Blowing suction type dust removal system

A technology of dust removal system and dust collector, applied in the direction of removing smoke and dust, auxiliary devices, cleaning methods and utensils, etc., can solve the problems of increasing labor intensity, affecting work efficiency, inability to use, etc., so as to reduce labor intensity and save energy costs. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

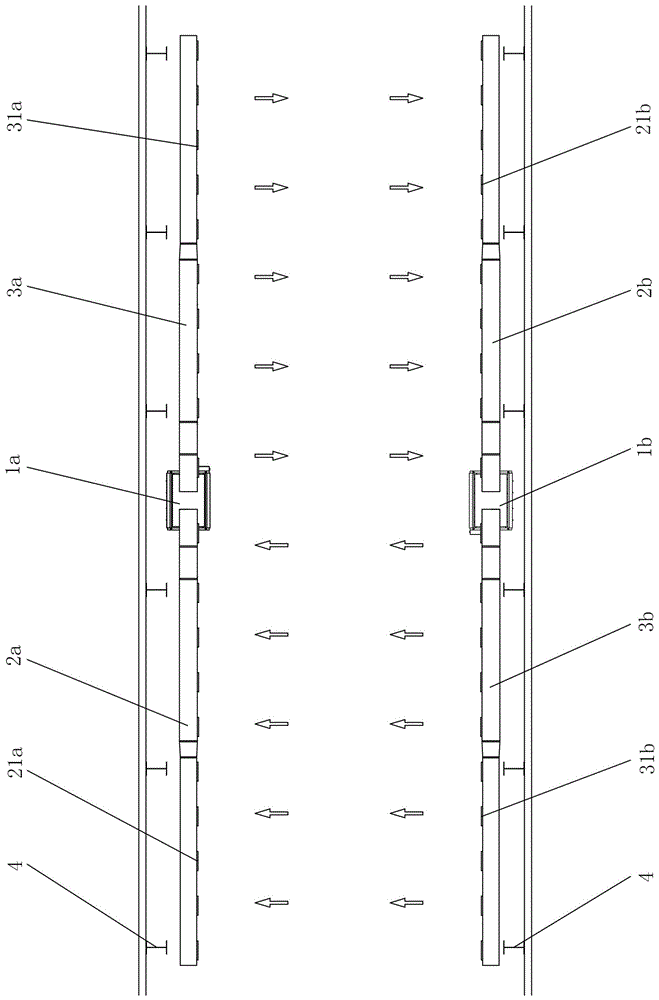

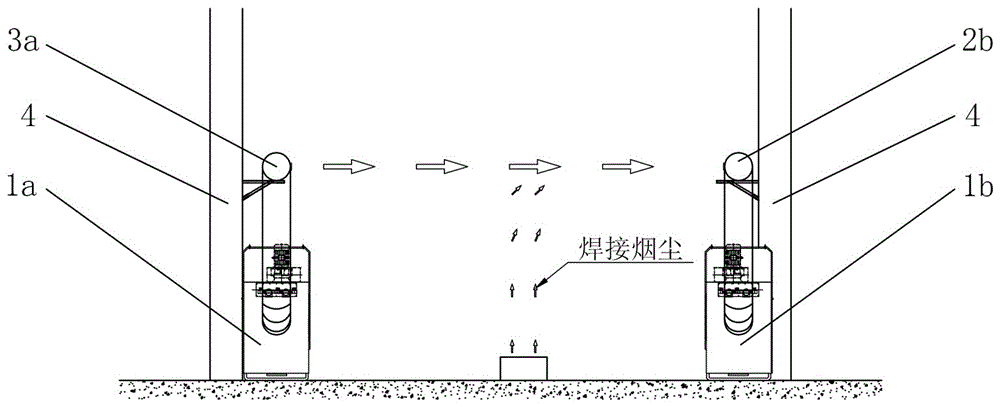

[0026] Such as Figure 1 to Figure 3 As shown, the blowing-suction dust removal system of the present embodiment includes two dust removal devices, the dust removal device includes a dust remover 1, a suction pipe 2 and an exhaust pipe 3, and the suction pipe 2 is connected to the air inlet 11 of the dust remover 1, The exhaust pipe 3 is connected to the air outlet 12 of the dust collector 1, and the gas discharged from the exhaust pipe 3 of each dust removal device passes through the soot suspension layer and can blow the smoke to the suction pipe 2 of another dust removal device. The two dust removal devices of this embodiment are respectively the first dust removal device and the second dust removal device, and the first dust removal device corresponds to the first dust remover 1a, the first air suction pipe 2a, and the first air exhaust pipe 3a; the second dust removal device The device corresponds to the second dust collector 1b, the second suction pipe 2b, and the second...

Embodiment 2

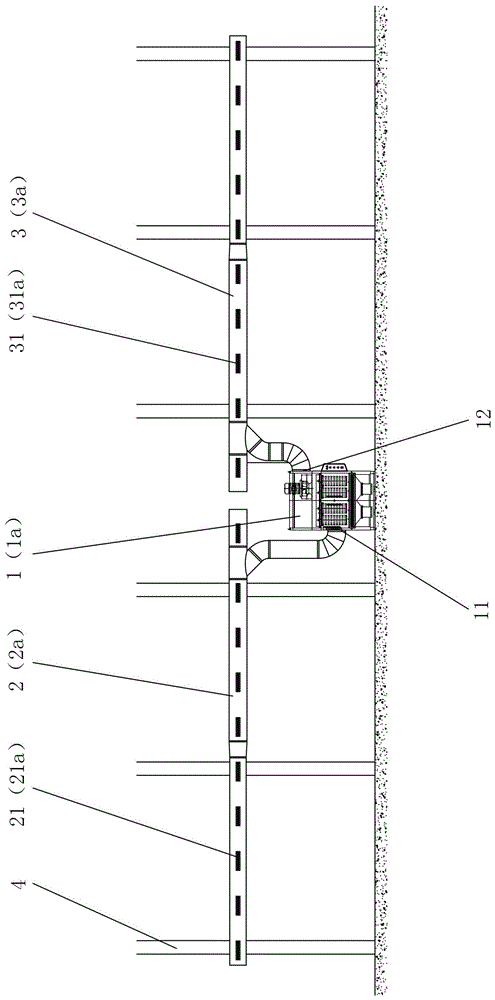

[0036] The blowing and suction type dust removal system of the present embodiment, such as Figure 6 As shown, a dust removal device is included. The dust removal device includes a dust collector 1, a suction pipe 2 and an exhaust pipe 3. The suction pipe 2 is connected to the air inlet 11 of the dust collector 1, and the exhaust pipe 3 is connected to the air outlet of the dust collector 1. 12 connection, the gas exhausted by the exhaust pipe 3 passes through the soot suspension layer and can blow the soot to the suction pipe 2. The structure of the dust removal device in this embodiment is the same as that in Embodiment 1 except that the arrangement of the suction pipe 2 and the exhaust pipe 3 is different. The dust removal device in this embodiment is arranged in a "匚" shape. The dust collector 1 is located at one end of the welding workshop, and the suction pipe 2 and the exhaust pipe 3 are respectively arranged on both sides of the workshop.

[0037] The dust removal pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com