Portable welding fume collecting and processing device

A processing device and portable technology, which is applied in auxiliary devices, smoke and dust removal, welding equipment, etc., can solve the problems that welding smoke and dust devices are difficult to carry, and achieve the effect of light weight, small size and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

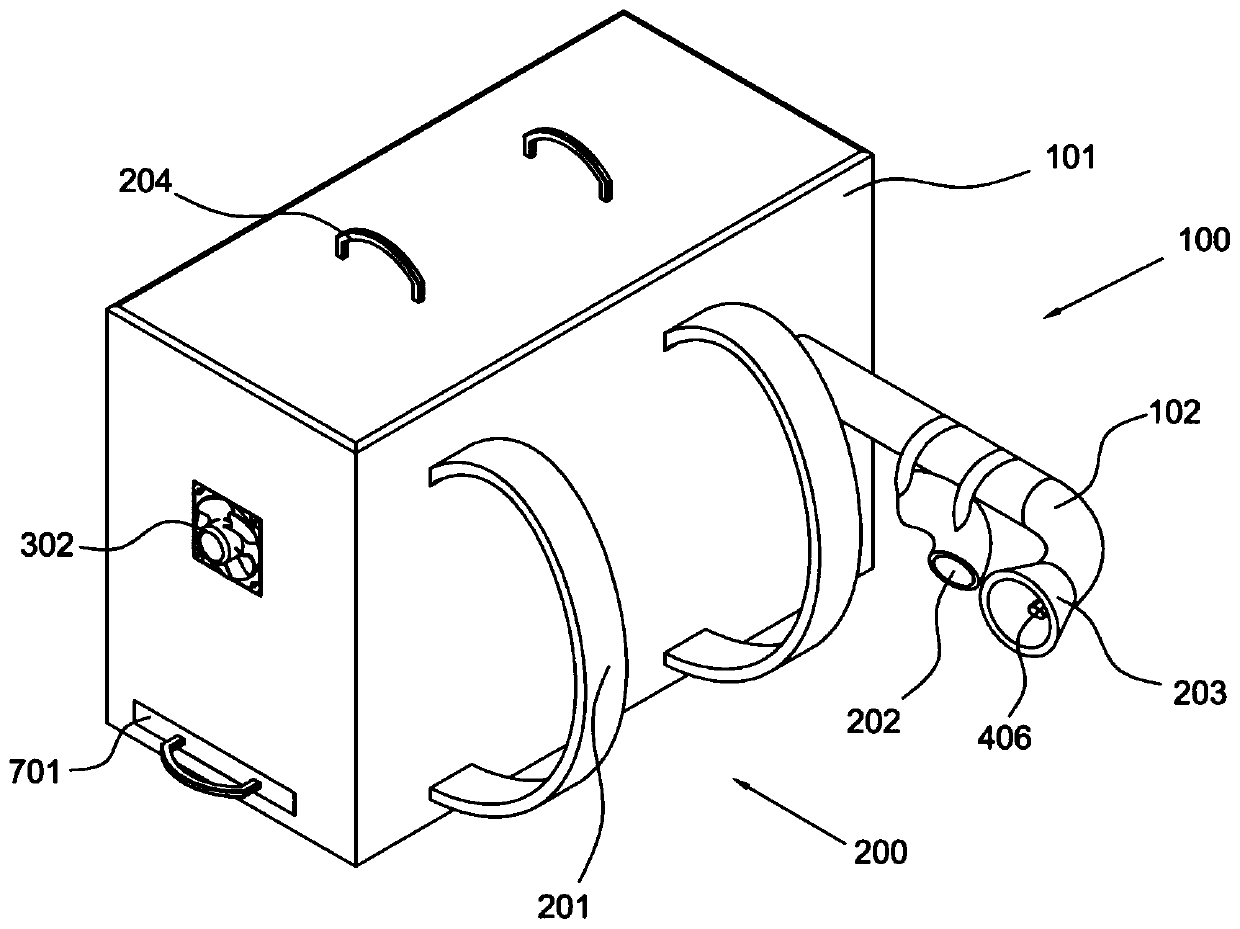

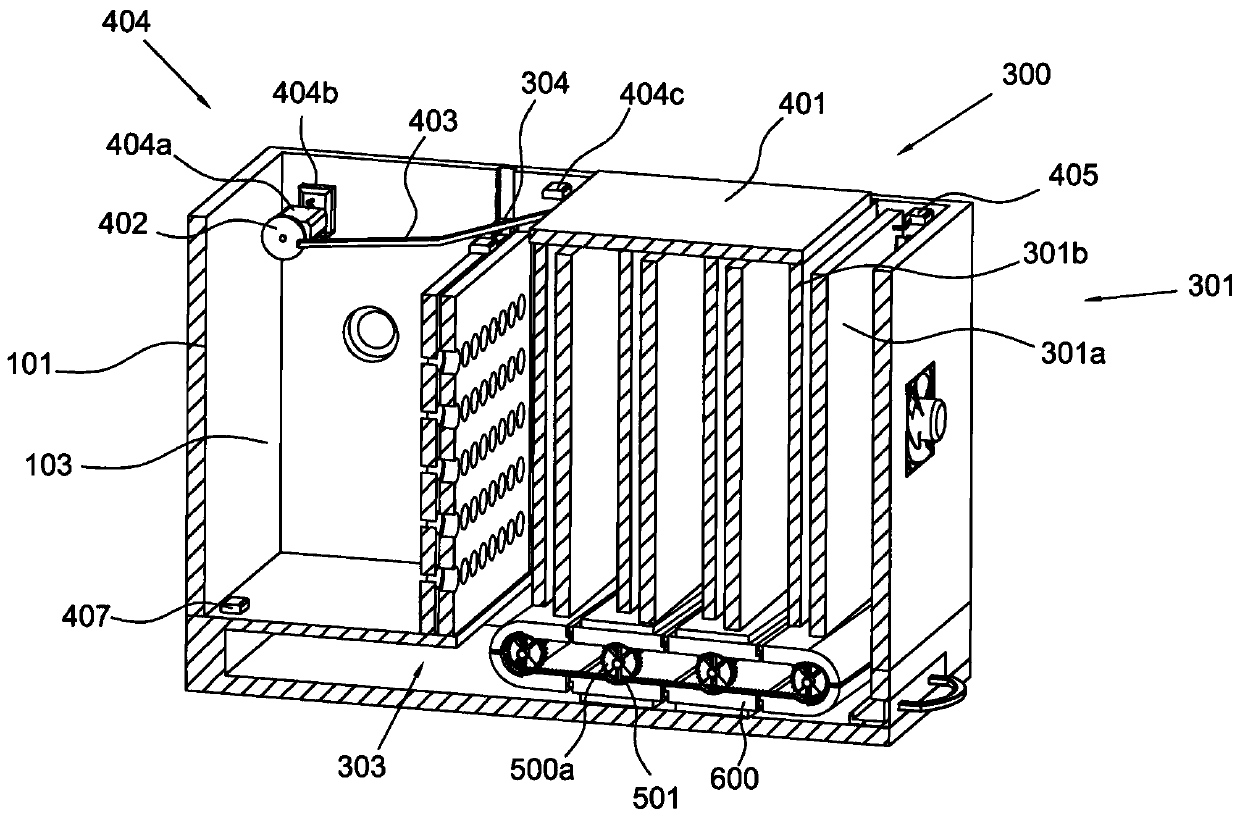

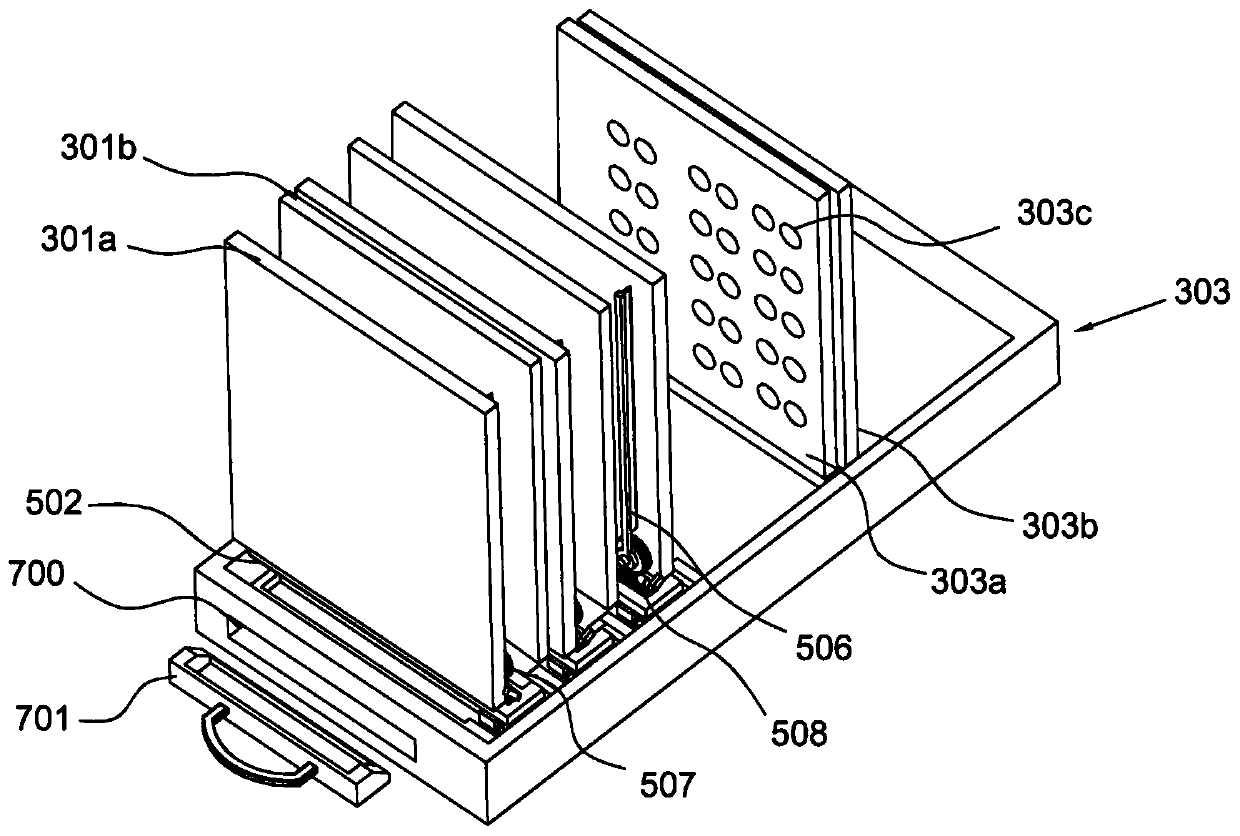

[0031] refer to figure 1 and figure 2 , a portable welding fume collection and treatment device, including a base assembly 100, including a box body 101, an air suction pipe 102 that communicates with the box body 101 and extends outward, and a storage chamber 103 opened inside the box body 101. The material of the box body 101 It is carbon fiber; the portable assembly 200 includes a strap 201 connected to the box body 101, a connecting sleeve 202 arranged on the suction pipe 102, and a handle 204 arranged on the box body 101, and the front end of the suction pipe 102 is provided with an air collecting hood 203; and, the collection assembly 300, the collection assembly 300 is arranged in the storage chamber 103, the collection assembly 300 includes the electrode plate 301 arranged in the storage chamber 103, the fan 302 arranged at the end of the box body 101 away from the suction pipe 102, and the fan 302 arranged in the storage chamber The cavity 103 is away from the recti...

Embodiment 2

[0039] refer to Figure 2-Figure 6 , this embodiment is different from the first embodiment in that: the drive unit 400 includes a connection plate 401 connected to the lower end of each cathode plate 301b, a drive plate 402 rotatably connected in the storage chamber 103, and a drive plate 402 connected to the connection plate The driving rod 403 between 401, wherein the driving plate 402 is horizontally arranged on the rotation plane, the connecting plate 401 is slidably connected in the horizontal direction, and the storage chamber 103 is provided with a driving member 404 connected to the driving plate 402, and the driving member 404 includes a first motor 404a, the controller 404b arranged in the storage chamber 103 and the voltage detector 404c arranged at the electrode plate 301, the controller 404b is electrically connected with the first motor 404a and the voltage detector 404c, and the dust detection cover 203 is provided with 406, the dust detector 406 is connected w...

Embodiment 3

[0047] refer to Figure 3-Figure 7 , this embodiment is different from the above embodiments in that: inside the storage chamber 103, there are several transmission gears 500 connected in rotation, the transmission gears 500 are coaxially provided with an arc-shaped plate 501, and the transmission gears 500 include two symmetrically arranged sector gears 500a, The number of arc plates 501 is two, and they are arranged symmetrically. The line between the arc plates 501 and the line between the sector gears 500a are perpendicular to each other, and the rotation plane of the transmission gear 500 is set vertically. The gear 500 is provided with a sieve moving plate 502 which is hinged with each other. A storage groove 503 is provided on the sieve moving plate 502. A gear tooth 504 meshing with the transmission gear 500 is provided on the lower surface of the sieve moving plate 502. The storage chamber 103 is provided with a drive The transmission gear 500 and the third motor 505 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com