Patents

Literature

98results about How to "Stable welding arc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength and high-tenacity gas shielded welding wire

ActiveCN101992365AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaManganeseMixed gas

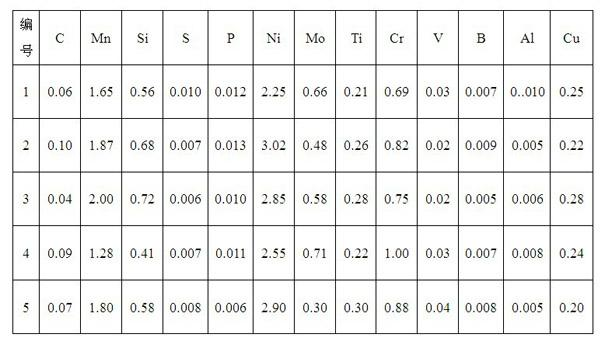

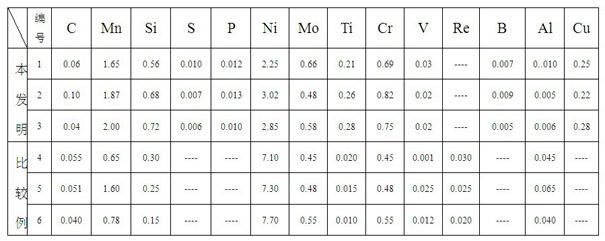

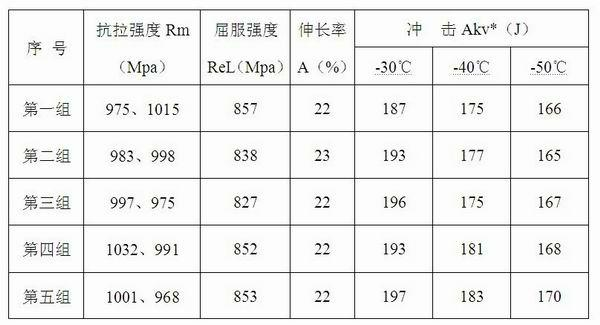

The invention discloses a high-strength and high-tenacity gas shielded welding wire. The welding wire comprises the following chemical composition in percentage by mass: 0.02 to 0.12 percent of carbon (C), 1.20 to 2.10 percent of manganese (Mn), 0.20 to 1.00 percent of silicon (Si), less than or equal to 0.010 percent of sulfur (S), less than or equal to 0.015 percent of phosphorus (P), 2.00 to 3.50 percent of nickel (Ni), 0.20 to 0.80 percent of molybdenum (Mo), 0.20 to 0.30 percent of titanium (Ti), 0.60 to 1.20 percent of chromium (Cr), less than or equal to 0.05 percent of vanadium (V), 0.005 to 0.010 percent of boron (B), less than or equal to 0.015 percent of aluminum (Al), less than or equal to 0.35 percent of copper (Cu) and the balance of iron (Fe). The welding wire is used for welding steels of a strength grade of between 850 and 950MPa; and under the protection of a mixed gas (80 percent of argon (Ar) and 20 percent of carbon dioxide (CO2)), the weld metal tensile strength of the welding wire is more than or equal to 850MPa, the yield strength is more than or equal to 720MPa, the elongation is more than or equal to 22 percent, and the low-temperature impact toughness Akv is more than or equal to 181J at the temperature of -30 DEG C, or more than or equal to 175J at the temperature of -40 DEG C, or more than or equal to 162J at the temperature of -50 DEG C.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

High-strength steel high-ductility gas shielded welding wire

InactiveCN101439446AProcess performance is stableStable welding arcWelding/cutting media/materialsSoldering mediaDuctilityArc welding

The invention relates to a high-tenacity gas-shielded welding wire for high-tensile steel. The welding wire solves problems of 780-850MPa-level low-alloy high-tensile steel welding material, including lack of matching performance and especially poor toughness and high cost. The technical proposal of the invention comprises that the chemical component consists of (counted by weight percentage) 0.05-0.13 percent of C, 1.4-1.9 percent of Mn, 0.4-0.8 percent of Si, 0.4-0.8 percent of Cr, 1.5-1.8 percent of Ni, 0.3-0.8 percent of Mo, 0.06-0.25 percent of Ti, 0-0.60 percent of Cu, not more than 0.025 percent of S, not more than 0.025 percent of P and the balance of Fe and unavoidable impurity elements. When gas-shielded welding is carried out on the welding wire, the welding line has the metal tensile strength of 780-850MPa; the ballistic work AkV at -20 DEG C is not less than 70J, thereby applying to gas-shielded arc welding of 780-850MPa-level low-alloy high-tensile steel.

Owner:SHOUGANG CORPORATION

Low dust high crack-resistance flux-cored wire all position flux-cored wire and preparation thereof

InactiveCN101239429AImprove crack resistanceImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaBorideCrack resistance

A low-dust crack-resistant full-position flux-cored wire is characterized in that the medicinal powder used by the flux-cored wire is composed of chemical components according to following percentage by weight: 25% of TiO2, 2% of SiO2, 1% of ZrO2, 1% of fluoride, 0.5% of Si, 8% of Mn, 1% of Al, 3% of Mg, 0.3% of Ti, 0.1% of boride, 0.1% of Re, 0.1% of Na2O, 0.1% of K2O, residue percent is iron powder; the preparing method comprises following steps: steel band longitudinal shearing, edge preprocessing, rolling, wire drawing, and winding. The advantages of the invention are: the weld dust is reduced, and the crack resistant property of welding joint is increased; the welding wire is provided with stable welding arc, little splash, good all position welding performance, good-looking weld joint, excellent detachability and good mechanical performance.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

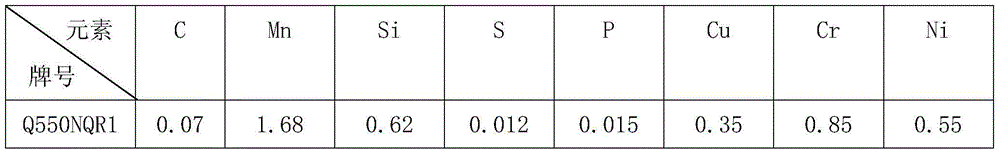

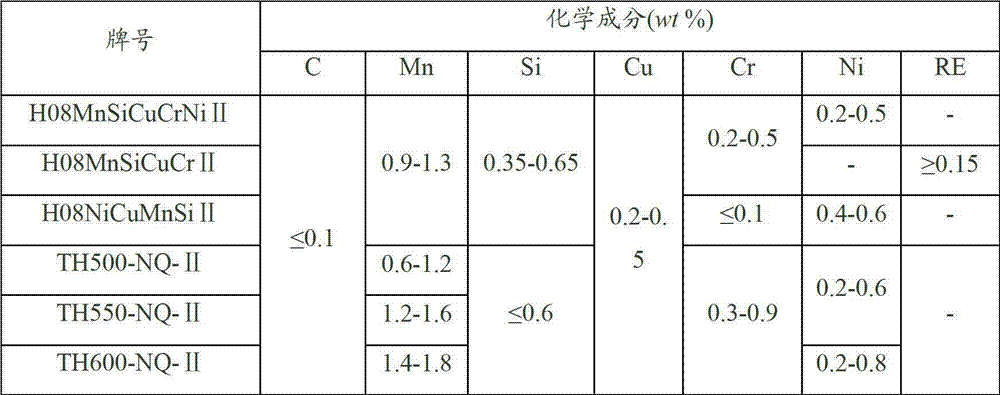

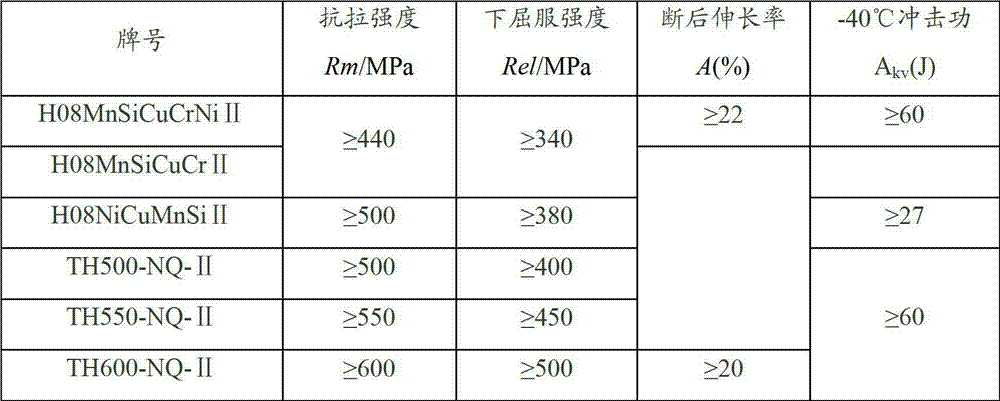

Weather-proof flux core wire used for coating-free bridge steel and preparing method of weather-proof flux core wire

ActiveCN106475706AImprove mechanical propertiesStable welding arcWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a weather-proof flux core wire used for coating-free bridge steel and a preparing method of the weather-proof flux core wire. The weather-proof flux core wire is composed of a steel skin and a powder core. The powder core comprises, by weight percent, 2%-8% of ferro-boron, 0.01%-2% of ferromolybdenum, 1%-6% of fluoride, 1.5%-8% of zircon sand, 2%-7% of magnesium powder, 2%-5% of quartz sand, 2%-8% of silicon iron, 5%-19% of electrolytic manganese, 1%-5% of ferromanganese, 1%-6% of nickel powder, 1%-8% of chromium metal, 1%-8% of copper powder, 2%-9% of ferrotitanium, 0.1%-5% of feldspar, 2%-8% of sodium titanate, 20%-40% of rutile and the balance iron powder. Compared with the prior art, the weather-proof flux core wire is stable in welding arc and little in splashing, slag removing is easy, a welding joint is formed attractively, the weather-proof flux core wire is suitable for all-position welding, the mechanical performance of the welding joint is good, the impact toughness at the temperature of minus 40 DEG C is larger than 80 J, and very high corrosion resistance is achieved.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Microtitanium-boron high-toughness gas protective welding stick

InactiveCN1328897AGood workmanshipStable welding arcWelding/cutting media/materialsSoldering mediaAlloyTitanium

The present invention relates to a micro titanium-boron high-toughness gas shielded welding wire, its chemical components (wt.%) are: C 0.03-0.10, Mn 1.00-1.80, Si 0.20-1.00, Ni 0.50-1.40, Ti 0.10-0.20, B 0.002-0.010, S less than or equal to 0.10, P less than or equal to 0.20 and the rest being Fe and other unavoidable impurity. When the welding wire is used to make protective welding by adopting mixed gas (80% Ar+20% CO2), the wield metal tensile strength is greater than or equal to 580 Mpa, -30 deg.C impact work Akv is greater than or equal to 80J, and it adapts to all-position welding. This invented welding wire possesses excellent processing property, and is suitable for gas protective arc welding of large-type structures of 600 MPa level low-alloy high strength steel, engineering machine, railway bridge, marine installation, high-pressure container and oil-gas transmission pipeline, etc.

Owner:武钢集团有限公司

High-strength low-temperature-resistant TiO2-series CO2 gas-shielded low-hydrogen type flux-cored wire

ActiveCN102528332AIncrease coverageArc stabilizationWelding/cutting media/materialsSoldering mediaHydrogen contentMetal

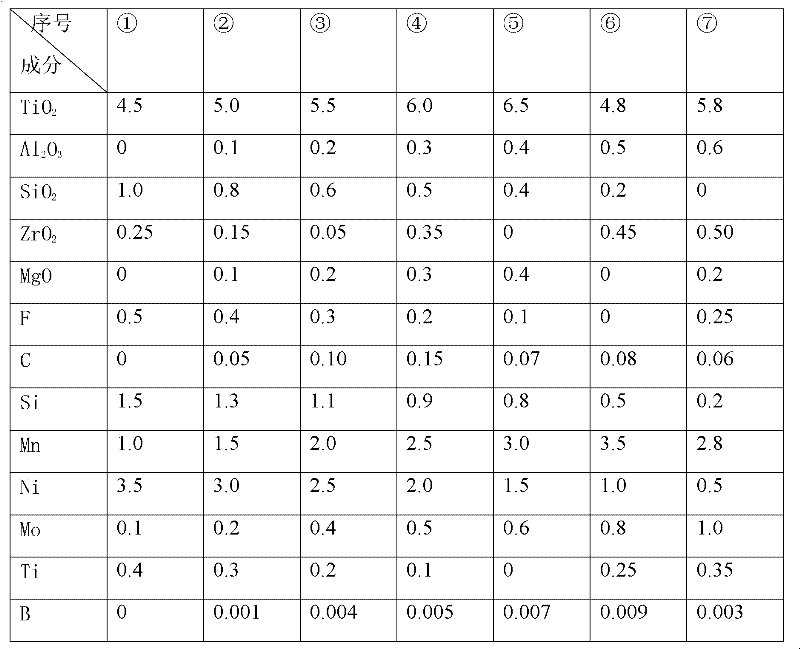

The invention discloses a high-strength low-temperature-resistant TiO2-series CO2 gas-shielded low-hydrogen type flux-cored wire, which comprises the following components in percentage by mass (based on total mass): 4.5-6.5% of TiO2, 0-0.6% of Al2O3, 0-1% of SiO2, 0-0.5% of ZrO2, 0-0.4% of MgO, 0-0.5% of F, 0-0.15% of C, 0.2-1.5% of Si, 1.0-3.5% of Mn, 0.5-3.5% of Ni, 0.1-1.0% of Mo, 0-0.4% of Ti and 0-0.009% of B. The cold-rolled steel strip for preparing the flux-cored wire comprises the following chemical ingredients by weight content: not more than 0.02% of C, not more than 0.010% of P, and not more than 0.008% of S. The tensile strength of the deposited metal can reach more than 760MPa, the low-temperature impact at -60 DEG C achieves more than 47J, and the diffusible hydrogen content is smaller than 4mL / 100g ( mercury method); and the flux-cored wire has excellent welding operational performance, and is suitable for port machines, ocean platforms, bridges and the like.

Owner:KUSN GINTUNE WELDING

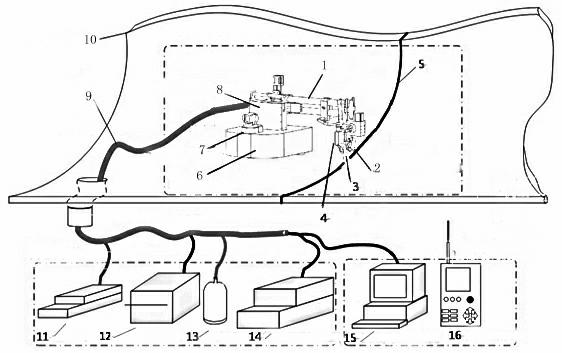

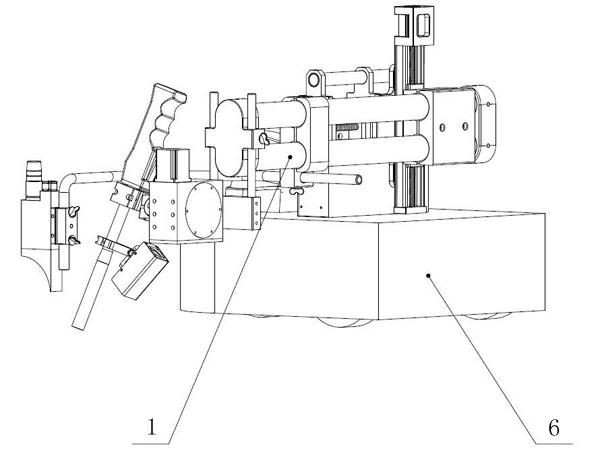

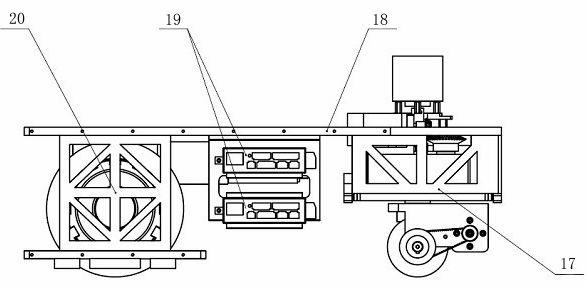

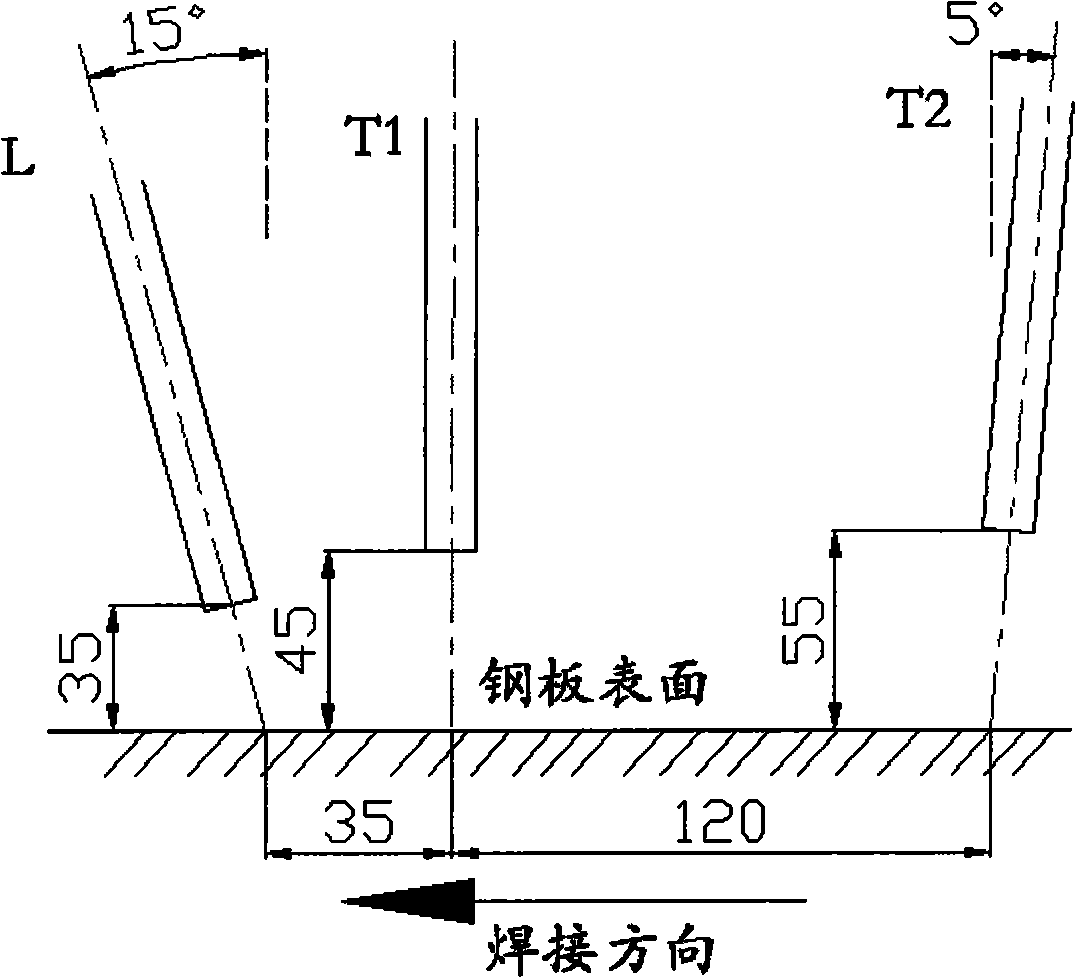

Autonomous mobile robot system for metal-inert-gas (MIG)/metal-active-gas (MAG) multilayer multipass welding of large thick plate

ActiveCN102689083AImprove performanceWith environmental monitoringElectrode supporting devicesDrive wheelShielding gas

The invention belongs to the technical field of welding of robots, and in particular relates to an autonomous mobile robot system for metal-inert-gas (MIG) / metal-active-gas (MAG) multilayer multipass welding of a large thick plate. The system comprises a robot body, a control system and an MIG / MAG welding system, wherein the robot body comprises a crawling mechanism and an operating mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; the MIG / MAG welding system comprises an MIG / MAG welding gun, an MIG / MAG welding power supply, a wire feeding machine, shielding gas and a weld cooling system; and the robot body, the control system and the MIG / MAG welding system are connected with one another through cables. The system has the advantages that a contact type magnet-wheel adsorption and non-contact type clearance adsorption composite mode and a three-wheel full-drive wheel type movement mode are used by the crawling mechanism, so that a robot can autonomously and flexibly move at all positions on the surface of an operating object, can be reliably adsorbed and can perform all-position welding operation, and the system is high in comprehensive performance.

Owner:DONGFANG ELECTRIC CORP LTD

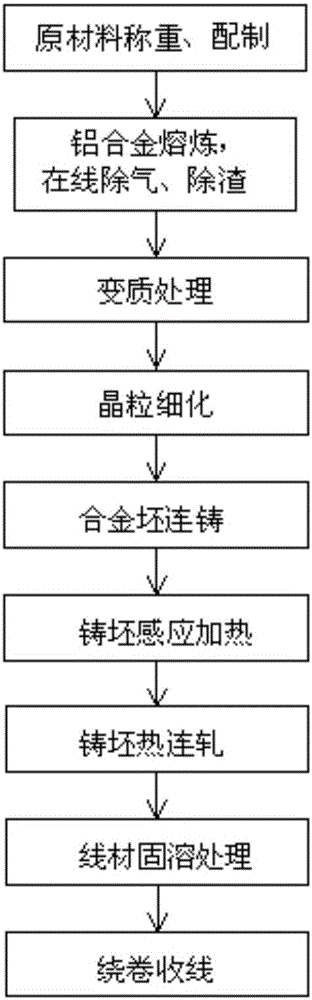

Continuous casting and rolling method for ZL114A welding wire rods

InactiveCN106244861AEasy to detectFor precise controlMetal rolling arrangementsWire rodSolution treatment

The invention belongs to the field of technical processes for cast aluminium alloys, and specifically relates to a continuous casting and rolling method for ZL114A welding wire rods. The method comprises the following steps: raw material weighing and preparation; aluminium alloy smelting, and online degassing and deslagging; modification treatment; grain refinement, alloy blank continuous casting; casting blank induction heating; casting blank hot-continuous rolling; wire solution treatment; and wire winding. The method disclosed by the invention overcomes the shortages of the prior art; online detection and accurate control can be realized for the chemical components of the produced aluminium alloy wire blanks; the alloy has a low hydrogen content inside and less inclusion, and is almost free from segregation; welding wires are good in welding manufacturability, and free from splashing and chip falling during a use process; welding arcs are stable; and welded joints have high interior quality and mechanical property.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

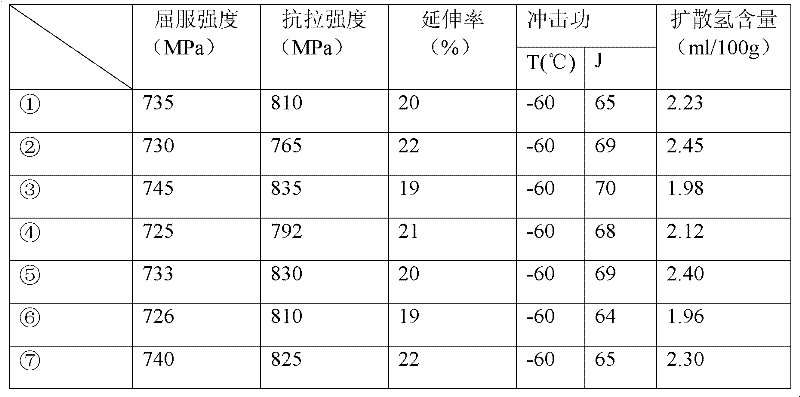

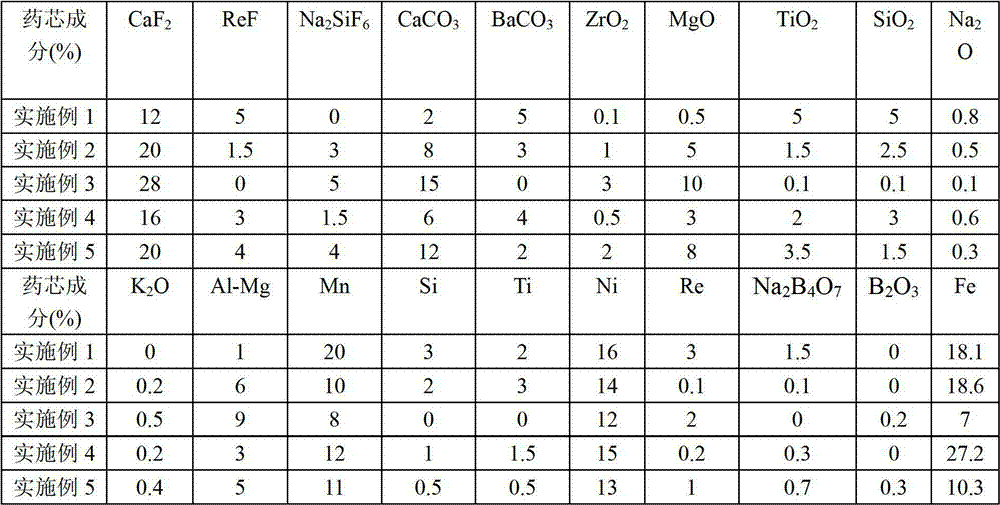

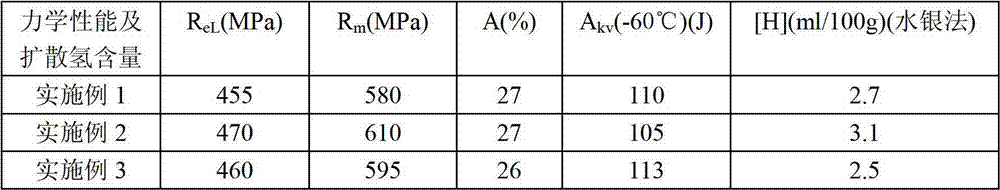

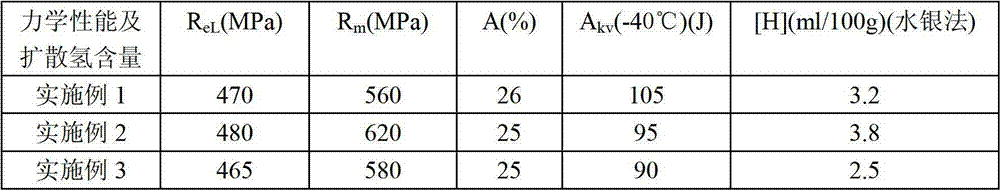

Ultralow-hydrogen high-toughness submerged arc welding flux core and submerged arc flux-cored wire

InactiveCN102848103AEasy to operateImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaBorideCrack resistance

The invention relates to an ultralow-hydrogen high-toughness submerged arc welding flux core and a submerged arc flux-cored wire. The welding flux core comprises the following components of: CaF2, Na2SiF6, ReF, BaCO3, CaCO3, MgO, TiO2, SiO2, ZrO2, boride, Na2O, K2O, Mn, Al-Mg, Ni, Ti, Si, Re and the balance of Fe. When the welding flux core is matched with a high-alkalinity sintering welding flux, the weld metal has the impact absorbed power of more than 80J at the temperature of 60 DEG C below zero; when the welding flux core is matched with a low-hygroscopicity smelting welding flux, the weld metal has the impact absorbed power of more than 90J at the temperature of 40 DEG C below zero; and when the welding flux core is matched with any one welding flux, weld diffusion hydrogen content is less than 5ml / 100g. The standard specific ultralow-hydrogen range is achieved; and the submerged arc flux-cored wire is high in cold crack resistance, has high in fracture toughness value, is suitable for low-alloy high-strength steel and can be used for welding important structures.

Owner:TIANJIN UNIV +1

Submerged arc sintered flux and production method thereof

InactiveCN101537550AEnsuring grain refinementStable welding arcWelding/cutting media/materialsSoldering mediaFerrosiliconRare earth

The invention relates to a hull building high efficiency welding process, and a welding technique for flux copper liner multi-filament single side automatic submerged arc welding, in particular to an automatic submerged arc welding sintered flux comprising a top surface flux and a liner flux and a production method thereof. The submerged arc sintered flux consists of the top surface flux and the liner flux. The top surface flux comprises the following components: 5 to 10 percent of CaO, 15 to 20 percent of MgO, 7 to 14 percent of Al2O3, 3 to 6 percent of MnO, 10 to 15 percent of SiO2, 5 to 10 percent of TiO2, 34 to 38 percent of Fe2O3, 2 percent of rare earth ferrosilicon, 1 percent of ferrotitanium, 0.5 percent of borax, and 0.5 percent of ferromanganese; and the liner flux comprises the following components: 15 to 20 percent of CaO, 30 to 35 percent of MgO, 5 to 10 percent of Fe2O3, 10 to 15 percent of MnO, 15 to 20 percent of SiO2, 5 to 10 percent of TiO2, and 4 to 5 percent of Na2O.

Owner:上海纪好旺造船科技发展有限公司

Electrogas welding gas shield flux-cored wire for large heat input welding

ActiveCN102009287AImprove low temperature toughnessImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaMagnesiumWelding joint

The invention discloses an electrogas welding gas shield flux-cored wire for large heat input welding, belonging to the technical field of high-efficiency high heat input welding. An SPCC (steel plate cold rolled commercial) steel tape with the size of 0.9*14 mm is used for manufacturing the flux-cored wire, the fill rate of powder is controlled to be within a range of 17-23%, and a welding wire with the diameter of phi1.6mm is manufactured. The flux core comprises the following raw materials: 1-3% of potassium or sodium fluoride, 3-6% of SiO2, 1-3% of one or two of rutile and zircon sand, 1-5% of one, two or three of strong deoxidizer magnesium powder, aluminite powder or aluminum and magnesium powder, 2-5% of one, two or three of strong deoxidizer titanium iron powder, silicon zirconiumpowder and zirconium iron powder and the balance iron powder. In addition, according to the intensity requirement of the welded steel plate and the low-temperature mechanical property requirement of a welding joint, in the flux core formula, a proper amount of alloying agent metal powder can be added, such as molybdenum iron powder, nickel powder and the like so as to obtain the alloy ingredient with a proper proportion. The flux-cored wire provided by the invention has the advantages that the flux-cored wire has good welding technology performance, less welding splash, beautiful welding lineshaping and good mechanical property of the welding joint.

Owner:SHOUGANG CORPORATION

Microtitanium-boron high-toughness gas protective welding stick

InactiveCN1152767CGood workmanshipStable welding arcWelding/cutting media/materialsSoldering mediaAlloyTitanium

The present invention relates to a micro titanium-boron high-toughness gas shielded welding wire, its chemical components (wt.%) are: C 0.03-0.10, Mn 1.00-1.80, Si 0.20-1.00, Ni 0.50-1.40, Ti 0.10-0.20, B 0.002-0.010, S less than or equal to 0.10, P less than or equal to 0.20 and the rest being Fe and other unavoidable impurity. When the welding wire is used to make protective welding by adopting mixed gas (80% Ar+20% CO2), the wield metal tensile strength is greater than or equal to 580 Mpa, -30 deg.C impact work Akv is greater than or equal to 80J, and it adapts to all-position welding. This invented welding wire possesses excellent processing property, and is suitable for gas protective arc welding of large-type structures of 600 MPa level low-alloy high strength steel, engineering machine, railway bridge, marine installation, high-pressure container and oil-gas transmission pipeline, etc.

Owner:武钢集团有限公司

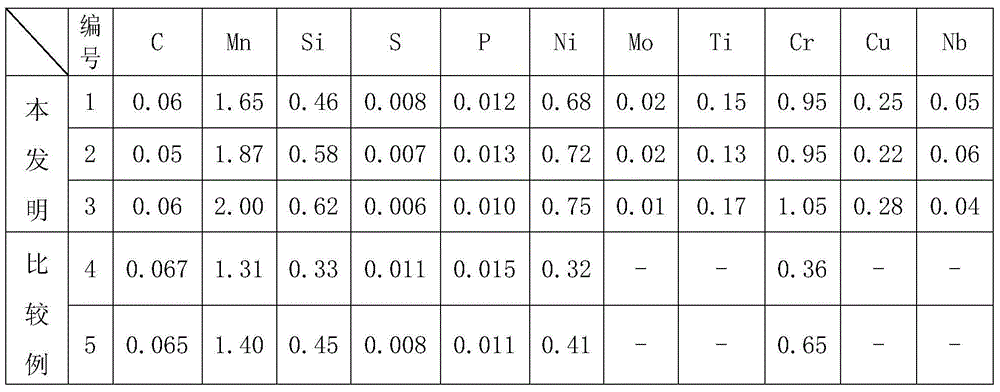

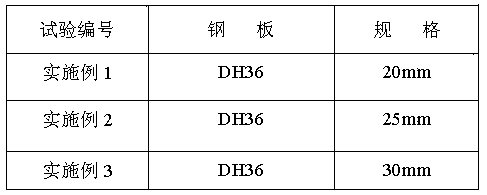

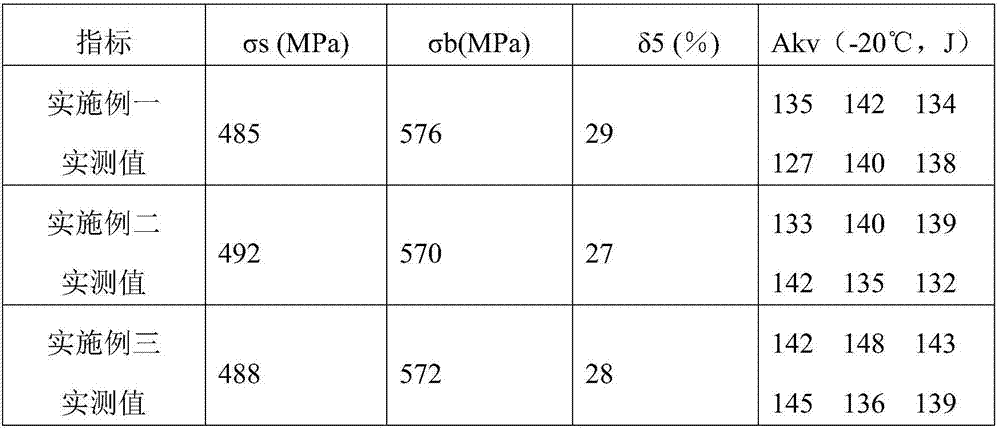

High-strength solid wire made of weathering resistant steel through gas shielded welding

ActiveCN103600178AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaChemical compositionWeather resistance

The invention discloses a high-strength solid wire made of weathering resistant steel through gas shielded welding. Chemical compositions of the solid wire include, by weight percentage, 0.05 to 0.15 of C, 1.65 to 2.10 of Mn, 0.40 to 0.80 of Si, smaller than or equal to 0.010 of S, smaller than or equal to 0.015 of P, 0.25 to 0.55 of Cu, 0.90 to 1.25 of Cr, 0.65 to 0.95 of Ni, 0.12 to 0.18 of Ti, 0.02 to 0.10 of Nb and the balance iron and other impurities. Deposited metal and welding connectors obtained through the solid wire have good atmospheric corrosion resistance. The solid wire has the advantages of being high in strength, high in weathering resistance and the like. Meanwhile, the solid wire has good comprehensive performance, the extension strength of the solid wire is larger than or equal to 680MPa, the yield strength of the solid wire is larger than or equal to 550MPa, the elongation of the solid wire is larger than or equal to 22%, and low-temperature impact Akv at 40 DEG C below zero is larger than or equal to 148J.

Owner:CRRC MEISHAN

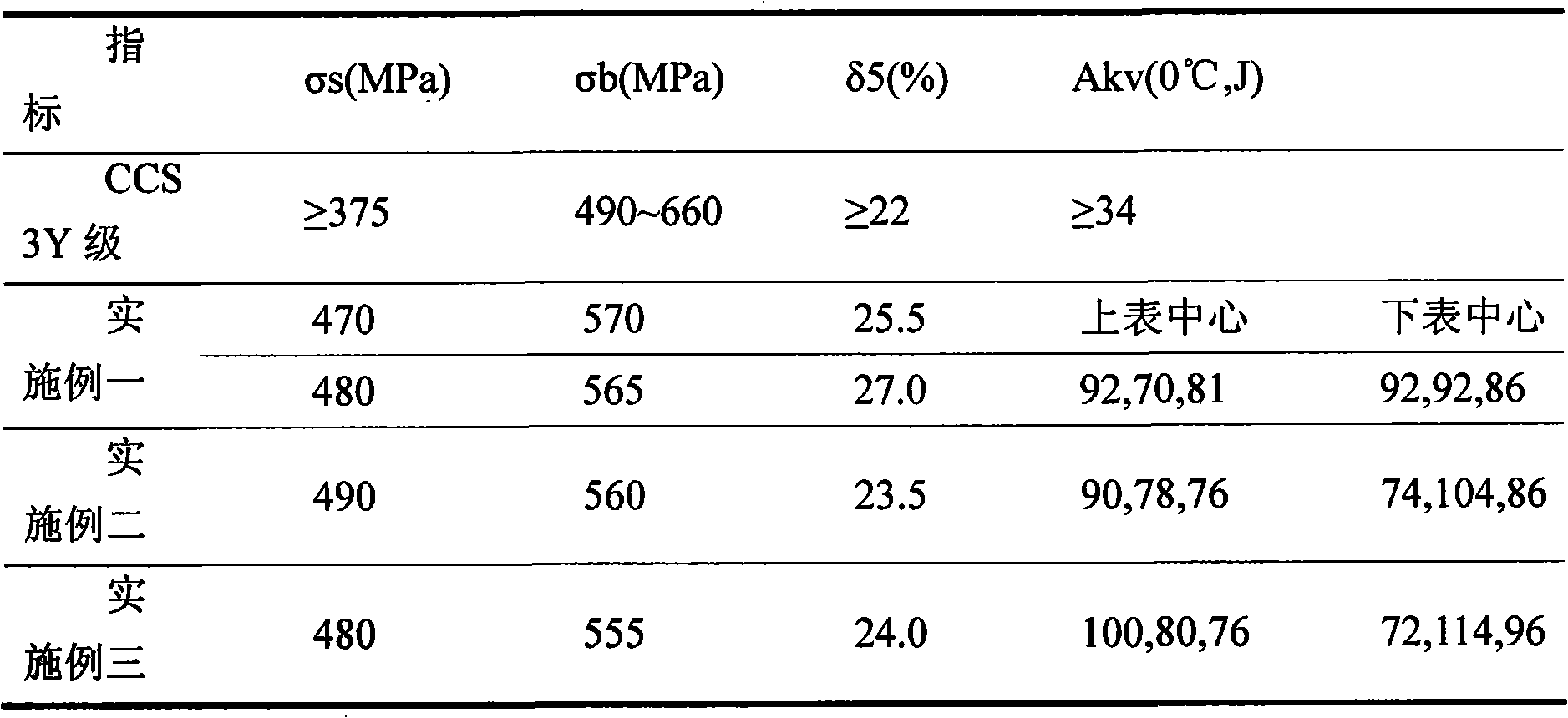

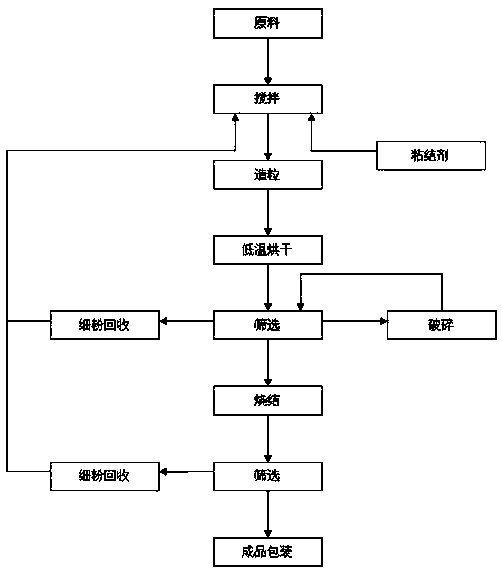

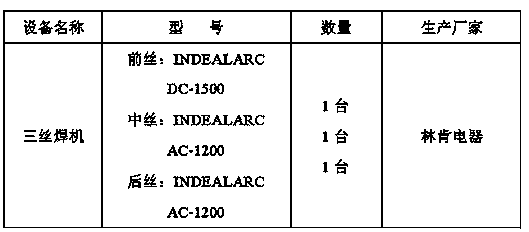

Sintered flux for efficient submerged arc welding and production technology thereof

ActiveCN103962751AStable welding arcEasy to remove slagWelding/cutting media/materialsSoldering mediaSubmerged arc weldingCalcium

The invention discloses sintered flux for efficient submerged arc welding and a production technology of the sintered flux. The sintered flux comprises front face flux and reverse face flux, the front face flux is composed of Al2O3, CaO, CaF2, MgO, SiO2, TiO2, B2O3, Fe powder and silicon calcium alloy, and the reverse face flux is composed of Al2O3, CaF2, MgO, MnO, SiO2, TiO2, Fe2O3 and silicon calcium alloy. The technology comprises the steps that batching is performed on raw materials according to ingredients of the sintered flux, the raw materials are put into a blender for even blending, a mixed material is obtained, bonding agents are added in the mixed material for granulation, low-temperature drying is performed at the temperature of 200 DEG C to 300 DEG C, after screening, sintering is performed, screening is performed again, and the product sintered flux is obtained. The sintered flux can meet the technological requirement of the good single face for being welded into double faces, the reverse face welding way is stably formed, and the sintered flux is suitable for high-speed welding, has the good mechanical performance and meets the 3Y standard required by classification societies of various countries.

Owner:锦州公略焊接技术有限公司

460 MPa-grade seamless flux-cored wire suitable for full-position welding and manufacturing method

ActiveCN107350659AStable welding arcGood all-position welding processabilityWelding/cutting media/materialsSoldering mediaSilicon alloyFilling rate

The invention relates to a 460 MPa-grade seamless flux-cored wire suitable for full-position welding and a manufacturing method. The flux-cored wire comprises a SPHC steel-tape sheath and filling powder, wherein the filling powder comprises, by weight percentage, 32-42% of rutile, 2-3% of quartz, 1.5-2.5% of sodium fluoride, 2-3% of zircon sand, 3-5% of feldspar, 14-16% of manganese silicon alloy, 3-5% of electrolytic manganese, 3-5% of low-carbon ferromanganese, 2-3% of aluminium magnesium alloy, 0.3-0.5% of ferroboron, 4-6% of nickel powder and the balance iron powder; and the filling rate of the powder is 14-16%. The manufacturing method comprises the steps of carrying out on-line filling and welding, reducing the diameter of the wire to phi 1.2mm-phi 1.6mm by using rollers and a wire drawing die, and carrying out annealing on the wire under the condition that the temperature is 700 DEG C and the time of heat preservation is 3 hours in the diameter reducing process. The 460 MPa-grade seamless flux-cored wire suitable for full-position welding is stable in welding arc under the protection effect of carbon dioxide gas, has good full-position welding manufacturability, and can be used for downhand welding, vertical-up welding, horizontal-position welding and overhead welding; and the formed welding seam is attractive in appearance.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Welding wire powder, flux-cored wire and preparation and application

ActiveCN108480875AImprove crack resistanceStable mechanical propertiesWelding/cutting media/materialsSoldering mediaFerrosiliconAluminium

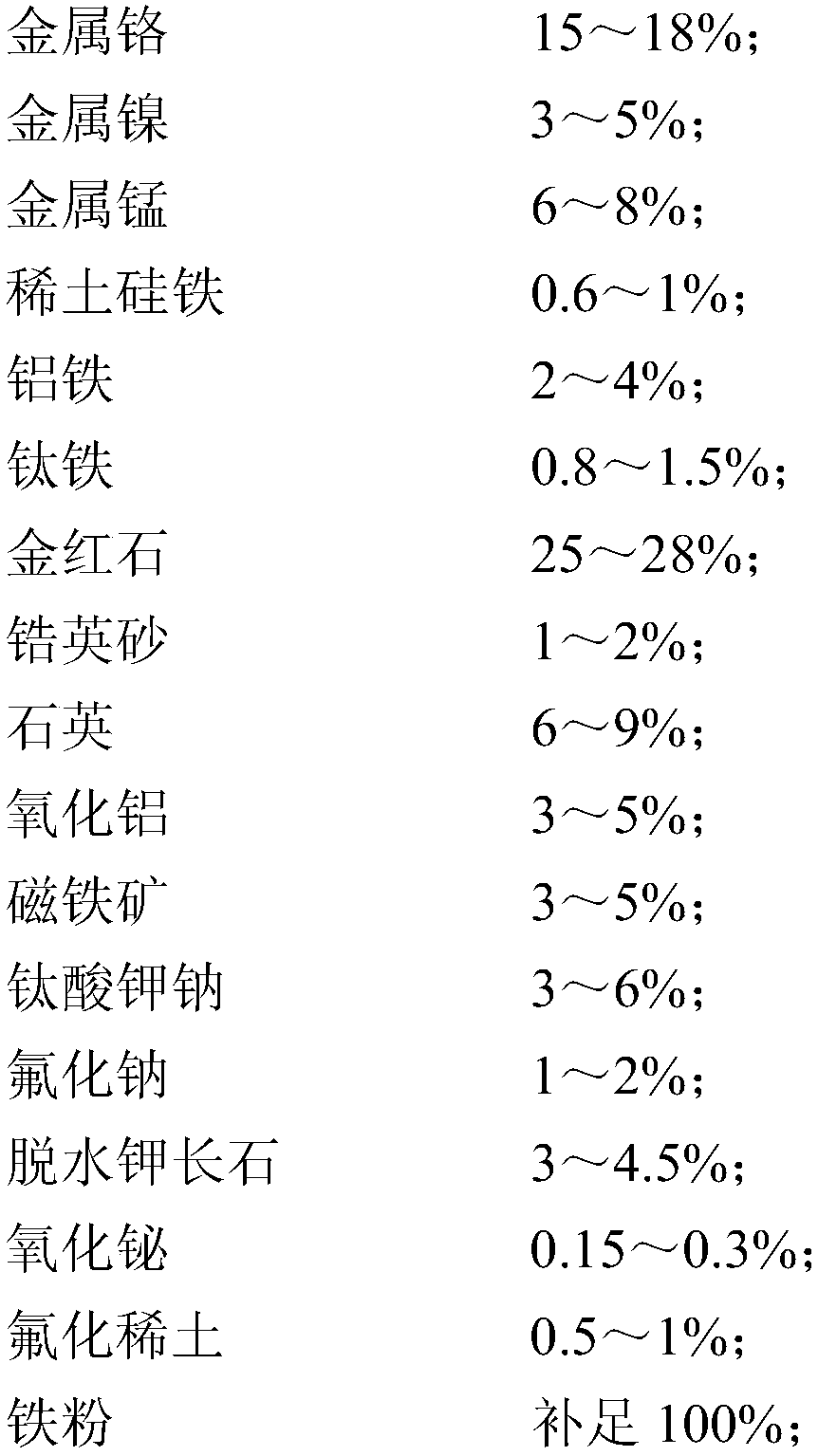

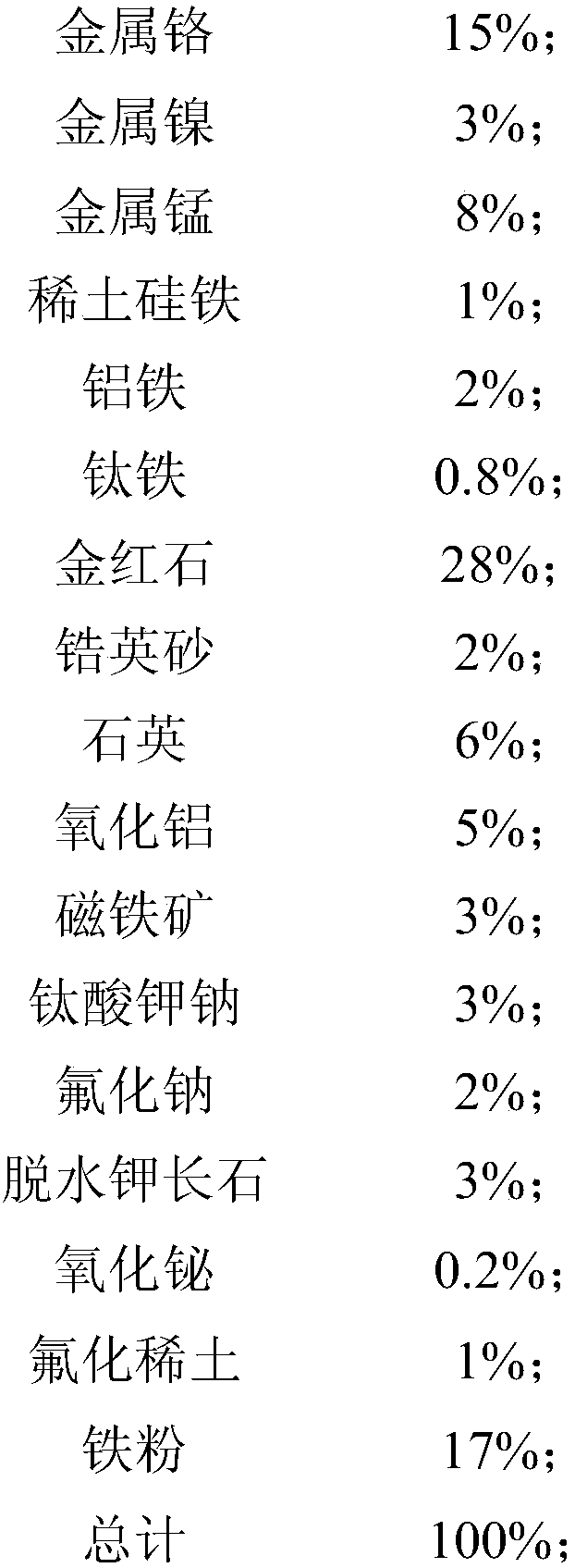

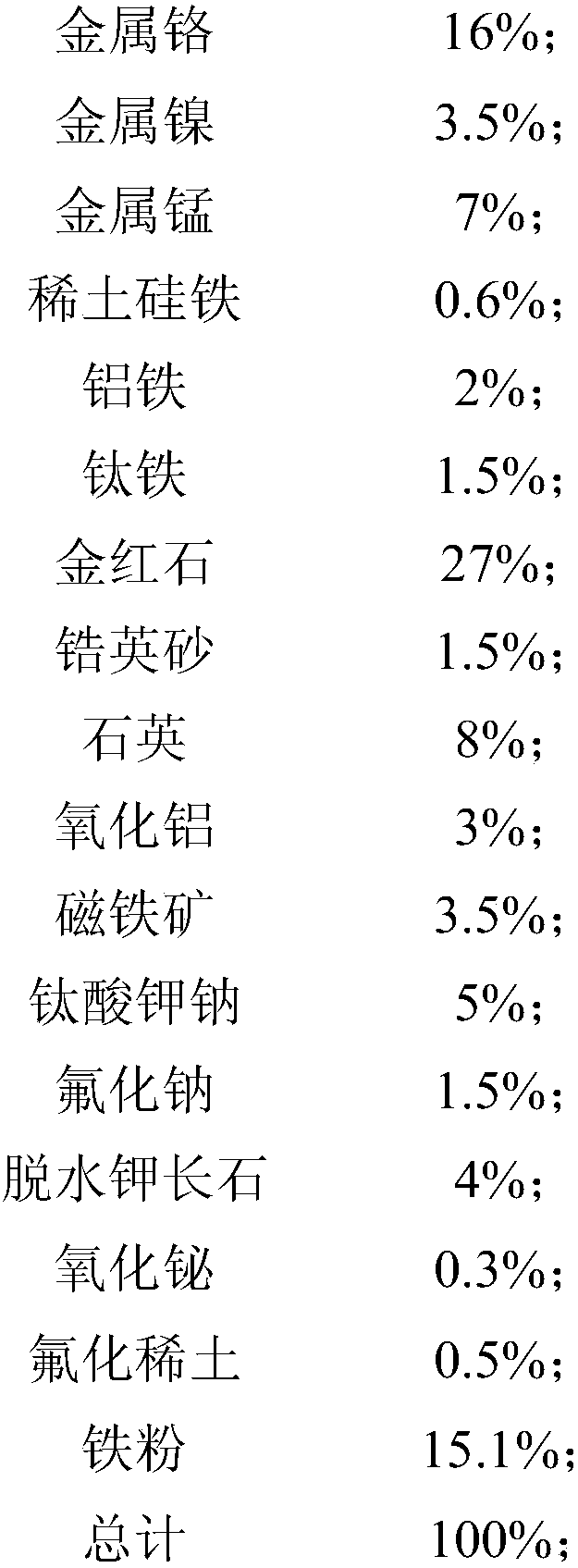

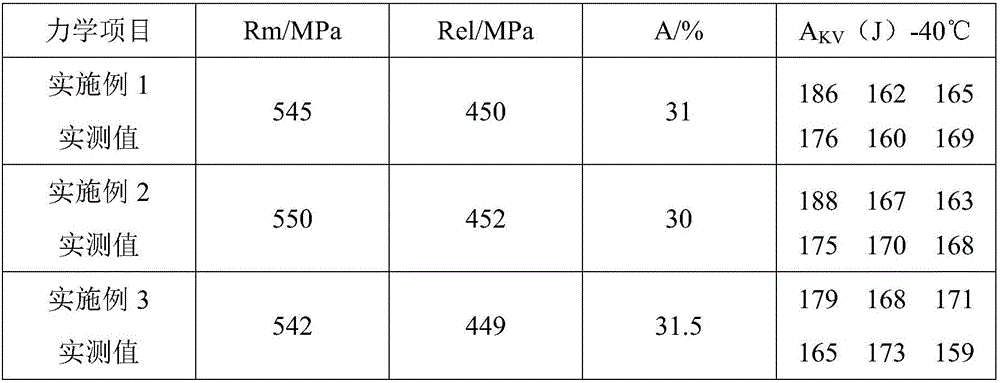

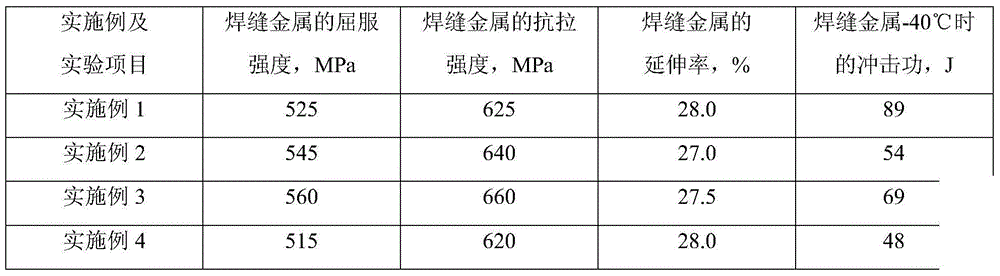

The invention belongs to the technical field of welding materials, and particularly relates to welding wire powder, flux-cored wire and preparation and application. The welding wire powder comprises,by mass, 15-18% of metal chromium, 3-5% of metal nickel, 6-8% of manganese metal, 0.6-1% of rare earth ferrosilicon, 2-4% of aluminum iron, 0.8%-1.5% of ferrotitanium, 25-28% of rutile, 1-2% of zirconsand, 6-9% of quartz, 3-5% of aluminum oxide, 3-5% of magnetite, 3-6% of potassium titanate, 1-2% of sodium fluoride, 3-4.5% of dehydrated potash feldspar, 0.15-0.3% of bismuth oxide, 0.5-1% of rareearth fluoride, and the balance iron powder. The invention further provides the flux-cored wire containing the powder. The flux-cored wire is good in welding process, small in splashing, good in spreading and fusing performance, stable in arc, easy to deslag, attractive in forming, and excellent in mechanical property.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High strength high tenacity high weather resistant gas protecting welding wire

InactiveCN1290661CThe smelting process is stableEasy to implementArc welding apparatusWelding/cutting media/materialsLine tubingChemical composition

Owner:武钢集团有限公司

Ship-building steel small-groove submerged-arc welding agent and preparation method thereof

InactiveCN106736044ALow hygroscopicityLow costWelding/cutting media/materialsSoldering mediaSlagRutile

The invention discloses a ship-building steel small-groove submerged-arc welding agent and a preparation method thereof. The ship-building steel small-groove submerged-arc welding agent comprises the following raw materials, by weight, of 15-28% of magnesite, 15-30% of white corundum, 10-25% of grammite, 10-20% of fluorite, 10-20% of rutile, 1-10% of manganese ores and 1-7% of silicon iron. The sum of the weight percentage of the components is 100%. The ship-building steel small-groove submerged-arc welding agent has low hygroscopicity; electric arc welding is stable; the slag detachability of the welding agent after welding is good; the appearance of a welded joint is attractive after forming; slag shells can automatic cock after welding; and no defects such as undercuts exist. The production efficiency is high, the comprehensive cost is low, the welding quality is good, and the welding agent is quite suitable for submerged arc welding under the condition of small grooves of ship-building steel.

Owner:SHANGHAI HULIN HEAVY IND +2

Gas protection welding wire for high-strength weathering steel and steel for gas protection welding wire

InactiveCN105195919AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaCopper platingWeathering steel

The invention provides a gas protection welding wire for high-strength weathering steel and steel for the gas protection welding wire. The steel for the gas protection welding wire comprises 0.015-0.08% of C, 0.70-1.50% of Mn, 0.20-0.80% of Si, 0.50-1.30% of Ni, 0.1-0.4% of Cu, 0.03-0.10% of Nb, 0.20% or less of Cr, 0.015% or less of S and 0.020% or less of P. The welding wire comprises 0.015-0.08% of C, 0.70-1.50% of Mn, 0.20-0.80% of Si, 0.50-1.30% of Ni, 0.15-0.50% of Cu, 0.03-0.10% of Nb, 0.20% or less of Cr, 0.015% or less of S and 0.020% or less of P. A copper plating layer is arranged on the surface of the welding wire, and the content of Cu accounts for 0.05-0.25% of the total weight of the welding wire. The welding wire is used for welding of steel of 600 MPa; when 80% Ar and 20% CO2 protection is adopted, deposited metal ReL is larger than or equal to 500 MPa, Rm is larger than or equal to 600 MPa, A is larger than or equal to 25%, and AKv at the temperature below -40 DEG C is larger than or equal to 40 J. The welding wire has the excellent welding technological performance, and is stable in welding arc, small in splashing, free of air hole, attractive in appearance and applicable to all-position welding.

Owner:ANGANG STEEL CO LTD

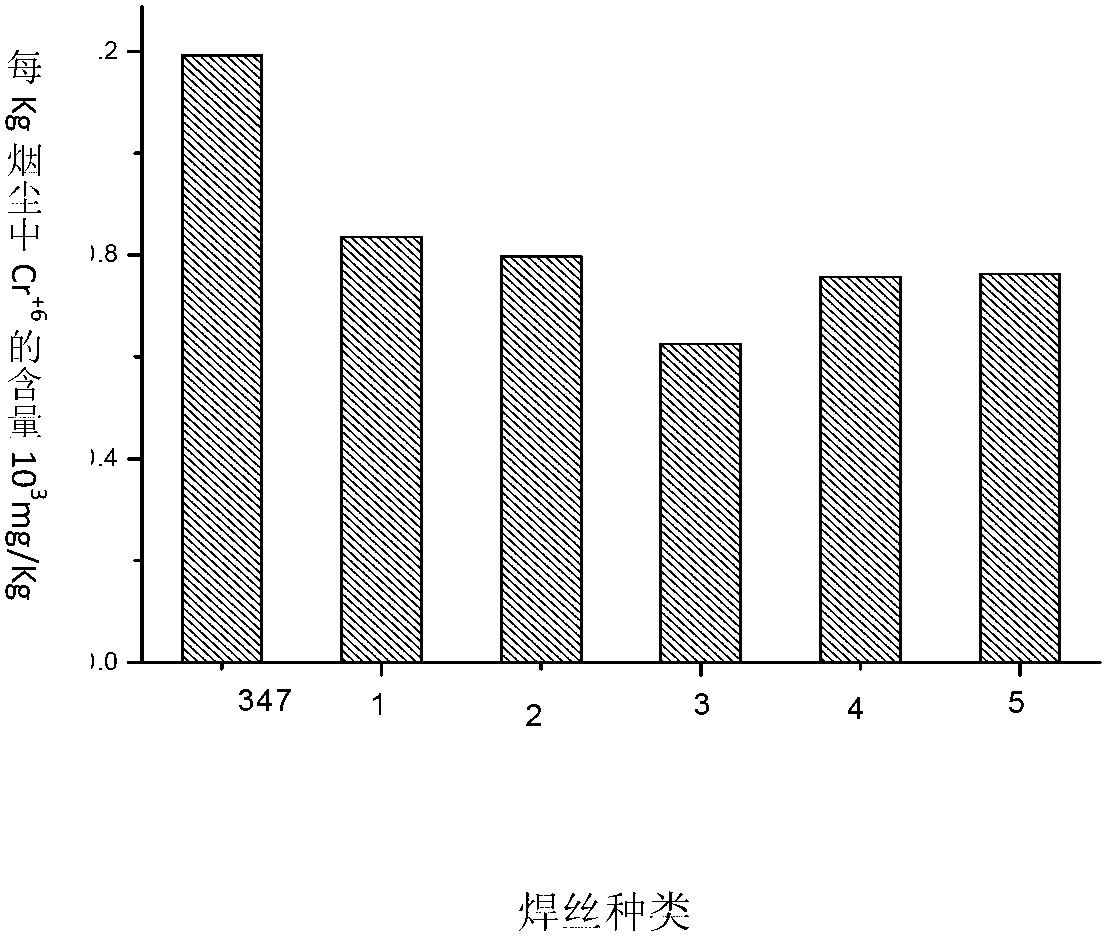

Chromium oxide green 308 austenitic stainless steel metal core welding stick and preparation method thereof

ActiveCN103008914ALow costEmission reductionArc welding apparatusWelding/cutting media/materialsManganeseFilling rate

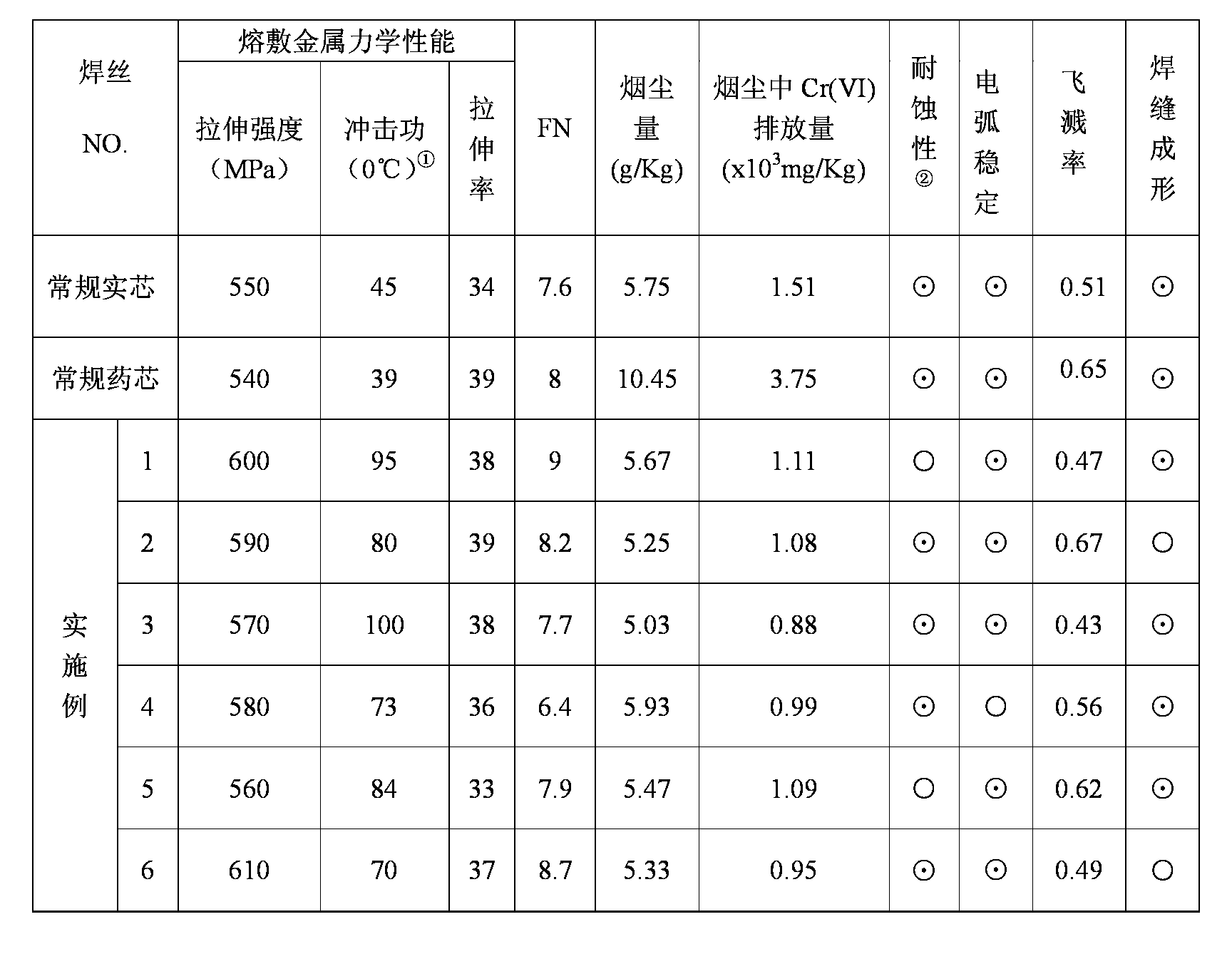

The invention relates to a chromium oxide green 308 austenitic stainless steel metal core welding stick and a preparation method thereof, and the welding stick and the preparation method thereof belong to the technical field of welding materials. The chemical components of the powder of a metal core are as follows: 0.03 weight percent to 0.065 weight percent of carbon (C), 52 weight percent to 58 weight percent of chromium (Cr), 26 weight percent to 30 weight percent of nickle (Ni), 4 weight percent to 6 weight percent of manganese (Mn), 0.66 weight percent to 1.5 weight percent of silicon (Si), 0.5 weight percent to 1 weight percent of titanium (Ti), 0.5 weight percent to 1 weight percent of zinc (Zn), 0.5 weight percent to 1 weight percent of zirconium (Zr), less than 0.03 weight percent of phosphorus (P), less than 0.03 weight percent of sulfur (S) the rest of ferrum (Fe). The filling rate is 26 percent to 38 percent. According to the chromium oxide green 308 austenitic stainless steel metal core welding stick and the preparation method thereof, under the condition of a little smaller amount of welding dust, the emission of toxic Cr (VI) can be reduced by 30 percent to 40 percent compared with the solid welding stick of the same type, and by 35 percent to 45 percent compared with a stainless steel flux-cored welding stick. Due to the adoption of the low-carbon steel strip, the cost of the welding stick can be greatly reduced, the welding stick has stable welding arc and little splash, a formed welding seam is attractive, and the comprehensive properties of deposited metal are excellent.

Owner:科威尔焊接(江苏)有限公司

Tungsten electrode argon arc welding transparent welding gun nozzle used for special angle

A transparent torch nozzle for the tungsten-argon arc welding in order to weld by a special angle is made of the refractory transparent Al2O3 (or MgO) ceramic. It can improve the weld qualility when the dead angle is welded.

Owner:HARBIN INST OF TECH

Stainless steel 347 metal core welding wire with low hexavalent chrome emission and preparation method of welding wire

ActiveCN103223561AStable welding arcBeautiful weld shapeArc welding apparatusWelding/cutting media/materialsWelding fumeMechanical property

A stainless steel 347 metal core welding wire with low hexavalent chrome emission and a preparation method of the welding wire are suitable for the field of welding materials. The welding wire comprises the following components: 0.025-0.07wt.% of C, 45-60wt.% of Cr, 25-31wt.% of Ni, 4-7wt.% of Mn, 0.66-1.5wt.% of Si, 0.3-2wt.% of Ti, 0.3-2wt.% of Zn, 0.3-2wt.% of Zr, 0.25-1.2wt.% of Nb, and the balance of Fe and unavoidable impurities. The welding wire and the preparation method ensure that the mechanical property of welding wire deposited metal is matched with that of base metal, and a stainless steel belt is replaced with a carbon steel belt, so that the cost is lowered; 30-60% of the total amount of hexavalent chrome (Cr<+6>) in welding fume is reduced; a welding operation environment is improved; and in addition, the welding wire and the preparation method have the advantages that splattering is low, and the combination property of the formed deposited metal is excellent.

Owner:栗卓新

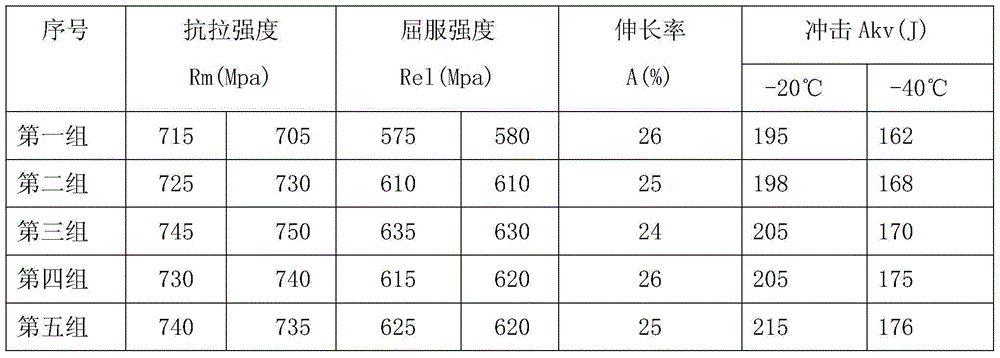

High-strength flux-cored wire capable of increasing penetration as well as preparation method and application of flux-cored wire

ActiveCN105345313AImprove securityReduced amount of filler metalWelding/cutting media/materialsSoldering mediaFerrosiliconRare earth

The invention discloses a high-strength flux-cored wire capable of increasing penetration as well as a preparation method and an application of the flux-cored wire. The flux-cored wire comprises powder and a tube wall for packing the powder, wherein the powder comprises components in percentage by mass as follows: 1%-5% of 75# ferrosilicon, 8%-15% of mid-carbon ferromanganese, 12%-18% of ferromolybdenum, 4%-9% of micro-carbon ferrochrome, 2%-5% of nickel metal powder, 1%-3% of ferrovanadium, 3%-6% of ferrotitanium, 1%-2% of a rare earth ferrosilicon alloy, 0-2.0% of K2CO3 powder, 0.5%-1.5% of potassium permanganate powder and the balance of Fe powder and inevitable impurities having no influence on the performance of the flux-cored wire. The high-strength flux-cored wire has the deeper penetration, so that a base material is not required to be grooved, or only a small groove is required to be formed and a large truncated edge is required to be reserved, the filler metal quantity is reduced, and the welding productivity is greatly improved. Meanwhile, the welding defect of incomplete fusion cannot be produced easily, and the safety of a welded structure is improved.

Owner:SHANDONG UNIV

Double-submerged-arc-welding thermal curing gasket welding flux for marine thick steel plate and preparing method for double-submerged-arc-welding thermal curing gasket welding flux

InactiveCN107309576AStable welding arcGood slag removalArc welding apparatusWelding/cutting media/materialsSlagSteel plates

The invention provides double-submerged-arc-welding thermal curing gasket welding flux for a marine thick steel plate and a preparing method for the double-submerged-arc-welding thermal curing gasket welding flux. The thermal curing gasket welding flux is made from base welding flux, resin and a curing agent. The base welding flux comprises, by weight, 20%-32% of magnesite clinker, 15%-30% of wollastonite, 15%-25% of aluminum oxide, 5%-15% of fluorite, 1%-10% of marble, 1%-10% of rutile, 1%-5% of silicon iron, and 1%-5% of manganese iron, the sum of the weight percentage of all constituents is 100%. The content of resin is 5%-15% of total weight of the base welding flux, and the content of the curing agent is 1%-3% of total weight of the base welding flux. After the double-submerged-arc-welding thermal curing gasket welding flux for the marine thick steel plate and the preparing method for the double-submerged-arc-welding thermal curing gasket welding flux are used, the welded arc is stable, slag detachability after welded is excellent, molding of the backside of a welding seam is attractive, the effects of being high in production efficiency, good in welding quality and low in welding flux cost are achieved, and the double-submerged-arc-welding thermal curing gasket welding flux for the marine thick steel plate and the preparing method for the double-submerged-arc-welding thermal curing gasket welding flux are suitable for a double-submerged-arc-welding technology of the marine thick steel plate.

Owner:SHANGHAI HULIN HEAVY IND +2

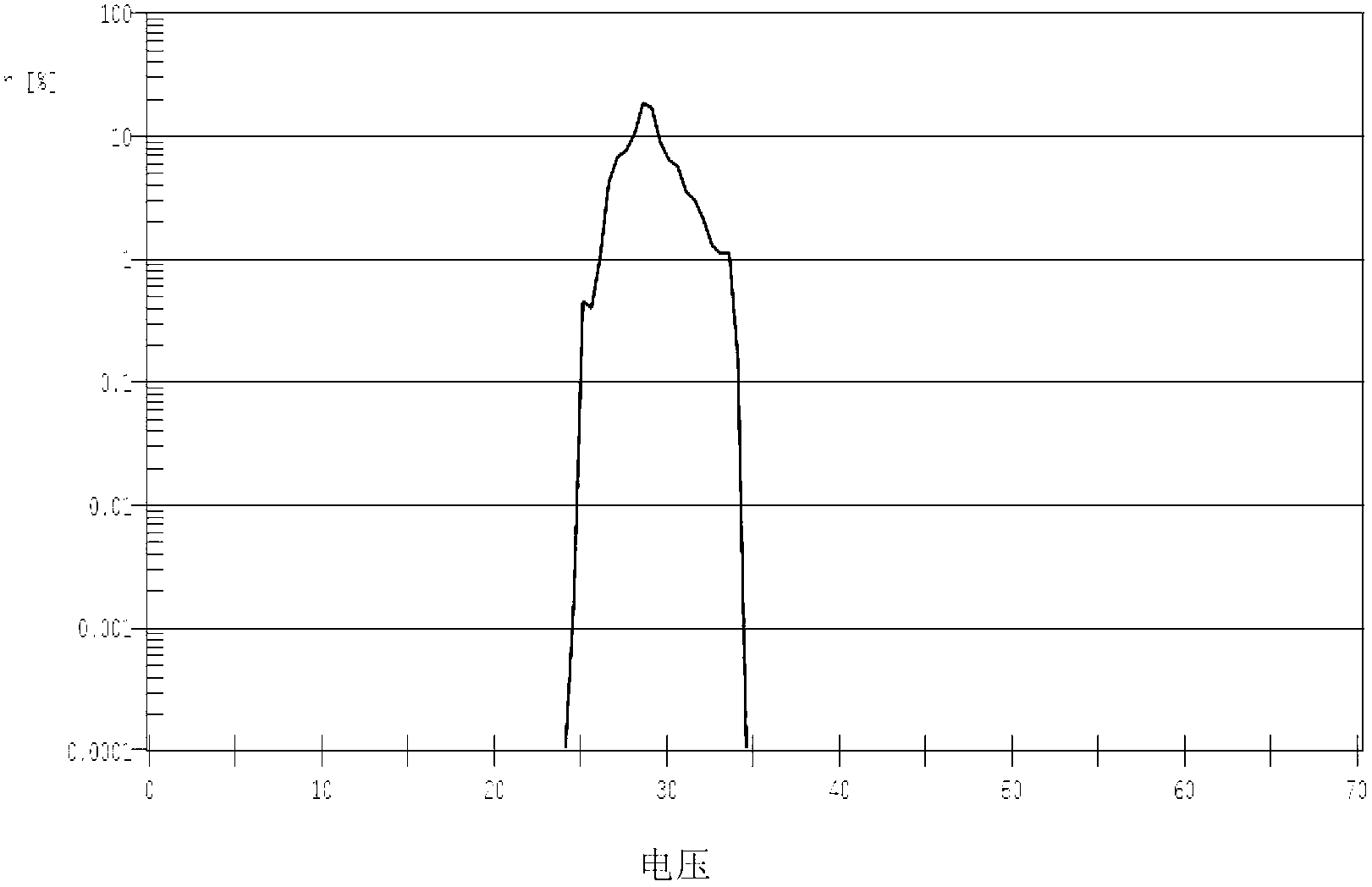

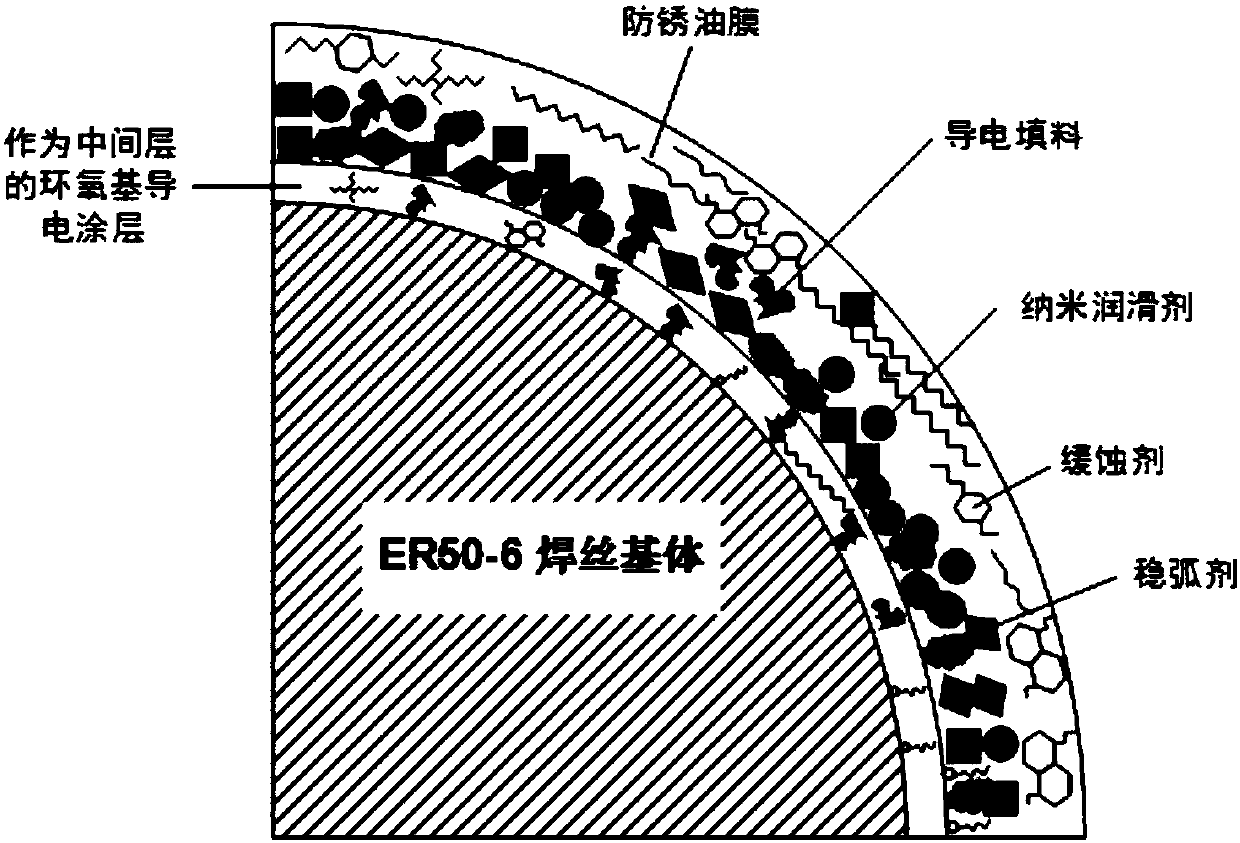

Dual-coating environment-friendly non-copper-coating robot solid welding rod with epoxy group electric conduction coating as middle layer and preparation method of same

ActiveCN107598413ASolve Adhesion ProblemsSolve conductivity problemsPolyether coatingsWelding/cutting media/materialsAdhesion forceEpoxy

The invention belongs to the field of welding rods and discloses a dual-coating environment-friendly non-copper-coating robot solid welding rod with an epoxy group electric conduction coating as a middle layer and a preparation method of the same. Dual coatings include the epoxy group electric conduction coating and a nano composite coating, wherein the epoxy group electric conduction coating is located between the nano composite coating and a matrix of the solid welding rod, and the mass ratio of the epoxy group electric conduction coating to the nano composite coating is (1.0-2.0): (2.3-4.2). By means of the dual-coating environment-friendly non-copper-coating robot solid welding rod with the epoxy group electric conduction coating as the middle layer and the preparation method of the same, the problems of poor adhesion force between the nano composite coating and the matrix of the welding rod and poor electric conductivity are solved.

Owner:BEIJING UNIV OF TECH

Sulfuric acid resistant pure austenitic stainless steel welding rod with high nickel-copper content and low hot cracking sensitivity and preparation method

ActiveCN109570824ANot prone to redness and crackingGood slag removalWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention discloses a pure austenitic stainless steel welding rod with high nickel-copper content and low hot cracking sensitivity. The sulfuric acid resistant pure austenitic stainless steel welding rod with high nickel-copper content and low hot cracking sensitivity is composed of a nickel-chromium-molybdenum-copper-iron alloy welding core and a coating which covers the surface of the welding core, wherein the coating is prepared from the components in parts by weight: 7-13 parts of rutile powder,4-8 parts of marble powder, 1.0-4.0 parts of fluorite powder 1.5-4.0 parts of mica powder, 1.5-3.0 parts of potassium feldspar powder, 2-3 parts of electrolytic manganese, 0.25-0.6 parts of niobium powder, 1.0-2.0 parts of metal chromium powder, 0.2-0.6 parts of molybdenum iron powder, 0.1-0.5 parts of sodium carbonate and 0.1-0.5 parts of sodium alginate. Compared with existing welding rods, the sulfuric acid resistant pure austenitic stainless steel welding rod with high nickel-coppercontent and low hot cracking sensitivity has excellent mechanical properties of deposited metal, high hot cracking resistance and excellent intergranular corrosion resistance.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

High-strength alloy solid cored welding wire

ActiveCN101716706BEasy to processLow costWelding/cutting media/materialsSoldering mediaMaterials scienceMetal

The invention relates to a high-strength alloy solid cored welding wire, which is characterized in that the welding wire comprises the following main chemical components in percentage by mass: 0.06 to 0.12 percent of C, 3.6 to 6.1 percent of Ni, 1.65 to 1.85 percent of Mn, 0.4 to 0.7 percent of Mo, 0.8 to 1.2 percent of Cr, 0.2 to 0.4 percent of Si, 0.03 to 0.06 percent of V, 0 to 0.05 percent ofRe, 0 to 0.015 percent of Ti, 0 to 0.015 percent of Al, 0 to 0.02 percent of Nb, and the balance of Fe. The welding wire adopts the design of Ni-Cr-Mo-Mn-V-Ti alloy, and is matched with other Si, Al,Re and Nb alloy elements, so that the comprehensive performance of steel grade such as obdurability, corrosion resistance, processability and the like are overall promoted. The welding wire has the advantages that: firstly, the welding wire has good processing technology performance, wire rod smelting and rolling and welding wire drawing processes thereof are easy to realize, and the welding wirehas lower cost; and secondly, the tensile strength sigma b of weld metal of the welding wire is more than or equal to 850MPa, the elongation delta 5 is more than or equal to 12 percent, and the impact work at the temperature of 50 DEG C below zero is more than or equal to 50J.

Owner:JIANGSU LIXIN ALLOY IND GENERAL

High-toughness gas protective welding wire for low alloy high-strength steel

InactiveCN1127390CLow costGood workmanshipWelding/cutting media/materialsSoldering mediaChemical compositionAlloy

The chemical composition of high-toughness gas shielded welding wire for low alloy high-strength steel contains (wt%): C 0.05-0.12, Mn 1.20-2.00, Ni 0.60-1.60, Si 0.30-1.20, Cu 0.10-0.50, Cu 0.10-0.60, Ti 0.10-0.20, B 0.02-0.010, S is less than or equal to 0.10, P is less than or equal to 0.20 and the rest is Fe and inevitable impurity elements. When said welding wire is used to make mixed gas (80% Ar+20% Co2) shielded arc welding the weld metal tensile strength is 700-800 MPa, and the persuccion power at -30 deg.C Akv is greater than or equal to 80J. Said invented with is applicable to gas shielded arc welding for 700 MPa low-alloy high-strength steel, and possesses good technological performance and is suitable for welding all positions.

Owner:武钢集团有限公司

High-corrosion-resistance gas protection welding wire

ActiveCN103028865BGood atmospheric corrosion resistanceImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaChemical compositionMetal

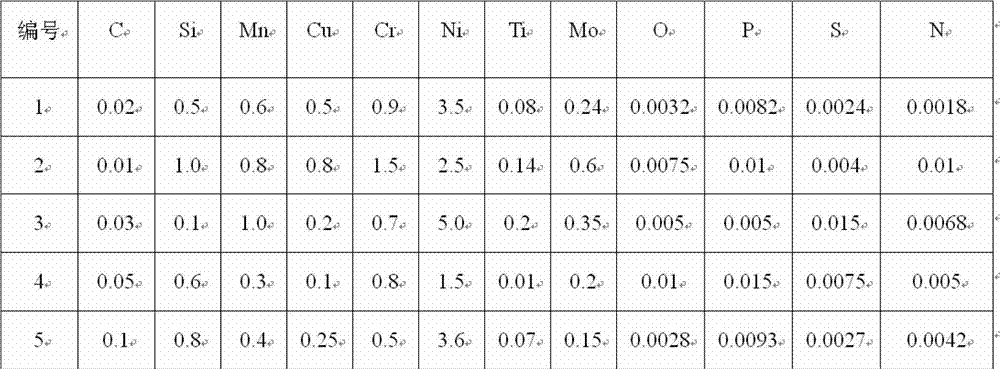

The invention belongs to the field of welding materials, and relates to a high-corrosion-resistance gas protection welding wire. The welding wire comprises the following chemical compositions in percentage by mass: 0.01-0.1 percent of C, 0.1-1.0 percent of Si, 0.3-1.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.015 percent of S, 1.5-5 percent of Ni, 0.5-1.5 percent of Cr, 0.1-0.8 percent of Cu, 0.01-0.2 percent of Ti, 0.15-0.6 percent of Mo, less than or equal to 0.01 percent of O, less than or equal to 0.01 percent of N and the balance of ferrum. The welding wire has stable welding performance, and obtained deposited metal is matched with the corrosion resistance of parent metal; and meanwhile, the welding wire has high comprehensive mechanical performance, and is particularly suitable for novel high-weather-proof steel.

Owner:CENT IRON & STEEL RES INST

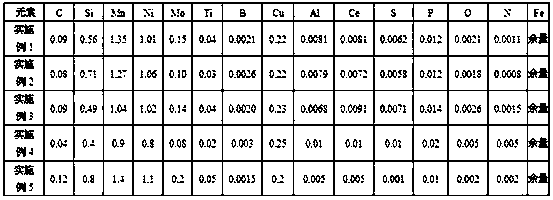

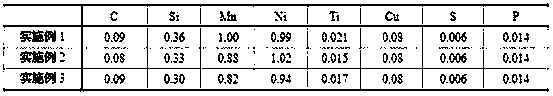

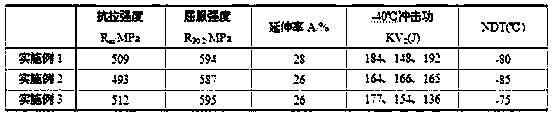

Gas shielded solid welding wire used for steel with yield strength being 460 MPa and manufacturing method

InactiveCN107598409AExcellent welding workabilityWell formed weldWelding/cutting media/materialsSoldering mediaIron powderMechanical property

The invention relates to a gas shielded solid welding wire used for steel with the yield strength being 460 MPa and a manufacturing method. The gas shielded solid welding wire comprises, by mass, 0.04%-0.12% of C, 0.9%-1.4% of Mn, 0.4%-0.8% of Si, 0.8%-1.1% of Ni, 0.08%-0.2% of Mo, 0.02%-0.05% of Ti, 0.0015%-0.0030% of B, 0.20%-0.25% of Cu, less than or equal to 0.01% of Al, less than or equal to0.010% of S, less than or equal to 0.020% of P, less than or equal to 0.005% of O, less than or equal to 0.005% of N, 0.0050%-0.010% of Ce, and the balance iron powder and unavoidable impurities. Whengas shielded welding with 80% of Ar and 20% of CO2 is conducted, the mechanical properties of deposited metal reach welding requirements of steel with the yield strength being 460 MPa and used for marine engineering, impact energy at -40 DEG C is over 120 J, and NDT is below -60 DEG C.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com