Melamine fumiture surface paper coated with ultrasonic violet curing coating and preparation method

A melamine paper and curing paint technology, applied in the field of building decoration materials, can solve the problems of unsatisfactory adhesion of the topcoat coating on melamine paper, cracking and peeling of the surface paint film, etc., and achieve recoatability, fast curing speed, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

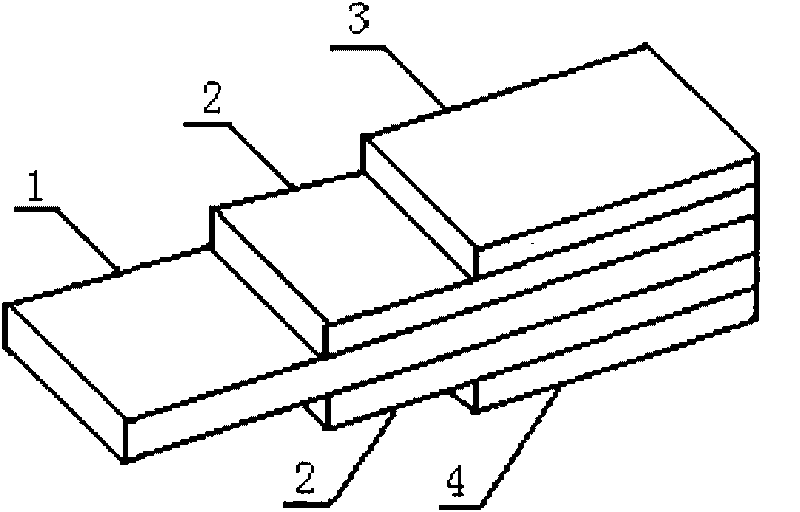

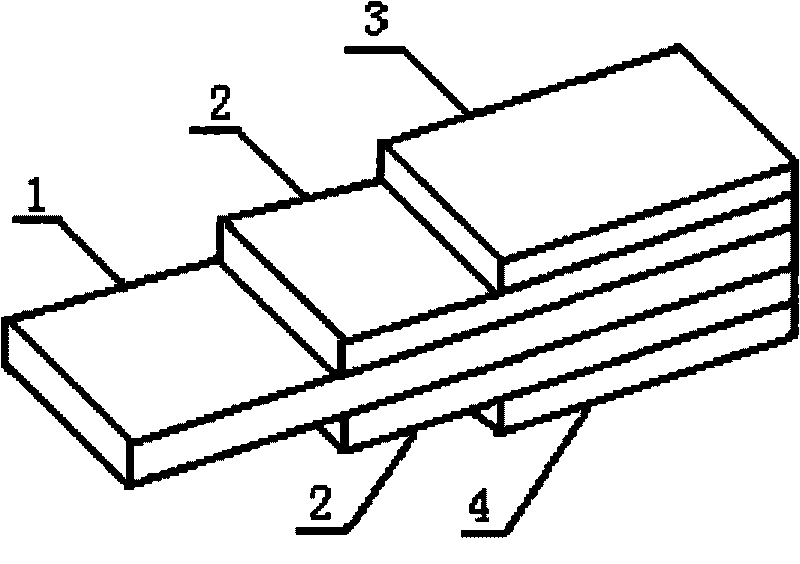

[0042] Embodiment 1. Imitation wood grain melamine paper

[0043] See figure 1 . Plain paper substrate 1 is 80g / m 2 For plain paper, first print the background color and wood grain pattern on the printing machine, dip the plain paper substrate 1 in a solution containing 50wt% melamine formaldehyde resin with a viscosity of 15 seconds, and control the amount of gluing to 150-160g / m 2 The resin solution is then put into 3 sections (4 meters each) for drying in a horizontal oven, the temperature is controlled at 130-140°C, the transmission speed is 20m / min, and then roll-coated on one side of the paper with the melamine adhesive layer 2 impregnated once One layer of UV-curable coating 3 with a thickness of 30um enters a photocuring machine equipped with two 9.6kw UV lamps (high-pressure mercury lamps) and a transmission speed of 20m / min. The other side of the paper is roller-coated with a viscosity of 15 seconds, containing 50wt% melamine formaldehyde resin solution, and the amo...

Embodiment 2

[0045] Example 2. Patterned melamine paper with patterns

[0046] See figure 1 . Plain paper substrate 1 is 120g / m 2 Ordinary paper, first print a pre-designed pattern on the printing machine, immerse the ordinary paper substrate 1 in a solution of melamine-formaldehyde resin with a viscosity of 18 seconds, and control the amount of gluing to 240-250g / m 2 The resin solution is then dried in a 4-section (4 meters per section) horizontal oven, the temperature is controlled at 170-180°C, the transmission speed is 10m / min, and then a layer of thickness is rolled on the paper side impregnated with melamine glue 2 UV-curable coating 3 of 50um enters a photocuring machine equipped with 3 15kw UV lamps (high-pressure mercury lamps) and a transmission speed of 10m / min. After curing, it is rolled on the other side of the paper impregnated with melamine glue 2 once One layer has a viscosity of 18 seconds, contains 60wt% melamine formaldehyde resin solution, and controls the amount of ...

Embodiment 3

[0048] Example 3. Solid color melamine paper

[0049] See figure 1 . Plain paper substrate 1 is 40g / m 2 Ordinary paper, first print bright red on the printing machine, immerse the ordinary paper substrate 1 in the viscosity of 12 seconds, containing 30wt% melamine formaldehyde resin solution, the amount of glue is controlled to 80 ~ 90g / m 2 The resin solution is then put into 2 sections (4 meters each) for drying in a horizontal oven, the temperature is controlled at 110-120°C, the transmission speed is 30m / min, and then a layer of thickness is rolled on one side of the paper impregnated with melamine glue 2 10um UV-curable coating 3, enter a light curing machine equipped with 1 18kw UV lamp (high-pressure mercury lamp), and the transmission speed is 30m / min, after curing, roll coat on the other side of the paper impregnated with melamine glue 2 once One layer has a viscosity of 12 seconds, contains 30wt% melamine-formaldehyde resin solution, and the amount of glue applied ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com