Chromium oxide green 308 austenitic stainless steel metal core welding stick and preparation method thereof

A technology of austenitic stainless steel and metal core, applied in metal processing equipment, welding equipment, welding equipment, etc., can solve the problem of high cost of stainless steel strip, and achieve the effect of excellent comprehensive performance, beautiful weld shape and small spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

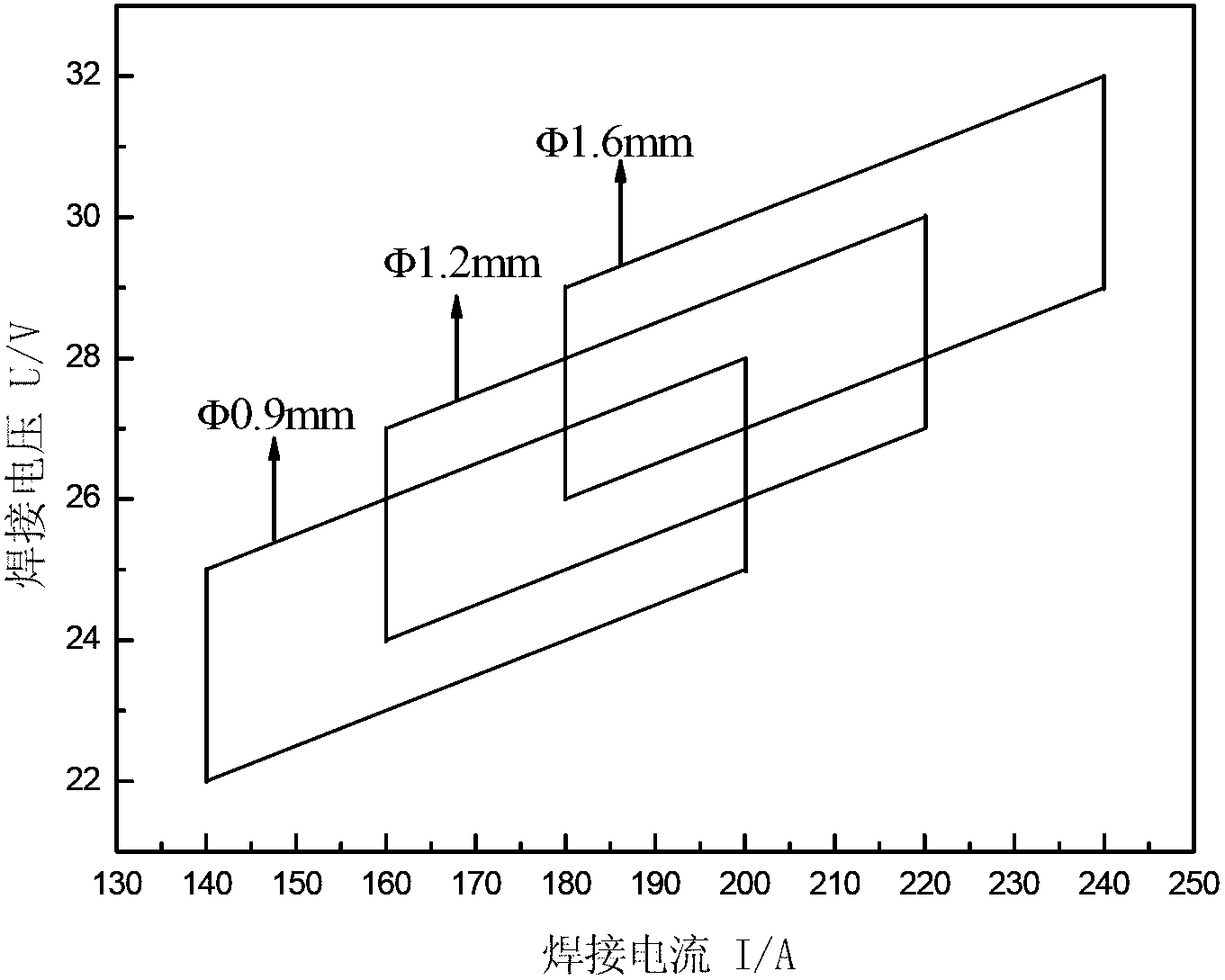

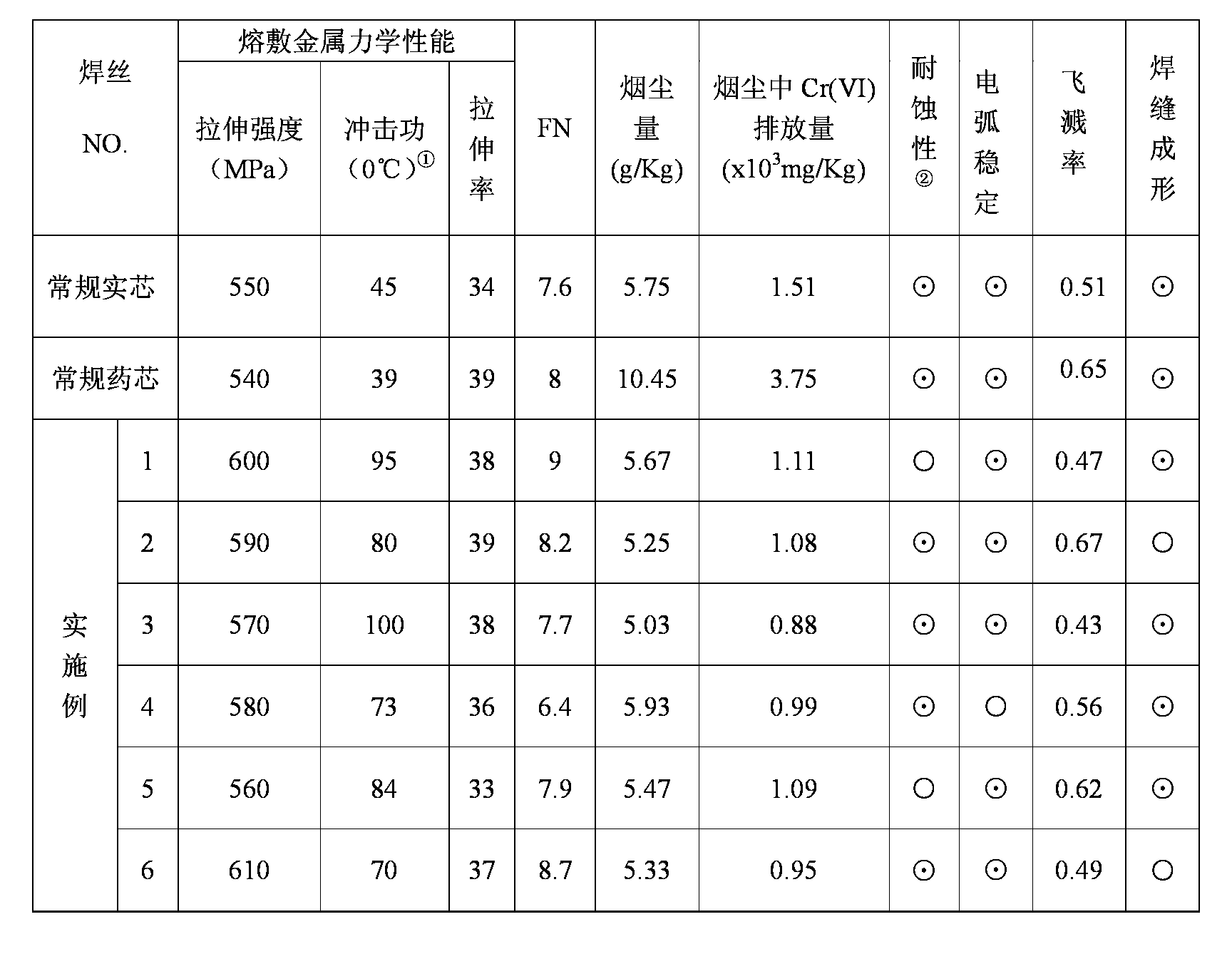

[0022] 1. A low-hexavalent chromium 308 austenitic stainless steel metal-cored welding wire, the mass percentage of the chemical composition in the welding wire is: C: 0.03wt.%; Cr: 48wt.%; Ni: 24wt.%; Mn: 4wt.%; Si: 0.66wt.%; Ti: 0.5wt.%; Zn: 0.5wt.%; Zr: 0.5wt.%; Fe: balance. The filling rate of the powder in the steel belt is 26%. Using 95%Ar+5%O 2 The welding process parameters of gas shielded welding are: voltage 25V; current 210A; wire feeding speed 420mm / min; gas flow rate 20L / min; The composition of the deposited metal prepared by the above process is: Cr: 19.2wt.%; Ni: 9.1wt.%; Mn: 1.2wt.%; Si: 0.41wt.%;

[0023] 2. A low-Cr (VI) 308 austenitic stainless steel metal-cored welding wire. The mass percentage of the chemical composition in the welding wire is: C: 0.03wt.%; Cr: 52wt.%; Ni: 26wt.%; Mn: 4wt.% ; Si: 0.66wt.%; Ti: 0.5wt.%; Zn: 0.5wt.%; Zr: 0.5wt.%; The filling rate of the powder in the steel belt is 28%. Using 96%Ar+4%O 2 The welding process parameters o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com