Copper-gallium target material, and preparation method and application thereof

A target, copper gallium technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of high impurity and gas content, slow sputtering rate, low yield, etc., to achieve high density , The effect of high yield and uniform grain size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

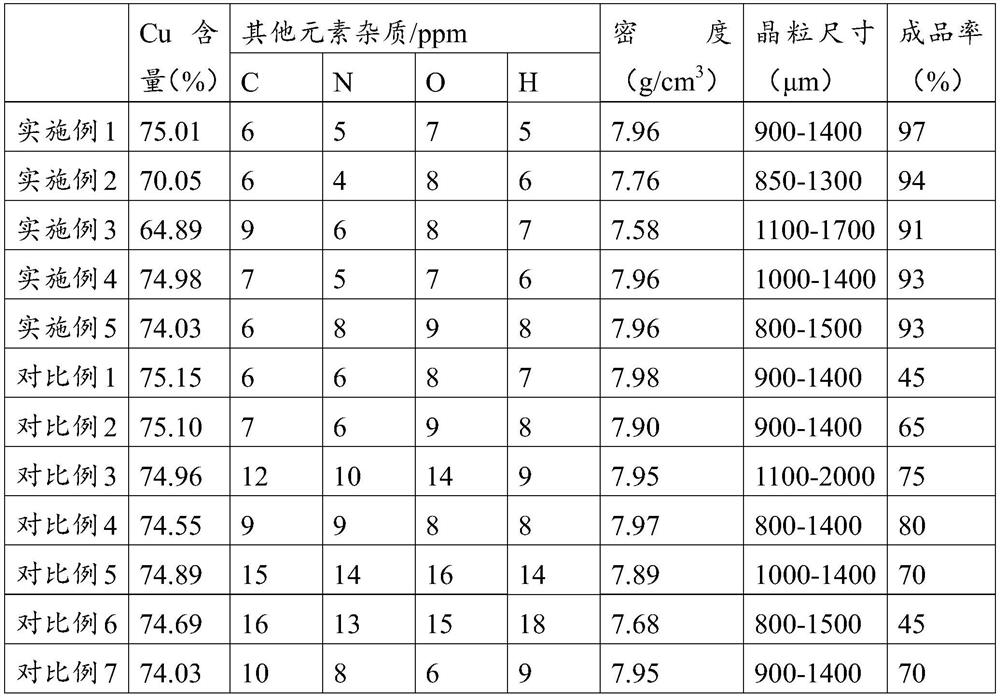

Examples

Embodiment 1

[0037] The synthesis steps of the copper gallium target in the embodiment of the present invention are as follows:

[0038] (1) Weigh 30Kg of copper-gallium alloy and put it into a graphite crucible, keep the vacuum in the crucible below 0.1Pa, raise the temperature to 1000°C at a heating rate of 20°C / min, fully stir and keep warm for 10min after the alloy is completely melted, Obtain copper-gallium alloy liquid, wherein the weight ratio of copper and gallium in the copper-gallium alloy taken is 75:25;

[0039] (2) Evenly spray boron nitride on the inside of the graphite mold and the outer surface of the graphite inner core, and then put the assembled graphite mold into a heating furnace for heating for 1 hour at a heating temperature of 180°C; Evenly cast on a high-purity graphite funnel with a hole diameter of 6mm, the copper-gallium alloy liquid flows into the graphite mold along with the funnel, wherein the temperature is maintained at 1000°C during the casting process, an...

Embodiment 2

[0042] The synthesis steps of the copper gallium target in the embodiment of the present invention are as follows:

[0043] (1) Weigh 30Kg of copper-gallium alloy and put it into a graphite crucible, keep the vacuum in the crucible below 0.1Pa, raise the temperature to 950°C at a heating rate of 15°C / min, fully stir and keep warm for 15min after the alloy is completely melted, Obtain copper-gallium alloy liquid, wherein the weight ratio of copper and gallium in the copper-gallium alloy taken by weighing is 70:30;

[0044] (2) Evenly spray boron nitride on the inside of the graphite mold and the outer surface of the graphite inner core, then put the assembled graphite mold into a heating furnace and heat it for 1 hour at a heating temperature of 230°C; Evenly cast on a high-purity graphite funnel with a hole diameter of 7mm, the copper-gallium alloy liquid flows into the graphite mold along with the funnel, wherein the temperature is maintained at 950°C during the casting proce...

Embodiment 3

[0047] The synthesis steps of the copper gallium target in the embodiment of the present invention are as follows:

[0048] (1) Weigh 30Kg of copper-gallium alloy and put it into a graphite crucible, keep the vacuum in the crucible below 0.1Pa, raise the temperature to 1050°C at a heating rate of 25°C / min, fully stir and keep warm for 10min after the alloy is completely melted, Obtain copper-gallium alloy liquid, wherein the weight ratio of copper and gallium in the copper-gallium alloy taken is 65:35;

[0049](2) Evenly spray boron nitride on the inside of the graphite mold and the outer surface of the graphite inner core, then put the assembled graphite mold into a heating furnace for heating for 1 hour at a heating temperature of 130°C; Evenly cast on a high-purity graphite funnel with an aperture of 8mm, the copper-gallium alloy liquid flows into the graphite mold along with the funnel, wherein the temperature is maintained at 1050°C during the casting process, and the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com