Halogen lamp foot-bending machine

A technology of bending machine and halogen lamp, which is applied in the direction of electrical components, etc., can solve problems such as unsatisfactory, broken lamp legs, disordered direction of lamp legs, etc., and achieves the effect of beautiful appearance and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

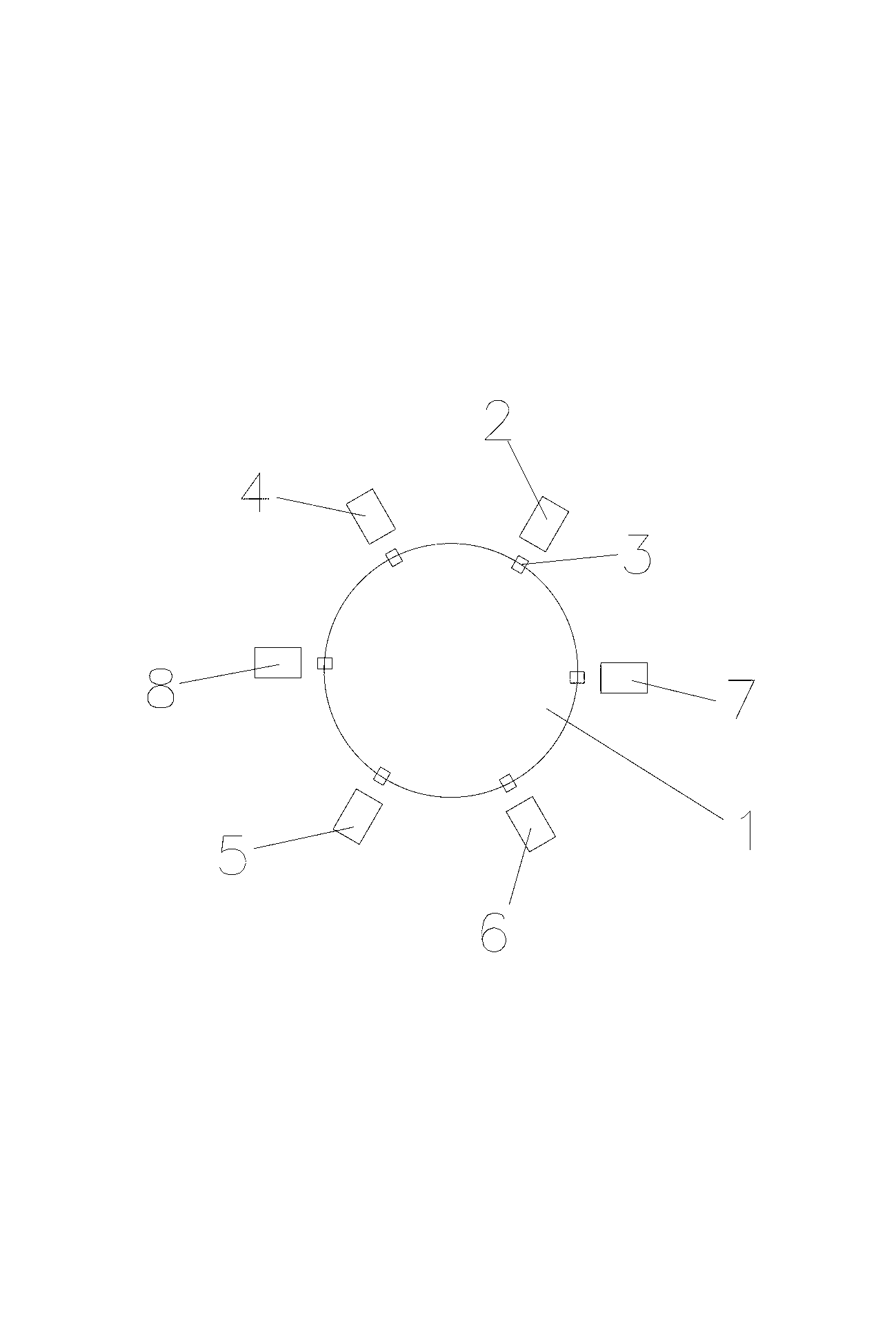

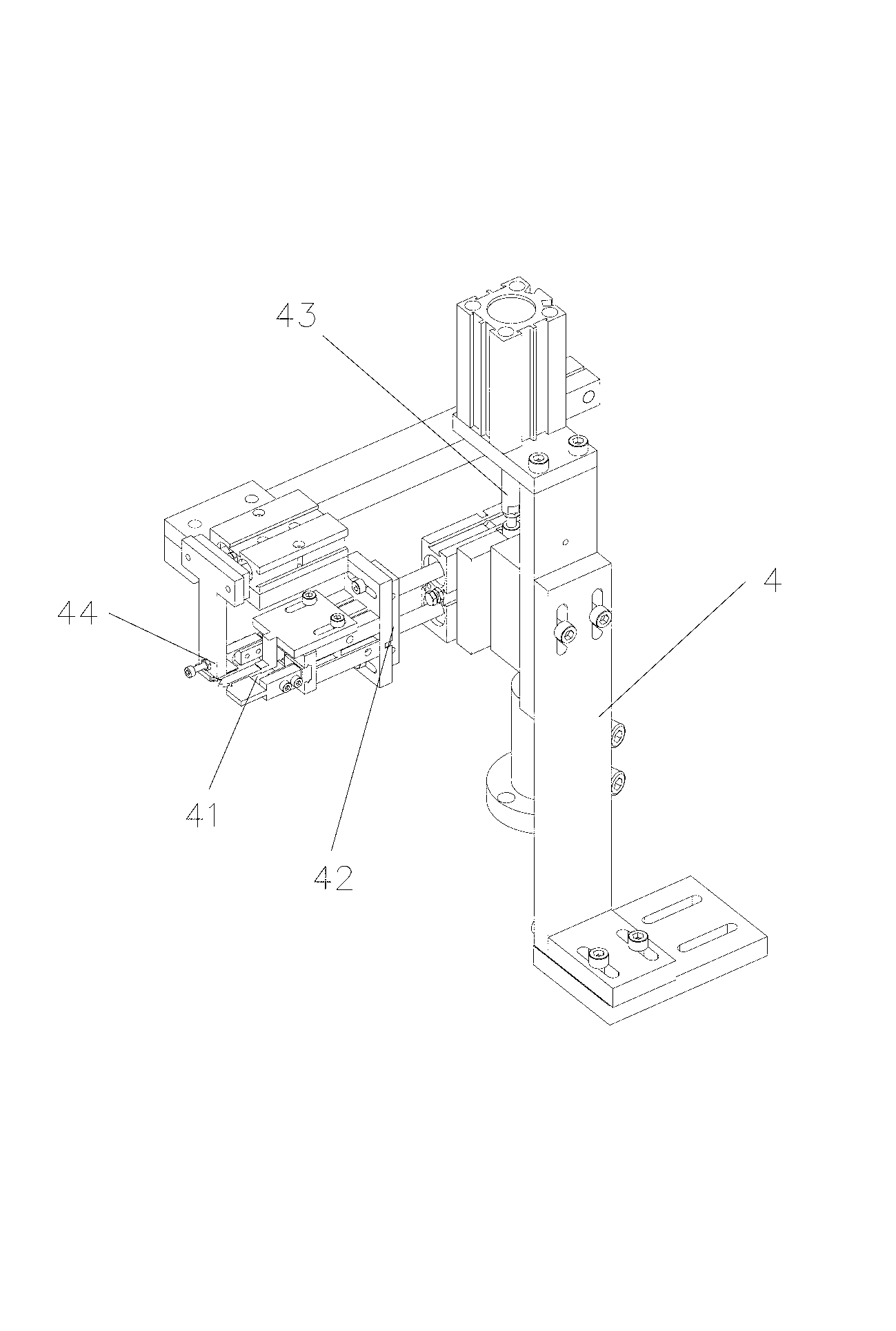

[0020] refer to Figure 1~5 , a halogen lamp bending machine, including a working platform, the center of the working platform is provided with a multi-station turntable 1, the multi-station turntable 1 is installed on an arc cam divider, and the multi-station turntable 1 is Each station in the radial direction is provided with a bulb fixture 3, and the outer side of the bulb fixture 3 is sequentially provided with a vibrating plate feeding mechanism 2, a lamp leg straightening mechanism 4, a leg bending mechanism 5, and a lamp leg shaping mechanism. mechanism 6 and blanking mechanism 7, a pre-bending mechanism 8 is provided between the lamp pin straightening mechanism 4 and the bending mechanism 5; by adding the pre-bending mechanism 8, the lamp pin is pre-bent before bending Bend to make it form a certain pre-bending angle, which can be more convenient for the subsequent bending work and improve the yield.

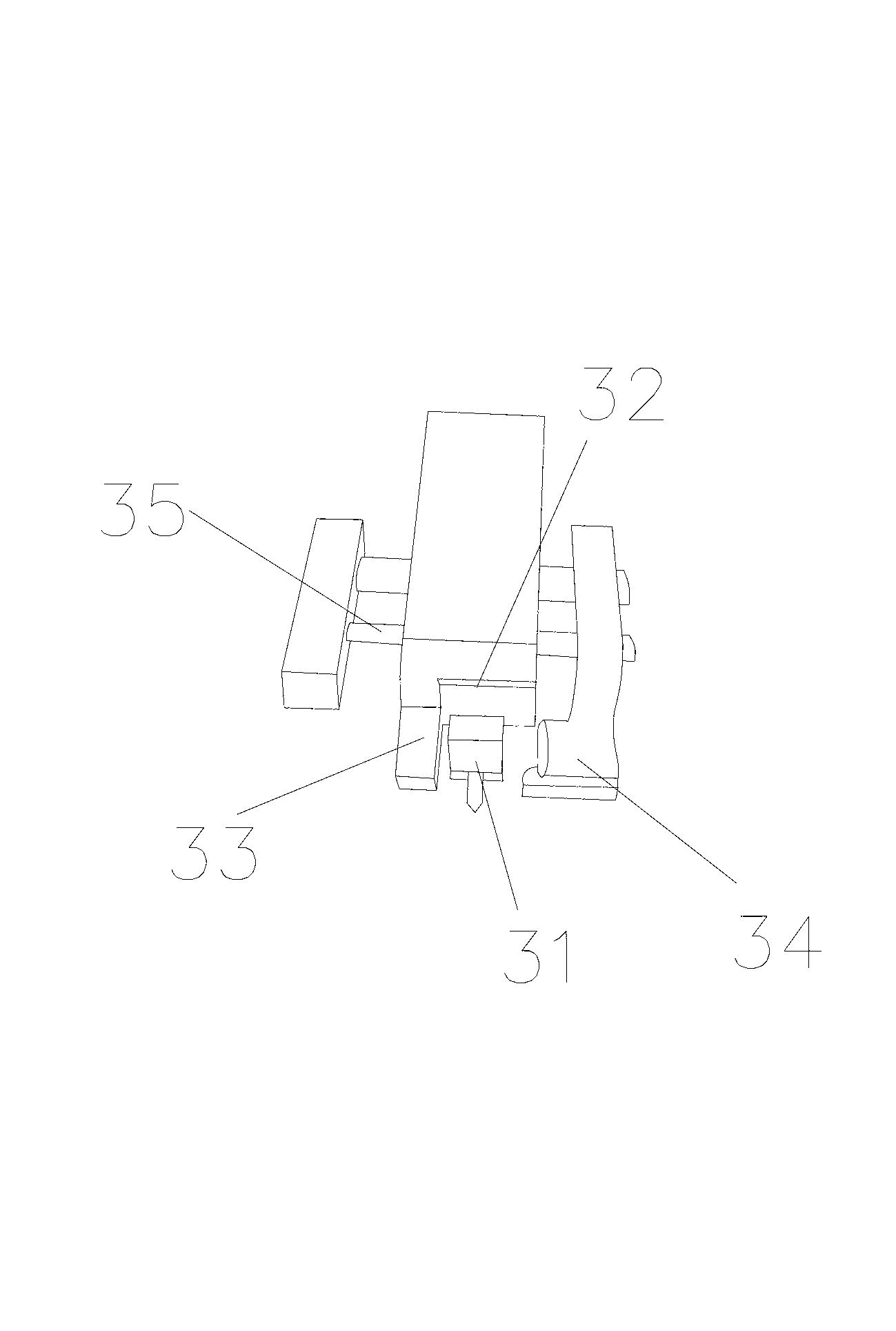

[0021] In order to facilitate the positioning of the bulb, the bul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com