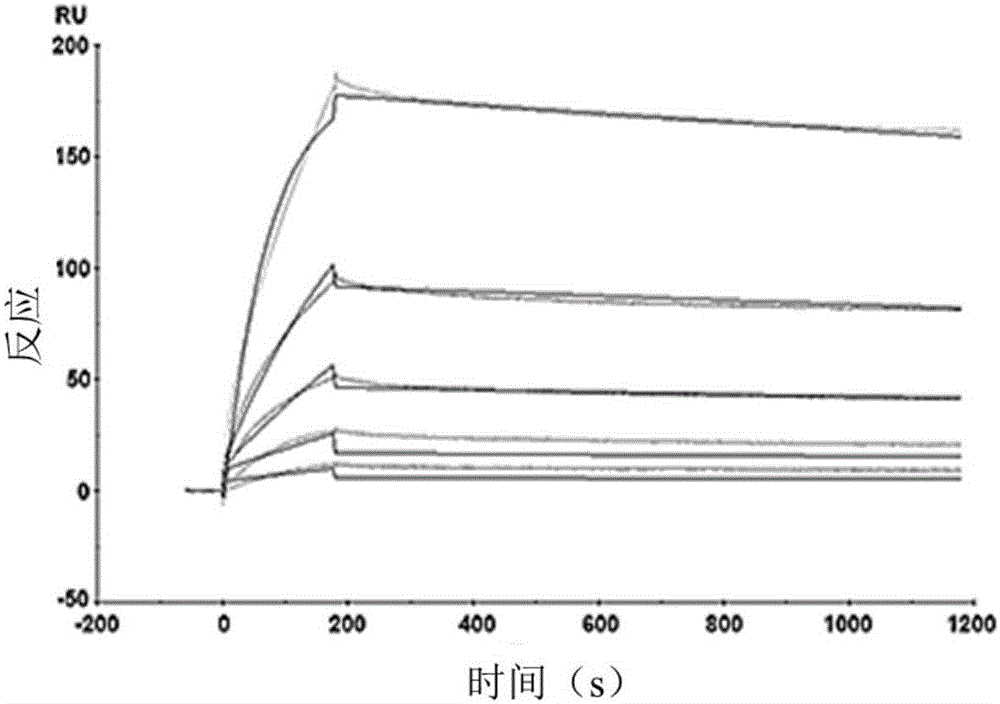

Fully-human-derived anti-HCV (hepatitis C virus) neutralizing antibody-TRN1001

ActiveCN106749644AHigh potencyHigh cross activityImmunoglobulins against virusesAntiviralsSide effectMonoclonal antibody

The invention discloses a fully-human-derived monoclonal antibody for neutralizing HCV (hepatitis C virus) and an application thereof and particularly discloses an antibody capable of recognizing and combining HCV envelope protein E2, a coding gene thereof, an expression vector and an application. The monoclonal antibody can stop the HCV from infecting susceptible cells and is fully-human-derived, and the antibody has greatly reduced immunogenicity, good affinity, good treatment effect and low side effects as compared with other animal-derived anti-HCV molecules.

Owner:JINAN UNIVERSITY +1

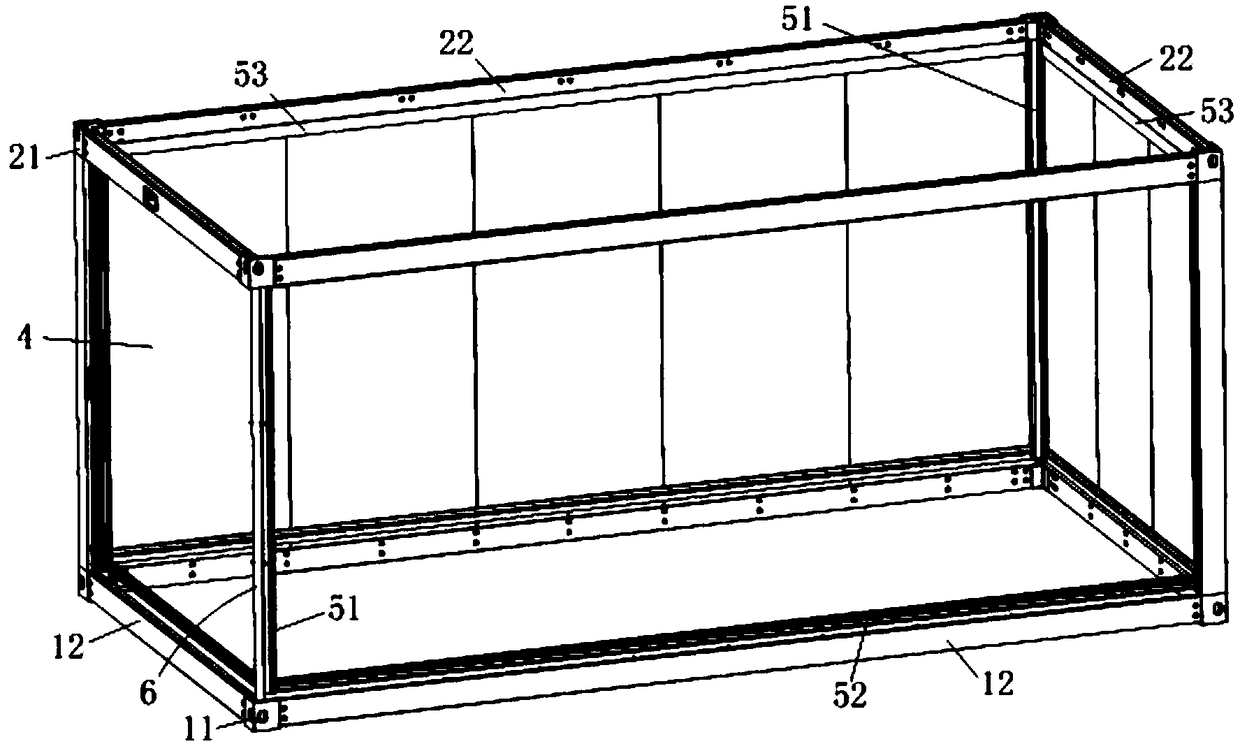

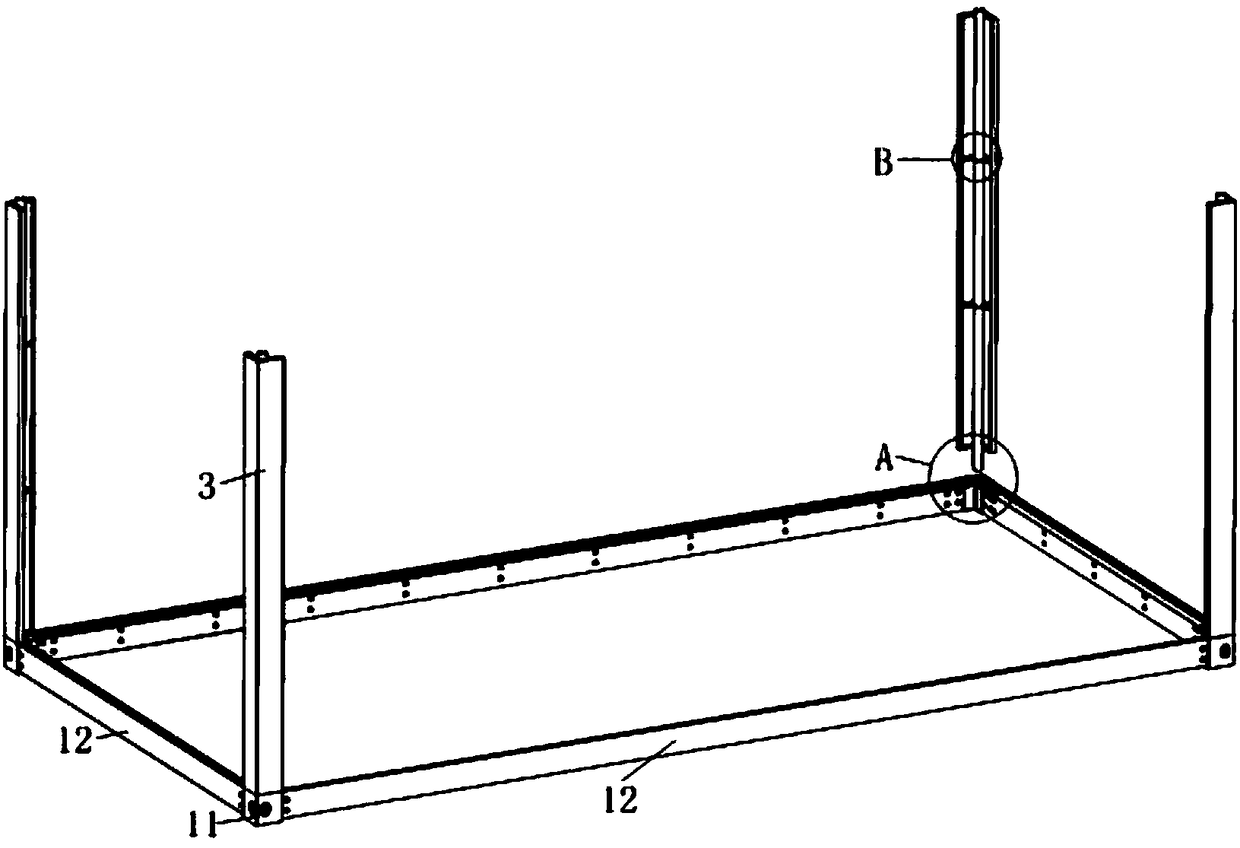

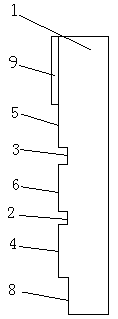

Container house stand column and wall plate system

PendingCN108560725AEasy to installAccurate limitBuilding constructionsMechanical engineeringWall plate

The invention relates to a container house stand column and wall plate system. The system comprises an outer bottom frame, an outer top frame, a stand column, four groups of wall plates and a pressingbar frame, wherein the outer bottom frame is a rectangular frame formed by enclosing of lower corner fittings and a bottom beam, and a lower connecting plate is arranged at the top of the lower corner fittings; the outer top frame is a rectangular frame formed by enclosing of upper corner fittings and a top beam, and an upper connecting plate is arranged at the bottom of the upper corner fittings; column connecting plates are respectively welded at upper and lower ends inside the stand column, the stand column is attached and fixedly connected to the upper connecting plate and the lower connecting plate through the upper and lower column connecting plates; the pressing bar frame is a rectangular frame enclosed by a corner pressing bar, an upper pressing bar and a lower pressing bar; a plurality of wall plate pressing pins are fixedly connected with the lower part inside the top beam, and is fastened with the upper pressing bar; and each group of wall plates comprises a plurality of wall plates which are in buckled connection on the same plane, and the wall plates are embedded among the rectangular frame assembled by the outer bottom frame, the outer top frame and the stand columnand the pressing bar frame. The container house stand column and wall plate system is convenient to assemble and construct, has high assembly efficiency and assembly quality, can realize standard production and improves the production efficiency.

Owner:ZHEJIANG PUTIAN INTEGRATED HOUSING

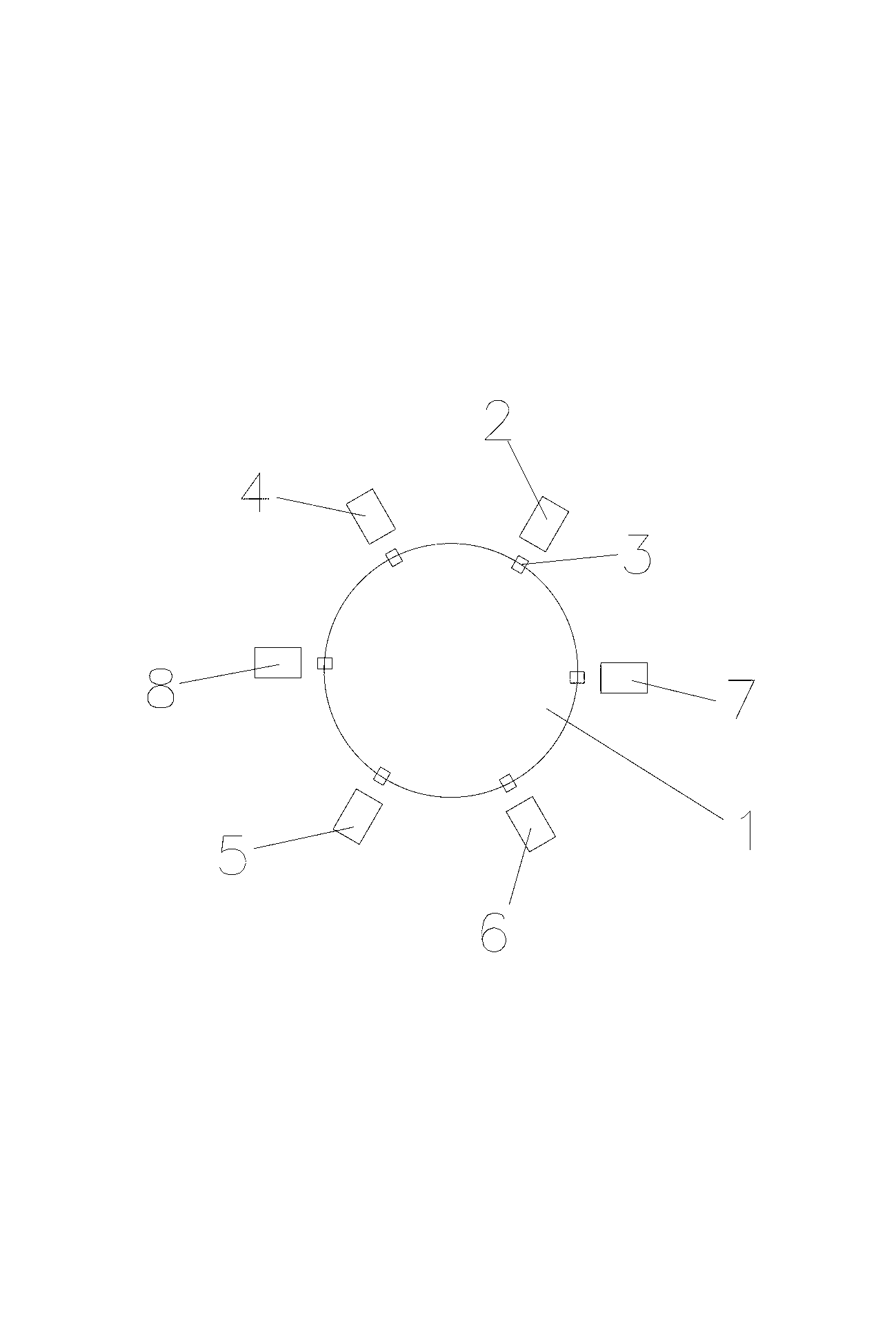

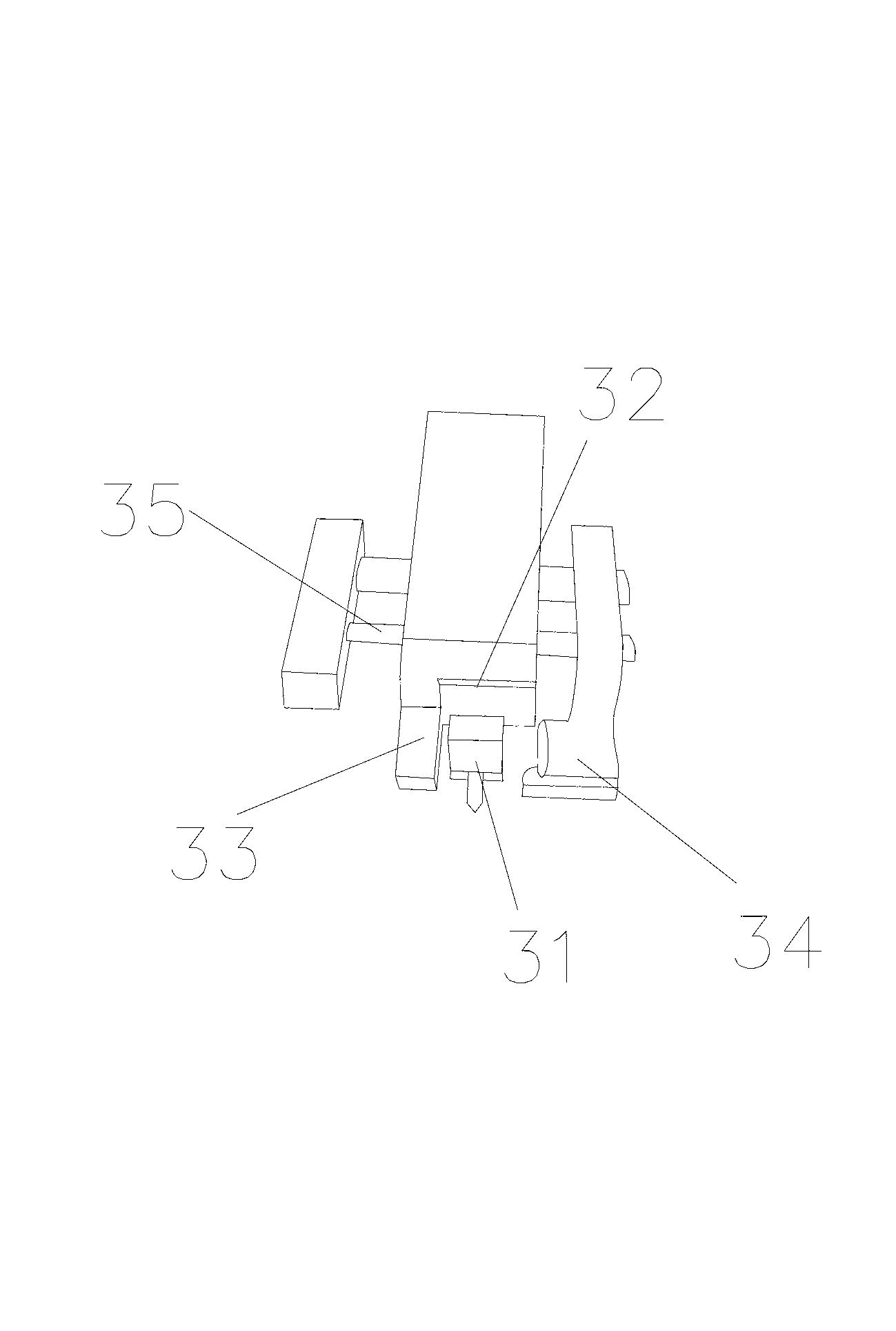

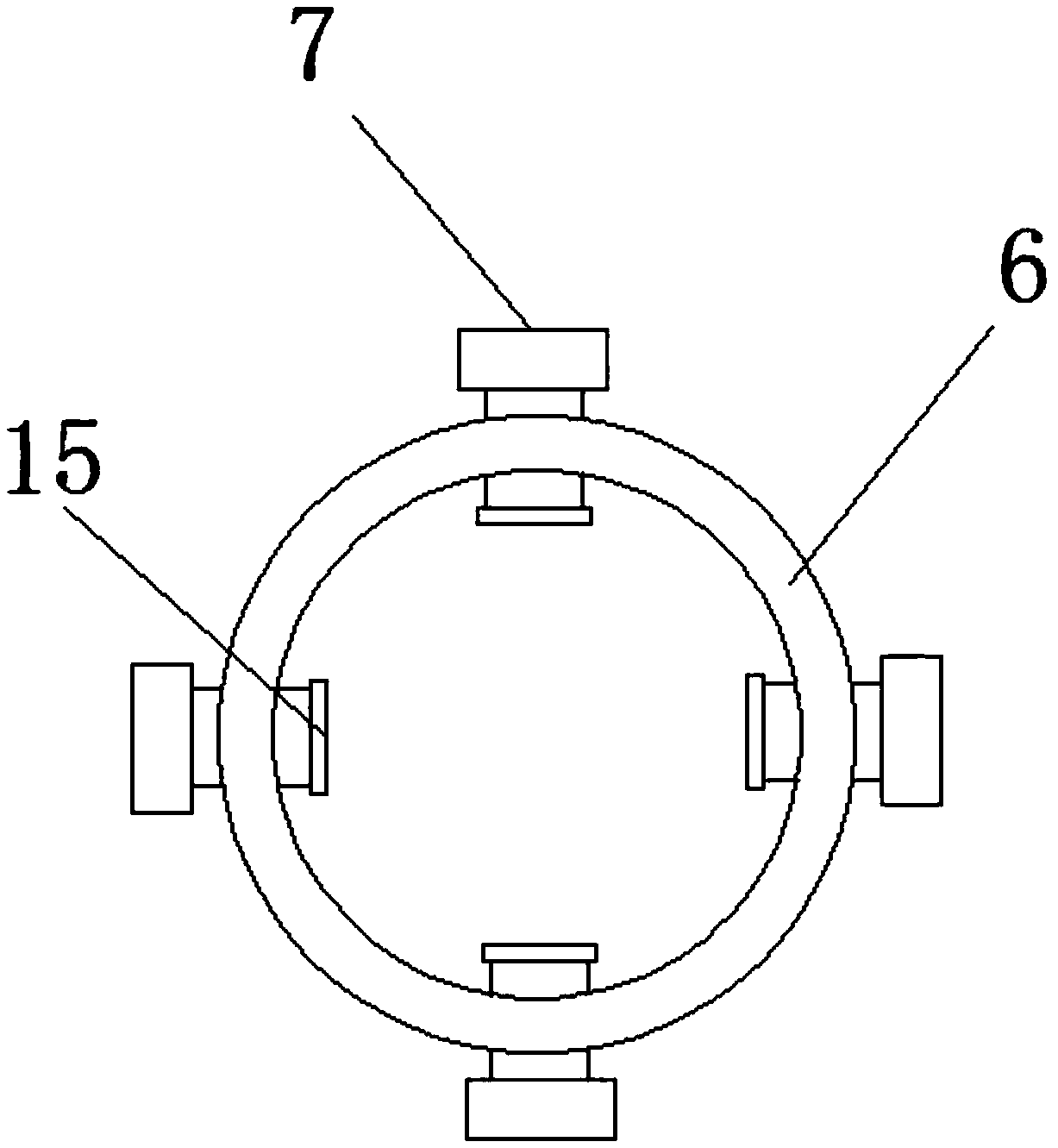

Halogen lamp foot-bending machine

ActiveCN102842484AImprove yieldNice appearanceElectrical apparatusMechanical engineeringHalogen lamp

The invention discloses a halogen lamp foot-bending machine comprising a work platform. A multi-station rotary plate is arranged in the center of the work platform. A bulb clamping device is arranged on each station along the radial direction of the multi-station rotary plate. A vibrating plate feeding mechanism, a lamp foot straightening mechanism, a foot-bending mechanism, a lamp foot reshaping mechanism and a blanking mechanism are arranged in sequence outside each bulb clamping device along the circumferential direction. A foot pre-bending mechanism is arranged between the lamp foot straightening mechanism and the foot-bending mechanism. As the foot pre-bending mechanism is arranged between the lamp foot straightening mechanism and the foot-bending mechanism, lamp feet are bent to a certain position in advance so that during a process bending the feet, foot-bending process of the lamp feet can be finished according to the former pre-bending position, and yield of the bent feet is greatly improved. The lamp foot reshaping mechanism enables appearance of the lamp feet to be attractive, so practical requirements of the lamp feet are met and industrialized and standardized production is achieved.

Owner:佛山新曜阳智能科技有限公司

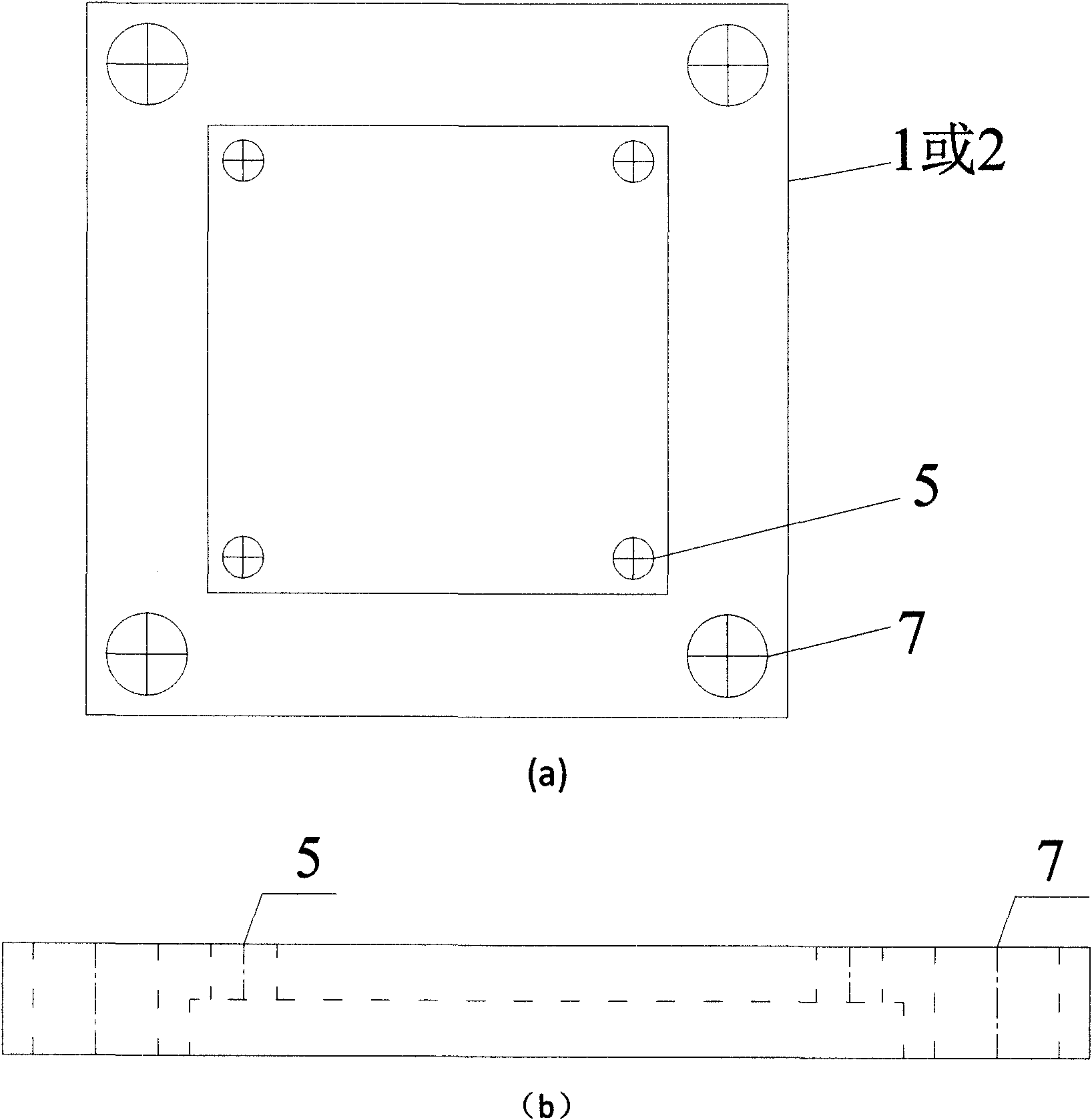

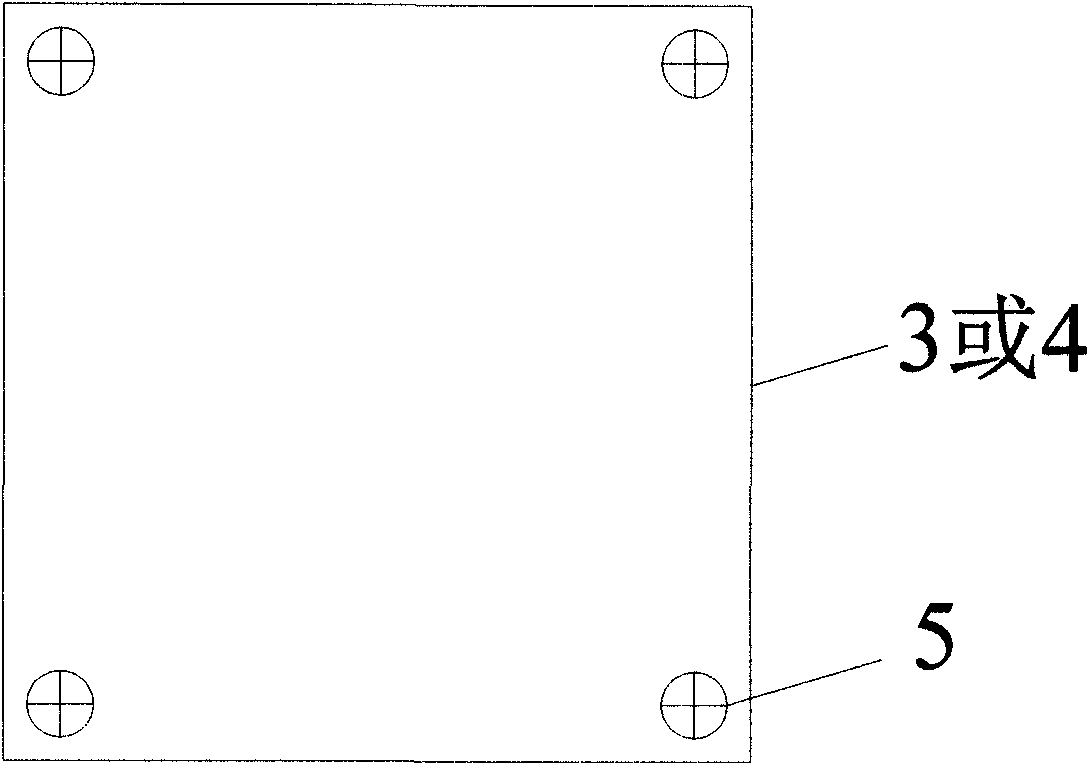

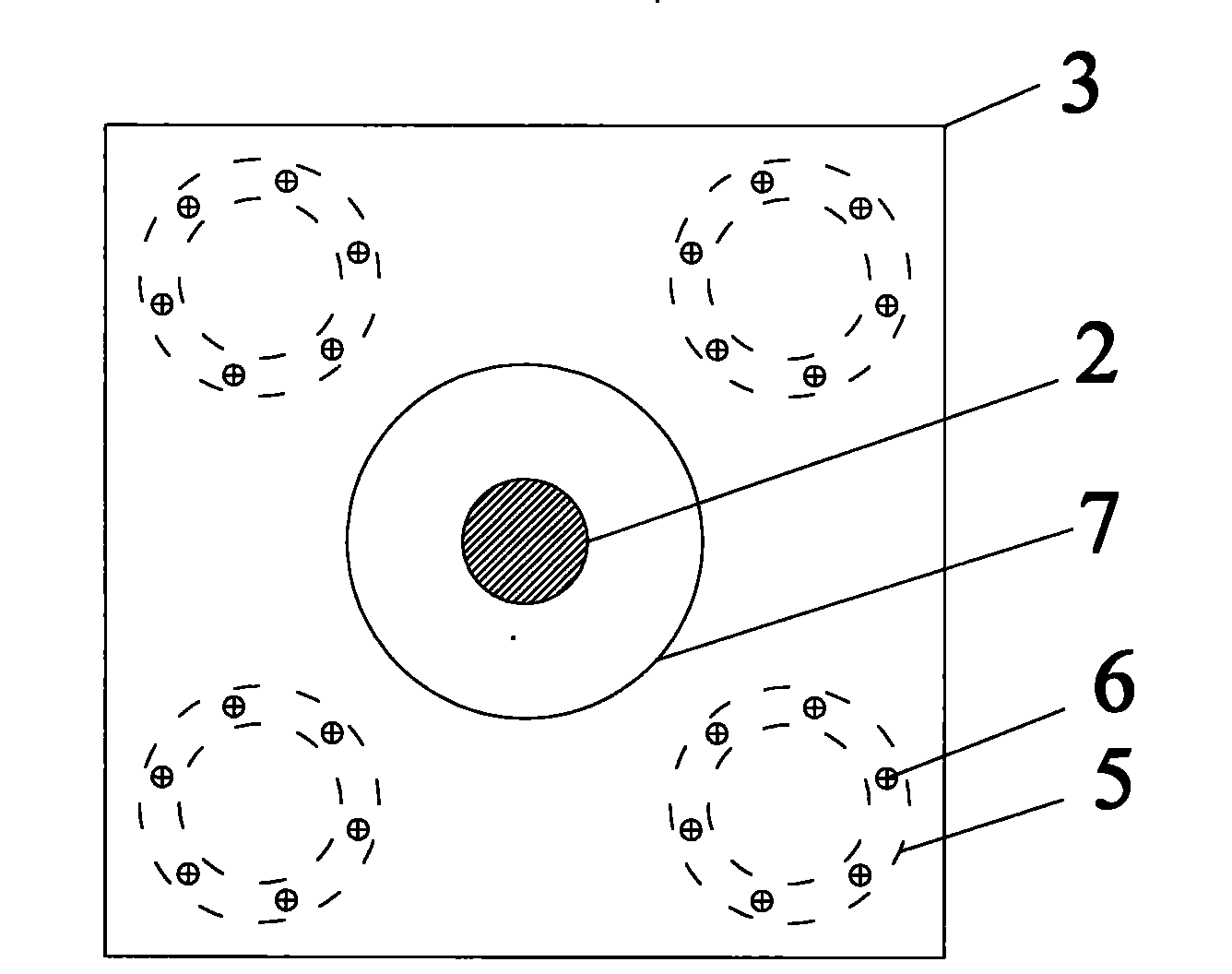

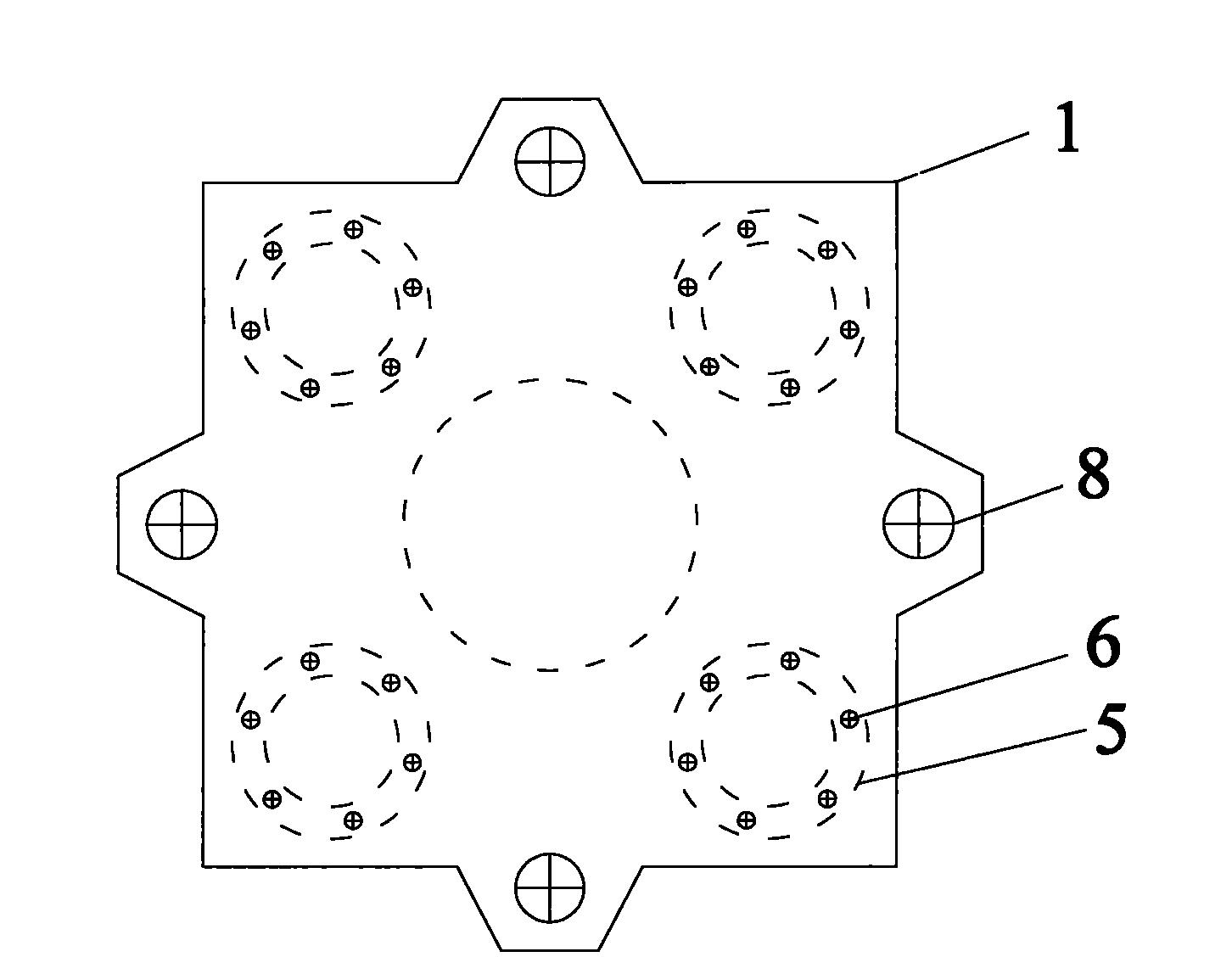

Vibration-isolating rubber cushion with adjustable rigidity

InactiveCN101864774ALow costProduction standardizationFoundation engineeringProtective buildings/sheltersIndustrial equipmentEngineering

The invention relates to a vibration-isolating rubber cushion with adjustable rigidity, comprising an upper end plate, a lower end plate, a steel plate unit and a rubber unit. The steel plate unit and the rubber unit are staggered and stacked to form a stacking unit which is provided with the upper end plate at the top and the lower end plate at the bottom, wherein the upper end plate and the lower end plate have the same structure, the top of the upper end plate and the bottom of the lower end plate are respectively provided with grooves the shapes and the sizes of which are consistent with those of the stacking unit, the grooves are internally provided with bolt holes arranged in a centrosymmetric arrangement mode, the stacking unit is provided with rigidity-adjusting bolt holes in the centrosymmetric arrangement mode, anchor bolt holes are arranged around the upper end plate and the lower end plate, and a rigidity-adjusting bolt respectively and sequentially penetrates through the bolt holes and the rigidity-adjusting bolt holes of the upper end plate and the bolt holes of the lower end plate. The invention has the advantages of adjustable rigidity, wide range of application, simple manufacture process, convenient transportation and flexible application, is suitable for standard mass production in factories and adjustment and mounting according to the needs of a user party and is suitable for resisting the vibration of structures and equipment, particularly resisting, lessening and shielding the vibration of special industrial equipment with small loads and frequent site adjustment.

Owner:TONGJI UNIV

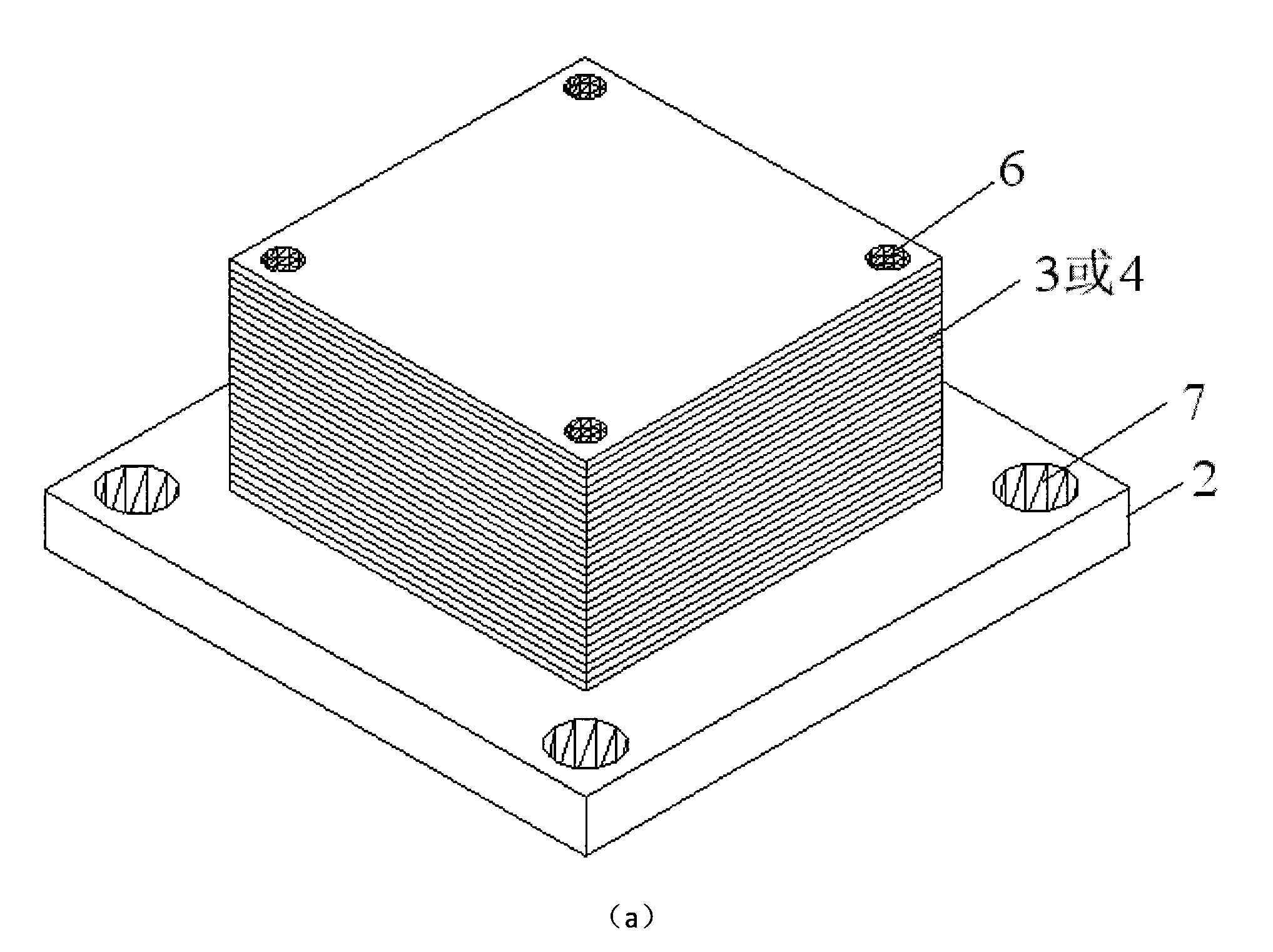

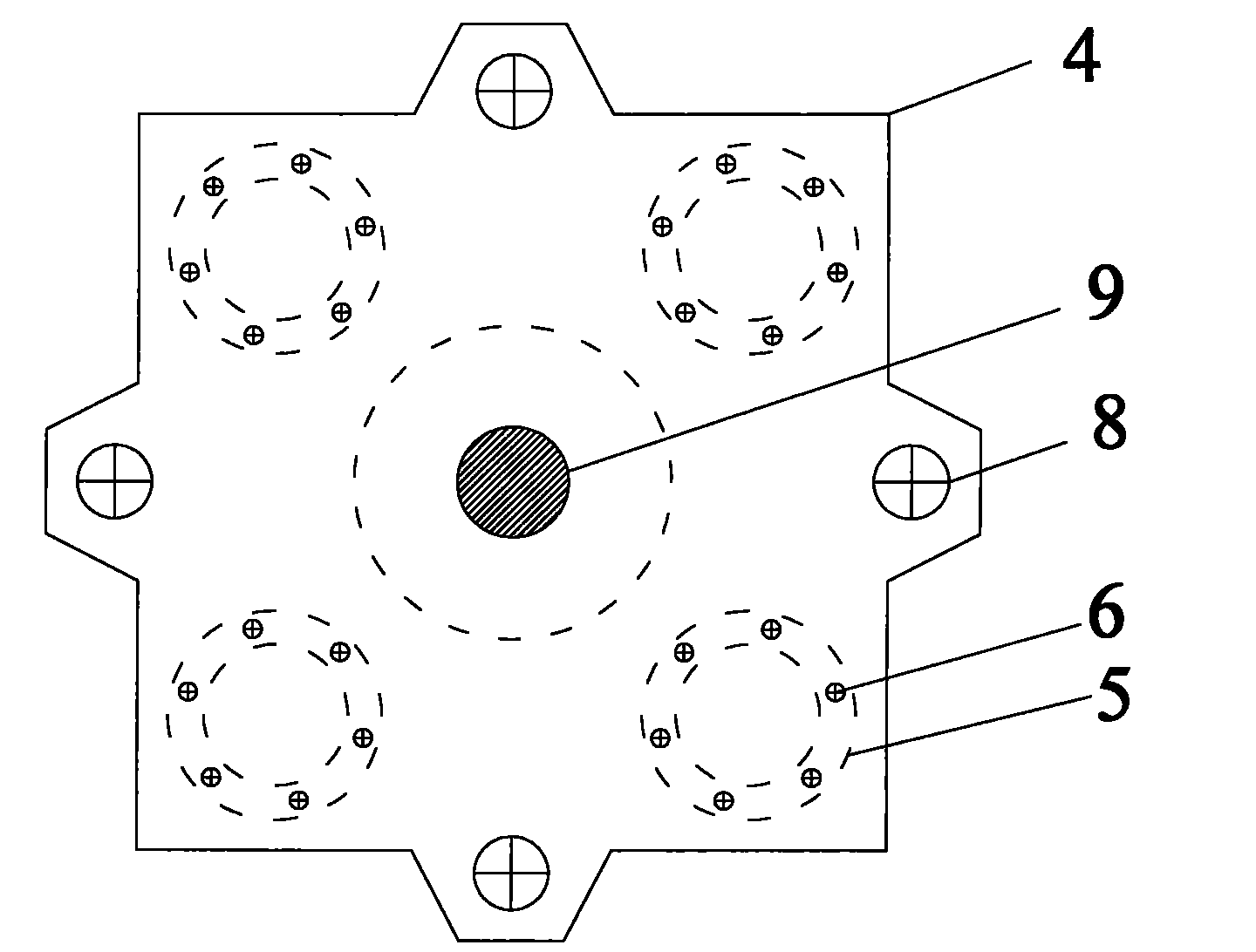

Package-type rubber vibration isolation cushion with limit function

InactiveCN101839026ALow costPrevent excessive displacementProtective buildings/sheltersShock proofingSteel platesCushion

The invention relates to a package-type rubber vibration isolation cushion with limit function, comprising a limit rod, miniature rubber vibration isolation units, laminated steel plates and end plates; wherein a plurality of miniature rubber vibration isolation units are fixed between each two laminated steel plates, the limit rod is a soft steel rod with the section gradually changed, the end with larger section is fixed on a lower end plate, and the limit rod penetrates the limit holes on the intermediate laminated steel plates from bottom to top. The invention has the advantages of variable structure size, adjustable energy consumption capability, wide application range, simple manufacturing process, convenient transportation and flexible application, is applicable to standardization mass production of factory and field selecting and mounting by requirement and can be applicable to vibration resistance of structure and equipment, especially vibration resistance, vibration reduction and vibration isolation of special industrial equipment with small load and frequent field debugging.

Owner:TONGJI UNIV

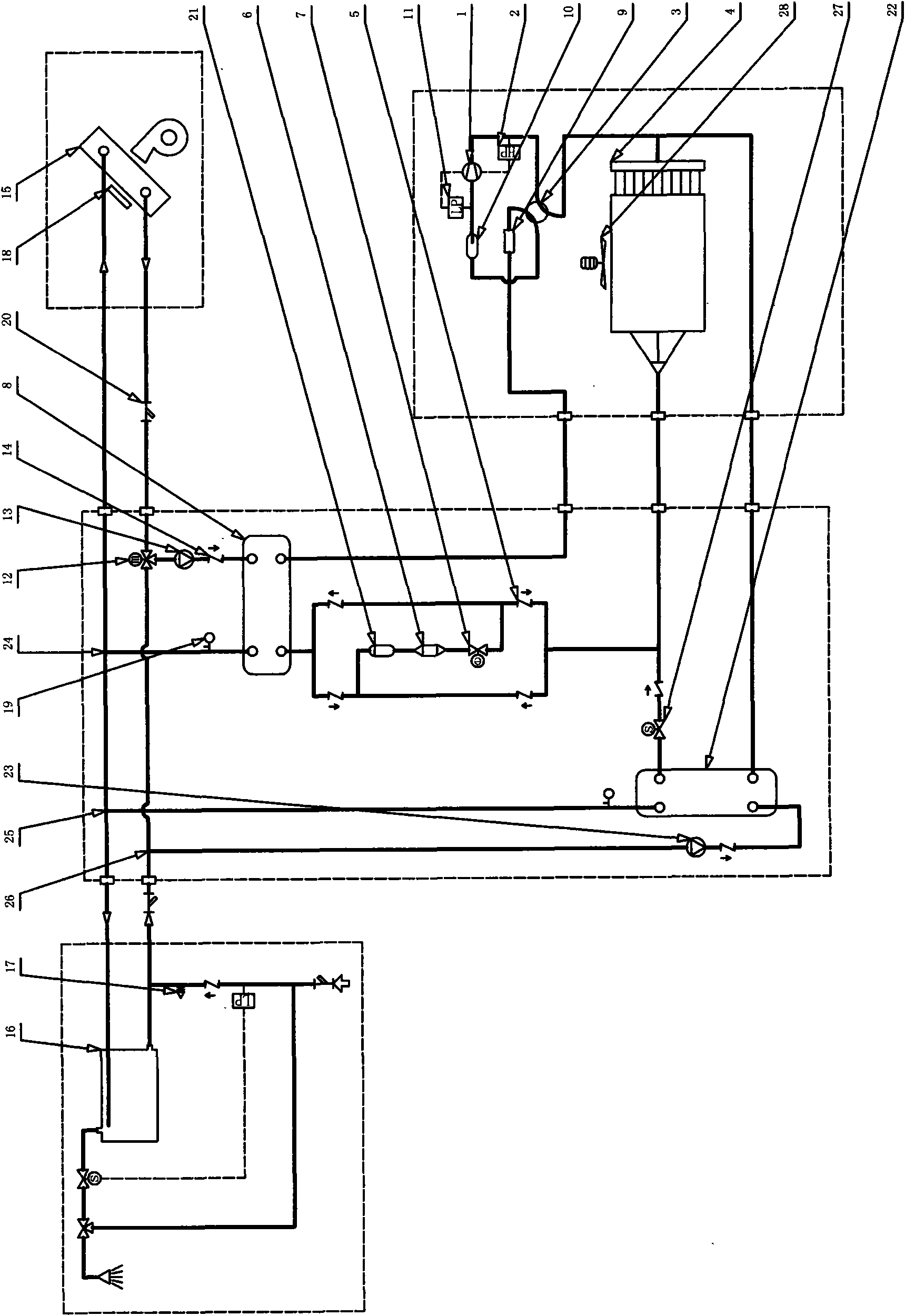

Air source heating-air conditioning-hot water three-way set

InactiveCN101592419AEliminate hidden dangersReduce `Switch outputFluid heatersCompression machines with several condensersEngineeringCheck valve

The invention relates to an air source heating-air conditioning-hot water three-way set. The asymmetric phase change rate with magnitude difference among parallel heat exchangers is formed by switching on and switching off the driving force of a refrigerating medium side and matching the guiding of a check valve of a refrigerant side to radically replace an electromagnetic valve switch refrigerant loop; and five functions of heating, air conditioning, hot water, air conditioning and hot water (an ordinary type / an energy saving type), and the like are realized in a mode of simpler structure, lower cost, more reliable operation and higher efficiency. The air source heating-air conditioning-hot water three-way set accords with a natural law of 'Dujiang Dam' action through inaction, radically eliminates hidden trouble of lack of fluorine of heat exchanger operation caused by stopping using refrigerant fluid stored in the heat exchanges in the prior three-way set, and is favorable for home application of products.

Owner:合肥天鹅制冷科技有限公司

Glossy ganoderma bag-tea preparing method

InactiveCN1742601AQuick Soak DissolveImprove product added valueTea substituesPlant ingredientsHigh pressureGanoderma lucidum

The preparation method of ganoderma lucidum tea bag includes the following steps: (1) pulverizing; (2) high-pressure steam sterilization, pressure is 1.000-2.110x100000 Pa, temperature is 120-135deg.C and time is 20-160 min.; (3) cooling, prepackaging by using paper bag of tea bag, sealing; (4) packaging by using aluminium film bag, sealing; and (5) secondary high-pressure steam sterilization.

Owner:GUANGDONG INST OF MICROORGANISM

Series welding sucking disc

InactiveCN102335799ASo as not to damageProduction standardizationWelding/cutting auxillary devicesAuxillary welding devicesSurface mountingEngineering

The invention relates to a series welding sucking disc, which is used for composing of solar cell silicon wafers. The series welding sucking disc is provided with a sucking disc body, wherein upper surfaces of two ends of the sucking disc body are symmetrically provided with throttle valves; the throttle valves are communicated with a pneumatic valve via a pneumatic tube; the lower surface of the sucking disc body is provided with a plurality of suction heads which are used for adjusting a distance between the solar cell silicon wafers according to the sizes of the solar cell silicon wafers; and the middle of the upper surface of the sucking disc body is symmetrically provided with two handles. According to the series welding sucking disc, the composing of solar cell silicon wafers with different specifications can be realized by regulating the throttle valves to be switched on or off and regulating a distance between the suction heads.

Owner:CHANGZHOU HAISHUO MACHINERY MFG

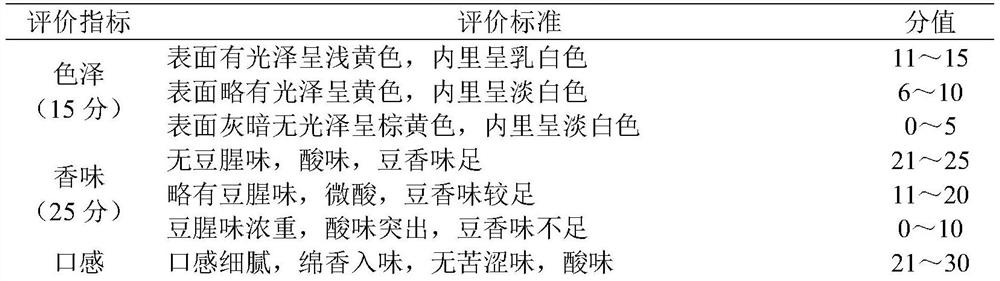

Method for preparing slurry-coated bean curd by using bean white fermentation liquor as coagulator

PendingCN112869027AUnique flavorImprove qualityFood preservationCheese manufactureBiotechnologySoybean product

The invention provides a method for preparing slurry-wrapped bean curd by using a bean white fermentation liquor as a coagulator. The method specifically comprises the following steps: preparing the bean white fermentation liquor, soaking, peeling, grinding into slurry, boiling the slurry, filtering, curdling the bean white fermentation liquor, standing, squeezing, refrigerating, soaking, cleaning, boxing and quickly freezing. The bean clear fermentation liquor is prepared by taking byproducts, namely bean clear liquor (commonly known as yellow serofluid and vinegar water), generated in the production process of bean products as raw materials and adopting a multi-strain probiotic periodic variable-temperature staged synergistic fermentation technology. The soybean whey fermentation liquor prepared by the technology is rich in nutrient substances such as organic acids, exopolysaccharides, gamma-aminobutyric acid, free soybean isoflavone, B vitamins and polypeptides, and the slurry-coated bean curd prepared by taking the soybean whey fermentation liquor as a coagulator is bright in external color and clear in corner angle, smooth and tender in internal juice, in a flowing state, unique in flavor and rich in nutrient substances.

Owner:湖南君益福食品有限公司

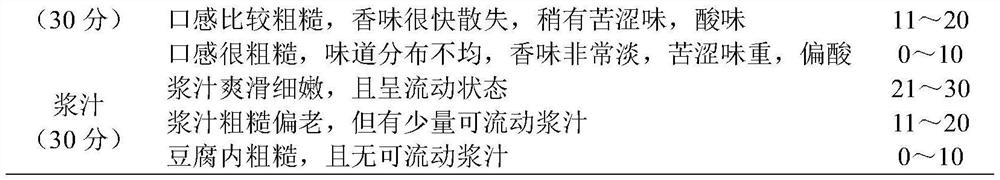

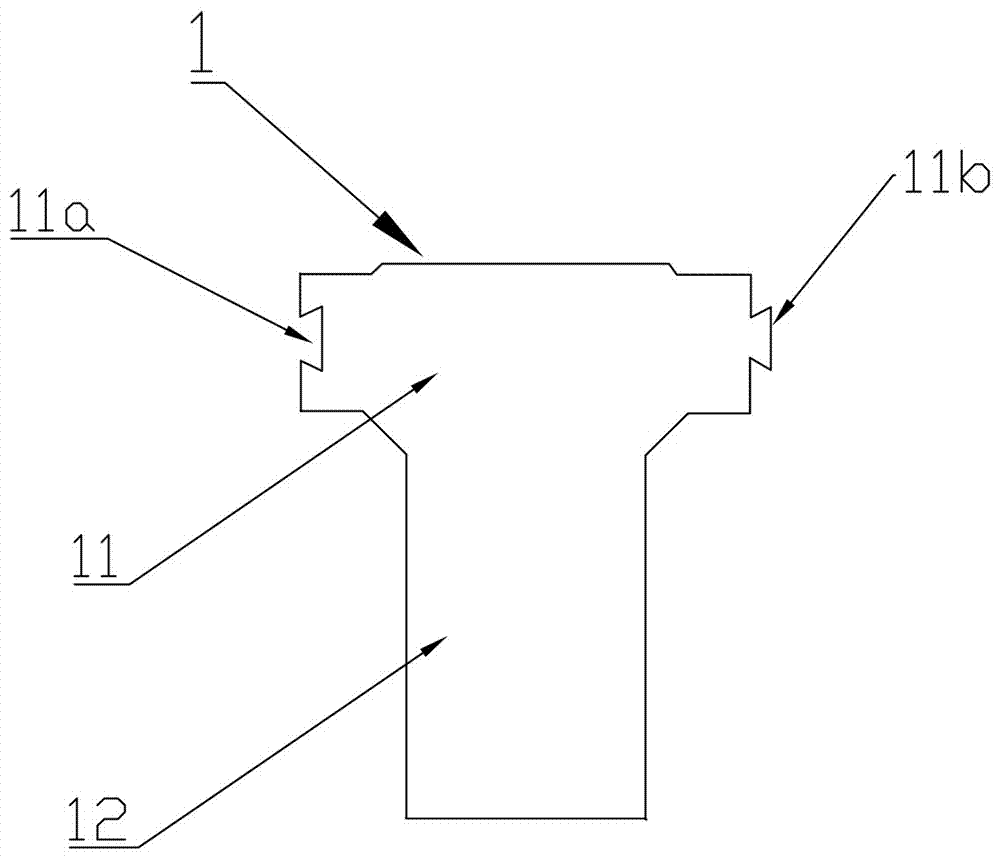

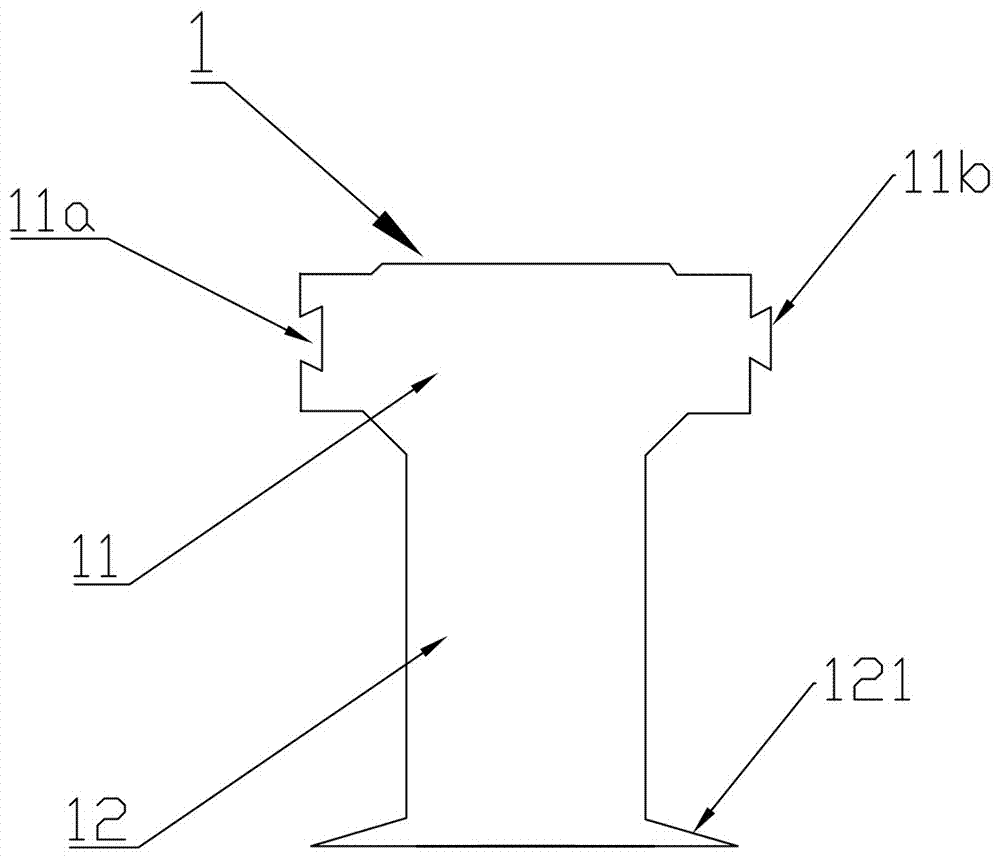

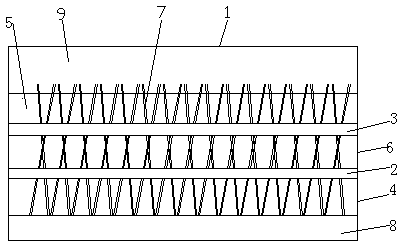

Split type linear motor iron core

PendingCN107147222AProduction standardizationImprove cooling effectMagnetic circuit shape/form/constructionPropulsion systemsWinding machineElectric machine

The invention provides a split type linear motor iron core. The split type linear motor iron core comprises a plurality of T-shaped main teeth spliced mutually; end part teeth are spliced beside the T-shaped main tooth at the head end and the T-shaped main tooth at the tail end respectively; an integrally formed single sheet is designed into a single-tooth structure; a female buckle and a male buckle matched therewith are arranged at the two ends of the connecting part of each T-shaped main tooth; iron cores of different lengths and different dimensions can be manufactured by the one-by-one splicing way, so that the manufacturing of the iron cores can be standard; meanwhile, the cost of re-mould-opening is omitted; the single sheet is prepared into the single-tooth structure, and a winding machine can perform direct winding on the T-shaped main teeth, so that a good heat conducting effect is achieved, and heat dissipation of the iron core is accelerated; direct winding on the T-shaped main teeth can be performed, and tooth shoes can be arranged at the bottom ends of the winding parts of the T-shaped main teeth, so that magnetic resistance can be lowered by virtue of the tooth shoes, and the magnetic flux of the iron core can be improved; and the winding machine can perform direct winding on the T-shaped main teeth, so that more coils can be wound around the single teeth, and high thrust density is realized.

Owner:东莞市川恩智能装备有限公司

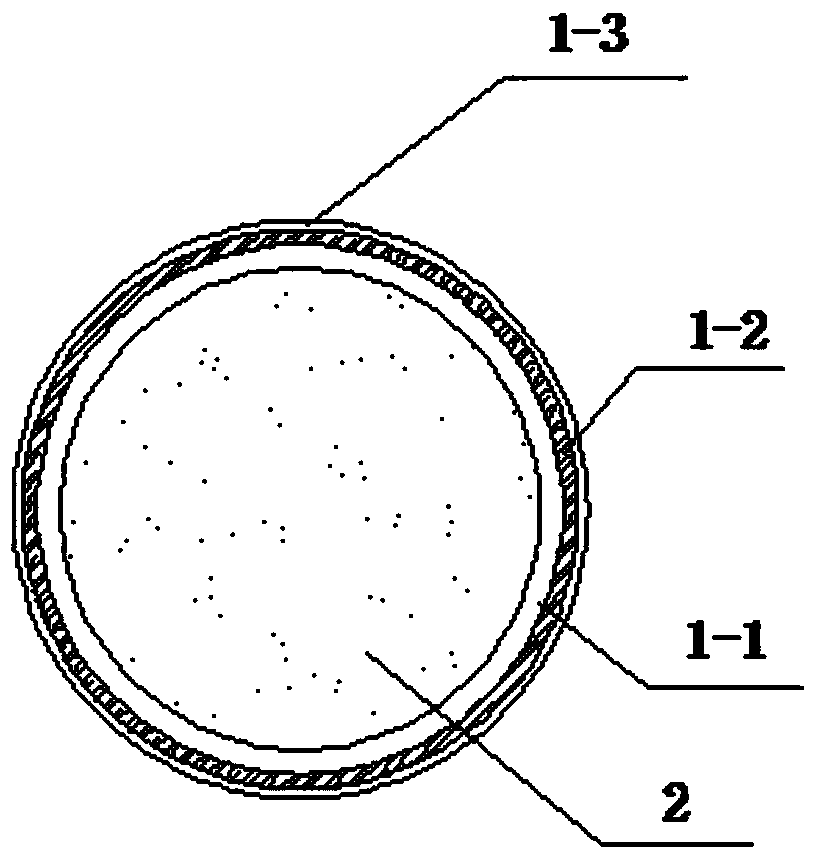

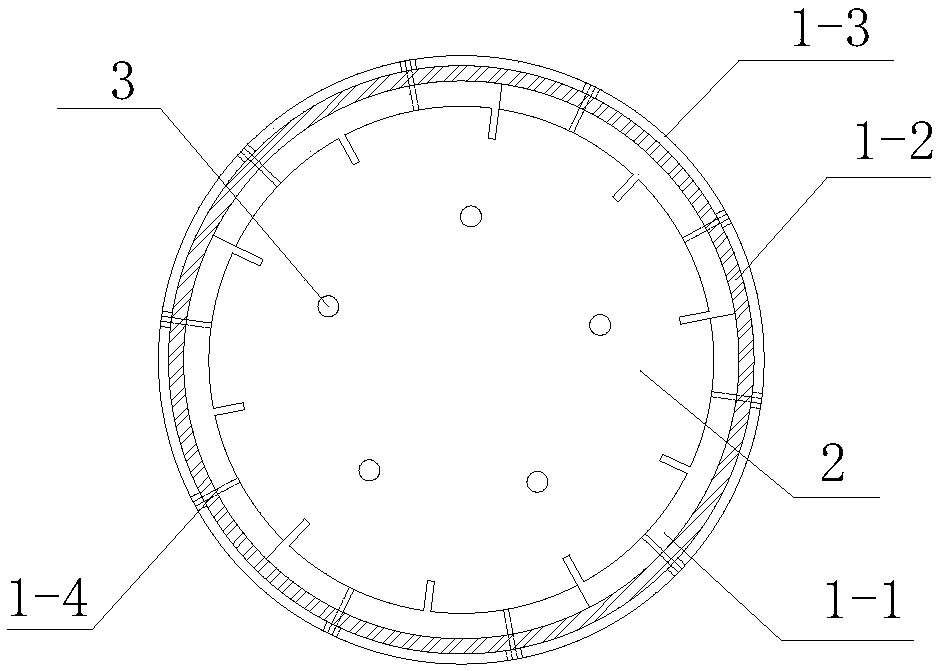

FRP section-steel composite pipe concrete combination column

InactiveCN108240071AGood mechanical propertiesIncrease stiffnessStrutsPillarsReinforced concreteEngineering

The invention relates to an FRP section-steel composite pipe concrete combination column. The combination column sequentially comprises an FRP wound pipe, a steel pipe and an FRP pultruded section from outside to inside. The pultruded section can be made into a ribbed section, and a section form can be designed to be a sealed tube and also can be designed into a form that multiple independent pultruded sections are annularly arranged along the inner wall of the steel pipe. Plain concrete or reinforced concrete fills up the interior to form the combination column. In an FRP section-steel composite pipe, the outer-layer wound FRP pipe can provide hoop constraint for the steel pipe, the FRP pultruded section and internal concrete, and the steel pipe can be protected from being corroded. The pultruded section can provide axle load and bending resistance for a column body, and the characteristics, namely low modulus and high ultimate elongation, of the FRP section are utilized for providingpost-yield stiffness under the condition of large horizontal deformation of the column body. The combination column provided by the invention is better in mechanical properties and applicable to engineering structures used in coastal and other high corrosion environments.

Owner:SHENYANG JIANZHU UNIVERSITY

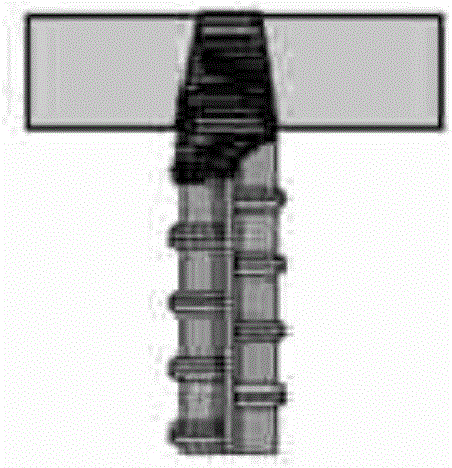

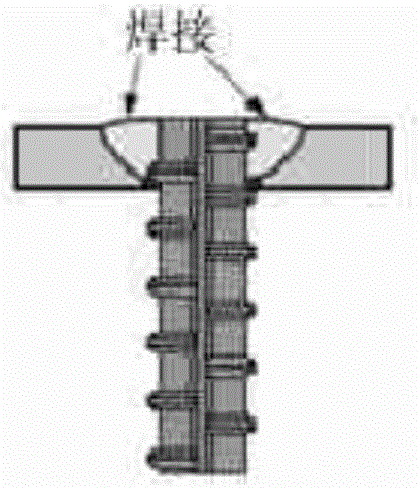

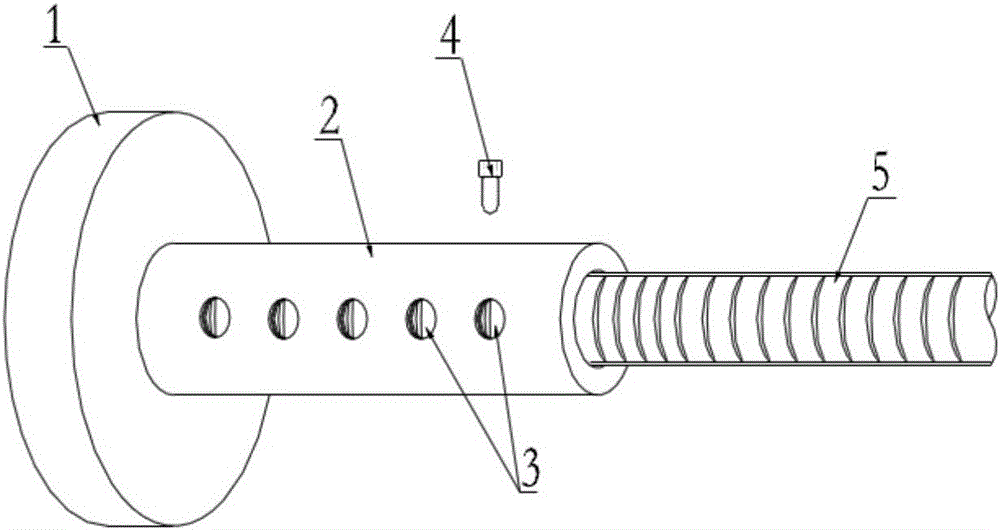

Reinforcement anchorage and mounting method thereof

ActiveCN105064615ASimple constructionConstruction quality is easy to controlBuilding reinforcementsBuilding material handlingRebarEngineering

Owner:上海核工程研究设计院股份有限公司

Manufacturing process of false eyelashes

InactiveCN108783697AImprove gluing efficiencyShorten the timeHair accessoriesToupeesMaterials scienceEyelash extensions

The invention provides a manufacturing process of false eyelashes. The manufacturing process comprises the following steps: a, carrying out glue adhering on an eyelash material; b, carrying out eyelash material combining; c, carrying out eyelash material cutting; d, carrying out eyelash material coiling; and e, carrying out eyelash material steaming. In the manufacturing process of false eyelashes, for the glue adhering process of the eyelash material, the glue adhering efficiency of the eyelash material is greatly improved, the whole manual spreading of the eyelash material only needs ten more seconds, and the time is reduced by tens of seconds compared with the time used for the traditional eyelash material placing adopting drawings and patterns.

Owner:叶县锦艳华美睫饰品有限公司

Limiting device for spring machining

The invention discloses a limit device for spring processing, which comprises a base, a motor and a reel, legs are arranged at the four corners of the bottom of the base, a motor is arranged on the top of the base, and the outer end of the drive shaft of the motor is fixed A reel is connected, the left side of the motor is provided with an external power supply, the outer wall of the reel is covered with a collar, the outer wall of the collar is inserted with a first bolt, and the right side of the collar is connected with a first As for the limiting block, a limiting hole is opened on the surface of the first limiting block. The present invention puts the limit ring on the reel to limit its actual position, the length of the spring can be controlled by moving the limit ring, and the distance between the spring bodies is better and more accurate through the expansion and contraction of the telescopic device to match the speed of the reel. The qualification rate of the spring is improved, and the inner cavity of the second limit block is provided with balls, so that the surface of the spring steel will not be worn during rolling, so that the quality of the spring is effectively improved.

Owner:NANJING LISHUI LIHUA SPRING FACTORY

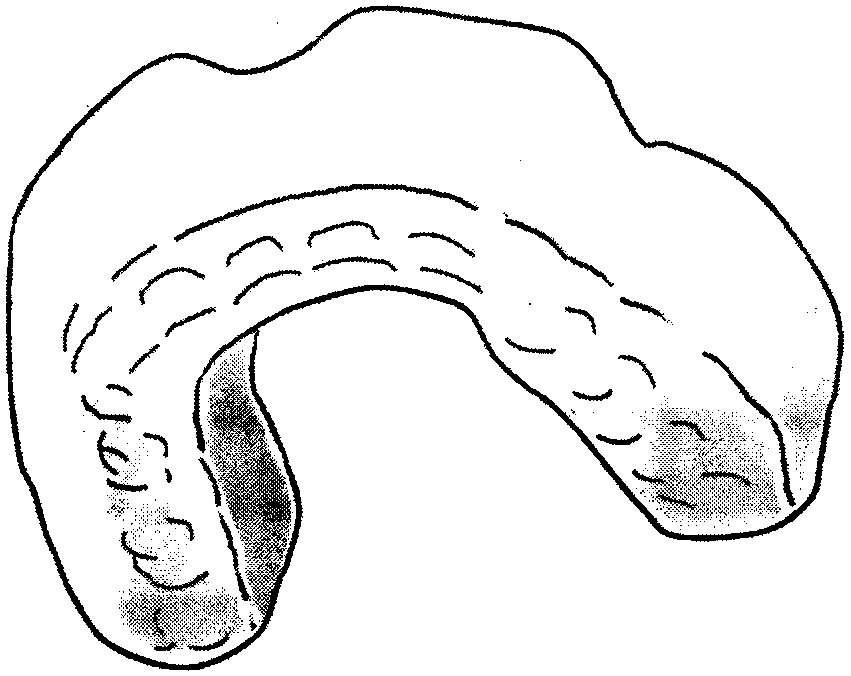

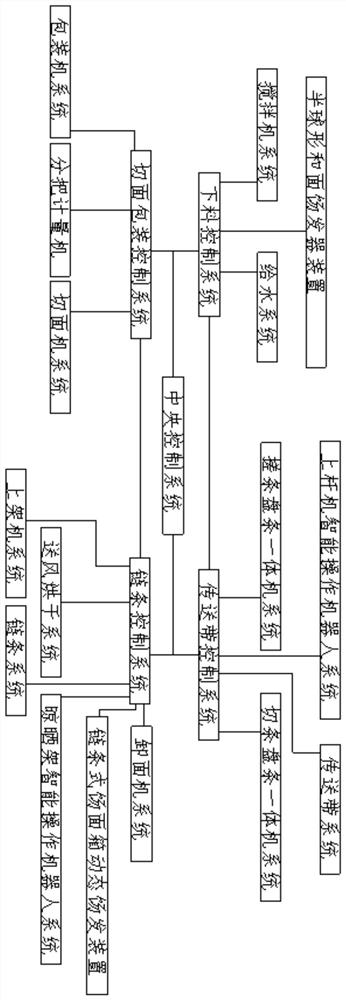

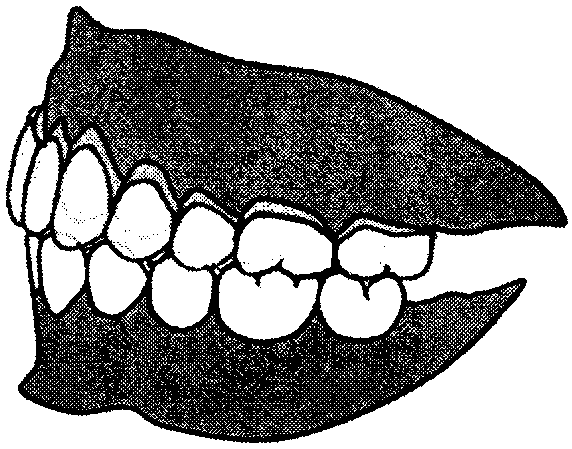

Digitally designed personalized sports tooth protector

InactiveCN110270080AProduction standardizationSave materialSport apparatusPersonalizationComputer-aided

For the defects of manufacturing methods and materials of conventional sports tooth protectors, the invention provides a digitally designed personalized sports tooth protector. The tooth protector is characterized by comprising the following steps: acquiring upper and lower jaw dentition and oral cavity soft and hard tissue data of a patient by using a digital impression technology, and matching the upper and lower jaw dentition in a virtual occlusal frame by using a face arch transfer and virtual fully-adjustable occlusal frame system to perform occlusion registration and lifting occlusion so as to reserve enough space for the sports tooth protector; designing the personalized sports tooth protector through computer aided design software, guaranteeing that the occlusal surface, the lip-cheek side and the palate side are matched with the dentition in shape, the edge is stretched properly, the lip-cheek side and the palate side are wrapped to exceed the range from dentition to gingiva and the protector is attached to the surface form of soft tissue and the lower jaw dentition occlusal surface makes uniform contact with the sports tooth protector worn on the upper jaw; using a novel machinable material polyether ether sulfone (PEES) with high strength and proper elasticity for cutting through computer-aided manufacturing equipment to obtain a finished product of the sports tooth protector, and making the finished product be tried on in the mouth of a sporter. The manufacturing method aims to simplify and optimize the manufacturing method, process and material of the personalized sports tooth protector, shorten the manufacturing period, reduce the size of a finished product, realize more accurate occlusion registration and bring more comfortable wearing experience to a patient.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Mounting device for automatic winding of motor coil

InactiveCN113067445AWind evenlyAchieve fully automatic windingManufacturing dynamo-electric machinesElectric machineryStructural engineering

The invention relates to the technical field of motor coil winding, and discloses a mounting device for automatic winding of a motor coil, the mounting device comprises a bearing frame, the upper side of the bearing frame is fixedly connected with a sliding rod, the outer side of the sliding rod is slidably connected with a first sliding block, and the upper side of the first sliding block is rotatably connected with a first connecting rod; the upper side of the first connecting rod is rotationally connected with a connecting block, the front side of the connecting block is fixedly connected with a rotating shaft, and the upper side of the rotating shaft is rotationally connected with a friction wheel. According to the mounting device for automatic winding of the motor coil, a first sliding block is driven to move up and down on a sliding rod, then a rotating shaft is driven to rotate under the action of a first connecting rod and a connecting block, so that a friction wheel is driven to rotate, and an iron core is driven to slowly rotate at a constant speed through rolling friction force; and by means of the structure, the effects that full-automatic winding is achieved, manpower consumption is reduced, and coils are evenly wound are achieved.

Owner:晴栀菀歌智能科技(上海)有限公司

Automatic control system and production method for manual hollow fine dried noodles

ActiveCN113925073ABeneficial to human healthReduce the amount addedProgramme controlMixing/kneading structural elementsAutomatic controlRobotic systems

The invention relates to the technical field of fine dried noodle production, and discloses an automatic control system for manual hollow fine dried noodle, which comprises a discharging control system, a conveying belt control system, a chain control system, a noodle cutting and packaging control system and a central control system. The discharging control system comprises a stirrer system, a discharging conveying belt, a water maker, a water storage tank, a water supply metering pump and a hemispherical dough kneading and fermenting device; the conveying belt control system comprises an integrated strip cutting and coiling machine system, a conveying belt system, an integrated strip twisting and coiling machine system and an intelligent operation robot system. According to the invention, intelligent equipment is used for replacing manpower, large-scale mass production can be achieved, the production process is still a fermenting stretching process substantially, production through an automatic control system is more standard, sanitary and healthy, and if automatic control production is used, the production time is short and generally needs 7-8 hours, and the adding amount of table salt is small, 24-hour of uninterrupted production can be achieved, and human health is better facilitated.

Owner:宁夏亲喜之面食品有限公司

Hericium erinaceus bag-tea preparing method

InactiveCN1742599AQuick Soak DissolveImprove product added valueTea substituesFungi medical ingredientsBearded toothHigh pressure

The preparation method of hericium erinaceus tea bag includes the following steps: (1) pulverizing; (2) high-pressure steam sterilization, pressure is 1.000-2.110x100000 Pa, temperature is 120-135deg.C and time is 20-160min.; (3) cooling, prepackaging by paper bag of tea bag, sealing; (4) packaging by using aluminium film bag, sealing; and (5) secondary high-pressure steam sterilization.

Owner:GUANGDONG INST OF MICROORGANISM

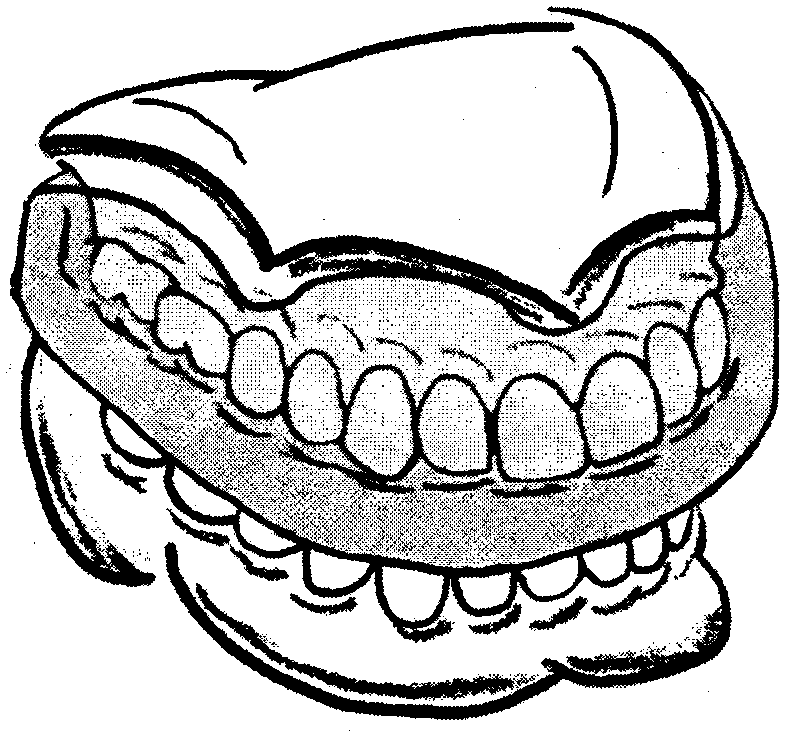

Whole-process digital designed produced personalized sleep bruxism protective occlusal splint

PendingCN110353868AHigh precisionSave materialNon-surgical orthopedic devicesComputer-aidedDentition

In view of the shortage of manufacturing methods and materials of a conventional sleep bruxism protective occlusal splint, the invention provides a sleep bruxism protective occlusal splint prepared byapplying digital impression, computer-aided design and computer-aided manufacturing. The sleep bruxism protective occlusal splint is characterized in that upper and lower jaw dentition data and the occlusal relationship after occlusal elevation are obtained by an intraoral scanning technology, and upper and lower jaw dentition digital models and the occlusal relationship are matched with a virtual occlusal frame system of a computer; with computer-aided design software, front and rear dental cusps can be guaranteed to be in even contact with the occlusal splint; a material is cut through a computer-aided manufacturing device, medical-grade engineering plastic polyether-ether-ketone (PEEK), polyether ether sulfone (PEES) or polyether sulfone (PES) with excellent performance is used, the selected material can be determined according to the order of severity of sleep bruxism and the type of a restoration body of teeth of a patient, a final restoration body is obtained and is worn into amouth, and the dentition is protected and abnormal wear is prevented. The method aims at simplifying and optimizing the manufacturing process of the sleep bruxism protective occlusal splint, reduces discomfort, saves cost, and is beneficial to environmental protection.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com