Patents

Literature

33results about How to "Reduce machining allowance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

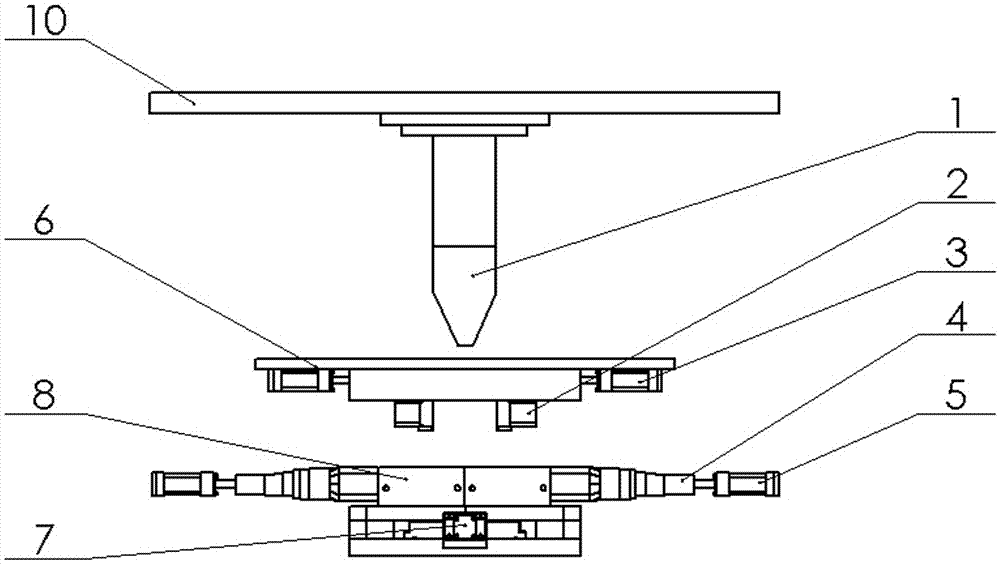

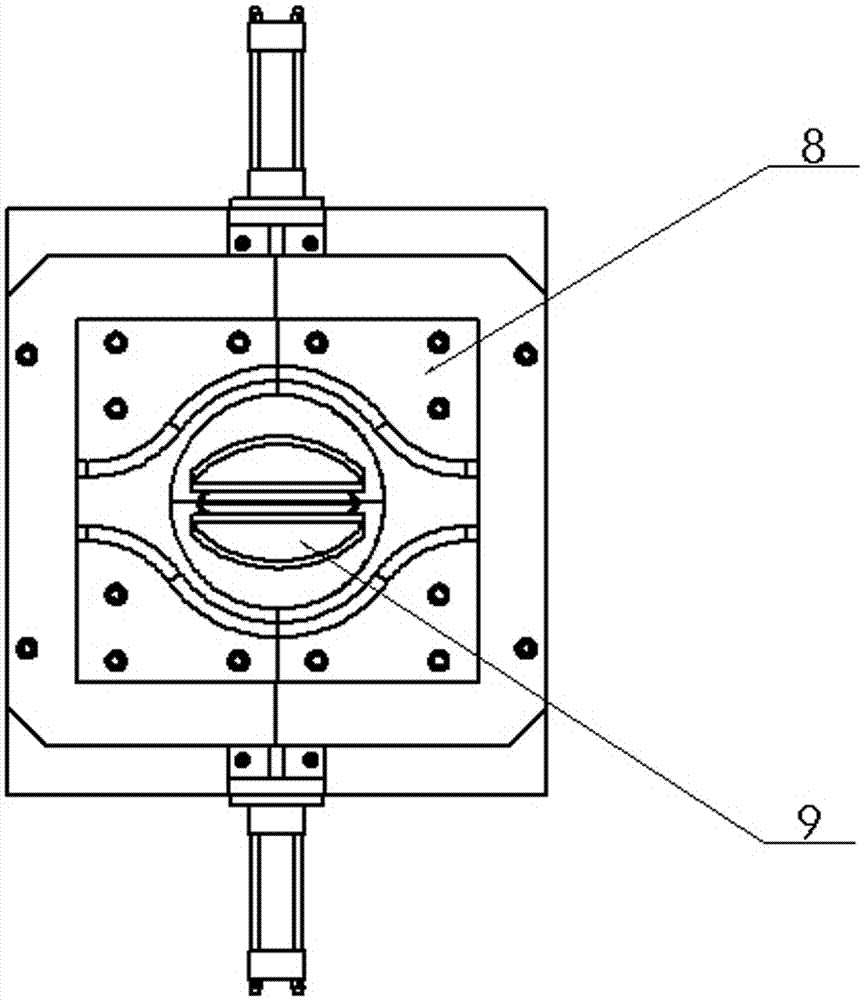

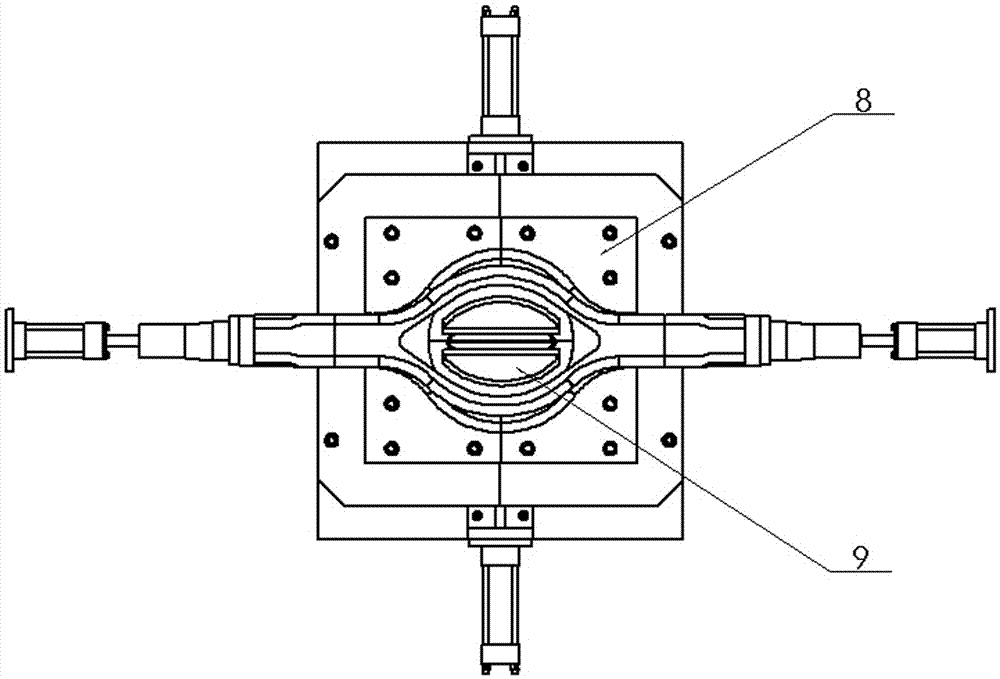

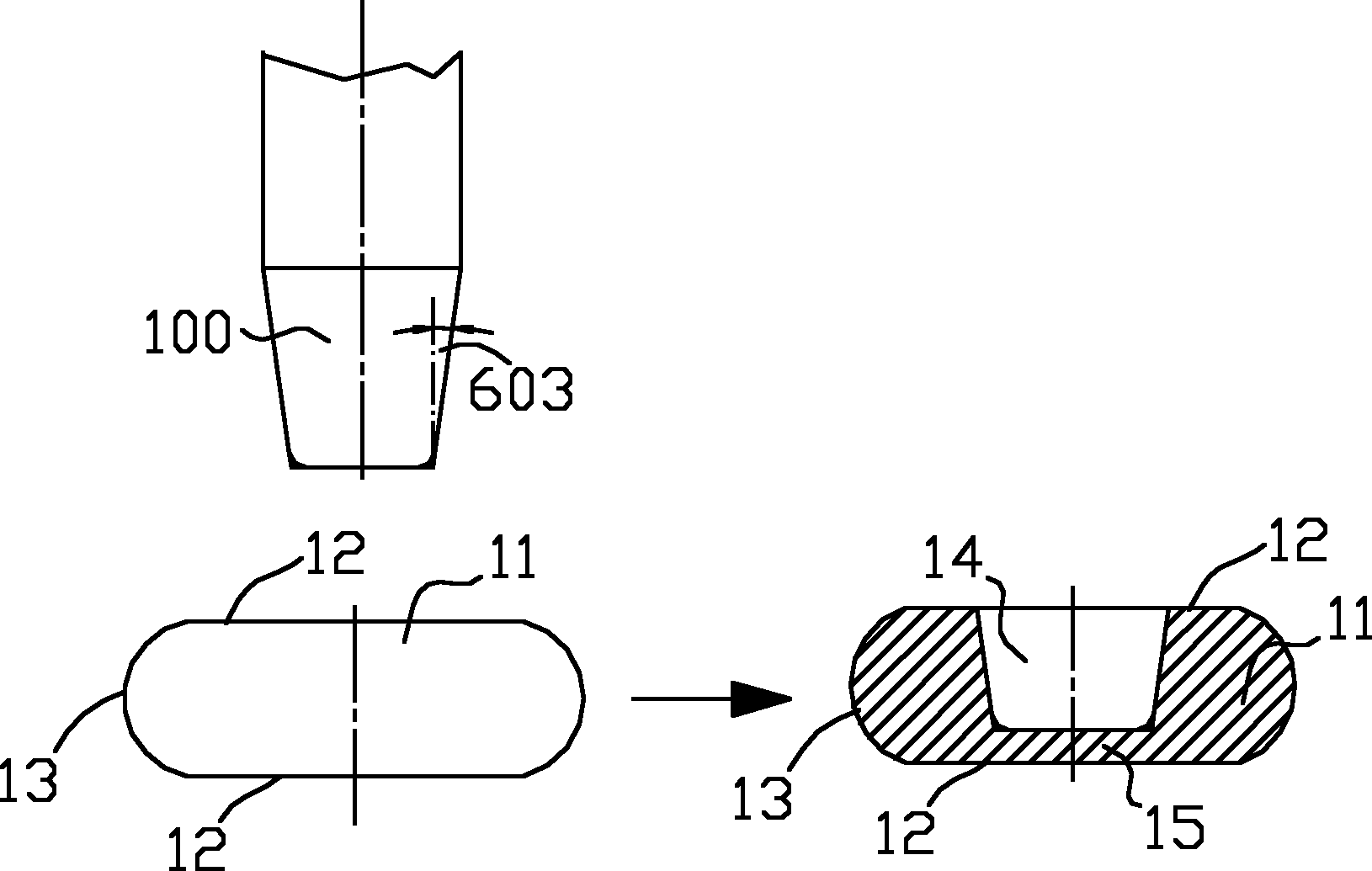

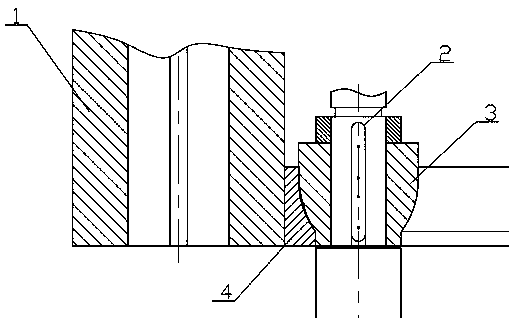

Forming method for banjo axle housing

ActiveCN105436350AEliminate product defectsImprove product qualityShaping toolsEngine componentsHydraulic cylinderEngineering

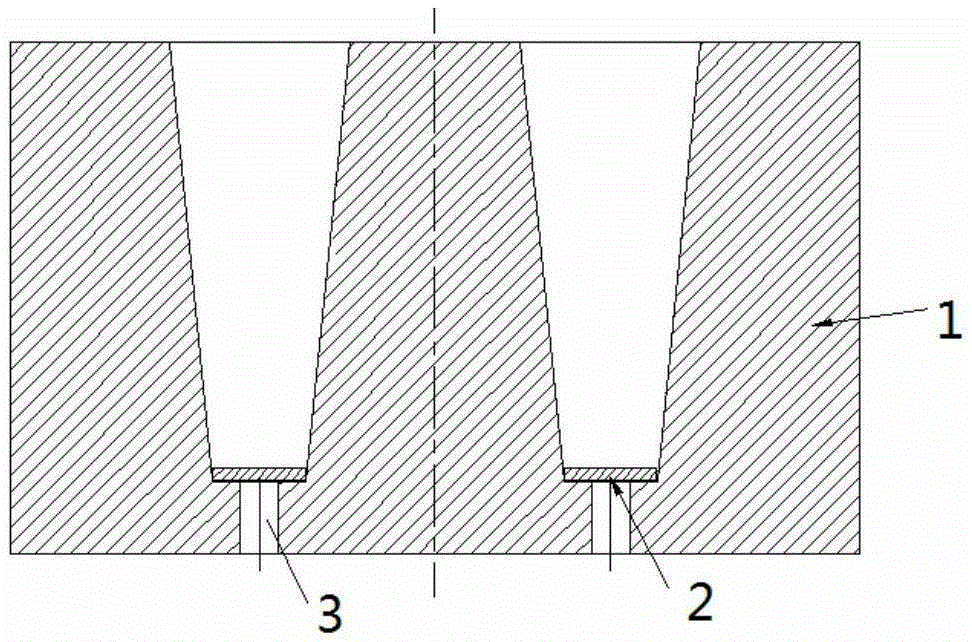

The invention discloses a forming method for a banjo axle housing. The forming method includes the following steps of (S1) blanking, (S2) extrusion of a shaft head, (S3) square pushing, (S4) manufacturing of a process groove, (S5) heating of a workpiece, (S6) radial expansion, (S7) shaping and (S8) upward resetting of a lower press sliding block and taking-out of the workpiece. According to the (S6), a wedge punch penetrates through a central hole of the lower press sliding block, pushes two radial expansion core molds to expand the radial direction of a workpiece central hole and axially squeezes the workpiece synchronously. According to the (S7), two axial shaping core molds are attached, the lower press sliding block moves downwards to enable the axial shaping core molds to be inserted into the position between two radial shaping core molds, an upper press sliding block moves downwards, and the wedge punch is inserted into the position between the two axial shaping core molds to shape the workpiece central hole and axially squeeze a hydraulic cylinder for axial limitation. The forming method integrates heat expansion and shaping, work procedures are reduced, a process chain is shortened, and the outline size accuracy is obviously improved.

Owner:吴志强 +1

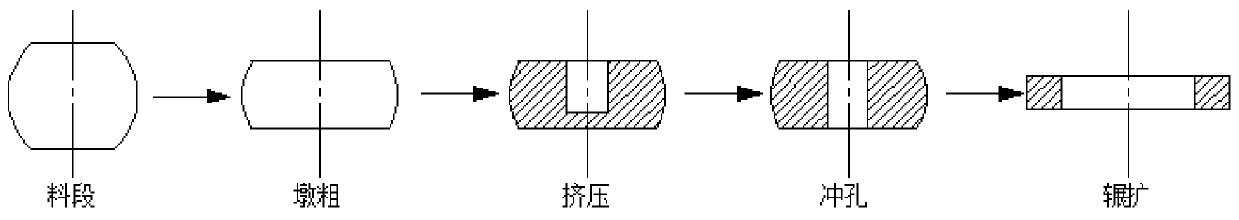

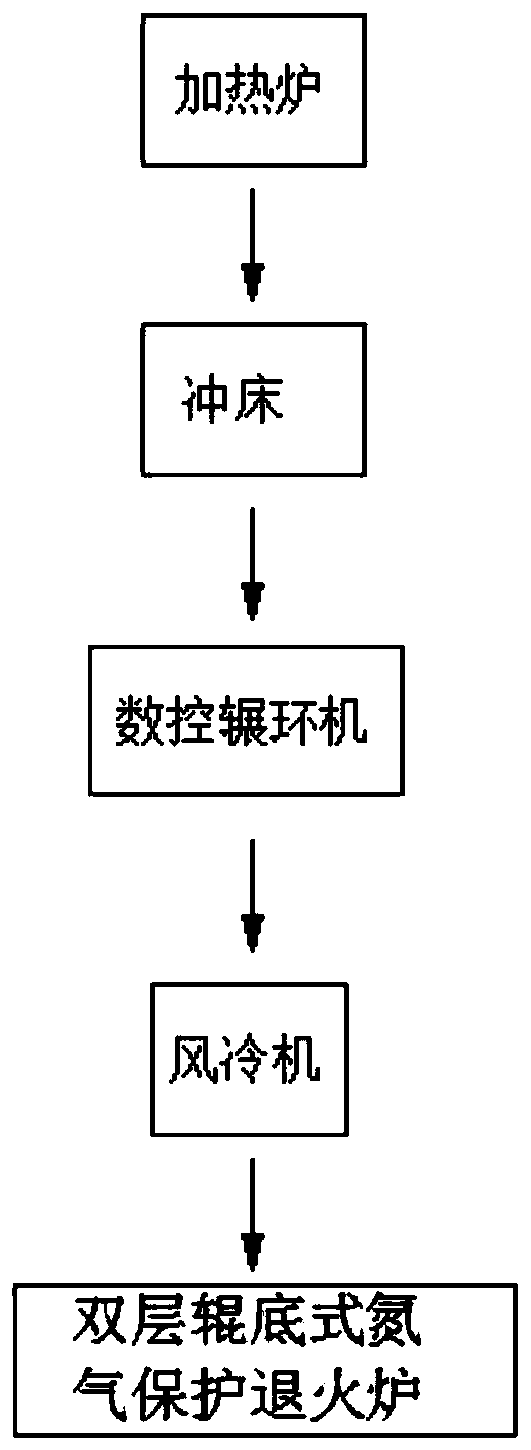

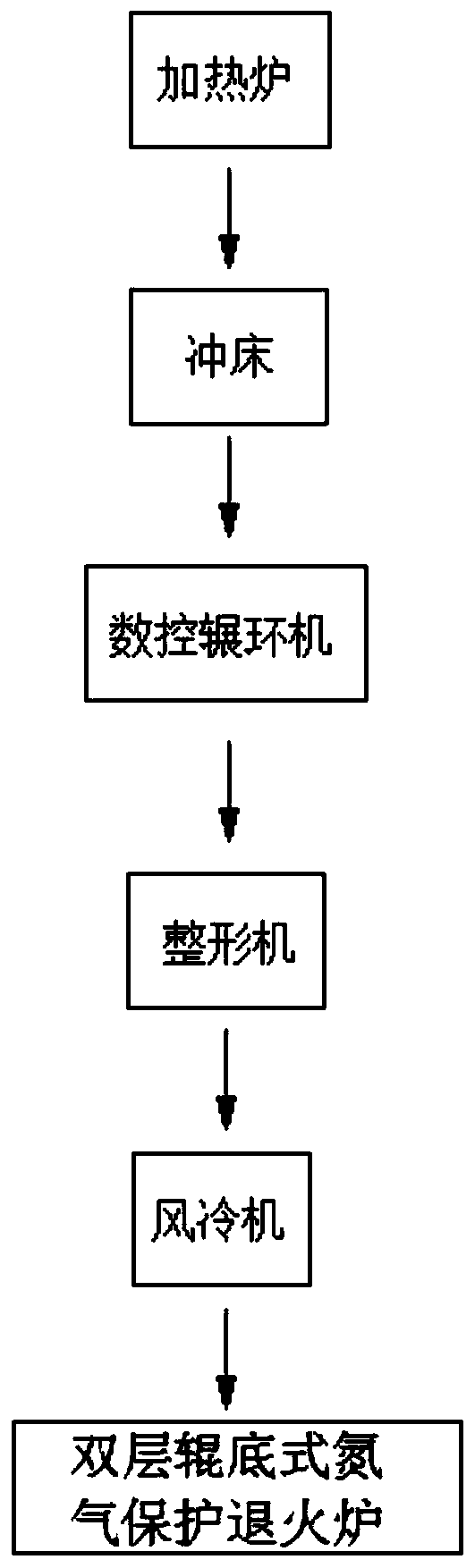

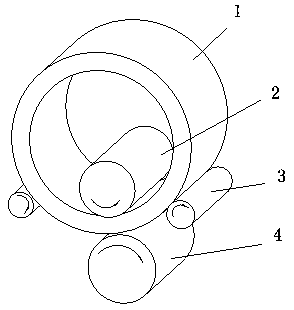

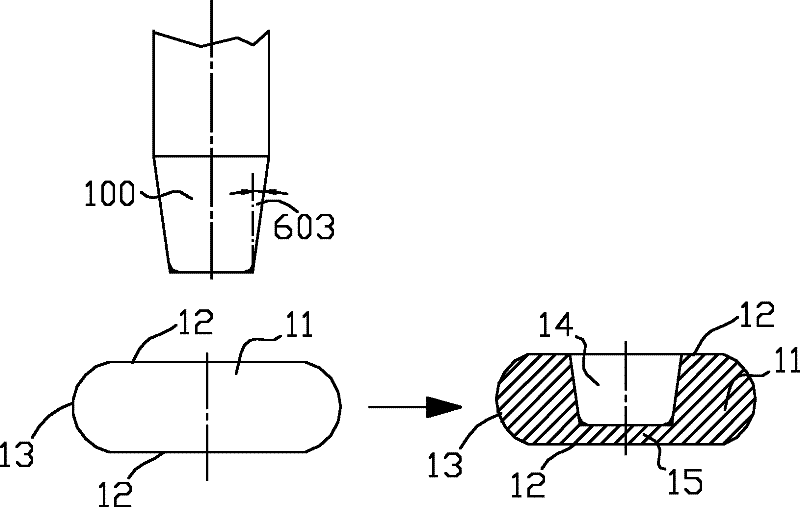

Bearing ring forging machining process and machining system

PendingCN109909437AHigh strengthHigh precisionMetal-working apparatusBearing componentsNumerical controlPunching

The invention discloses a bearing ring forging machining process and machining system, and relates to the technical field of bearing ring forging machining. The process includes the following steps that firstly, a steel material section of a high-carbon chromium bearing is heated to 1130 DEG C to 1180 DEG C; secondly, the heated material section is forged in the axial direction, and a material section subjected to upsetting is obtained; thirdly, the material section subjected to upsetting is extruded so that the middle portion of the material section subjected to upsetting can be indented, theindented portion of the middle portion of the material section is punched through, and a material section subjected to axial punching is obtained; fourthly, ring rolling is conducted on the materialsection, subjected to axial punching, through a numerical control ring rolling machine, and a ring is obtained; fifthly, the ring is air-cooled for 6 min to 8 min to 600 DEG C or below; and sixthly, spheroidizing annealing is conducted on the air-cooled ring through a double-layer roller hearth type nitrogen protection annealing furnace. The machining system comprises a heating furnace, a punchingmachine, the numerical control ring rolling machine, an air cooling machine and the double-layer roller hearth type nitrogen protection annealing furnace. By means of the bearing ring forging machining process and machining system, the surface roughness degree of the bearing ring can be decreased, no decarburized layers are generated after spheroidizing annealing, and therefore the cutting machining allowance is reduced, steel is saved, and the raw material utilization rate is increased.

Owner:临清市同兴轴承锻造有限公司

Heat treatment method of medium carbon low-alloy steel railway wheel

ActiveCN107586938AEasy to useReduce depthIncreasing energy efficiencyFurnace typesSlow coolingMechanical property

The invention provides a heat treatment method of a medium carbon low-alloy steel railway wheel, comprising the following processes: heating by quenching a railway wheel at 840-860 DEG C after rollingand slow cooling, cooling by spraying water after discharging, tempering at 500+ / -10 DEG C, carrying out power frequency induction heating at 890-910 DEG C, and carrying out pressure-air cooling. Theheat treatment method aims to remarkably reduce depth of an abnormal structure area on near surface of a tread or completely eliminate the abnormal structure layer on the basis of maintaining original mechanical properties of the wheel, so as to improve use performance of the wheel and lower cutting process cost.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

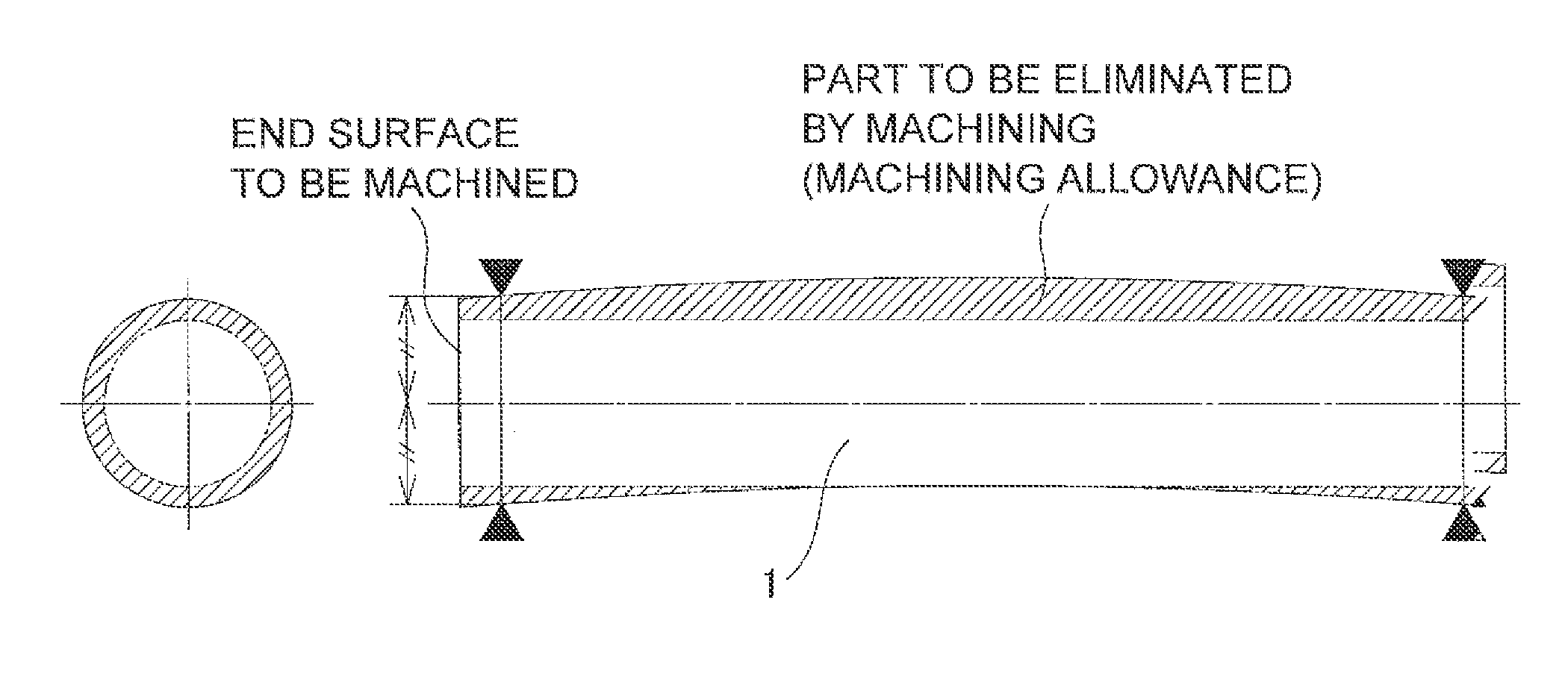

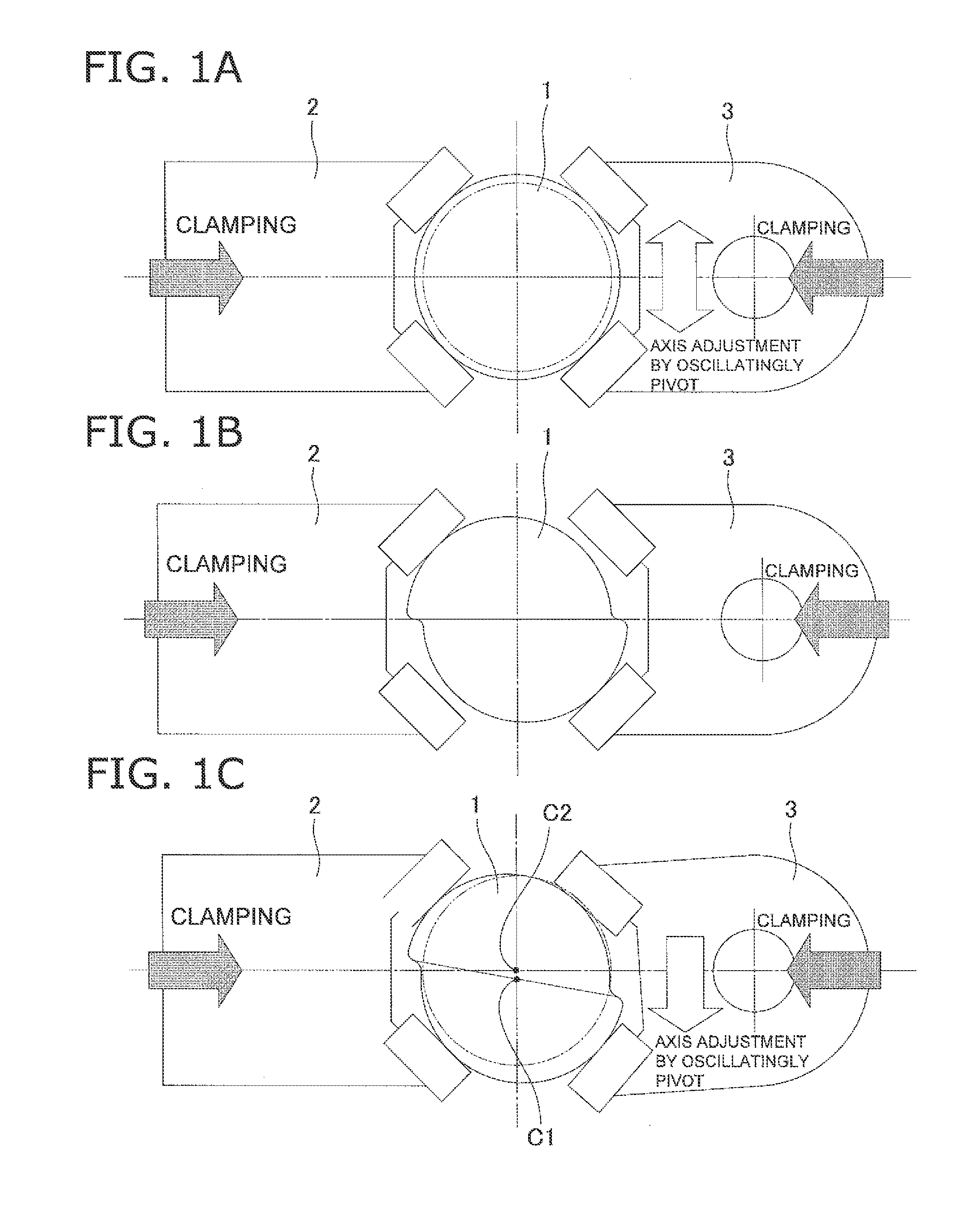

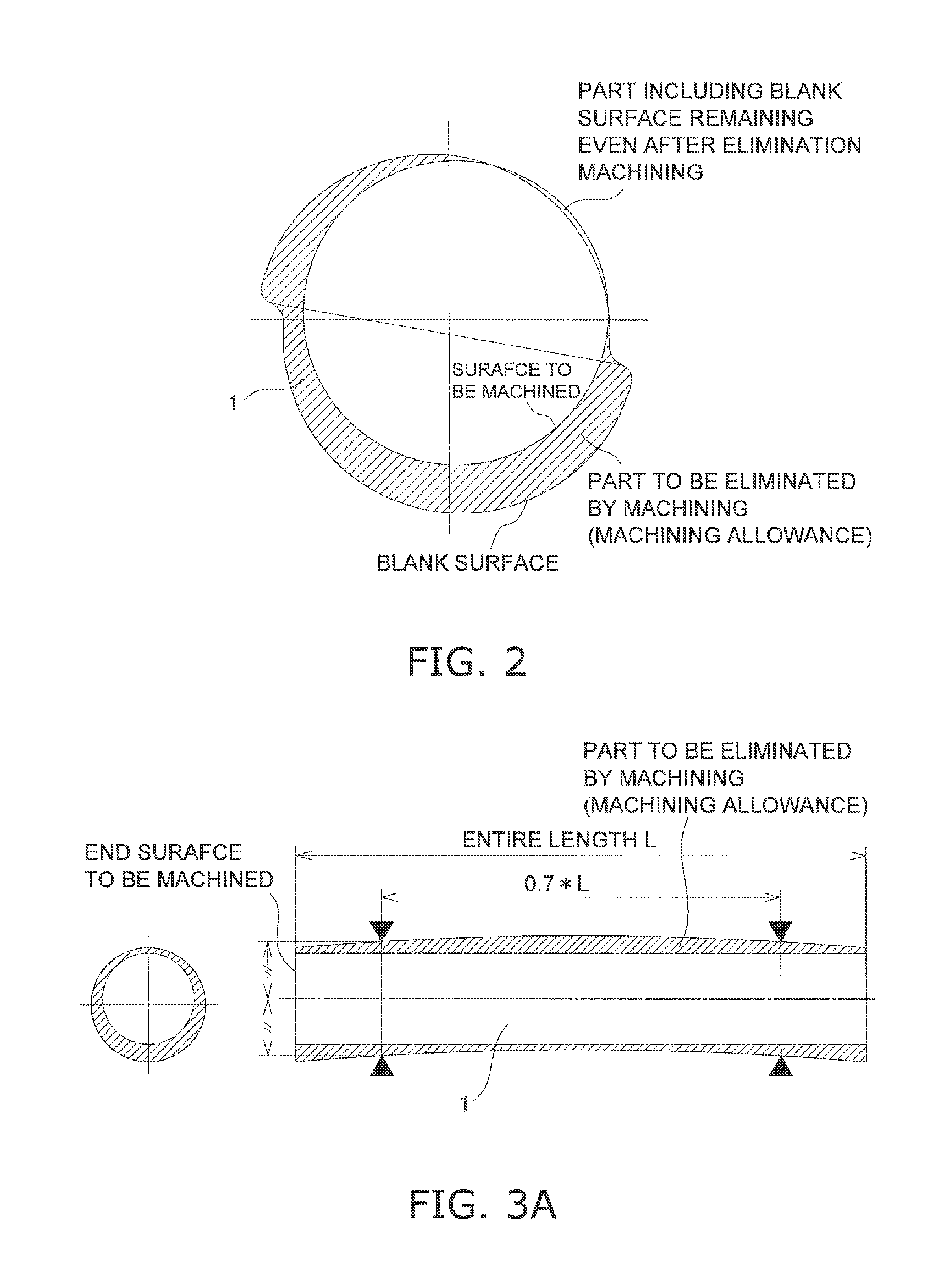

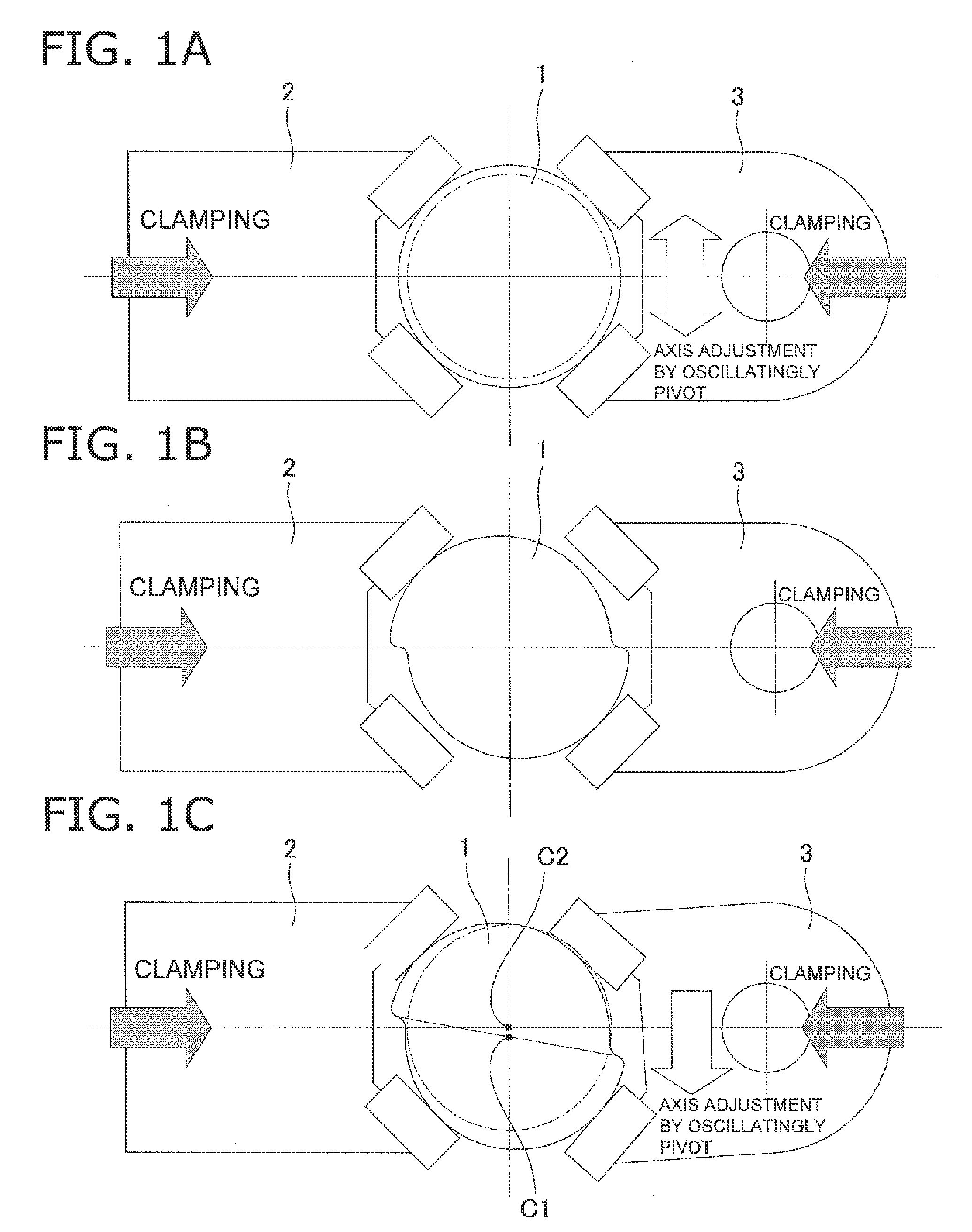

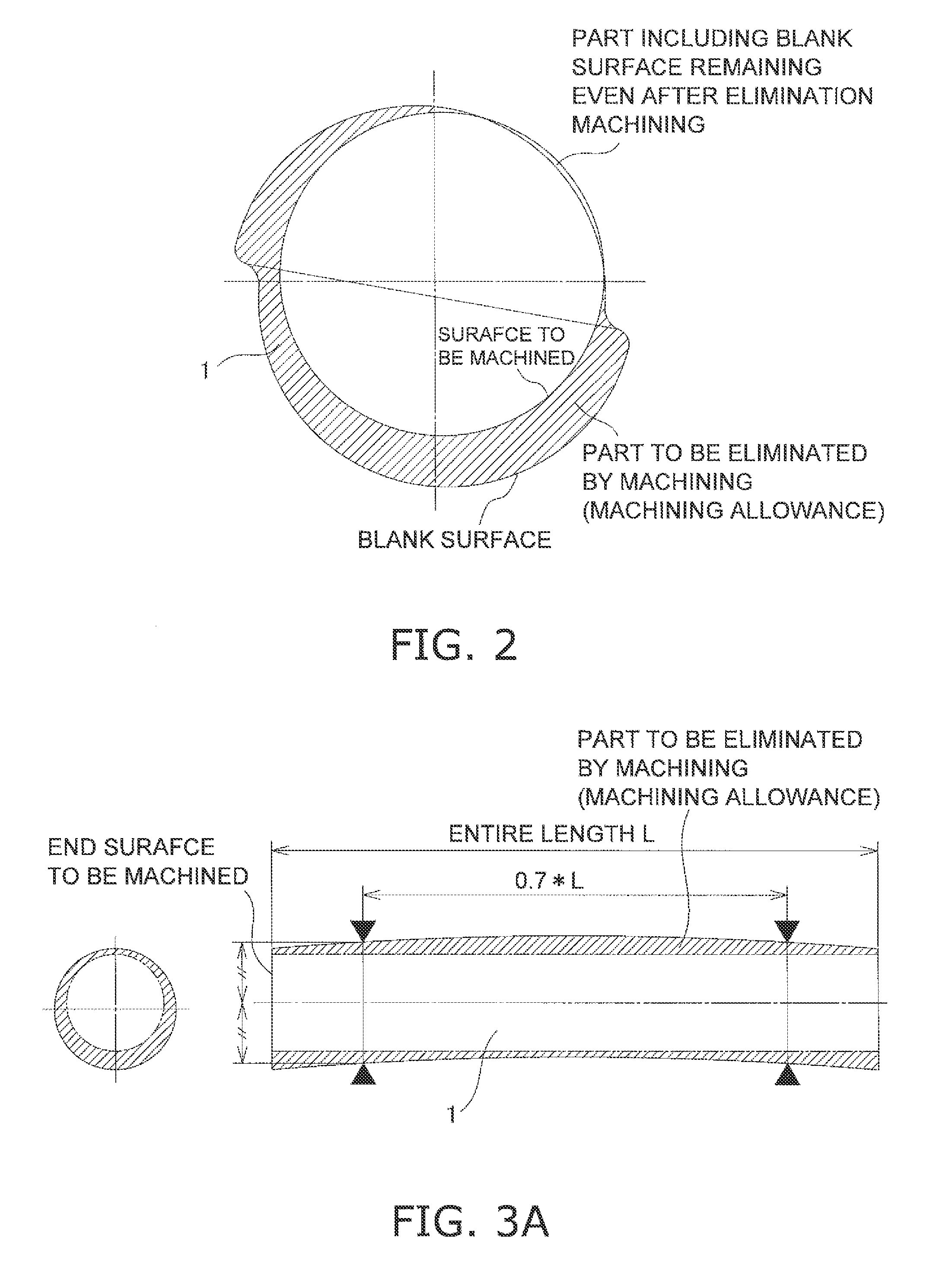

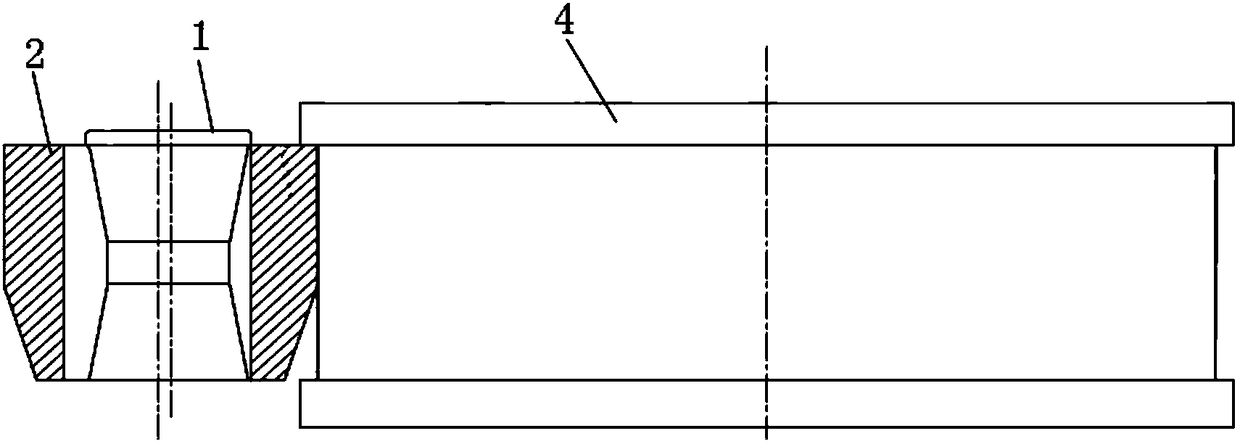

Center hole machining method for shaft blank and center hole machining apparatus

ActiveUS20120259452A1Reduce material costsThe relative position is appropriateCamsDrilling/boring measurement devicesEngineeringMachining

A center hole machining method includes first to fifth steps. The first step includes obtaining outer peripheral shape data of a plurality of portions of the shaft blank in an axial direction. The second step includes obtaining a center axis by comparing measured data of the portions of the shaft blank with design data. The third step includes calculating a minimum distance from the center axis to the outer periphery in each of the portions of the shaft blank. The fourth step includes shifting the center axis in a direction of making the minimum distance greater than the machining dimension and repeatedly executing the third step when the minimum distance is less than or equal to the machining dimension. The fifth step includes boring the center hole in an end surface of the shaft blank at a position arranged on a line extended from the center axis.

Owner:KOMATSU NTC LTD

Method for forging upper shell of nuclear power equipment with outer bench

ActiveCN102825192AReduce forging allowanceReduce machining allowanceMetal-working apparatusNuclear powerMetal

The invention discloses a method for forging an upper shell of nuclear power equipment with an outer bench. The method comprises the following steps of: forging an electroslag ingot into an upper shell with the outer bench by a 16500-ton hydraulic press, wherein material of the electroslag ingot is Grade 3 Class 2 of SA-508 and weight of the electroslag ingot is 300-340 ton; the forging method is as follows in details: step 1, drawing out the electroslag ingot; step 2, carrying out oxygen-acetylene cutting and blanking the electroslag ingot; step 3, upsetting the electroslag ingot; step 4, forging a centre hole; step 5, drawing out and segregating the electroslag ingot; and step 6, carrying out chambering. According to the method disclosed by the invention, temperature in a forging process is strictly controlled to keep the temperature of forging pieces to be 850-1240 DEG C constantly; a forging ratio of the electroslag ingot in each step is guaranteed; the outer bench of the upper shell is forged and formed directly, so that forging allowance and machining allowance are reduced; and in addition, the forged and formed forge pieces are not easily to be cracked, and the forge pieces are uniform in wall thick, dense in material, uniform in composition, reasonable in metal flow line distribution and stable in property.

Owner:SHANGHAI ELECTRIC SHMP CASTING & FORGING CO LTD +1

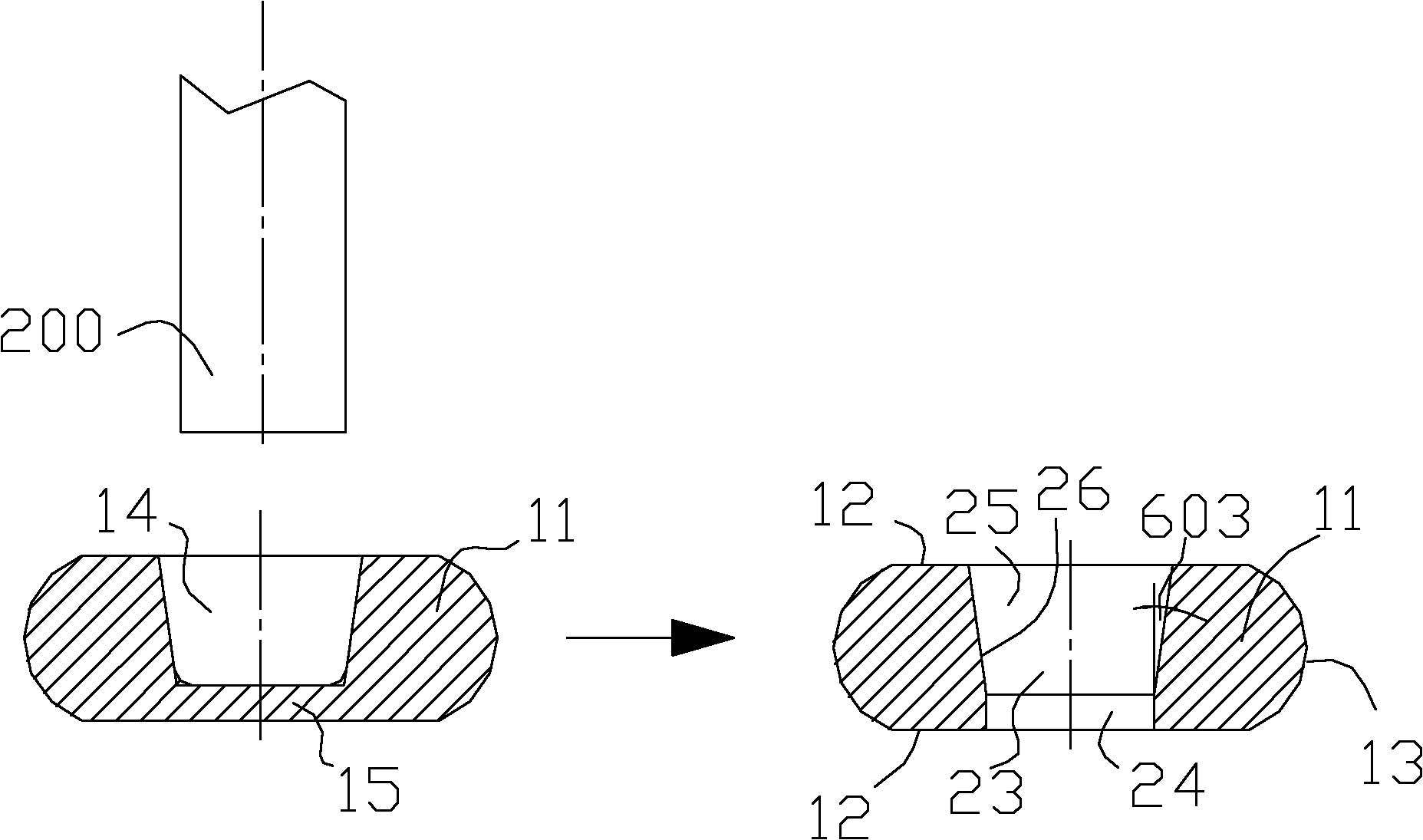

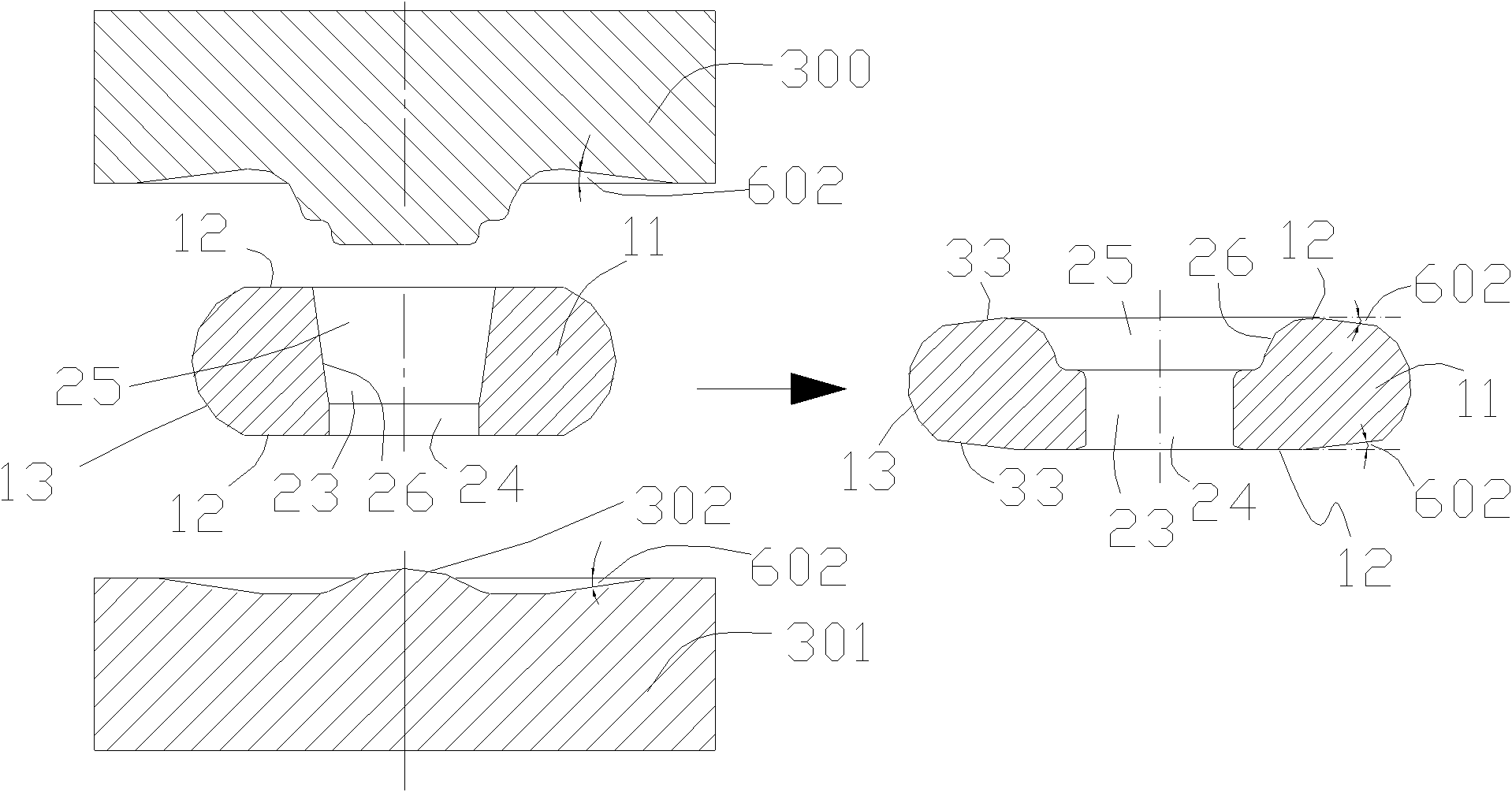

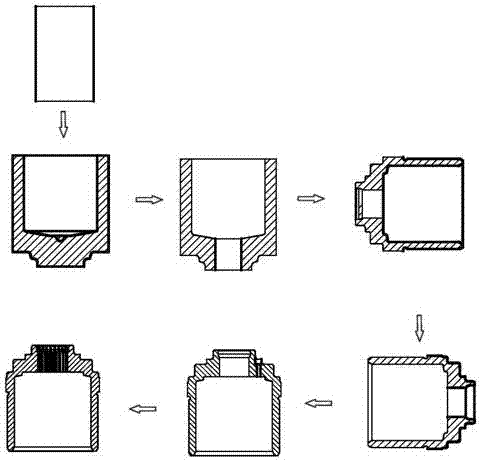

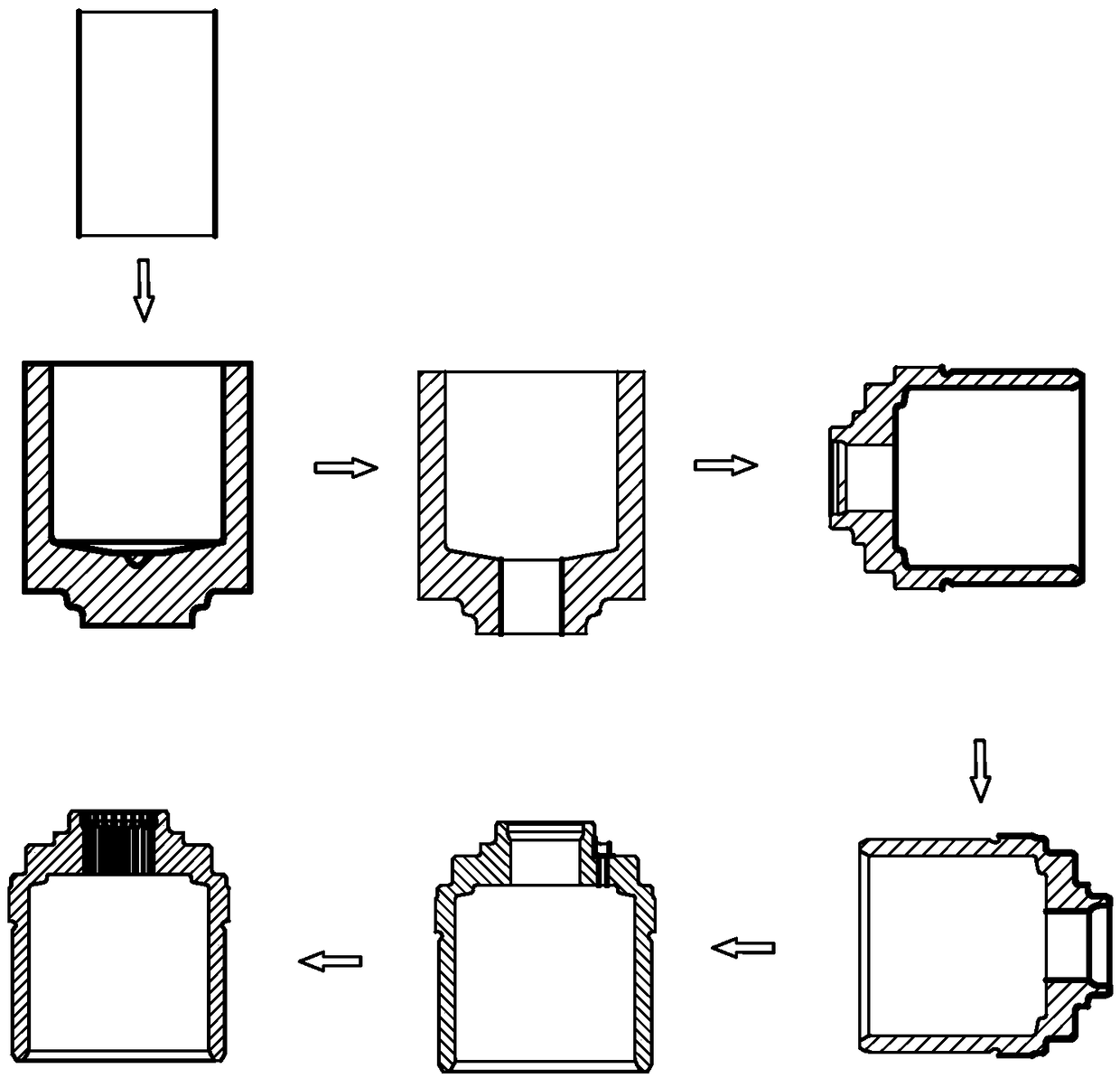

Method for manufacturing intermediate formed body of driven gear of rear axle of small and medium-sized automobile

InactiveCN101966554AIncrease productivityImprove mechanical propertiesWheelsMaterial consumptionEngineering

The invention discloses a method for manufacturing an intermediate formed body of a driven gear of a rear axle of a mall and medium-sized automobile, which can improve production efficiency and reduce material consumption. The method comprises the following steps of: upsetting a blank into a workpiece; punching the workpiece and removing connected skin; pre-shaping and reaming the workpiece; and finally performing rolling formation on the workpiece to form the intermediate formed body. Compared with the prior art, the method has the advantages of reducing cutting allowance and saving raw materials because the rolling formation is adopted to eliminate defects that upper and lower end faces are not flat, the ovality of the excircle is large and the like. The upsetting, reaming, connected skin removal and the pre-shaping can be finished by an open crank press; and the open crank press can accurately control the axial height of the workpiece, so that the possibility of generating burrs, fins and the other defects in the processing process is reduced.

Owner:SICHUAN JIANGYOU ZHONGHENG SPECIAL STEEL

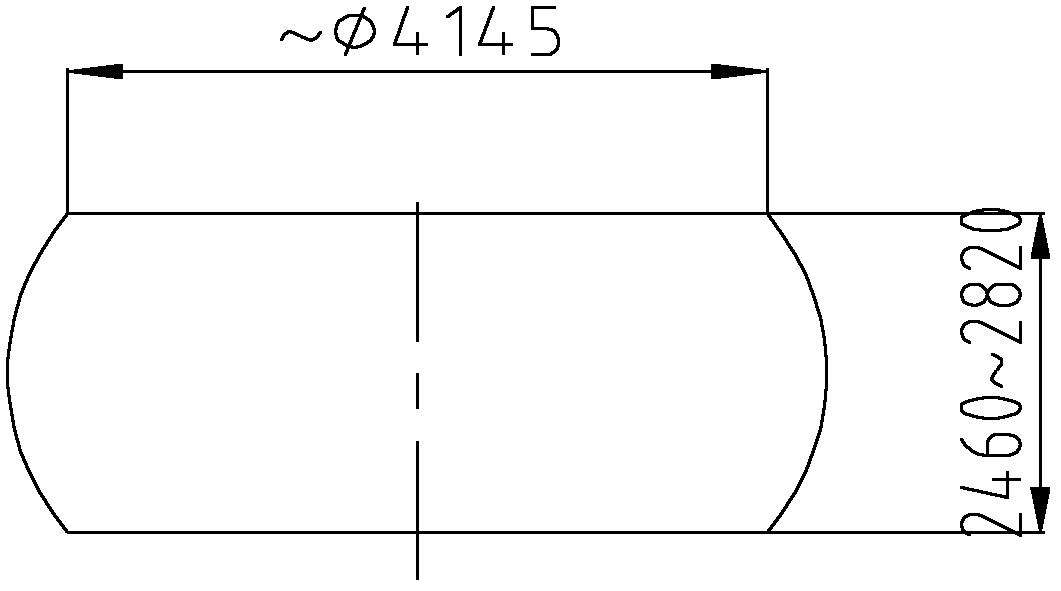

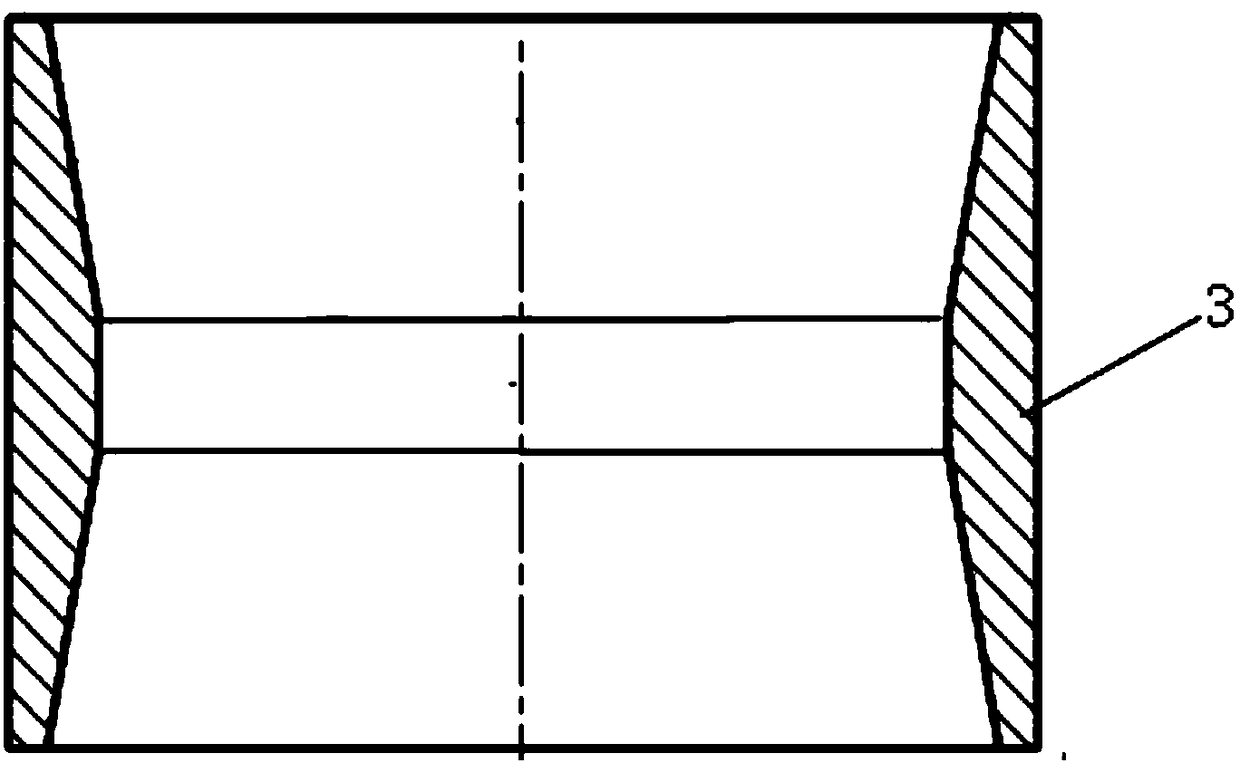

Large cylindrical forge piece forging and rolling composite production technology

InactiveCN108994249AIncrease profitReduce machining allowanceMetal rollingHollow articlesIngotFriction force

The invention discloses a large cylindrical forge piece forging and rolling composite production technology. The technology comprises the steps that a steel ingot is sufficiently deformed on free forging equipment to complete blank forming, a large cylindrical forge piece blank is installed between an upper roller and a lower roller of cylindrical forge piece rolling equipment, and deformed undercontinuous rolling of the upper roller and the lower roller, the wall thickness is reduced, and the diameter is enlarged; meanwhile, a guide roller on the rolling equipment is automatically rotated under the effect of friction force and moves outwards along with increasing of the diameter of a cylindrical forge piece, the circular degree and rolling stability of the cylindrical forge piece are controlled by applying certain guide force to the cylindrical forge piece, and finally rolling of the large cylindrical forge piece is completed. The technology is the novel circular part rotary rollingforming technology, has the advantages that the machining allowance is small, the material utilization rate is high, the product size precision is high, the production efficiency is high, energy is saved, and the comprehensive cost is low compared with a traditional free forming technology, and therefore has the quite good practical popularization value.

Owner:LANZHOU LS ENERGY EQUIP ENG RES INST

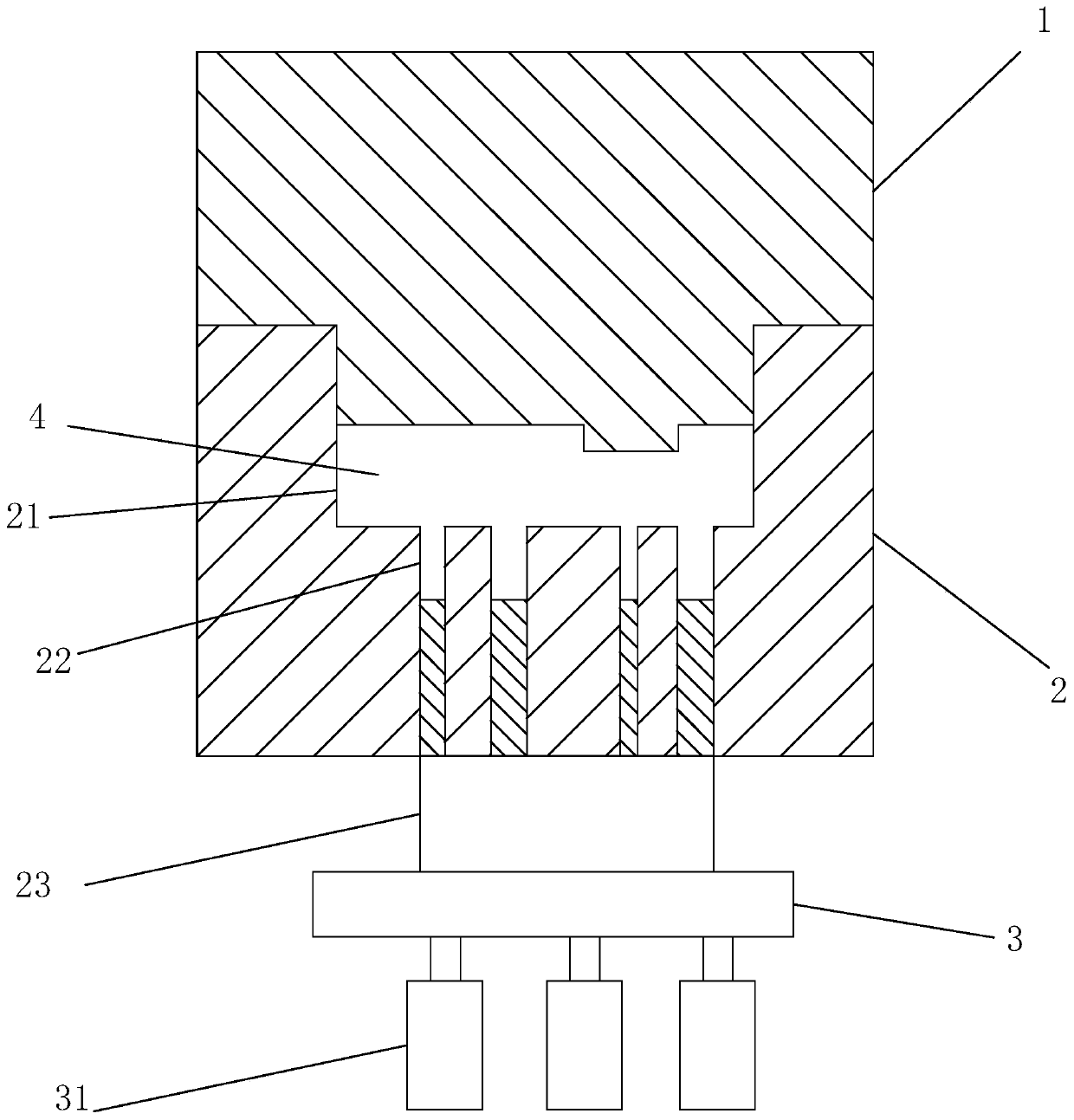

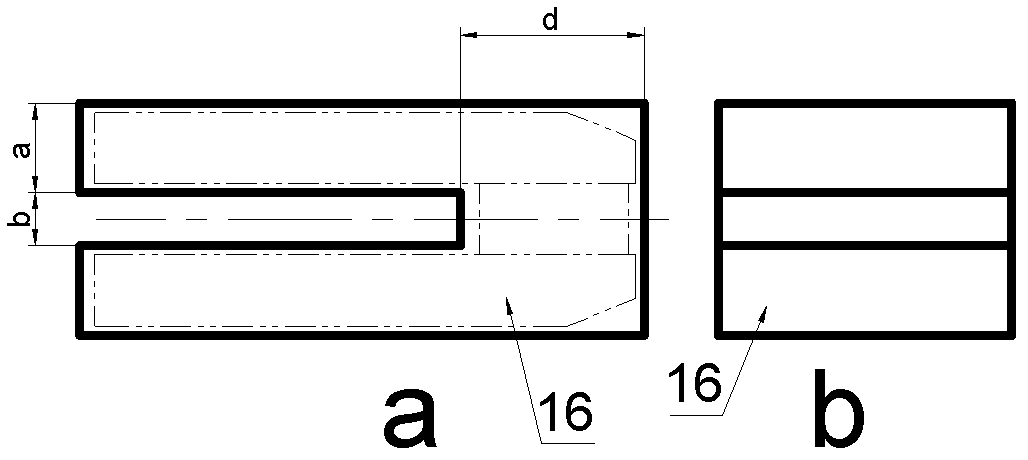

Forging process of scroll for novel energy automobile integral type scroll compressor

InactiveCN110125318AEvenly filledSolve the problem of high aspect ratioRailway componentsForging/hammering/pressing machinesIntermediate frequencyHeating temperature

The invention discloses a forging process of a scroll for a novel energy automobile integral type scroll compressor. According to the forging process, a forging die is involved, the forging die comprises an upper die and a lower die, the lower die comprises cavities, the cavities comprise an upper mold cavity and a lower mold cavity, wherein the upper mold cavity is located in the upper portion and is used for forming the bottom of a scroll, the lower mold cavity is positioned at the lower portion and is used for forming a scroll wall, a back pressure body is arranged in the lower die, and anejection mechanism used for driving the back pressure body to eject a forge piece is arranged below the back pressure body. The forging process comprises the following steps that S1, blanking is conducted, a blank is cut into a disc-shaped blank with the phi 104 * 17 mm-phi 104 * 19 mm; S2, heating is conducted, the heating temperature is controlled to be 400-450 DEG C, and an automatic feeding mechanism is using for pushed 4-5 blanks into a intermediate frequency furnace every minute; S3, finish forging is conducted, and the back pressure is controlled to be 10-16T. According to the technicalscheme, the process has the advantages that back pressure forging is adopted, the lower cavity can be guaranteed to be uniformly filled, so that the forming problem that a forge piece is large in high-thickness ratio and small in wall thickness is well solved.

Owner:昆山众诚精密锻造有限公司

Method for manufacturing hub motor shell

ActiveCN102386708AReduce machining allowanceReduce material wasteMechanical energy handlingSupports/enclosures/casingsSmeltingMachining

The invention discloses a method for manufacturing a hub motor shell, and the method comprises the following steps of: 1) smelting: smelting steel used for the shell by adopting a converter or an electric furnace, carrying out external refining, adjusting compositions, and transferring the steel into a pouring basket to be subjected to standing after requirements are met; 2) preparing a mould: designing an external mould and a mould core according to the shell structure of the hub motor, then brushing a painting on the surfaces of the external mould and the mould core, then heating to 200-220 DEG C and continuously heating to a preheating temperature of 420-450 DEG C after the painting is dried; 3) die casting: adjusting temperature of molten steel smelted in the step 1) to be 1480-1520 DEG C, quantitatively pouring the molten steel into a die casting machine, then filling the molten steel into the mould by utilizing a punch, adjusting die casting parameters to complete die casting and then demoulding to obtain a die casting blank of the motor shell; and 4) machining: carrying out local machining on the two ends of the shell until the two ends meet design sizes.

Owner:无锡天宝电机有限公司

Center hole machining method for shaft blank and center hole machining apparatus

ActiveUS9120161B2Reducing rotational imbalanceReduce machining allowanceCamsDrilling/boring measurement devicesEngineeringMachining

A center hole machining method includes first to fifth steps. The first step includes obtaining outer peripheral shape data of a plurality of portions of the shaft blank in an axial direction. The second step includes obtaining a center axis by comparing measured data of the portions of the shaft blank with design data. The third step includes calculating a minimum distance from the center axis to the outer periphery in each of the portions of the shaft blank. The fourth step includes shifting the center axis in a direction of making the minimum distance greater than the machining dimension and repeatedly executing the third step when the minimum distance is less than or equal to the machining dimension. The fifth step includes boring the center hole in an end surface of the shaft blank at a position arranged on a line extended from the center axis.

Owner:KOMATSU NTC LTD

Cold forging process of clutch sleeve

The invention discloses a cold forging process of a clutch sleeve. The cold forging process comprises the steps of: blanking-spheroidizing annealing-shot blasting-pretreatment-cold forging-inner hole drilling-thermal refining-sleeve boring-sleeving outside. The forging temperature of cold forging is room temperature; the product structure grains are finer, and the surfaces are not oxidized and decarbonized, so that the size precision is high, and the surface roughness is low; a traditional phosphorus saponification treatment lubricant treatment process is mature; and the mold service life is greatly prolonged.

Owner:JIANGSU CHUANGYI PRECISION FORGING

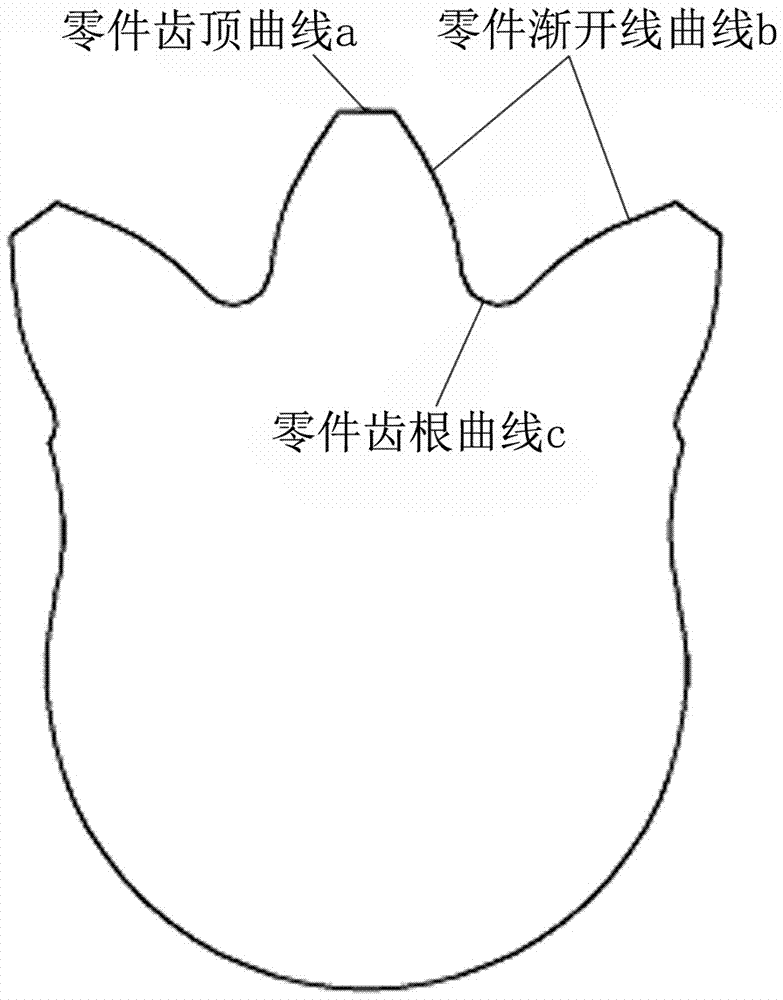

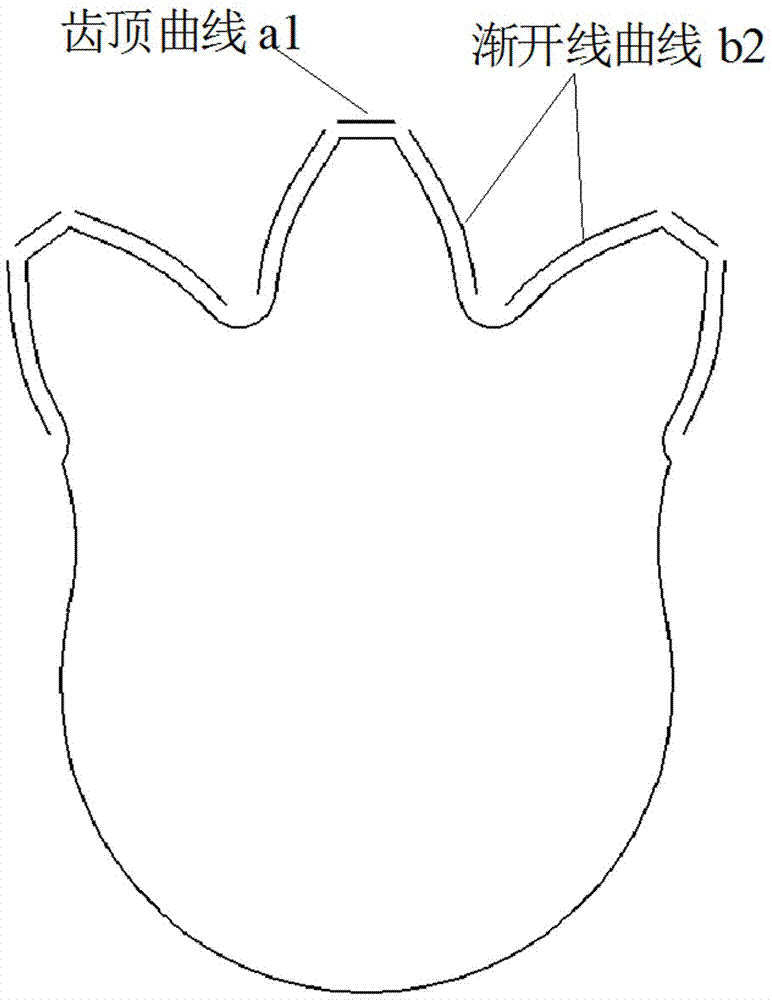

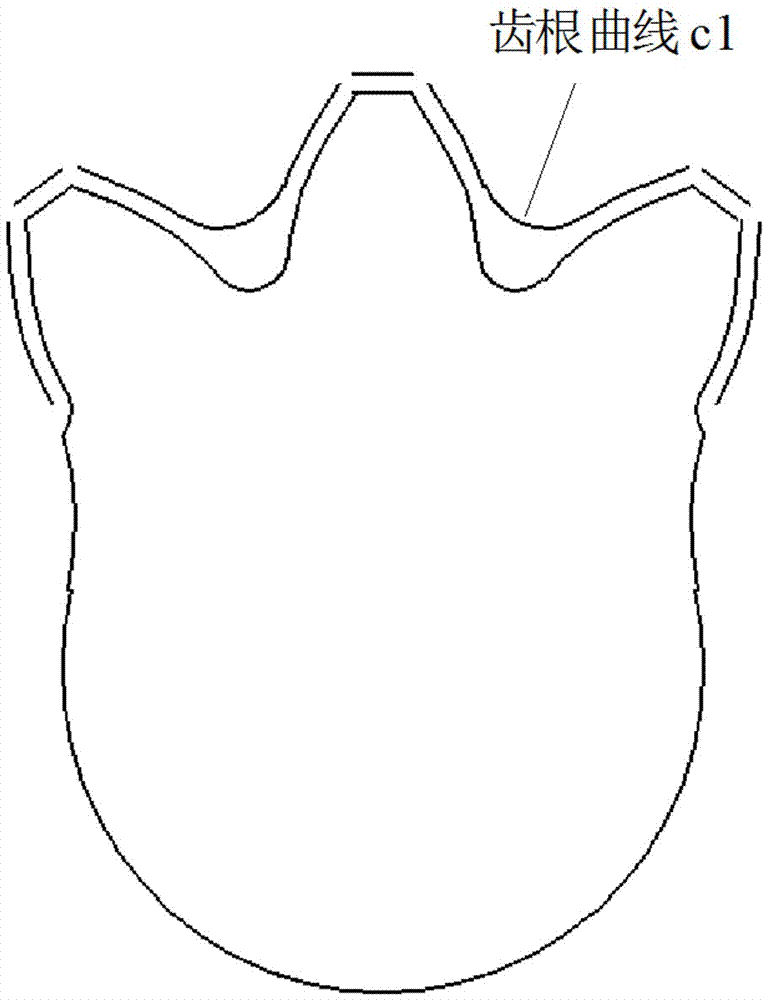

Method for designing hot-forging die tooth form of rockshaft with teeth

ActiveCN105447287AExtend your lifeGuaranteed service lifeGeometric CADForging/hammering/pressing machinesParts toothOrthodontics

The invention discloses a method for designing a hot-forging die tooth form of a rockshaft with teeth. The method comprises the following steps that the tooth form shape is drawn according to tooth form parameters of the rockshaft, and the tooth form shape is decomposed into a part tooth crest curve a, a part involute curve b and a part tooth root curve c; the part tooth crest curve a and the part involute curve b offset outwards in an equally-spaced mode to obtain a tooth crest curve a1 and an involute curve b1; fitting is performed on the outer side of the part tooth root curve c to obtain different tooth root curves, and a tooth root curve c1 applicable to forge piece material flowing is drawn; the tooth root curve c1 and the involute curve b1 are connected into a whole in a fitting mode; gaps between the tooth crest curve a1 and the involute curve b1 are in smooth transition connection through an arc; the curve composed of the tooth crest curve a1, the involute curve b1, the tooth root curve c and the arc connecting the tooth crest curve a1 and the involute curve b1 is a die tooth form curve. According to the method, the service life of the die can be prolonged, and the tooth form working allowance is reduced.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Green forging process method of transition segment

The invention belongs to the technical field of forging, and particularly relates to a forging process method of a transition segment. According to the forging process method of the transition segment, a forging blank is manufactured by adopting the process scheme of hammer cogging by free forging and profiling rolling forming. The forging process method specifically comprises the steps of calculation of the size of the rolled blank, determination of process parameters such as the raw material ingot weight, re-inspection of raw materials, furnace charging and heating, rolling, hot chopping ofa water riser, heading, punching, reaming profiling rolling, post-forging heat treatment, rough machining, non-destructive testing, performance heat treatment, sampling testing and finish turning. According to a manufacturing method provided by the invention, the amount of the raw materials used can be reduced by more than 10%; and profiling rolling can further improve the blank quality, the machining efficiency is improved, the manufacturing cycle is shortened, and the overall manufacturing cost is reduced.

Owner:SHANDONG IRAETA HEAVY IND

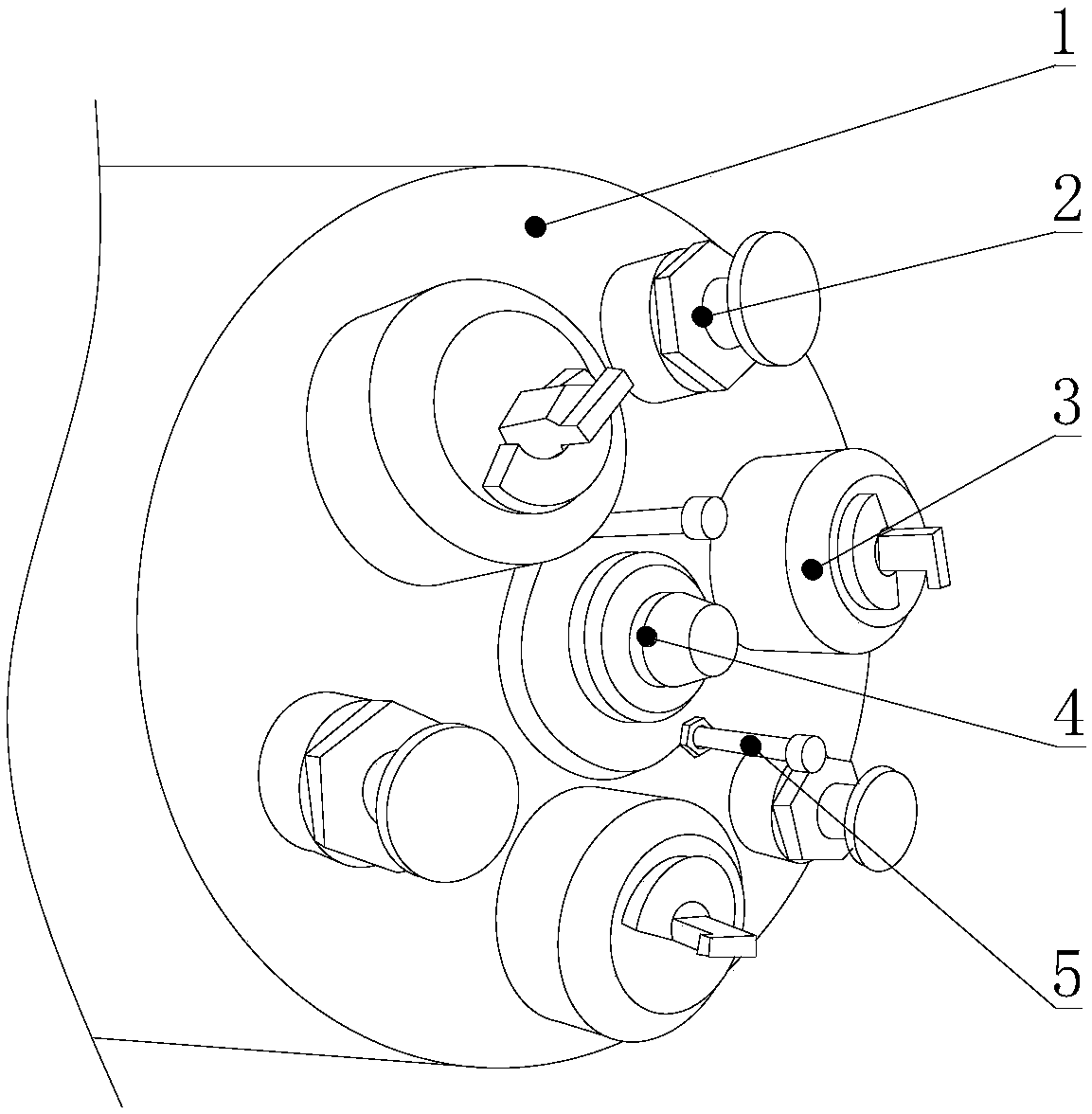

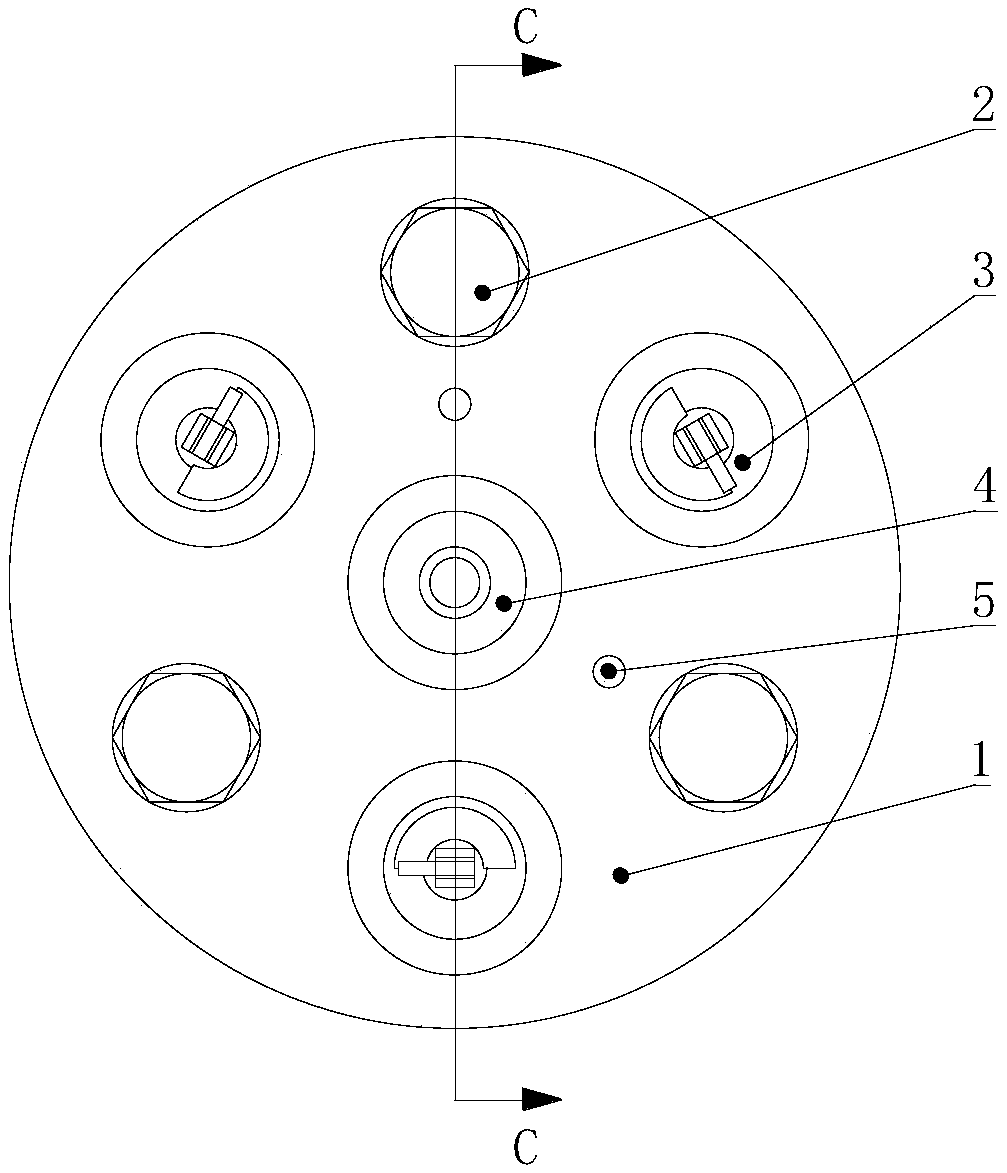

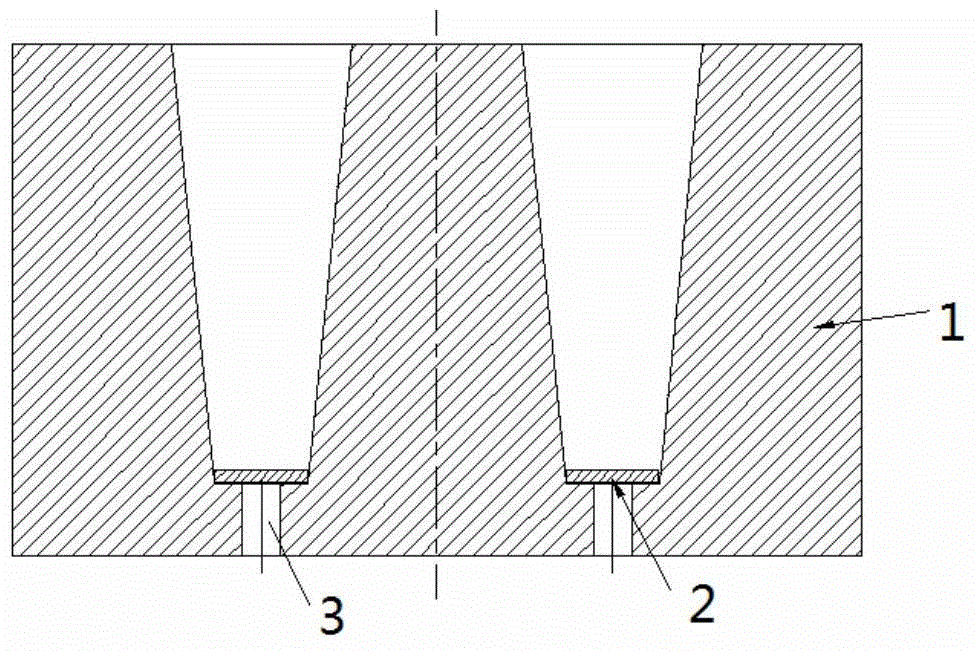

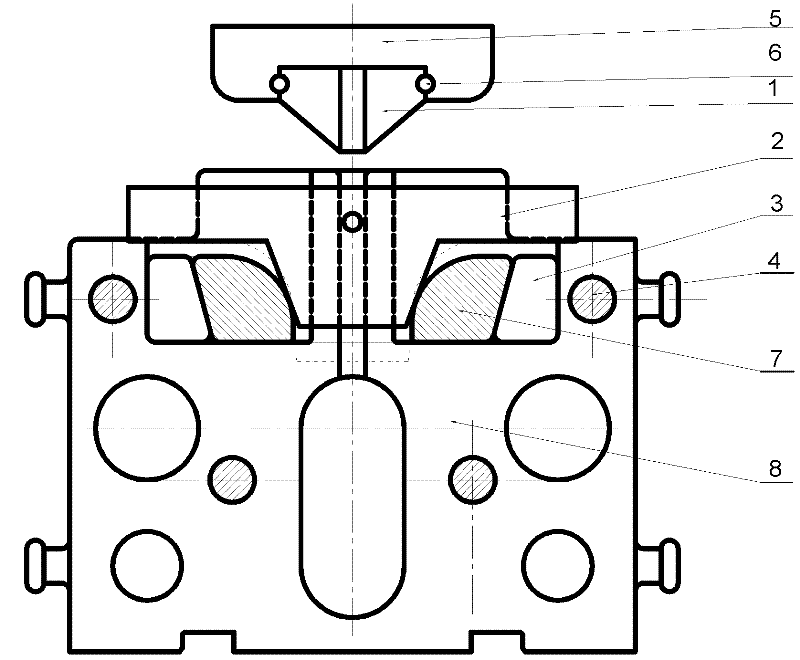

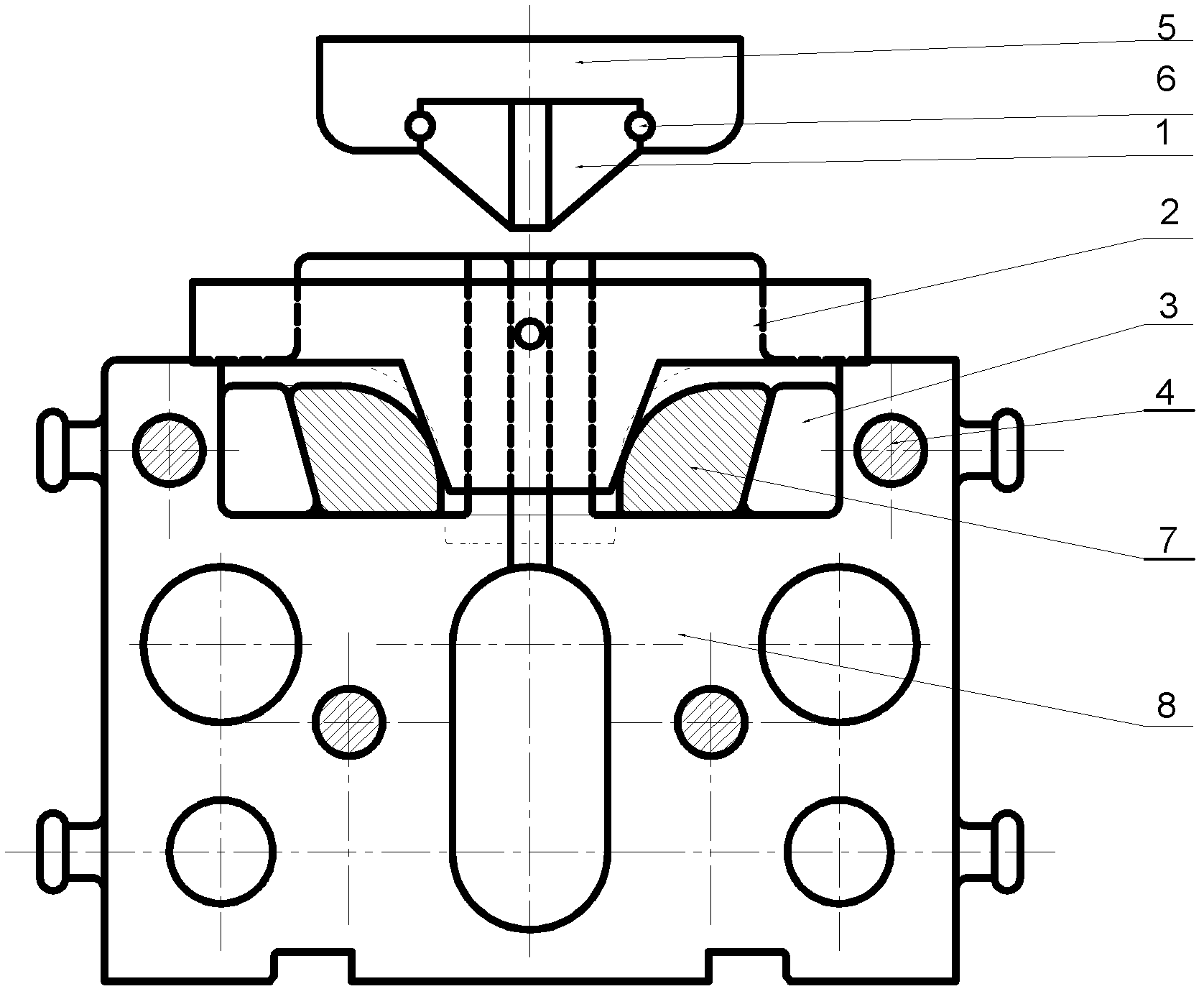

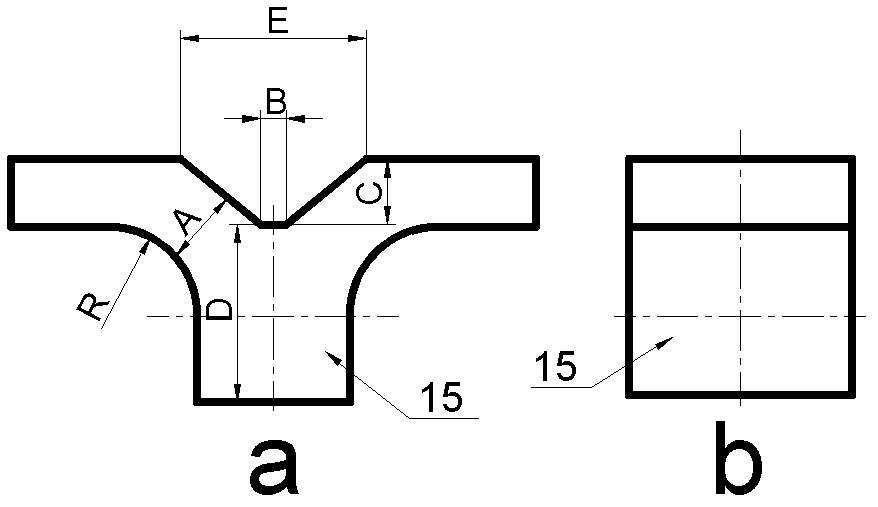

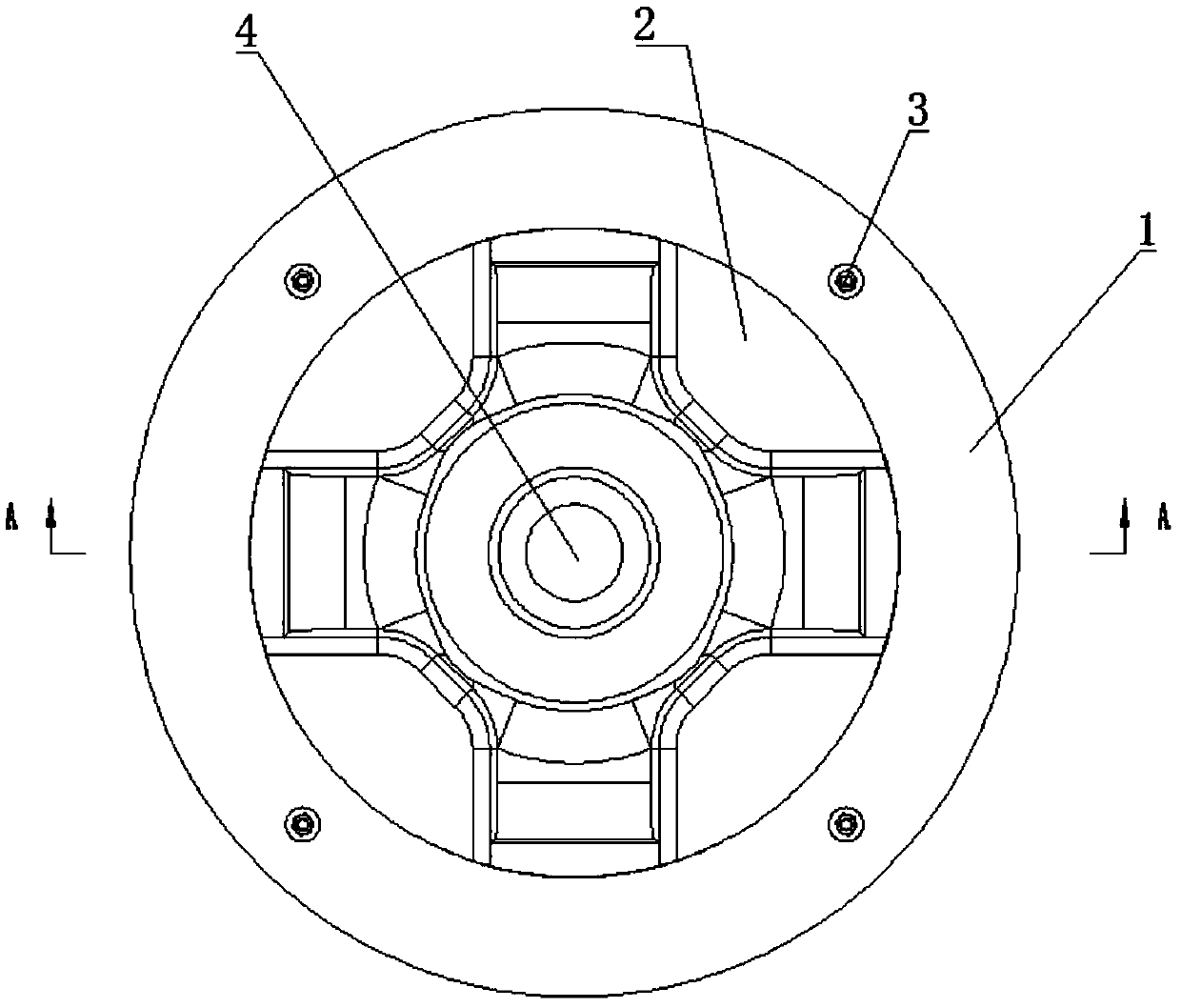

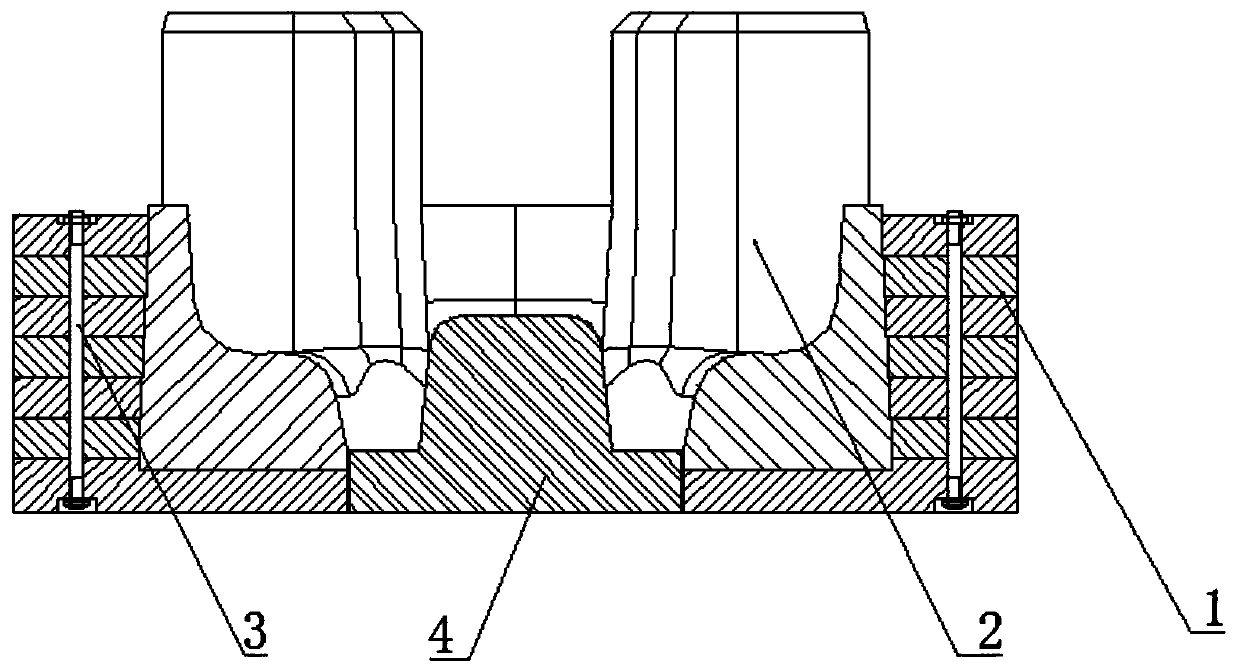

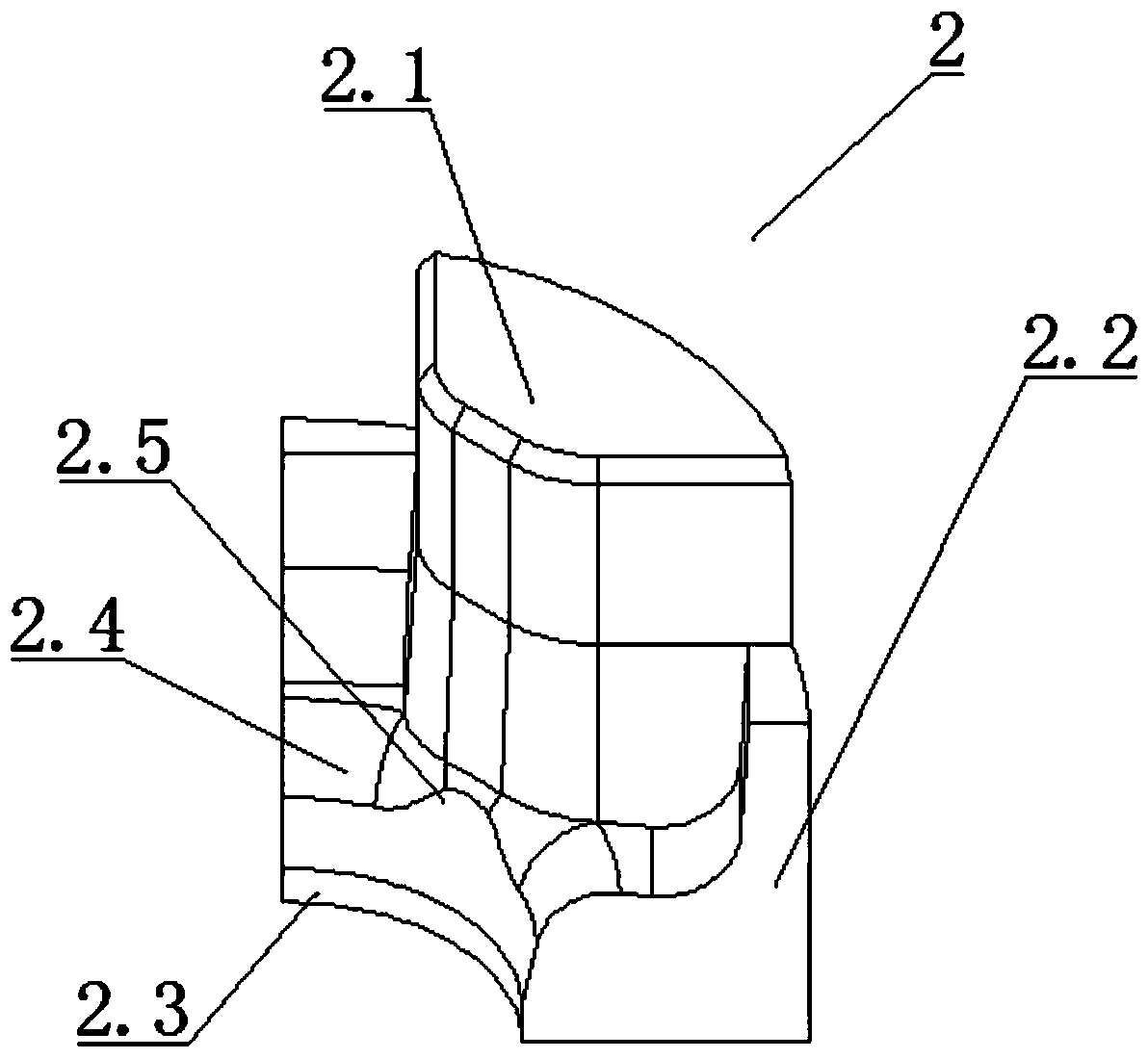

Hinge beam integral die-forging and forming combined die and hinge beam machining method thereof

ActiveCN107900270AIncrease profitReduce machining allowanceForging/hammering/pressing machinesEngineeringMultiple layer

The invention relates to a hinge beam integral die-forging and forming combined die. The hinge beam integral die-forging and forming combined die comprises a concave die and convex dies; the concave die consists of an outer hoop plate assembly, four concave die sections and a center punch which are fixed together by a screw; the outer hoop plate assembly comprises multiple layers of outer hoop plate rings and an outer hoop bottom plate; the center punch consists of a cylindrical punch bottom plate at the bottom and a frustoconical punch projection on the upper part, and the punch projection and the punch bottom plate are coaxial; and each concave die section consists of a convex section of which the top surface is fan-shaped, an arc-shaped vertical plate of which a side surface is L-shapedand a die section bottom plate with a 1 / 4 periphery, and a connecting ridge is arranged at a position where each die section bottom plate is connected with the corresponding arc-shaped vertical plate. The two convex dies which are perfectly matched with the concave die are used in machining. A using method of the combined die is provided. By a process mode of optimizing a die cavity and the like,the problem that the position of a lug of an existing forging and pressing die cannot be full is solved, and the method with small residual machining allowance is implemented.

Owner:烟台台海材料科技有限公司

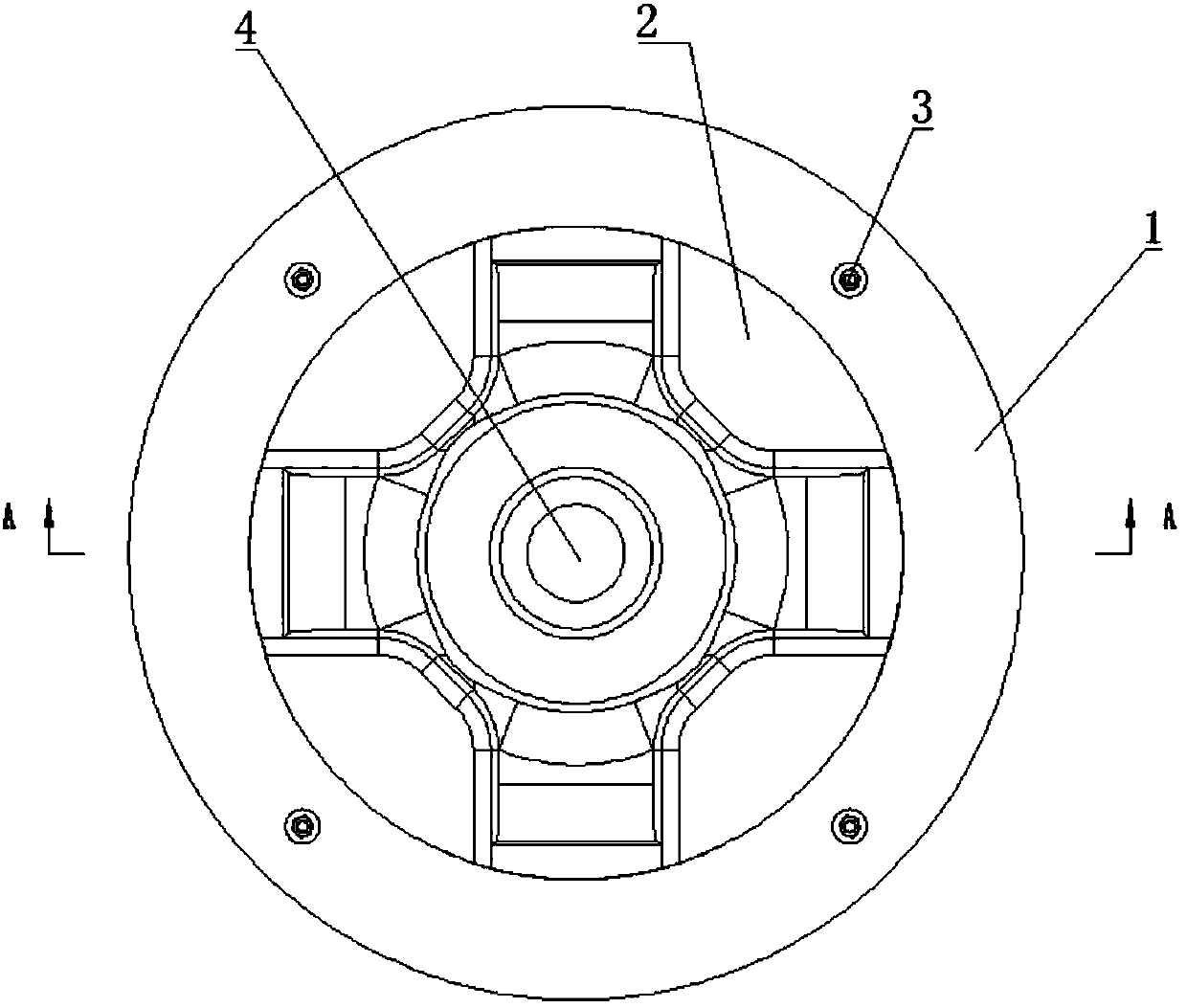

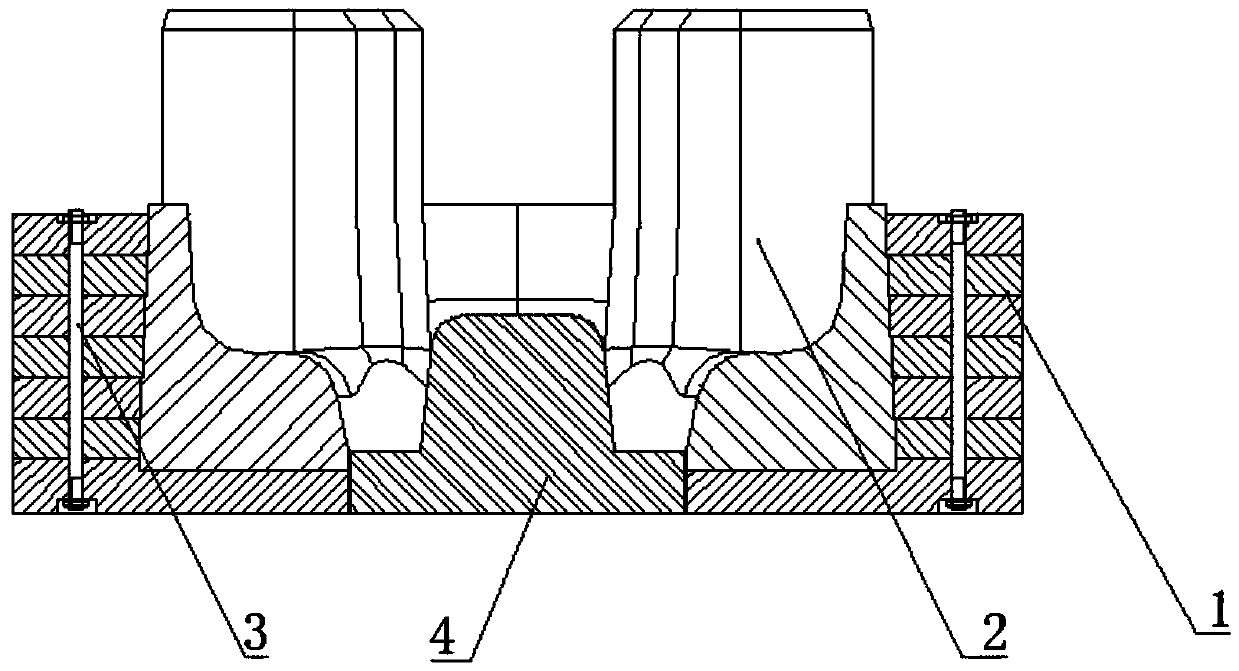

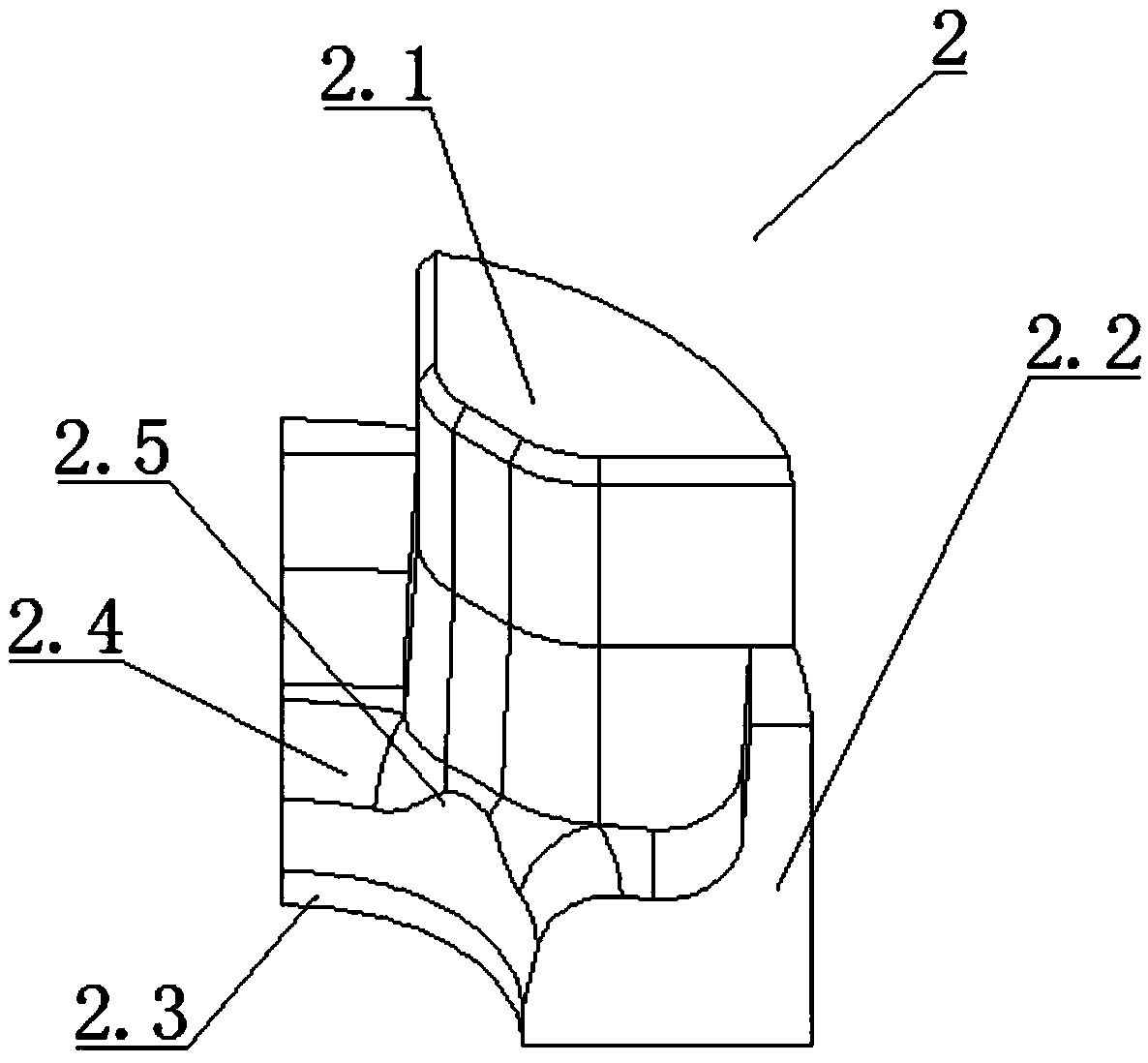

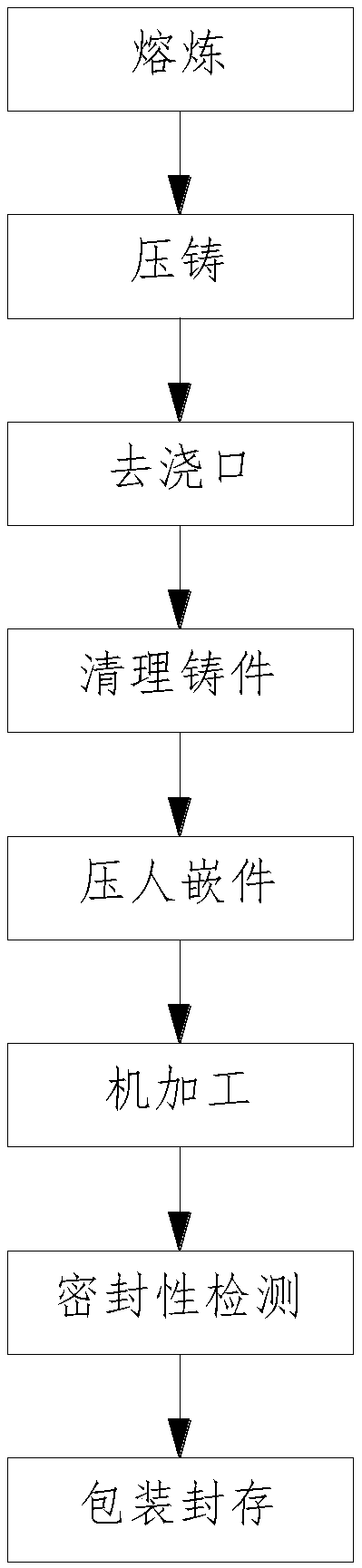

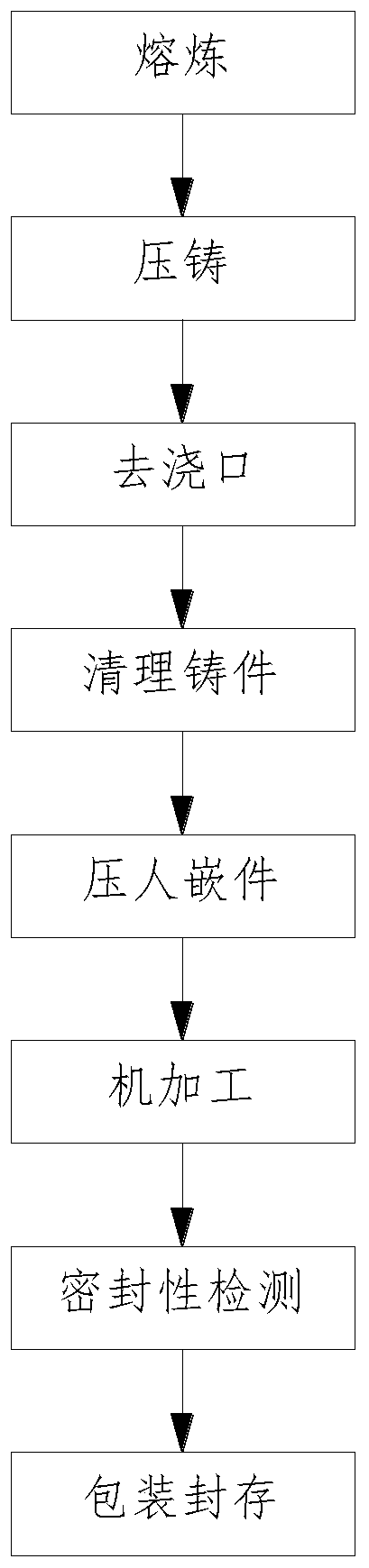

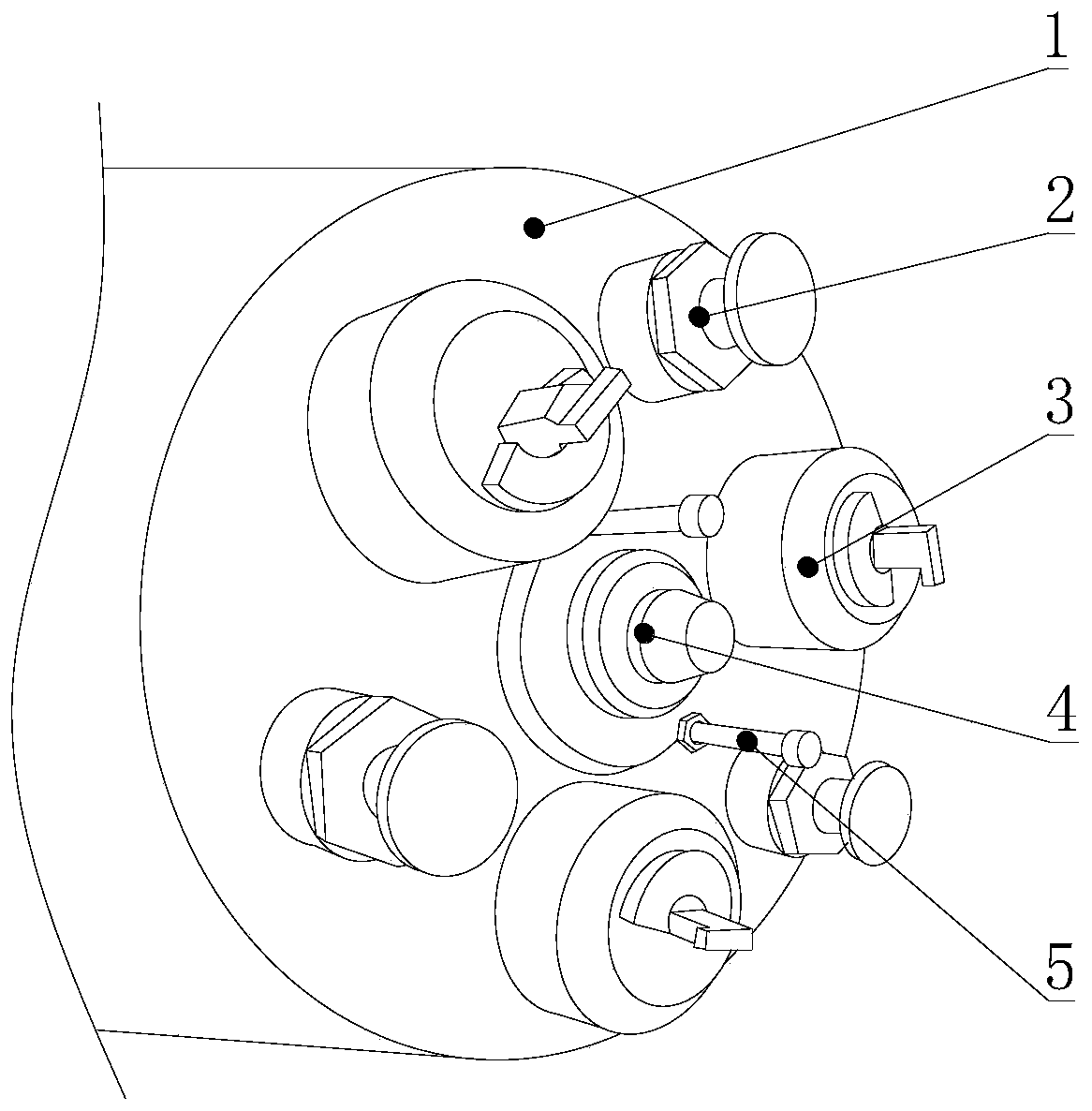

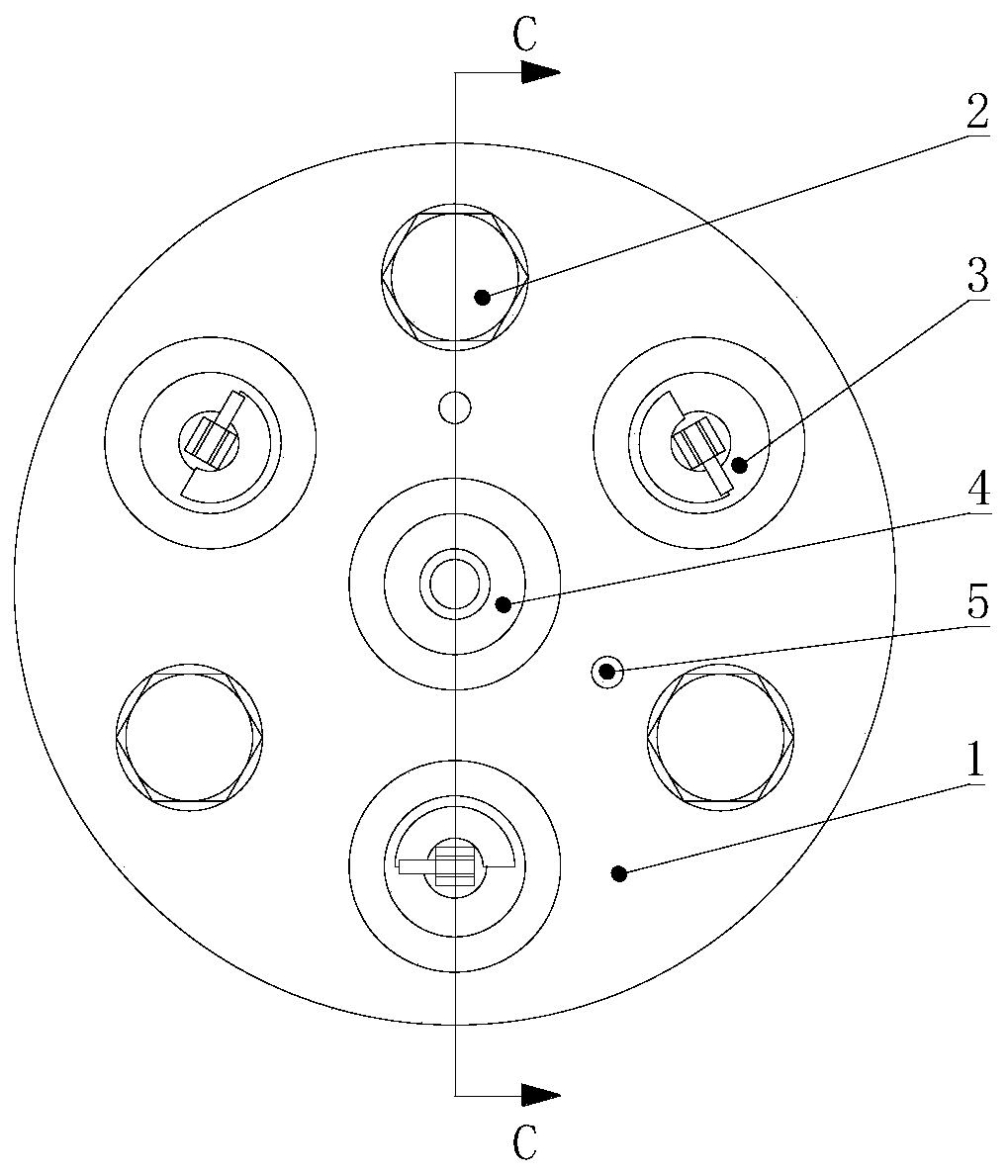

Preparation method for silicone oil clutch housing

The invention provides a preparation method for a silicone oil clutch housing. The preparation method comprises the following steps that S1, molten steel is smelted; S2, the molten steel is injected into a forming mould for pressure casting; S3, waste at a sprue is removed; S4, the surface of a casting is cleaned till the surface is smooth, and casting burrs are removed; S5, an insert is pressed into the casting; S6, the casting is mechanically machined to form the silicone oil clutch housing; S7, the silicone oil clutch housing is subjected to leakproofness detection; S8, the silicone oil clutch housing which is qualified after a leakproofness test is packaged and sealed for storage. The casting is fabricated through the forming mould, the precision of the casting can be guaranteed, the mechanical machining allowance is reduced, machining efficiency is improved, and meanwhile raw materials can be saved.

Owner:SHANDONG HESHAN MACHINERY

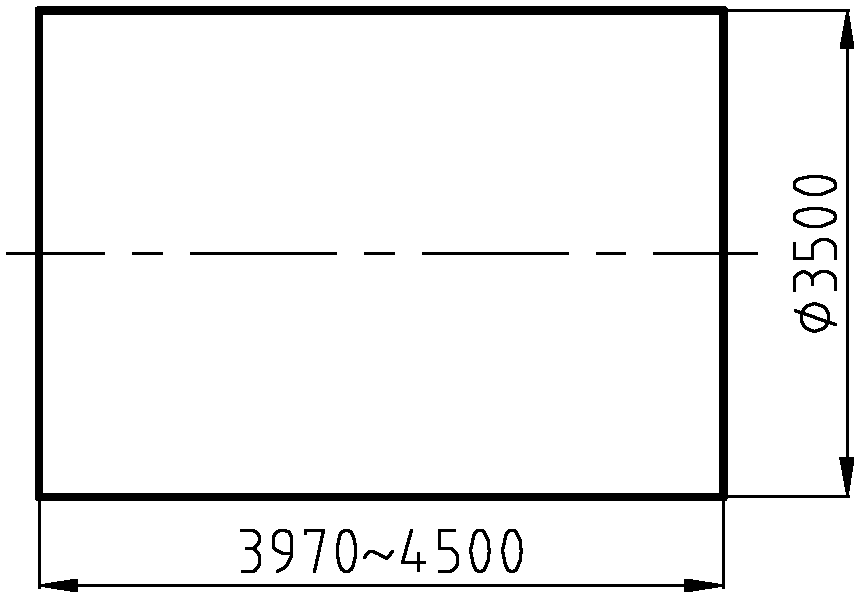

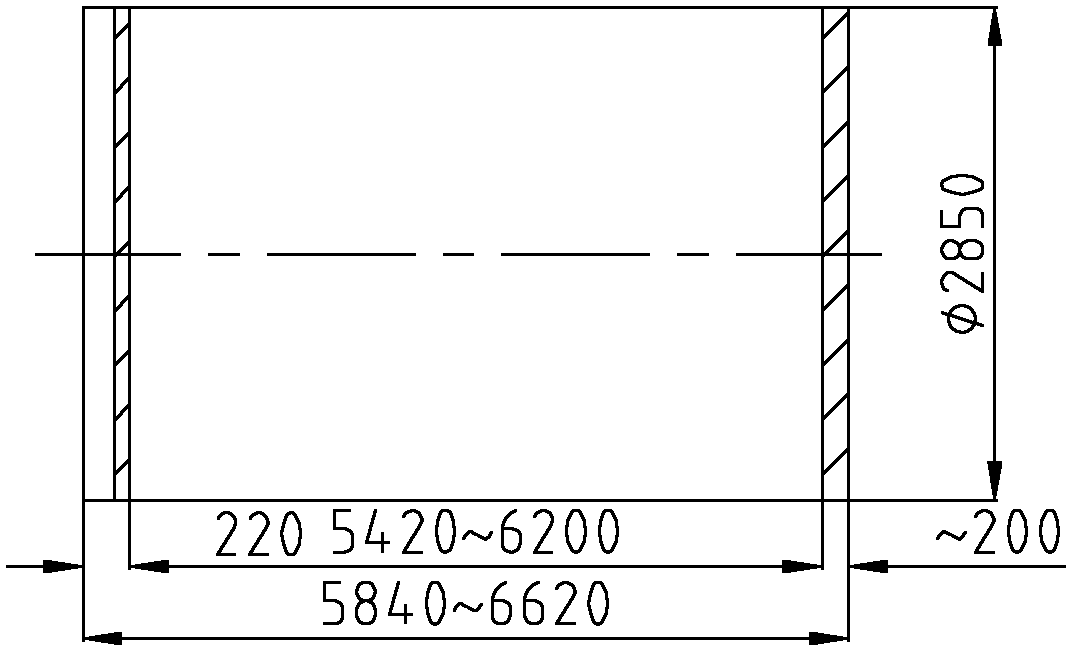

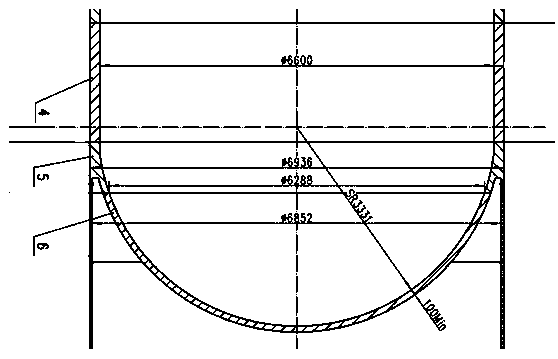

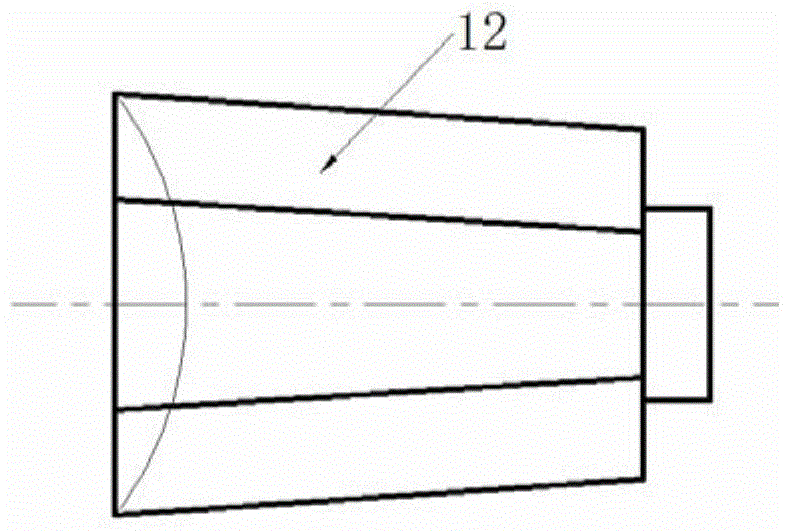

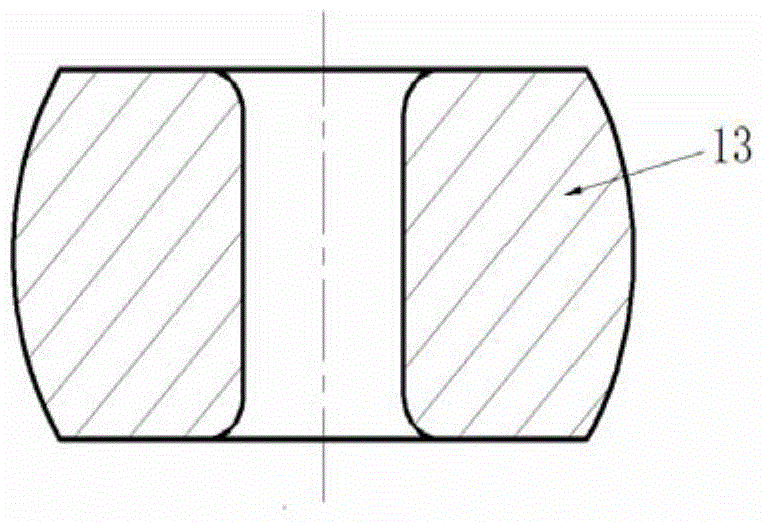

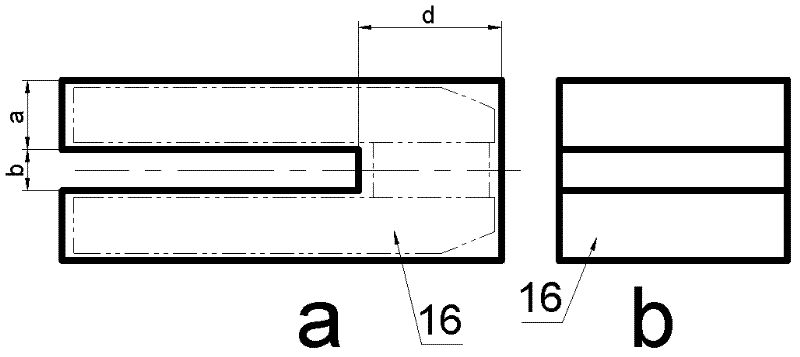

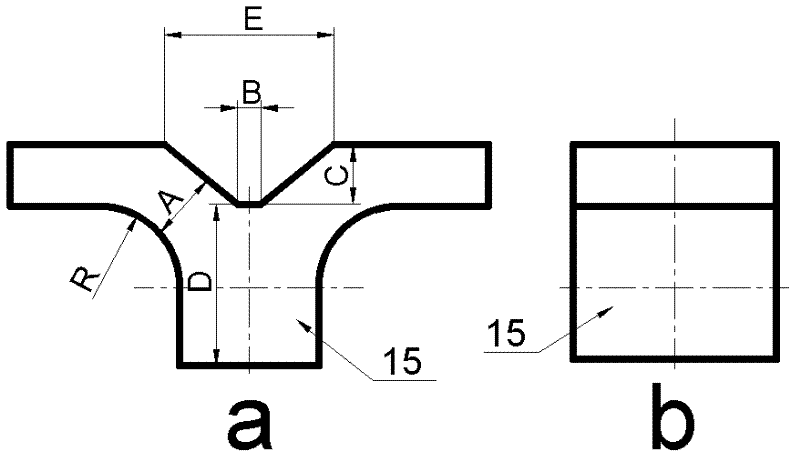

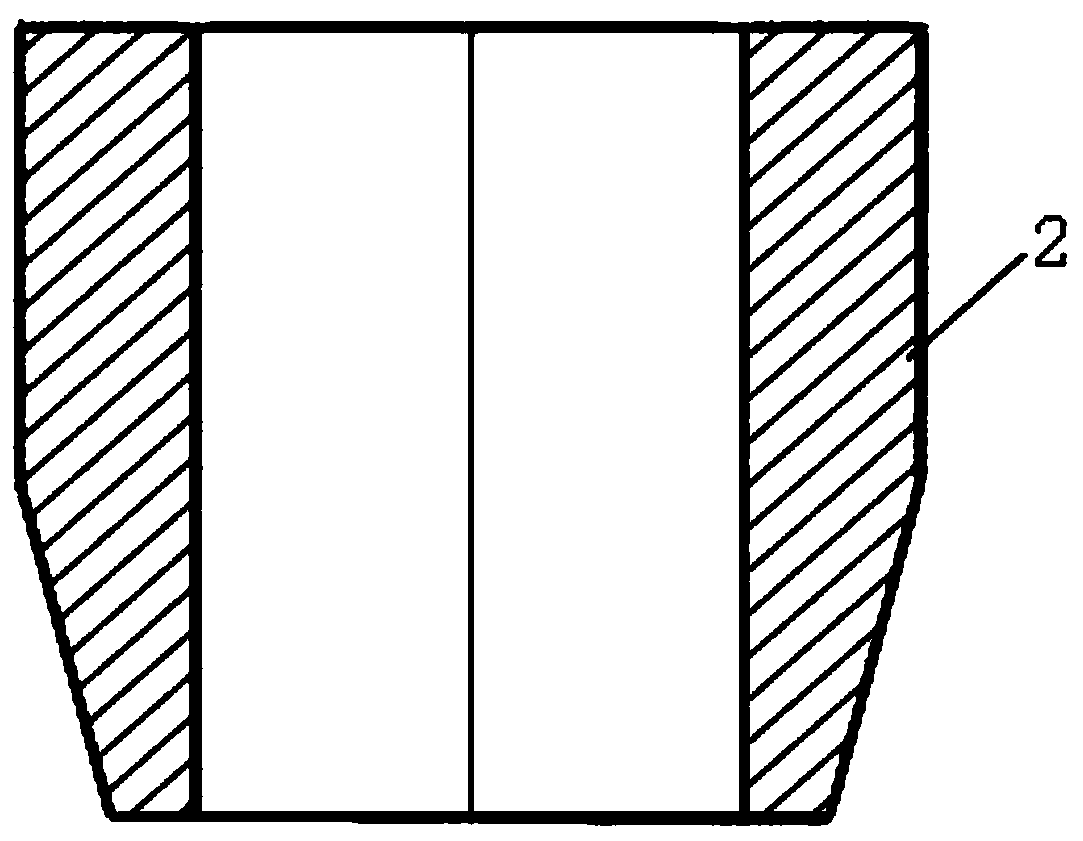

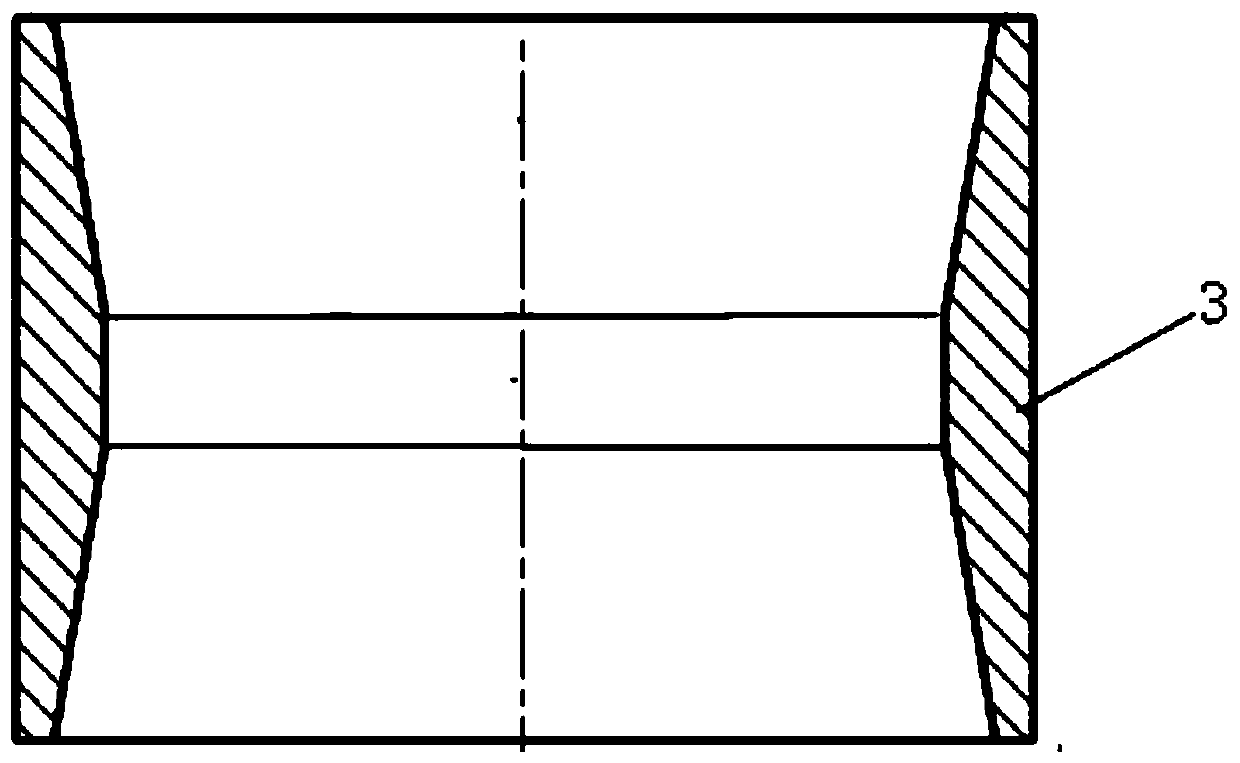

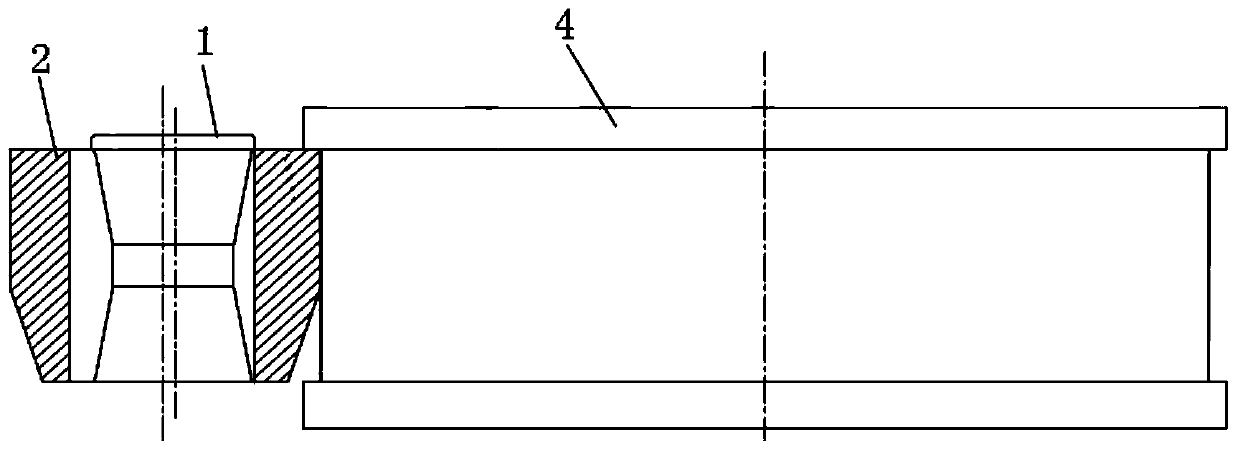

Technology for Die Forging Low Speed Diesel Engine Cylinder Head with Free Forging Press

ActiveCN105328111BLow costGuaranteed concentricityForging/hammering/pressing machinesEngine componentsLow speedCylinder head

The invention discloses a die forging technology adopting a free forging press for low-speed diesel engine cylinder heads. Steel ingots are upset, punched, chambered and drawn and then undergo head cutting and tail removing to be divided into separate blanks needed by the cylinder heads; a pre-forging die and a finish forging die are prepared, four pre-forging releasing ejection holes are uniformly formed in the bottom of the pre-forging die, four finish-forging releasing ejection holes are uniformly formed in the bottom of the finish forging die, and a pre-forging releasing ejection plate is arranged on the bottom of the pre-forging die. The interior and the exterior of a pre-forging die cavity have reverse taper, a finish forging die cavity is shaped like a simplified cylinder head contour, and machining allowance is reserved. The cylindrical blanks fully insulated are placed into the pre-forging die cavity and are pre-forged in the free forging press, and according to the shape characteristics of the cylinder heads, the cylindrical blanks are machined to form pre-forging material with the upper end walls thickened and the lower end walls thinned; the pre-forging material is placed into the finish forging die cavity for finally forming the low-speed diesel engine cylinder heads. The die forging technology has the advantages that blank manufacturing is easy, the operation is convenient, the procedure work is convenient, the machining allowance is small, the size accuracy is high, the production cost is low and the production efficiency is high, and is suitable for die forging of the low-speed diesel engine cylinder heads of various types.

Owner:武汉重工铸锻有限责任公司

Die bending and forging finishing process of crank blank of low-speed diesel engine

ActiveCN102554087AReduce turnaround timeAvoid opening and foldingMetal-working apparatusSteelmakingCrank

The invention relates to a die bending and forging finishing process of a crank blank of a low-speed diesel engine, wherein a production method is as follows: an upset crank blank is obtained through the processes of steelmaking, upsetting of a steel ingot and drawing, and then the upset crank blank is molded into a standard crank blank by the press function of a finishing punch and a backward extrusion function of an arc molding block of a finishing die through the finishing punch on an oil press of 8000T. In comparison with a traditional method, the process in the invention is capable of guaranteeing full fibers of a crank pin and a crank arm, and getting rid of secondary forging in the die forging process simultaneously, thereby achieving a purpose of finishing the forging by one time, decreasing the flowing time in the crank production process, preventing from folding a crank opening, disposing oxide skin accumulation of the opening, decreasing machining allowance of forgings, improving the internal quality of the crank forgings, the qualification rate of forging flaw detection and the material utilization rate.

Owner:武汉重工铸锻有限责任公司

A heat treatment method for medium-carbon low-alloy steel road wheels

ActiveCN107586938BEasy to useReduce depthFurnace typesIncreasing energy efficiencySlow coolingMechanical property

Owner:MAGANG (GROUP) HOLDING CO LTD +1

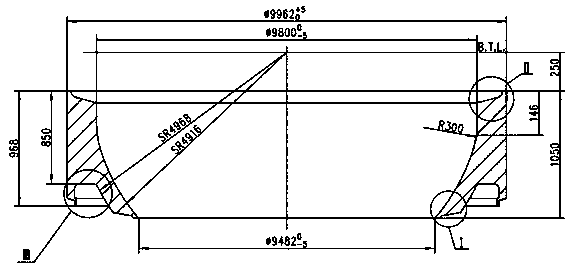

Improved method for driving roll used for hot rolling moulding of rail traffic bearing collar

ActiveCN108284185AIncrease profitReduce manufacturing costRollsMetal rolling arrangementsEngineeringImproved method

The invention discloses an improved method for a driving roll used for hot rolling moulding of a rail traffic bearing collar. The improved method is characterized in that hot rolling moulding technological parameters of a high-speed train bearing collar piece are determined according to a collar blank structure; the driving roll is adopted for rolling moulding; a concave position and an initial concave amount of a concave part of a hot rolling prefabricated collar piece are determined; the hot rolling prefabricated collar piece is subjected to thermal treatment; the final concave amount at theconcave part of the pressure-quenched high-speed train bearing collar is determined; metal at the concave position is compensated on the premise of unchanging the size of the metal by changing the structure of the driving roll; and therefore the aim that no concave parts exist at the central part of the hot-rolling moulded-thermally-treated high-speed train bearing collar is realized. By adoptingthe improved method, the condition that the concave part is eradicated in a cutting mode is avoided; the utilization rate of metal is improved; machining time is reduced; and production cost of the collar piece is lowered.

Owner:WUHAN UNIV OF TECH

Cold Forging Process of Clutch Sleeve

The invention discloses a cold forging process of a clutch sleeve. The cold forging process comprises the steps of: blanking-spheroidizing annealing-shot blasting-pretreatment-cold forging-inner hole drilling-thermal refining-sleeve boring-sleeving outside. The forging temperature of cold forging is room temperature; the product structure grains are finer, and the surfaces are not oxidized and decarbonized, so that the size precision is high, and the surface roughness is low; a traditional phosphorus saponification treatment lubricant treatment process is mature; and the mold service life is greatly prolonged.

Owner:JIANGSU CHUANGYI PRECISION FORGING

Method for manufacturing intermediate formed body of driven gear of rear axle of small and medium-sized automobile

InactiveCN101966554BIncrease productivityImprove mechanical propertiesWheelsMaterial consumptionEngineering

The invention discloses a method for manufacturing an intermediate formed body of a driven gear of a rear axle of a mall and medium-sized automobile, which can improve production efficiency and reduce material consumption. The method comprises the following steps of: upsetting a blank into a workpiece; punching the workpiece and removing connected skin; pre-shaping and reaming the workpiece; and finally performing rolling formation on the workpiece to form the intermediate formed body. Compared with the prior art, the method has the advantages of reducing cutting allowance and saving raw materials because the rolling formation is adopted to eliminate defects that upper and lower end faces are not flat, the ovality of the excircle is large and the like. The upsetting, reaming, connected skin removal and the pre-shaping can be finished by an open crank press; and the open crank press can accurately control the axial height of the workpiece, so that the possibility of generating burrs, fins and the other defects in the processing process is reduced.

Owner:SICHUAN JIANGYOU ZHONGHENG SPECIAL STEEL

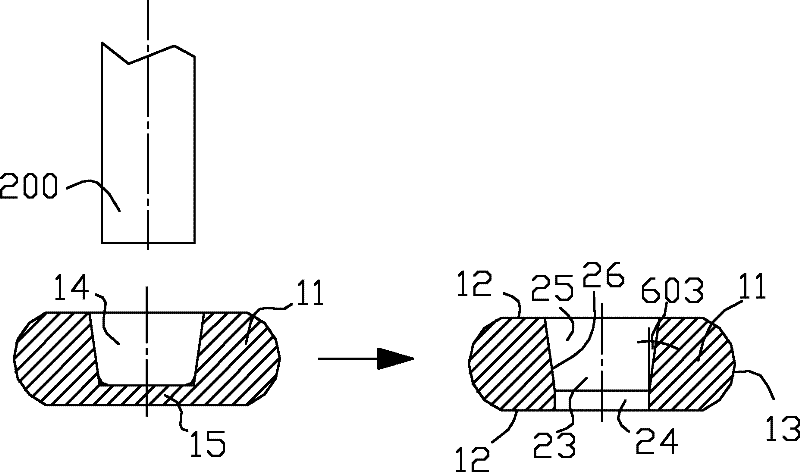

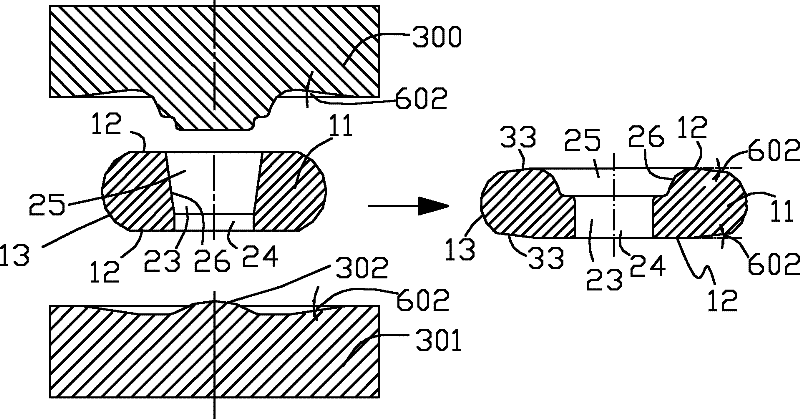

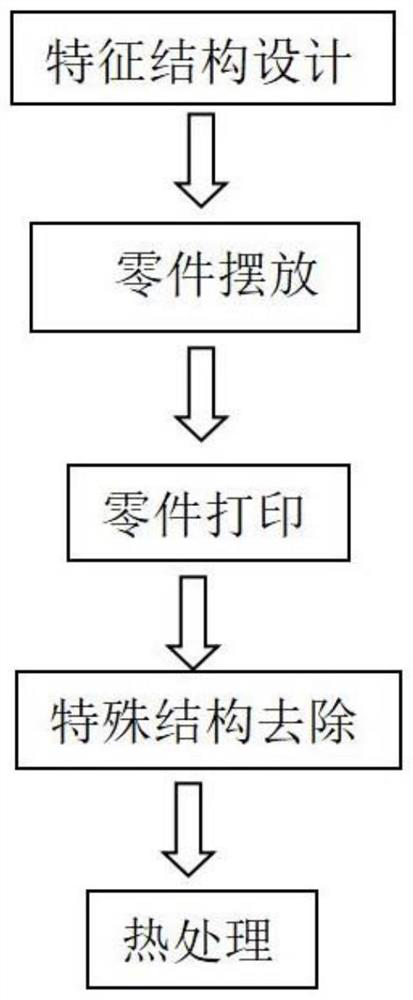

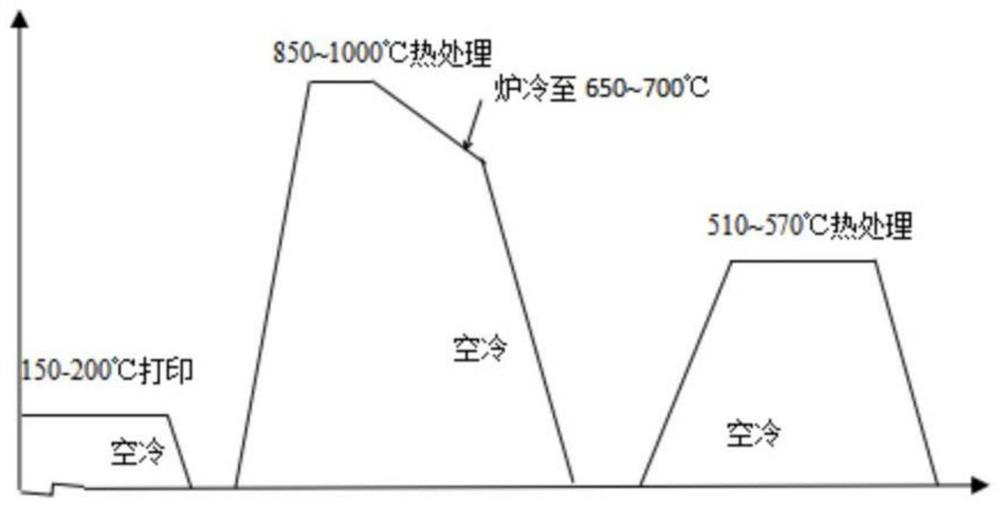

Control method for controlling deformation of 3D printing thin and high part

PendingCN114309647AReduce deformationReduce machining allowanceAdditive manufacturing apparatus3d printMachining process

The invention relates to a control method for controlling deformation of a 3D printing thin and high part, and belongs to the technical field of 3D printing. According to the control method, through design of a feature structure, a conical feature structure is designed at the top of a thin and high part; the long axis direction of the workpiece is parallel to the air blowing direction or an included angle smaller than 45 degrees is formed between the long axis direction and the air blowing direction; when the part is printed and formed, the base plate is heated to 150-200 DEG C, and printing is conducted in a checkerboard mode; after forming is finished, the feature structure is removed; and in the heat treatment process, the workpiece is vertically placed, and two-step heat treatment is adopted. According to the 3D printing thin and high part machining method, the deformation degree of the thin and high part can be obviously reduced, the machining allowance of the thin and high part is reduced, and the risk of wall breaking of the water paths in the machining process of the thin and high part workpiece is reduced. And the extremely small deformation can ensure that the wall thickness of the waterway in the thin and high part is uniform, and guarantee is provided for the finished product quality of injection molding parts.

Owner:上海镭镆科技有限公司

Die bending and forging finishing process of crank blank of low-speed diesel engine

ActiveCN102554087BReduce turnaround timeAvoid opening and foldingMetal-working apparatusSteelmakingFiber

The invention relates to a die bending and forging finishing process of a crank blank of a low-speed diesel engine, wherein a production method is as follows: an upset crank blank is obtained through the processes of steelmaking, upsetting of a steel ingot and drawing, and then the upset crank blank is molded into a standard crank blank by the press function of a finishing punch and a backward extrusion function of an arc molding block of a finishing die through the finishing punch on an oil press of 8000T. In comparison with a traditional method, the process in the invention is capable of guaranteeing full fibers of a crank pin and a crank arm, and getting rid of secondary forging in the die forging process simultaneously, thereby achieving a purpose of finishing the forging by one time, decreasing the flowing time in the crank production process, preventing from folding a crank opening, disposing oxide skin accumulation of the opening, decreasing machining allowance of forgings, improving the internal quality of the crank forgings, the qualification rate of forging flaw detection and the material utilization rate.

Owner:武汉重工铸锻有限责任公司

A combined mold for integral forging of hinged beams and a method for processing hinged beams

ActiveCN107900270BIncrease profitReduce machining allowanceForging/hammering/pressing machinesMachiningMultiple layer

The invention relates to a hinge beam integral die-forging and forming combined die. The hinge beam integral die-forging and forming combined die comprises a concave die and convex dies; the concave die consists of an outer hoop plate assembly, four concave die sections and a center punch which are fixed together by a screw; the outer hoop plate assembly comprises multiple layers of outer hoop plate rings and an outer hoop bottom plate; the center punch consists of a cylindrical punch bottom plate at the bottom and a frustoconical punch projection on the upper part, and the punch projection and the punch bottom plate are coaxial; and each concave die section consists of a convex section of which the top surface is fan-shaped, an arc-shaped vertical plate of which a side surface is L-shapedand a die section bottom plate with a 1 / 4 periphery, and a connecting ridge is arranged at a position where each die section bottom plate is connected with the corresponding arc-shaped vertical plate. The two convex dies which are perfectly matched with the concave die are used in machining. A using method of the combined die is provided. By a process mode of optimizing a die cavity and the like,the problem that the position of a lug of an existing forging and pressing die cannot be full is solved, and the method with small residual machining allowance is implemented.

Owner:烟台台海材料科技有限公司

Manufacturing method of casting cold heading mold

InactiveCN106917045BExtend your lifeLow costSolid state diffusion coatingElectric furnaceSlagMolten steel

A cast cold-heading mold is prepared from chemical components as follows: 0.6%-1.0% of C, 0.8%-1.2% of Si, 0.7%-1.0% of Mn, less than or equal to 0.03% of P, less than or equal to 0.03% of S, 4.5%-5.5% of Cr, 1.0%-1.5% of Mo, 0.7%-1.2% of V, 1.0%-1.3% of Ni and 0.5%-1.0% of Cu. Smelting is performed with a medium-frequency induction furnace, after deoxidizing and slag removal, molten steel is poured into a precoated sand cold-heading mold cast, and a part blank of the cast cold-heading mold is obtained; the blank is subjected to strengthening and toughening treatment and then subjected to surface hardening treatment, and surface gas nitriding treatment is performed on the cast cold-heading mold after machining. Compared with a manufacturing method for a forged cold-heading mold, a manufacturing method for the cast cold-heading mold has the advantages that the service life of the mold is prolonged, manufacturing procedures are simplified, the workload is reduced, the cost is reduced, the material utilization rate is increased, steel for the mold is reduced, and a lot of loss of raw materials during cutting machining and forging heating is reduced.

Owner:广西大学行健文理学院

A processing technology for d-connection pipe of four-way reversing valve

The present invention discloses a four-way reversing valve D connection tube processing process, which comprises that: 1, a cooper tube to be processed is subjected to material feeding through an automatic material feeding machine; 2, an automatic tube bending machine performs automatic tube bending on the cooper tube from the step 1, wherein the automatic tube bending process is performed by using a special D connection tube automatic folding-bending machine to process; 3, tube end forming is performed, wherein the tube end forming completes the final product forming on a special D connection tube end machine; and 4, the formed D connection tube is subjected to cleaning, inspection and warehousing. Compared with the processing process in the prior art, the processing process of the present invention has the following characteristics that: the whole four-way reversing valve D connection tube processing process from material feeding to finished product obtaining adopts automation production equipment so as to increase production efficiency, reduce labor cost, ensure product quality, and achieve good effects in the field of energy saving, emission reducing and clean production.

Owner:浙江长兴和良智能装备有限公司

An improved method for driving rollers for hot rolling forming of bearing rings for rail transit

ActiveCN108284185BIncrease profitReduce manufacturing costRollsMetal rolling arrangementsEngineeringImproved method

The invention discloses an improved method for a driving roll used for hot rolling moulding of a rail traffic bearing collar. The improved method is characterized in that hot rolling moulding technological parameters of a high-speed train bearing collar piece are determined according to a collar blank structure; the driving roll is adopted for rolling moulding; a concave position and an initial concave amount of a concave part of a hot rolling prefabricated collar piece are determined; the hot rolling prefabricated collar piece is subjected to thermal treatment; the final concave amount at theconcave part of the pressure-quenched high-speed train bearing collar is determined; metal at the concave position is compensated on the premise of unchanging the size of the metal by changing the structure of the driving roll; and therefore the aim that no concave parts exist at the central part of the hot-rolling moulded-thermally-treated high-speed train bearing collar is realized. By adoptingthe improved method, the condition that the concave part is eradicated in a cutting mode is avoided; the utilization rate of metal is improved; machining time is reduced; and production cost of the collar piece is lowered.

Owner:WUHAN UNIV OF TECH

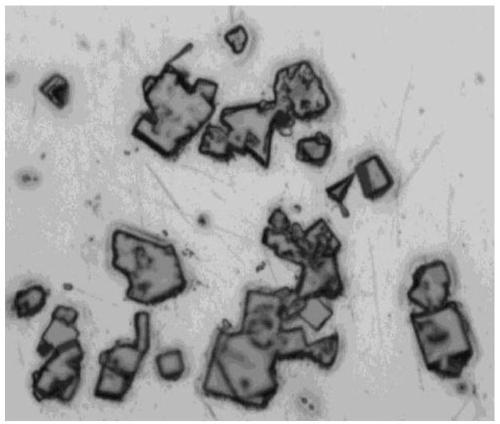

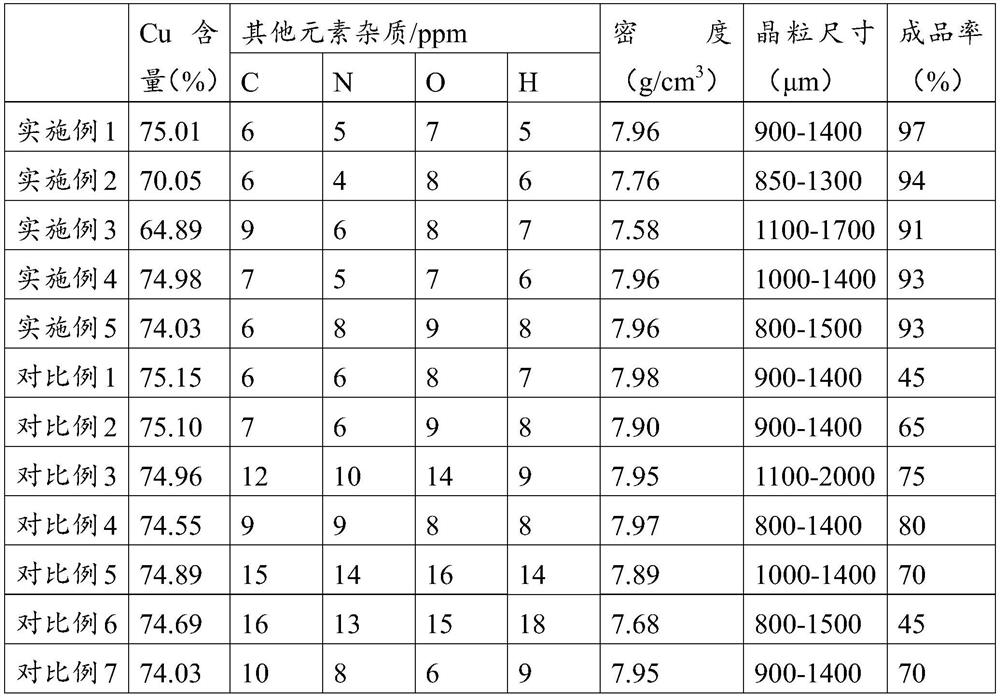

Copper-gallium target material, and preparation method and application thereof

The invention discloses a copper-gallium target material, and a preparation method and an application thereof, and belongs to the technical field of metal target materials. The copper-gallium alloy is prepared by taking the copper-gallium alloy as a raw material, heating, melting, casting and cooling. According to the invention, the copper-gallium alloy is preferably selected and directly used as a raw material for preparing the copper-gallium target material, and meanwhile, the casting temperature and the casting rate are preferably selected so that the prepared product is free of segregation, pores and cracks, high in density and uniform in grain size distribution; and the copper-gallium target material prepared by the preparation method is high in yield which can reach more than 91%, the oxygen content is lower than 10ppm, and the copper-gallium target material can well meet the requirement of vacuum sputtering coating so that the copper-gallium target material can be applied to thin layer manufacturing of solar cells.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

Die forging technology adopting free forging press for low-speed diesel engine cylinder heads

ActiveCN105328111AGuaranteed concentricityReduce machining allowanceForging/hammering/pressing machinesEngine componentsLow speedCylinder head

The invention discloses a die forging technology adopting a free forging press for low-speed diesel engine cylinder heads. Steel ingots are upset, punched, chambered and drawn and then undergo head cutting and tail removing to be divided into separate blanks needed by the cylinder heads; a pre-forging die and a finish forging die are prepared, four pre-forging releasing ejection holes are uniformly formed in the bottom of the pre-forging die, four finish-forging releasing ejection holes are uniformly formed in the bottom of the finish forging die, and a pre-forging releasing ejection plate is arranged on the bottom of the pre-forging die. The interior and the exterior of a pre-forging die cavity have reverse taper, a finish forging die cavity is shaped like a simplified cylinder head contour, and machining allowance is reserved. The cylindrical blanks fully insulated are placed into the pre-forging die cavity and are pre-forged in the free forging press, and according to the shape characteristics of the cylinder heads, the cylindrical blanks are machined to form pre-forging material with the upper end walls thickened and the lower end walls thinned; the pre-forging material is placed into the finish forging die cavity for finally forming the low-speed diesel engine cylinder heads. The die forging technology has the advantages that blank manufacturing is easy, the operation is convenient, the procedure work is convenient, the machining allowance is small, the size accuracy is high, the production cost is low and the production efficiency is high, and is suitable for die forging of the low-speed diesel engine cylinder heads of various types.

Owner:武汉重工铸锻有限责任公司

A kind of preparation method of silicone oil clutch housing

The invention provides a preparation method for a silicone oil clutch housing. The preparation method comprises the following steps that S1, molten steel is smelted; S2, the molten steel is injected into a forming mould for pressure casting; S3, waste at a sprue is removed; S4, the surface of a casting is cleaned till the surface is smooth, and casting burrs are removed; S5, an insert is pressed into the casting; S6, the casting is mechanically machined to form the silicone oil clutch housing; S7, the silicone oil clutch housing is subjected to leakproofness detection; S8, the silicone oil clutch housing which is qualified after a leakproofness test is packaged and sealed for storage. The casting is fabricated through the forming mould, the precision of the casting can be guaranteed, the mechanical machining allowance is reduced, machining efficiency is improved, and meanwhile raw materials can be saved.

Owner:SHANDONG HESHAN MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com