Patents

Literature

33 results about "Parts tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

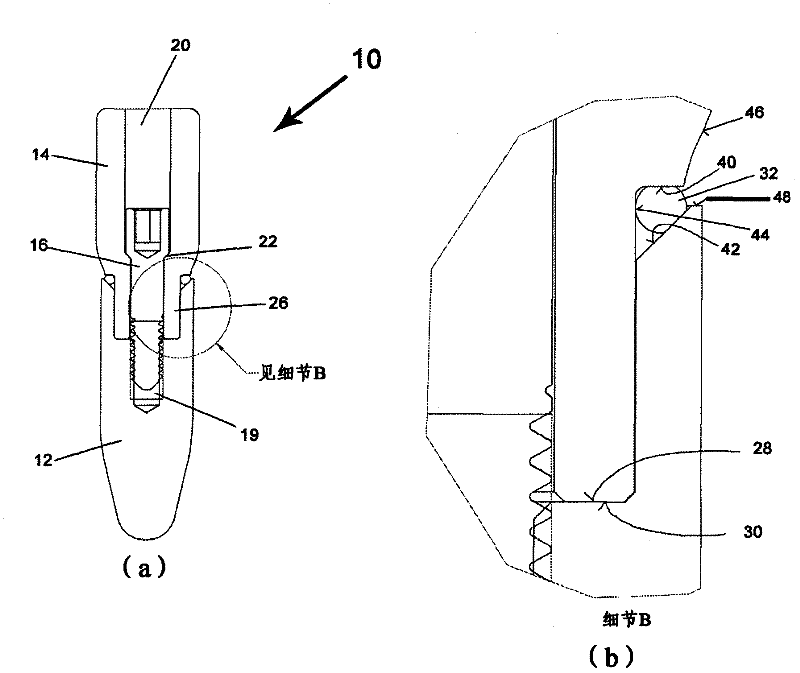

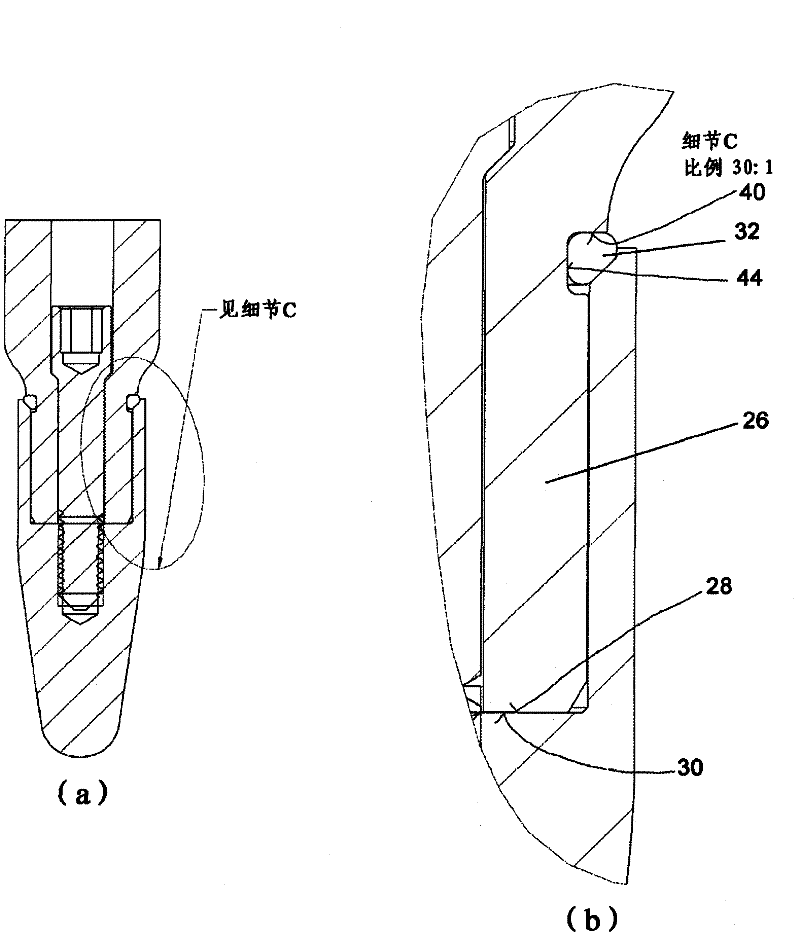

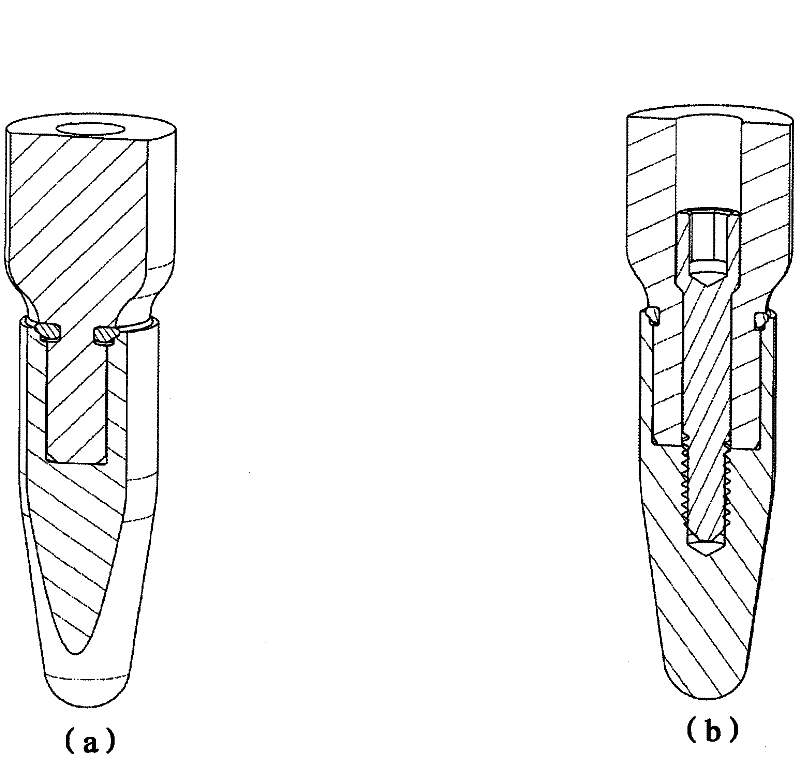

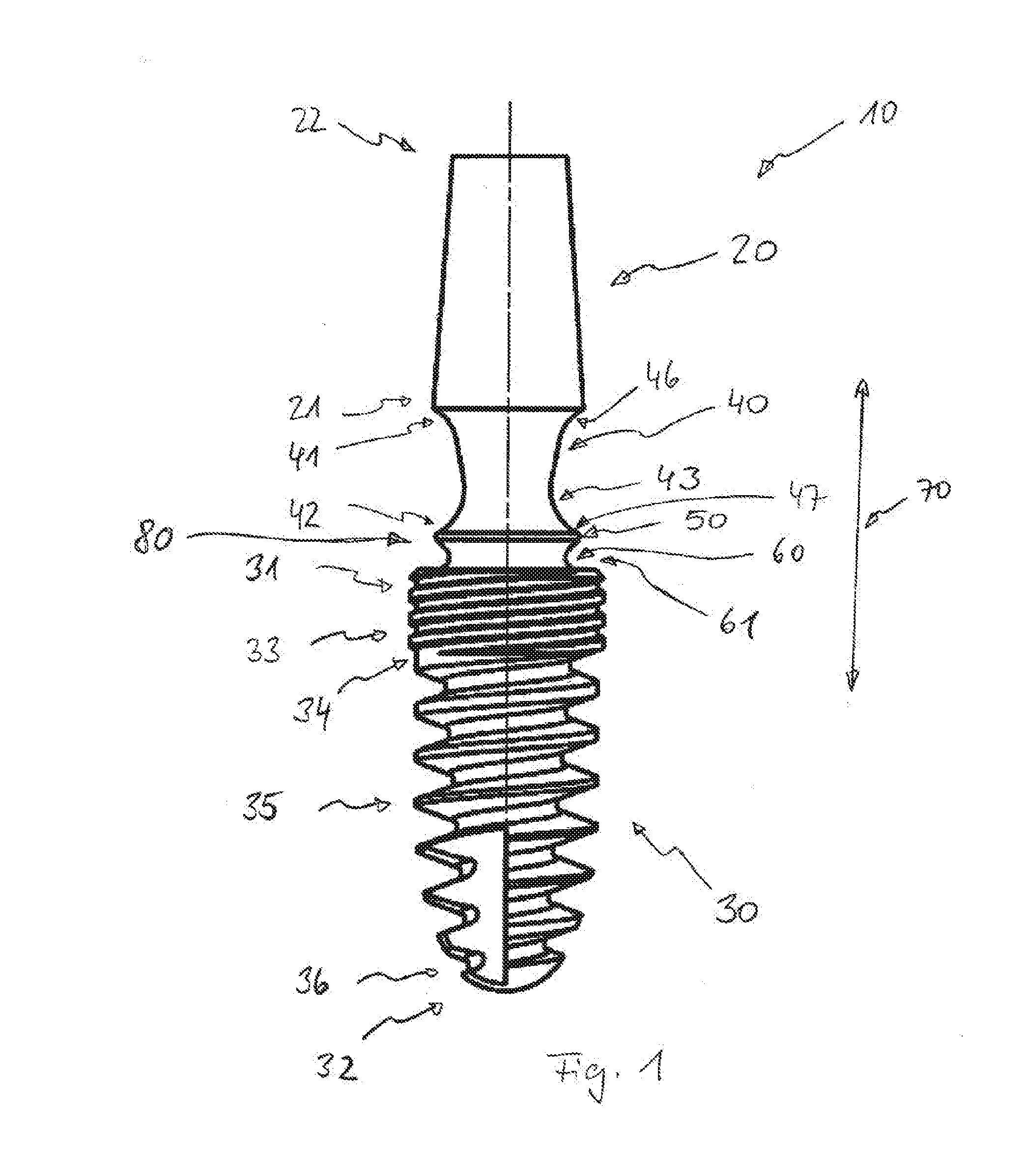

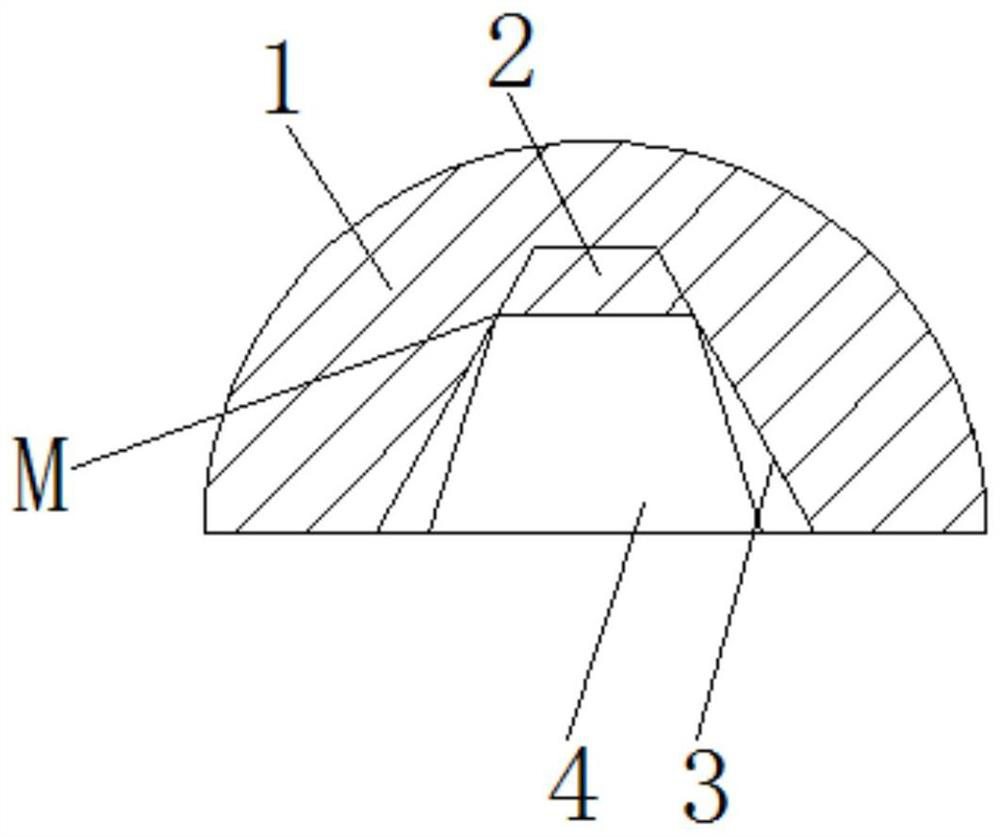

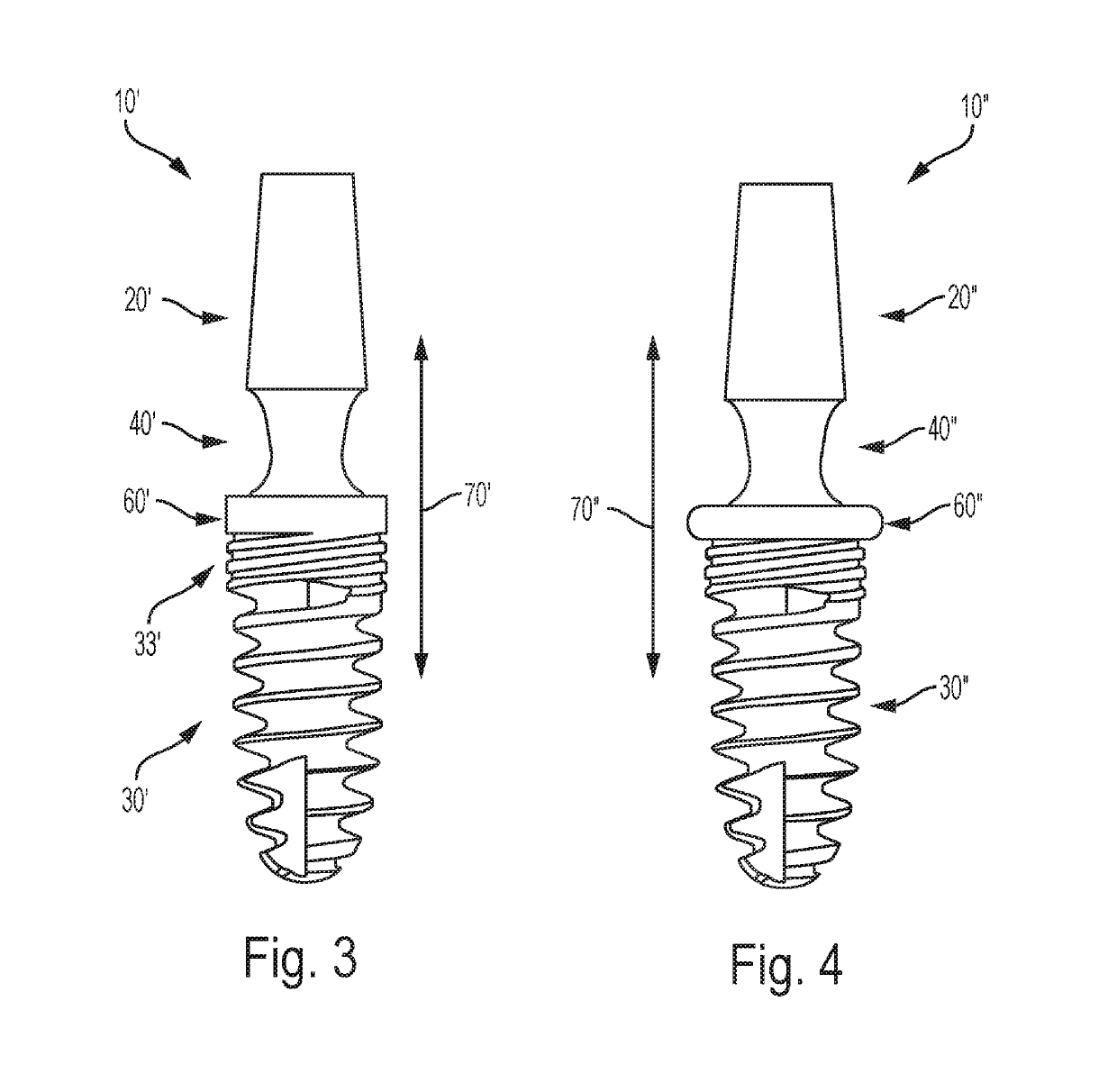

Tooth implant

The invention relates to a multi-part tooth implant with at least a proximal implant part and a distal implant part that are to be connected to each other such that a connection site is obtained when the two implant parts are in the connected state. An annular sealing element is arranged at this connection site and, in the fitted state of the tooth implant, is clamped between mutually opposite sealing surfaces, namely a sealing surface of the proximal implant part and a sealing surface of the distal implant part, such that the sealing element has an outer surface portion that forms part of the outer contour of the tooth implant. The two sealing surfaces initially approach each other in a direction oriented outwards from a central longitudinal axis of the tooth implant. The sealing surfaces merge into outer surfaces of the tooth implant at the place where, in the outer contour of the fitted tooth implant, a surface portion formed by the sealing element in each case adjoins a surface portion formed by the respective implant part. These outer surfaces move away from each other in the outwardly oriented diretion.

Owner:MEHROF IMPLANT TECH GMBH

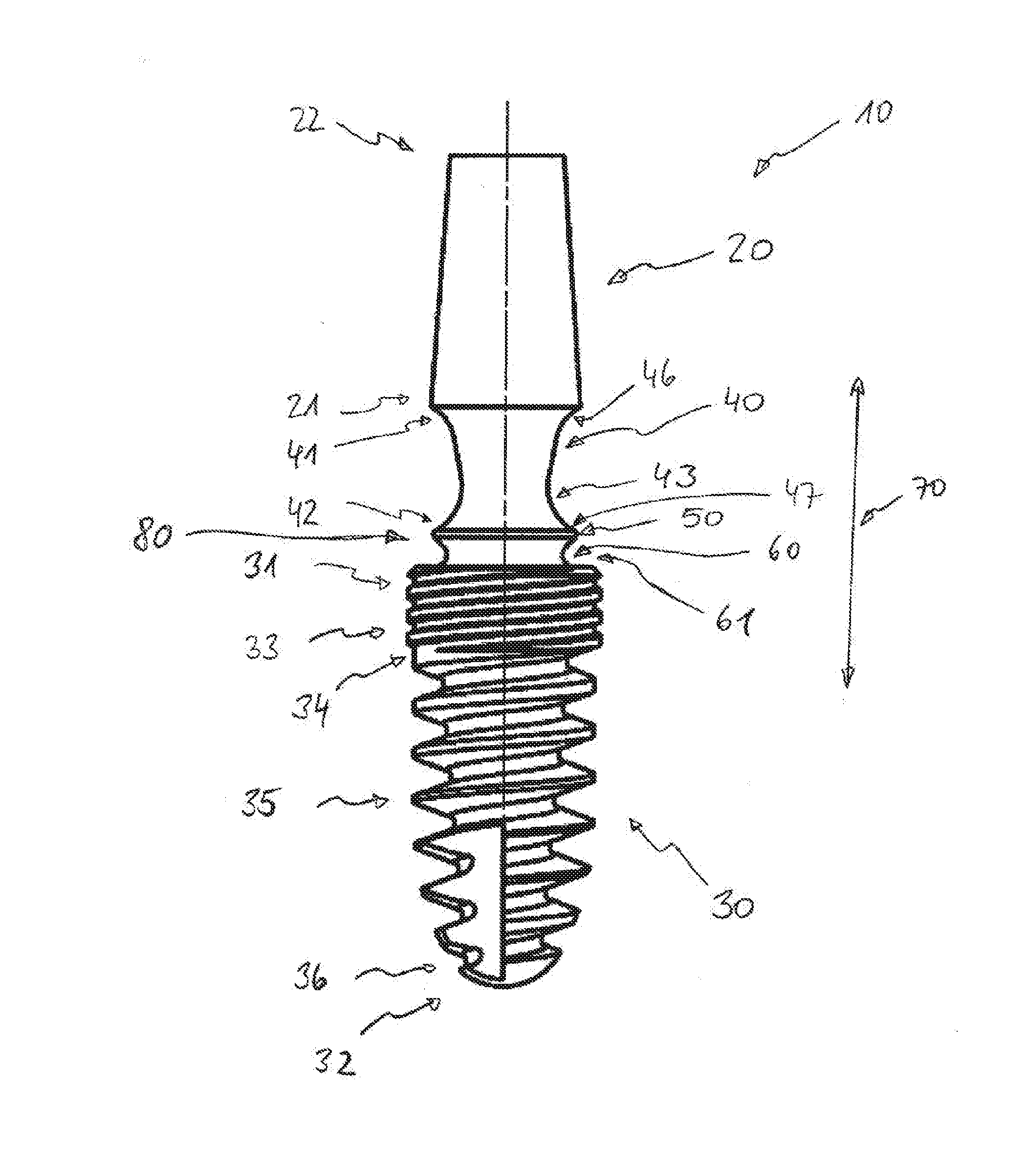

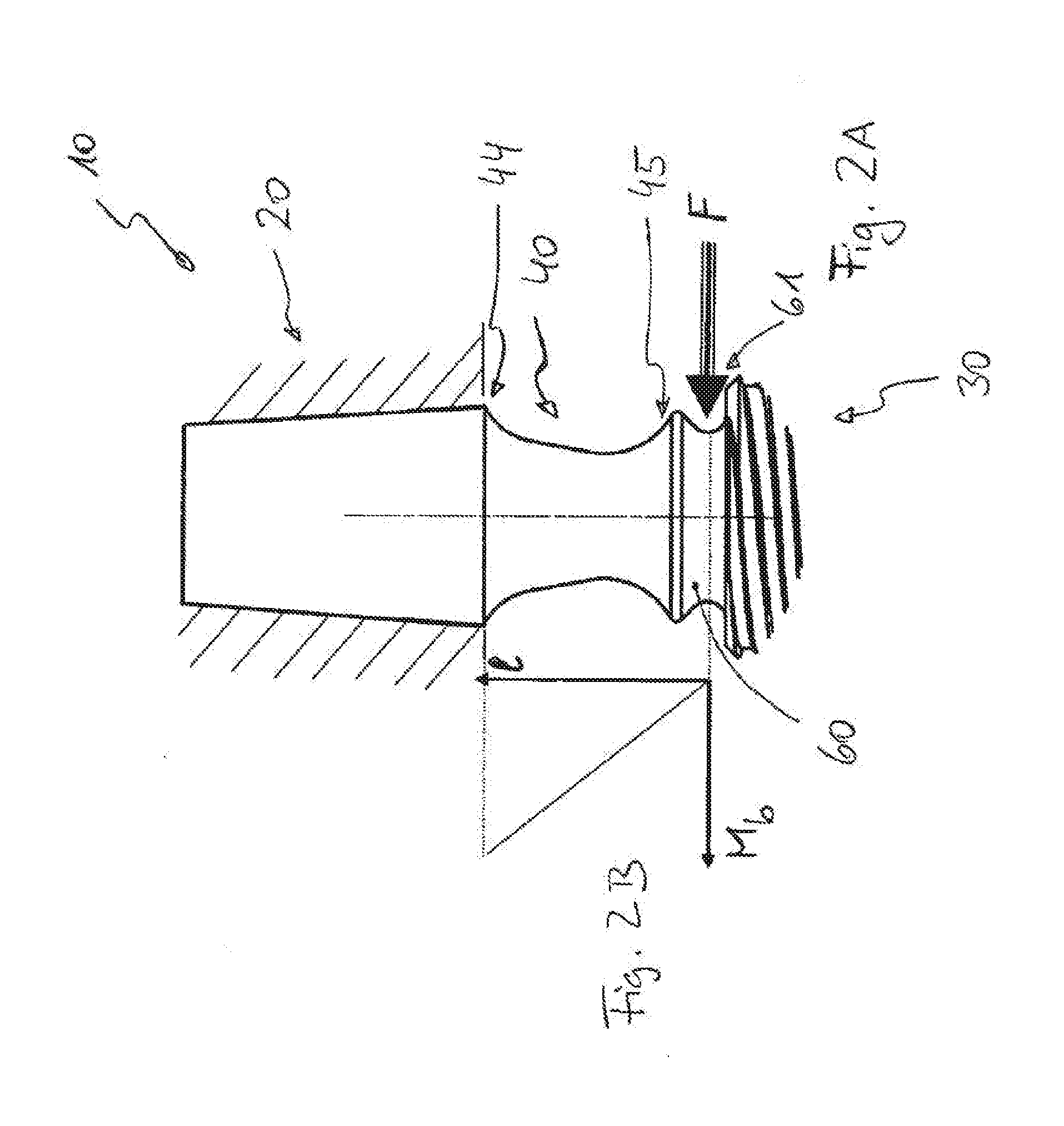

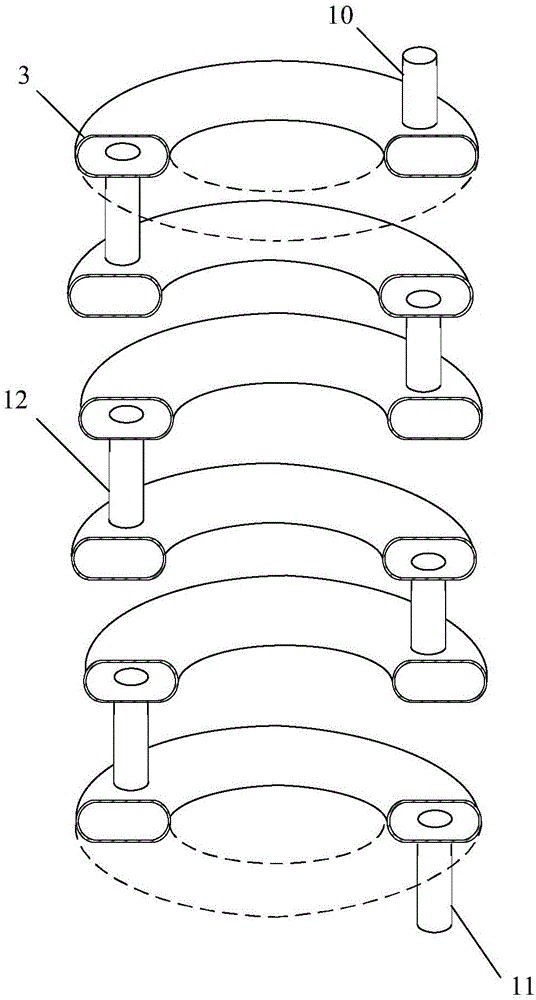

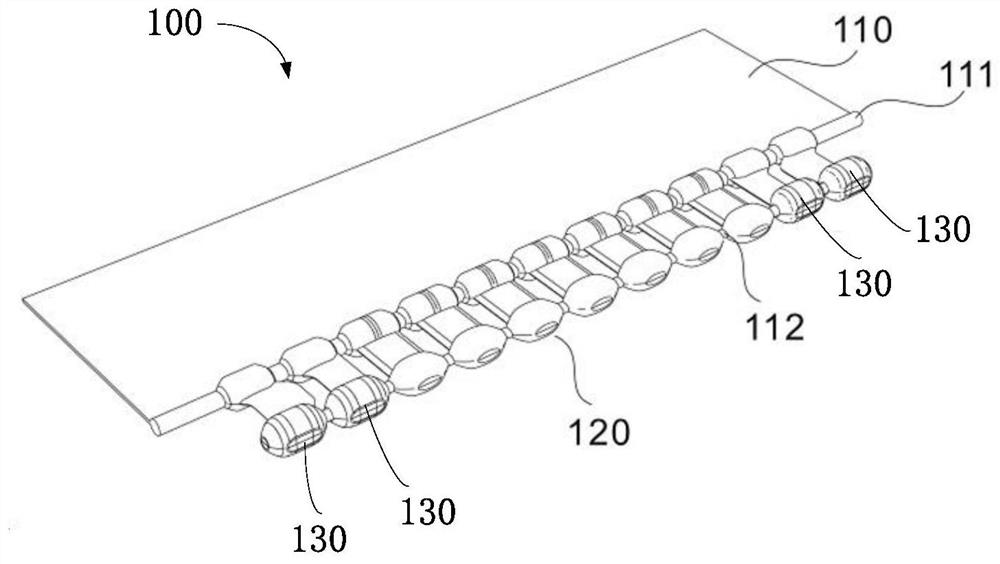

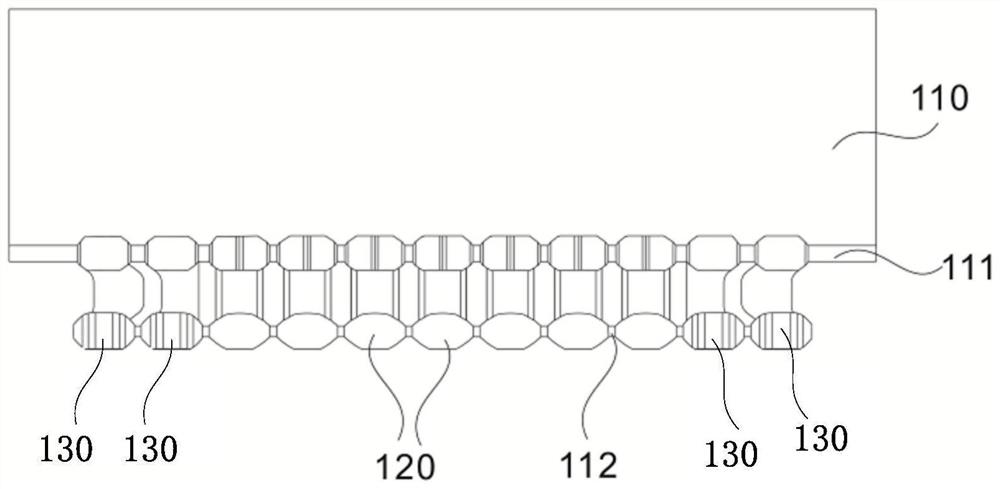

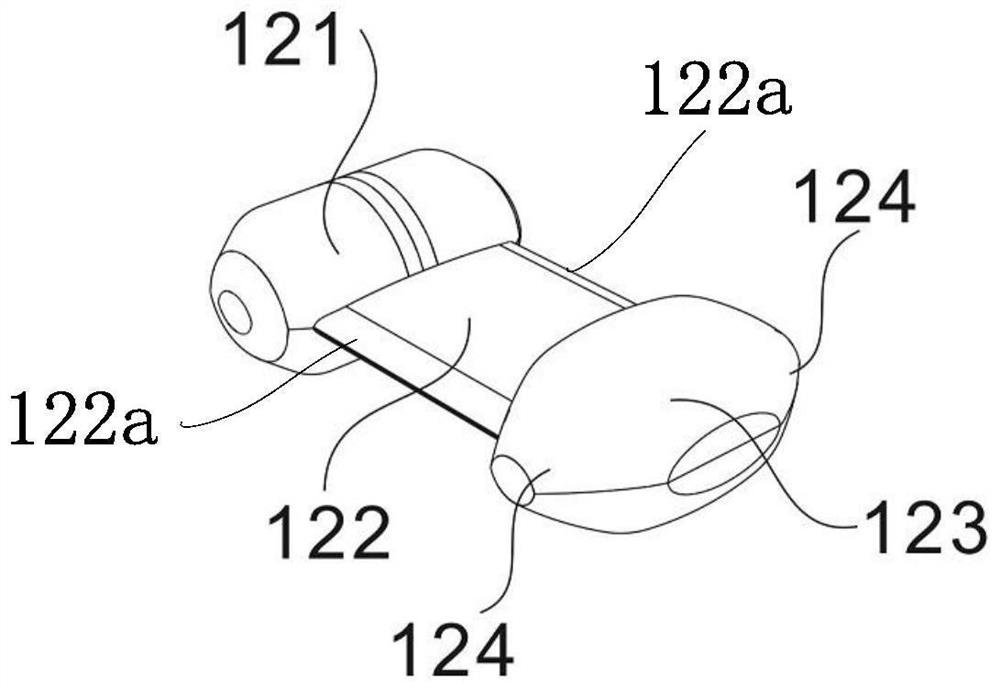

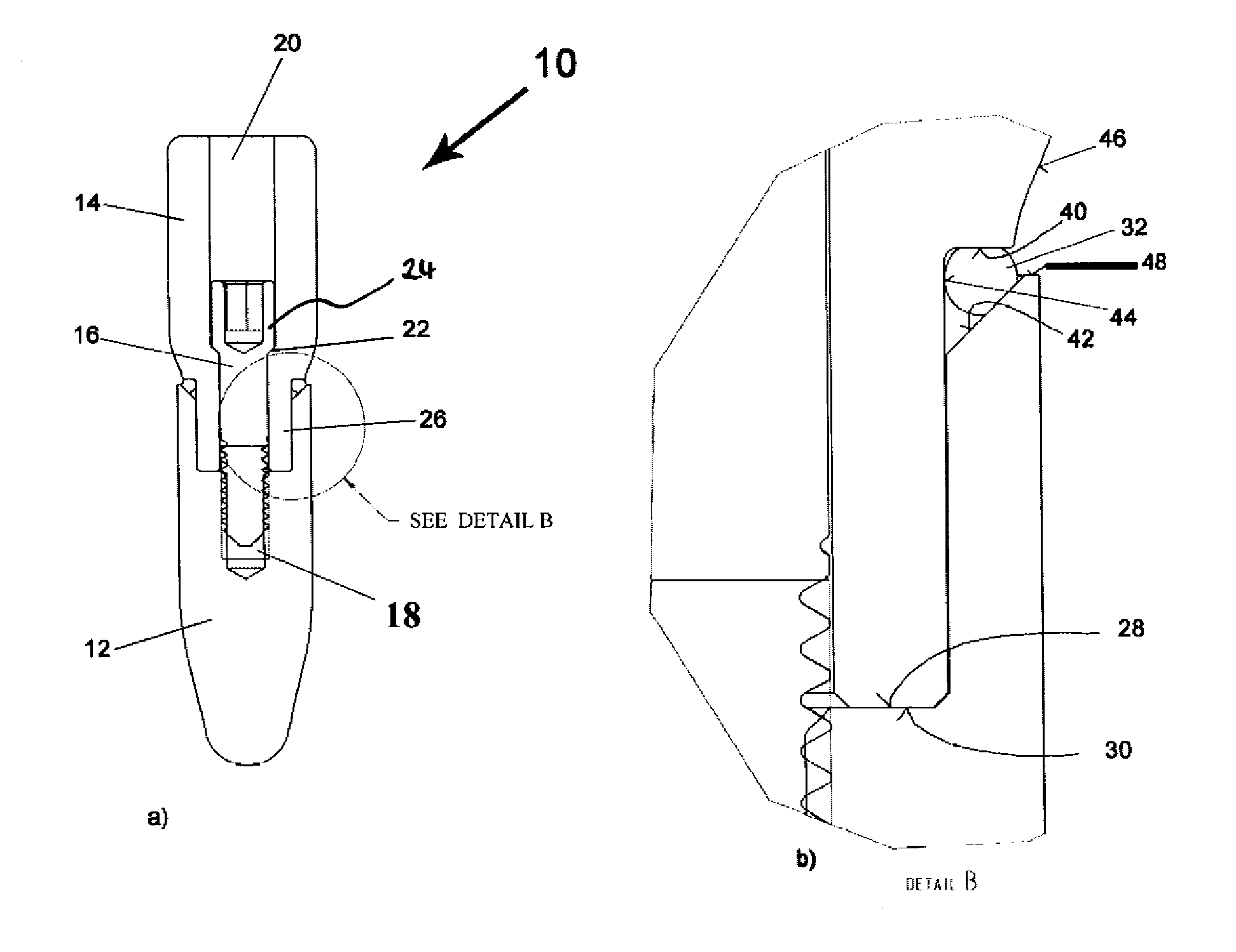

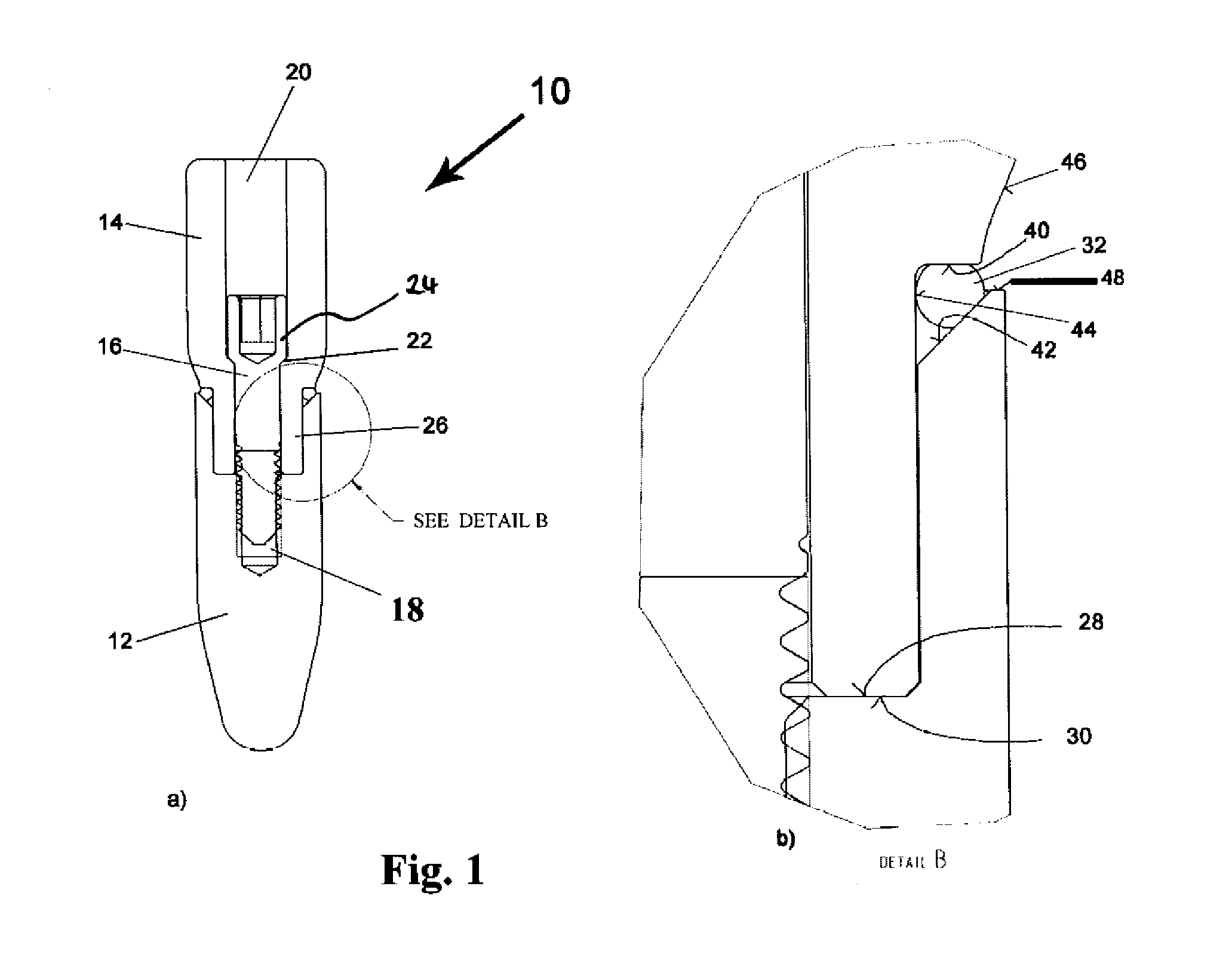

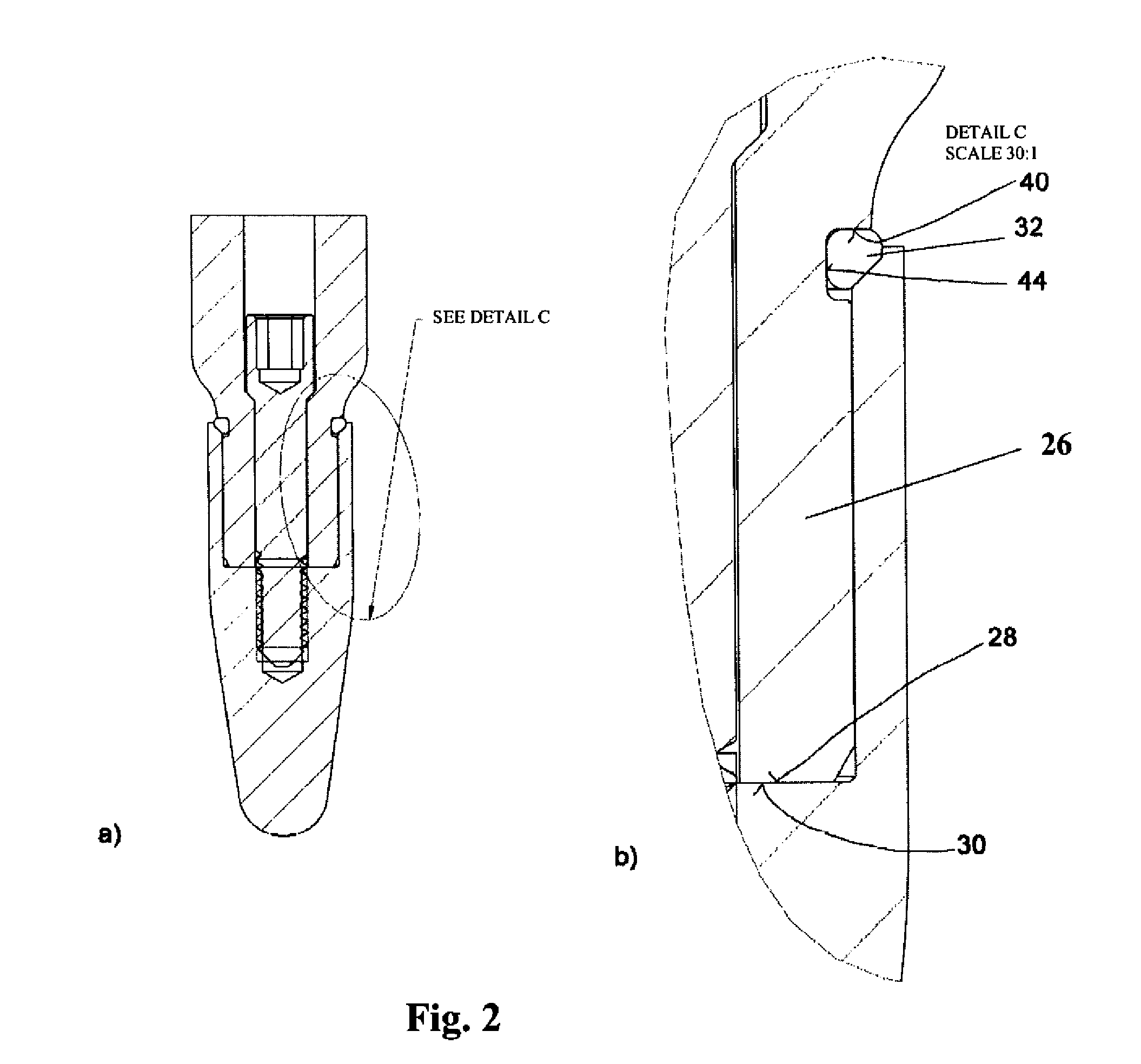

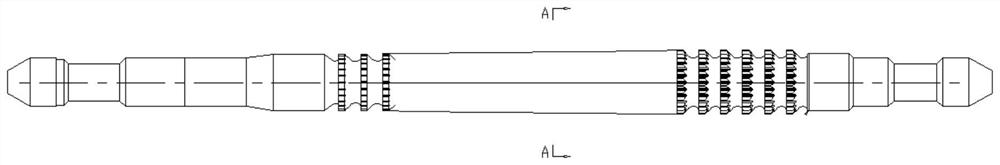

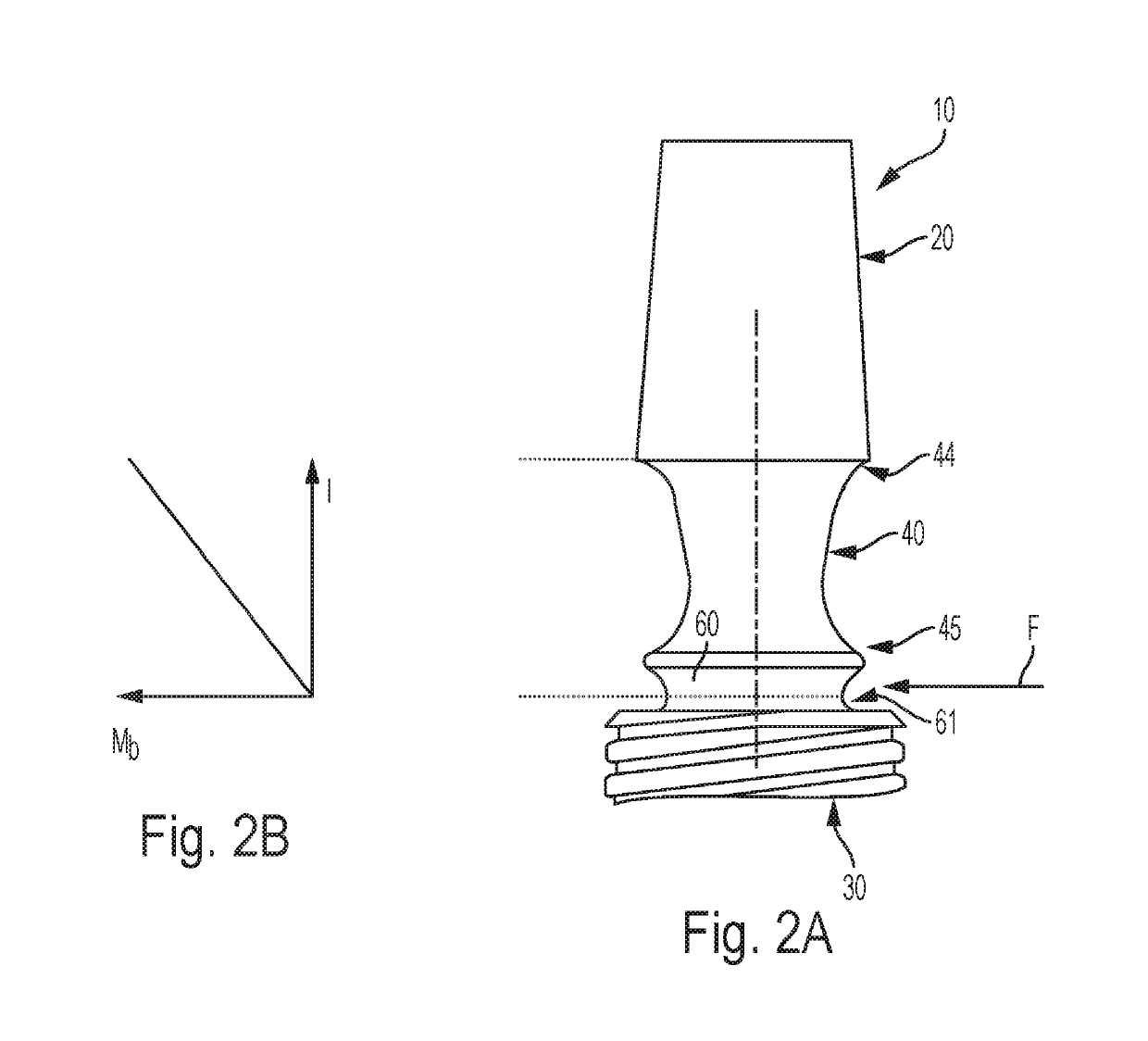

One-part tooth implant, device for bending an implant, and method for bending an implant

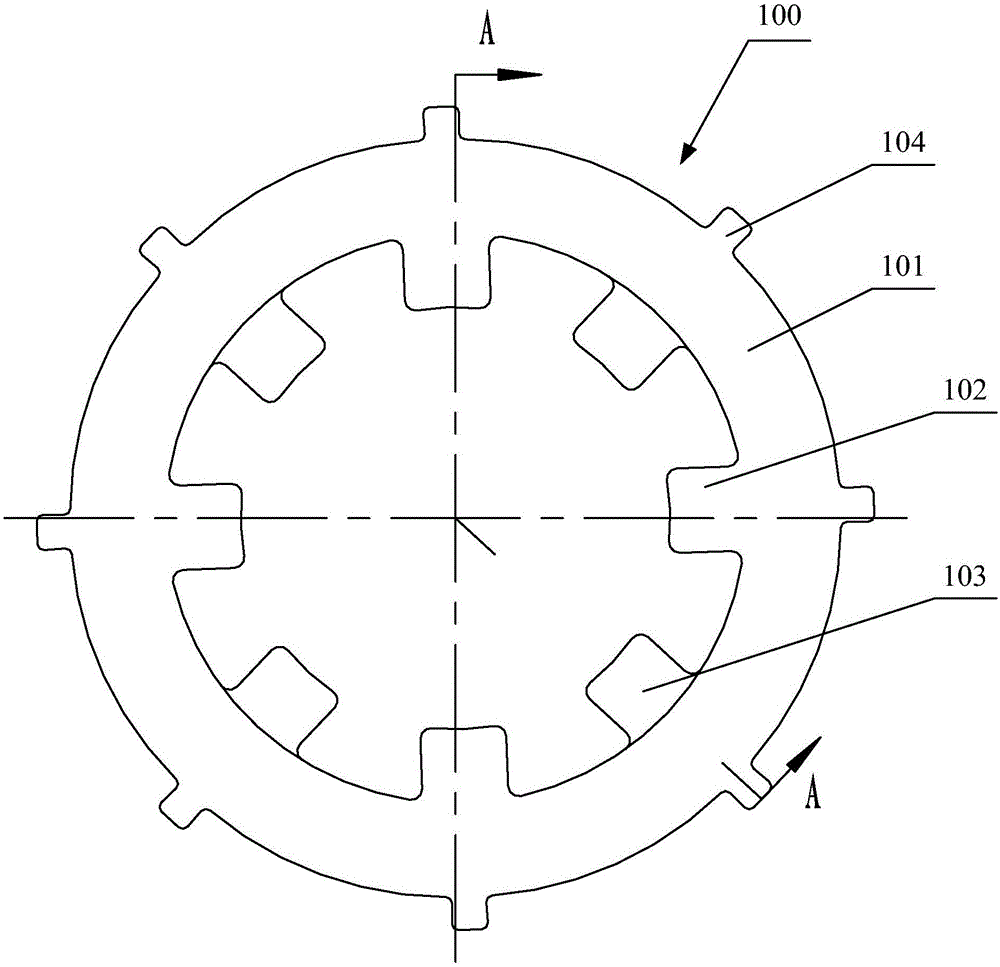

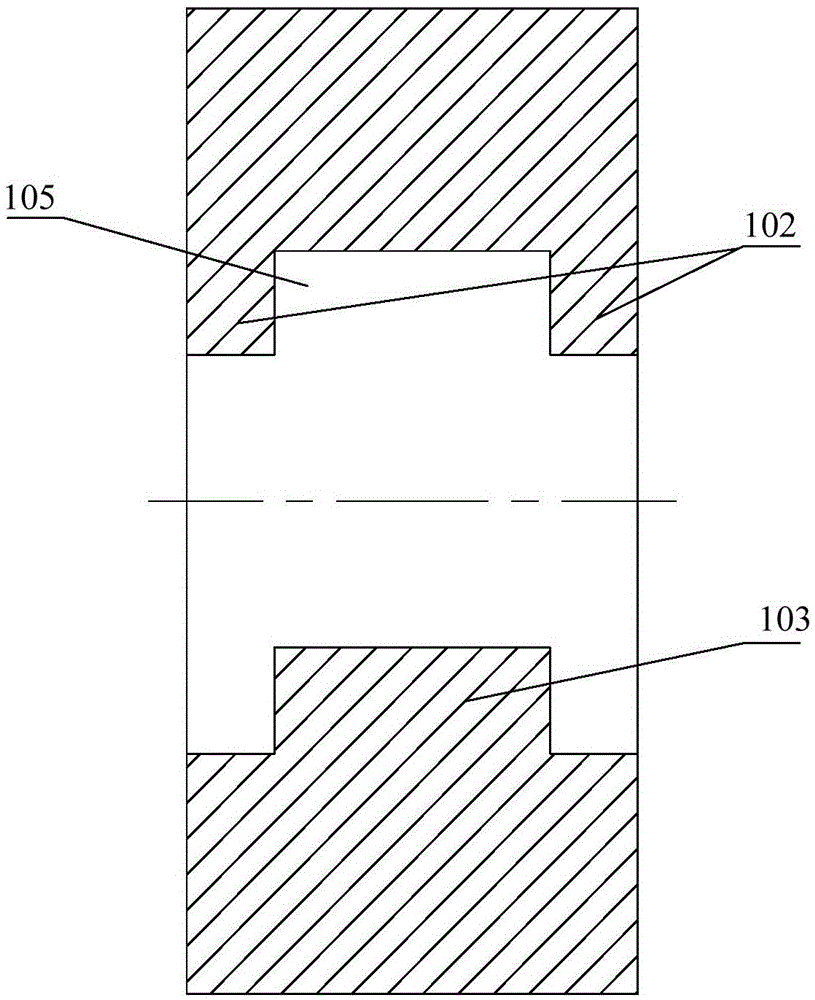

The invention relates to an implant (10) for anchoring in the human (optionally also in the animal) maxilla or mandible, a device (100) (an instrument) for bending an implant (10), a system, which comprises an implant (10) and a device (100) for bending an implant (10), and a method for bending an implant. As a result of the bending geometry, an implant (10) is provided which is bendable in a simple and materially-careful manner, in particular also after implantation, i.e., already anchored in the jaw bone. The device (100) for bending the implant (10) enables, as a result of the pliers-shaped design having corresponding holding (113) and support (123) units, the bending of the implant (10) in a simple manner, in particular the bending after implantation thereof, so that a treatment which protects the implantation region is ensured, in particular, no damage of the bone bed is induced. In addition, a method for bending the implant (10) is provided.

Owner:HAGER & MEISINGER

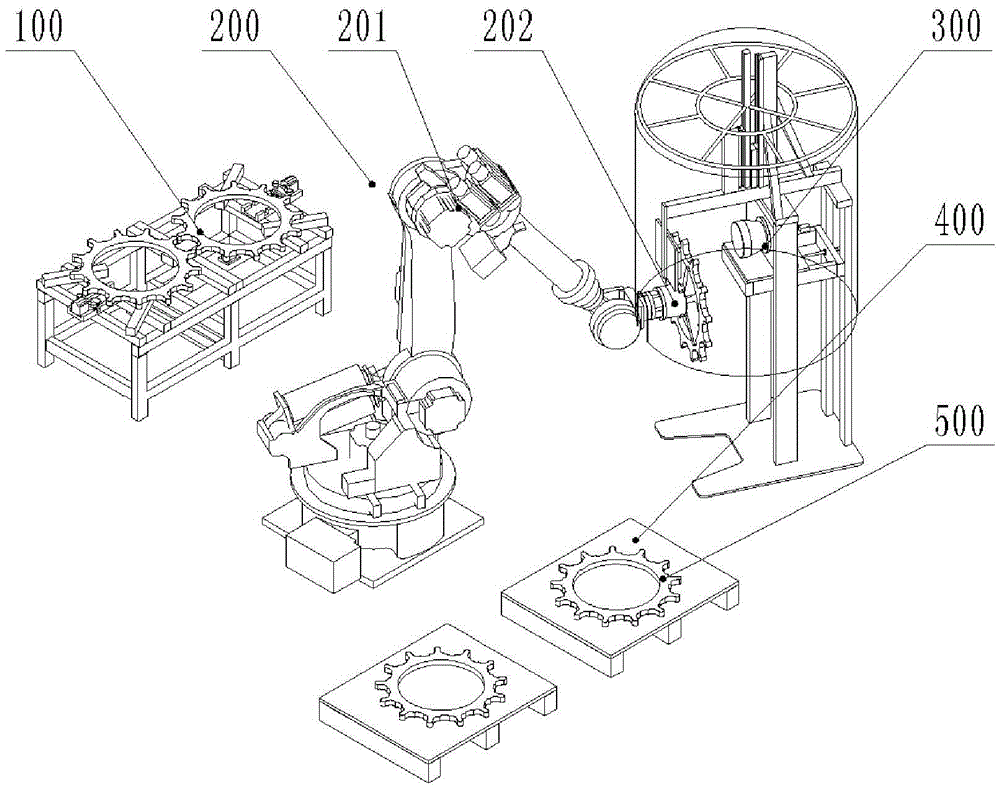

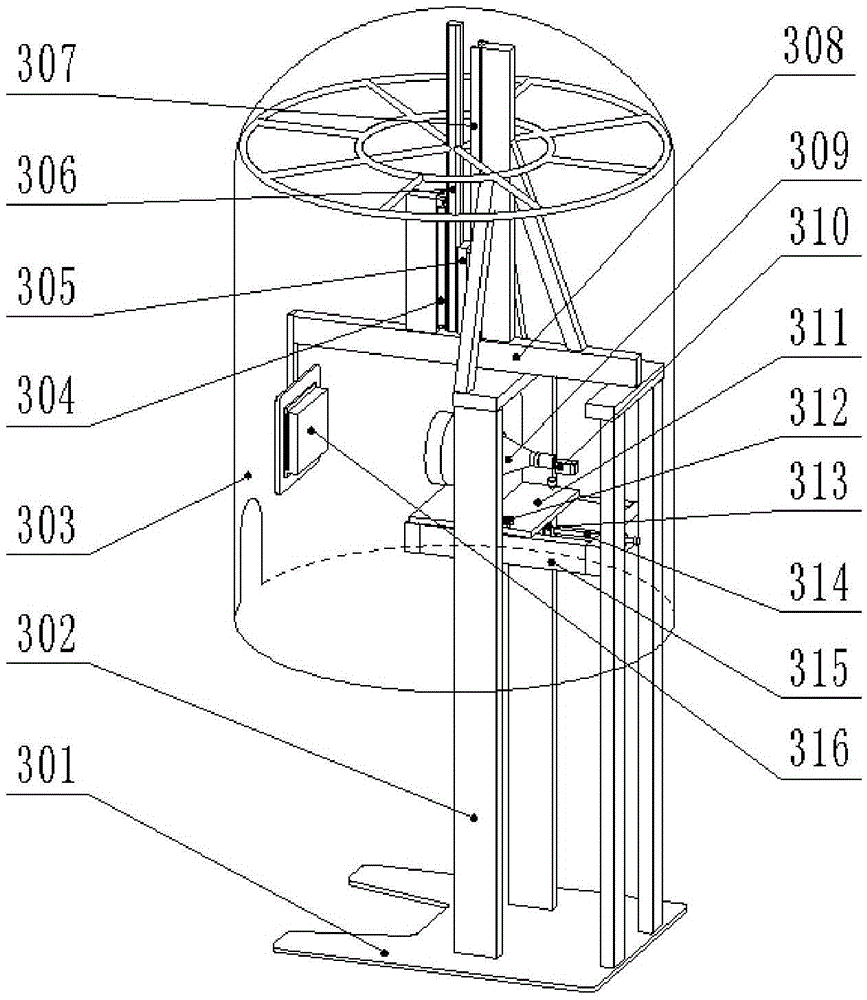

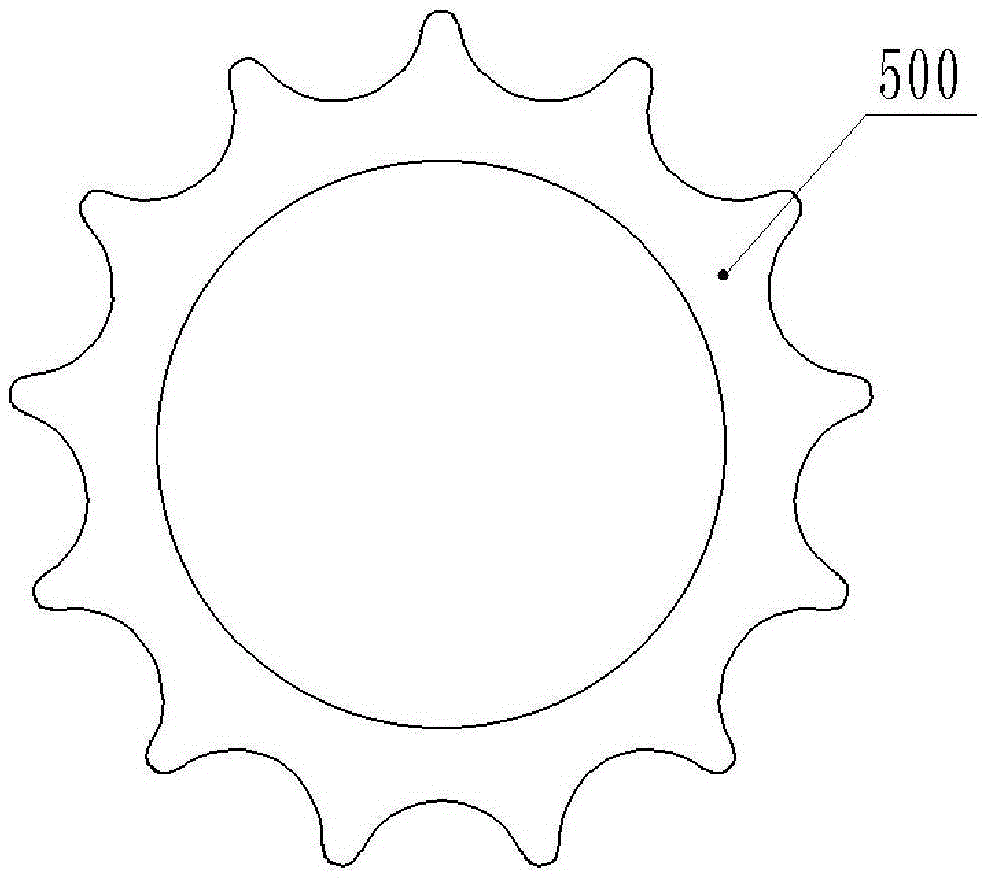

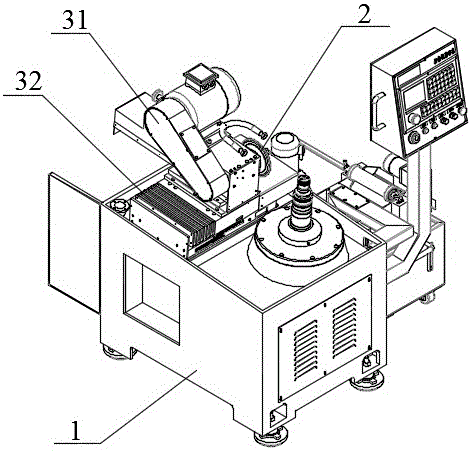

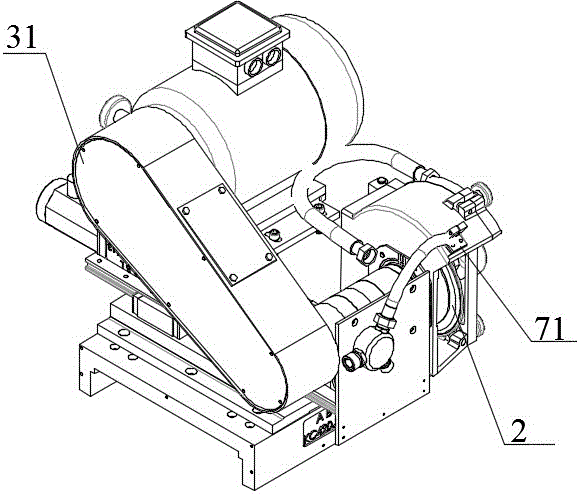

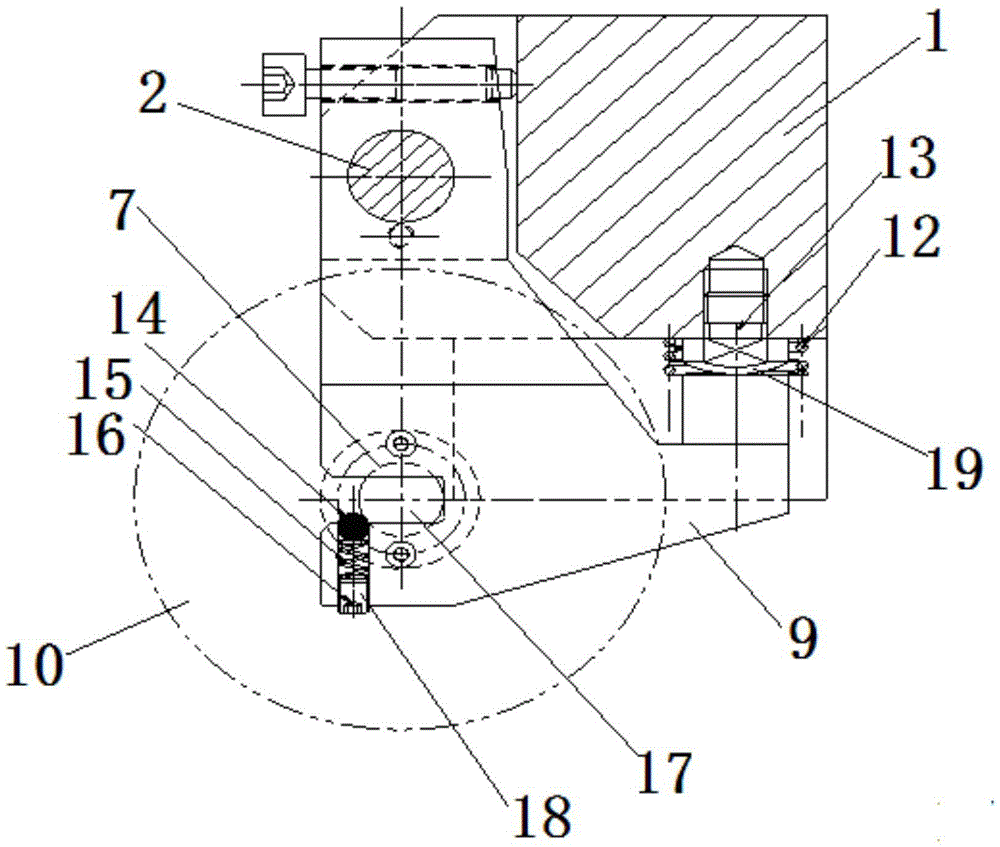

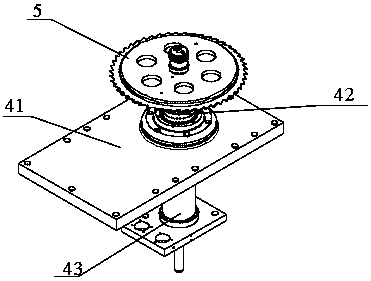

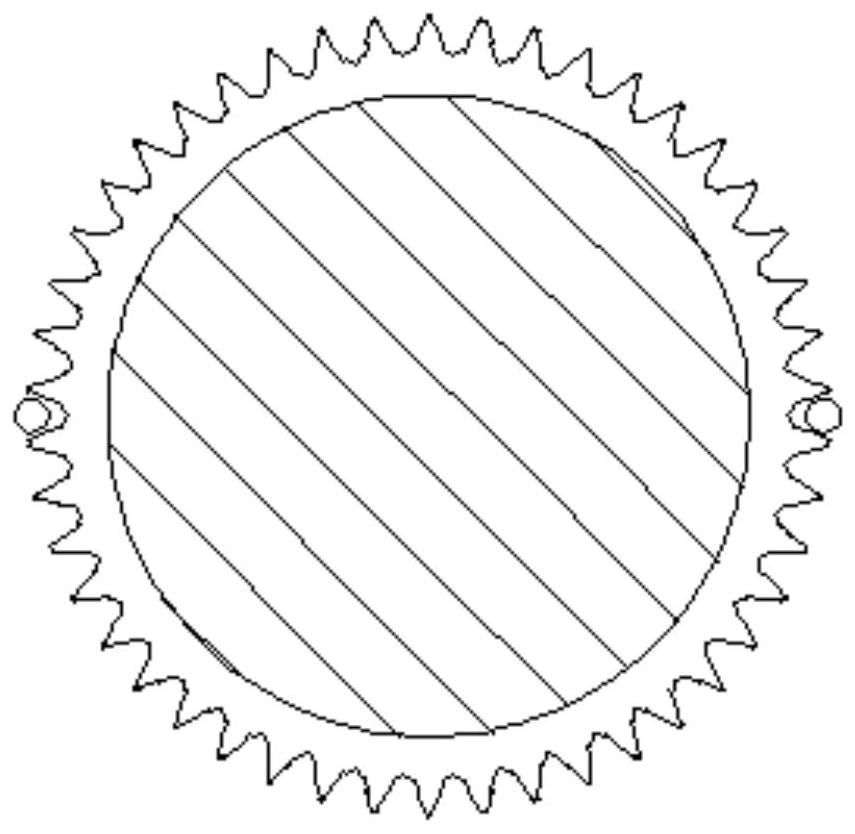

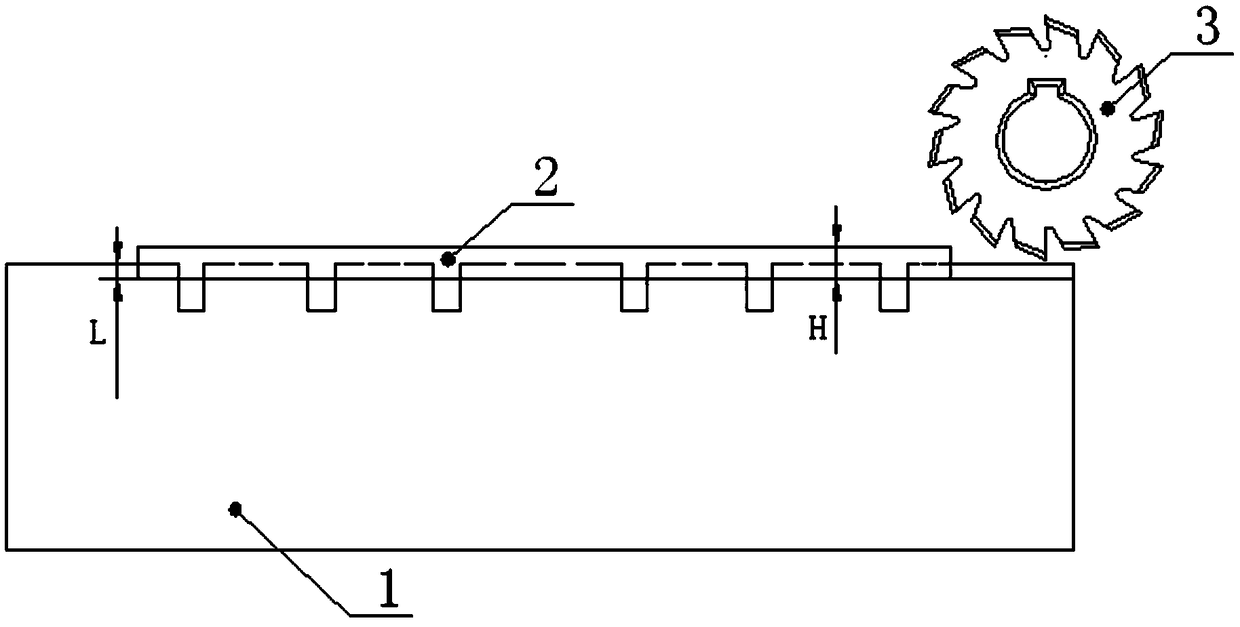

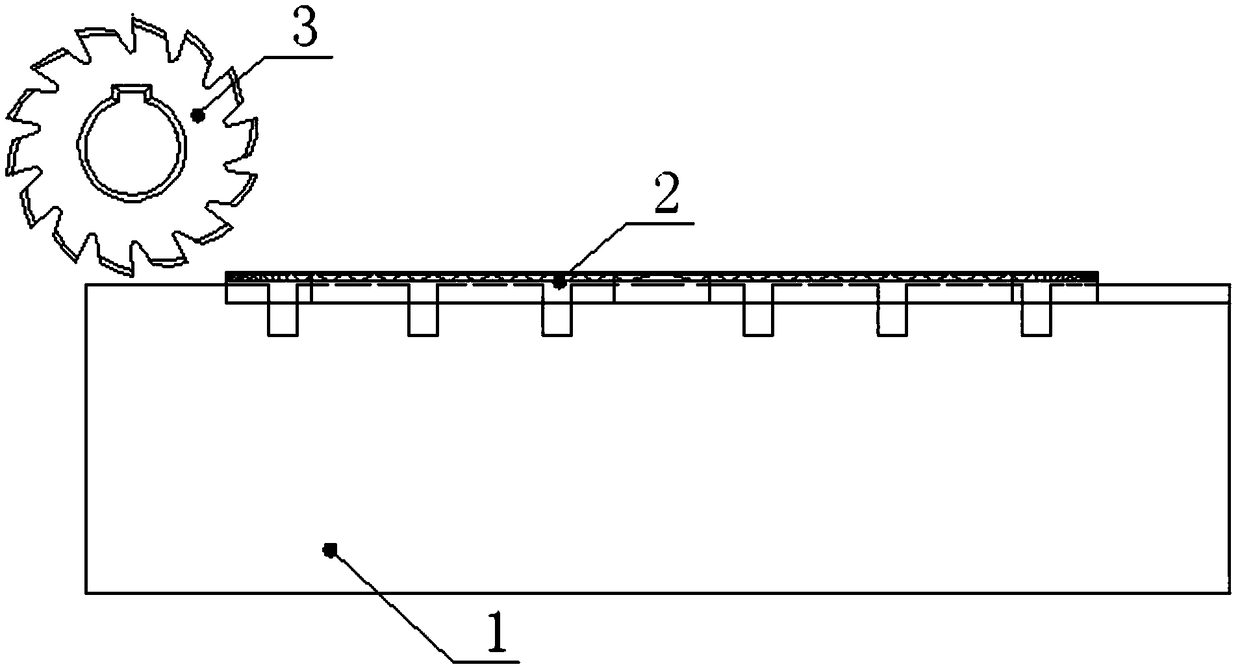

Large-scale sprocket tooth-form automatic measurement device based on machine vision

InactiveCN105486231ARealize automatic acquisition and measurementReduce the difficulty of inspectionUsing optical meansRobotic systemsMachine vision

The present invention discloses a large-scale sprocket tooth-form automatic measurement device based on a machine vision. The device provided by the invention comprises a loading bin, a conveying robot system, a vision detection system and a blanking bin. The loading bin is configured to locate sprocket parts prior to measurement; the conveying robot system is configured to complete the loading, the displacement and the blanking of the sprocket parts; the vision detection system is configured to collect the quality information of the sprocket parts one by one through adoption of the machine vision technology; the blanking bin is configured to dispose sprocket parts which have been measured. According to the invention, the automatic collection measurement of the large-scale sprocket part tooth-form data is realized, so that the difficulty of the sprocket part tooth-form measurement is effectively reduced, the whole detection process is not influenced by human factors, and the accuracy of the detection quality of products is effectively ensured. The quality information collected by machine vision may be stored in a computer to provide an effective feedback to the link of the part manufacture, and the preparation may be further performed for the statistics process control and the digital manufacture.

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

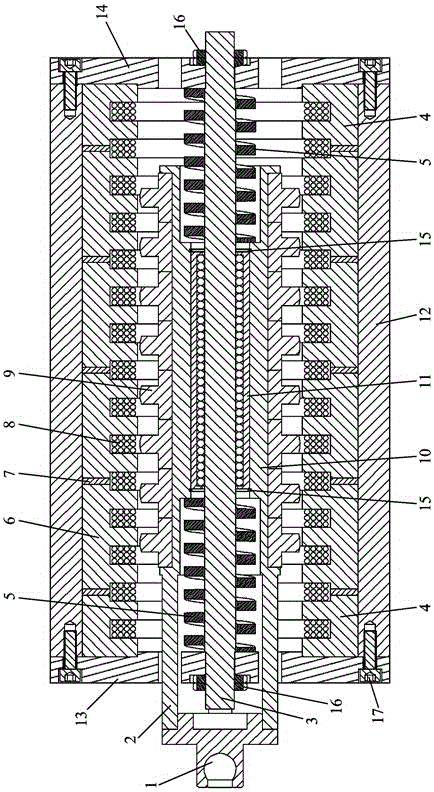

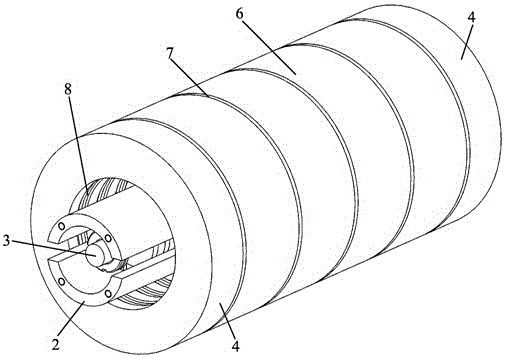

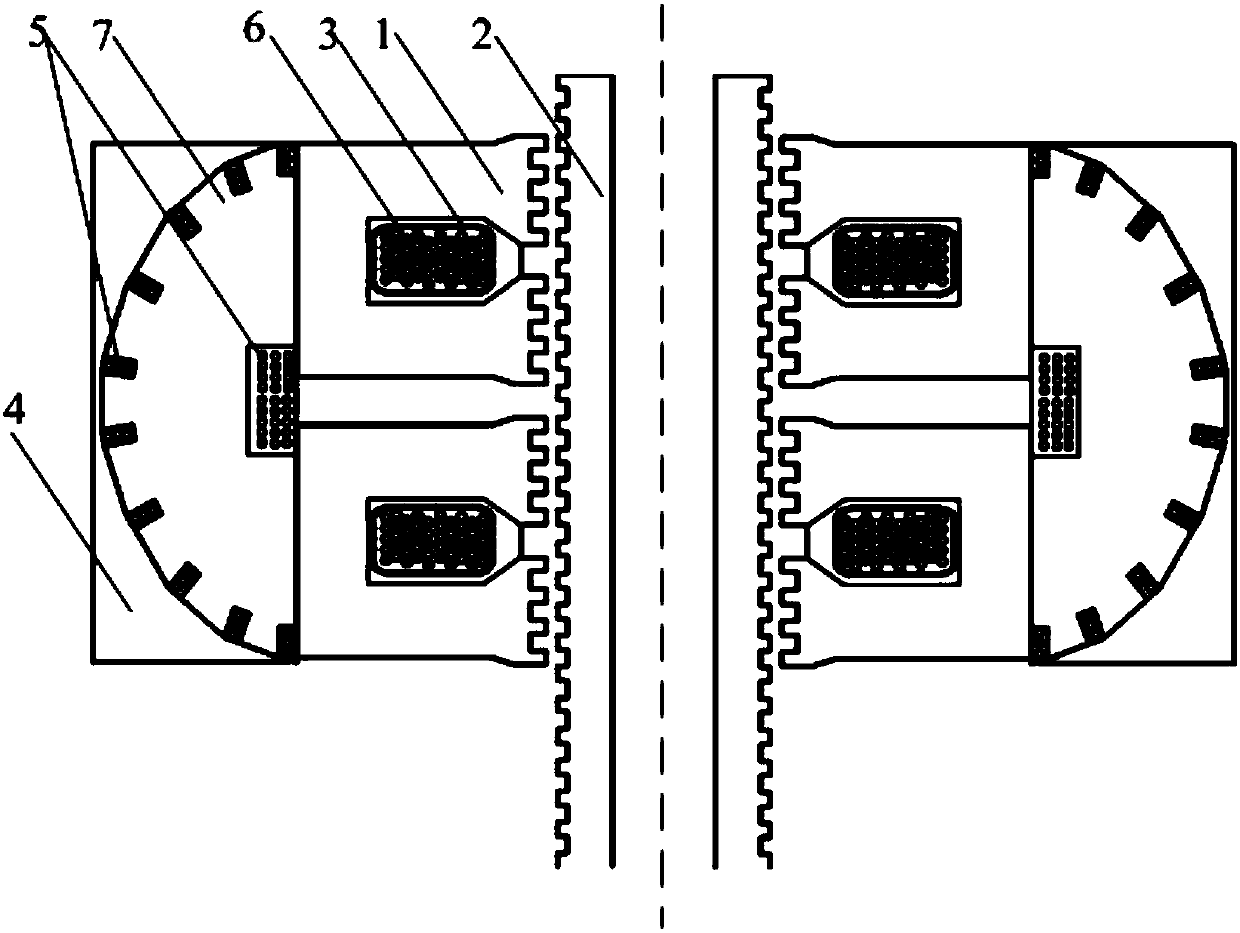

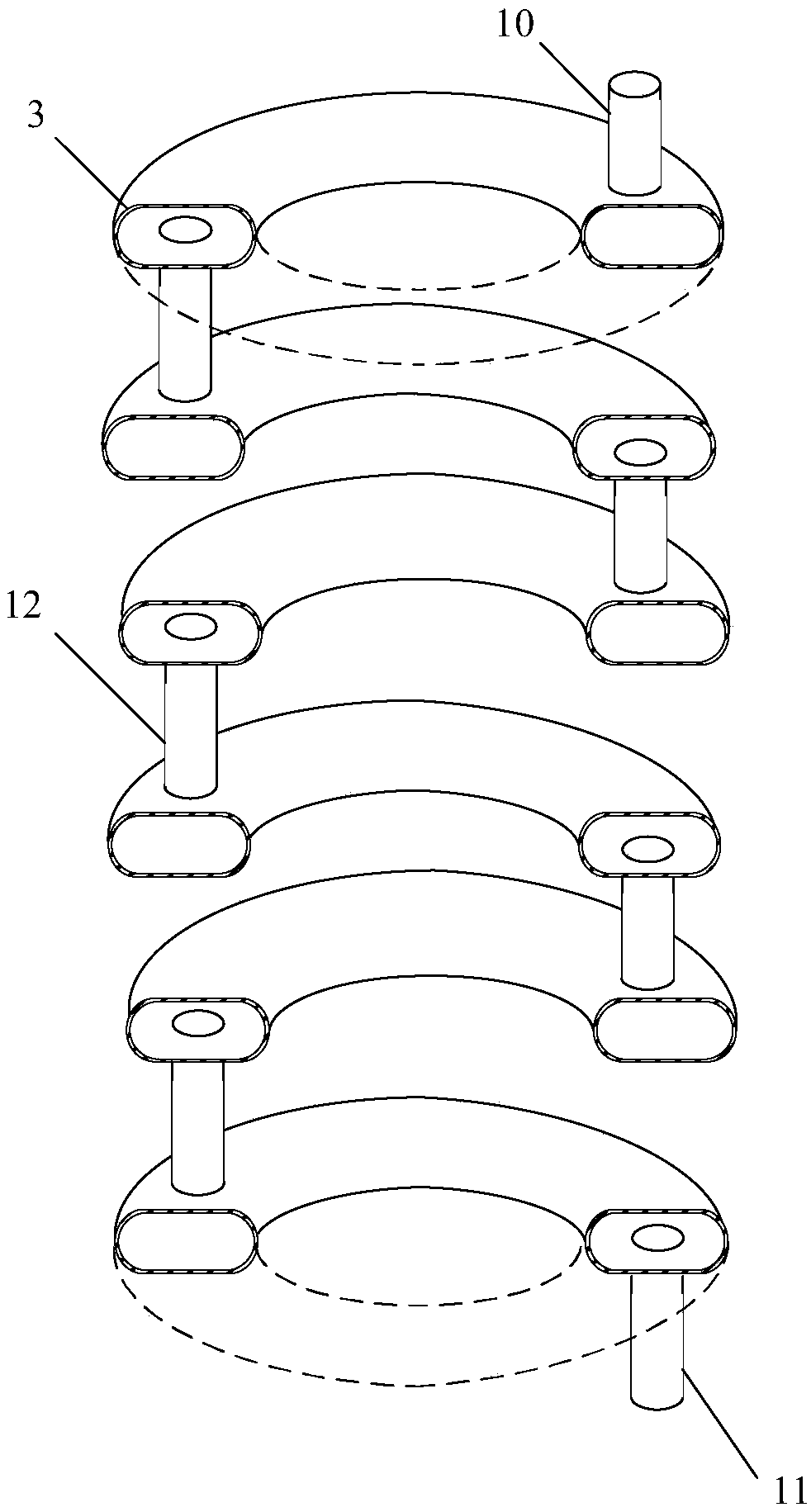

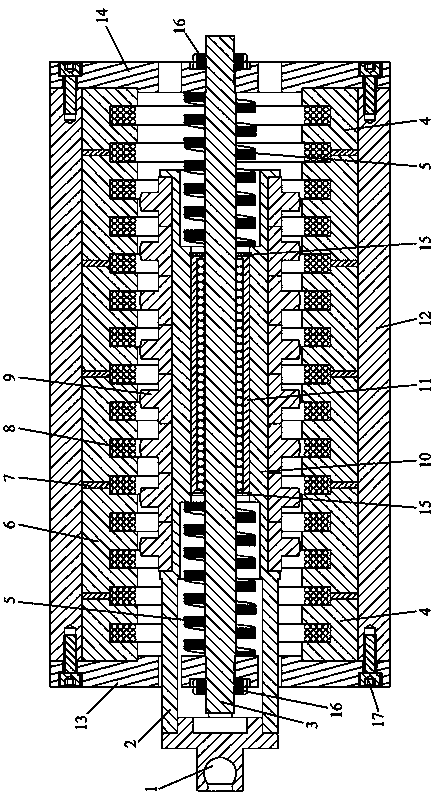

Permanent magnet linear oscillation motor with stator

ActiveCN105932853AImprove power densityImprove robustnessDynamo-electric machinesParts toothWork Performances

The invention relates to a permanent magnet linear oscillation motor with a stator. The permanent magnet linear oscillation motor is characterized by at least comprising a connecting shaft end, output bearing bushes, a rotor mandrel, a stator end part tooth ring, resonant springs, a stator middle tooth ring, permanent magnet steel rings, armature windings, rotor tooth rings, a rotor mounting sleeve, a linear sliding bearing and an engine base sleeve, wherein the rotor mandrel is arranged at the center of the engine base sleeve along the axial direction; the rotor mandrel is fixed between a front end cover of the motor and a rear end cover of the motor through locking nuts; the rotor mounting sleeve is arranged at the middle part of the rotor mandrel; the rotor tooth rings are sequentially nested into the excircle surface of the rotor mounting sleeve along the axial direction to form a linear motor secondary rotor; the linear sliding bearing is arranged at the inner side of the rotor mounting sleeve and is axially fixed by a snap spring; and a linear motor primary stator is fixed inside the engine base sleeve and outside the rotor tooth rings. The linear motor has more advantages as a high-thrust, high-power density and strong-robustness servo direct drive vibration source; and the working performance is better.

Owner:XIDIAN UNIV

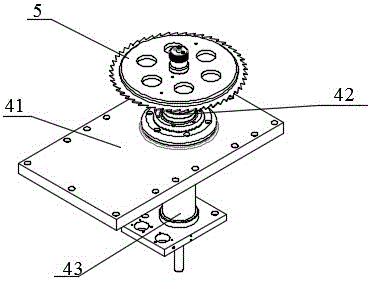

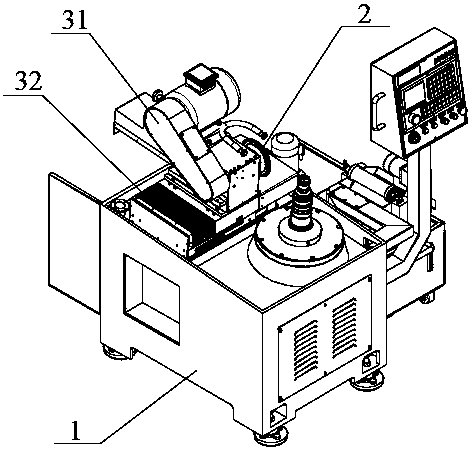

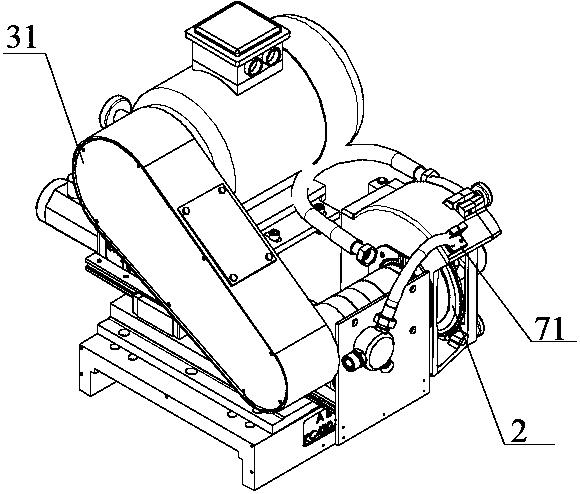

Numerical control tooth grinding method of circular saw blade

ActiveCN106238825AImprove work efficiencySawing tools dressing arrangementsNumerical controlMotor drive

The invention discloses a numerical control tooth grinding method of a circular saw blade. The numerical control tooth grinding method comprises the following steps: Step one, a grinding wheel component is constructed at an operation end of an XY-axis translation mechanism, a work spindle and a work motor are constructed at a Z-axis translation mechanism, and the work spindle is driven by the work motor; Step two, driving parameters of a numerical control cabinet for controlling the XY-axis translation mechanism, the Z-axis translation mechanism and the work motor are set; Step three, the Z-axis translation mechanism, according to the driving parameters, adjusts the circular saw blade mounted at the work spindle to be in a middle part tooth grinding station in the Z-axis direction, the work motor drives the work spindle to carry out stepping rotation according to the driving parameters, and the XY-axis translation mechanism drives the grinding wheel component to polish grinding teeth of the circular saw blade one by one; and Step four, the Z-axis translation mechanism, according to the driving parameters, adjusts the circular saw blade of the work spindle to be in an upper chamfer station or in a lower chamfer station of the circular saw blade of the work spindle, the work motor drives the work spindle to rotate according to the driving parameters, and the XY-axis translation mechanism drives the grinding wheel component to polish lower chamfers or upper chamfers of the grinding teeth of the circular saw blade at a high speed.

Owner:浙江阿波罗工具有限公司

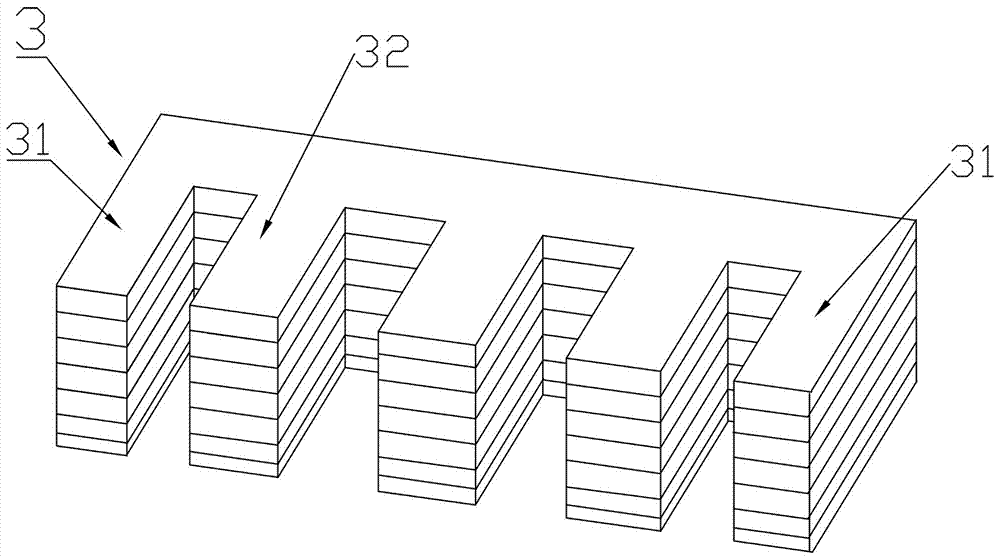

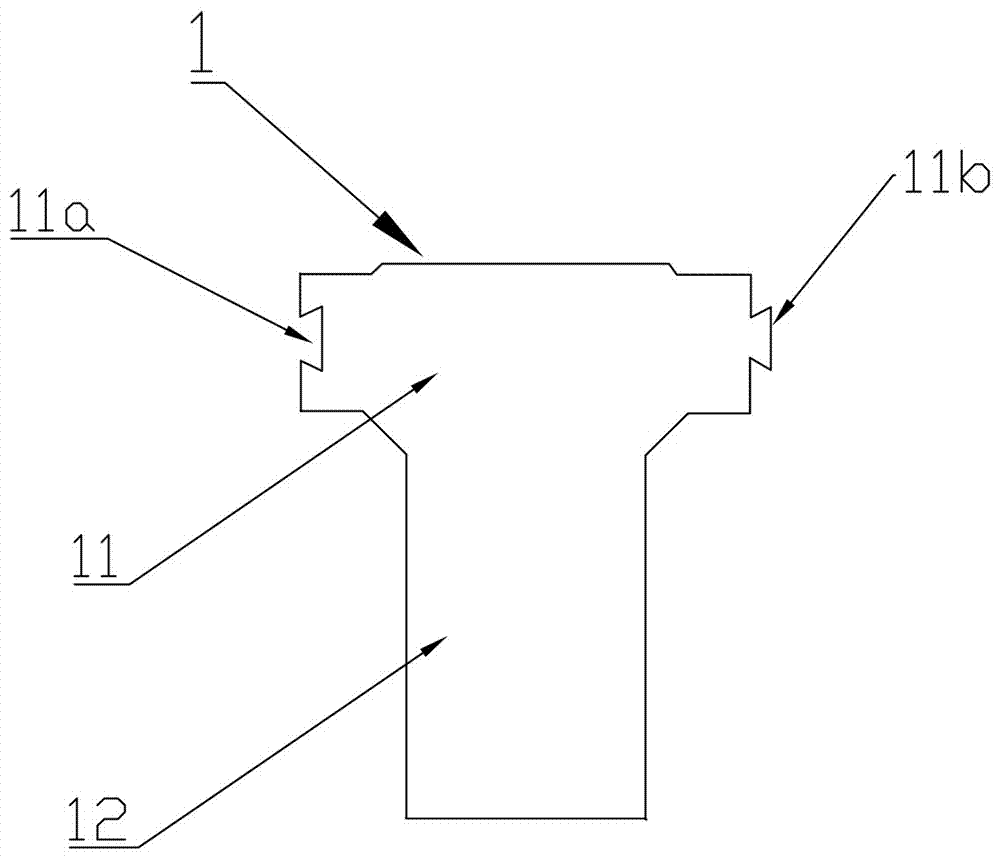

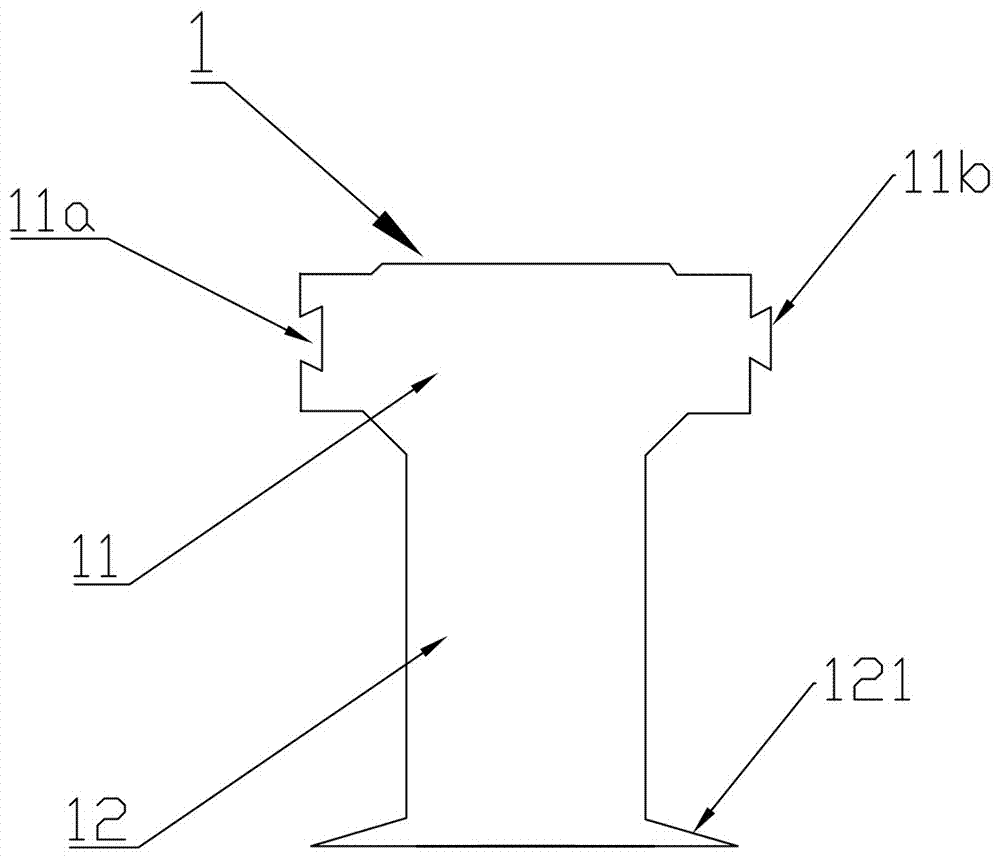

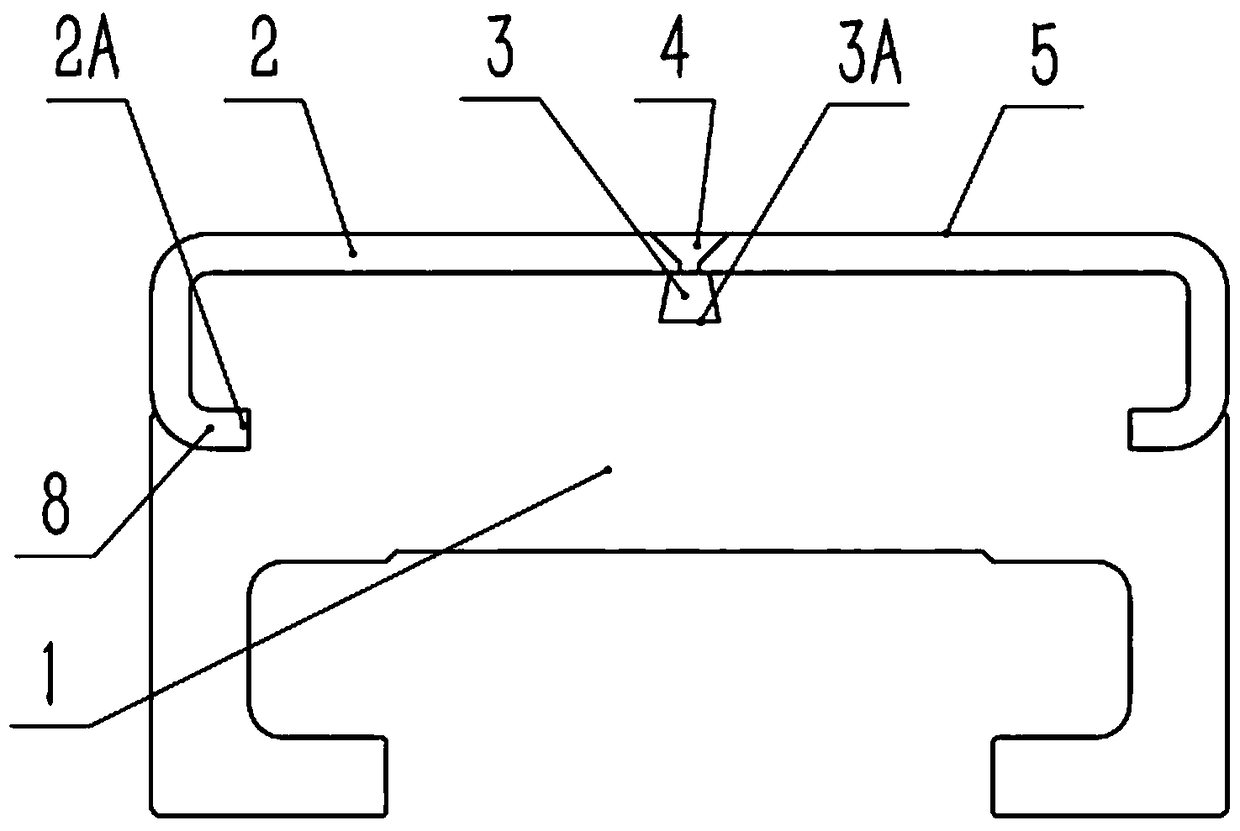

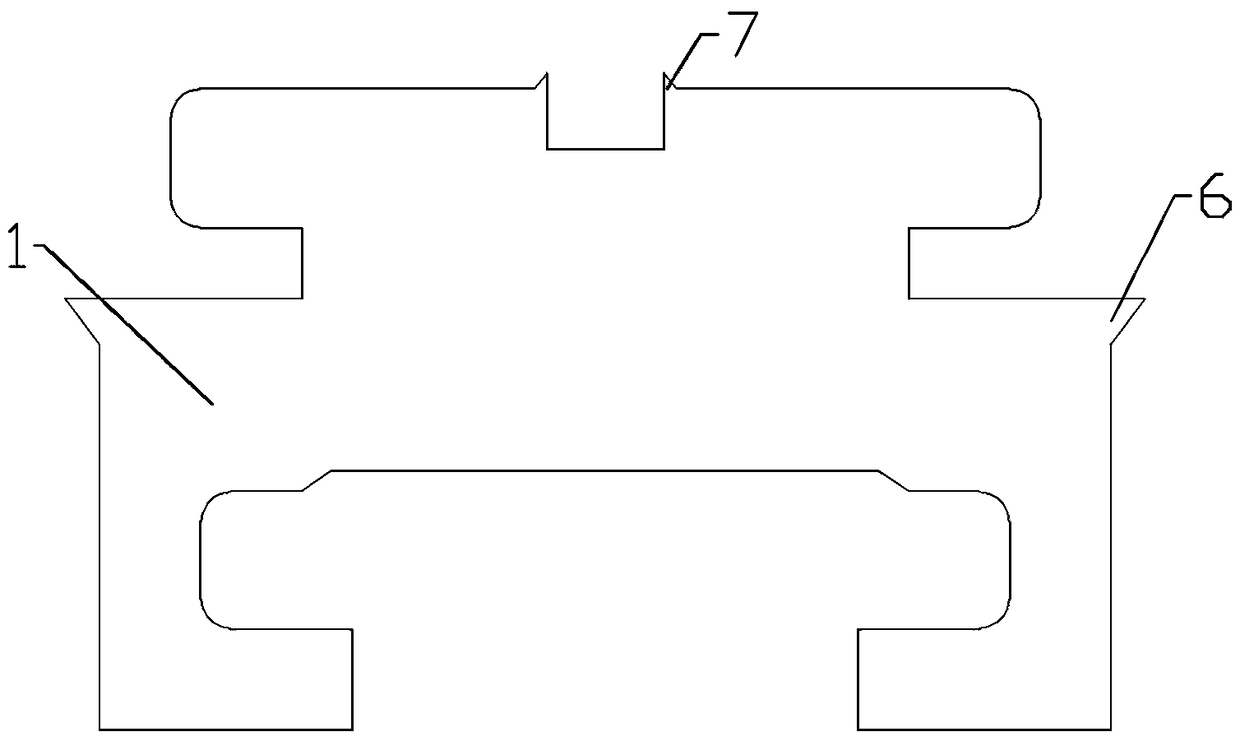

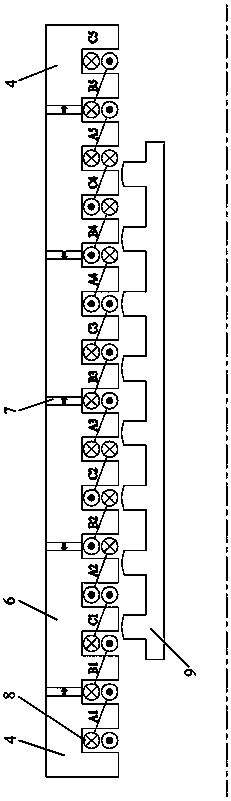

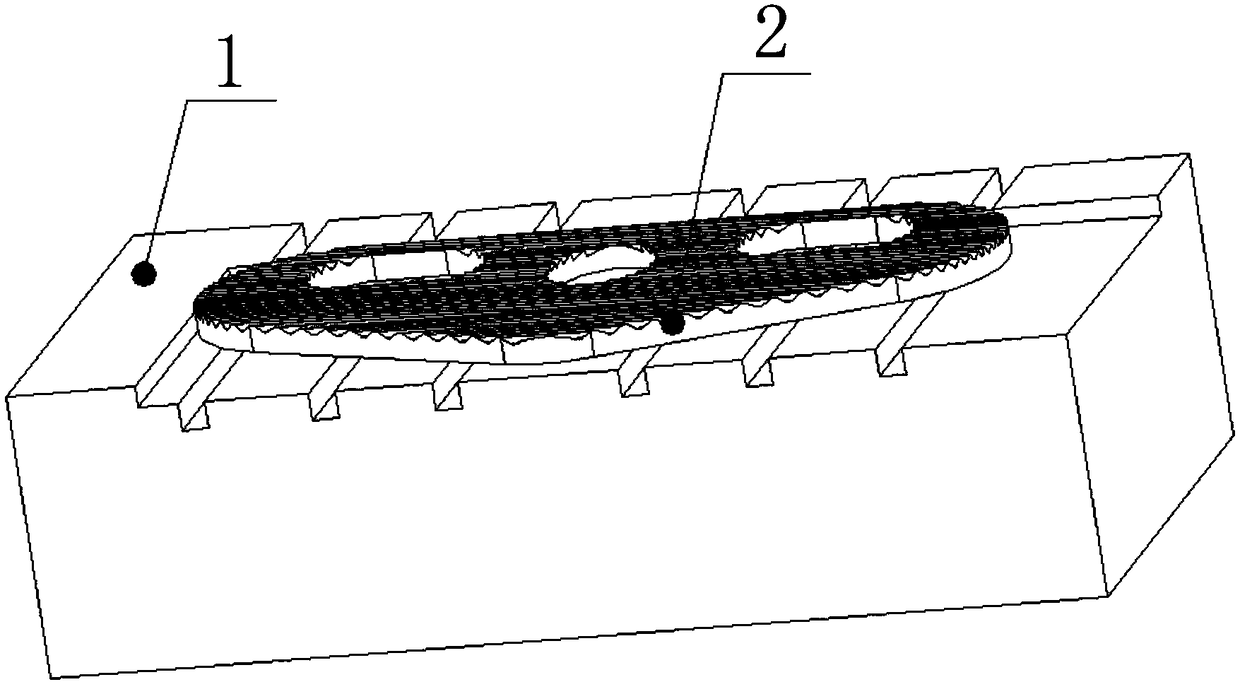

Split type linear motor iron core

PendingCN107147222AProduction standardizationImprove cooling effectMagnetic circuit shape/form/constructionPropulsion systemsWinding machineElectric machine

The invention provides a split type linear motor iron core. The split type linear motor iron core comprises a plurality of T-shaped main teeth spliced mutually; end part teeth are spliced beside the T-shaped main tooth at the head end and the T-shaped main tooth at the tail end respectively; an integrally formed single sheet is designed into a single-tooth structure; a female buckle and a male buckle matched therewith are arranged at the two ends of the connecting part of each T-shaped main tooth; iron cores of different lengths and different dimensions can be manufactured by the one-by-one splicing way, so that the manufacturing of the iron cores can be standard; meanwhile, the cost of re-mould-opening is omitted; the single sheet is prepared into the single-tooth structure, and a winding machine can perform direct winding on the T-shaped main teeth, so that a good heat conducting effect is achieved, and heat dissipation of the iron core is accelerated; direct winding on the T-shaped main teeth can be performed, and tooth shoes can be arranged at the bottom ends of the winding parts of the T-shaped main teeth, so that magnetic resistance can be lowered by virtue of the tooth shoes, and the magnetic flux of the iron core can be improved; and the winding machine can perform direct winding on the T-shaped main teeth, so that more coils can be wound around the single teeth, and high thrust density is realized.

Owner:东莞市川恩智能装备有限公司

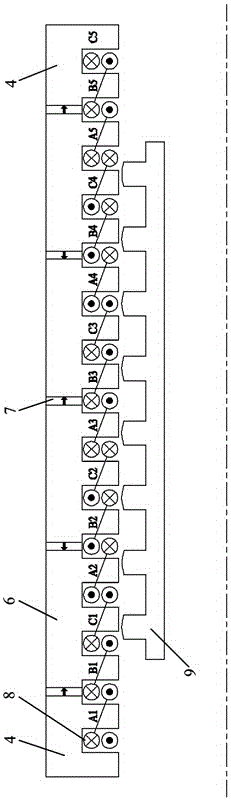

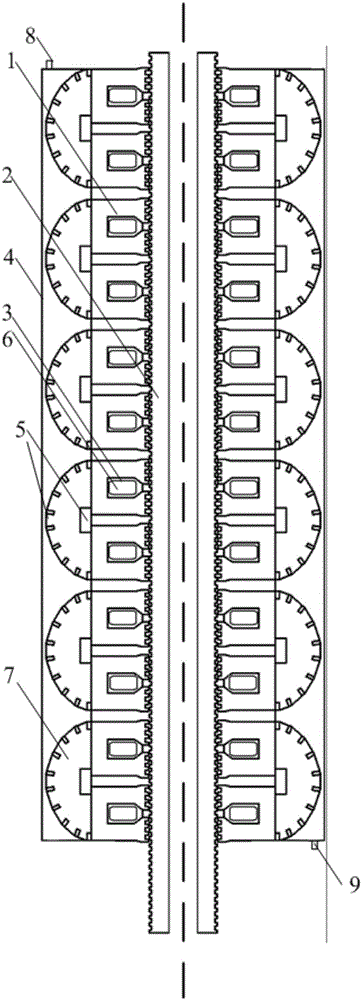

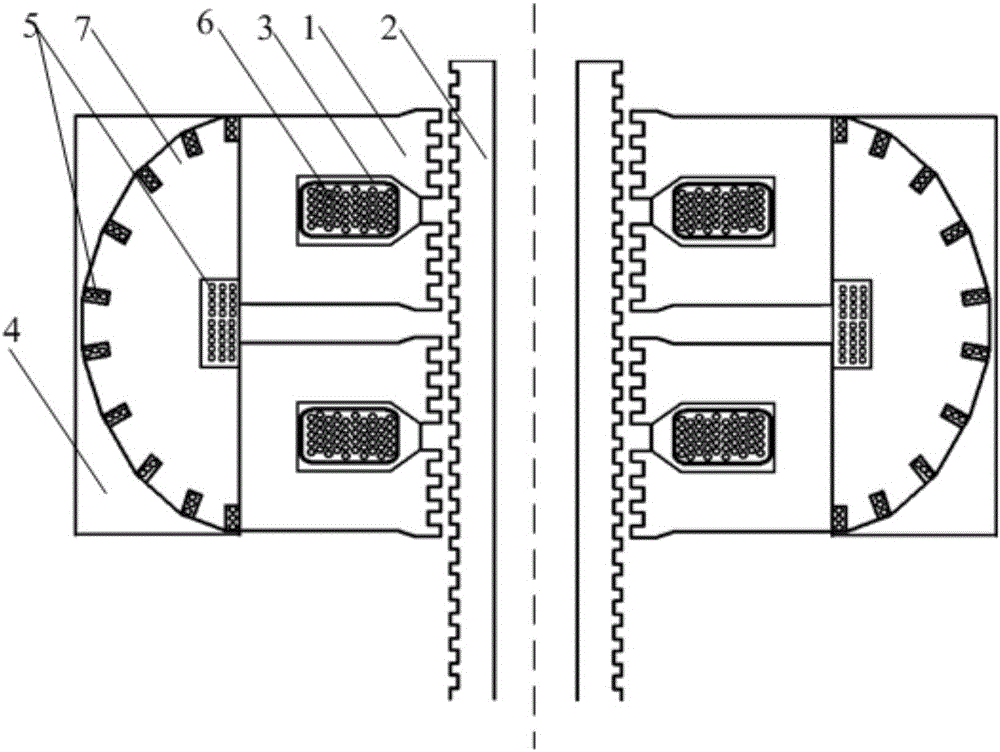

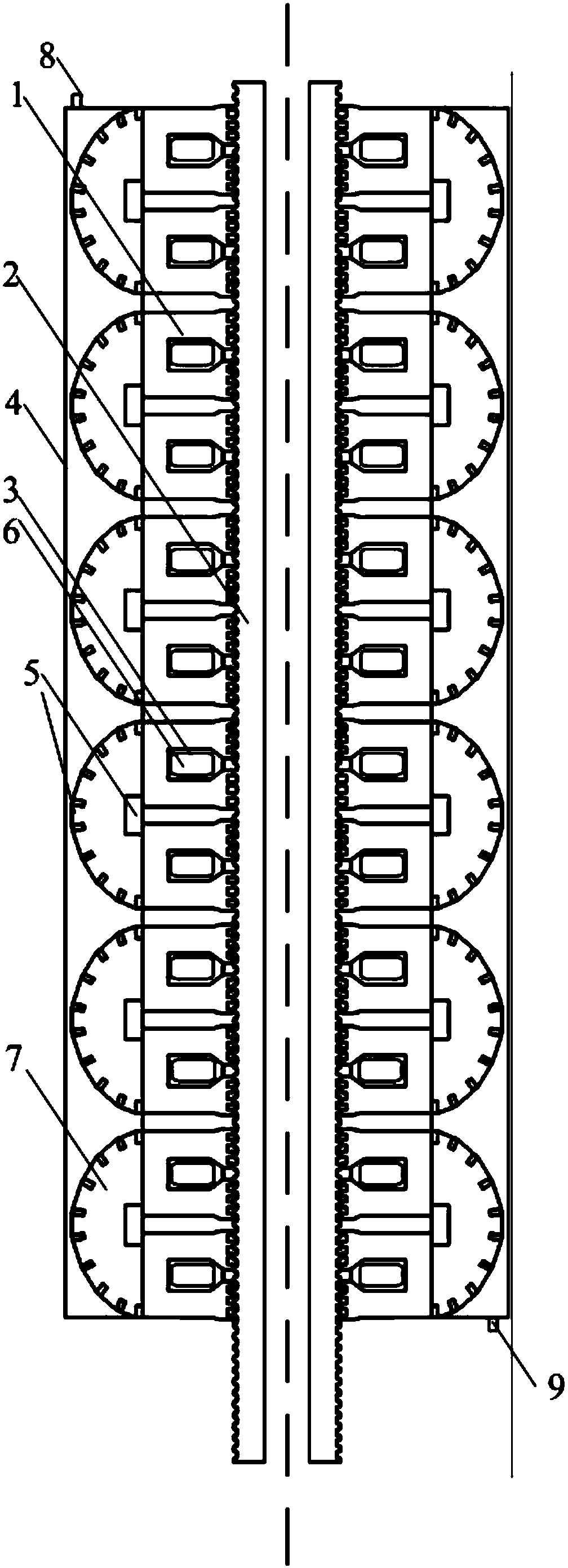

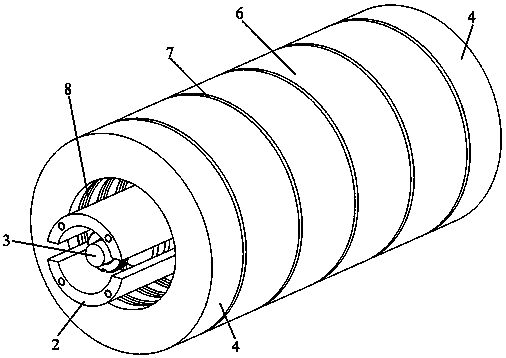

Full-superconducting primary excitation linear generator for direct-drive type wave power generation

ActiveCN105811738AIncrease magnetic densityIncrease the effective magnetic flux areaPropulsion systemsSuperconductor elements usageSpacing toothLow speed

The invention discloses a full-superconducting primary excitation linear generator for direct-drive type wave power generation. The full-superconducting primary excitation linear generator comprises a primary stator and a secondary mover, wherein the primary stator comprises multiple groups of stator units arranged in a straight line; each stator unit comprises a U-shaped core, primary armature windings and primary exciting windings; the U-shaped core comprises two primary cores; an opening of the U-shaped core faces the secondary mover; the primary armature windings are arranged in the primary cores; the primary exciting windings are arranged in the U-shaped core; the secondary mover is the core which does not contain a winding and has a cogging structure; and a corresponding cogging structure is arranged on each primary core. According to the full-superconducting primary excitation linear generator, an arc-shaped structure exciting winding sleeves the outside of each primary core; and a cooling system does not move, so that the complexity level is reduced. The magnetic field conversion rate and the terminal voltage can be increased by a multi-tooth structure secondary; the defect of a low low-speed voltage is compensated; and by unequally-spaced teeth, the voltage frequency and amplitude generated when the generator moves to the end part are increased by reducing the end-part tooth pitch.

Owner:SOUTHEAST UNIV

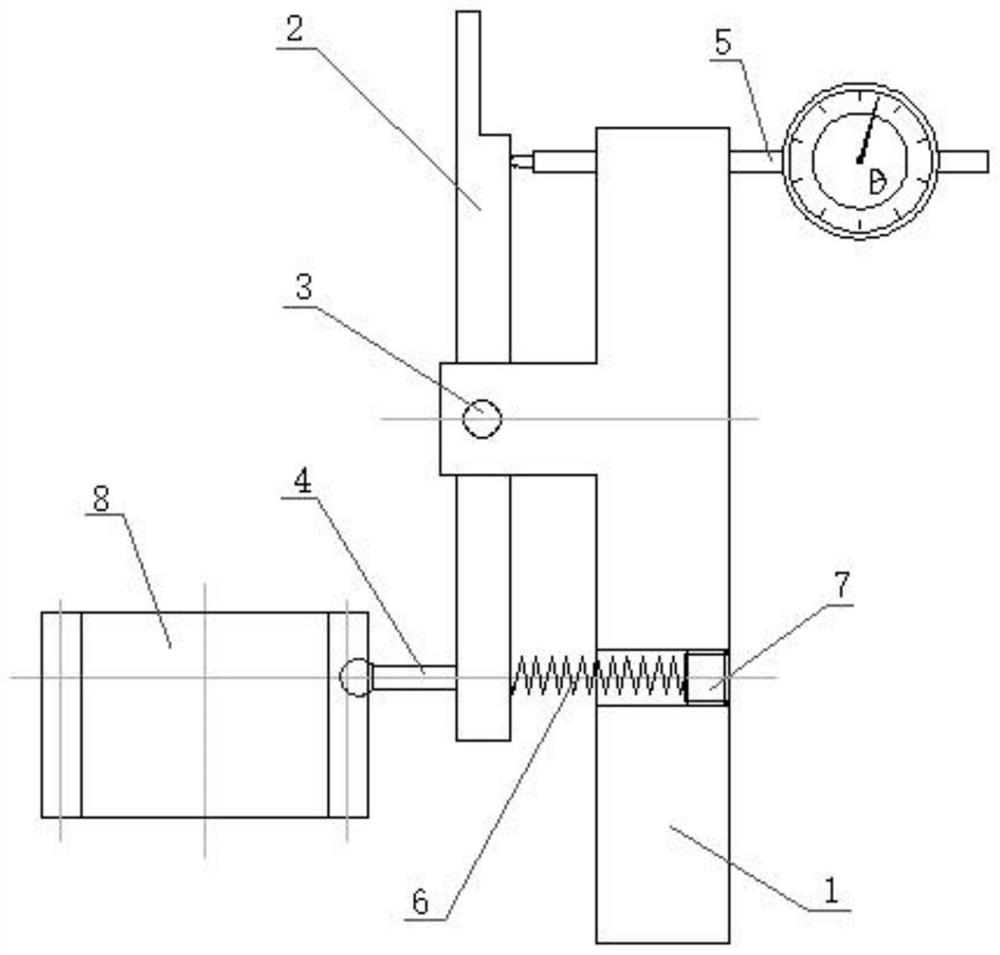

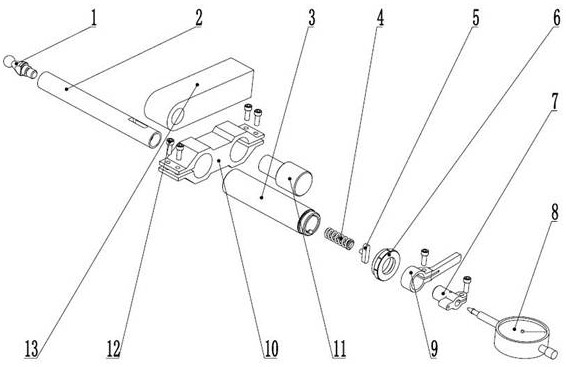

Tooth surface runout detection device

PendingCN112595203AImprove detection accuracyImprove efficiencyMechanical measuring arrangementsGear wheelParts tooth

The invention discloses a tooth surface runout detection device which comprises a base, a driving lever, a ball rod measuring head and a dial indicator, the driving lever is connected with the base through a pin shaft, the driving lever can swing around the pin shaft, the dial indicator and the ball rod measuring head are fixed at the upper end and the lower end of the driving lever respectively,and a return spring connected with the driving lever is further arranged on the base. The driving lever can drive the ball rod measuring head and the dial indicator to automatically return in a free state. The tooth surface runout detection device is designed by adopting an equal armed lever principle, can detect tooth surfaces of gears or spline parts with different specifications by replacing the ball rod measuring head, and has the advantages of high detection precision, high efficiency, convenience in operation, simple structure and the like.

Owner:HUBEI SANJIANG SPACE WANSHAN SPECIAL VEHICLE

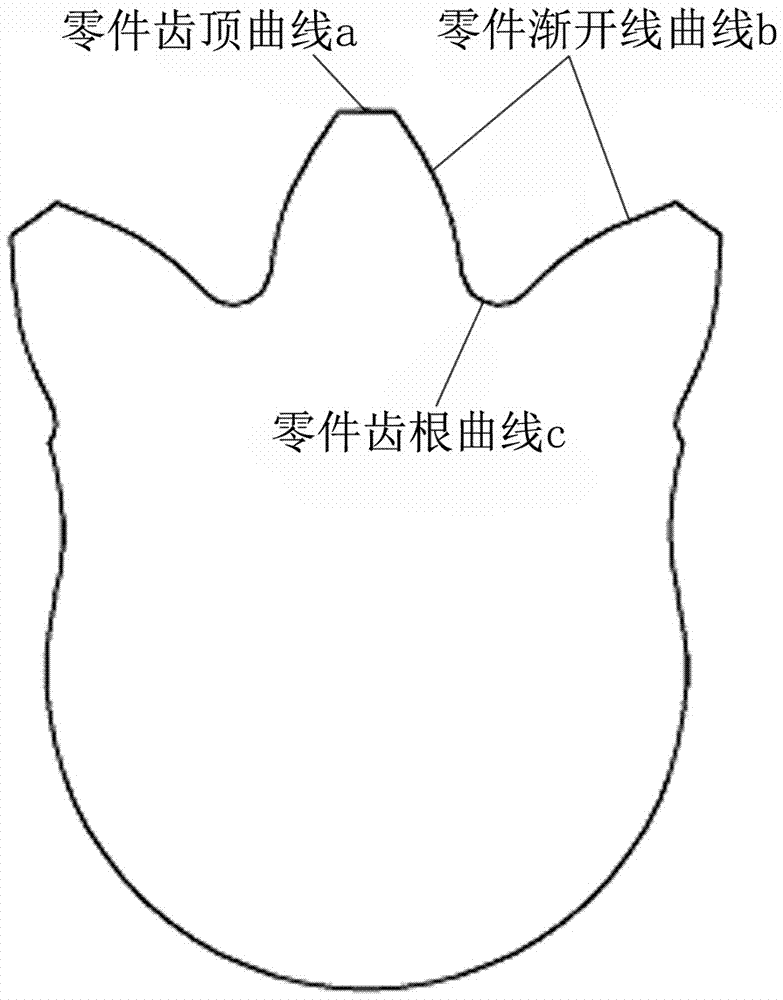

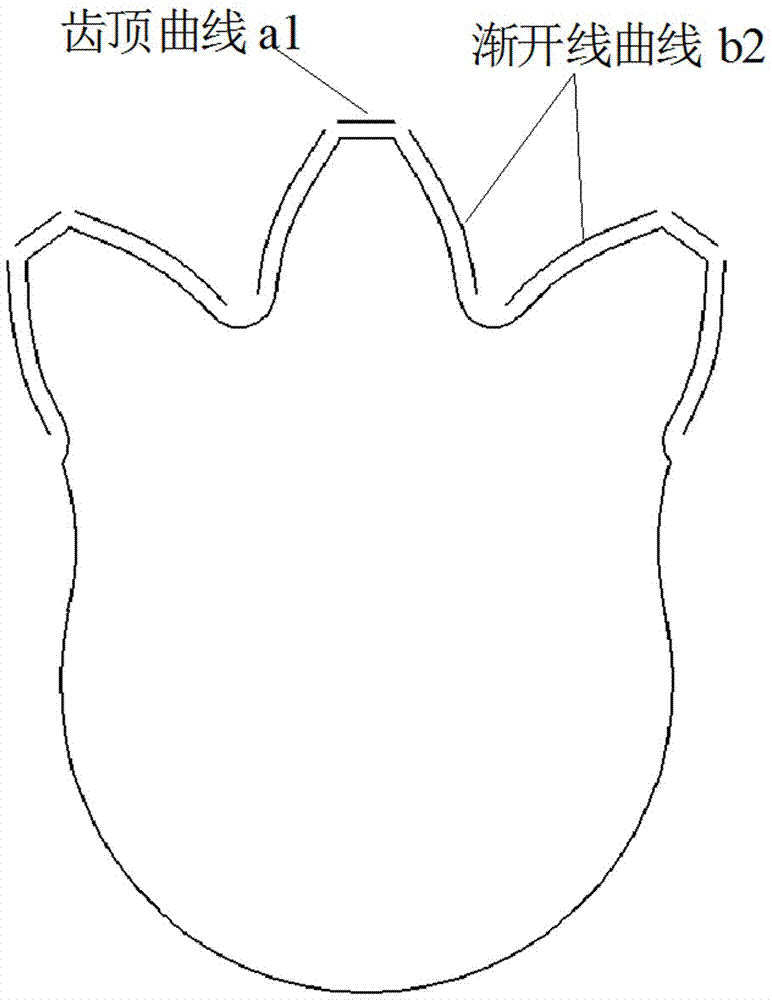

Method for designing hot-forging die tooth form of rockshaft with teeth

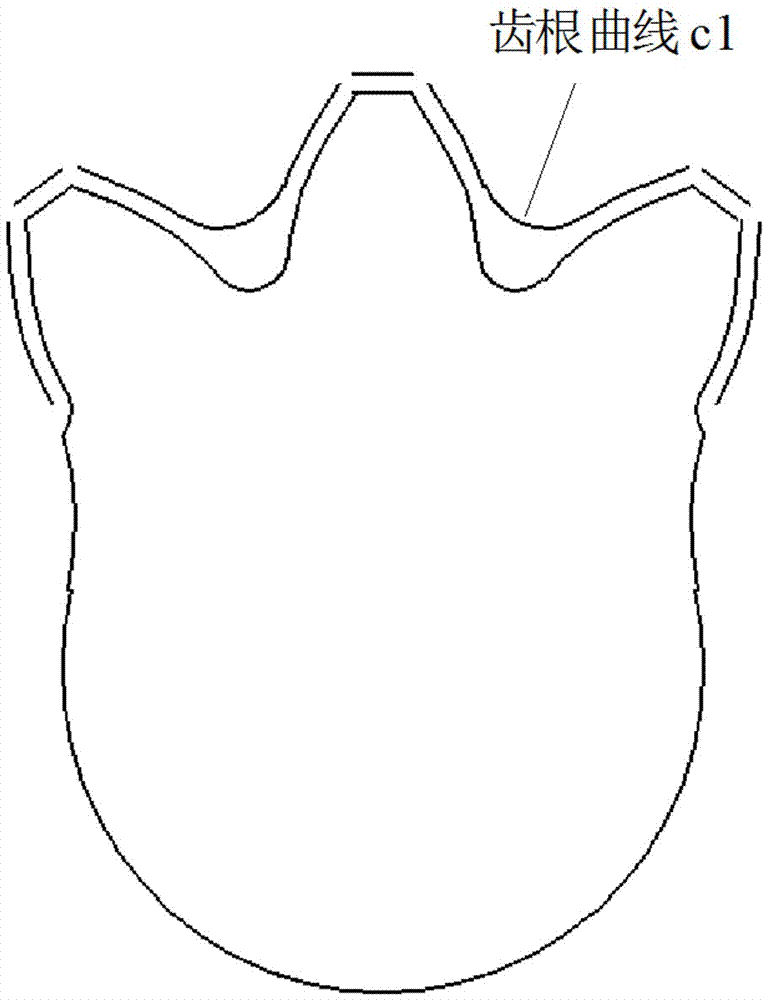

ActiveCN105447287AExtend your lifeGuaranteed service lifeGeometric CADForging/hammering/pressing machinesParts toothOrthodontics

The invention discloses a method for designing a hot-forging die tooth form of a rockshaft with teeth. The method comprises the following steps that the tooth form shape is drawn according to tooth form parameters of the rockshaft, and the tooth form shape is decomposed into a part tooth crest curve a, a part involute curve b and a part tooth root curve c; the part tooth crest curve a and the part involute curve b offset outwards in an equally-spaced mode to obtain a tooth crest curve a1 and an involute curve b1; fitting is performed on the outer side of the part tooth root curve c to obtain different tooth root curves, and a tooth root curve c1 applicable to forge piece material flowing is drawn; the tooth root curve c1 and the involute curve b1 are connected into a whole in a fitting mode; gaps between the tooth crest curve a1 and the involute curve b1 are in smooth transition connection through an arc; the curve composed of the tooth crest curve a1, the involute curve b1, the tooth root curve c and the arc connecting the tooth crest curve a1 and the involute curve b1 is a die tooth form curve. According to the method, the service life of the die can be prolonged, and the tooth form working allowance is reduced.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Sliding chain

PendingCN114468483AAvoid direct contactAvoid sliding problemsSlide fastenersParts toothOral problems

The invention discloses a sliding chain which comprises a parent part assembly and a child part assembly, the parent part assembly comprises a parent part base band and parent part teeth, and tooth inner cavities and cloth seam parts on the side walls of the tooth inner cavities are formed in the parent part teeth; the sub-component assembly comprises a sub-component base band and sub-component teeth, each sub-component tooth comprises a fixed tooth column, a connecting part and a sub-component tooth ball which are sequentially connected, the fixed tooth columns are fixed to the sub-component base band, the sub-component tooth balls are matched with the tooth inner cavities, and the connecting parts are matched with the cloth seam parts, so that the sub-component tooth balls can slide along the tooth inner cavities which are sequentially arranged. The child part assembly of the sliding chain can freely slide relative to the mother part assembly, and when the sliding chain is applied to the connection position of a hat, the hat can rotate along with rotation of the head; and moreover, the direct contact between the teeth of the primary piece and the base band of the secondary piece is avoided, and the problem of unsmooth sliding caused by increase of sliding friction force due to fluffing of the base band of the secondary piece is avoided.

Owner:ZHEJIANG WEIXING IND DEV +1

Machining method for fuel element special-shaped parts

InactiveCN110052784AImprove processing efficiencyEliminate errorsManufacturing technologyParts tooth

The invention belongs to the technical field of manufacturing of nuclear fuel elements, and particularly relates to a machining method for fuel element special-shaped parts. The method comprises the steps that 1, a cylindrical blank is clamped on a five-axis machining center chuck for correction, and tool setting is carried out for machining; 2, a large amount is removed on a five-axis machining center in an insert milling mode; 3, on the five-axis machining center, a workpiece is clamped on an indexing head and roughly and finely milled to obtain 120-degree three equal-part teeth; and 4, drilling and tapping are carried out on the machining center, and a screw is used for trial assembly to verify the depth of a taper hole. The problems that in the machining process, the machining efficiency is low, the tool service life is short, machining precision is unstable due to repeated clamping, and the machining efficiency is low since working procedures are long and complicated are solved.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

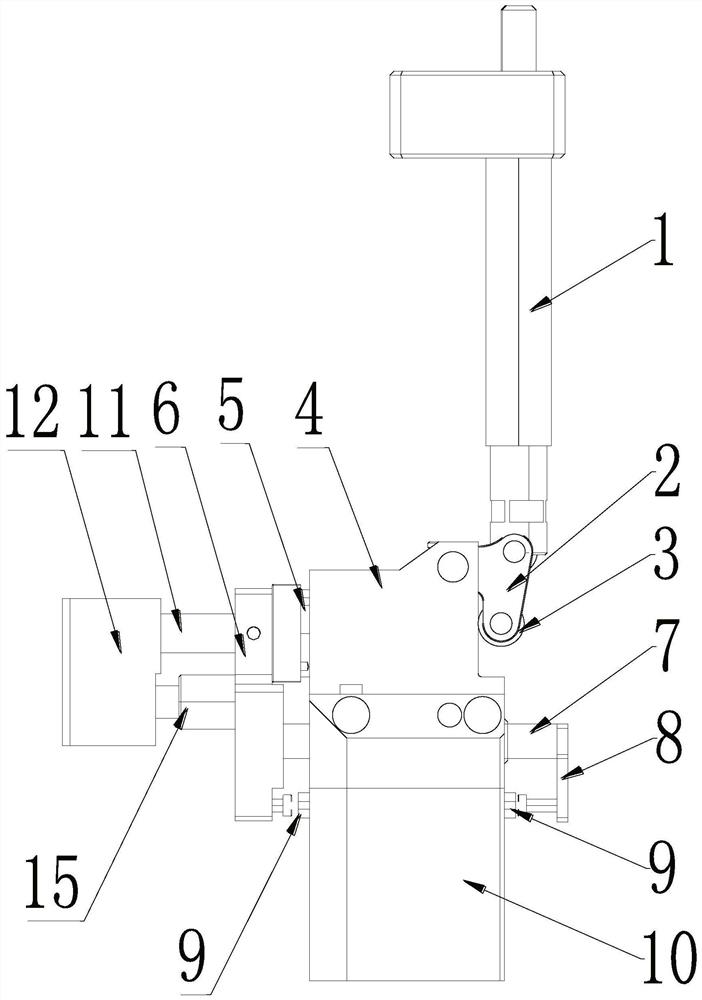

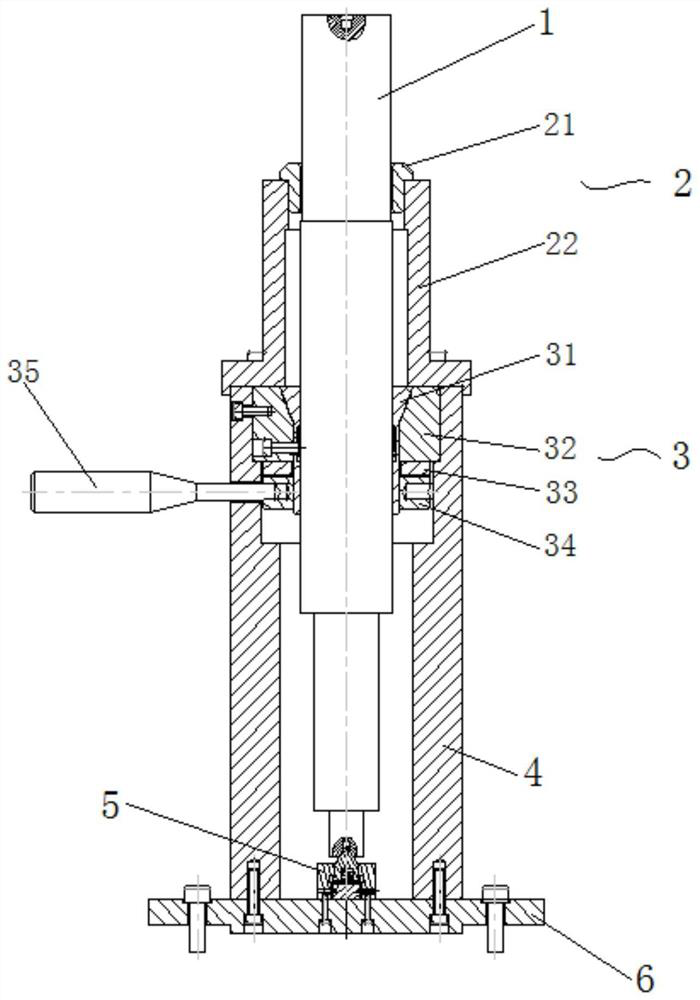

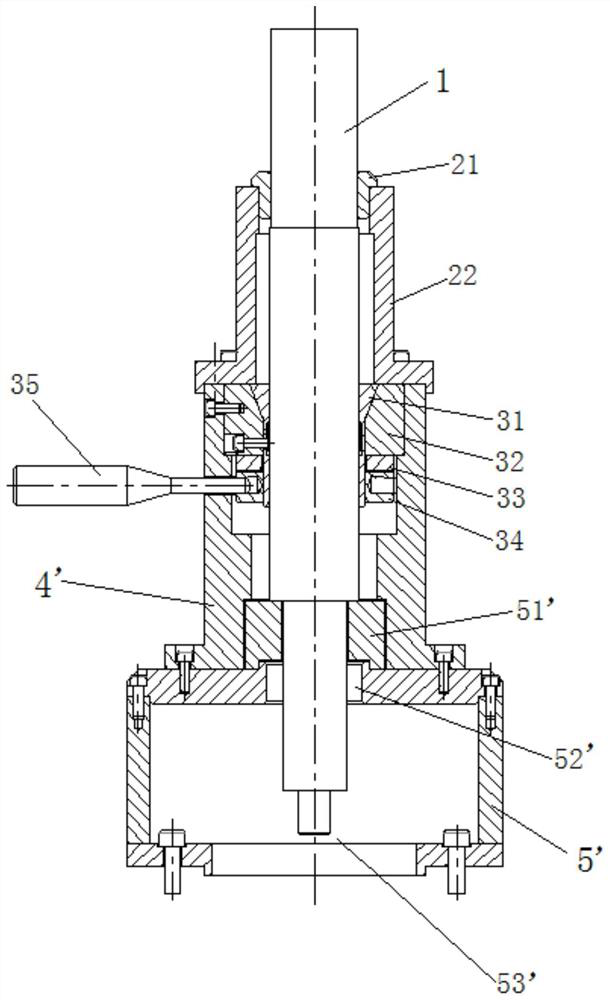

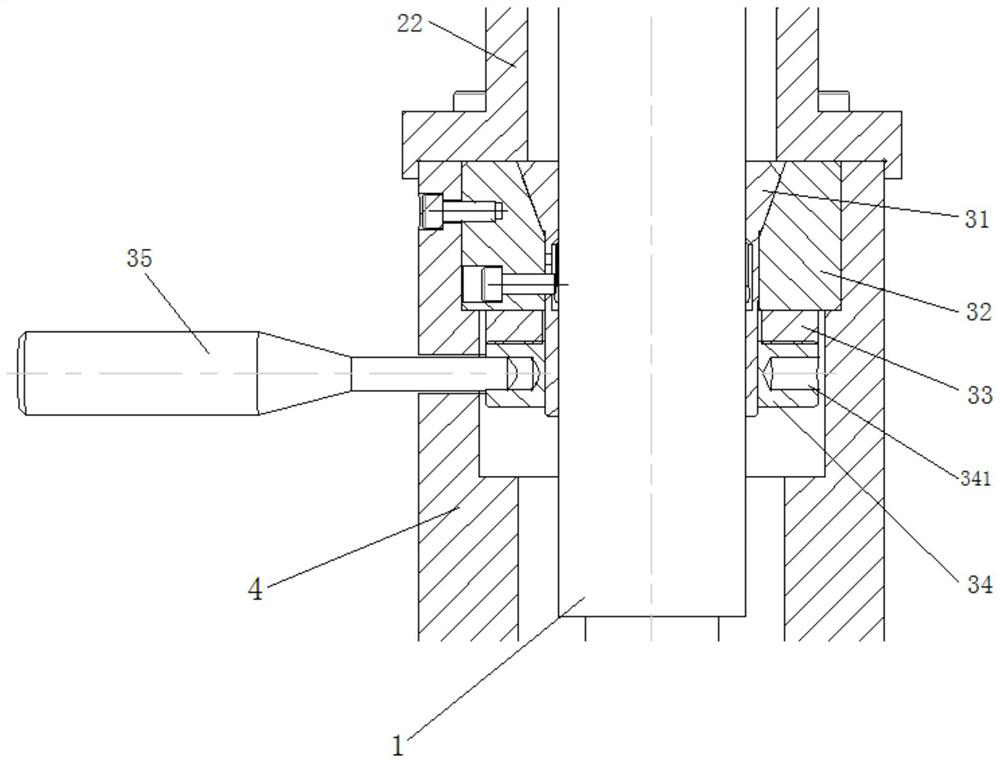

Chamfering knife rest device for lathe

ActiveCN103737122AImprove processing qualityLow costGear-cutting machinesGear teethParts toothEngineering

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

External rotor core, damping rotor and motor

ActiveCN105162269AReduce the number of punch teethReduce the number of internal and external teethMagnetic circuit stationary partsManufacturing cost reductionPunching

An embodiment of the invention discloses an external rotor core which sequentially comprises a first end part tooth segment, a central part groove segment and a second end part tooth segment in the axial direction. The external rotor core is formed by laminating a type of external rotor punching sheets. The external rotor punching sheet comprises a punching sheet body and a plurality of punching sheet teeth which are uniformly distributed on the inner wall of the punching sheet body. The punching sheet teeth, forming the first end part tooth segment and the second end part tooth segment by lamination, of the external rotor punching sheet are end surface inner teeth. The punching sheet teeth, forming the central part groove segment by lamination, of the external rotor punching sheet are central inner teeth. The center inner teeth and the end surface inner teeth are mutually staggered, so that positioning grooves are formed between the end surface inner teeth of the first end part tooth segment and the end surface inner teeth of the second end part surface tooth segment, and the positioning grooves are used for engaging with iron core outer teeth of an inner rotor iron core. The invention can reduce the manufacturing cost and the maintenance cost. The invention also discloses a damping rotor and a motor.

Owner:GREE ELECTRIC APPLIANCES INC +1

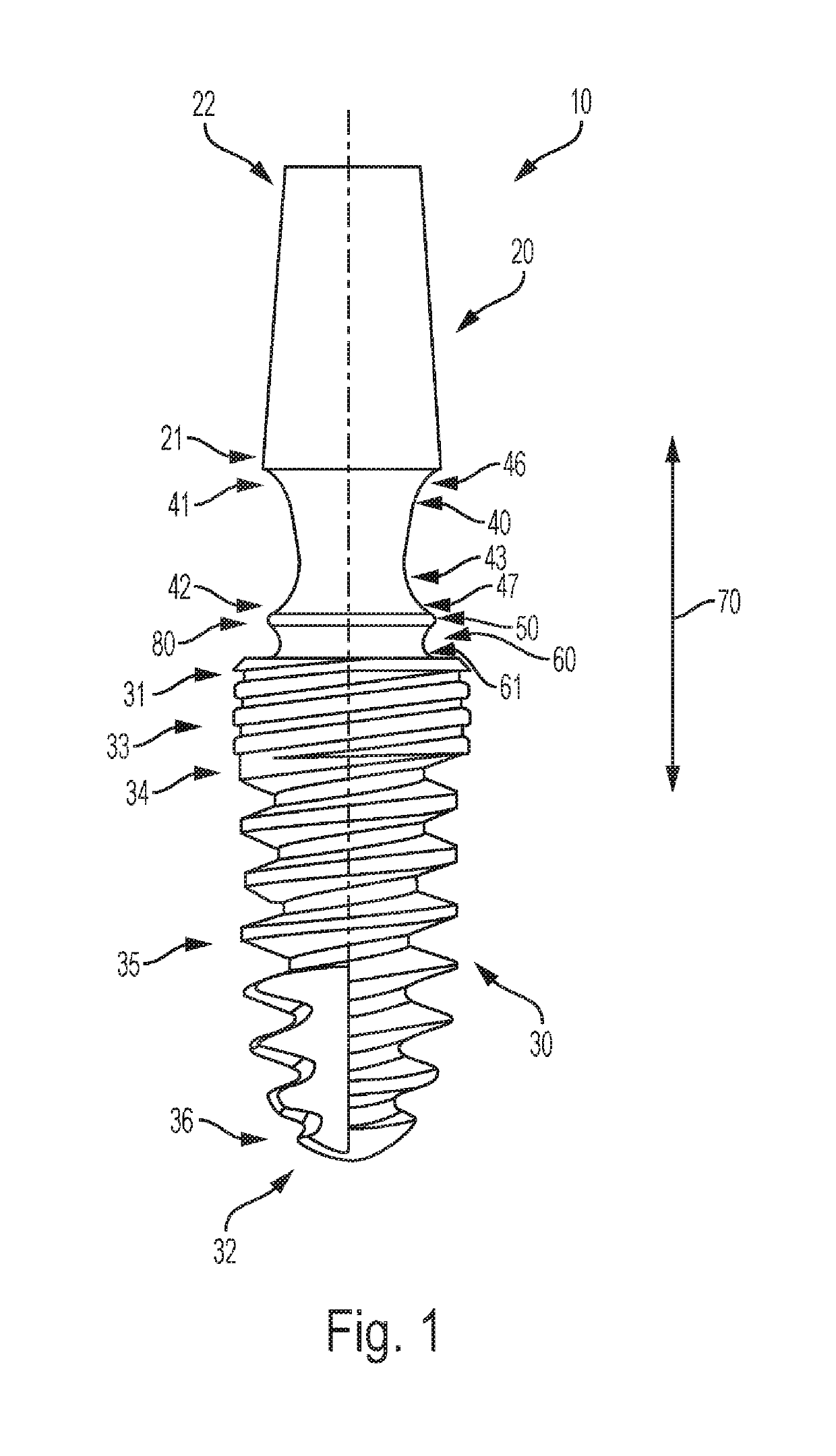

Tooth implant

ActiveUS9474589B2Avoid disadvantagesFixed and accurateDental implantsParts toothBiomedical engineering

The invention relates to a multi-part tooth implant with at least a proximal implant part and a distal implant part that are to be connected to each other such that a connection site is obtained when the two implant parts are in the connected state. An annular sealing element is arranged at this connection site and, in the fully assembled state of the tooth implant, is clamped between mutually opposite sealing surfaces, namely a sealing surface of the proximal implant part and a sealing surface of the distal implant part, such that the sealing element has an outer surface portion that forms part of the outer contour of the tooth implant. The two sealing surfaces initially approach each other in a direction oriented outwards from a central longitudinal axis of the tooth implant. The sealing surfaces merge into outer surfaces of the tooth implant at the place where, in the outer contour of the fully assembled tooth implant, a surface portion formed by the sealing element in each case adjoins a surface portion formed by the respective implant part. These outer surfaces move away from each other in the outwardly oriented direction.

Owner:MEHROF IMPLANT TECH GMBH

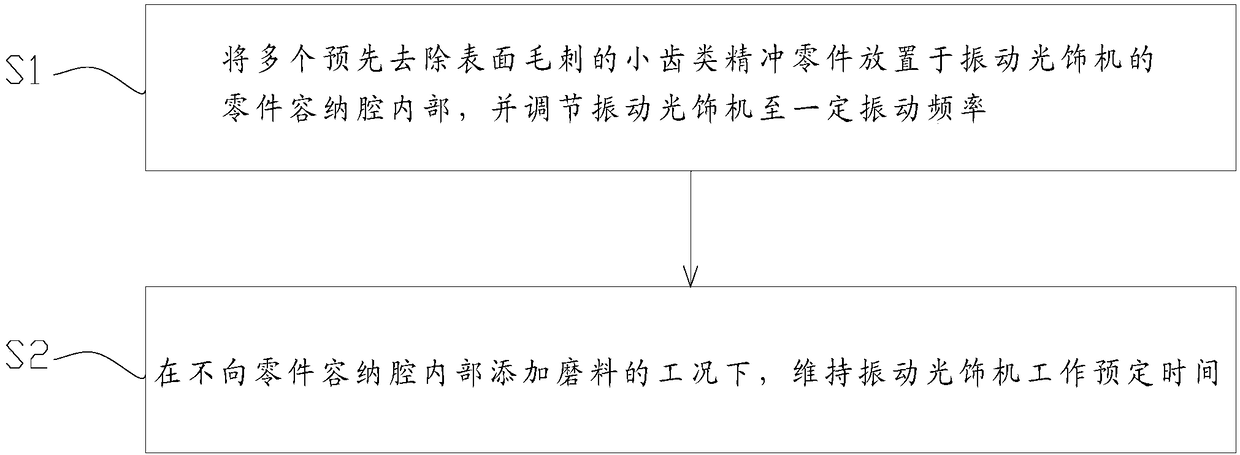

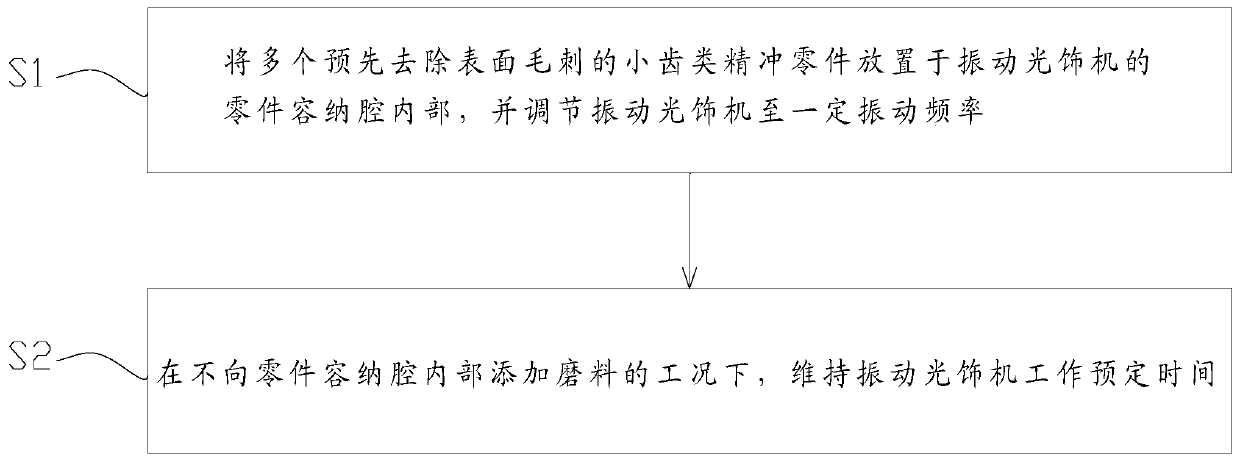

Process of removing residual burrs in toothlet fine blanking part tooth

The invention discloses a process of removing residual burrs in a toothlet fine blanking part tooth. The process particularly comprises the following steps: placing a plurality of toothlet fine blanking parts, on the surfaces of which burrs are removed in advance, in a part accommodating cavity of a vibrating finisher; adjusting the vibrating finisher to be at a certain vibration frequency; and under the working condition of not adding an abrasive into the part accommodating cavity, keeping the vibrating finisher working for a predetermined time. Compared with a process of removing residual burrs in a toothlet fine blanking part tooth by means of shot blasting in the prior art, the process provided by the invention utilizes meshing collision between part teeth to remove the residual burrsin the part teeth, is higher in efficiency and lower in cost, can not only cause no damage to the appearance quality of the parts but also improve the surface finish degree of the parts, and leads tono environmental pollution in the process.

Owner:HUBEI HAPM MAGNA SEATING SYST CO LTD

Steel-aluminum composite conductor rail and manufacturing method thereof

The invention relates to conductor rails for rail transit, in particular to a steel-aluminum composite conductor rail and a manufacturing method thereof. The steel-aluminum composite conductor rail comprises an aluminum base and is characterized in that a plate-shaped wear-resistant body is arranged at the upper end of the aluminum base, wear-resistant body clamp grooves are arranged in two sidesof the upper end of the aluminum base, the wear-resistant body comprises two single wear-resistant body parts, the section of each single wear-resistant body part is L-shaped, the lower end of each single wear-resistant body part bends inwardly to form a bent part, single wear-resistant body part teeth are evenly arranged at the edge of each bent part, a central-embedded-strip mounting groove is formed in the upper end of the aluminum base, a central embedded strip is arranged in the central-embedded-strip mounting groove, the two sides of the central embedded strip compresses against the lateral wall of the central-embedded-strip mounting groove, and the lower end of the central embedded strip is evenly provided with central-embedded-strip teeth. The steel-aluminum composite conductor rail is manufactured through insertion, rolling, welding, milling and cutting. The manufactured steel-aluminum composite conductor rail is tight and firm in bidirectional combination, high in overall dimensional precision, flexible and diversified in section shape and simple and efficient in manufacturing process.

Owner:洛阳固岳轨道科技有限公司

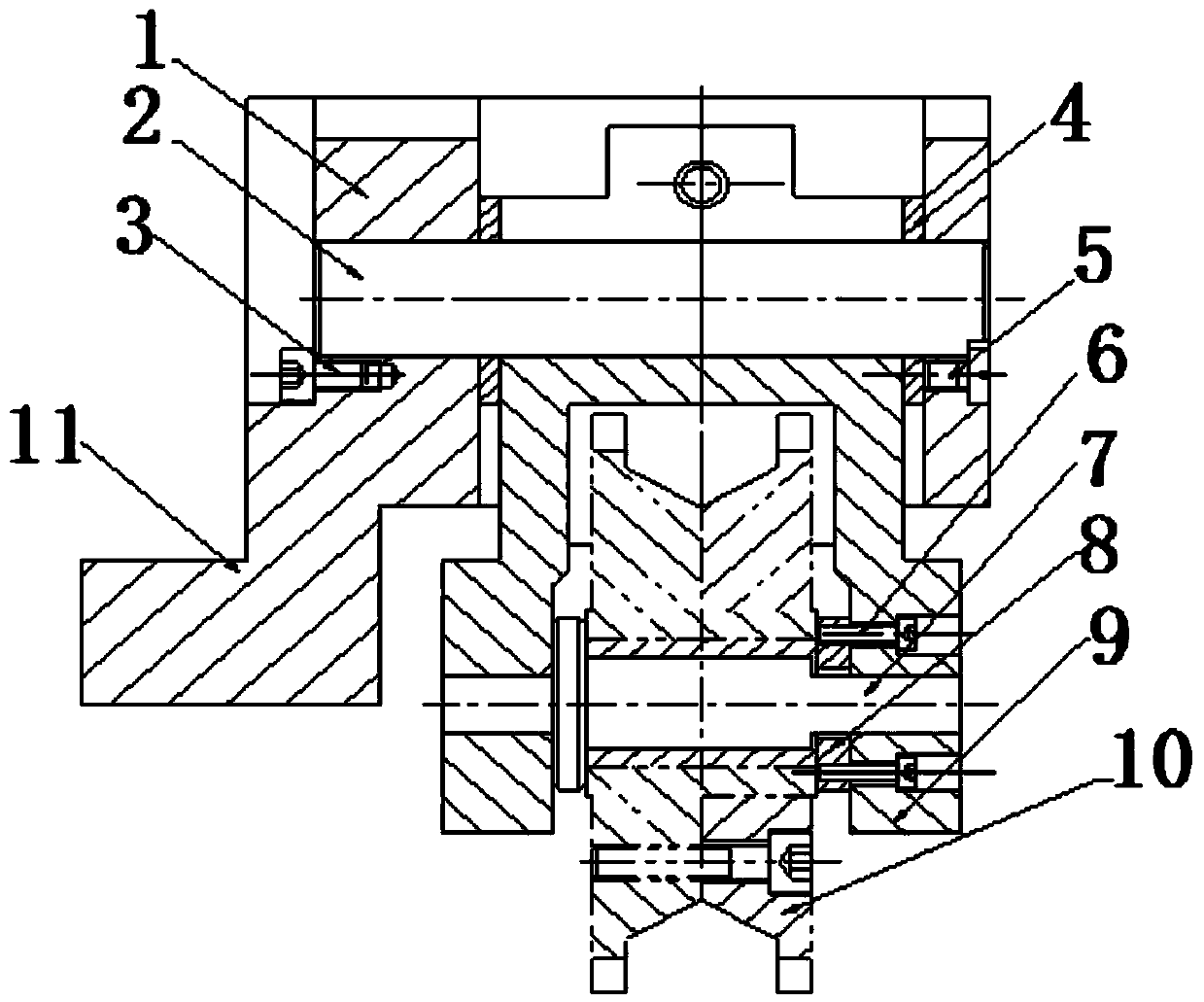

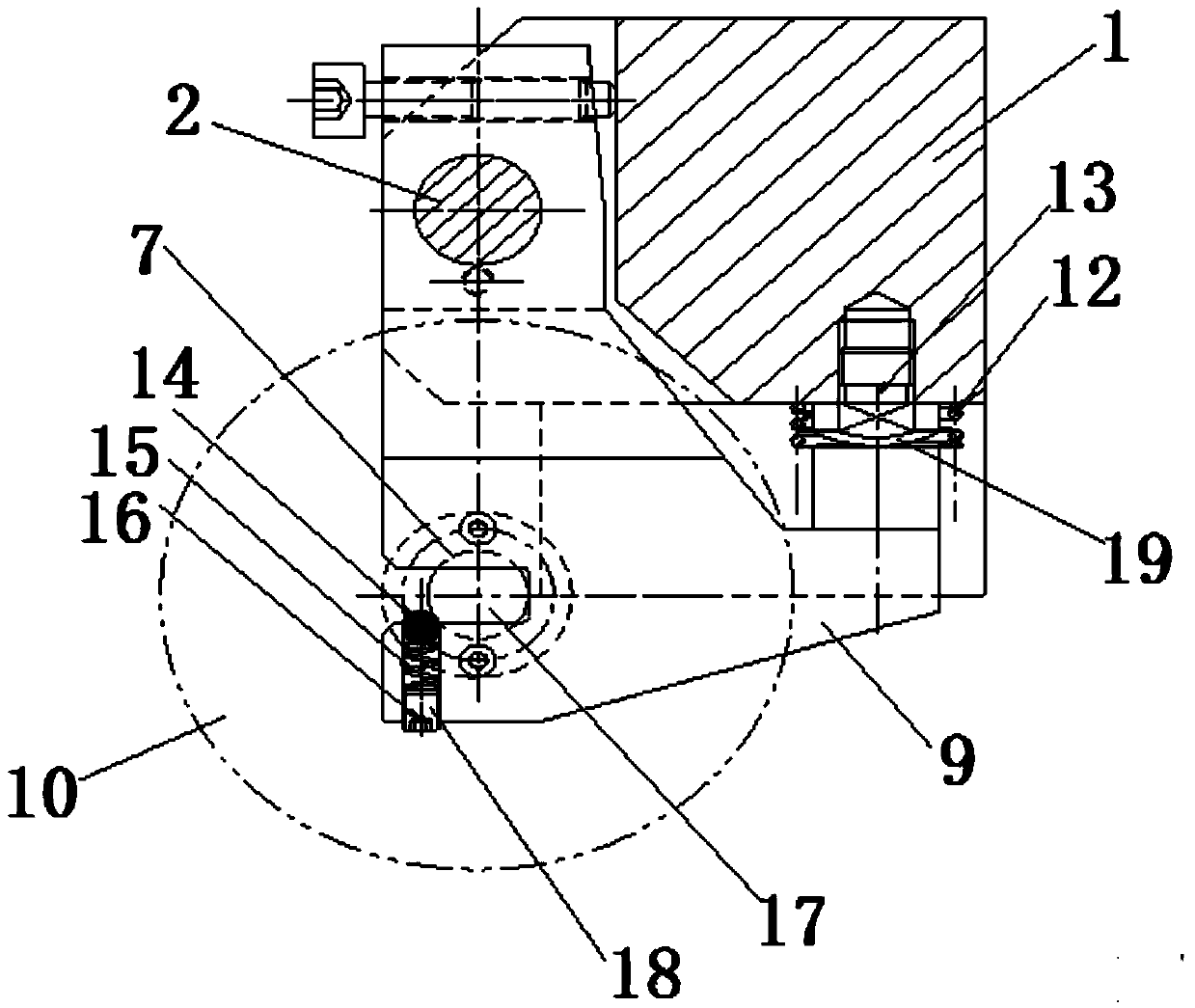

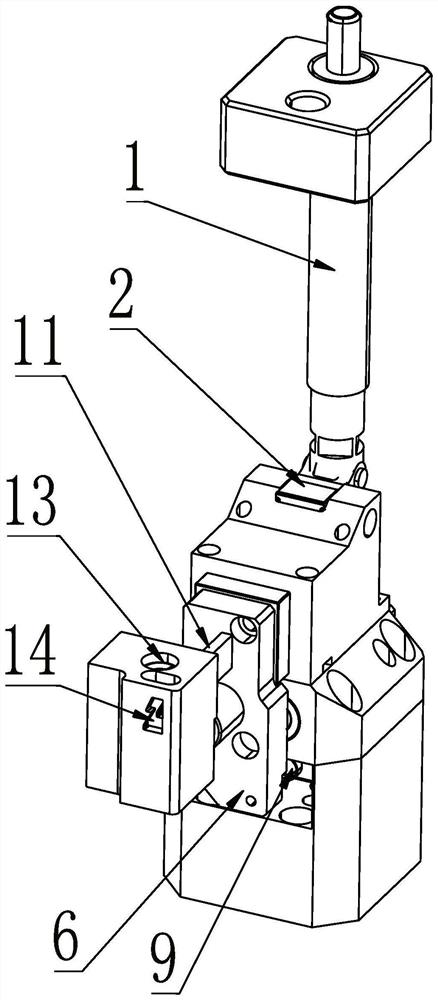

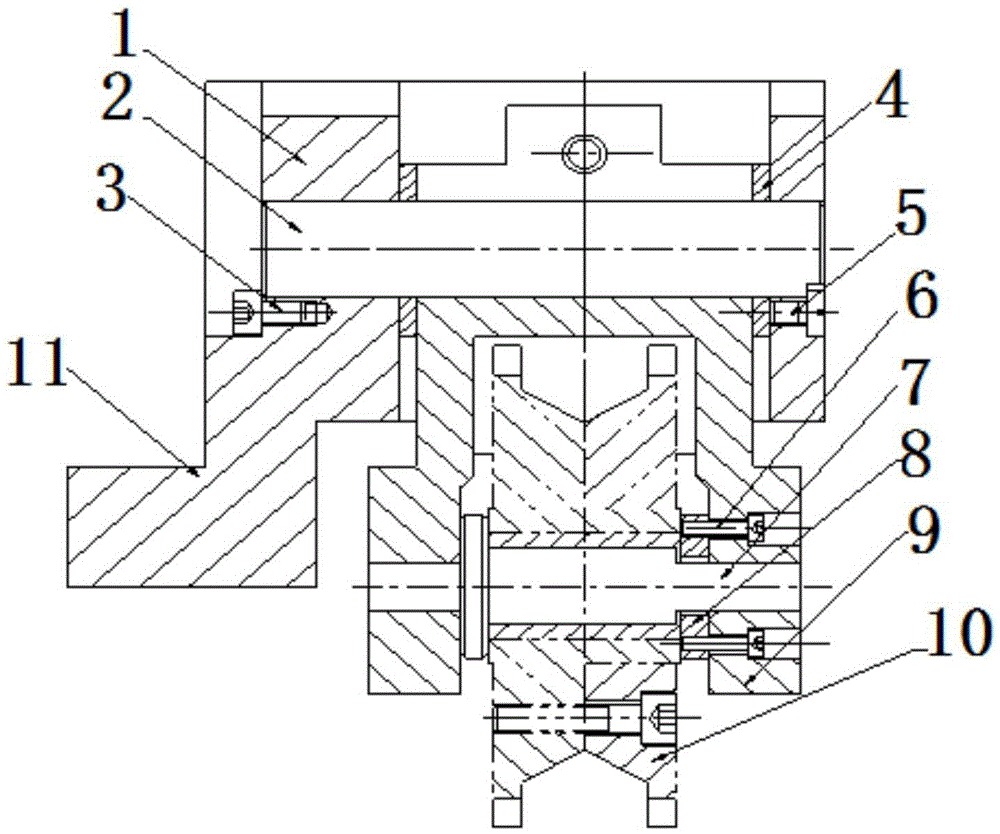

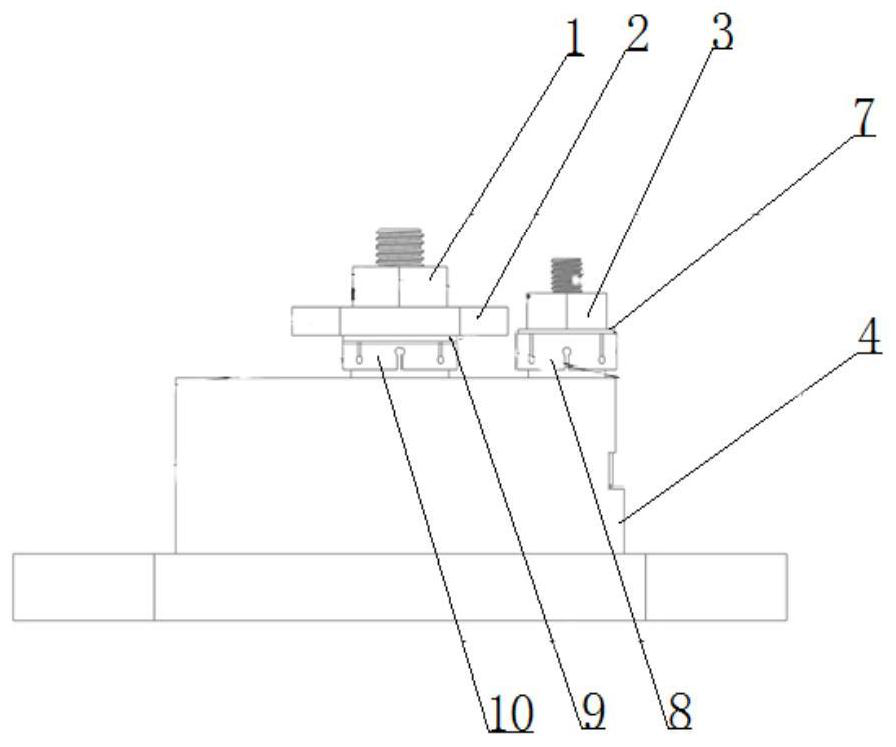

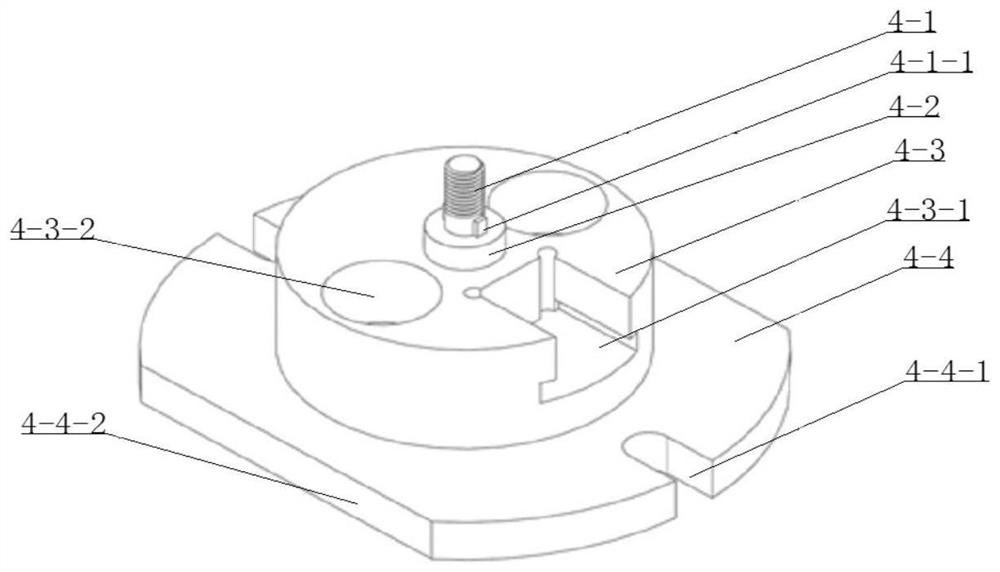

Magnesium alloy part tooth-pushing mechanism and mold

The invention discloses a magnesium alloy part tooth-pushing mechanism. The magnesium alloy part tooth-pushing mechanism comprises a positioning block, a tooth cutter, a self-return linear slide mechanism and a jacking mechanism, wherein a positioning hole and a tooth cutter through hole are formed in the positioning block; the positioning hole communicates with the inner cavity of the tooth cutter through hole; the tooth cutter which is adaptive to the tooth cutter through hole is movably arranged in the tooth cutter through hole in a penetrating mode; the tooth cutter is arranged in a slidedirection of the self-return linear slide mechanism; the tail end of the tooth cutter is connected to a slide part of the self-return linear slide mechanism; the jacking mechanism and the tooth cutterare separately positioned at the two ends of the self-return linear slide mechanism; and the jacking mechanism jacks the slide part, so that the tooth cutter is pushed to slide across the positioninghole. The magnesium alloy part tooth-pushing mechanism disclosed by the invention, the tooth pushing structure acts once for processing out a tooth-shaped structure on a workpiece conveniently and quickly; and the tooth pushing mechanism is easily integrated onto a mold of a trimming and material-removing head slag ladle, so that processes are favorably saved, production efficiency is improved, and cost is reduced.

Owner:CHONGQING BOAO MG AL MANUFACUTURE

A fully superconducting primary excitation linear generator for direct drive wave power generation

ActiveCN105811738BLower requirementAvoid complexityPropulsion systemsSuperconductor elements usageSpacing toothWave power generation

The invention discloses a full-superconducting primary excitation linear generator for direct-drive type wave power generation. The full-superconducting primary excitation linear generator comprises a primary stator and a secondary mover, wherein the primary stator comprises multiple groups of stator units arranged in a straight line; each stator unit comprises a U-shaped core, primary armature windings and primary exciting windings; the U-shaped core comprises two primary cores; an opening of the U-shaped core faces the secondary mover; the primary armature windings are arranged in the primary cores; the primary exciting windings are arranged in the U-shaped core; the secondary mover is the core which does not contain a winding and has a cogging structure; and a corresponding cogging structure is arranged on each primary core. According to the full-superconducting primary excitation linear generator, an arc-shaped structure exciting winding sleeves the outside of each primary core; and a cooling system does not move, so that the complexity level is reduced. The magnetic field conversion rate and the terminal voltage can be increased by a multi-tooth structure secondary; the defect of a low low-speed voltage is compensated; and by unequally-spaced teeth, the voltage frequency and amplitude generated when the generator moves to the end part are increased by reducing the end-part tooth pitch.

Owner:SOUTHEAST UNIV

A Stator Permanent Magnet Linear Oscillating Motor

ActiveCN105932853BImprove power densityImprove robustnessDynamo-electric machinesWork performanceParts tooth

The invention relates to a permanent magnet linear oscillation motor with a stator. The permanent magnet linear oscillation motor is characterized by at least comprising a connecting shaft end, output bearing bushes, a rotor mandrel, a stator end part tooth ring, resonant springs, a stator middle tooth ring, permanent magnet steel rings, armature windings, rotor tooth rings, a rotor mounting sleeve, a linear sliding bearing and an engine base sleeve, wherein the rotor mandrel is arranged at the center of the engine base sleeve along the axial direction; the rotor mandrel is fixed between a front end cover of the motor and a rear end cover of the motor through locking nuts; the rotor mounting sleeve is arranged at the middle part of the rotor mandrel; the rotor tooth rings are sequentially nested into the excircle surface of the rotor mounting sleeve along the axial direction to form a linear motor secondary rotor; the linear sliding bearing is arranged at the inner side of the rotor mounting sleeve and is axially fixed by a snap spring; and a linear motor primary stator is fixed inside the engine base sleeve and outside the rotor tooth rings. The linear motor has more advantages as a high-thrust, high-power density and strong-robustness servo direct drive vibration source; and the working performance is better.

Owner:XIDIAN UNIV

A lathe chamfering tool holder device

ActiveCN103737122BImprove processing qualityLow costGear-cutting machinesGear teethParts toothMechanical engineering

Owner:WUHU WANLIYANG TRANSMISSION CO LTD

The Method of NC Grinding of Circular Saw Blades

The invention discloses a numerical control tooth grinding method of a circular saw blade. The numerical control tooth grinding method comprises the following steps: Step one, a grinding wheel component is constructed at an operation end of an XY-axis translation mechanism, a work spindle and a work motor are constructed at a Z-axis translation mechanism, and the work spindle is driven by the work motor; Step two, driving parameters of a numerical control cabinet for controlling the XY-axis translation mechanism, the Z-axis translation mechanism and the work motor are set; Step three, the Z-axis translation mechanism, according to the driving parameters, adjusts the circular saw blade mounted at the work spindle to be in a middle part tooth grinding station in the Z-axis direction, the work motor drives the work spindle to carry out stepping rotation according to the driving parameters, and the XY-axis translation mechanism drives the grinding wheel component to polish grinding teeth of the circular saw blade one by one; and Step four, the Z-axis translation mechanism, according to the driving parameters, adjusts the circular saw blade of the work spindle to be in an upper chamfer station or in a lower chamfer station of the circular saw blade of the work spindle, the work motor drives the work spindle to rotate according to the driving parameters, and the XY-axis translation mechanism drives the grinding wheel component to polish lower chamfers or upper chamfers of the grinding teeth of the circular saw blade at a high speed.

Owner:浙江阿波罗工具有限公司

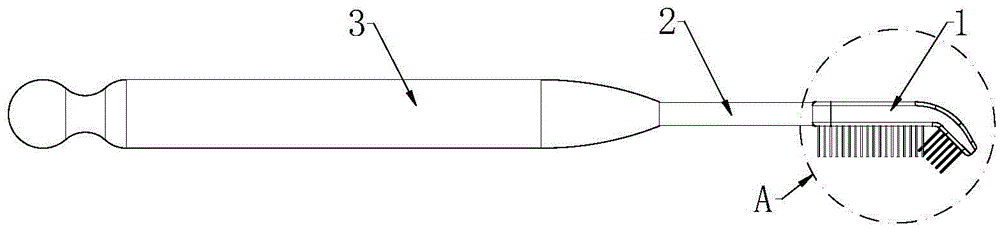

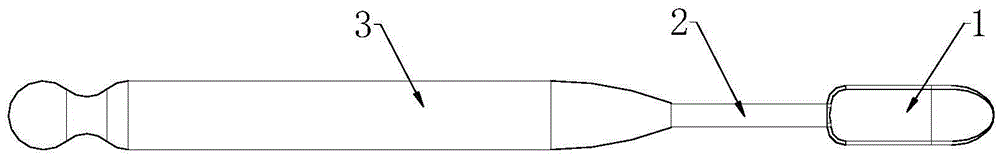

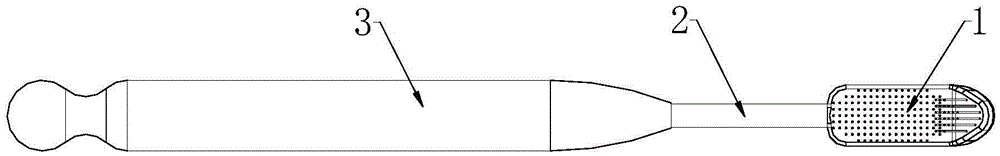

Efficient tooth cleaning toothbrush

The invention discloses an efficient tooth cleaning toothbrush, which comprises a brush head, a connecting part and a handle, wherein the brush head comprises a brush head body front part and a brush head body back part; the brush head comprises a brush head body and brush hair; the roots of the brush hair are planted on the inner wall surface of the brush head body; the brush head body comprises the brush head body front part and the brush head body back part; the brush head body front part is hooked back and bent towards the inner wall surface of the brush head body back part, so that an included angle alpha is formed between the inner wall surface of the brush head body front part and the inner wall surface of the brush head body back part, and the alpha is greater than 90 degrees but smaller than 180 degrees; the brush hair comprises front brush hair arranged at the brush head body front part and back brush hair arranged at the brush head body back part; the root planting direction of the brush hair is vertical to the brush head body front part; and the root planting direction of the back brush hair is vertical to the brush head body back part. The efficient tooth cleaning toothbrush has the advantages that the efficient tooth cleaning toothbrush can be effectively attached to the tooth surfaces; tooth seams and back part teeth in the oral cavity can be effectively cleaned; and the teeth are comprehensively cleaned.

Owner:SHENZHEN HAIDA BEIER IND CO LTD

Spline broach lifting tailstock grinding process

The invention discloses a spline broach lifting tailstock grinding process which comprises a part body, a part tooth profile, a machined surface and a broach tooth profile. When the part body is machined, the broach tooth profile is lifted to be subjected to surface treatment according to the use condition, the tail of a broach is lifted, a new tooth profile is designed, and therefore when the broach is placed flat for use, the tooth tip of each tooth falls on the part theoretical tooth profile line. By calculating the process size before machining, the machining precision is greatly improved, the machining quality is improved, and the problems that in the machining process, severe friction occurs between the broach tooth profile surface and the machined surface of the part, the quality of the machined surface becomes poor, the diameter of the broach becomes larger and larger along with advancing of the broach, the machined surface is increased tooth by tooth, friction is increasingly severe, squeal and vibration occur, galling, scaling, tearing and other defects occur to the machined surface, and the broach can be broken or a machine tool can be jammed when the defects are severe are solved.

Owner:汉中市智海精密机械工具有限责任公司

Thin plate part tooth profile machining tool and method thereof

The invention belongs to the field of machining, relates to a thin plate part tooth profile machining tool and a method thereof and provides a thin plate part positioning tool. Through the tool, toothprofile machining is achieved, the tool is coated with metal cohesive glue at first, and a to-be-machined part is glued to the tool; then part clamping is achieved through the tool directly; the partis cut evenly in a layered mode through a tooth profile cutter; and finally the part is separated from the tool. The problem that the thin plate part tooth profile part is difficult to machine due tounstable clamping is solved, the part reject rate is greatly lowered, the product quality and machining precision are ensured, and the tool has quite high application value.

Owner:JIANGXI CHANGHE AVIATION IND

One-part tooth implant, device for bending an implant, and method for bending an implant

Owner:HAGER & MEISINGER

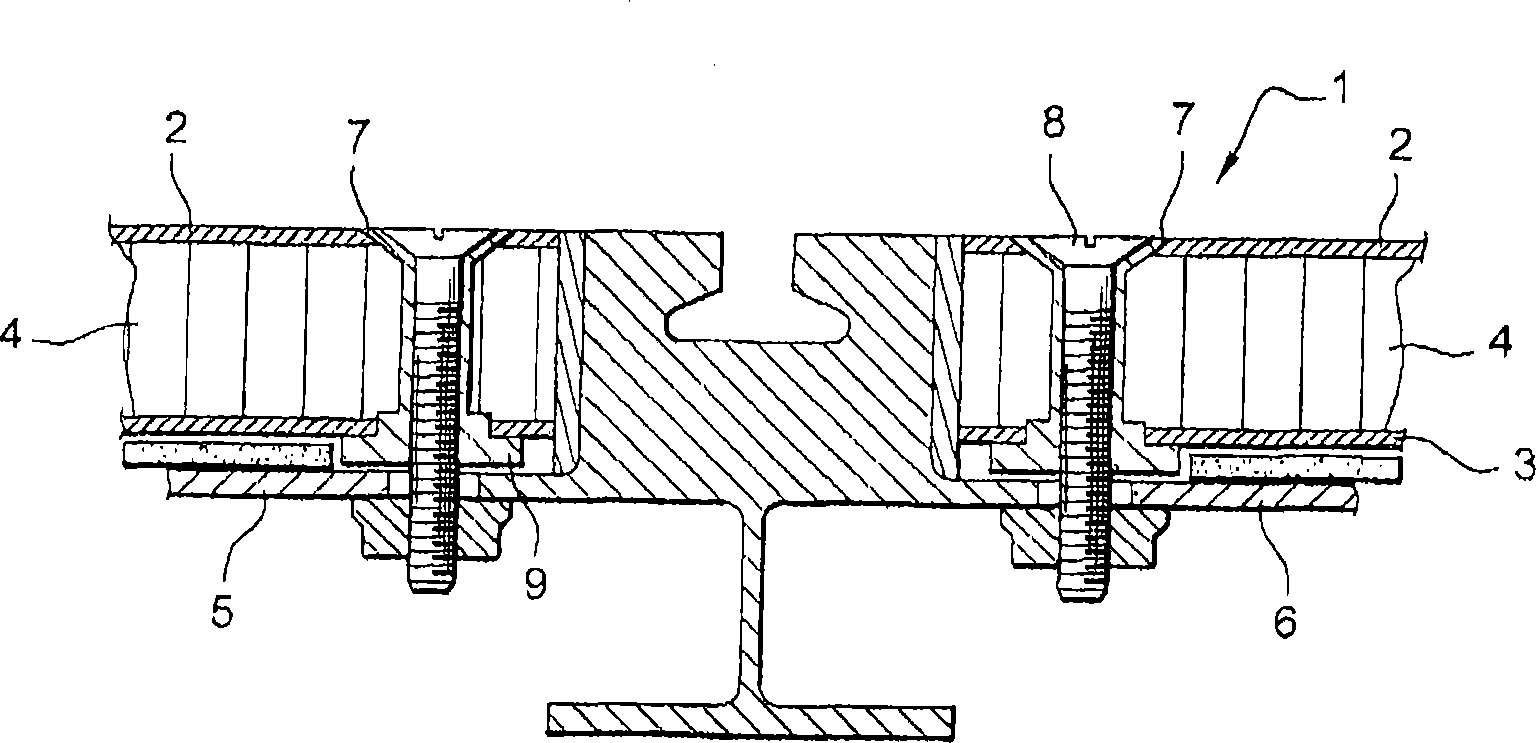

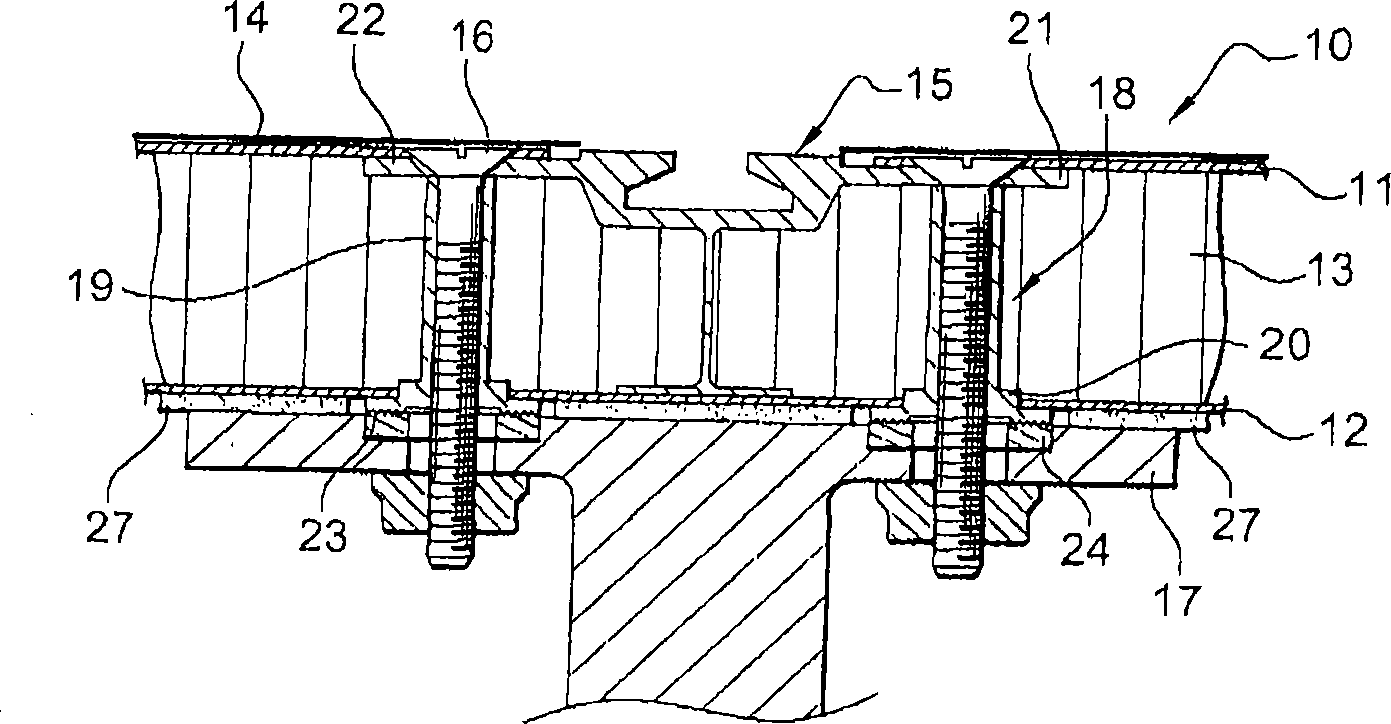

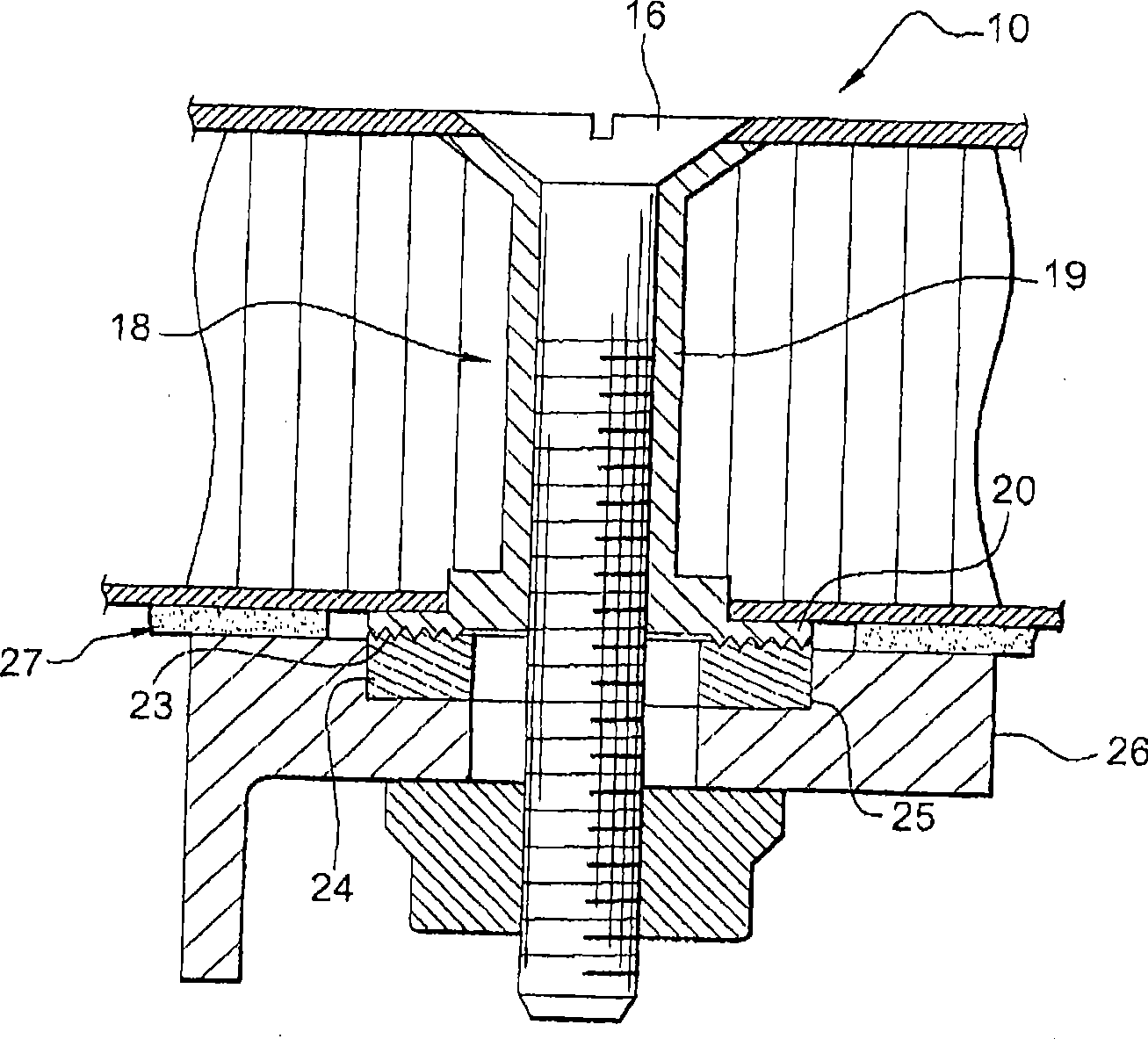

Device for fixing a lightweight panel on a support

InactiveCN101273207BRealize the assemblyFuselage framesEfficient propulsion technologiesEngineeringFlange

The invention concerns a device for fixing a lightweight panel on a support. Said device comprises an insert (18) including at least one flange (20), said insert being designed to receive a bolt-type fixing member (16). The invention is characterized in that said flange (20) has an outer surface comprising tooth elements (23) and the device comprises a part made of ductile material (24) includingan opening for passing through the fixing member (16). The tooth elements (23) are designed to co-operate, when the panel is being fixed on the support, with the ductile part (24) to enable said panel to be fixed without deforming it.

Owner:AIRBUS OPERATIONS (SAS)

Chamfering clamp for shaft part tooth profile

PendingCN111805011AAchieve the goal of axial clamping fixtureGear-cutting machinesGear teethAxial displacementParts tooth

The invention discloses a chamfering clamp for a shaft part tooth profile. A cylindrical supporting body is arranged, a clamping assembly is coaxially arranged in the supporting body, and the clampingassembly comprises a tensioning body and a radial limiting body which are sequentially arranged in a sleeved mode from inside to outside; and an adjusting body further sleeves the tensioning body, radial displacement of the adjusting body is converted into axial displacement, the adjusting body drives the tensioning body and the radial limiting body to move relatively in the axial direction, andthe tensioning body is forced to be tightened in the radial direction. According to the chamfering clamp, through reasonable arrangement of a clamp structure, when the clamp is used for machining shaft parts, no axial power mechanism needs to be additionally arranged, and the purpose of axially clamping the part is achieved.

Owner:BAOJI FAST GEAR

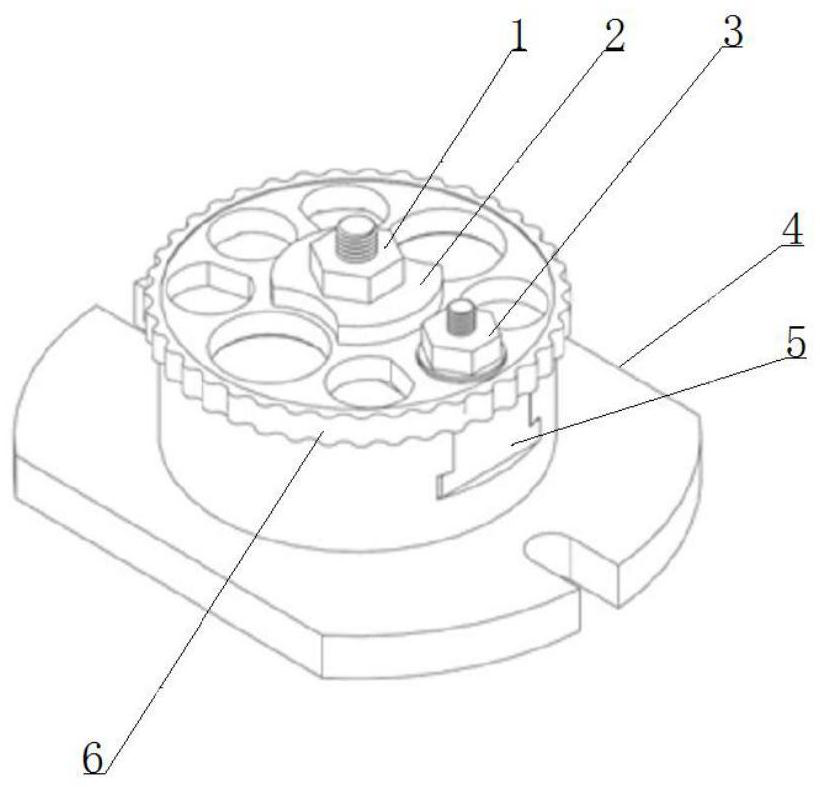

A positioning and tightening device for high-speed machining of cycloidal gears

ActiveCN110842598BReduce the number of card loadingEnsure consistencyPositioning apparatusGear-cutting machinesParts toothGear wheel

The invention relates to a positioning tightening device for high-speed machining of cycloidal gears, comprising a support base, a floating positioning piece, a first tensioning positioning sleeve, a second tensioning positioning sleeve, and a pressure plate; the swimming positioning piece and the supporting base The seat is inserted into the T-shaped slot through the T-shaped positioning block to cooperate, and the two tensioning positioning sleeves are respectively set and tightened on the first tensioning mandrel on the support base and the second tensioning mandrel on the floating positioning piece , the two tensioning positioning sleeves are respectively inserted into the center hole and the side avoidance hole of the tooth blank of the part in a tension-fitting manner; the pressure plate is set on the first screw rod, and the lower end of the pressure plate is pressed against the upper end of the tooth blank of the part through the first gasket Contact, above the pressure plate, there is a first nut that is locked with the first screw; on the second screw, there is a second nut that is locked above the part tooth blank, and the second nut is connected to the upper end of the part tooth blank through the second gasket. Press down on the contacts. The device realizes accurate positioning and one-time clamping processing of the tooth blank of the part.

Owner:天津旗领机电科技有限公司

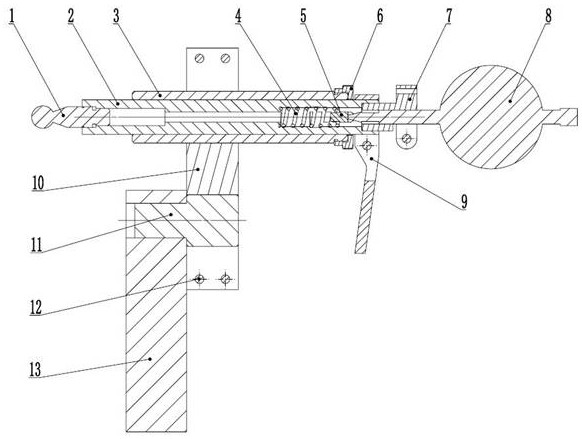

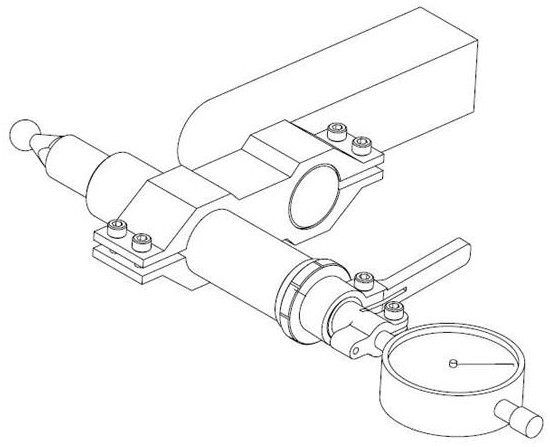

Pull rod type tooth jump inspection tool

PendingCN113959291ACheck that the positioning is accurateEasy to operateMechanical measuring arrangementsMachine buildingGear wheel

The invention relates to a gear shaft part tooth jump detection tool in the field of machine manufacturing, in particular to a pull rod type tooth jump detection tool. The structure comprises a measuring head, an inner pull rod, an outer sleeve rod, a spring, a spring positioning key, a locking nut, a dial indicator fixing sleeve, a dial indicator, a handle, a frame body, a locking screw, a connecting bolt and a support. According to the working mode, the tooth jump detection function is achieved through relative movement of the inner pull rod and the outer sleeve rod. The outer sleeve rod, the support and the frame body serve as a fixed body; a measuring head is arranged at the front end of the inner pull rod, a handle is arranged at the rear end of the inner pull rod, the measuring head retreats out of a gear groove by pulling the handle, the workpiece is rotated, the handle is released, the measuring head enters the next gear groove through the elastic force of an internal spring, and the purpose of detecting circumferential tooth jump is achieved. According to the invention, the tooth jump of various gear shafts can be conveniently and rapidly inspected on a machine tool, and then the process of correcting the central hole of the gear shaft is executed. The tool has the characteristics of quick operation, accurate inspection, time saving and great improvement of the production efficiency.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

A process for removing residual burrs in fine-blanking parts of small teeth

The invention discloses a process of removing residual burrs in a toothlet fine blanking part tooth. The process particularly comprises the following steps: placing a plurality of toothlet fine blanking parts, on the surfaces of which burrs are removed in advance, in a part accommodating cavity of a vibrating finisher; adjusting the vibrating finisher to be at a certain vibration frequency; and under the working condition of not adding an abrasive into the part accommodating cavity, keeping the vibrating finisher working for a predetermined time. Compared with a process of removing residual burrs in a toothlet fine blanking part tooth by means of shot blasting in the prior art, the process provided by the invention utilizes meshing collision between part teeth to remove the residual burrsin the part teeth, is higher in efficiency and lower in cost, can not only cause no damage to the appearance quality of the parts but also improve the surface finish degree of the parts, and leads tono environmental pollution in the process.

Owner:HUBEI HAPM MAGNA SEATING SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com