Patents

Literature

351 results about "Welding fume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fumes generated by the process of joining or cutting pieces of metal by heat, pressure, or both. Molecular Weight Properties vary depending upon the specific component of the welding fumes.

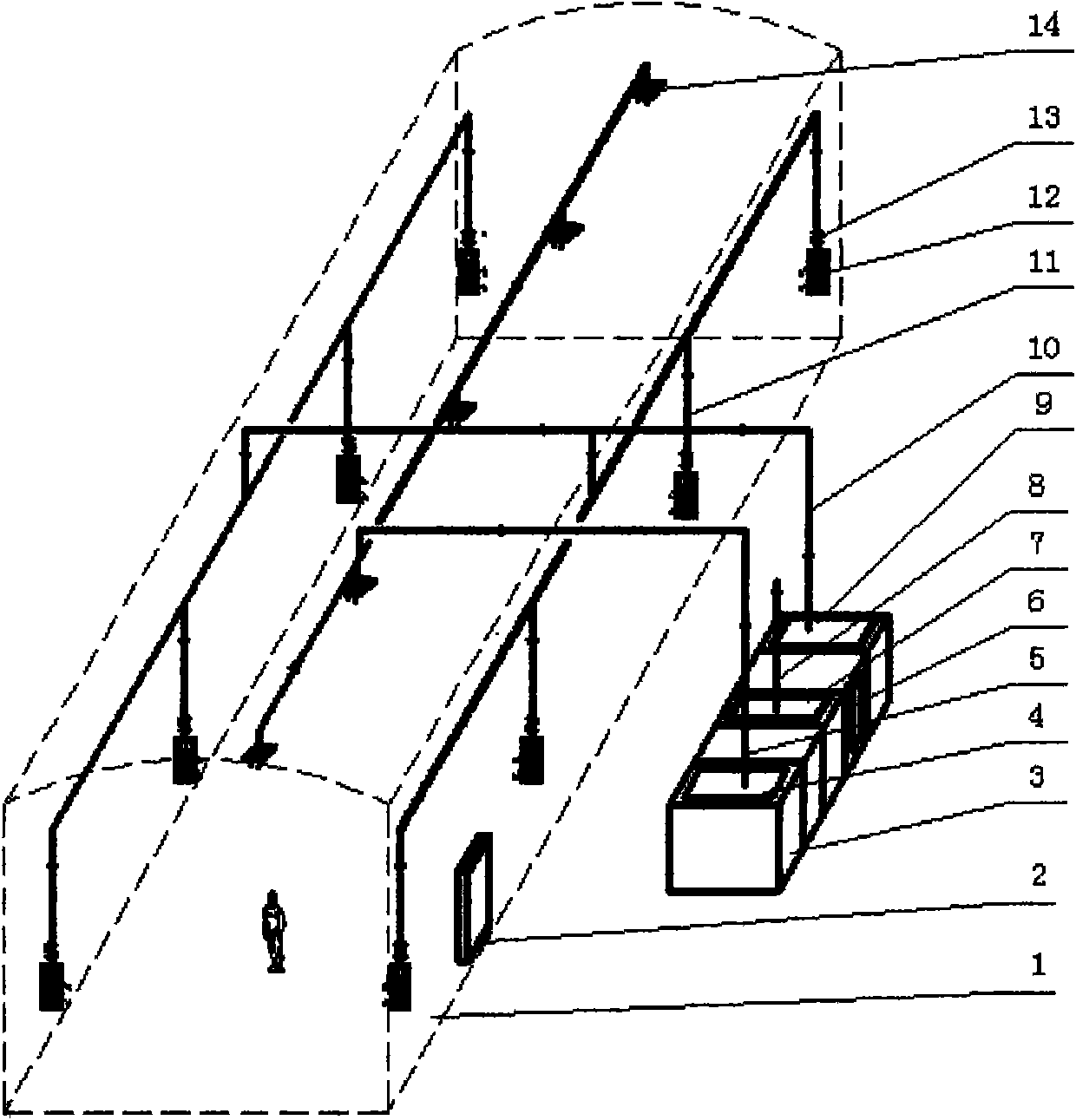

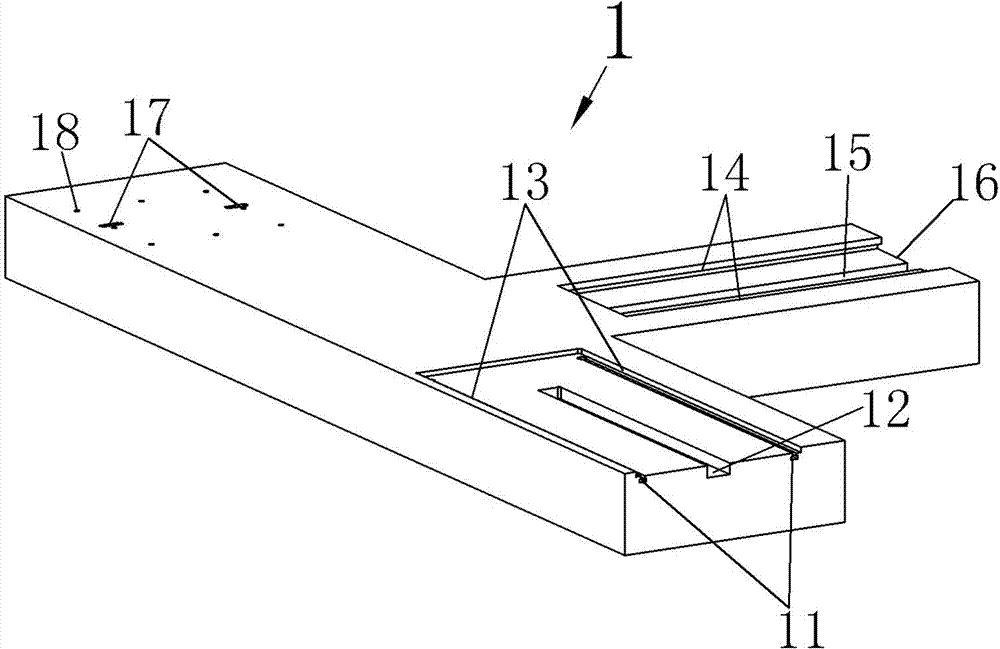

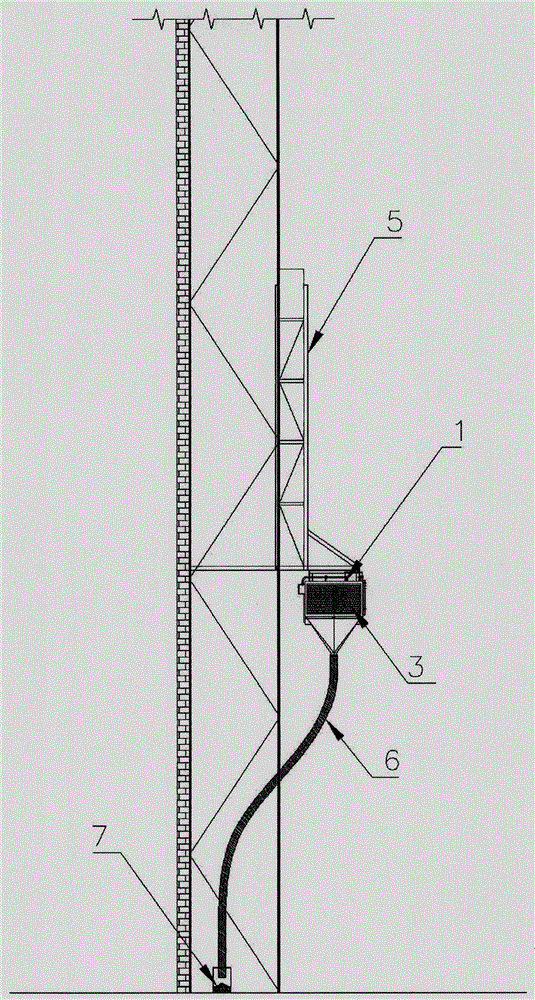

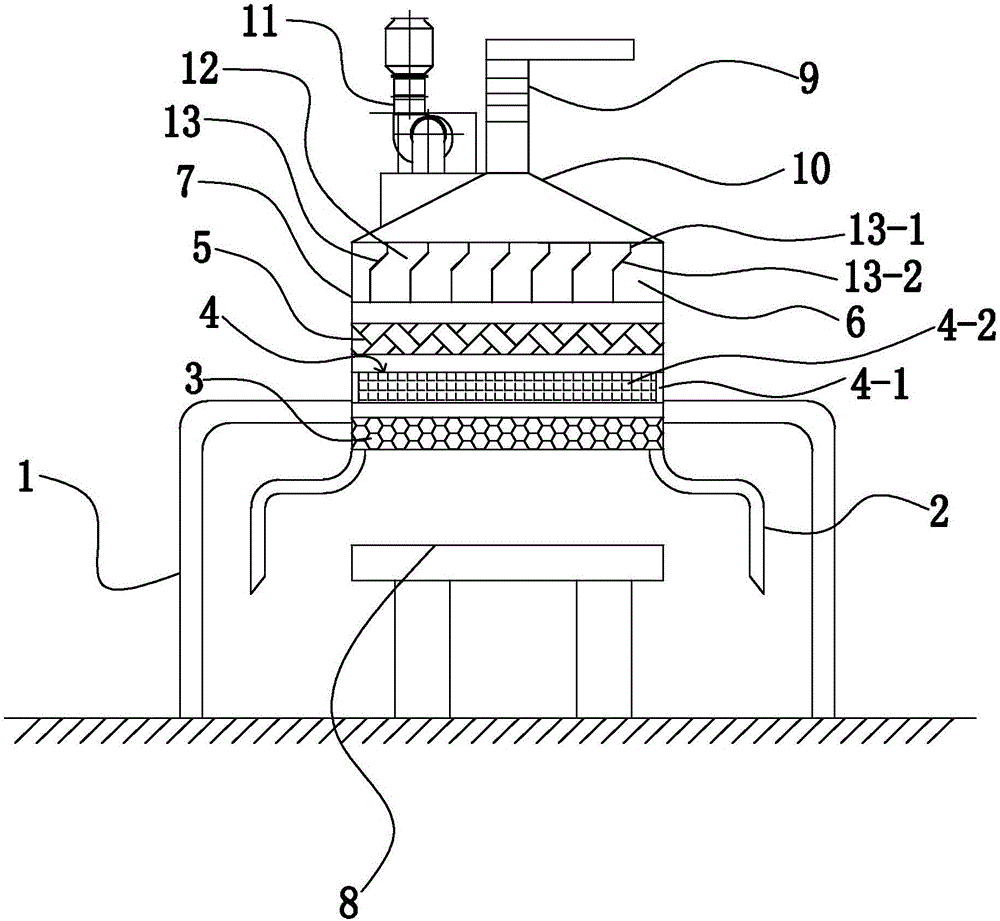

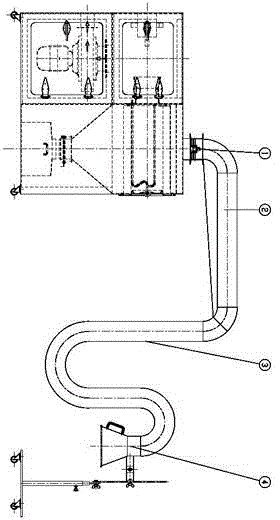

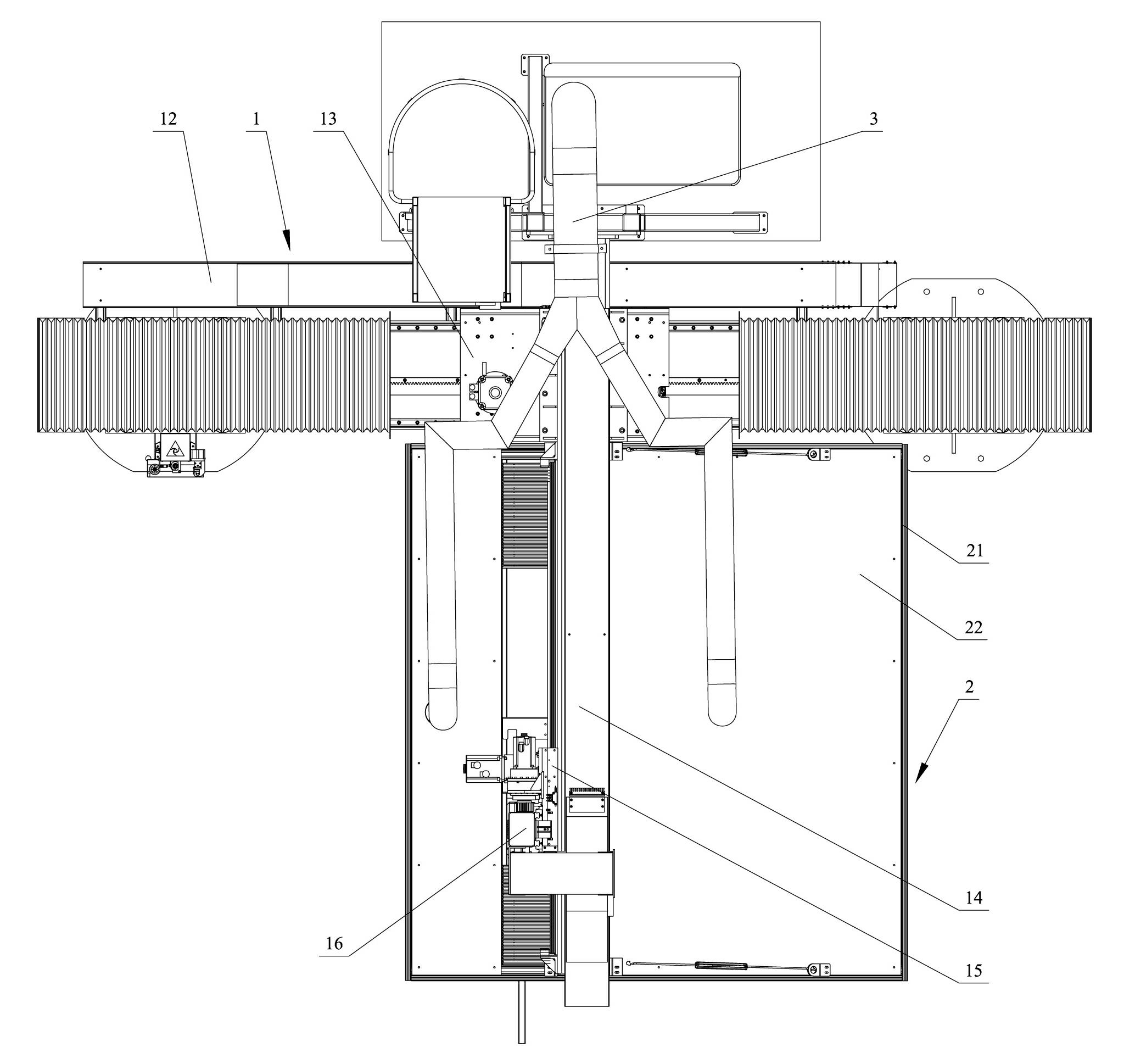

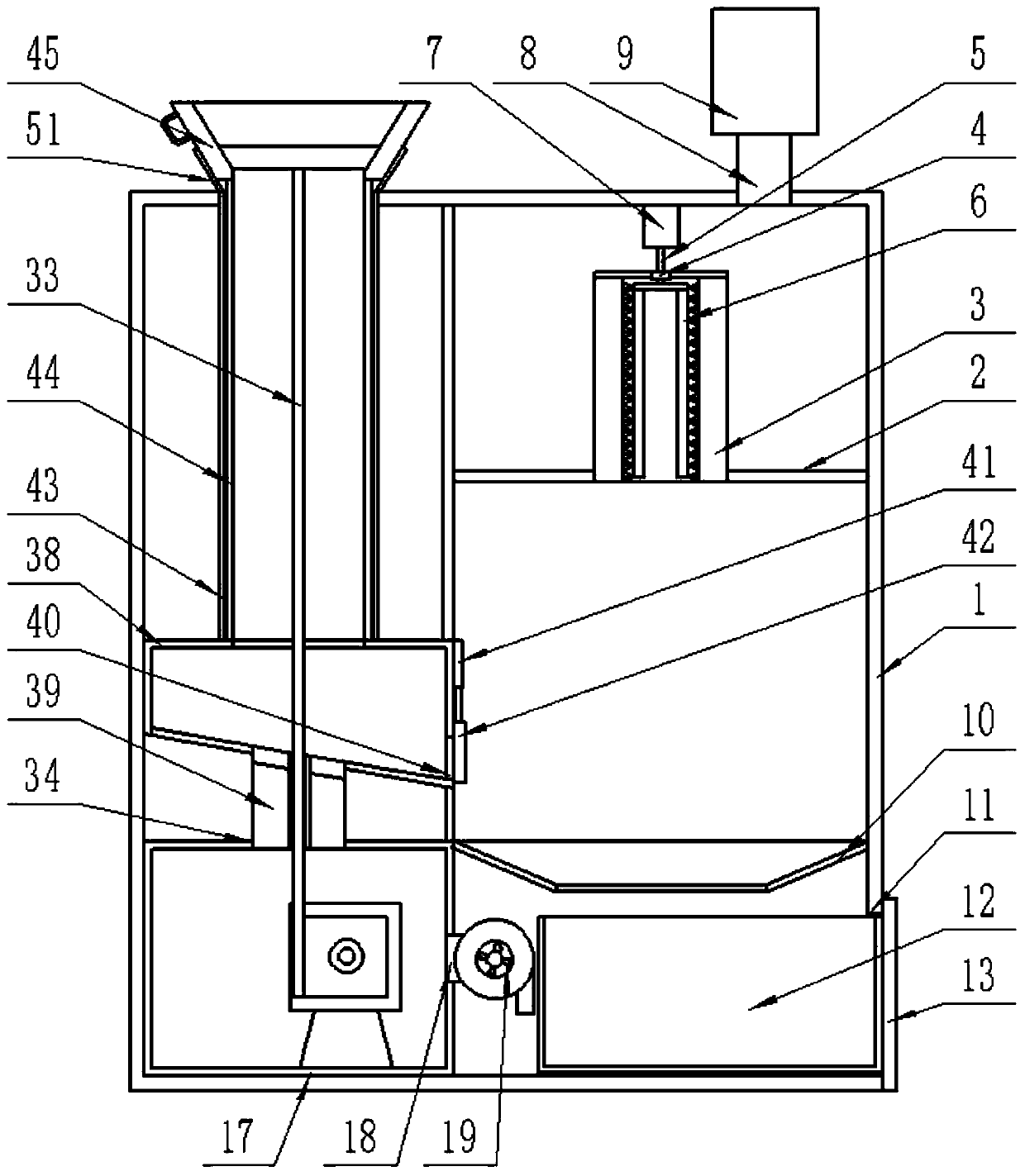

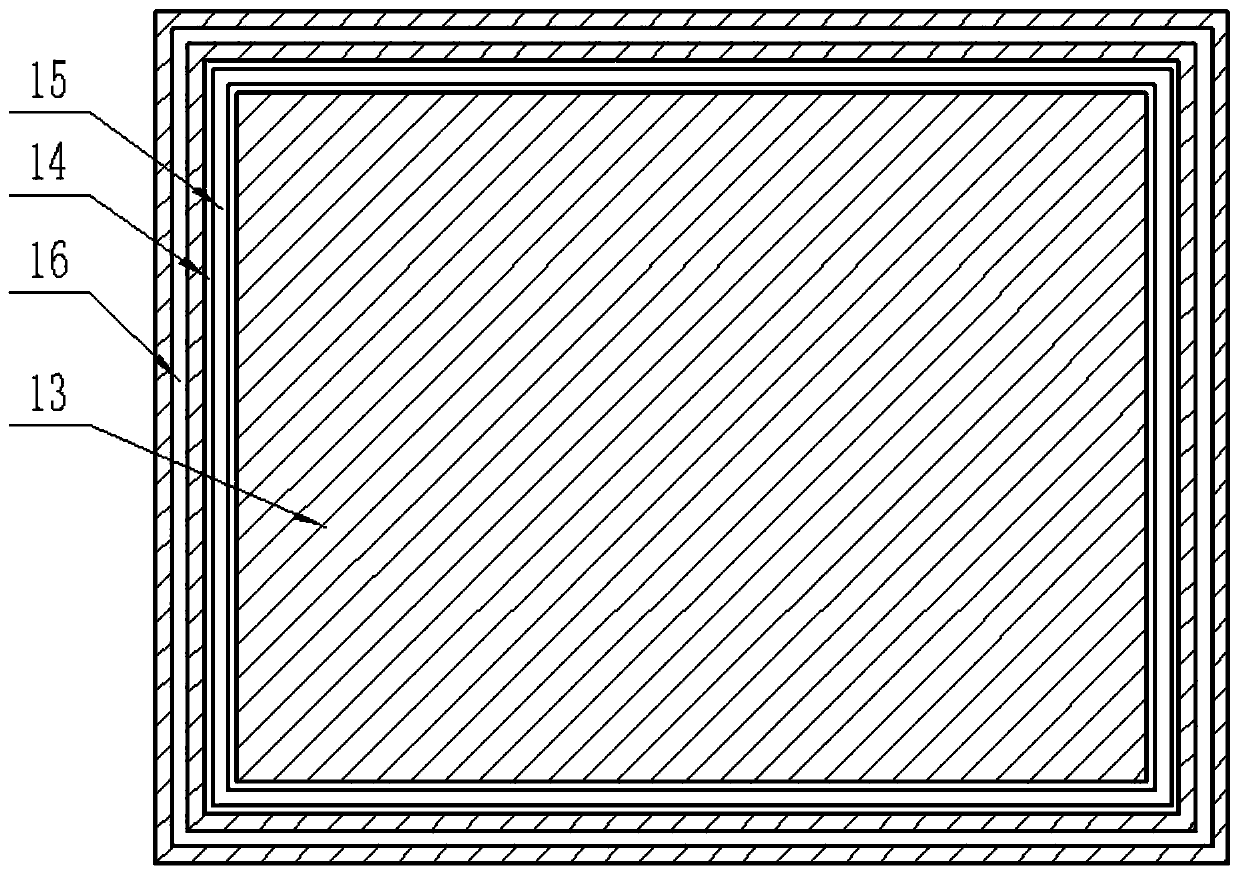

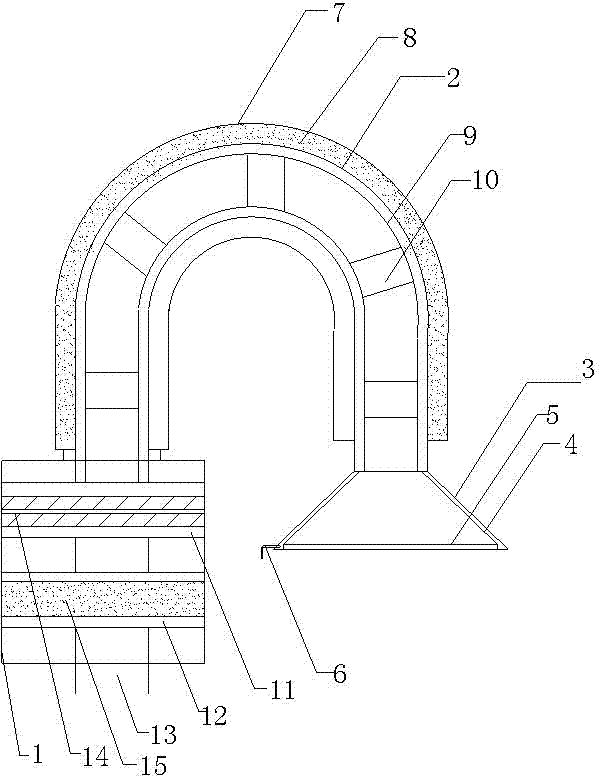

Dedusting system of whole factory building

ActiveCN101619881ACause secondary pollutionDoes not affect productivityLighting and heating apparatusAir conditioning systemsAir treatmentWelding fume

The invention discloses a dedusting system of a whole factory building, which comprises an air funnel, an air handling unit, a top air-return opening, an air supply pipeline and an air-return pipeline, wherein the air handling unit is arranged outside a workshop, the air funnel is arranged at the lower part of the inner side of the workshop, one end of the air supply pipeline is connected with the air funnel, and the other end of the air supply pipeline is connected with the air handling unit through the air supply pipeline; the top air-return opening is arranged at the top inside the workshop, one end of the air-return pipeline is connected with the top air-return opening and the other end of the air-return pipeline is connected with the air handling unit. The air supply direction of the air funnel is adjusted to change the air distribution of returned air, welding fume with higher temperature drifts upwards under the action of hot buoyancy, the fume further drifts upwards by the push of air sent out from the air funnel and does not move transversely, thereby the welding fume can be avoided from passing through the respiratory zone of the human body; and the fume and harmful gases are sucked into the air handling unit through the air-return pipeline under the suction action of the air-return opening at the top of the workshop and can not be directly removed outdoors, thereby the secondary pollution can not be caused.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

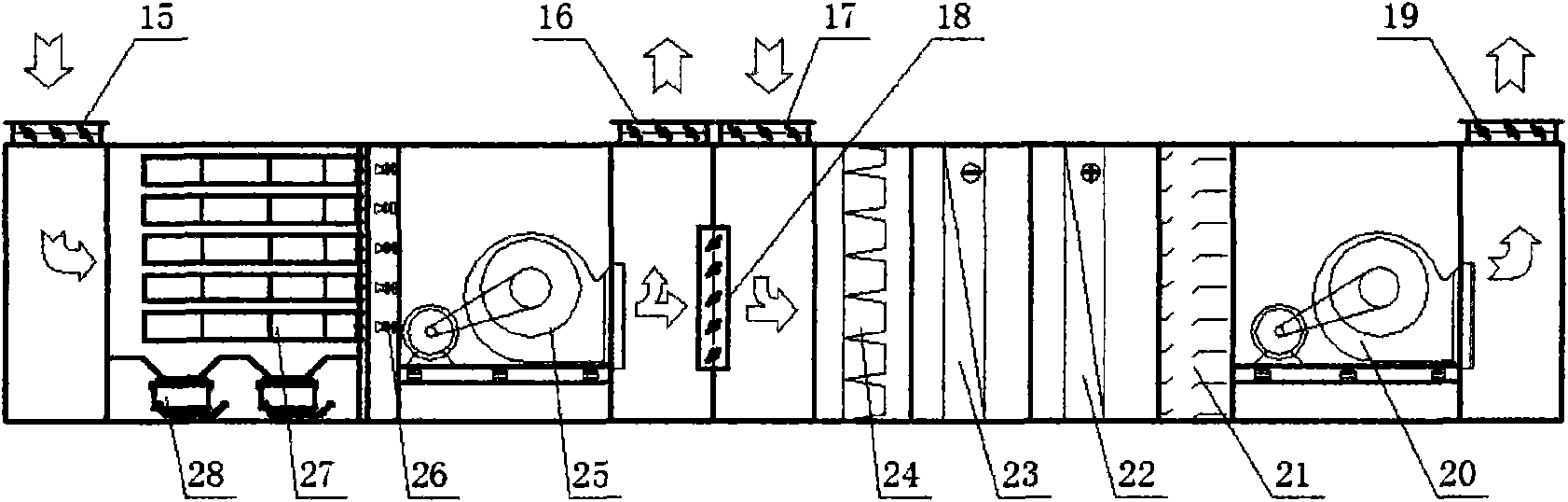

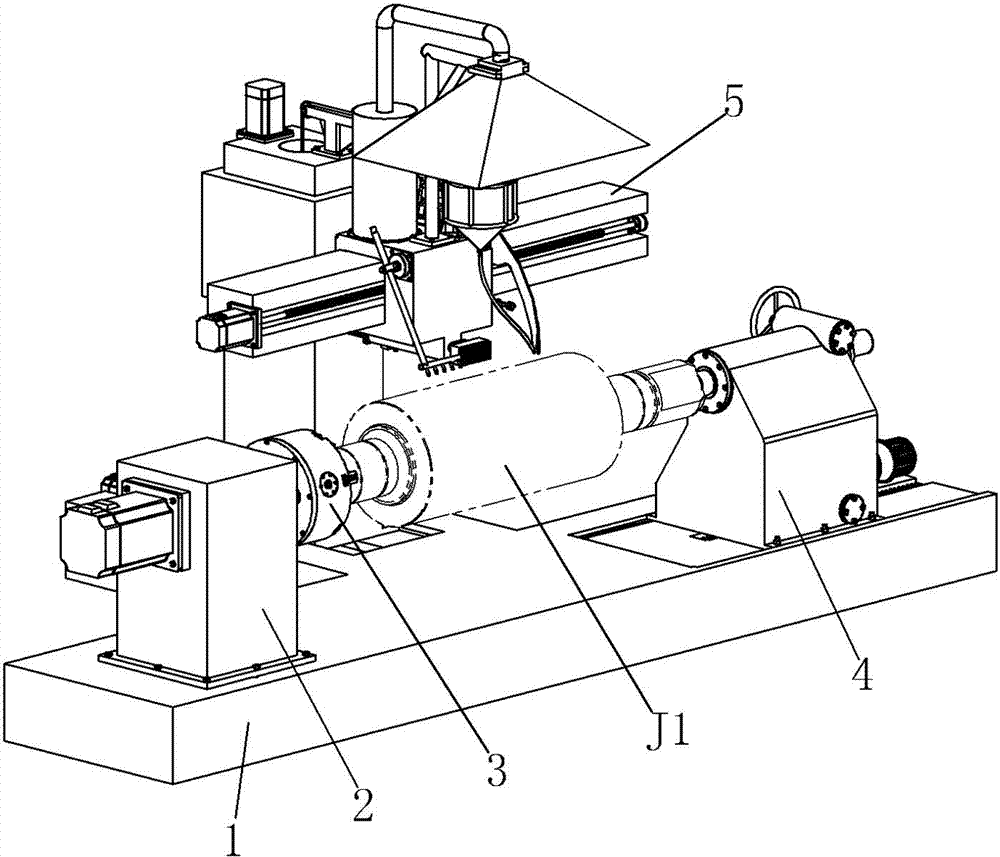

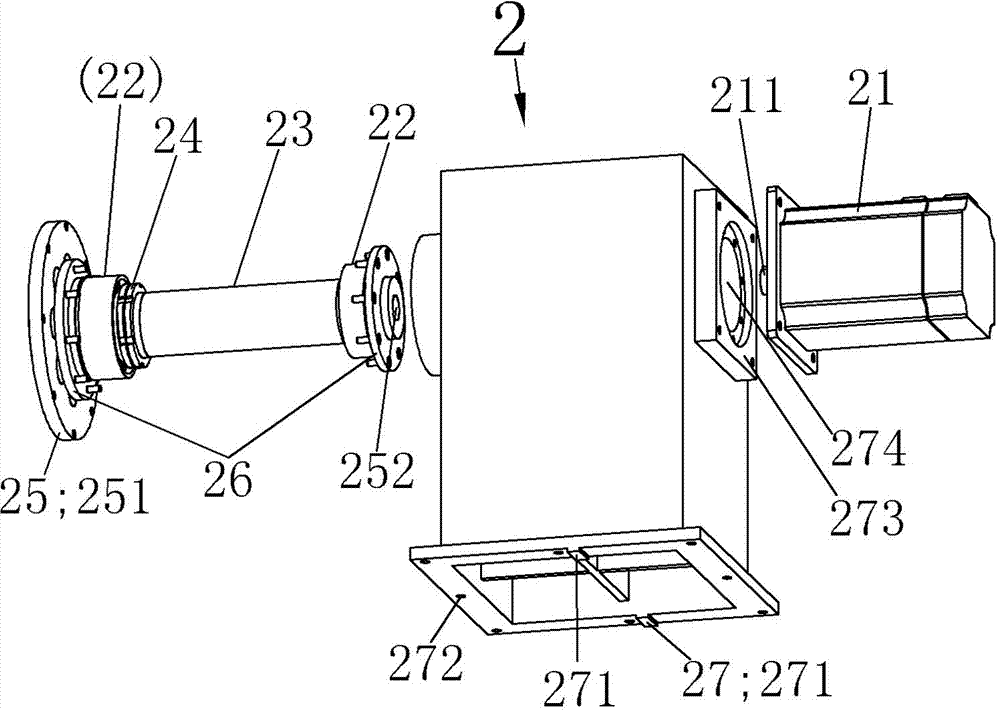

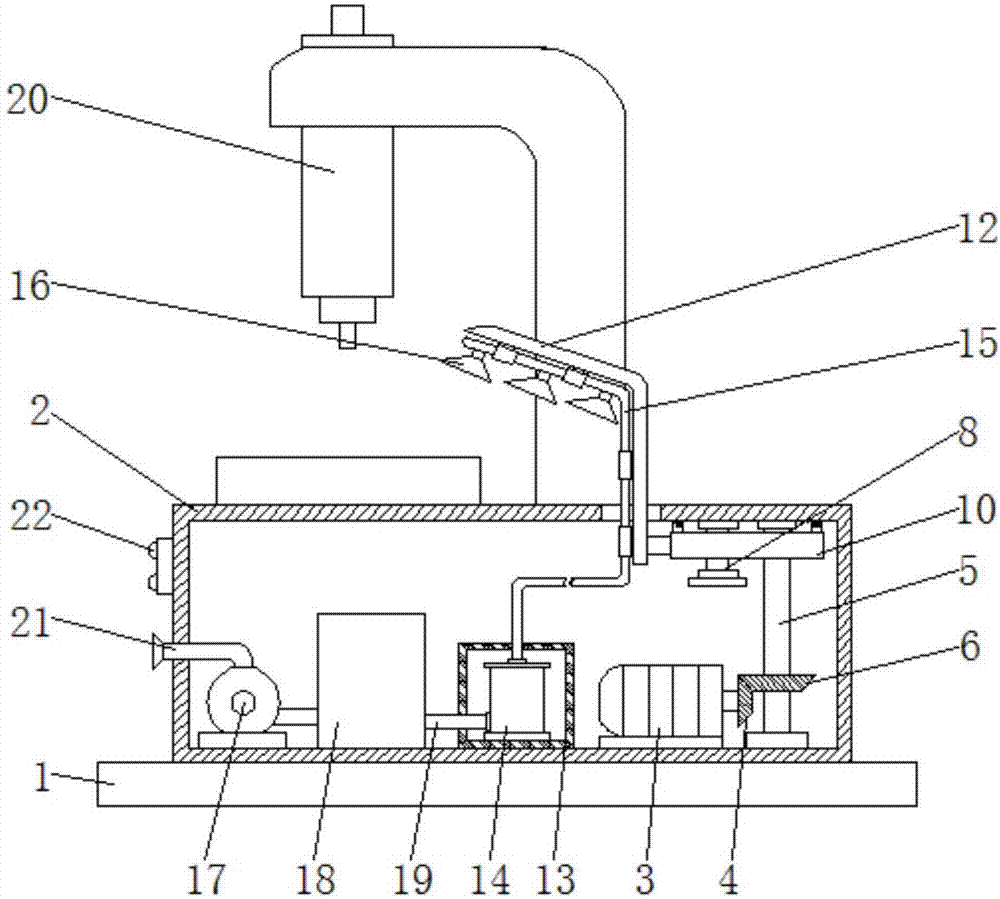

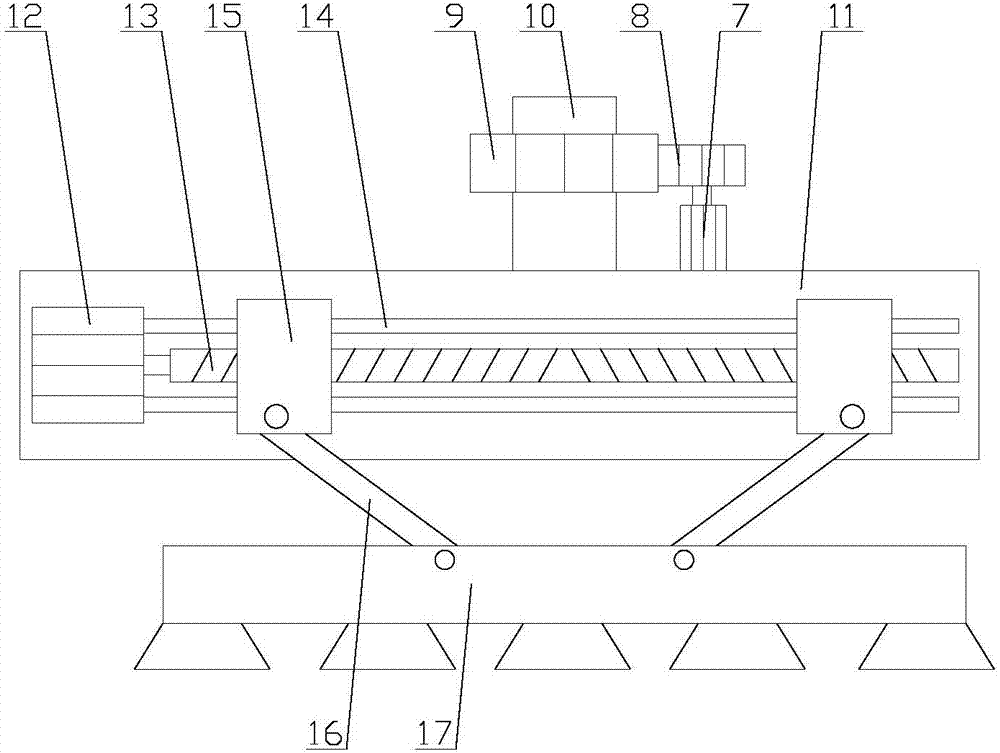

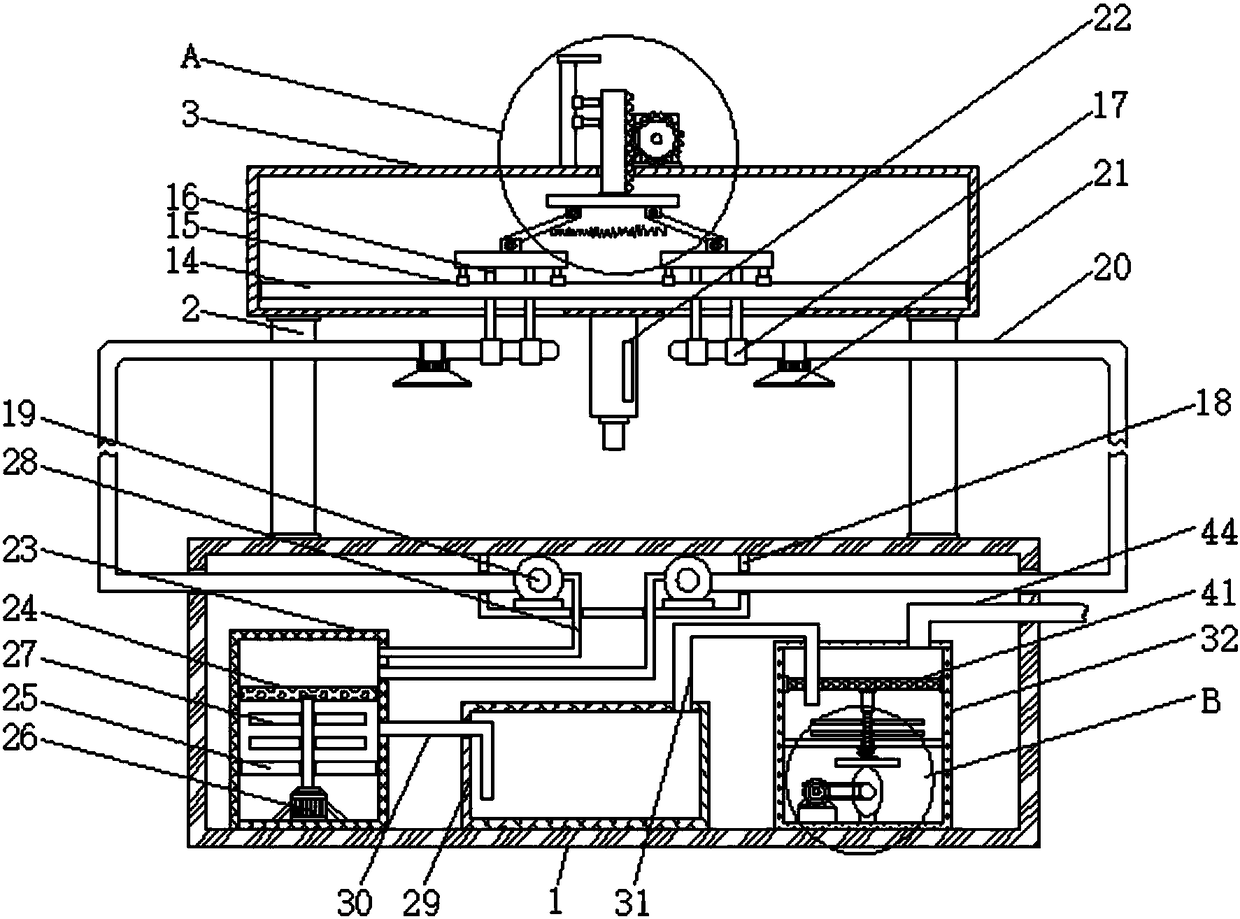

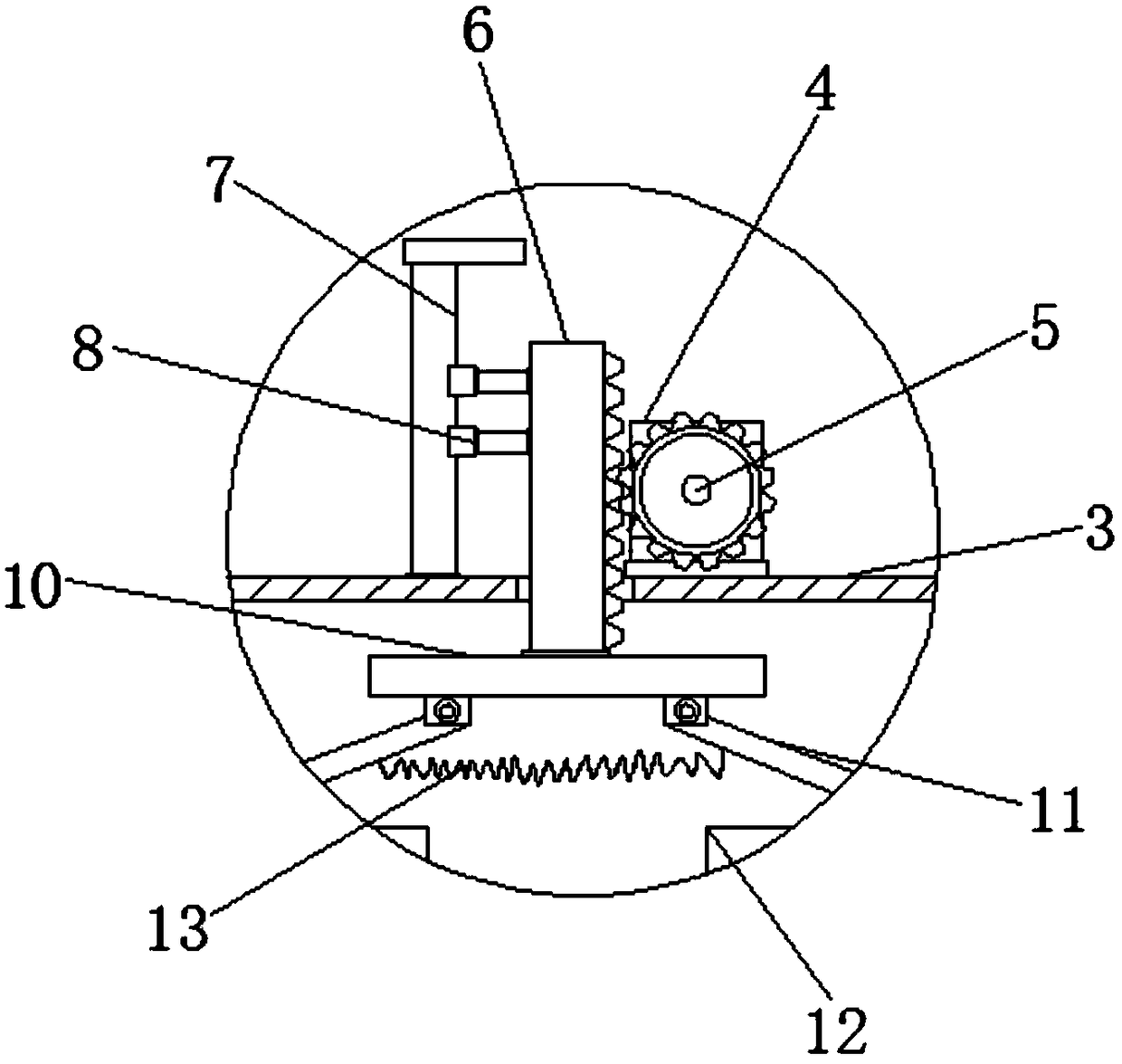

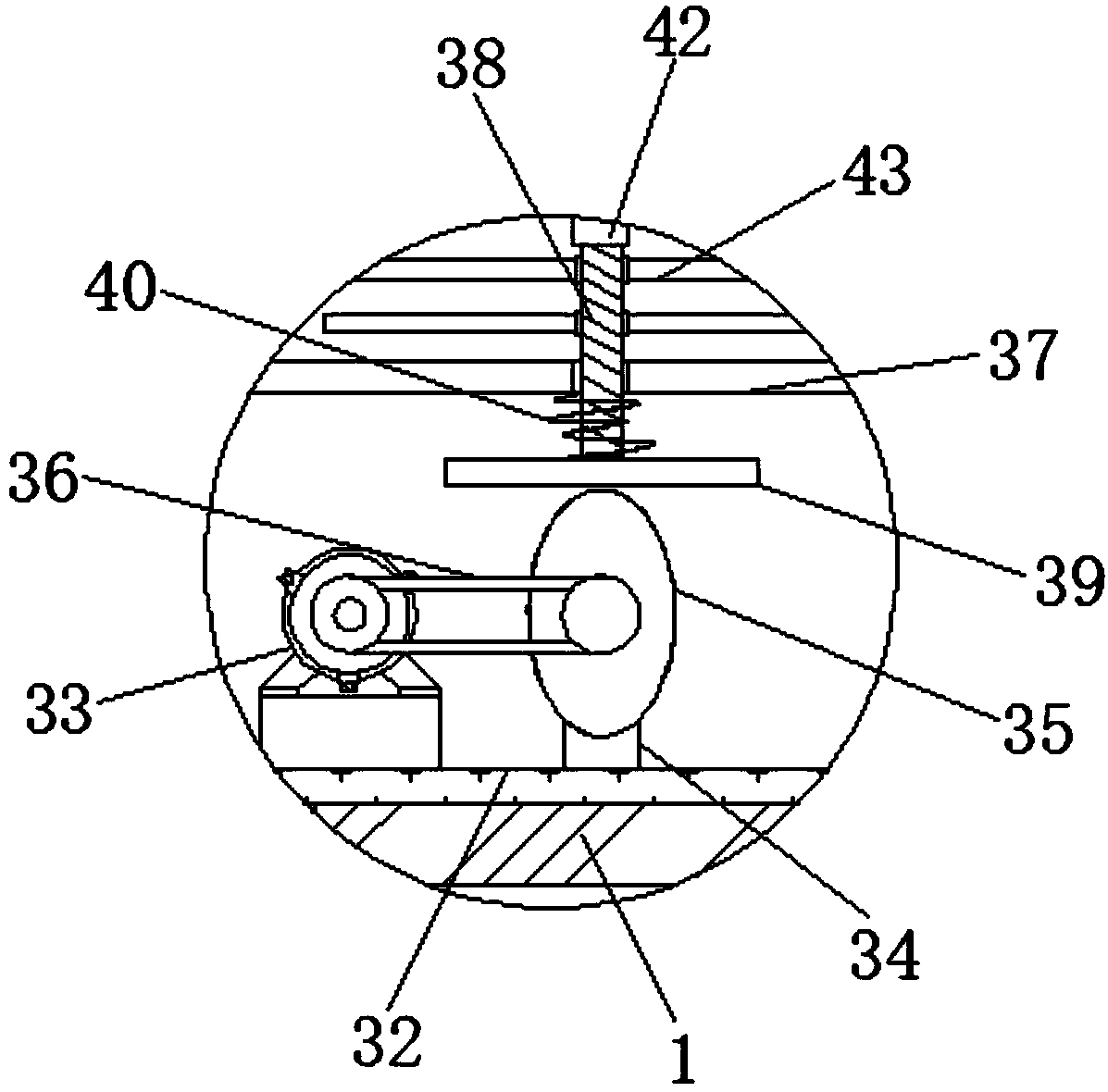

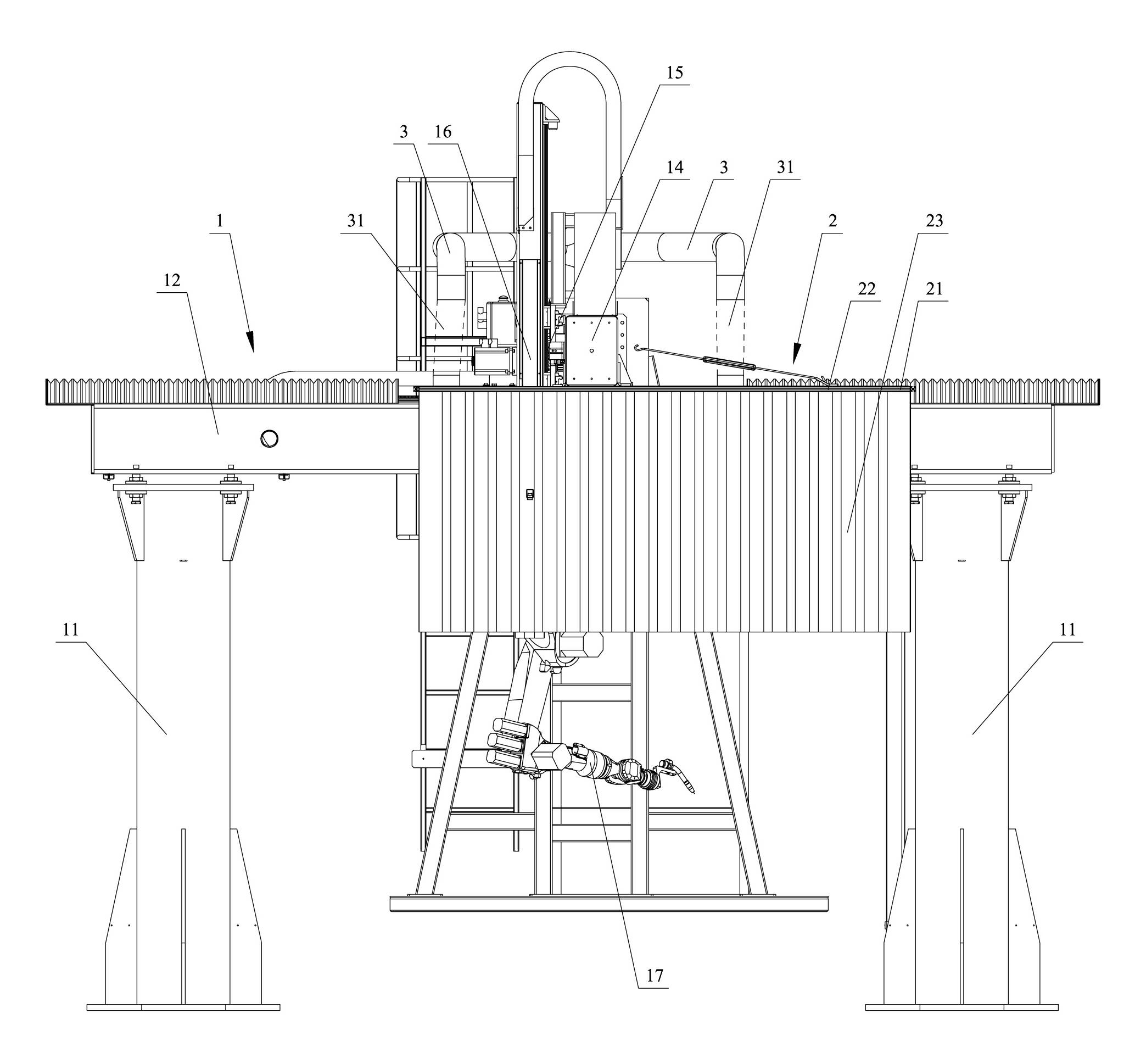

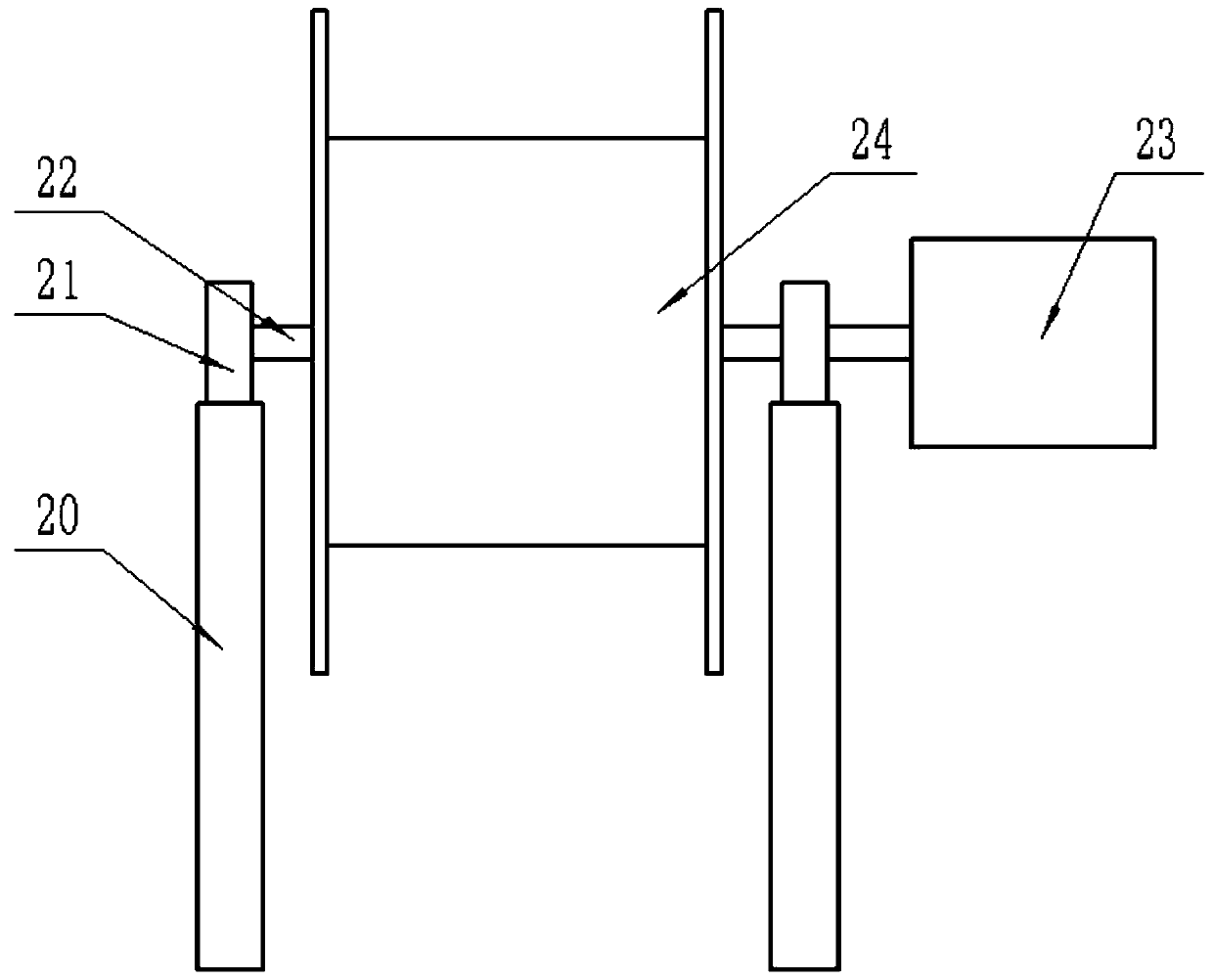

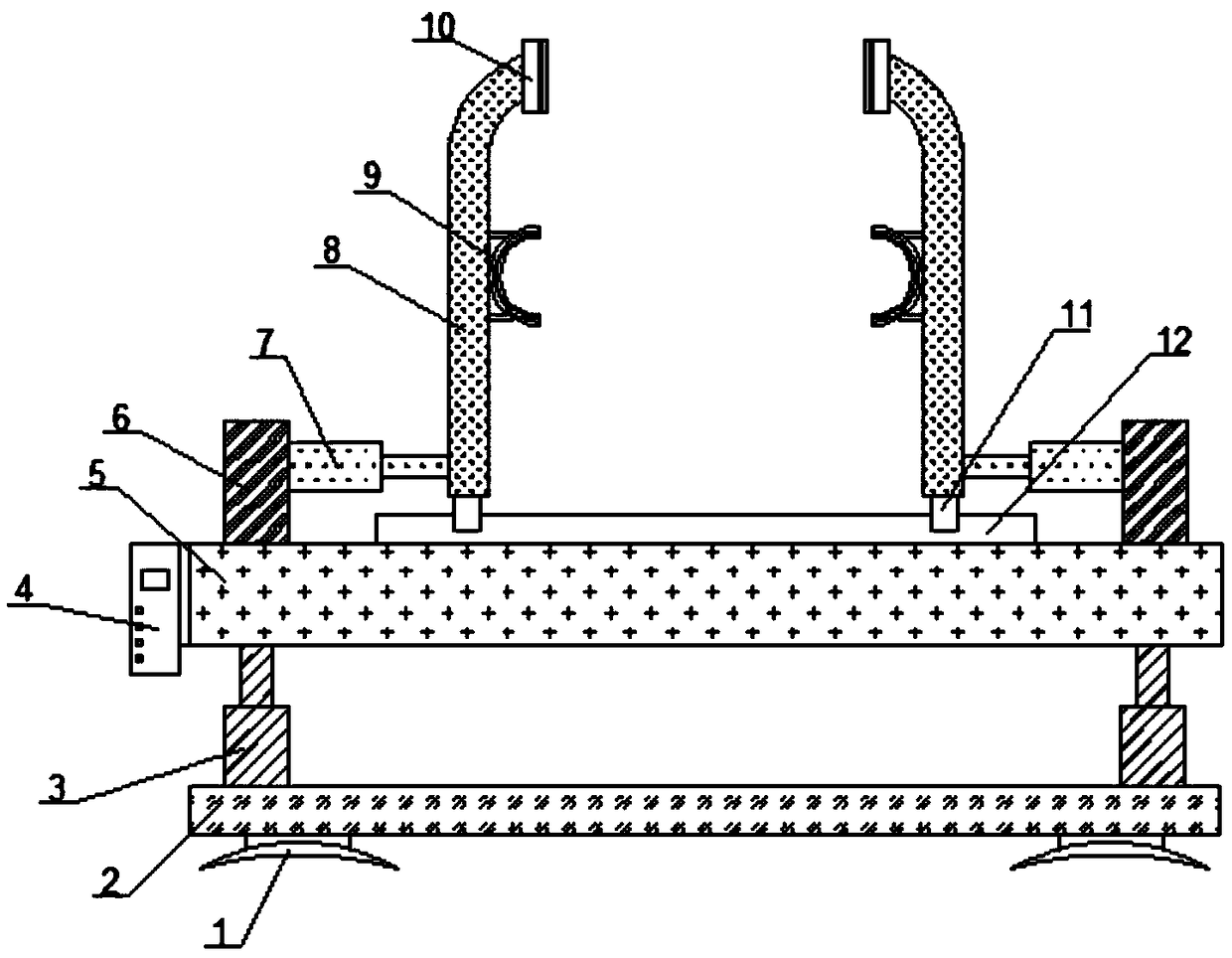

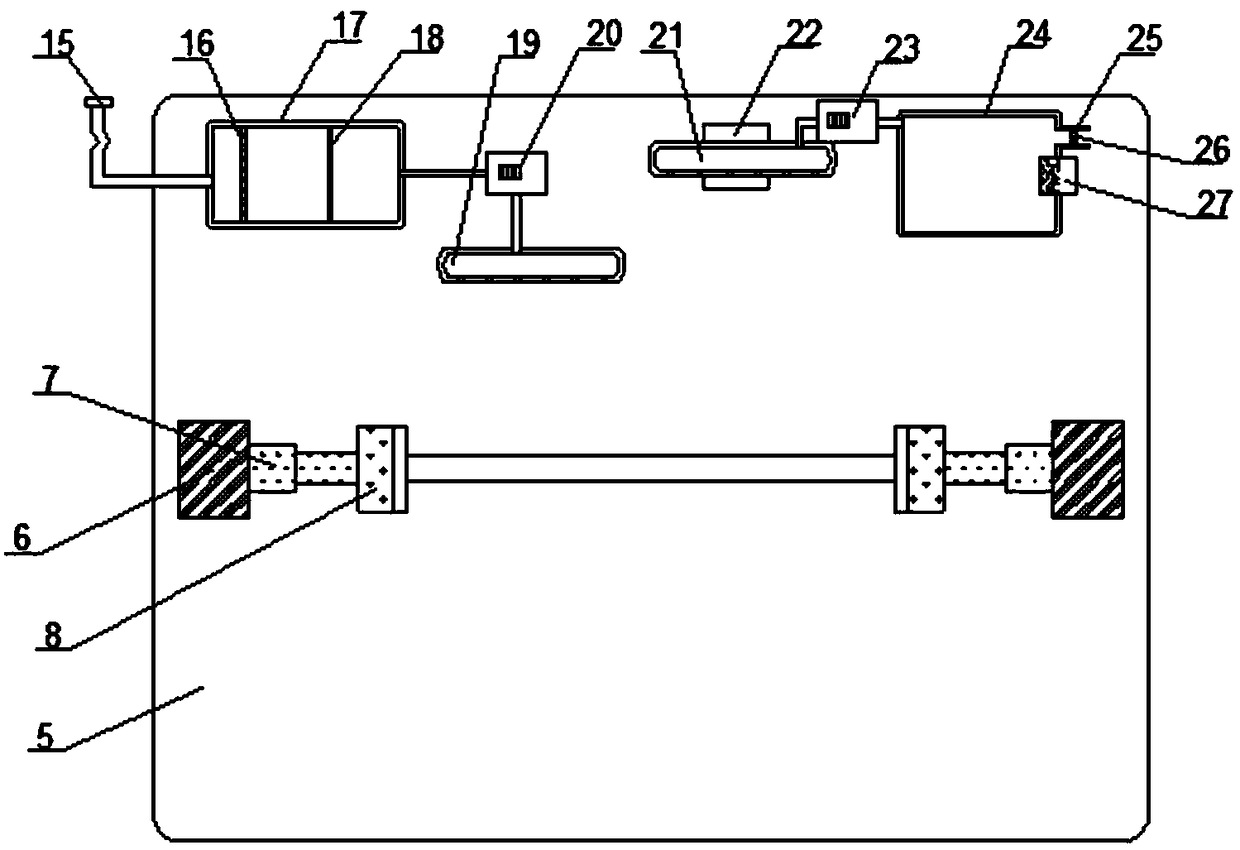

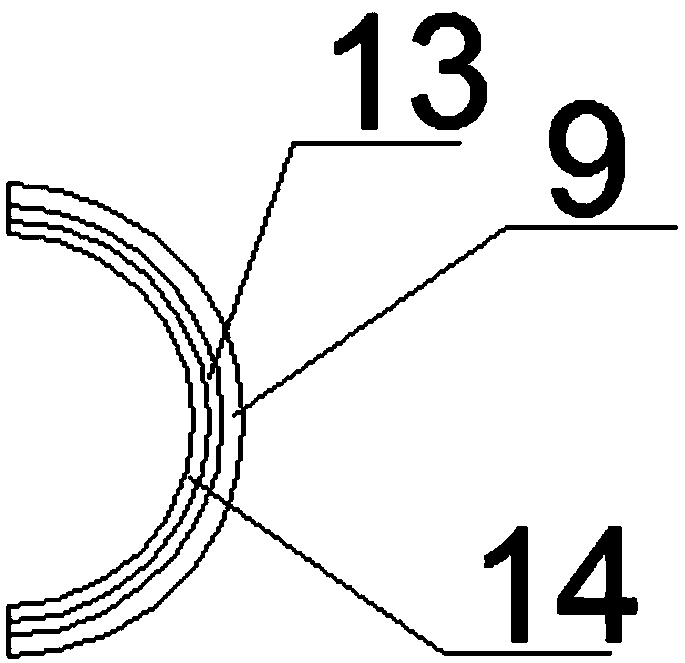

Roller repairing surfacing machine

InactiveCN107088696AReliable clamping functionReduce distortionWelding/cutting auxillary devicesAuxillary welding devicesSurface cleaningTailstock

The invention discloses a roller repairing surfacing machine and belongs to the field of metal welding. The roller repairing surfacing machine has a pre-welding preheating function, an automatic surfacing function, a welding fume removing function and a welding surface cleaning function, and also has the characteristics that a surfacing station can be adjusted rapidly, and the dimension expansion capacity of a surfacing workpiece is high. The roller repairing surfacing machine is provided with a foundation base, a headstock, a six-jaw chuck, a tailstock centre device and a working device. According to the technical scheme, a single stand column cross beam structure is adopted by the working device, surfacing, preheating, welding fume removing and welding surface cleaning are integrated onto one working head, thus, the structure is compact, and energy saving and environmental friendliness are achieved; a repairing roller is clamped through the six-jaw chuck and the tailstock center device, and clamping is fast and reliable; and the roller repairing surfacing machine is simple in structure, easy to manufacture and convenient to maintain.

Owner:KUNMING UNIV

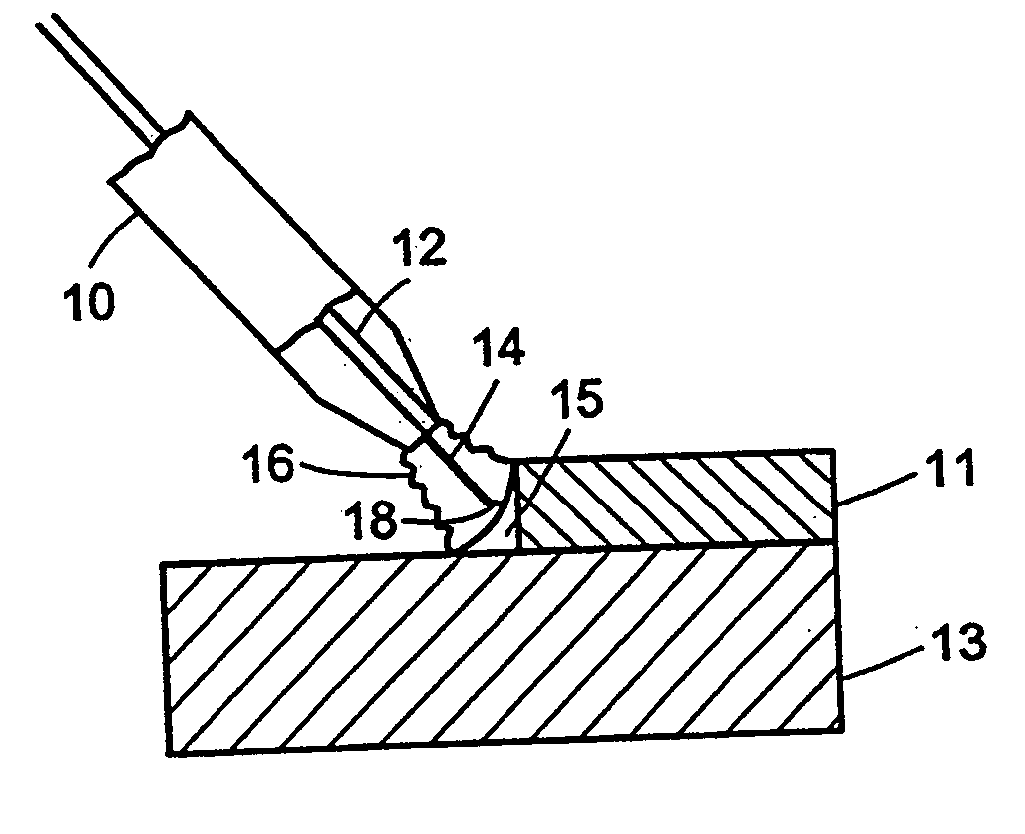

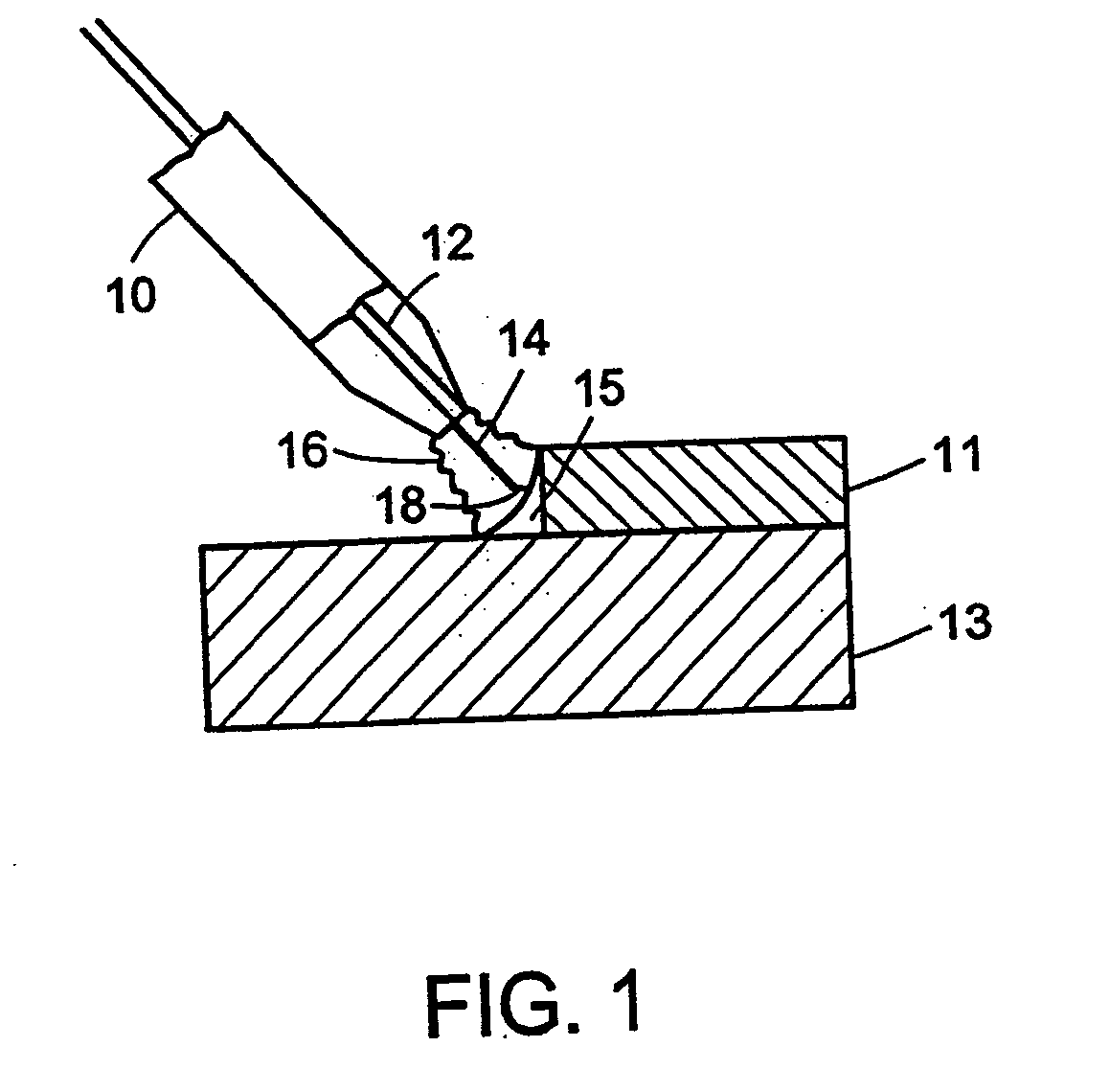

Metal-core gas metal arc welding of ferrous steels with noble gas shielding

ActiveUS20050205525A1Reduce penetrationThin wallArc welding apparatusWelding/cutting media/materialsNoble gasLow voltage

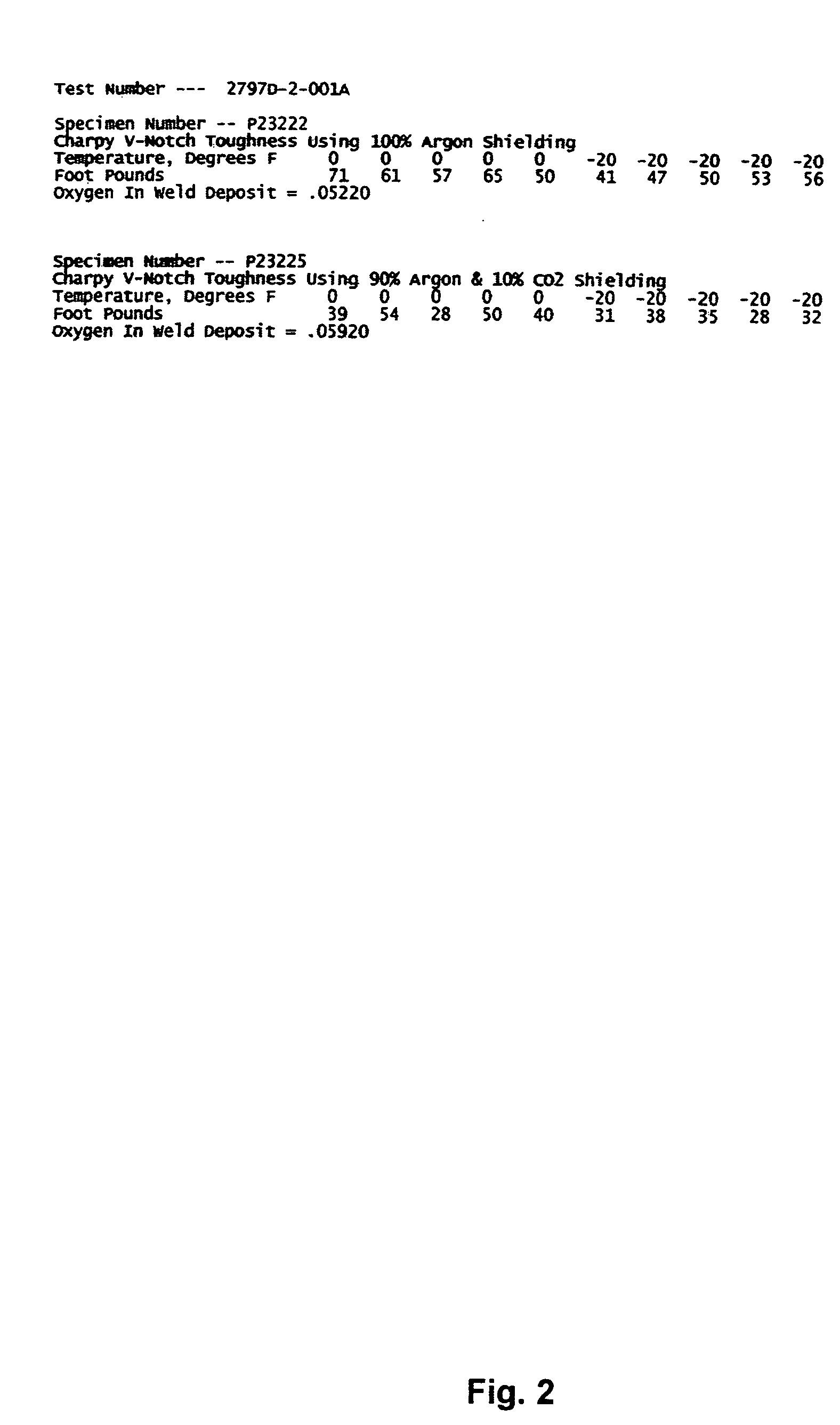

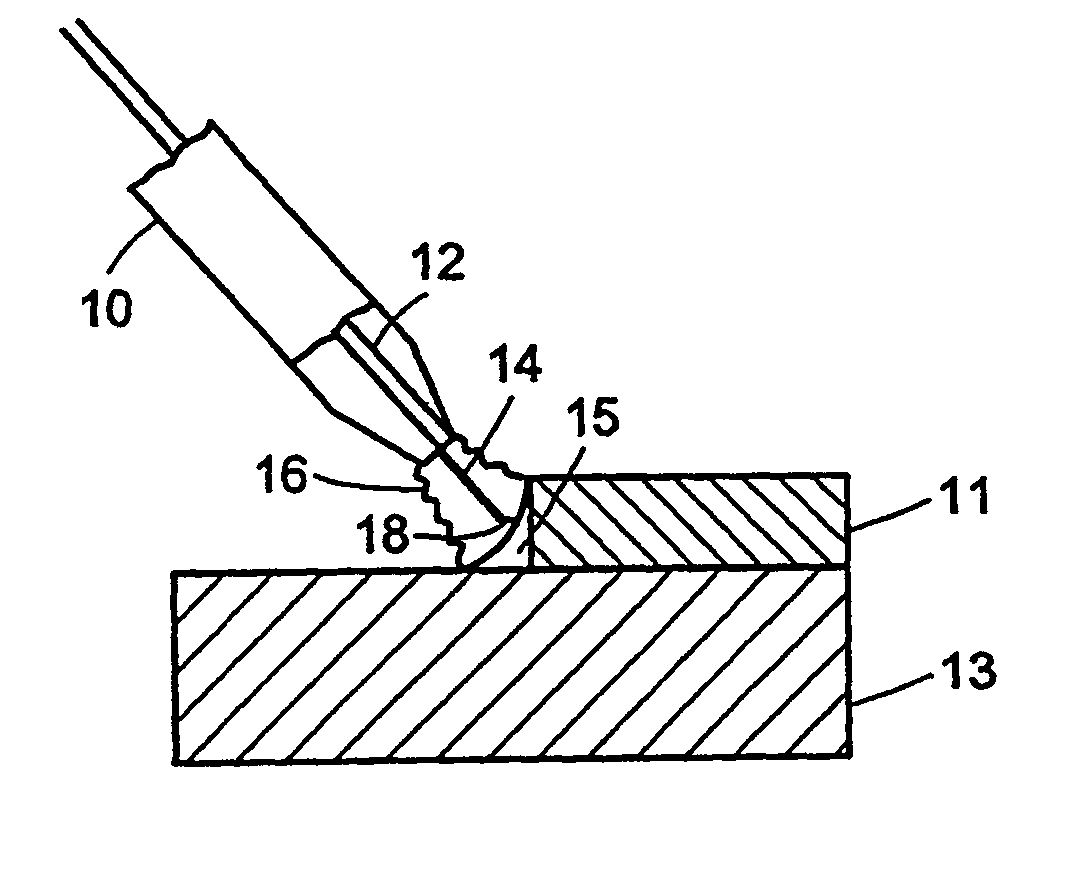

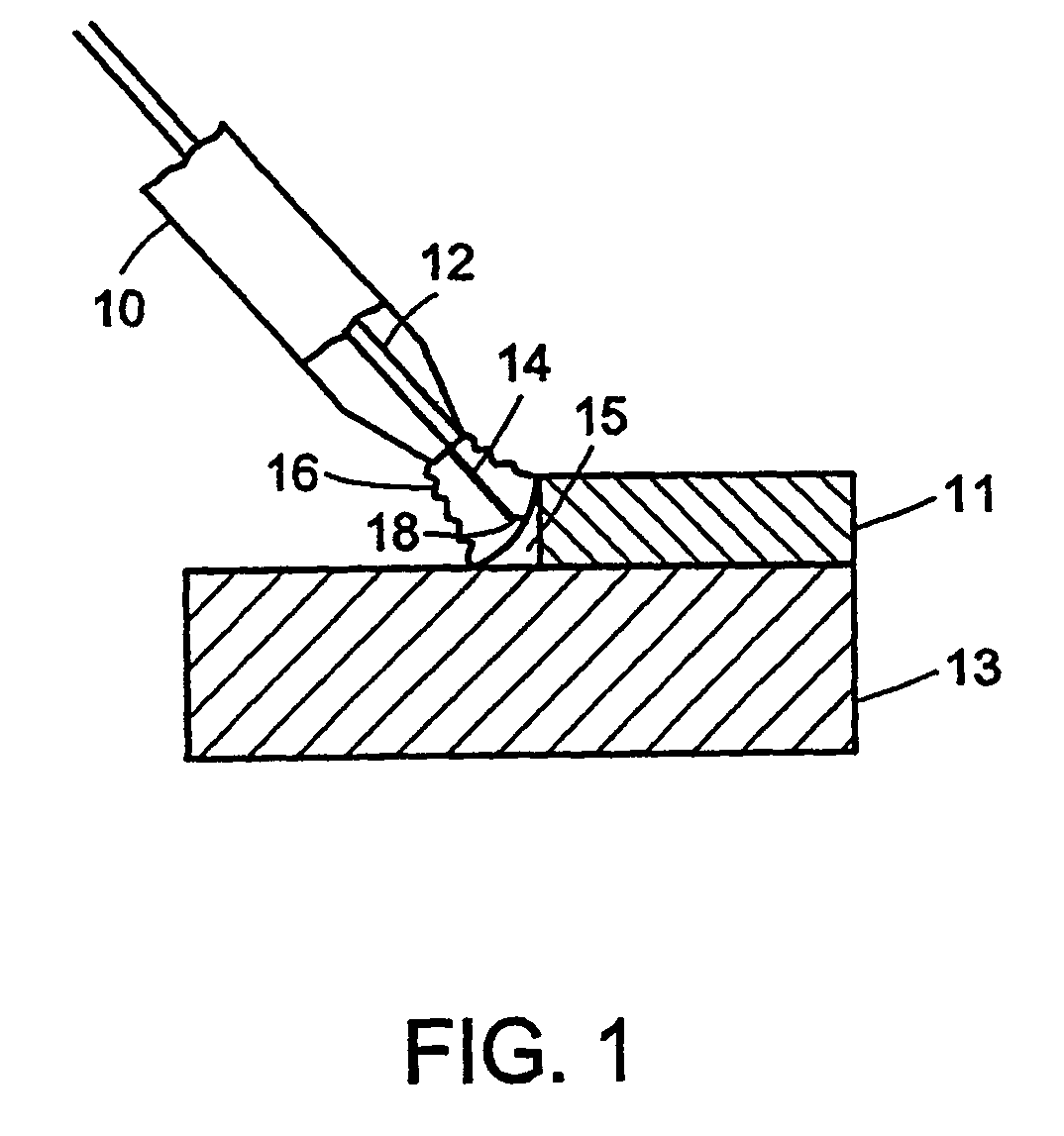

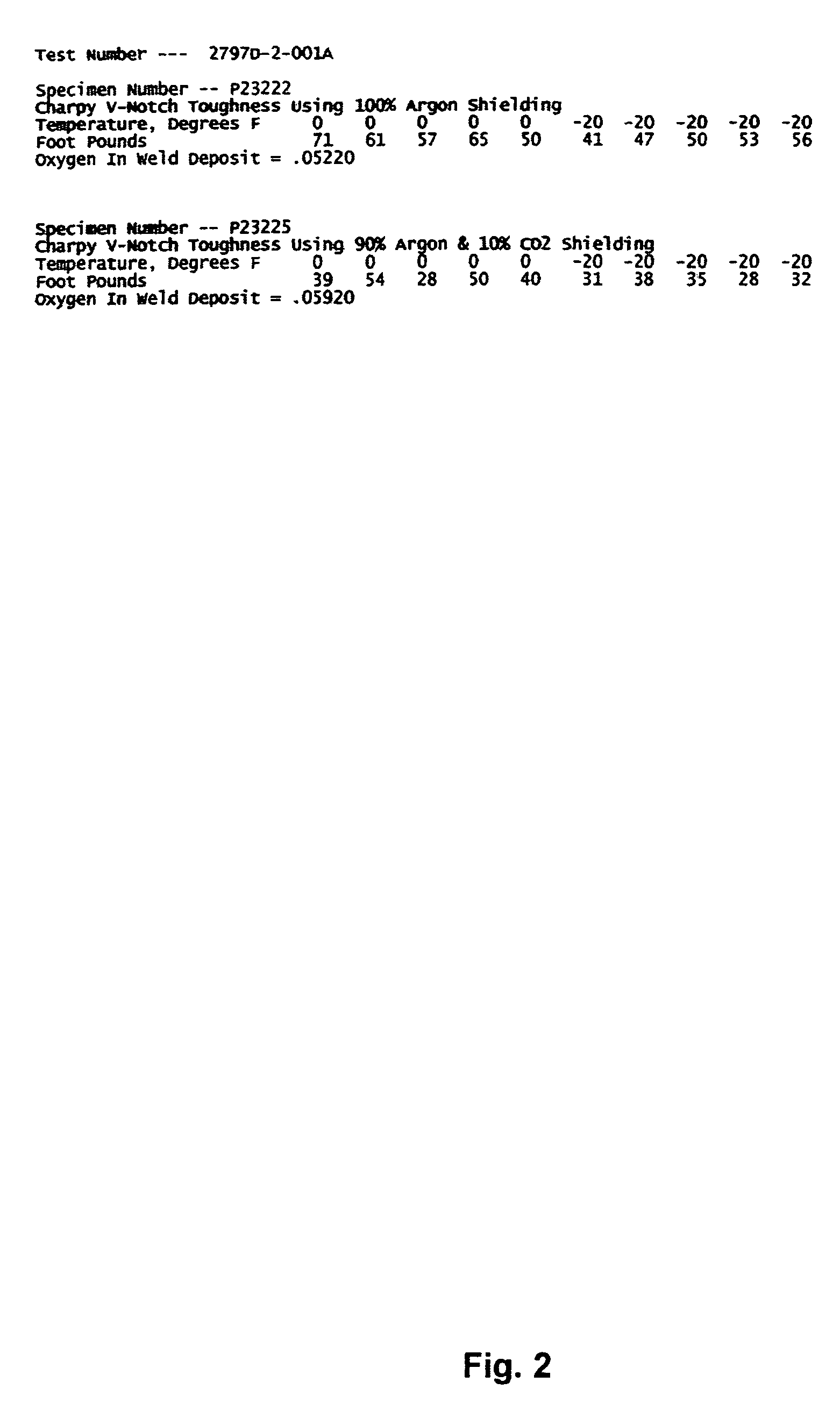

The gas-metal arc welding of metal-core wile electrodes in the pure Ar shielding gas for carbon steel, low alloy steel, and ferritic stainless steel is described. Such shielding gas provides several benefits not realized ??the gas-metal arc welding process with solid wires. When compared to standard argon / oxygen containing gas mixtures normally used for metal cored wires, these benefits include reduced silicate islands on the weld surface for improved weld appearance, reduced welding fume, and lower weld spatter, all of which provide easier clean-up after the welding operation. Benefits also include reduced arc penetration desirable for welding on thinner materials or handling poor joint fit-up. Lower voltage requirement further makes it possible to weld on thinner materials. Lower oxygen content in the weld deposits provide better toughness and easier welding in all-positions.

Owner:HOBART BROS

Metal-core gas metal arc welding of ferrous steels with noble gas shielding

ActiveUS7863538B2Reduce the amount requiredQuality improvementArc welding apparatusWelding/cutting media/materialsNoble gasLow voltage

The gas-metal arc welding of metal-core wile electrodes in the pure Ar shielding gas for carbon steel, low alloy steel, and ferritic stainless steel is described. Such shielding gas provides several benefits not realized ??the gas-metal arc welding process with solid wires. When compared to standard argon / oxygen containing gas mixtures normally used for metal cored wires, these benefits include reduced silicate islands on the weld surface for improved weld appearance, reduced welding fume, and lower weld spatter, all of which provide easier clean-up after the welding operation. Benefits also include reduced arc penetration desirable for welding on thinner materials or handling poor joint fit-up. Lower voltage requirement further makes it possible to weld on thinner materials. Lower oxygen content in the weld deposits provide better toughness and easier welding in all-positions.

Owner:HOBART BROS

Self-protecting flux-cored wire containing polyvinylidene resin

InactiveCN101279409AHigh and stable impact toughnessAdd a small proportionWelding/cutting media/materialsSoldering mediaSlagHazardous substance

The invention relates to a self-shielded flux-cored wire containing polyvinylidene fluoride resin, which comprises a shuck manufactured by adopting the home-made SPCC common mild-carbon steel strip. The invention is characterized in that flux core of the common mild-carbon steel strip consists of villaumite, carbonate, oxide, Manganese (Mn), Silicon (Si), Aluminum (Al), Magnesium (Mg), Nickel (Ni) and ferrous powder jointly; wherein, the components of the flux core include 20 percent to 45 percent of the villaumite, 4 percent to 13 percent of the carbonate, 4 percent to 15 percent of the oxide, 1 percent to 5 percent of Mn, 1 percent to 3 percent of Si, 3 percent to 8 percent of Al, 3 percent to 7 percent of Mg, 0 percent to 5 percent of Ni and ferrous powder serving as the rest. The invention has the advantages that the defects that the pore sensitivity of the self-shielded flux-cored wire is high and the impact toughness of the deposited metal is not excellent; when the multi-layer welding is carried out, the surface blowhole is not generated, the complete slag coverage is achieved, the slag can be easily detached, the weld can be formed well and the impact toughness of the deposited metal is high and stable; the concentration of the hazardous substances in the welding fume is lowered and the invention is beneficial to the health of the welder.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

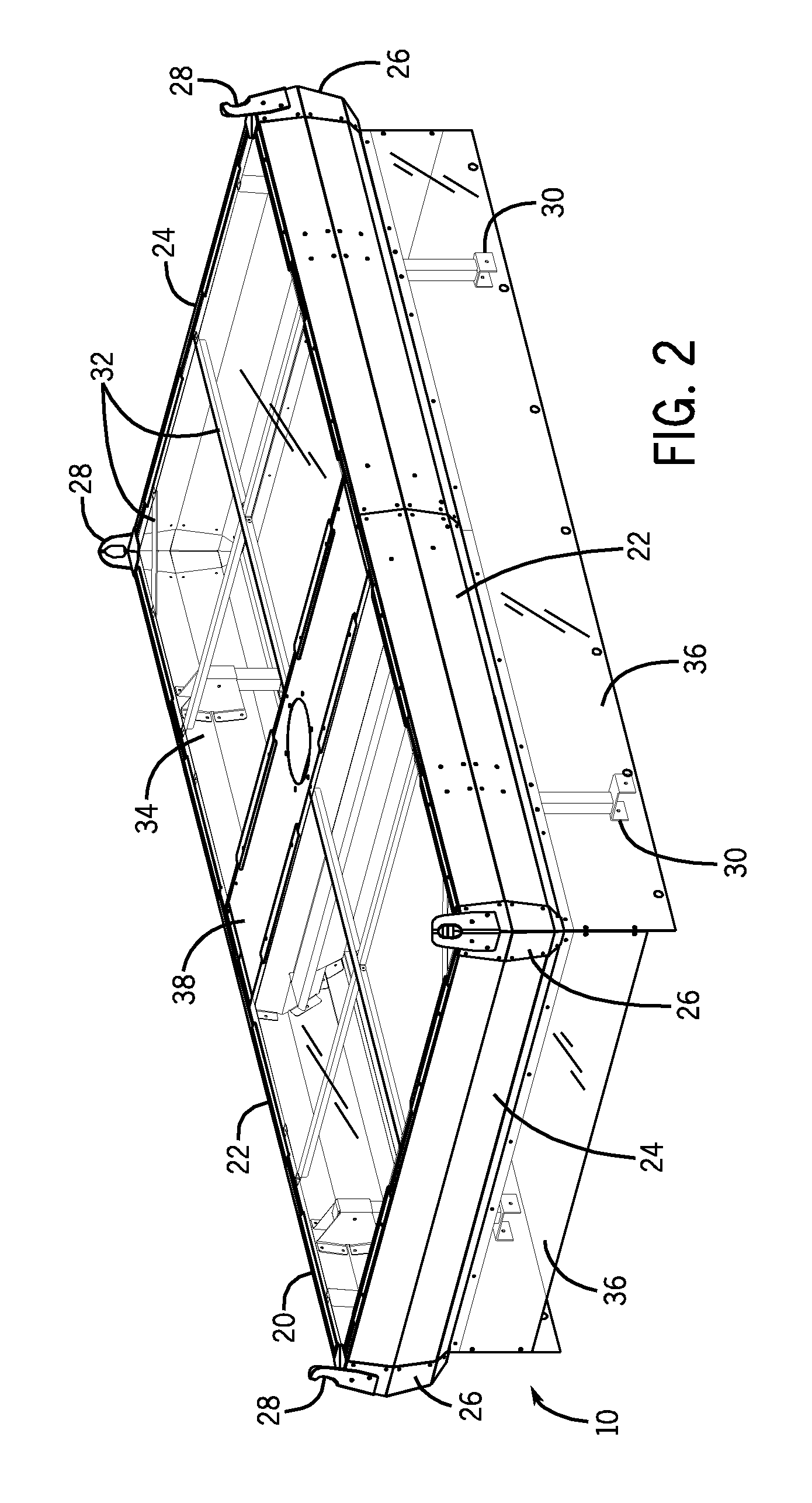

Welding fume extractor

ActiveUS20130122795A1Speed up the extraction processDomestic stoves or rangesGas current separationParticulatesEngineering

A fume extraction hood is designed to be positioned above a welding, cutting, or other metal-working location and to remove hot gases, smoke and fumes produced during these processes. The hood forms a box-like structure with an extractor rail structure disposed in an internal volume of the hood. The extractor rail structure comprises panels that force sharp turns in the gases, causing particulate matter to drop out of the gases both outside and inside the extractor rail. A primary path for gases accelerates and re-directs the gases entering into the extractor rail, and within the rail. The rail may form a dropout tray that can be removed for cleanout of collected particulate. The side and end rails of the hood may create a secondary path for gas not directly intaken into the extractor rail. This secondary path is re-directed towards the extractor rail, where gas is collected and particulate is forced to drop out as it joins the primary path.

Owner:ILLINOIS TOOL WORKS INC

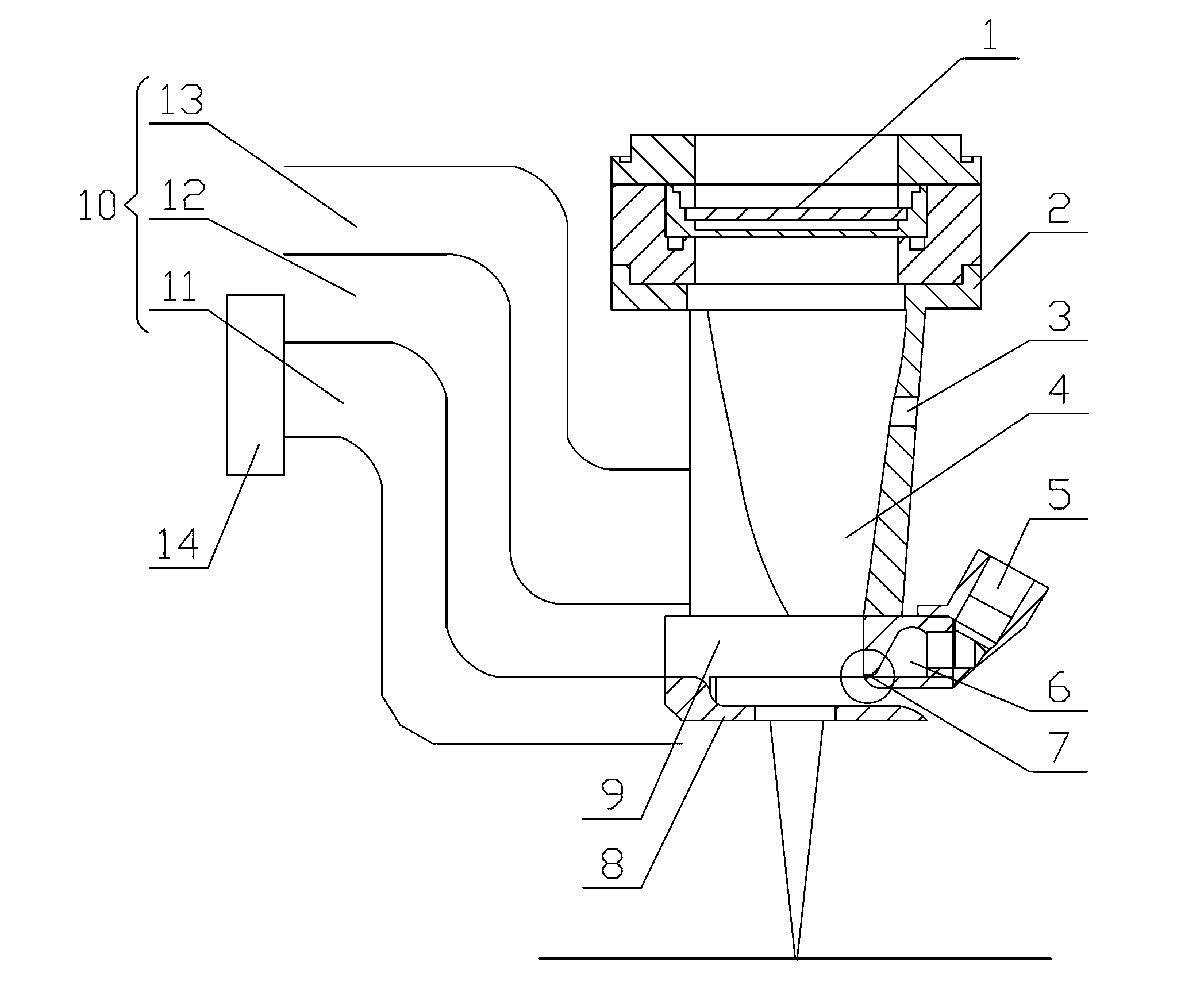

Transverse air curtain for laser welding and use method thereof

InactiveCN103212806AEfficient dischargeGood welding environmentLaser beam welding apparatusWelding fumeLaser beam welding

The invention relates to a transverse air curtain for laser welding. The transverse air curtain for laser welding comprises a window protection mirror, an air curtain bracket, an anti-splash plate, an air curtain connecting plate and an air guide cylinder, wherein the top of the air curtain bracket is provided with the window protectionmirror; the bottom of the air curtain bracket is connected with the anti-splash plate through the air curtain connecting plate; the air guide cylinder is arranged on one side of the air curtain bracket and the air curtain connecting plate and comprises a welding fume exhaust passage, a compressed air exhaust passage and a complemental air exhaust passage; and the other end of the welding fume exhaust passage is connected with a welding fume absorber. Compared with the prior art, the transverse air curtain has the beneficial effects that the transverse air curtain has the characteristics of simple structure, convenience in use and high practicability, the window protection mirroris effectively prevented from being polluted, meanwhile, welding fume and compressed air sprayed out by the transverse air curtain are effectively eliminated, a laser head is protected to the greatest extent and long-term stable work of the laser welding is realized.

Owner:鞍山煜宸科技有限公司

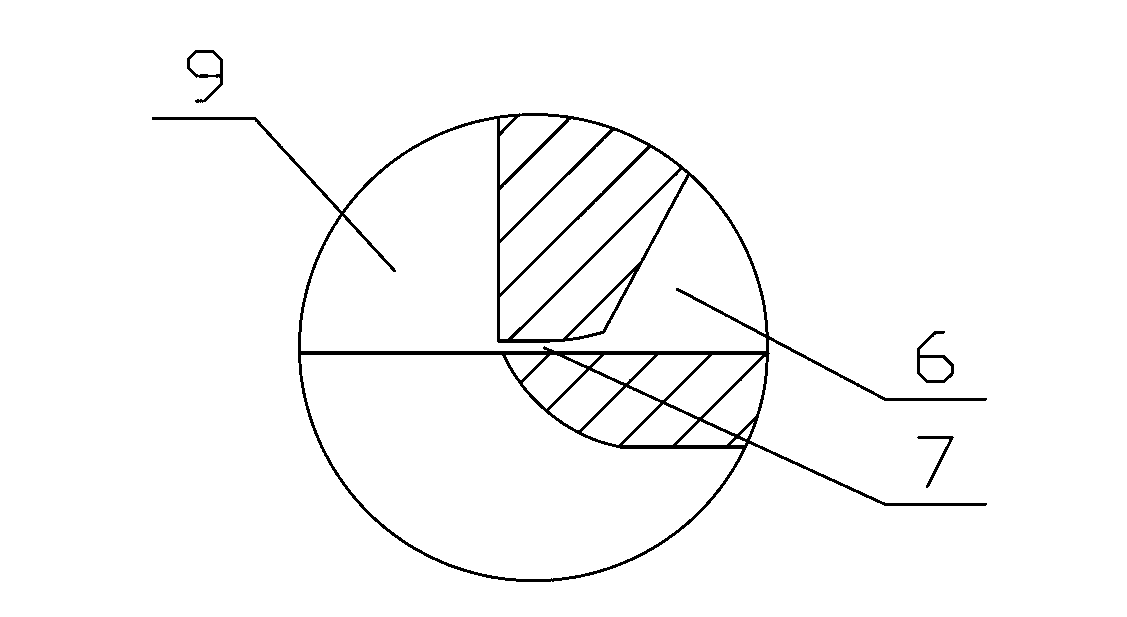

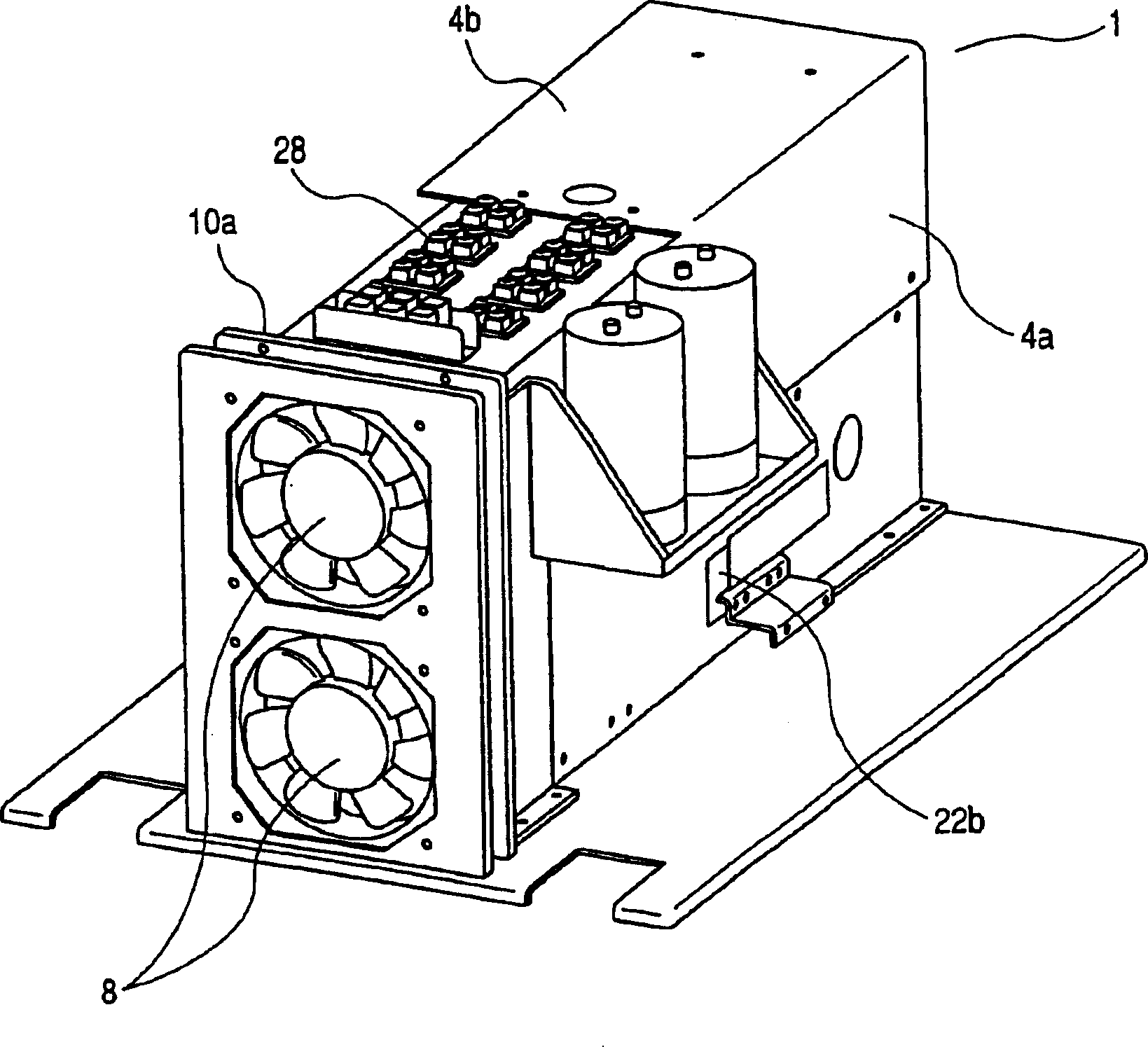

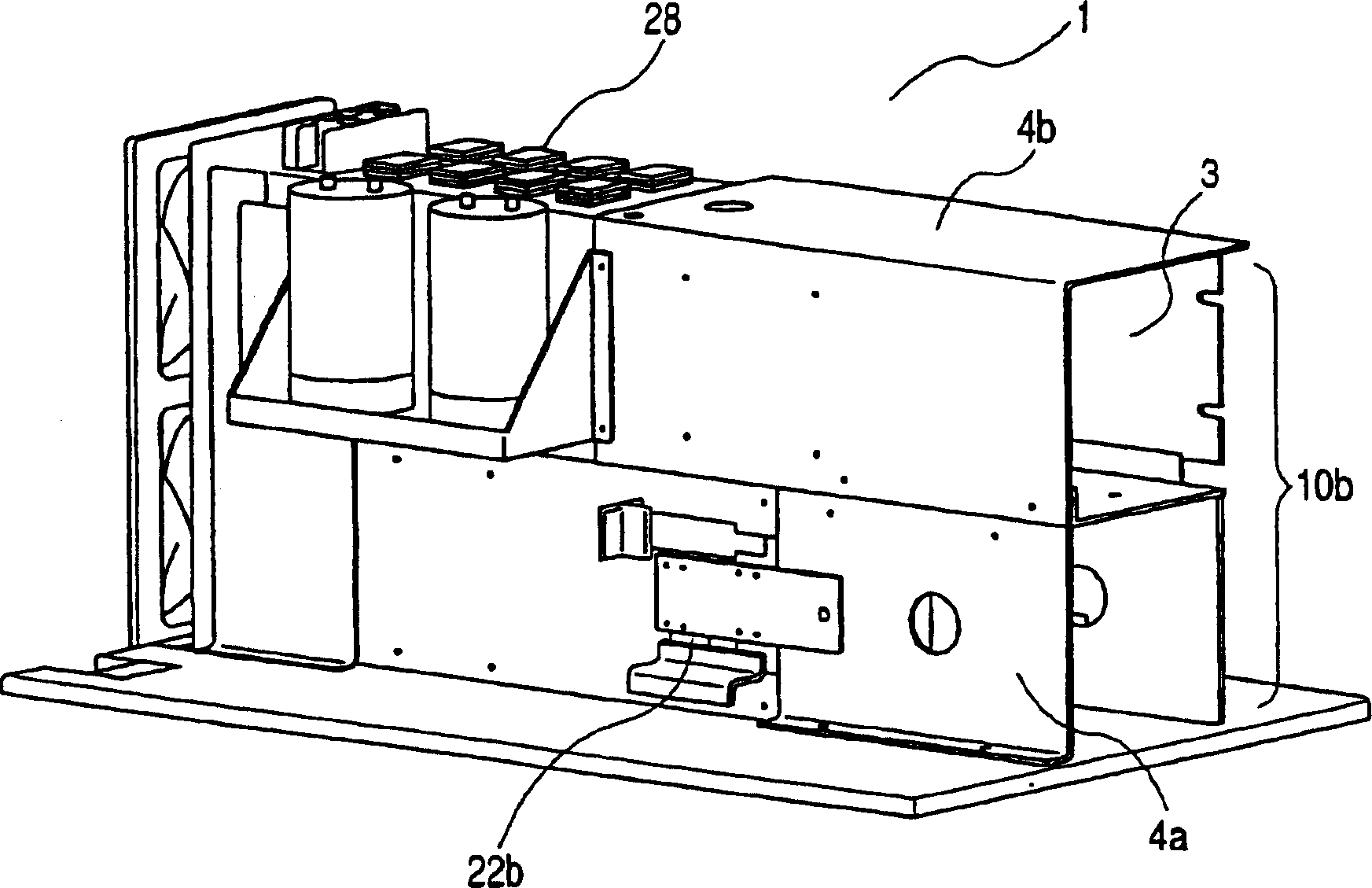

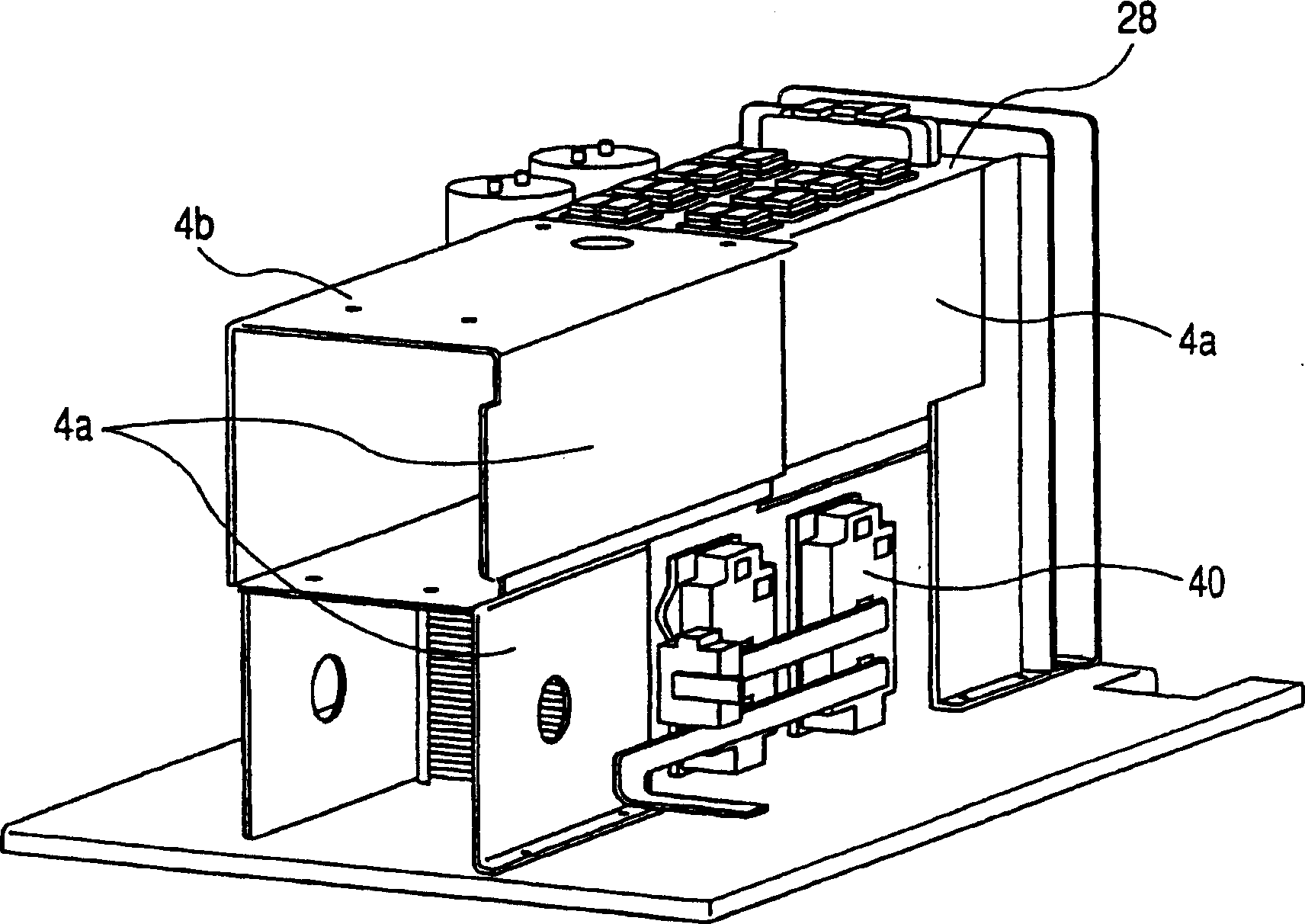

Arc welding control device

InactiveCN1826204AAvoid accumulationAvoid stickingShielding gas supply/evacuation devicesModifications for power electronicsEngineeringMechanical engineering

Cooling by directly blowing air outside an apparatus toward the entire main circuit has deposited or attached dust, weld fumes or the like to conductive units inside the apparatus, thus requiring a substantial time for maintaining the apparatus. An arc welding control device having a radiation unit that exhausts to the outside air heated by a heating electric element and is built in a casing, wherein the radiation unit has a tunnel shape provided with an outer peripheral portion forming a hollow portion to let air flow therethrough, thereby making it possible to prevent depositing or attaching of dust, weld fumes or the like to the conductive units inside the apparatus.

Owner:PANASONIC CORP

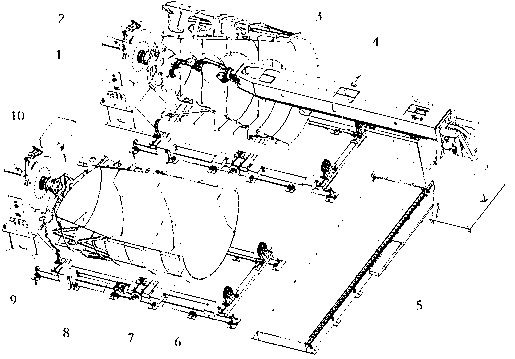

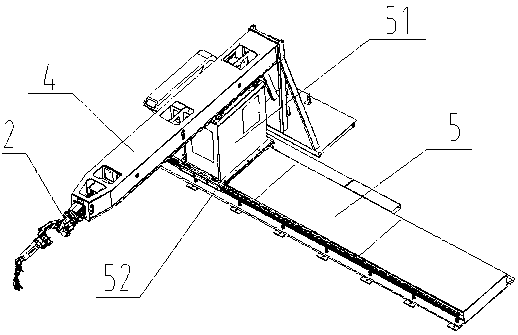

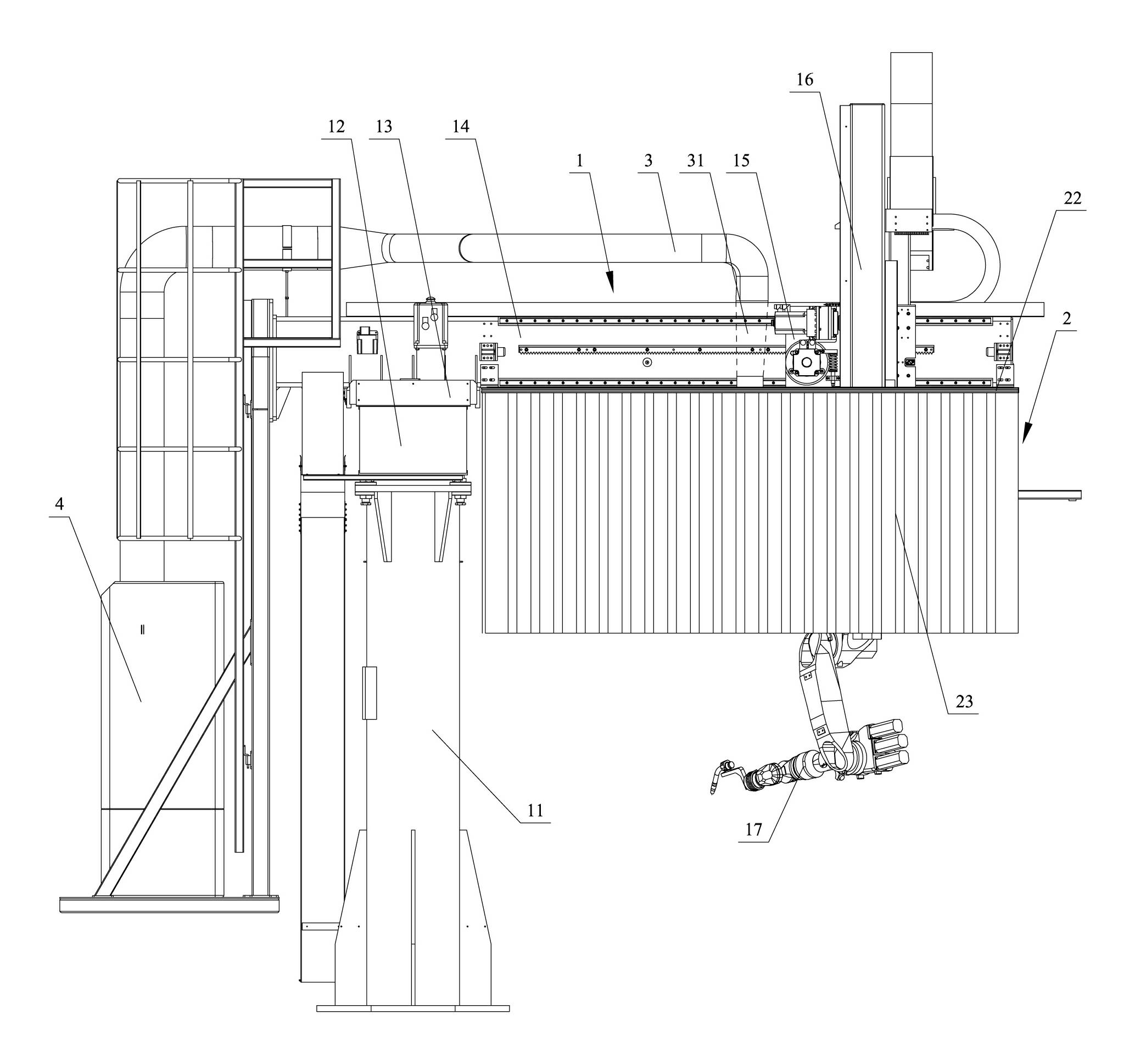

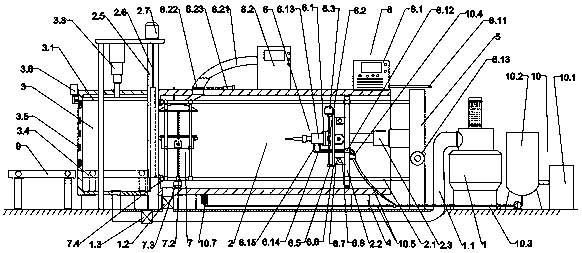

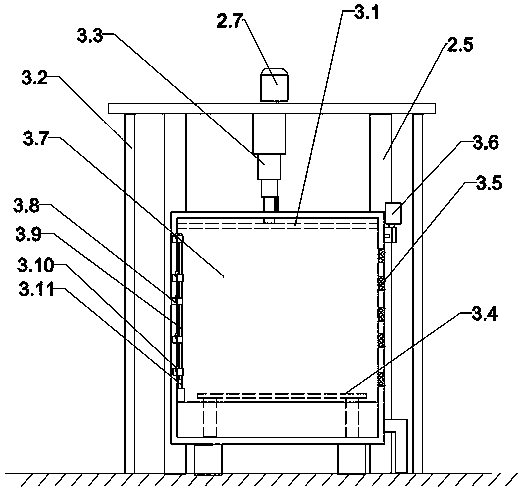

Blade robot welding system

InactiveCN103302439ALarge working spaceGreat system flexibilityWelding/cutting auxillary devicesAuxillary welding devicesUniversal jointMonitoring system

The invention relates to the field of machinery, in particular to a blade robot welding system for welding agitating vessel tools. The system comprises an adjustable roller carrier, the agitating vessel tools arranged on the adjustable roller carrier, controllers arranged on the adjustable roller carrier, a uniaxial position changer connected with the agitating vessel tools through universal connectors, a robot for welding the agitating vessel tools and a robot movement device for moving the robot. When the blade robot welding system works, the robot is fixedly arranged on a telescopic arm, and has a maximum working space and system flexibility, and the agitating vessel tools are arranged on the uniaxial position changer, and are connected with the uniaxial position changer through universal joints, so that the agitating vessel tools are effectively prevented from being non-concentric with the uniaxial position changer when rotating; and a workpiece can be driven by the uniaxial position changer to rotate on the adjustable roller carrier, the robot finishes automatically welding inner cavities of the agitating vessel tools according to a welding procedure which is compiled in advance, and in the whole welding process, a camera of an image monitoring system is used for tracking and monitoring, and welding fume is collected.

Owner:CHANGSHA HUAHENG ROBOT SYST

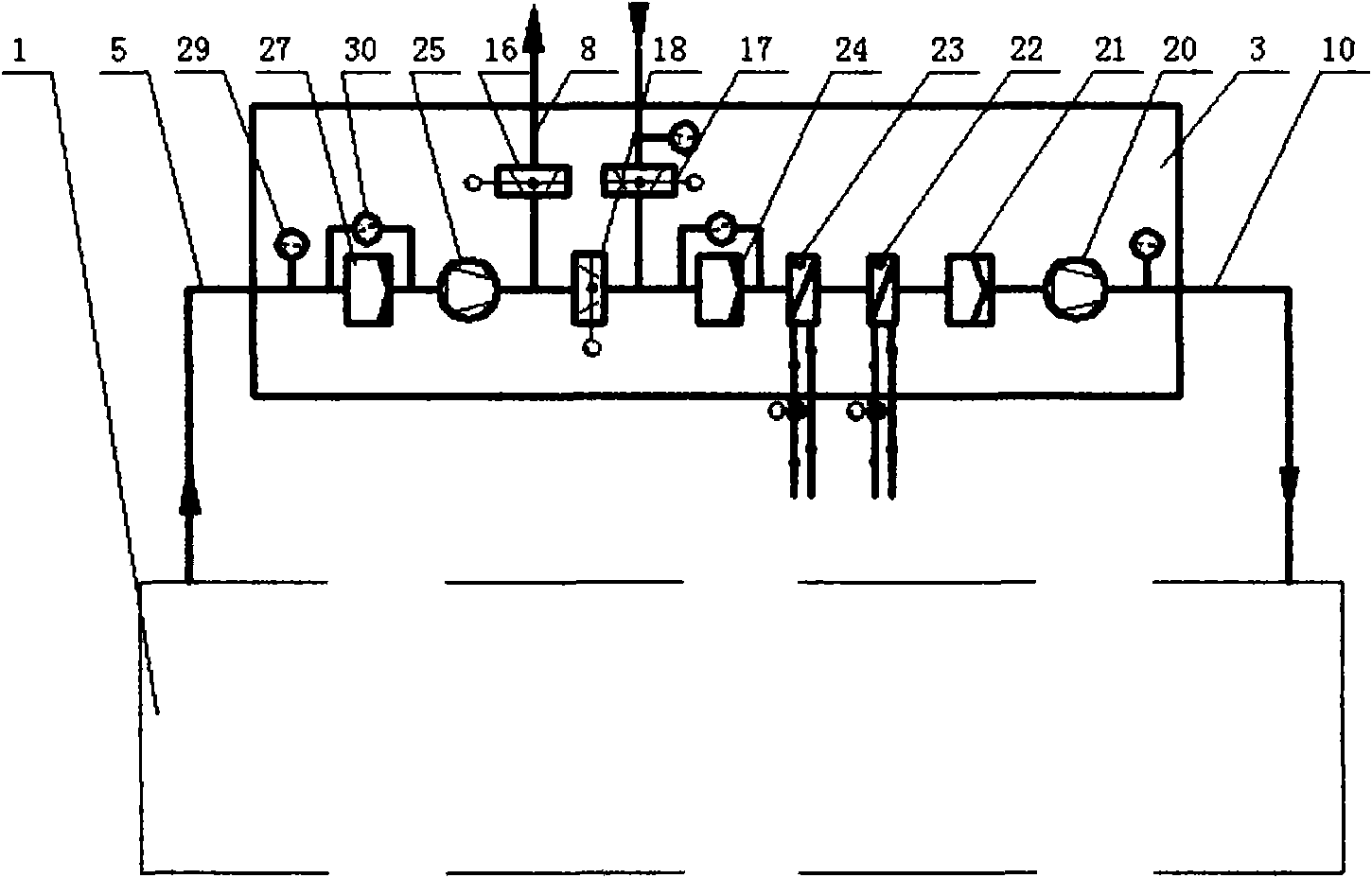

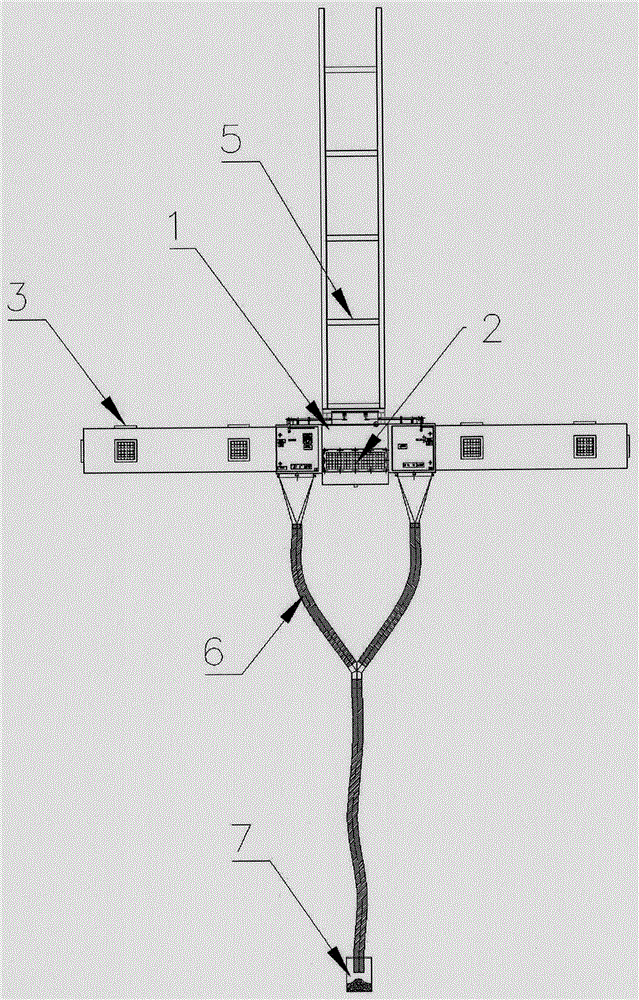

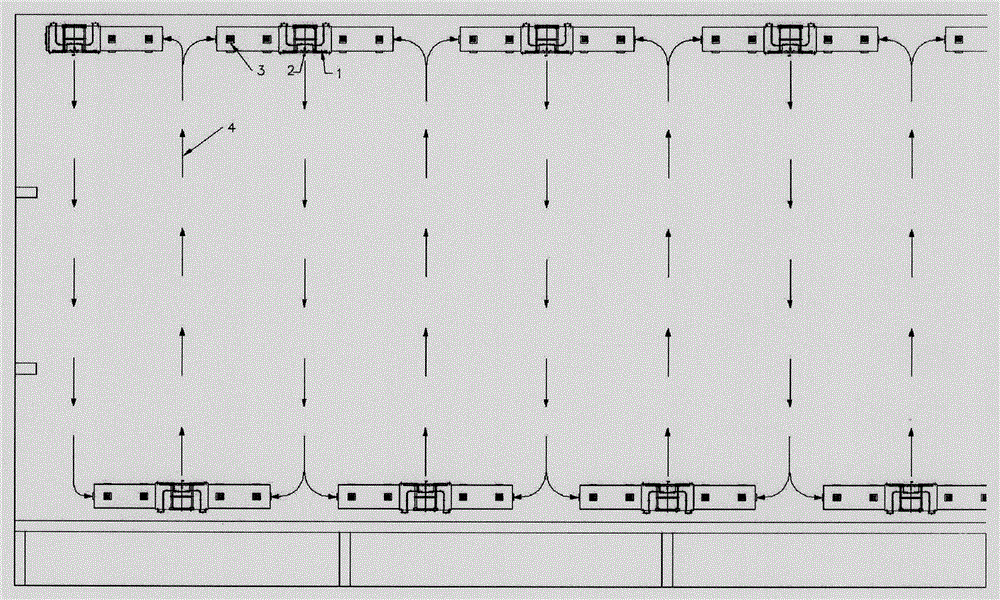

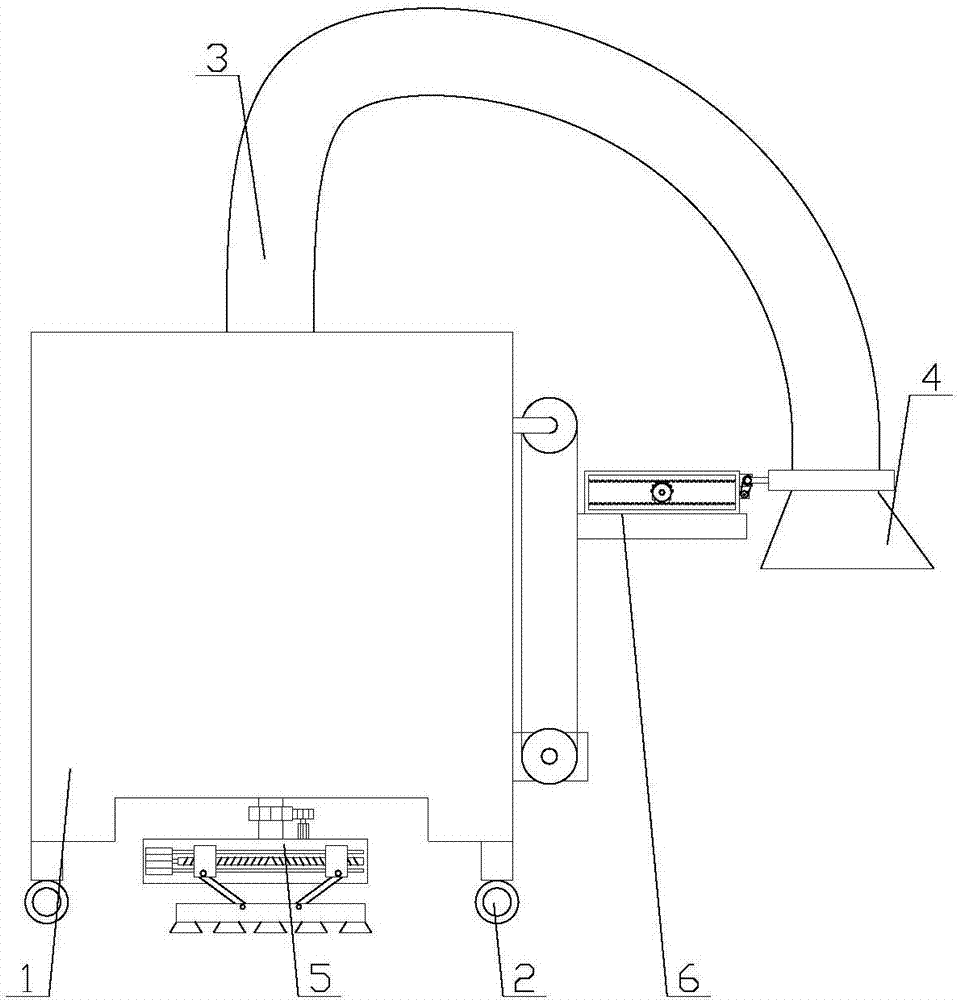

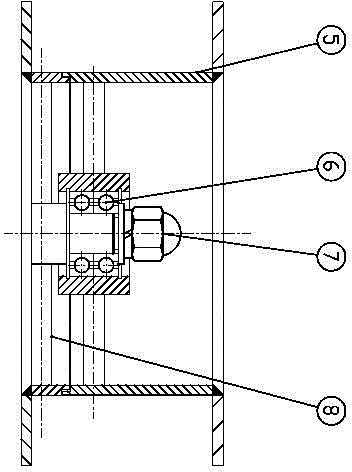

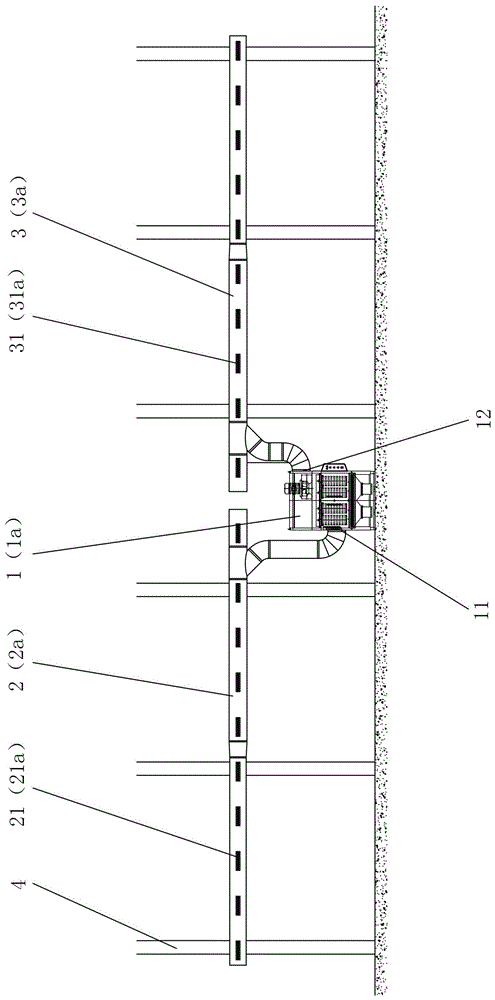

Blowing and inhaling type welding fume dust removal system

InactiveCN106731369AEffective controlWill not affect operationCombination devicesGas treatmentInhalationEngineering

The invention relates to a welding fume dust removal system and especially relates to a blowing and inhaling type welding fume dust removal system. For solving the problems that the welding fume is small in particle size, welding work stations are large in number, welding work pieces are large in size, and the welding fume is difficult to capture, the invention provides the blowing and inhaling type welding fume dust removal system, which utilizes jet flow as power and transports harmful substances, such as the welding fume, to an air suction port; and then the welding fume is filtered and discharged through an electrostatic dust remover. In addition, diffusion of the harmful substances, such as the welding fume, is inhibited and controlled by the jet flow. The system integrates both air flow blowing and inhalation, wherein the air blowing port is arranged opposite to the air suction port to form blowing and inhaling air flow, which is used for inducing, controlling and filtering the air flow of the harmful substances, such as the welding fume.

Owner:BEIJING TIMELAND GENERAL EQUIP CO LTD

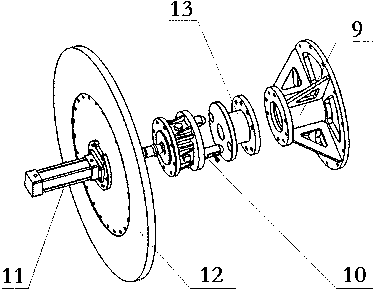

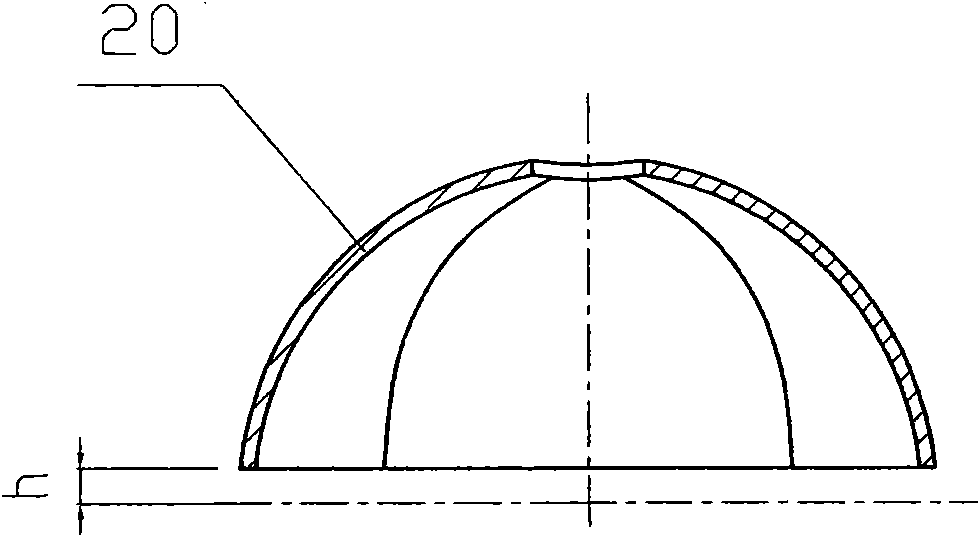

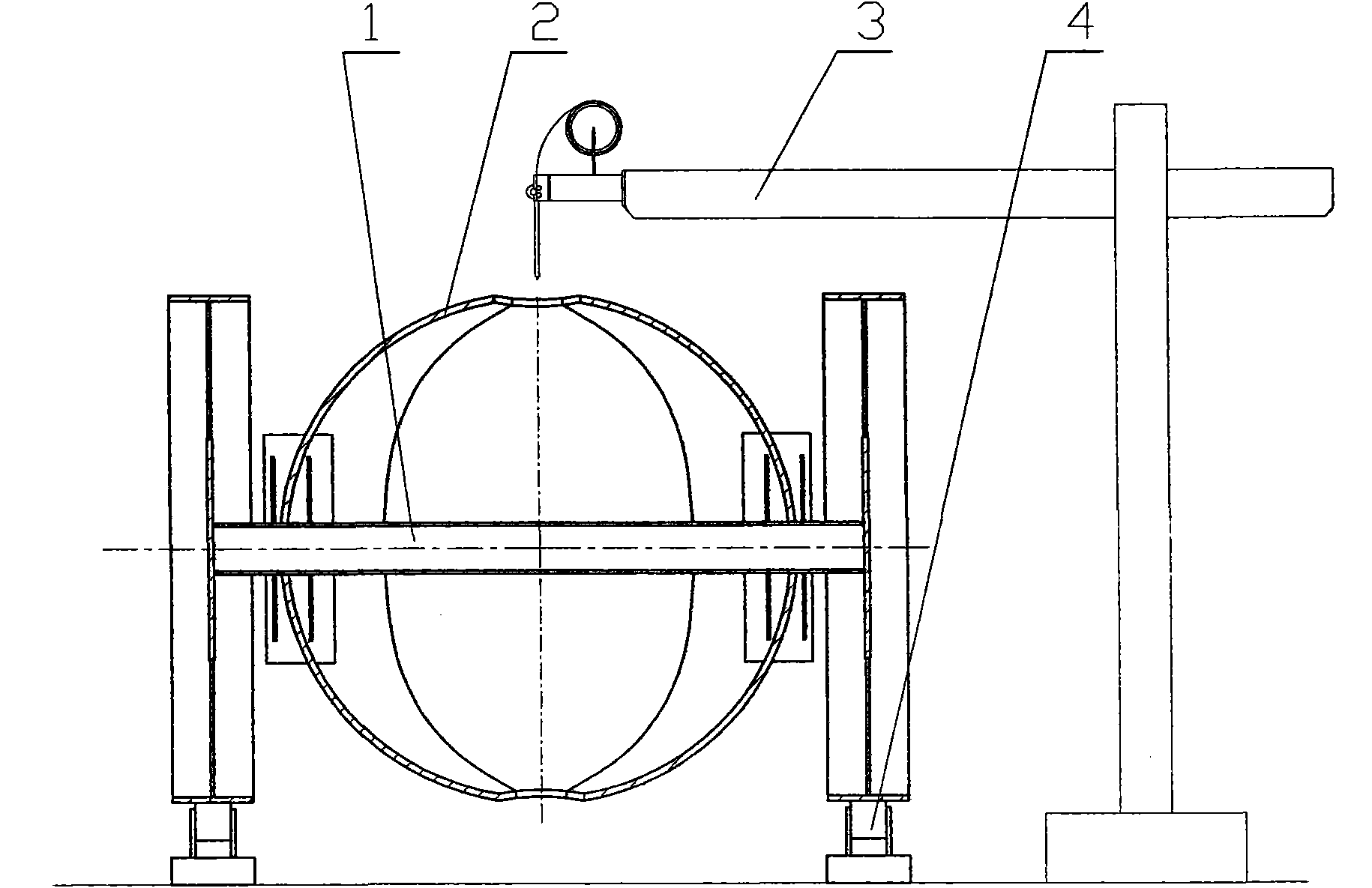

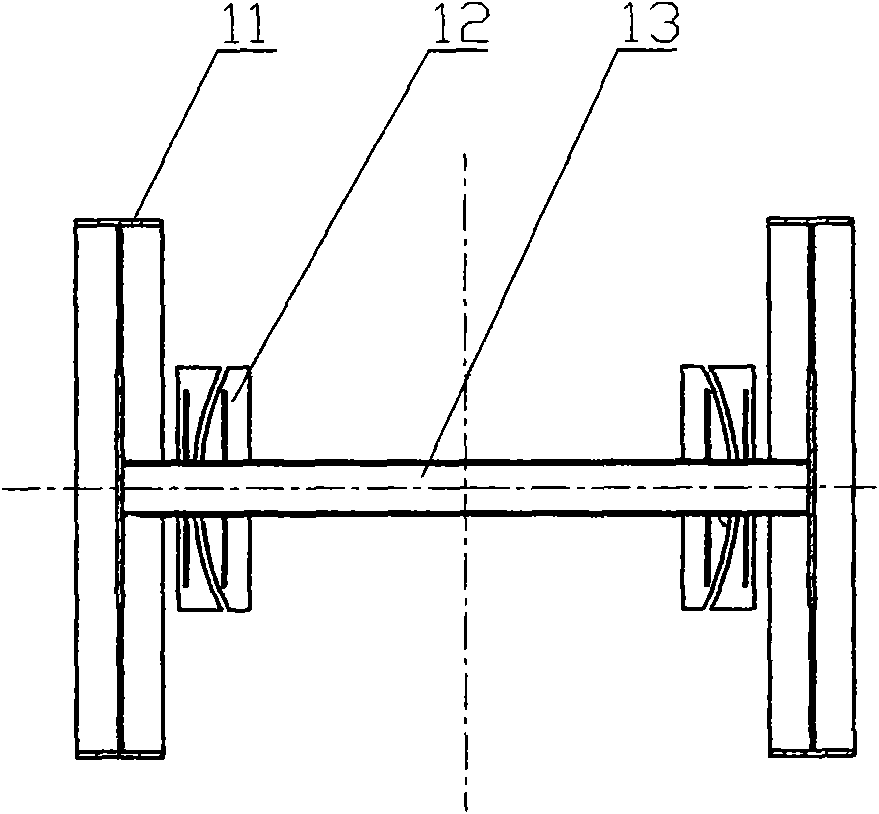

Submerged automatic arc welding tool for segment-shaped seal head

The invention discloses a submerged automatic arc welding tool for a segment-shaped seal head, relates to a welding tool for spherical seal heads, and solves the problems of low welding efficiency, low welding line quality and heavy welding fume pollution in the prior art. The tool consists of two rotating wheels, a workbench and eight groups of fixing clamping plates, wherein the two rotating wheels are fixed at the two ends of the workbench respectively; the eight groups of fixing clamping plates are symmetrically arranged on the upper plane and the lower plane of the workbench close to the rotating wheels respectively; the thickness H of the workbench is two times that h of the segment of the segment-shaped seal head; and the two rotating wheels are arranged on a roller respectively, and the roller is driven by a motor and a speed reducer. The thickness of the workbench just makes up the segment of two spherical seal heads, so that a sphere is formed and rotates around a fixed axis; and the tool can be used for performing submerged automatic arc welding. Therefore, the tool is suitable for the submerged automatic arc welding of large-diameter spherical seal heads.

Owner:TAIYUAN HEAVY IND

Low-dust environment-protection carbon-steel electric welding bar

InactiveCN1404960AImprove protectionSave resourcesWelding/cutting media/materialsSoldering mediaManganeseEngineering

The low-dust environment-protecting type carbon steel electric welding rod is made up by using reduced ilmenite, rutile, mica, white mud, medium manganese, marble, clay, pyrauxite, feldspar, wollastonite and natural cereal skin as main raw material. Said electric welding rod possesses excellent welding property, high deposition rate, can reduce welding smoke and dust, and is favorable for protecting environment, and its cost is low.

Owner:魏玉刚

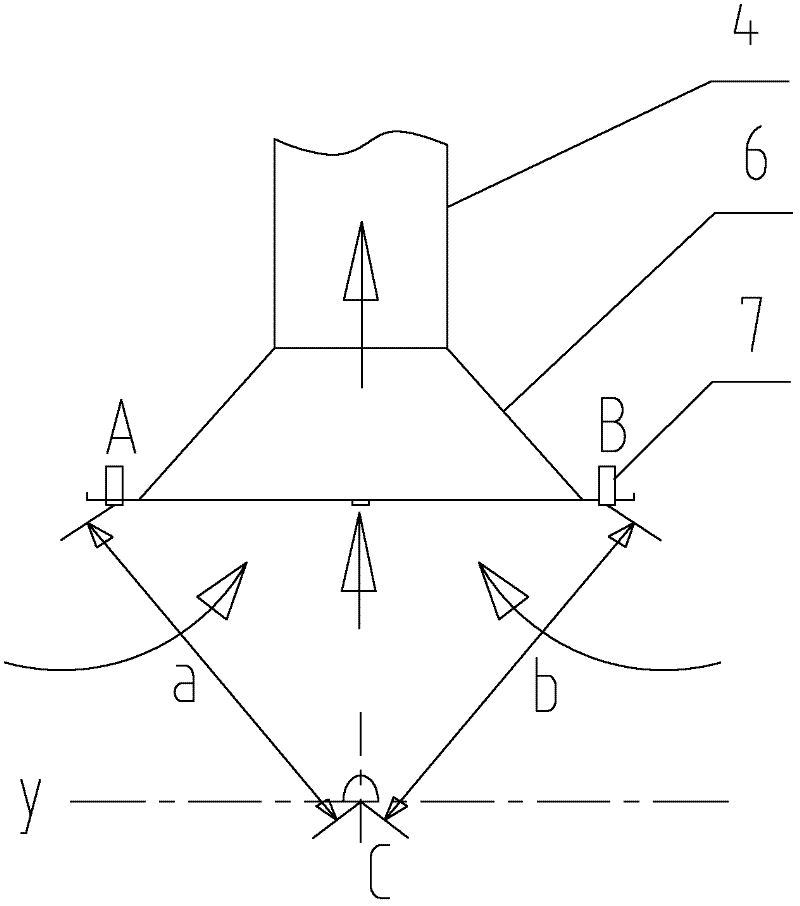

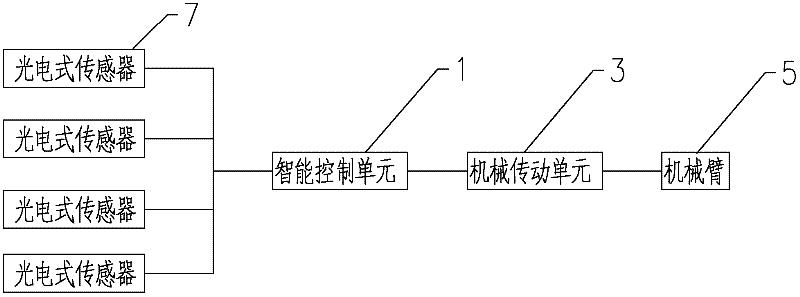

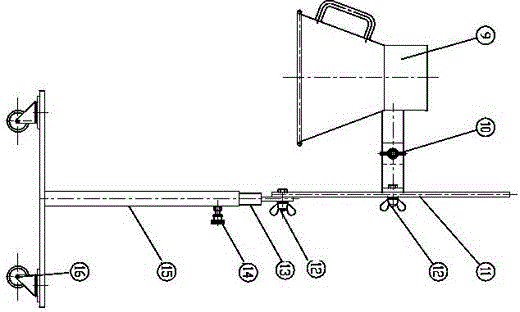

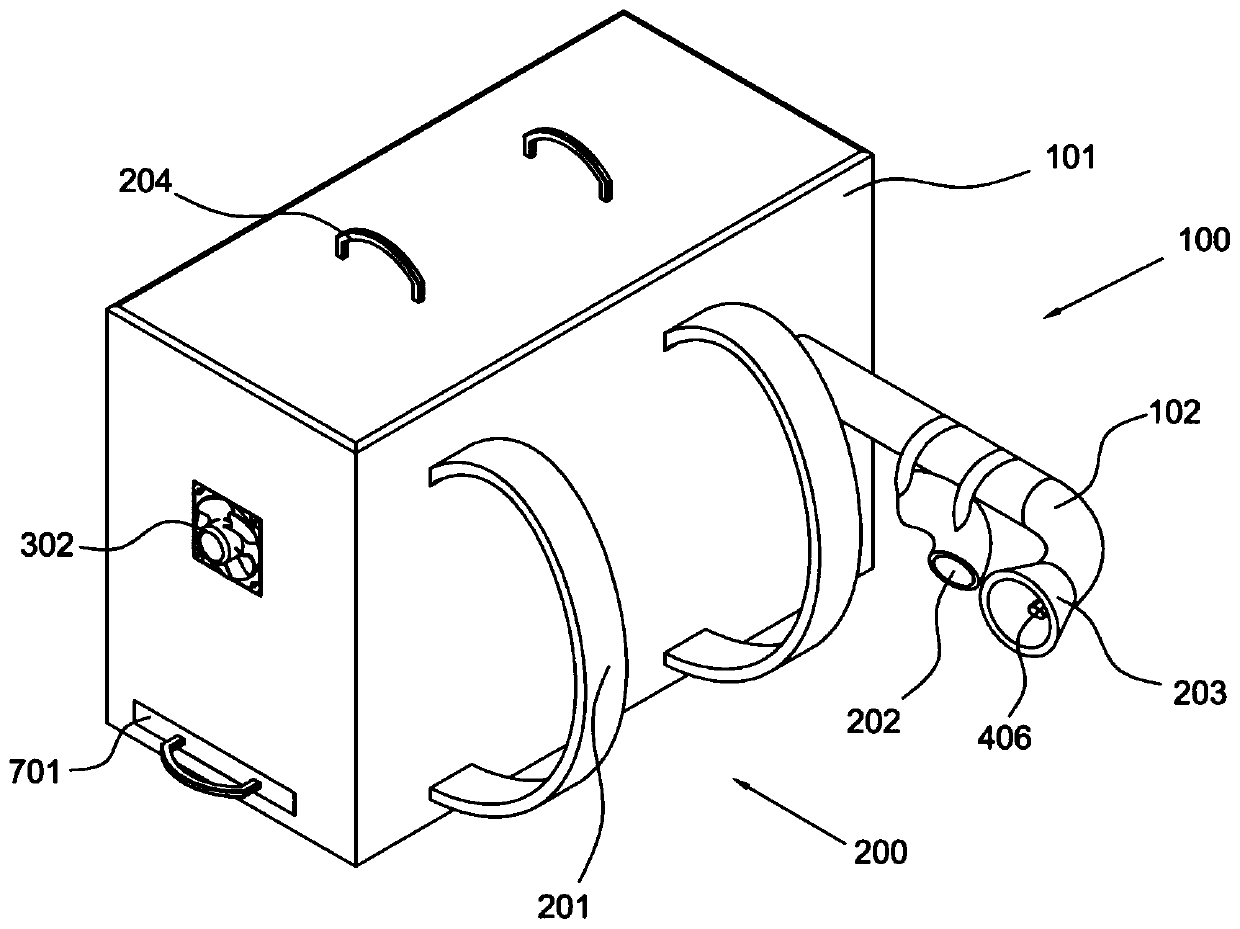

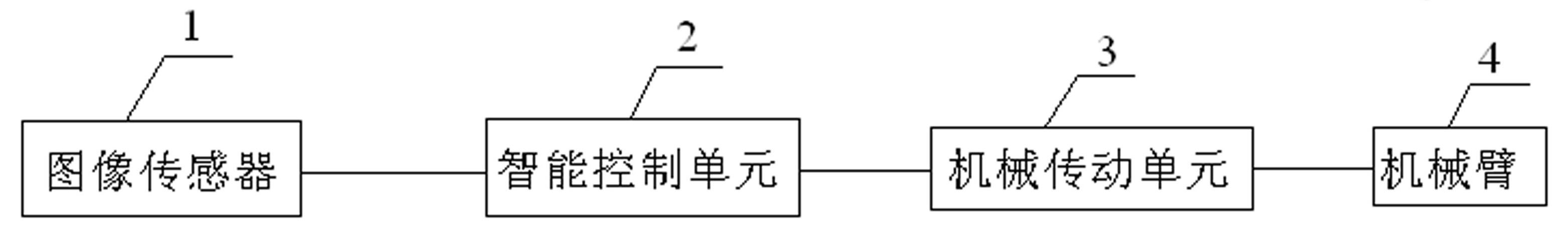

A welding smoke collection device and method capable of automatically tracking and positioning welding points

InactiveCN102266862AImplement trackingEffective collection and processingDirt cleaningEngineeringDistance sensors

A welding fume collection device and method capable of automatically tracking and positioning welding points. The welding fume collection device includes a tracking control system and a welding fume exhaust pipe. The tracking control system includes a group of photoelectric sensors, an intelligent control unit, and a mechanical drive. The welding smoke collection method of the unit and the mechanical arm is to use the photoelectric sensors installed at different positions on the exhaust mask to sense the visible light, infrared rays or ultraviolet rays emitted by the solder joints, and the distance between the solder joint movement and the photoelectric sensors can be changed. The strength of the welding spot arc sensed by each photoelectric sensor changes, and each photoelectric sensor outputs an electrical signal to the intelligent control unit according to the sensed welding spot arc light intensity, and calculates the direction and direction of the welding spot movement. The distance is controlled by the mechanical transmission unit to drive the mechanical arm to move. The invention has high working efficiency, low energy consumption, low equipment cost, and can automatically realize the tracking of solder joints.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

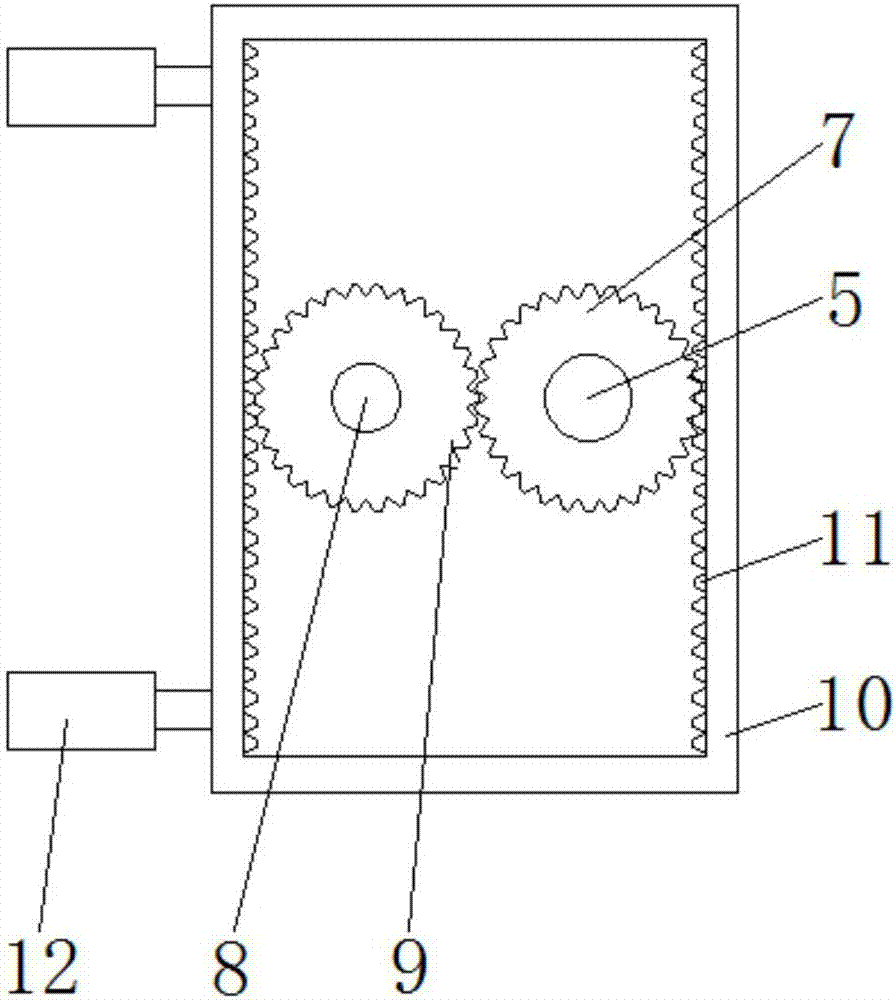

Welding fume recycling-purifying device

InactiveCN106076014AGood recovery and purification effectLow design costCombination devicesDispersed particle filtrationUltrasound attenuationGlass fiber

The invention relates to a welding fume recycling-purifying device. The welding fume recycling-purifying device comprises a frame and a fume recycling-purifying device which is fixedly arranged on the frame, wherein the fume recycling-purifying device comprises a shell, and a turbulent ball catching layer, a fume filtering layer, a fume adsorption layer and a fume ventilation layer which are distributed in sequence in the shell from bottom to top; gaps are reserved among the turbulent ball catching layer, the fume filtering layer, the fume adsorption layer and the fume ventilation layer; the turbulent ball catching layer, the fume filtering layer and the fume adsorption layer are detachably connected to the inside of the shell. Compared with the prior art, the welding fume recycling-purifying device has the advantages of low design cost, simple structure and good fume recycling-purifying effect; waste fume produced by welding is absorbed by comprehensively utilizing turbulent ball catching, glass fiber filter element board filtering and active carbon adsorption, and reaches an emission standard after being purified; meanwhile, a sound-attenuation board with a certain oblique angle is arranged, so that noise can be reduced in the running process of a fan; the welding fume recycling-purifying device has a compact structure and a high automation degree, and is convenient and easy to operate.

Owner:平湖拓伟思自动化设备有限公司

Spot welding machine welding fume purifying device with environment-friendly function

InactiveCN107442917AWith environmental protection functionPromote environmental protectionResistance welding apparatusPhysical healthDrive shaft

The invention discloses a spot welding machine welding fume purifying device with an environment-friendly function and relates to the technical field of spot welding machine purifying equipment. The spot welding machine welding fume purifying device comprises a bottom plate; a case is fixedly connected to the top of the bottom plate; a motor is fixedly connected to the bottom of the inner wall of the case through a connecting block; an output shaft of the motor is sleeved with a first bevel gear; and a transmission shaft is rotatably connected to the position, located on one side of the motor, at the bottom of the inner wall of the case through a bearing seat. According to the spot welding machine welding fume purifying device with the environment-friendly function, the environmental protection property of a spot welding machine is greatly improved, welding fume discharged by the spot welding machine is well collected and purified in a centralized mode, the situations that the welding fume is directly discharged into air and pollutes the environment around the spot welding machine are prevented, and the situation that workers suck the large amount of welding fume, and thus the physical health of the workers is greatly damaged is well avoided, so that normal spot welding work of the workers is guaranteed, and using of people for the spot welding machine is quite facilitated.

Owner:湖州同晟管理咨询有限公司

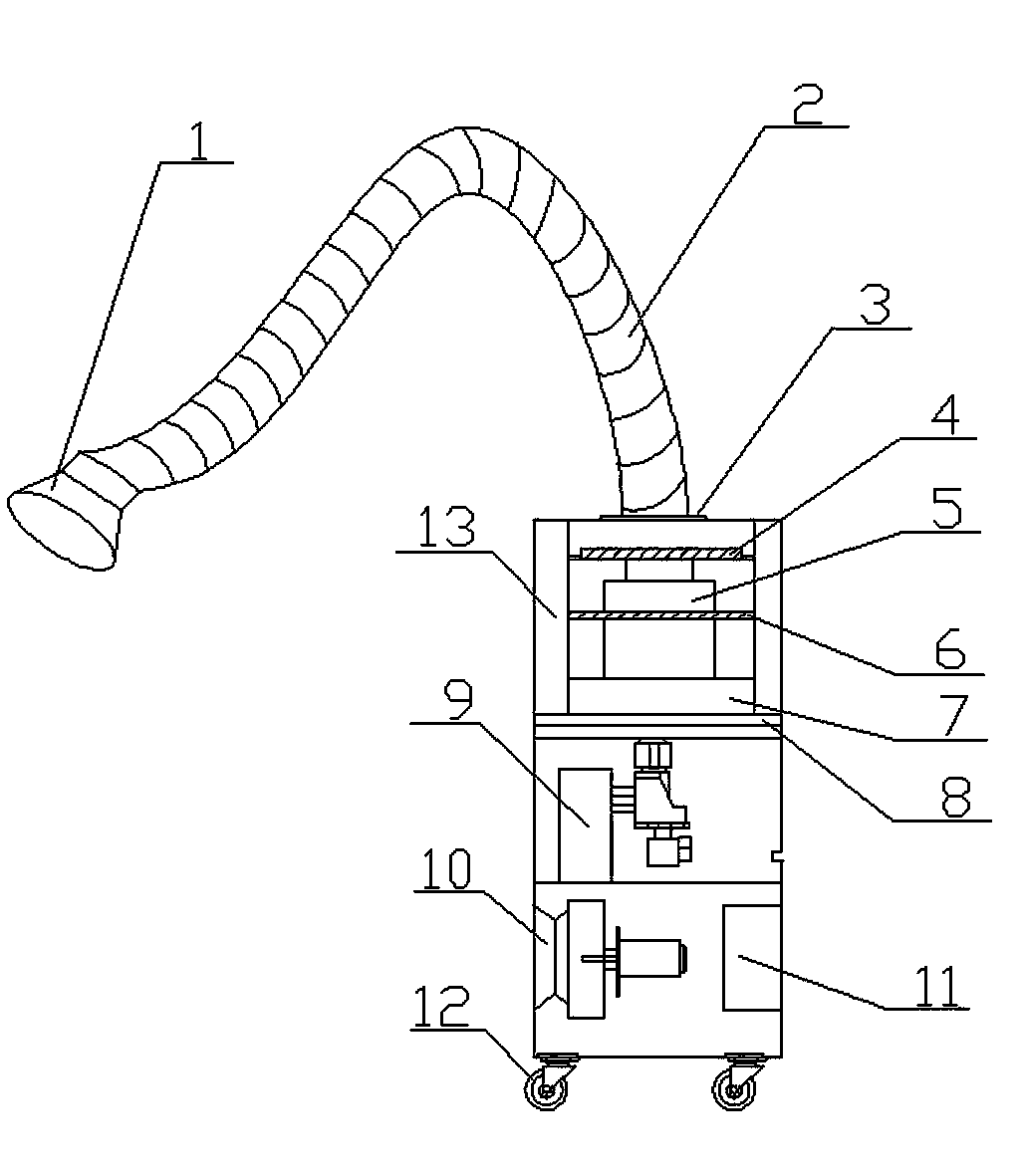

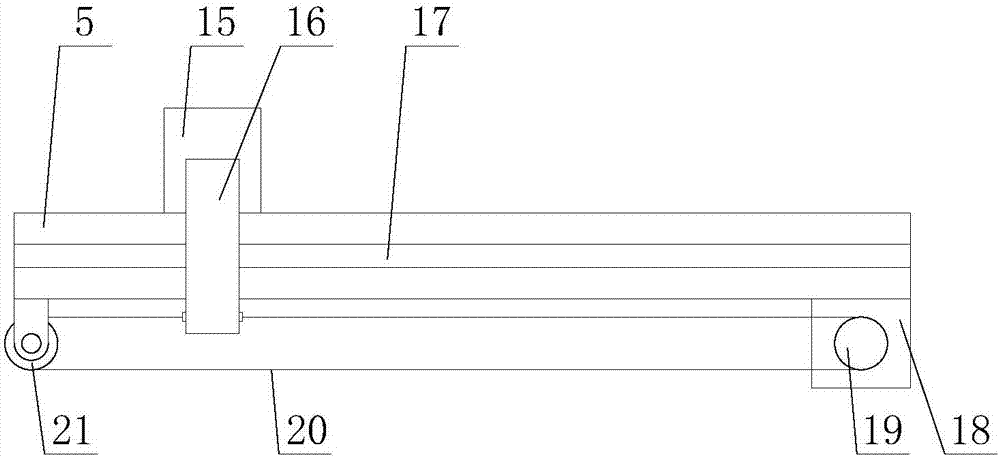

Welding fume purifying device capable of improving working efficiency of workers and good in purifying effect

InactiveCN107442543AImprove work efficiencyImprove purification effectDirt cleaningEngineeringWelding fume

The invention relates to a welding fume purifying device capable of improving the working efficiency of workers and good in purifying effect. The welding fume purifying device comprises a main body, trundles, an air suction arm and an air suction cover. The main body further comprises a bottom adjusting mechanism and a side face adjusting mechanism. The bottom adjusting mechanism comprises a rotating assembly and a supporting assembly. The side face adjusting mechanism comprises a fixing ring, a lifting assembly and a horizontal movement assembly. According to the welding fume purifying device capable of improving the working efficiency of workers and good in purifying effect, by means of cooperated work of the bottom adjusting mechanism and the side face adjusting mechanism, the position of the air suction cover is automatically adjusted, the air suction cover sucks fume along with movement of a fume source, convenience is brought to welding work of workers, and the working efficiency of workers is improved; and meanwhile, the fume suction cover can be precisely and automatically adjusted to the fume source to suck fume to the greatest degree, and the purifying effect is enhanced.

Owner:SHENZHEN LEYE TECH CO LTD

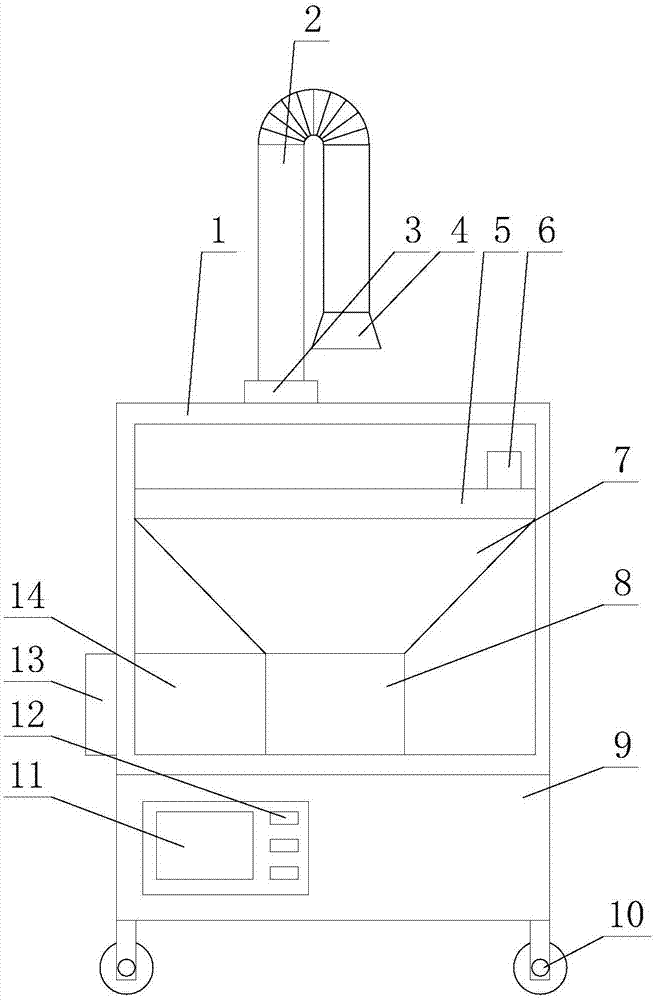

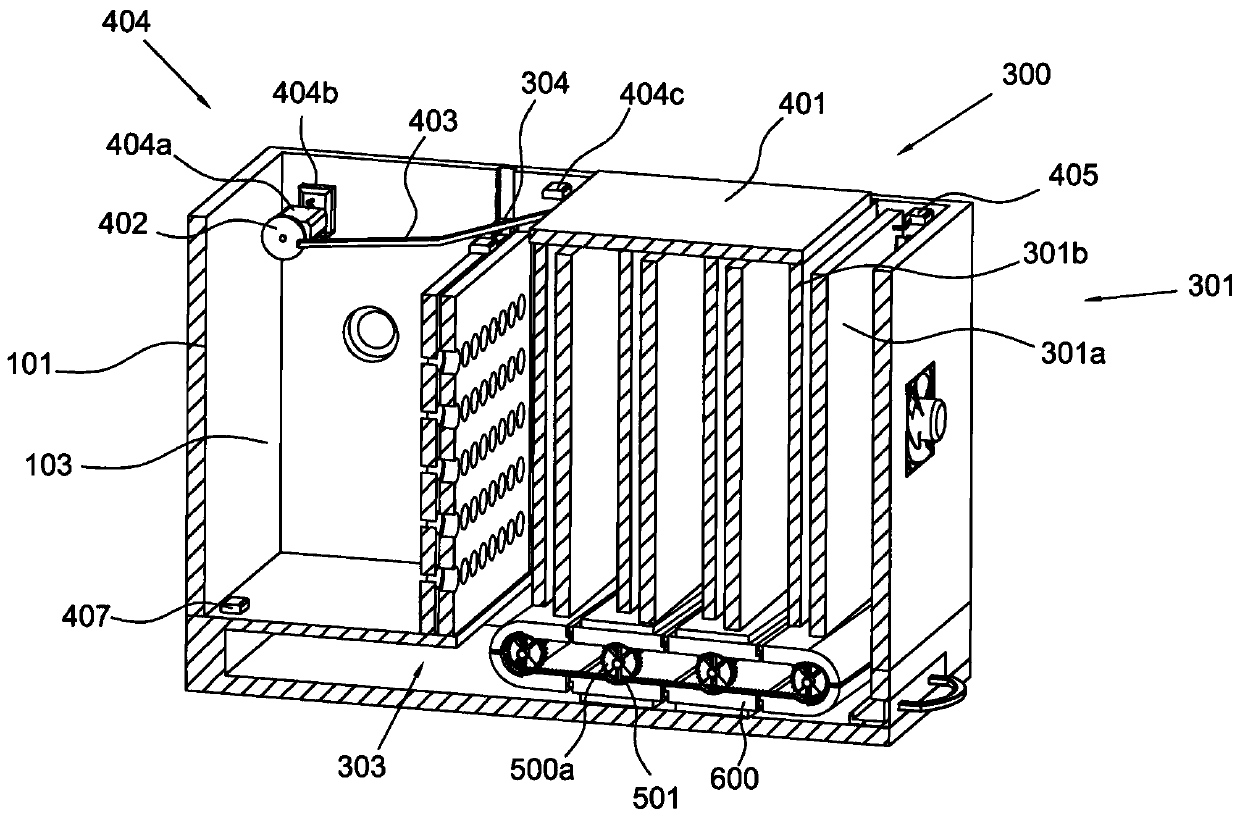

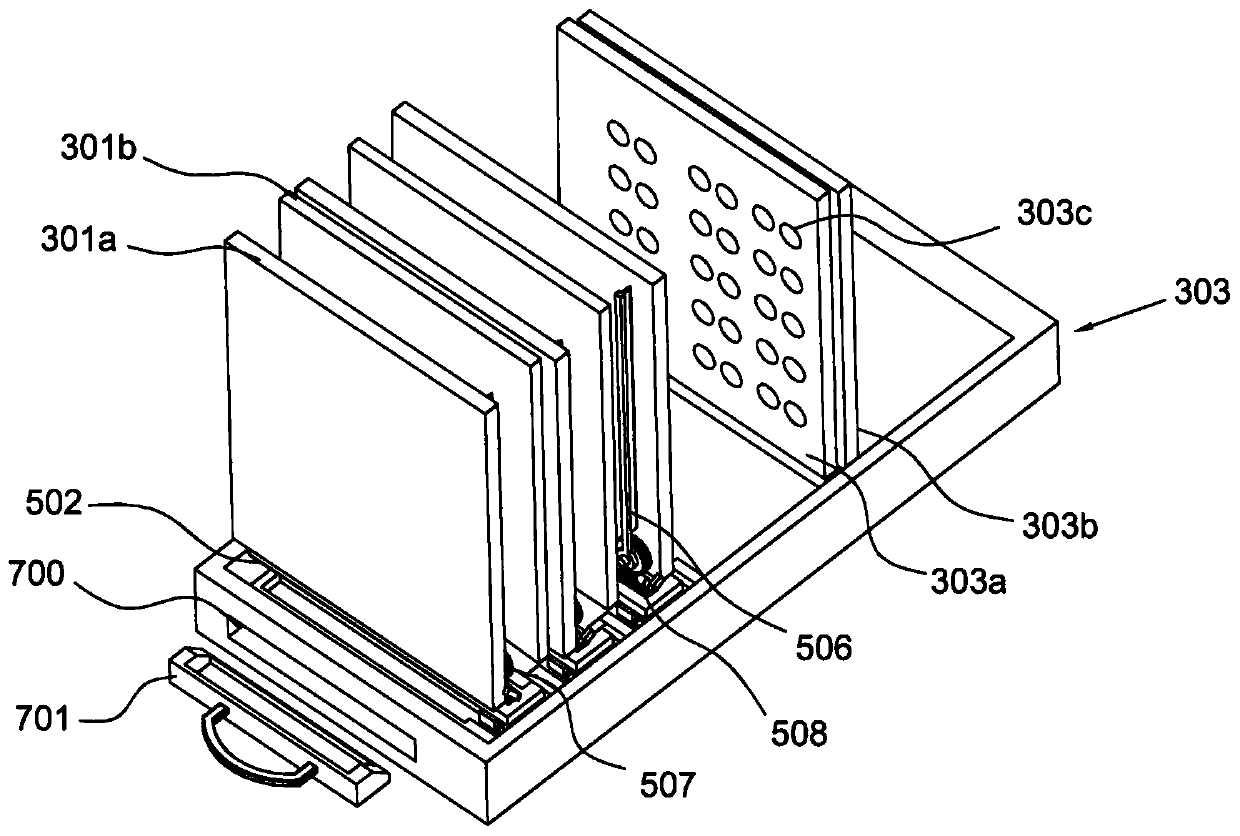

Welding fume purifier

InactiveCN103816727AImprove filtration efficiencyImprove filtering effectDispersed particle filtrationWater vaporAir filter

The invention discloses a welding fume purifier which comprises a box body, a dust hood and an air sucking arm, wherein the dust hood is mounted on the air sucking arm; the air sucking arm is fixedly arranged on the box body through a connecting flange; the air sucking arm is connected with a coarse filtration system arranged inside the box body; the coarse filtration system is connected with an air filter; the air filter is connected with an efficient filtration system; the efficient filtration system is connected with an active carbon filter; a pulse jetting device is mounted on the box body arranged at the lower end of the active carbon filter; a fan is mounted on the box body arranged at the lower end of the pulse jetting device; an electric control cabinet is mounted on the box body arranged at one end of the fan; and universal trundles are mounted at the bottom of the box body. The welding fume purifier has the beneficial effects that due to the combination of the coarse filtration system, the air filter, the efficient filtration system and the active carbon filter, the dust, smoke and water vapor in the air can be filtered out, and the filtration effect is excellent.

Owner:MINGSHENG CHEM MACHINERY NANTONG

Welding device with welding fume removal function

InactiveCN108296683AHas the function of removing welding smokeEasy dischargeCombination devicesWelding/cutting auxillary devicesWelding fumePollution

The invention discloses a welding device with a welding fume removal function and relates to the technical field of welding equipment. The welding device with the welding fume removal function comprises a bottom box. Supporting columns are fixedly connected to the two sides of the top of the bottom box. A top box is fixedly connected to the top ends of the supporting columns. A first motor is fixedly connected to one side of the top of the top box. A gear is fixedly connected to one end of an output shaft of the first motor. A toothed plate is arranged on one side of the gear in an engaged mode. The bottom of the toothed plate penetrates through the top box and extends into the top box. A vertical plate is fixedly connected to the other side of the top of the top box. According to the welding device with the welding fume removal function, an inner box is fixedly connected to the top of the inner wall of the bottom box so that the quantity of fume discharged in the welding process is effectively reduced, and environment pollution caused by welding is relieved; and the supporting columns are fixedly connected to the two sides of the top of the bottom box, welding fume is sucked by two suction nozzles in a moving mode, and thus, pollution caused by welding fume can be effectively reduced.

Owner:沈小荣

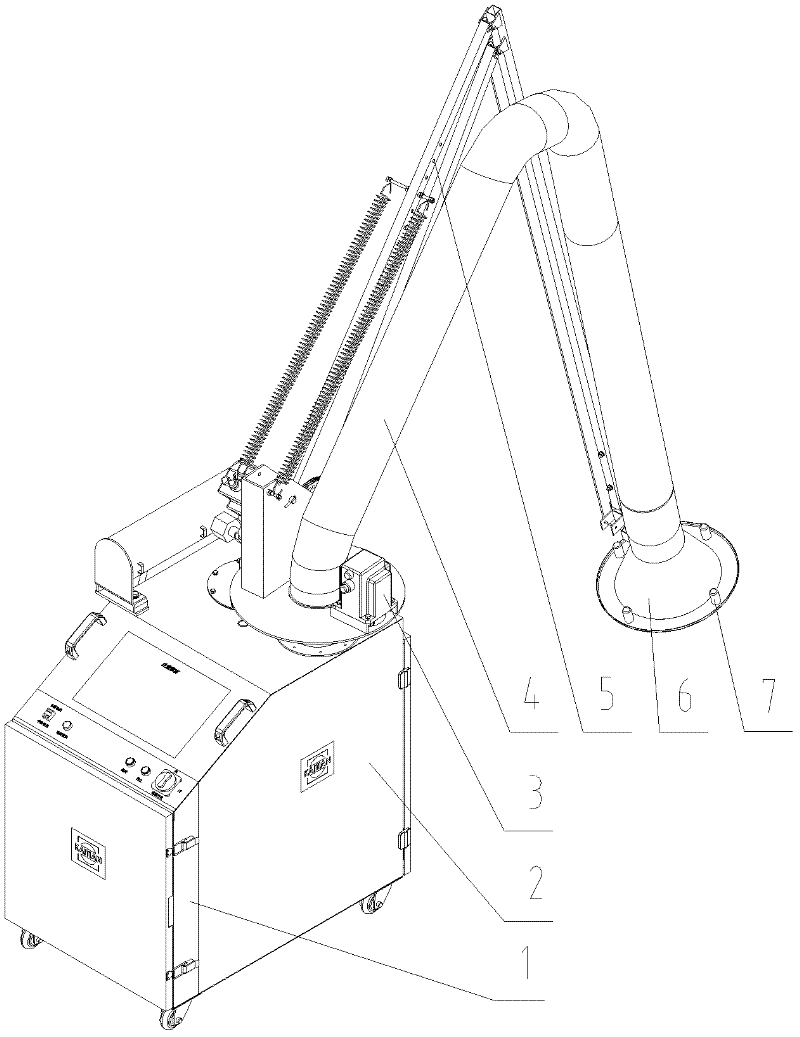

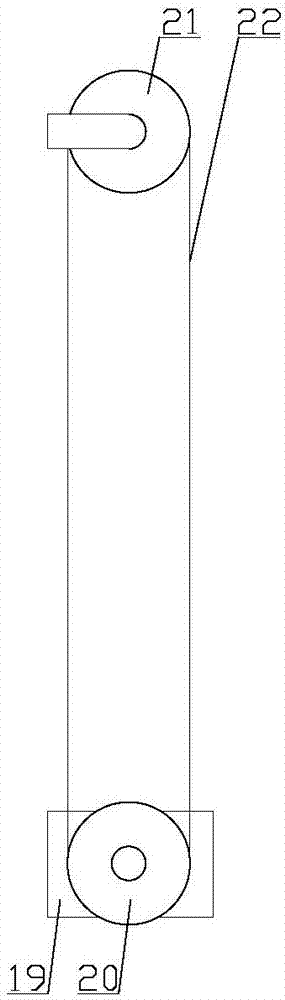

Novel universal flexible arm

ActiveCN104526201AOvercoming Welding Dust Removal ProblemsMeet welding dust removal requirementsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding fume

The invention relates to a novel universal flexible arm. The novel universal flexible arm comprises a rotary connector, a flexible arm body and a dust suction hood. The lower portion of the rotary connector is fixed to a dust remover, and the upper end of the rotary connector is connected with the flexible arm body. True universal dust removal is achieved, and the problems that large workpieces cannot be welded through an existing welding fume dust remover and the existing welding fume dust remover cannot be used remotely are solved. The rotary connector is used for truly achieving the purpose that the flexible arm body is rotated in horizontal space by 360 degrees, the flexible arm body and a movable support can achieve dust removal operation in different directions and at different heights, and remote dust removal is achieved. The novel universal flexible arm is wide in application range, stable in hovering and suitable for table type and hanging type installation modes and the like, and can be used in cooperation with the dust remover and also be used independently, the work efficiency in the welding process is improved, and welding fume can be more effectively collected.

Owner:QINGDAO DOUBLESTAR ENVIRONMENTAL PROTECTION EQUIP

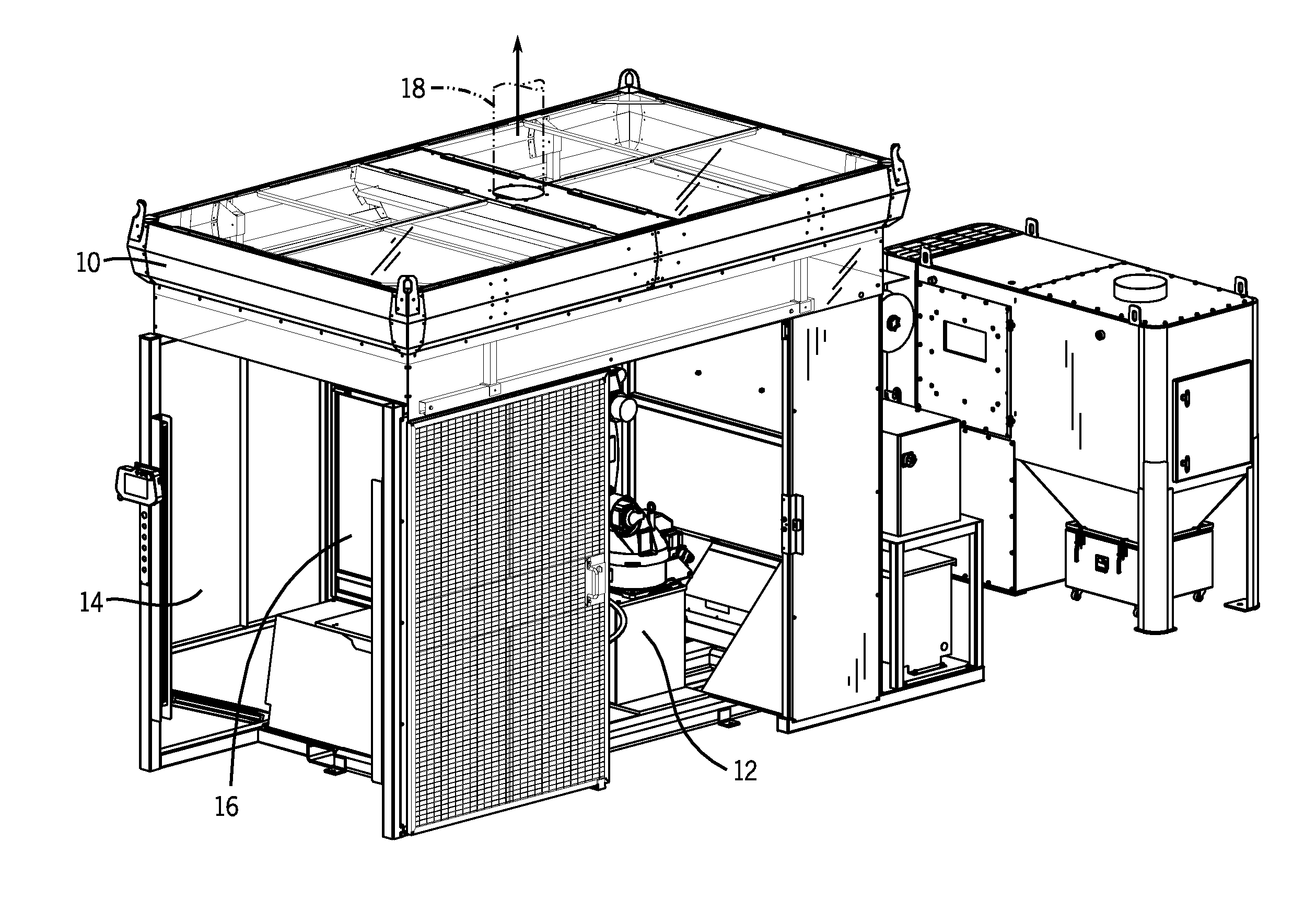

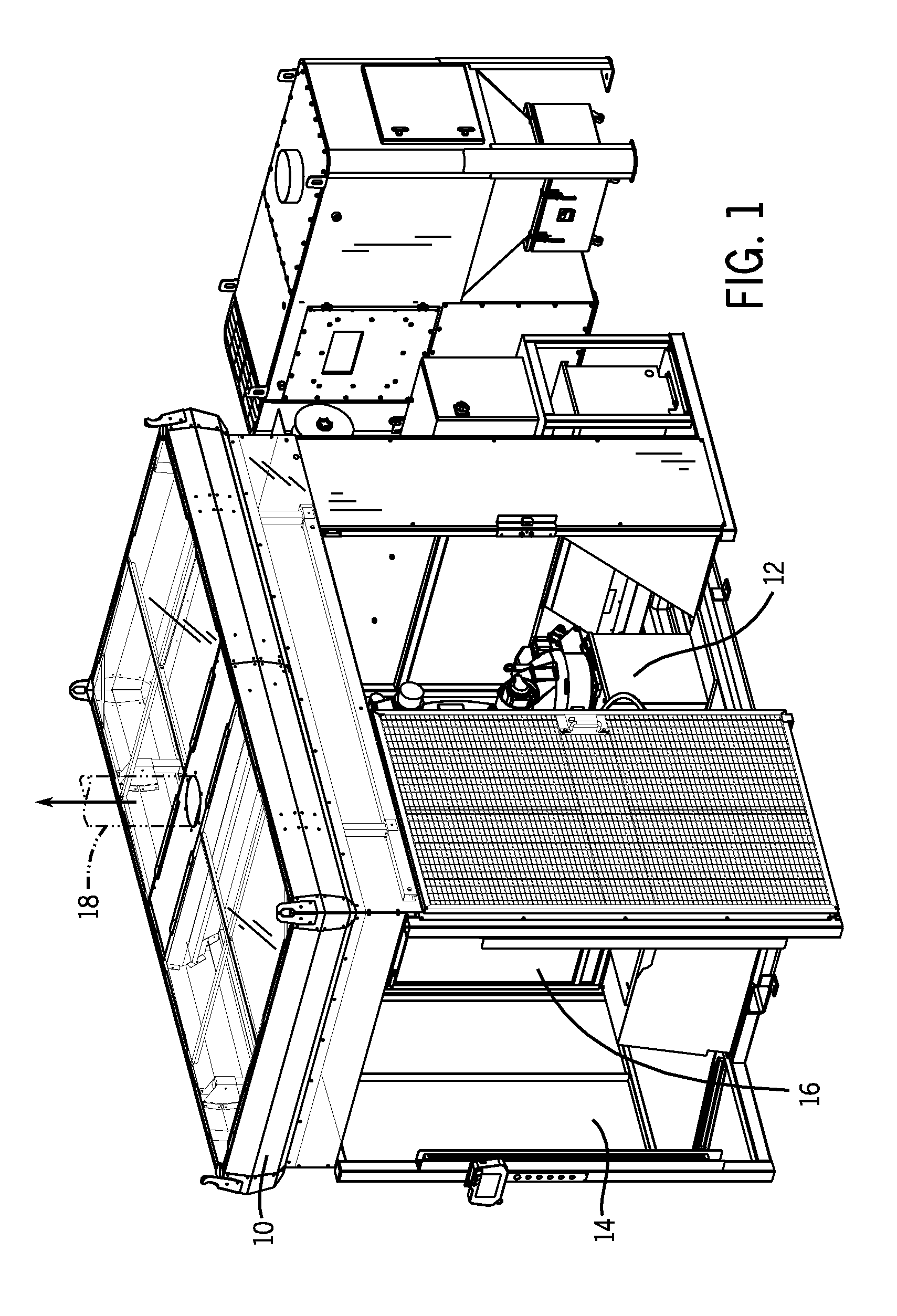

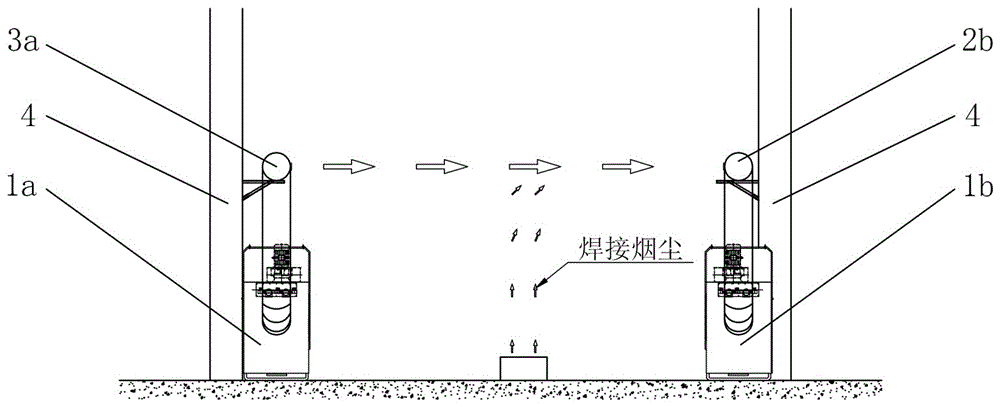

Fume welding and dust removing system for robot welding work station

ActiveCN102527688AEffective absorption and filtrationHarm reductionWelding/cutting auxillary devicesDirt cleaningEngineeringWelding fume

The invention relates to a fume welding and dust removing system for a robot welding work station. The fume welding and dust removing system is used for absorbing fume generated by welded arcing points during filter welding and comprises a movable dust exhaust hood, a dust removing pipeline and a welding fume processer, wherein the dust exhaust hood is arranged above the welded arcing points and covers the welded arcing points; the dust exhaust hood comprises a framework and is provided with an upper end face, a lower end face and side surfaces; the upper end face and the lower end face are respectively provided with end face plates for sealing the upper end face and the lower end face; an exhaust opening is formed in the lower end face; an arc light preventing falling curtain is arranged on the framework for shielding the side surfaces; one end of the dust removing pipeline is connected with the welding fume processor; the other end of the dust removing pipeline is connected with the upper end face of the dust exhaust hood; and when the robot welding work station works, the welding fume processor works, so that negative pressure generates inside the dust exhaust hood, the fume enters the dust exhaust hood through the exhaust opening and is absorbed to the fume processor through the dust removing pipeline for filtering. According to the fume welding and dust removing system disclosed by the invention, the fume generated by welding can be effectively absorbed and filtered and the harm on a human body caused by welding fume is minimized.

Owner:XUZHOU HUAHENG ROBOT SYST

Factory building welding exhaust gas purification apparatus

InactiveCN109692533AReduce filtration efficiencySimple structureDispersed particle filtrationTransportation and packagingWelding fumeExhaust gas

The invention discloses a factory building welding exhaust gas purification apparatus. The apparatus comprises a welding fume purifier, a welding fume purifying device is arranged in the welding fumepurifier, a cleaning device is arranged in the welding fume purifying device, a vacuum gas suction and recovery device is arranged below the welding fume purifying device, a universal telescopic gas suction tube device is arranged above the vacuum gas suction and recovery device, a cleaning device is arranged below the side surface of the welding fume purifier, a rotatable connecting short rod isarranged in the universal telescopic gas suction tube, the connecting short rod swings to drive the universal telescopic gas suction tube to move to purify fume, and the gas suction using a gas suction pump makes the universal telescopic gas suction tube return into the welding fume purifier to make the apparatus conveniently used by a user. The apparatus has the advantages of simple structure andstrong practicability.

Owner:柳州若思纳米材料科技有限公司 +1

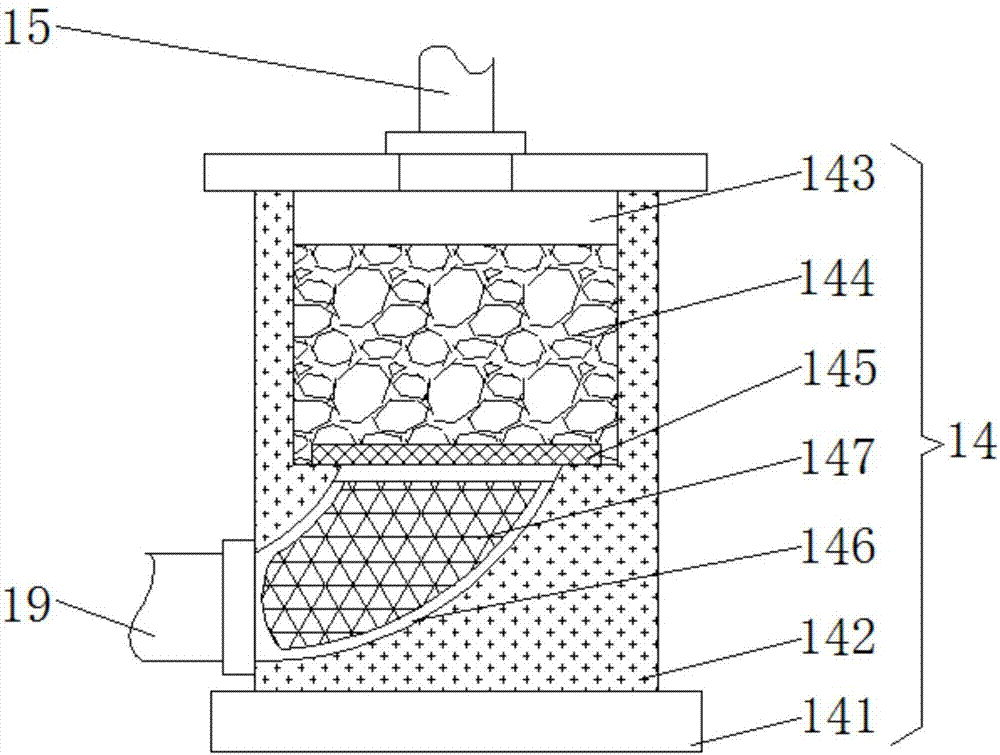

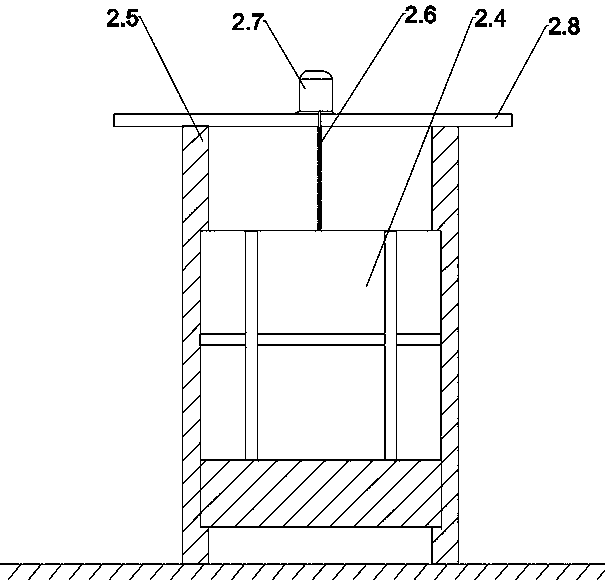

Vacuum welding equipment and using method thereof

ActiveCN109570722AReduce vacuum timeIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding fume

The invention provides vacuum welding equipment and a using method thereof. The vacuum welding equipment comprises a vacuum device, a welding vacuum chamber, a feeding vacuum chamber, an electron beamwelding device, a welding worktable, an argon arc welding device and a nitrogen generation device; the welding vacuum chamber and the feeding vacuum chamber are provided with a piston sealing plate and a lifting sealing plate correspondingly; the electron beam welding device is arranged on the piston sealing plate, and the welding worktable can be overturned by 180 degrees and rotated by 360 degrees; the argon arc welding device is mounted on the piston sealing plate in a replaceable mode, and the nitrogen generation device can provide liquid nitrogen for a welding gun and a weldment for cooling; and the vacuum device is connected to the welding vacuum chamber and the feeding vacuum chamber for vacuumizing. Continuous production can be conducted without interrupts, the volumes of the vacuum chambers can be adjusted according to the size of the weldment, welding processes can be switched, a welding fume treatment device is arranged, thus the very environment-friendly effect is achieved, and production requirements of the modern novel vacuum welding equipment are met.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Preparation method of filtering material used for welding fume

ActiveCN105126452ALow costWidely distributedPhysical/chemical process catalystsOther chemical processesRespiratorCarbonization

The invention relates to a preparation method of an air purifying filtering material, and more specifically discloses a preparation method of a filtering material used for welding fume. The preparation method is used for solving a problem of conventional welder anti-dust respirators that adsorption and dedusting performance is poor. The preparation method comprises following steps: 1, medical stone powder is prepared; 2, medical stone nano-grade particles are prepared; 3, surface modification is carried out so as to obtain surface modified particles; 4, heating blending is carried out so as to obtain a high polymeric compound; 5, carbonization is carried out so as to obtain a carbonization product; 6, melt spinning is carried out so as to obtain medical stone functional fiber; 7, catalytic activation modification is carried out so as to obtain catalytic activation modified medical stone fiber; and 8, spunlace moulding is carried out so as to obtain a medical stone functional filtering material which is the filtering material used for welding fume. The filtering material is taken as a dedusting filtering material.

Owner:HARBIN INST OF TECH

Welding fume purifier with self-cleaning function based on internet of things

InactiveCN107185317AImprove stabilityImprove purification effectDispersed particle filtrationTransportation and packagingThe InternetEngineering

The invention relates to a welding fume purifier with a self-cleaning function based on the internet of things. The welding fume purifier comprises a shell, a first air inlet pipe, a connecting mechanism, a dust suction inlet, a cleaning mechanism, a filtering mechanism and a base. The filtering mechanism comprises a filter layer, a second air inlet pipe, a fan, an air outlet pipe and an air outlet. The cleaning mechanism comprises a brush, a movable rod, a groove, a first motor, a first driving shaft, a steel wire rope and a pulley. The connecting mechanism comprises a supporting frame, a driving assembly and two clamping assemblies. The driving assembly comprises a sliding block, a second driving shaft, a second motor and a first transfer rod. According to the welding fume purifier with the self-cleaning function based on the internet of things, the first air inlet pipe can be disassembled through the connecting mechanism, the stability of the welding fume purifier motion process is improved, the operation risk is lowered, the filtering layer is cleaned through the cleaning mechanism, the purifying effect is improved, the time of artificial cleaning is shortened, and the working efficiency is improved.

Owner:泉州泉港润美环保科技有限公司

Welding fixture for gear selecting and shifting flexible shaft support assembly

InactiveCN109079395AHeight adjustableEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHigh frequency electromagnetic radiation

The invention discloses a welding fixture for a gear selecting and shifting flexible shaft support assembly. The welding fixture comprises a base plate, a clamping table, a clamping plate and a purifying tank, wherein electrohydraulic cylinders are arranged at the top of the base plate through bolts; the output ends of the electrohydraulic cylinders are connected with the clamping table; a high frequency electromagnetic radiation detector is arranged on one side of the clamping table through a mounting member; sliding rails are arranged at the top of the clamping table; clamping plates are arranged at the upper ends of the sliding rails; an arc-shaped clamping plate is arranged on the inner side of each clamping plate; a vertical clamping plate is arranged at the upper end of each arc-shaped clamping plate; fixed plates are arranged on two sides of the sliding rails; an electric telescopic rod is arranged on the inner side of each fixed plate through a mounting member; in addition, oneend of each electric telescopic rod is connected with the corresponding clamping plate; a rotating seat is arranged at one end of the top of the clamping table; a second fan is connected to one sideof the rotating seat through a connecting seat. The welding fixture disclosed by the invention has the advantages of simple operation and convenience in clamping, and can be used for absorbing and purifying welding fume and is suitable for popularization and use.

Owner:XIANGYANG ZHONGXINGHE AUTO PARTS CO LTD

Welding fume purifier

InactiveCN104275043AAvoid accumulationNo pollution in the processDispersed particle filtrationDirt cleaningFiltrationWater vapor

The invention discloses a welding fume purifier. The purifier comprises a machine body, wherein the top of the machine body is connected with an air sucking arm by virtue of a flange; an air sucking cover made of a heat-resistant steel material is arranged at one end of the air sucking arm; an anti-condensation layer is arranged inside the air sucking cover along the inner wall of the air sucking cover; an opening is formed in the upper end of the anti-condensation layer; the lower end of the air sucking cover is folded inwards and upwards to form an anti-condensation folded side; the lower part of the anti-condensation layer is connected into the anti-condensation folded side; a metal flexible pipe cylinder is inserted into the inner side of the air sucking arm; a plurality of plates rotating by virtue of shafts are uniformly arranged on the inner wall of the metal flexible pipe cylinder; a dust removal chamber is also formed in the machine body; the air sucking arm is connected with the dust removal chamber; a smell removal chamber connected with an air outlet is formed in the lower part of the dust removal chamber. The welding fume purifier is simple in structure, convenient to operate and reasonable in design, is capable of filtering dust, fume and water vapor, and has an excellent filtration effect.

Owner:SUZHOU CHENGYUAN PHOTOELECTRIC TECH

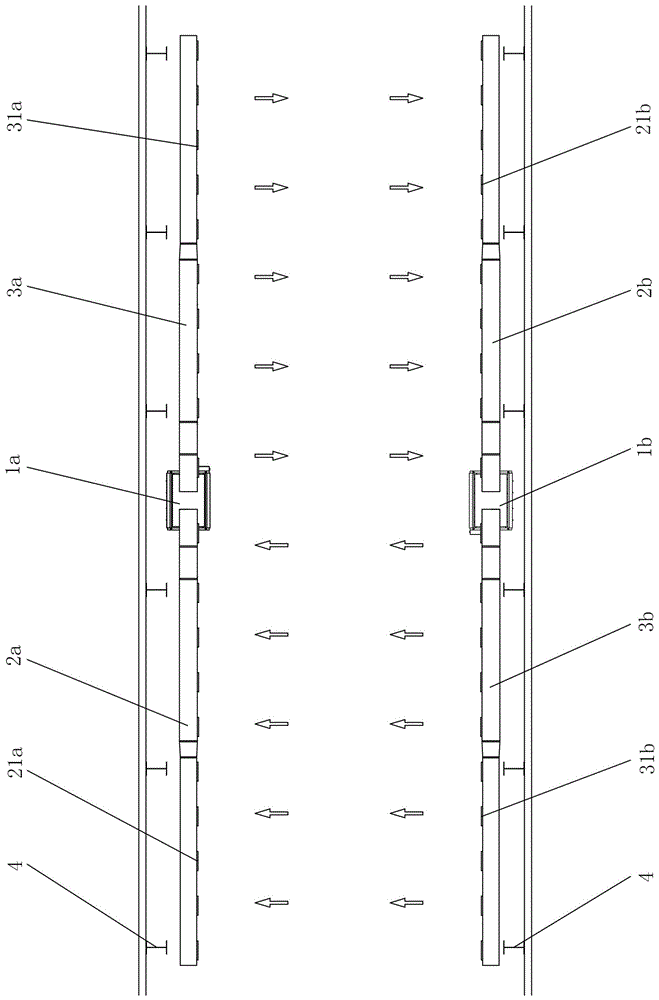

Blowing suction type dust removal system

PendingCN106824964AEasy to operateReduce energy costsWelding/cutting auxillary devicesDirt cleaningEngineeringWelding fume

The invention discloses a blowing suction type dust removal system. The blowing suction type dust removal system comprises one or two dust collecting devices, wherein each dust collecting device comprises a dust collector, an air suction pipe and an air exhaust pipe, the air suction pipes are connected with air inlets of the ash collectors, and the air exhaust pipes are connected with air outlets of the ash collectors. When the blowing suction type dust removal system comprises two dust collecting devices, gas exhausted from the air exhaust pipe of one dust collecting device passes through a fume suspension layer, and fume can be blown to the air suction pipe of the other dust collecting device; when the blowing suction type dust removal system comprises one dust collecting device, gas exhausted from the air exhaust pipe passes through a weld fume suspension layer, and the fume can be blown to the air suction pipe. The blowing suction type dust removal system has the advantages that the structure is simple, the operation is facilitated, energy is saved, the purification efficiency is high, the purification effect is good, and the relief of manual labor intensity and the increase of working efficiency are facilitated.

Owner:WELLDONE ENVIRONMENTAL PROTECTION EQUIP CHANGSHA

Portable welding fume collecting and processing device

ActiveCN111515024AHigh coincidenceReduce volumeWelding/cutting auxillary devicesDirt cleaningFiberCarbon fibers

The invention discloses a portable welding fume collecting and processing device which comprises a basic assembly which comprises a box body, an air suction pipe communicating with the box body and extended outside and a storage cavity arranged in the box body, wherein the box body is made of carbon fibers; a portable assembly which comprises straps connected to the box body, a connecting sleeve arranged on the air suction pipe and a handle arranged on the box body, wherein an air collecting hood is arranged at the front end of the air suction pipe; and a collection assembly, wherein the collecting assembly is arranged in the storage cavity. The device is small in size, light in weight and convenient to carry; data detected by the dust detector is transmitted to a database in which a largeamount of experimental data is stored in the detector; after data comparison, the spacing of the optimal rectifying plate hole coincidence degree, the voltage and an electrode plate is obtained, a database transmits the data to a driving system, the driving system executes a command, a point-to-point collecting and processing mode is adopted, welding fume is collected and processed from the source, and the collecting and processing efficiency of the welding fume can reach 90% or above.

Owner:JIANGSU UNIV OF SCI & TECH

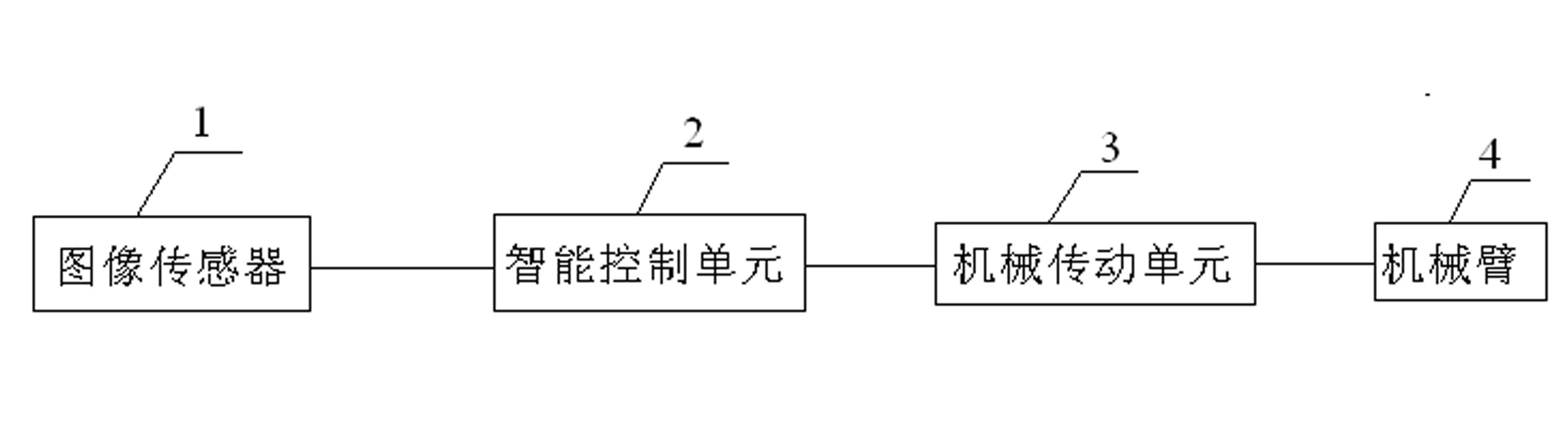

Welding fume collecting device and method capable of automatically tracking and positioning welding point

InactiveCN101829870AImplement trackingEffective collection and processingWelding/cutting auxillary devicesDirt cleaningInfraredControl system

The invention discloses a welding fume collecting device and a welding fume collecting method capable of automatically tracking and positioning a welding point. The welding fume collecting device comprises a tracking control system and a welding fume exhaust tube, wherein the tracking control system comprises an image sensor, an intelligent control unit, a mechanical transmission unit and a mechanical arm; the image sensor is connected with the intelligent control unit; the intelligent control unit is connected with the mechanical transmission unit; the mechanical transmission unit is connected with the mechanical arm; and the image sensor is arranged at the end part of the mechanical arm. The welding fume collecting method comprises the following steps of: sensing visible light or infrared rays emitted by the welding point by using the image sensor, wherein the welding point is a light spot in a sensed image; transmitting image information to the intelligent control unit through the image sensor, analyzing and processing the image information through the intelligent control unit, calculating the change direction and distance of a light spot coordinate, and controlling the mechanical transmission unit to drive the mechanical arm to move; and when the light spot coordinate value is the same as the preset point coordinate value, stopping the movement of the mechanical arm. The device and the method have high working efficiency and low energy consumption, and can automatically realize the tracking of the welding point.

Owner:欧朝旭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com