Method for laser preparation of titanium nitride gradient coating on surface of titanium and titanium alloy

A gradient coating and titanium alloy technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of coarse grain of nitride layer, large surface roughness, easy deformation of substrate, etc., to achieve Small friction coefficient, low surface roughness, and improved pitting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Laser treatment of 4mm thick TA2 thin plate, the specific steps are as follows:

[0034] 1. First, polish the surface of the titanium alloy substrate, and scrub with acetone to remove oil;

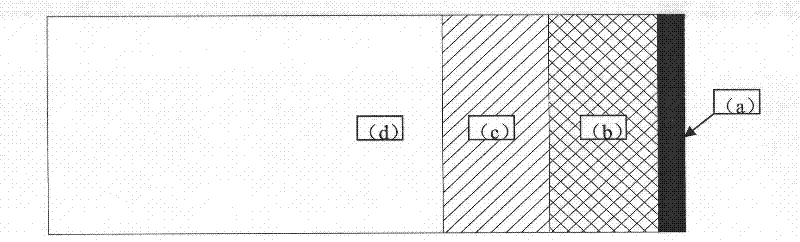

[0035] 2. Spray 0.03-0.1mm thick SiO with aluminum and vanadium powder added as modifier on the cleaned substrate 2 light-absorbing paint;

[0036] 3. Preheat the blackened substrate to 100-300°C;

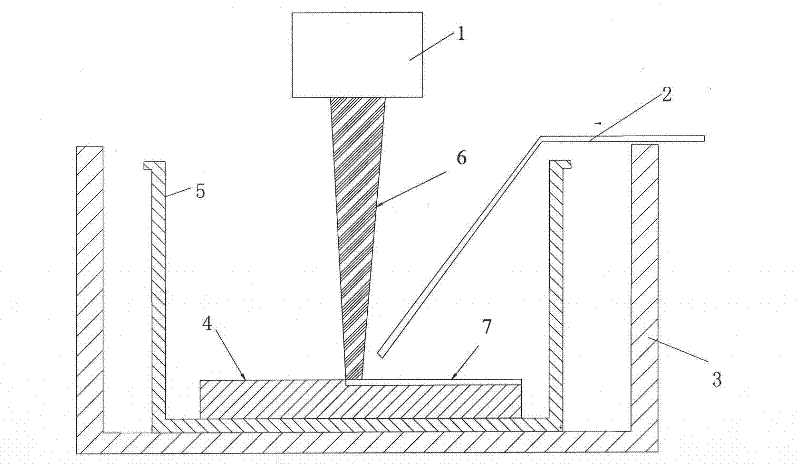

[0037] 4. Put the preheated matrix in a semi-airtight container filled with reaction gas, perform laser scanning treatment, and perform ultrasonic vibration treatment at the same time. The specific implementation steps are: put the sample on the semi-airtight stage, The container is placed in the ultrasonic vibration generator, and the reaction gas is passed into the semi-airtight container for a period of time, and the sample is scanned by a high-power laser to directly form a golden yellow titanium nitride gradient coating, the laser is turned off, and then stopped gas input.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com