Split type linear motor iron core

A linear motor, split technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of reducing the effective magnetic flux of the iron core, low thrust density of the linear motor, and large iron core reluctance, etc., to increase the magnetic flux, The effect of good thermal conductivity and high thrust density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

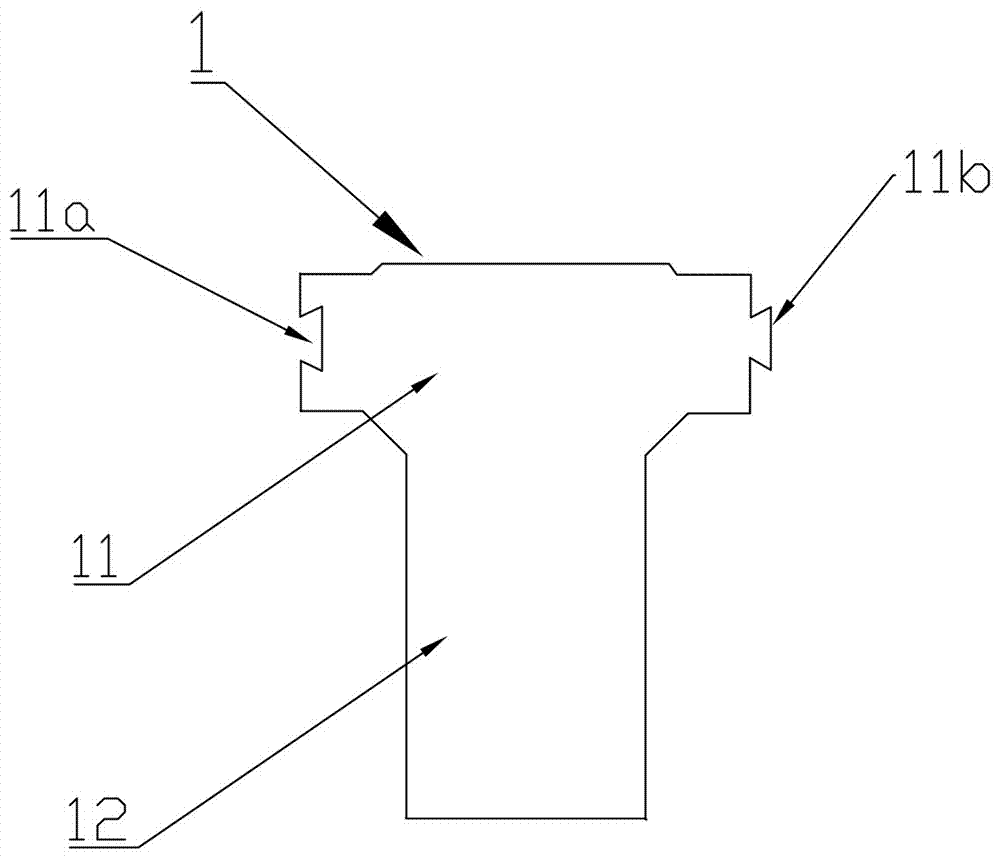

[0021] Embodiment 1: as figure 2 and Figure 5 A split type linear motor iron core shown includes a "T"-shaped main tooth 1 and a strip-shaped end tooth 2, and the materials of the "T"-shaped main tooth 1 and the strip-shaped end tooth 2 Both are silicon steel sheets; the "T"-shaped main tooth 1 includes an integrally formed horizontal strip-shaped connecting portion 11 and a vertical strip-shaped winding portion 12, and one end of the connecting portion 11 is provided with a hollow female buckle 11a , the other end is provided with a protruding male buckle 11b that cooperates with the female buckle 11a. There are various shapes of the male and female buckles, which can be dovetail, round, semicircular, T-shaped, and other irregular shapes. The size can be different, and it is preferably dovetail shape; the strip-shaped end teeth 2 include an integrally formed end connecting portion 21 and a sealing end portion 22, one end of the end connecting portion 21 is provided with a ...

Embodiment 2

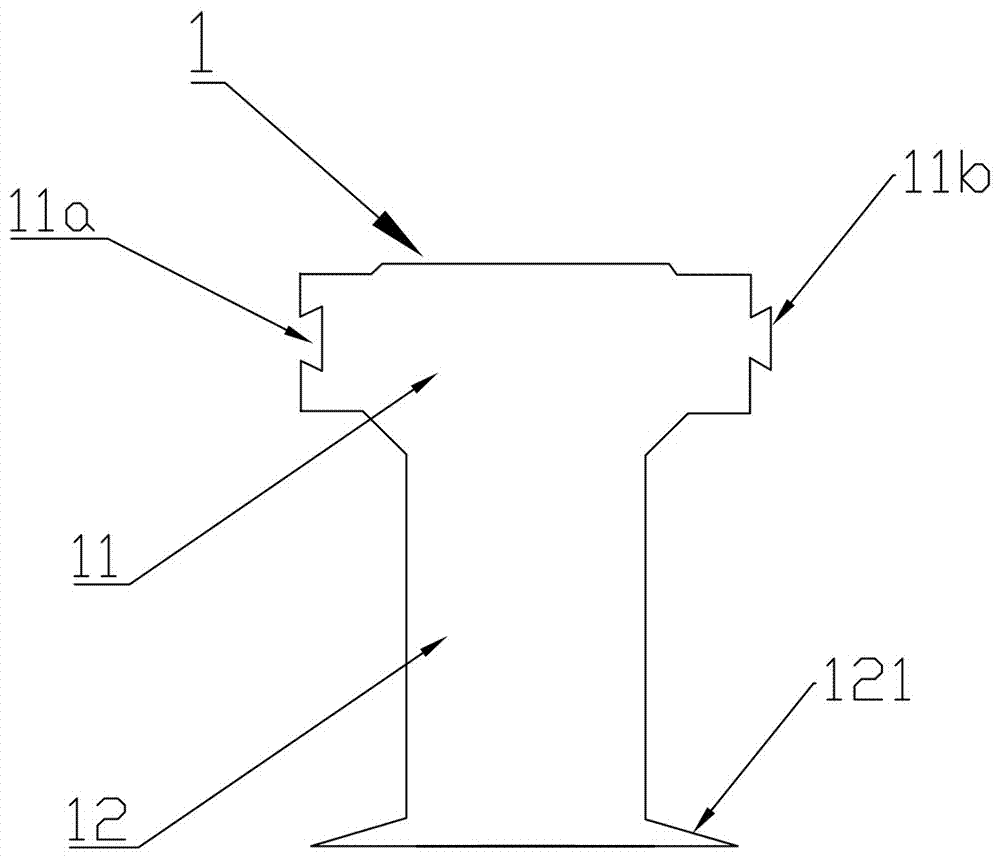

[0023] Embodiment 2: as image 3 As shown, the bottom end of the winding portion 12 has tooth shoes 121 protruding to the left and right sides.

Embodiment 3

[0024] Embodiment 3: as Figure 4 As shown, the bottom end of the winding portion 12 also has a rectangular notch 122 for improving the cogging effect, and there are 1 to 4 rectangular notches 122 .

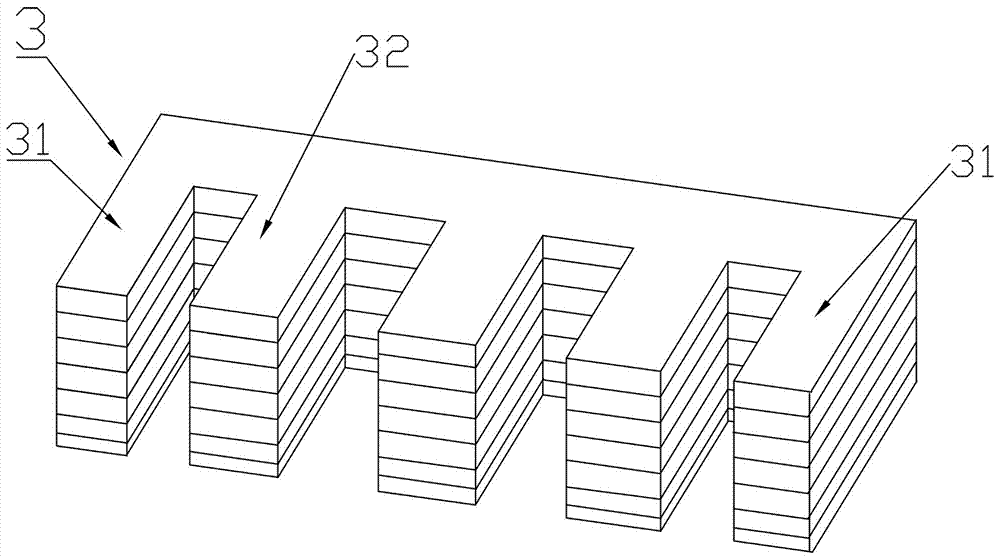

[0025] It is assembled as Figure 6 As shown, in the past, when manufacturing the iron core of the linear motor, it is necessary to select a single piece 3 of different length and size according to the length of the linear motor. For some non-standard length linear motors, it is often necessary to re-open the mold according to the required size. Single piece 3; now the integrally formed single piece 3 is designed as a single-tooth structure, and the two ends of the connecting part 11 of the "T"-shaped main tooth 1 are respectively provided with a female buckle 11a and a male buckle 11b matched with it. It can be made into iron cores of different lengths and sizes. When they are spliced to a certain length, the strip-shaped end teeth 2 are spliced on the first and last "T"-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com