Welding fixture for gear selecting and shifting flexible shaft support assembly

A technology of flexible shaft support and welding fixture, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the problems of ineffective treatment of welding smoke and inconvenient use of welding fixtures, etc., and achieves a large friction coefficient and prevents workpieces damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

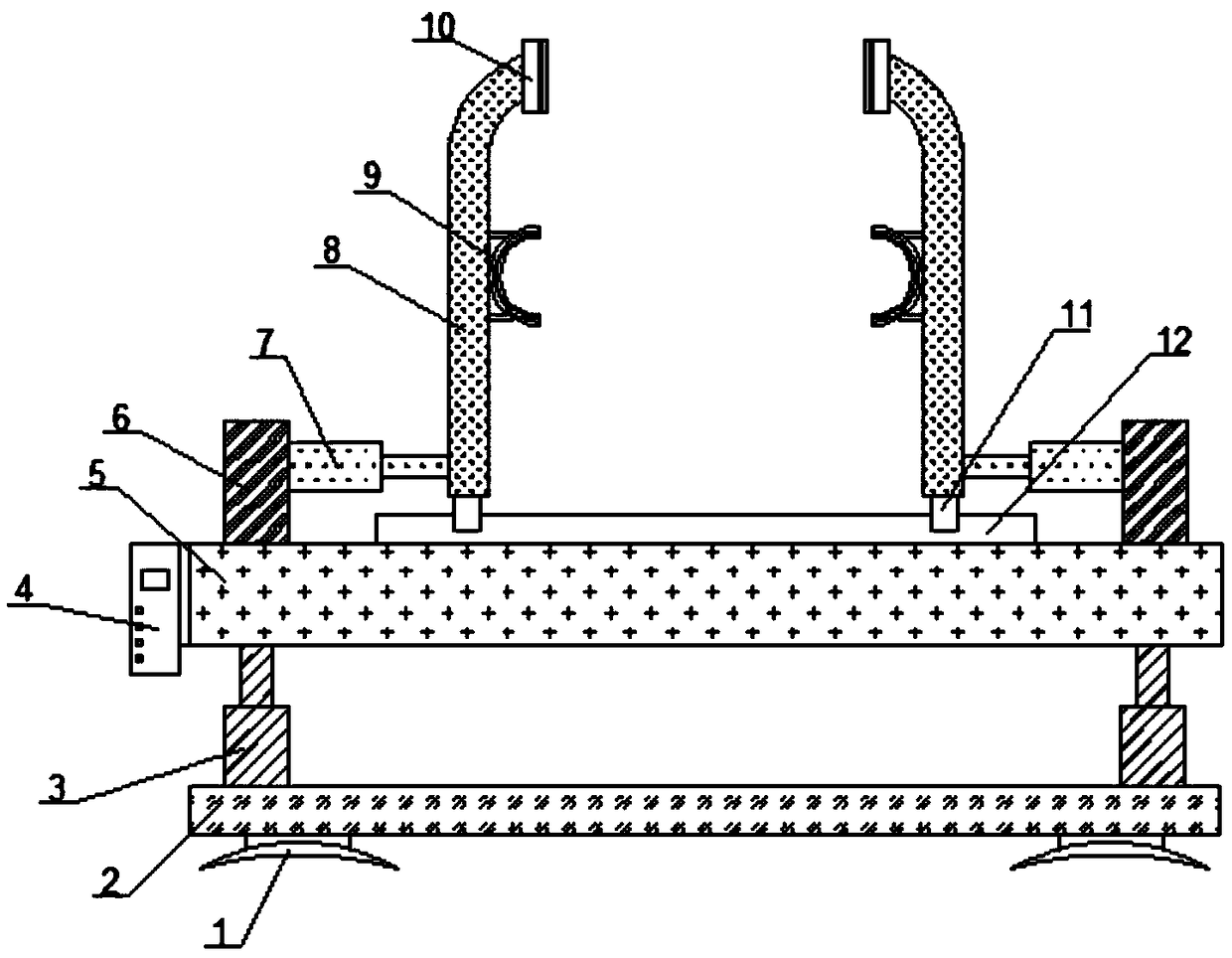

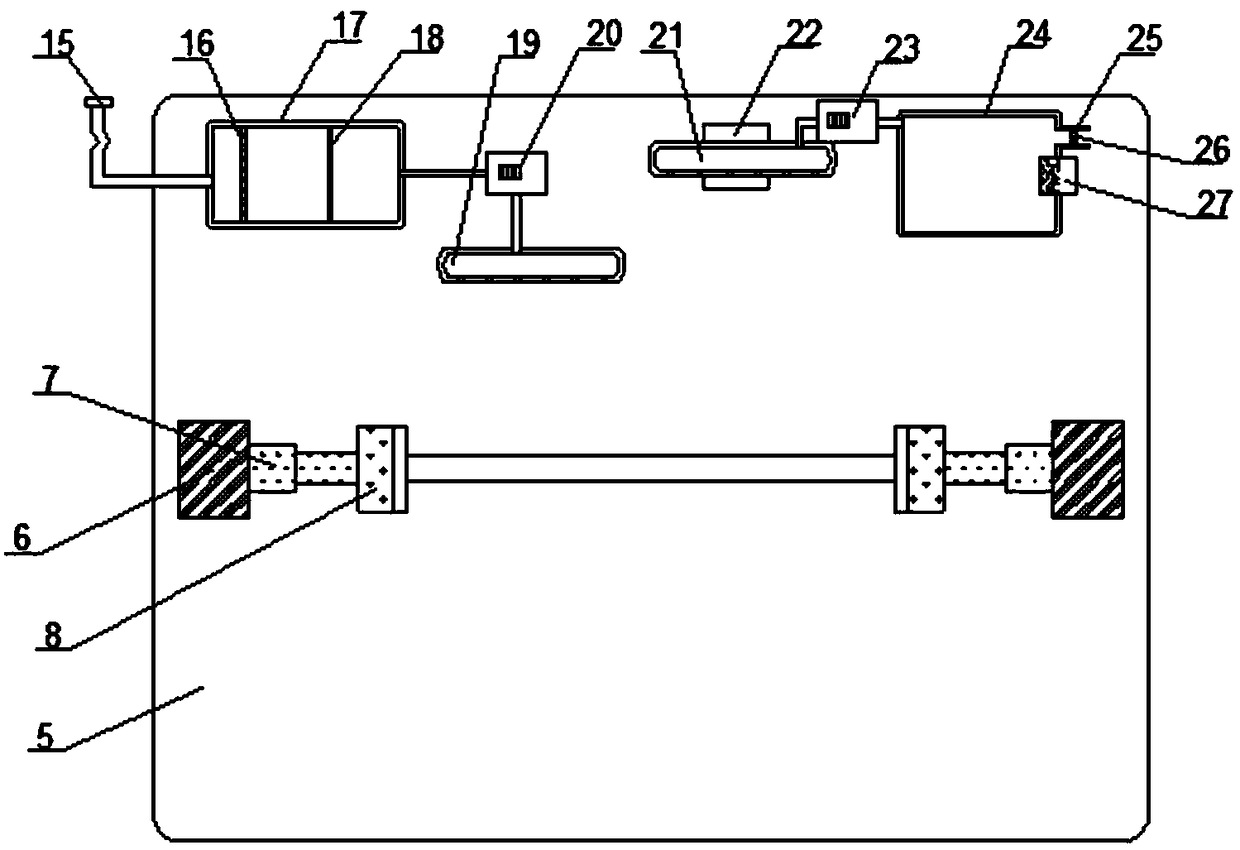

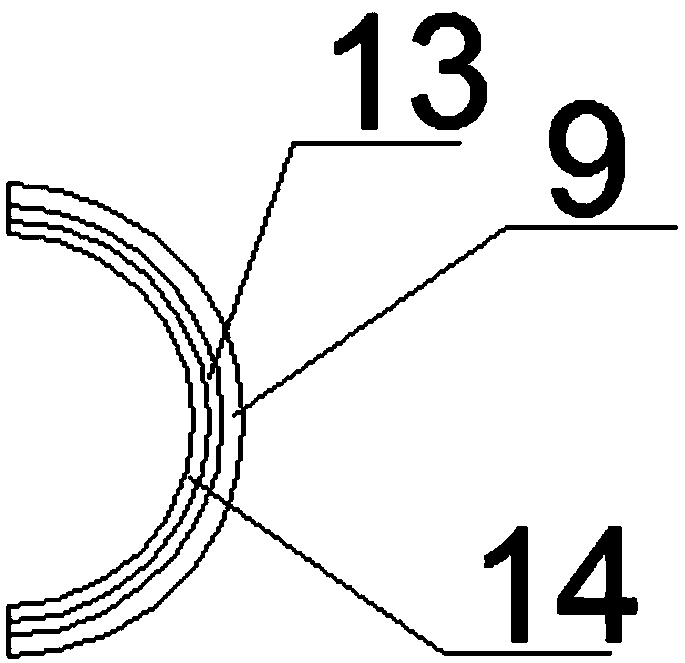

[0023] Such as Figure 1-3 As shown in the figure, a welding fixture for the flexible shaft support assembly of the shift selector includes a base plate 2, a clamping platform 5, a splint 8 and a purification box 17. The top of the base plate 2 is equipped with an electric hydraulic cylinder 3 through bolts. The output end of the electro-hydraulic cylinder 3 is connected to the clamping table 5, and a high-frequency electromagnetic radiation detector 4 is installed on one side of the clamping table 5 through a mounting piece, and a slide rail 12 is arranged on the top of the clamping table 5, and the slide The upper end of the rail 12 is provided with a splint 8, the inner side of the splint 8 is provided with an arc-shaped clamping plate 9, the upper end of the arc-shaped clamping plate 9 is provided with a vertical clamping plate 10, and the two sides of the slide rail 12 are provided with fixed Plate 6, the inner side of the fixed plate 6 is equipped with an electric telesc...

Embodiment 2

[0037] Such as Figure 1-3 As shown in the figure, a welding fixture for the flexible shaft support assembly of the shift selector includes a base plate 2, a clamping platform 5, a splint 8 and a purification box 17. The top of the base plate 2 is equipped with an electric hydraulic cylinder 3 through bolts. The output end of the electro-hydraulic cylinder 3 is connected to the clamping table 5, and a high-frequency electromagnetic radiation detector 4 is installed on one side of the clamping table 5 through a mounting piece, and a slide rail 12 is arranged on the top of the clamping table 5, and the slide The upper end of the rail 12 is provided with a splint 8, the inner side of the splint 8 is provided with an arc-shaped clamping plate 9, the upper end of the arc-shaped clamping plate 9 is provided with a vertical clamping plate 10, and the two sides of the slide rail 12 are provided with fixed Plate 6, the inner side of the fixed plate 6 is equipped with an electric telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com