Method for designing hot-forging die tooth form of rockshaft with teeth

A technology for a hot forging die and a design method, which is applied in the field of metal hot precision forging, can solve the problems of increased tooth shape machining allowance, crushing deformation, and shortening the service life of the forging, so as to reduce the machining allowance and improve the use. performance, the effect of improving the life of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

[0019] The tooth profile design method of the toothed rocker shaft hot forging die of the present invention comprises the following steps:

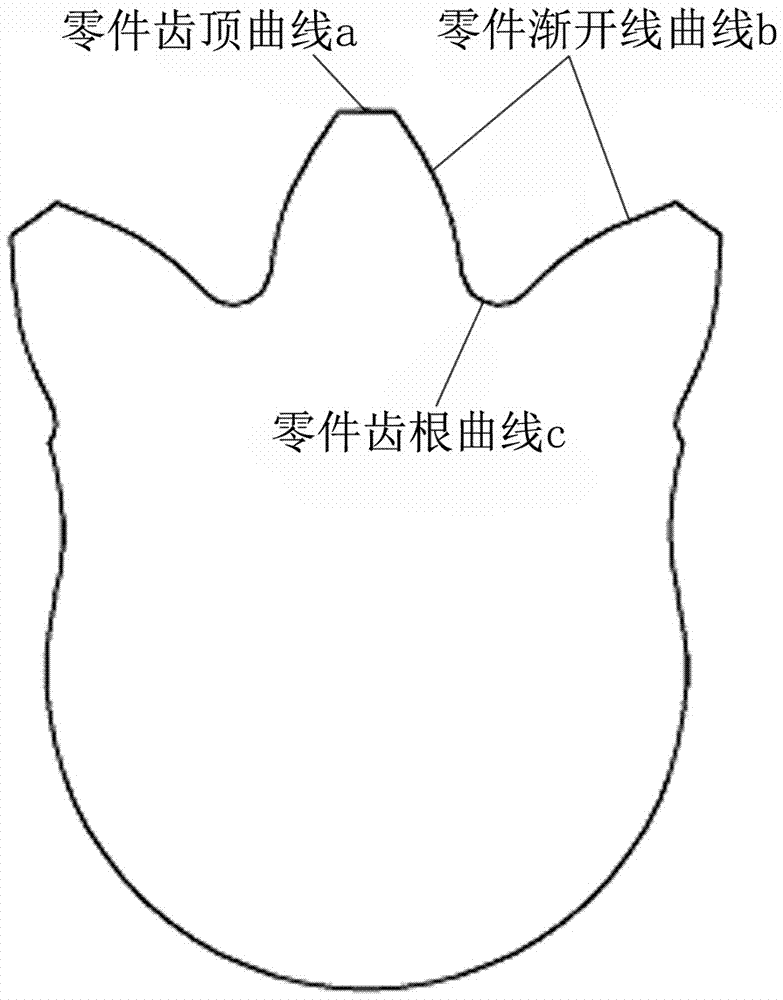

[0020] (1) Draw the tooth shape of the rocker shaft parts according to the tooth shape parameters of the rocker shaft, and decompose the tooth shape into three parts: the part addendum curve a, the part involute curve b, and the part dedendum curve c (such as figure 1 shown);

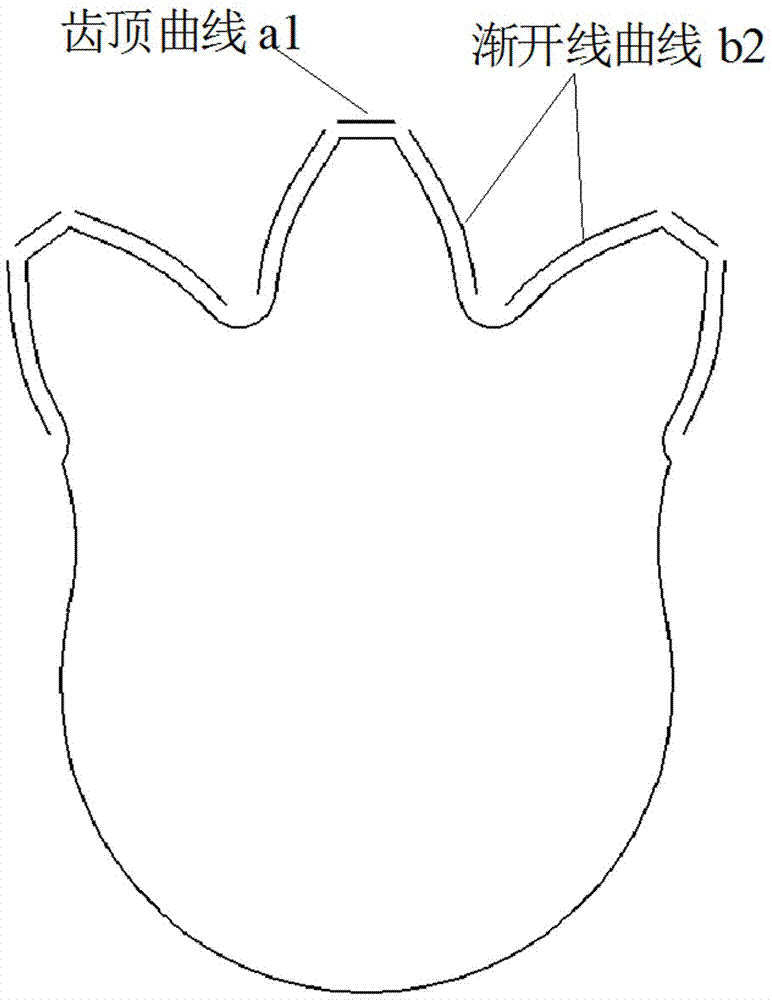

[0021] (2) Offset the addendum curve a and the involute curve b of the part drawn in step (1) equidistantly outward to obtain the addendum curve a1 and the involute curve b1 (such as figure 2 shown);

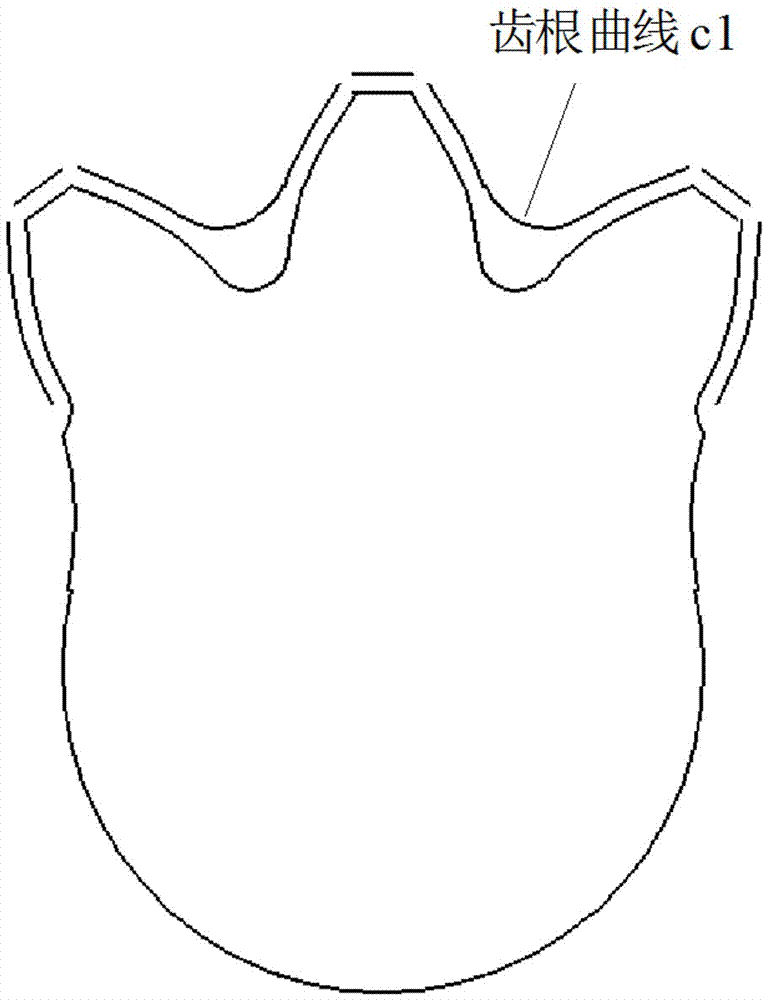

[0022] (3) Fit different dedendum curves on the outer side of the part dedendum curve c drawn in step (1), use material forming numerical simulation software to simulate and calculate the stress state and temperature field distribution of different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com