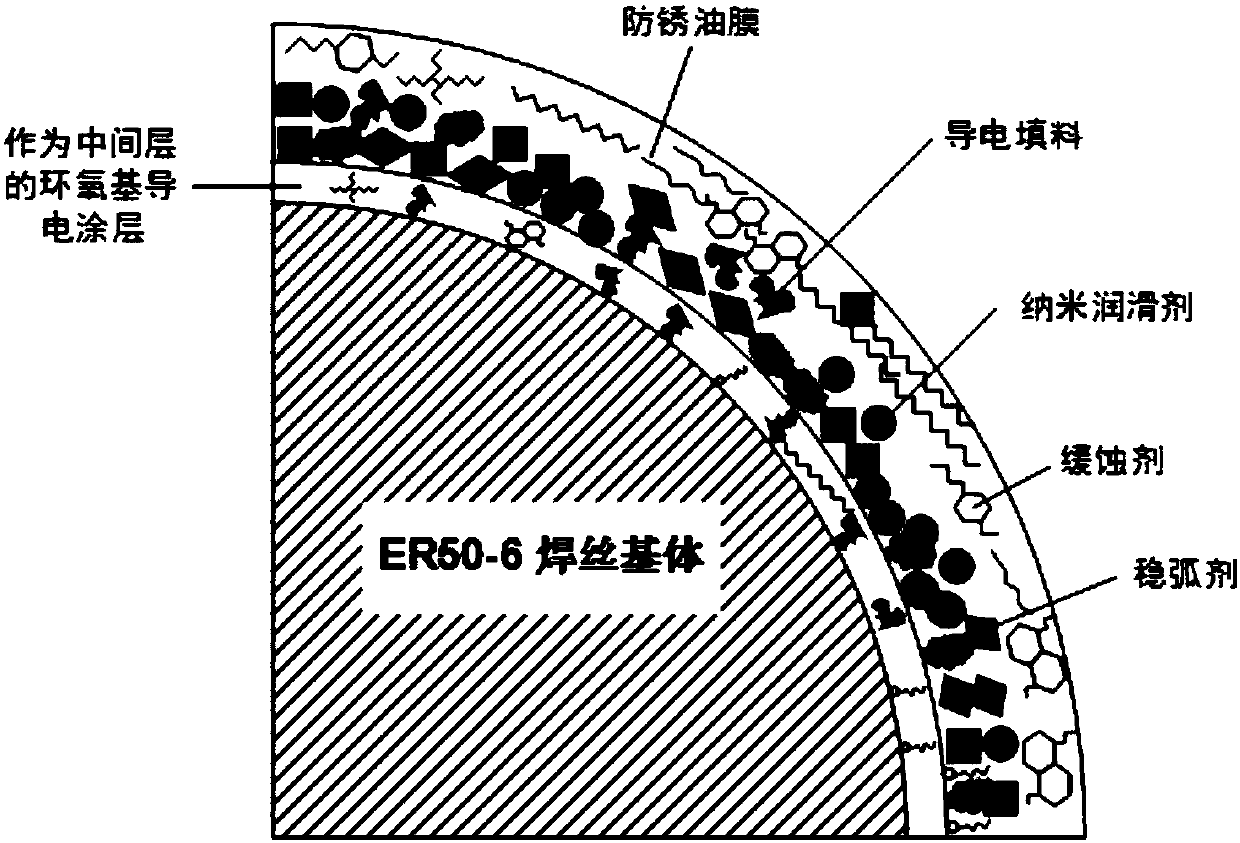

Dual-coating environment-friendly non-copper-coating robot solid welding rod with epoxy group electric conduction coating as middle layer and preparation method of same

A conductive coating and solid welding wire technology, applied in the direction of conductive coating, epoxy resin coating, coating, etc., can solve the problems of increased wire feeding resistance, pollution of the surrounding environment, poor rust resistance and poor conductivity of welding wire, and achieve welding Stable arc, low coating peeling rate, excellent wire feedability and alignment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An epoxy-based conductive coating is used as a double-coated solid welding wire for an environmentally friendly non-copper-plated robot as an intermediate layer, wherein every 10kg of welding wire contains 1.1g of an epoxy-based conductive coating.

[0036] The epoxy-based conductive coating is composed of the following substances by weight percentage: 36% polyoxyalkylene glycol diglycidyl ether, 12% dicyandiamide, 7.3% calcium carboxylate, 10% nickel powder, 15% carbon fiber powder, 0.9% oleic acid, 1.3% sodium dodecylbenzene sulfonate, 8% dimethyl phthalate, 9.5% low molecular weight polyamide.

[0037] The epoxy-based conductive coating is prepared as follows:

[0038] (1) Put the polyoxyalkylene glycol diglycidyl ether resin in a blast drying oven at a constant temperature of 110°C, keep it warm for 3 hours, and remove the moisture in the resin;

[0039] (2) Dissolve nickel powder and carbon fiber powder in absolute ethanol, add oleic acid and sodium dodecylbenzene...

Embodiment 2

[0045] An epoxy-based conductive coating is used as a double-coated solid welding wire for an environment-friendly non-copper-plated robot as an intermediate layer, wherein every 10kg of welding wire contains 1.6g of an epoxy-based conductive coating.

[0046] The epoxy-based conductive coating is composed of the following substances by weight percentage: 38% dicyclopentadiene dioxide, 13% diethylenetriamine, 8.7% 2,4,6-tris(dimethylaminomethyl)phenol (DMP- 30), 3.9% graphene, 10.8% carbon black, 8% carbon powder, 1.2% sodium stearate, 0.5% γ-aminopropyltriethoxysilane, 7% dibutyl phthalate, 8.9% polyepichlorohydrin.

[0047] The epoxy-based conductive coating is prepared as follows:

[0048] (1) Put the dicyclopentadiene dioxide resin into a blast drying oven at a constant temperature of 105° C., keep it warm for 3 hours, and remove the moisture in the resin;

[0049] (2) Dissolve graphene, carbon black, and carbon powder in absolute ethanol, add sodium stearate and γ-amino...

Embodiment 3

[0055] An epoxy-based conductive coating is used as a solid welding wire for a double-coated environmental protection non-copper-plated robot as an intermediate layer, wherein every 10kg of welding wire contains 2.0g of an epoxy-based conductive coating.

[0056] The epoxy-based conductive coating is composed of the following substances by weight percentage: 45% bisphenol A diglycidyl ether, 15% triethylenediamine, 5.1% dimethylimidazole, 4% nickel powder, 5% carbon fiber powder, 7 % multi-walled carbon nanotubes, 0.5% oleic acid, 0.7% sodium stearate, 7% tricresyl phosphate, 10.7% polydibutylene epoxy resin.

[0057] The epoxy-based conductive coating is prepared as follows:

[0058] (1) Put the bisphenol A diglycidyl ether resin in a blast drying oven at a constant temperature of 115°C, keep it warm for 3 hours, and remove the moisture in the resin;

[0059] (2) Dissolve nickel powder, carbon fiber powder, and multi-walled carbon nanotubes in absolute ethanol, add oleic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com