Device and method for continuously coating fiber with metallic conductive function film through magnetron sputtering

A technology of magnetron sputtering and metal plating, which is applied in the direction of sputtering plating, metal material coating process, ion implantation plating, etc., to achieve high production efficiency, good process stability and repeatability, and the effect of tight and firm film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

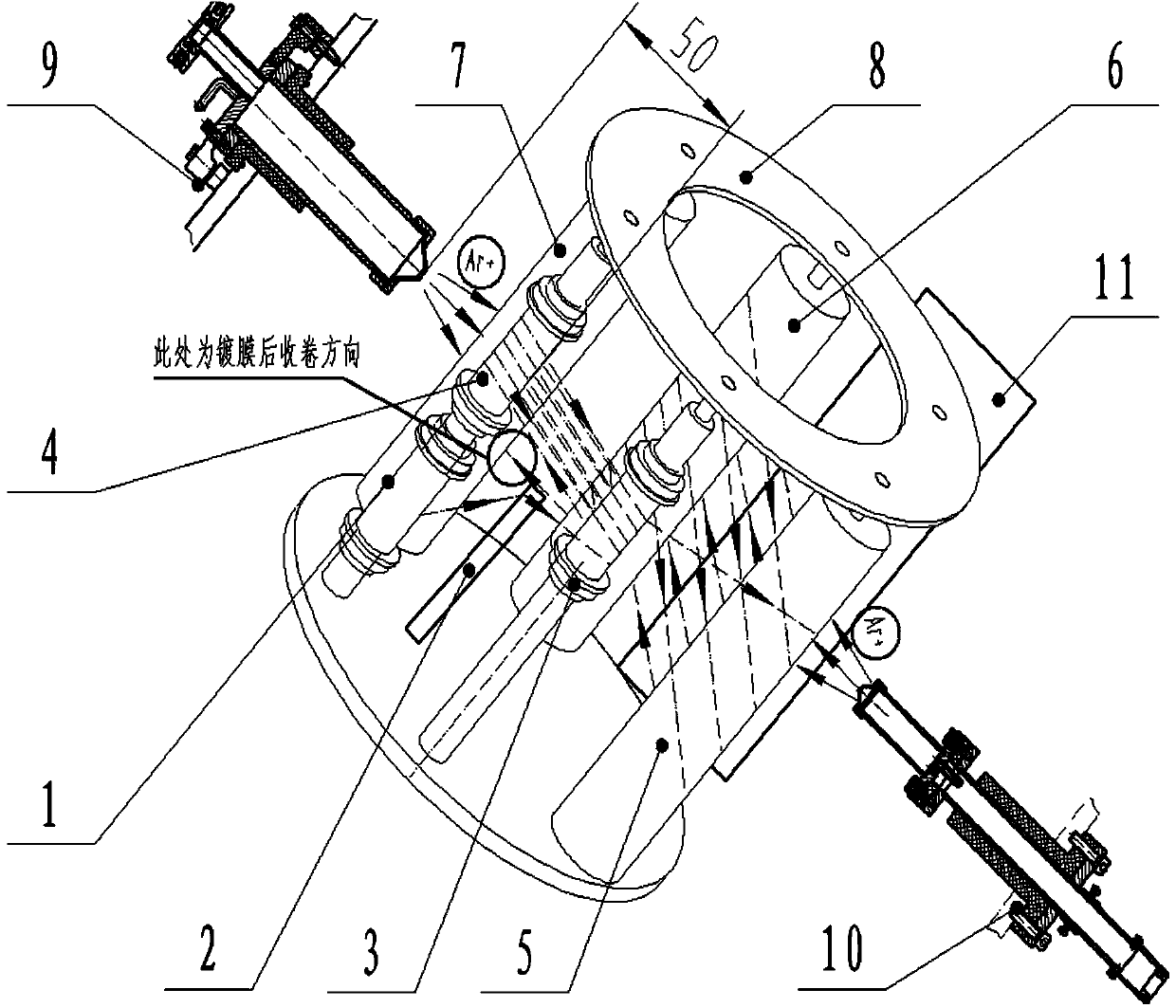

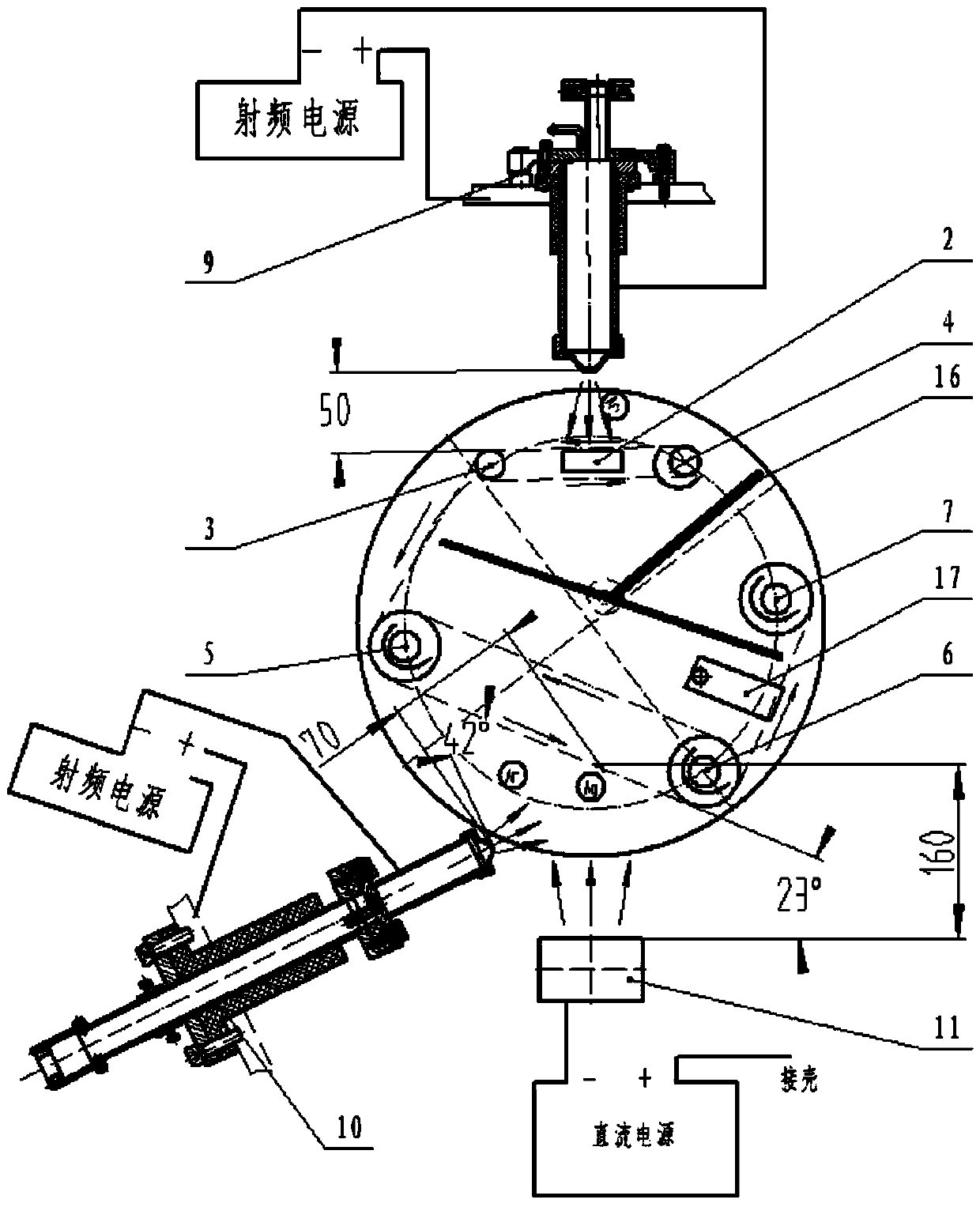

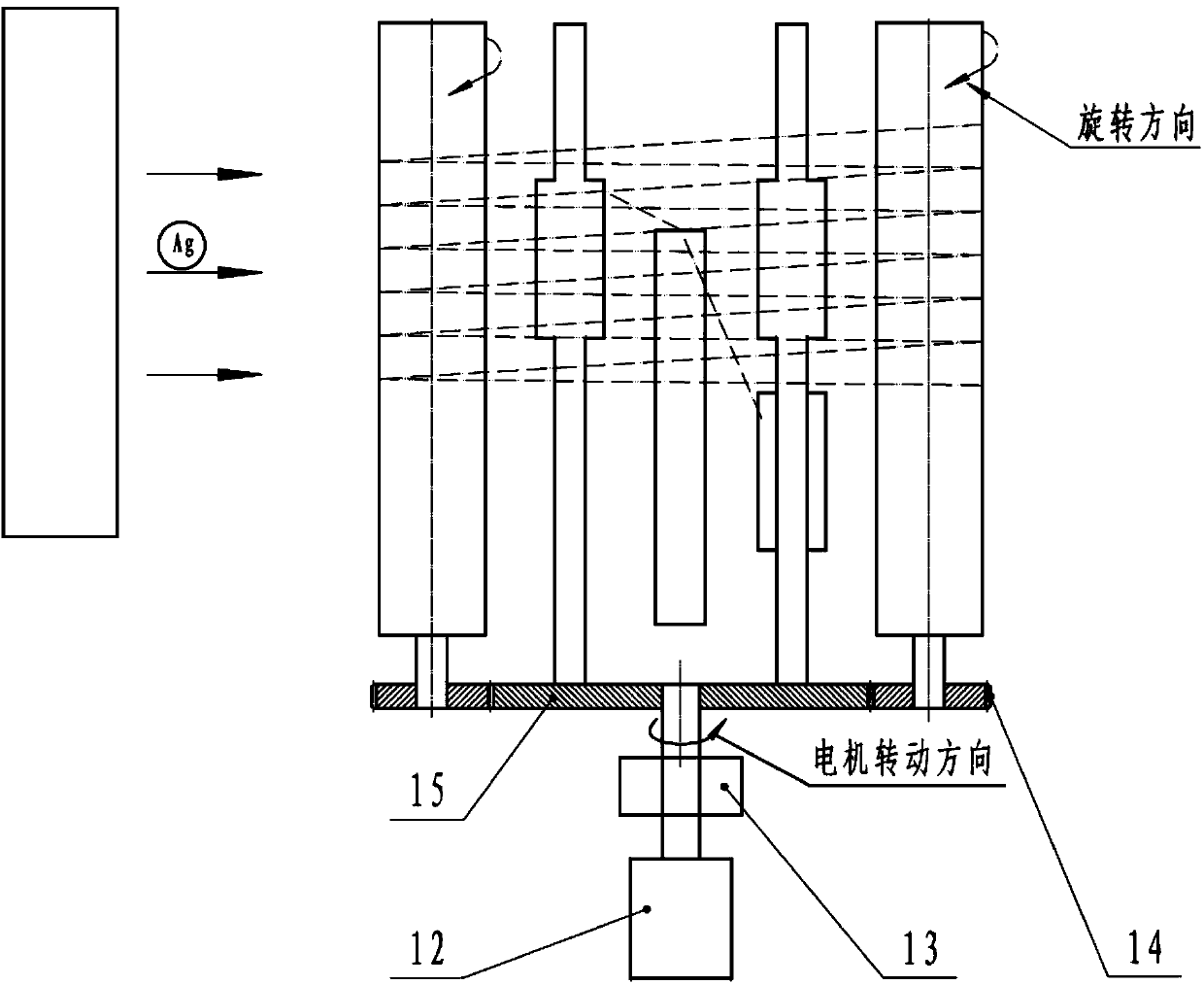

[0037] The monofilament fiber is first passed through the tension controller 2 by the unwinding device 1, and then passes through the guide device A3 and the guide device B4 to form a 4-turn cycle so that the fiber thread passes through the plasma cleaning device 9 in parallel for cleaning and coarsening treatment. The distance is 60mm, and the power 50W. The processed fiber thread is transferred from the guide device A3 to the guide device C5, and the guide device C5 and the guide device D6 form a pair of turns, and the number of turns is 18 turns, so that the fiber thread passes through the plasma-assisted coating device 10 (the distance is 80mm, the power 10W) and a rectangular magnetron sputtering target 11 (distance 170mm, power 90W), and finally adjust the position of the fiber thread through the fiber displacement device 17, so that the fiber thread is collected in the winding device 7.

[0038] After the fiber thread is wound, the vacuum chamber is evacuated to 2.0×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com