Forging process of scroll for novel energy automobile integral type scroll compressor

A technology for scroll compressors and new energy vehicles, applied in the field of forging, can solve the problems of weakened parts strength, poor forging flow lines, large machining allowances, etc., and achieves good flow lines, high forming accuracy, and machining allowances. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

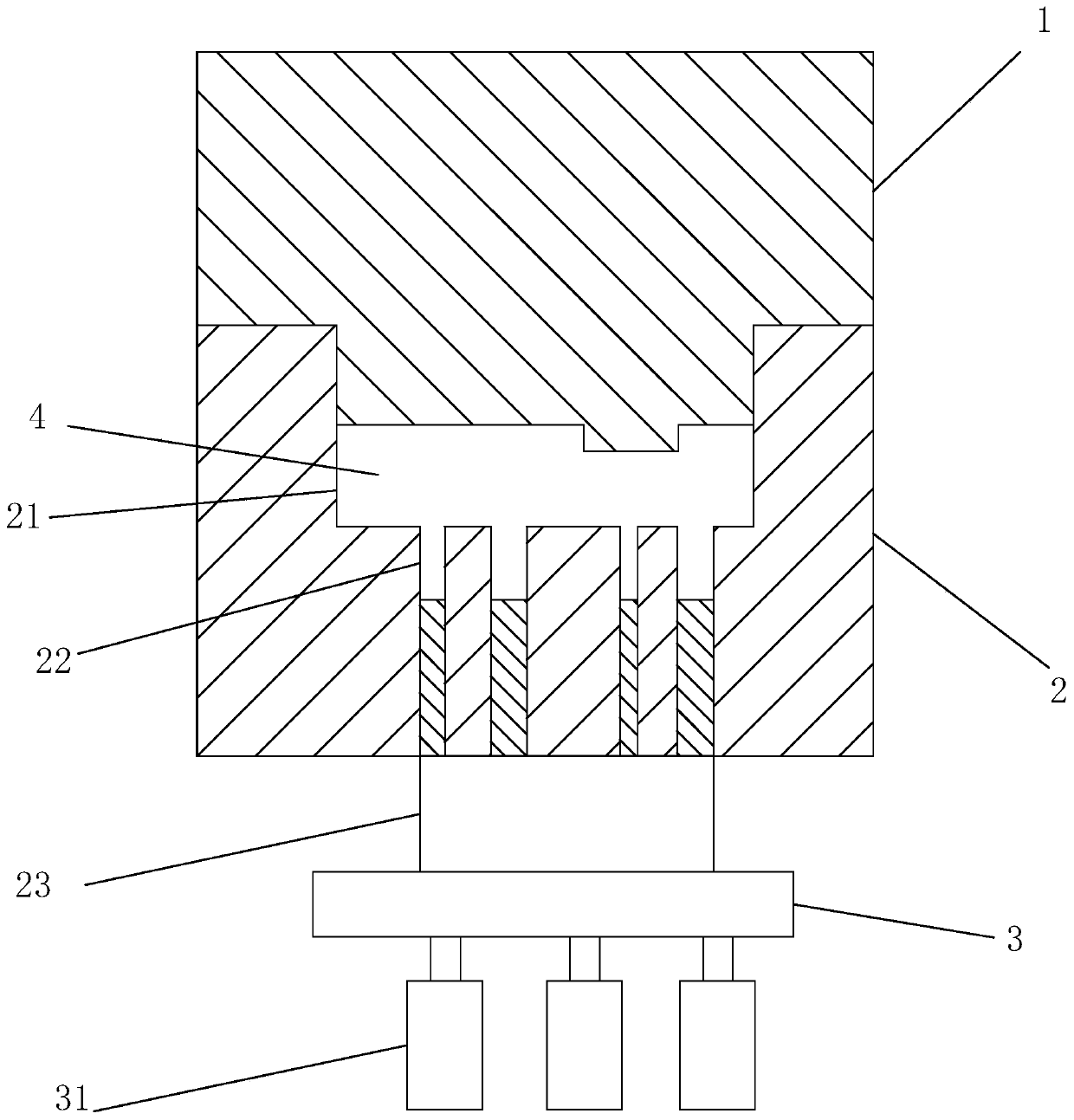

[0025] A kind of forging process of the scroll used in the integrated scroll compressor of new energy vehicles, refer to figure 1 , which includes a forging die, the forging die includes an upper die 1 and a lower die 2, the lower die 2 includes a cavity, and the cavity includes an upper cavity 21 on the upper part for forming the scroll bottom and a lower part for forming the scroll In the lower cavity 22 of the rotating wall, a back pressure body 23 is arranged in the lower mold 2 , and an ejection mechanism for driving the back pressure body 23 to eject the forging 4 is arranged under the back pressure body 23 . The ejection mechanism includes a supporting plate 3 connected to the bottom of the back pressure body 23 and a nitrogen gas spring 31 connected below the supporting plate 3 , and the back pressure body 23 is driven by the nitrogen gas spring 31 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com