RV reducer comprising constant-depth tooth spiral bevel gear

A technology of spiral bevel gears and equal-height teeth, applied in the field of RV reducer, can solve the problems of strong sensitivity of installation error, impact of engagement and engagement, unstable transmission, etc., so as to achieve weak sensitivity of installation error, The effect of high coincidence and smooth meshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

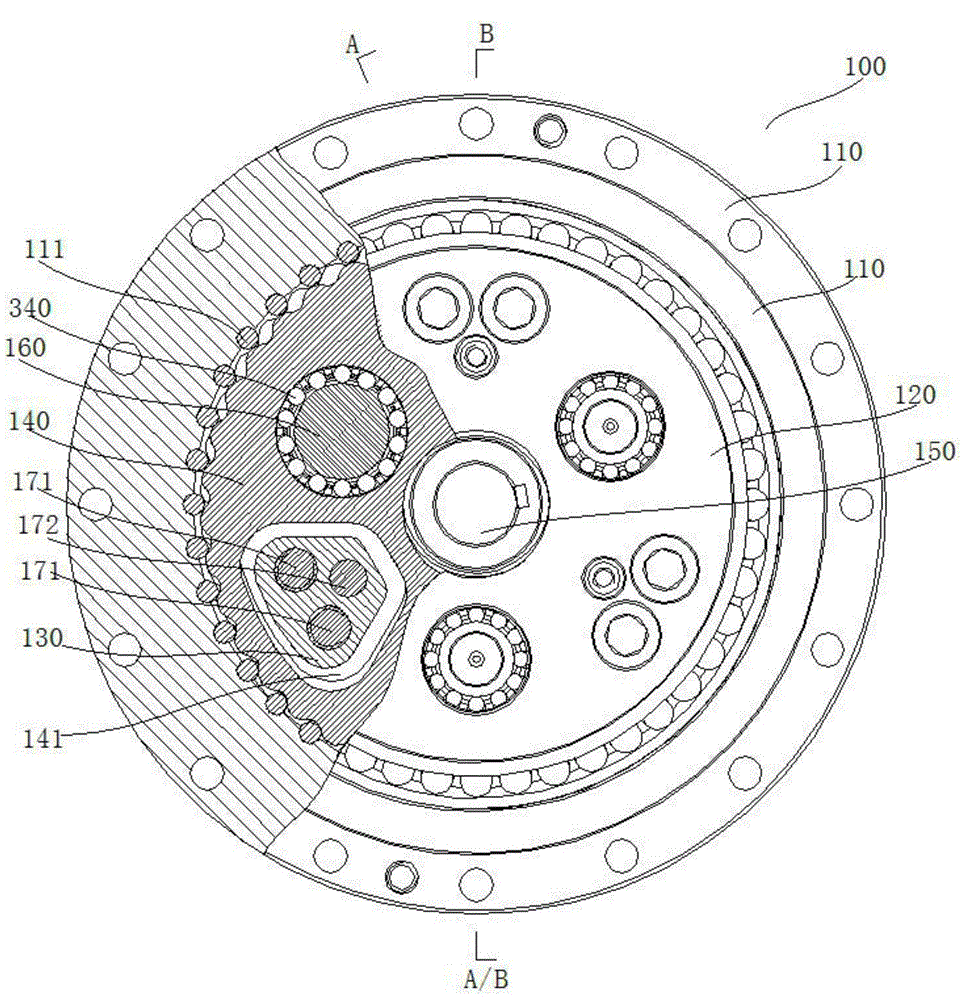

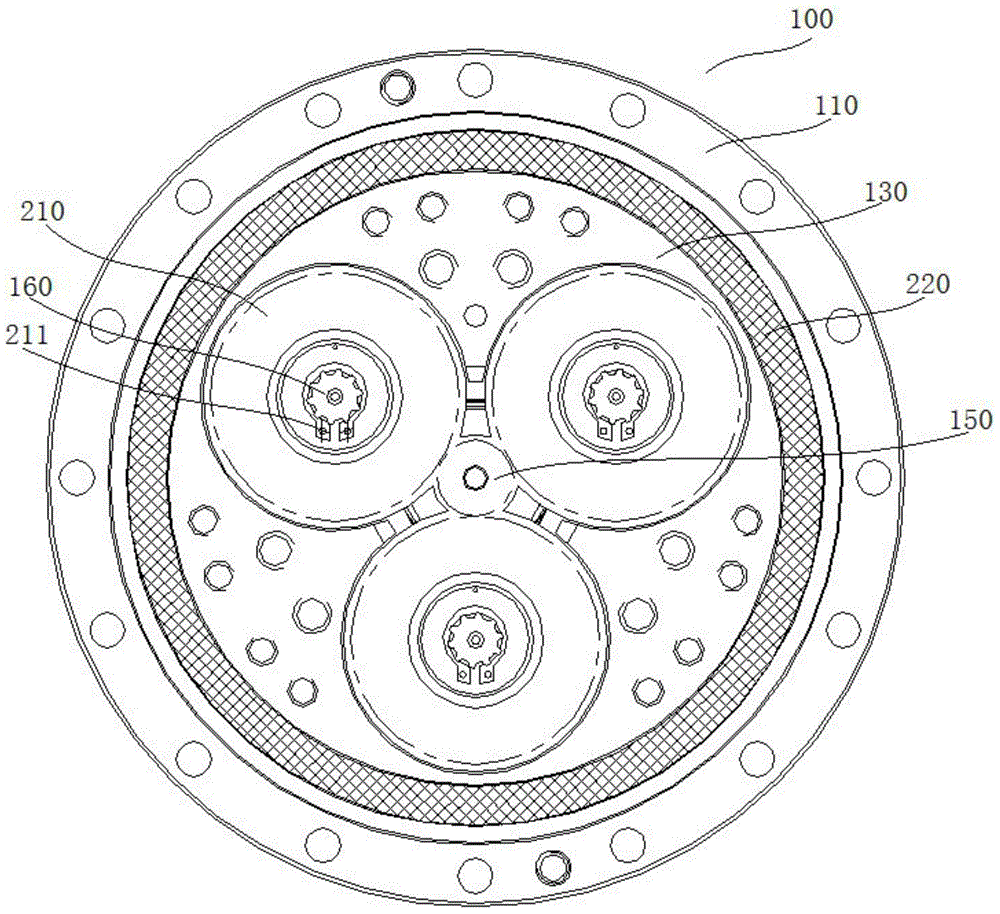

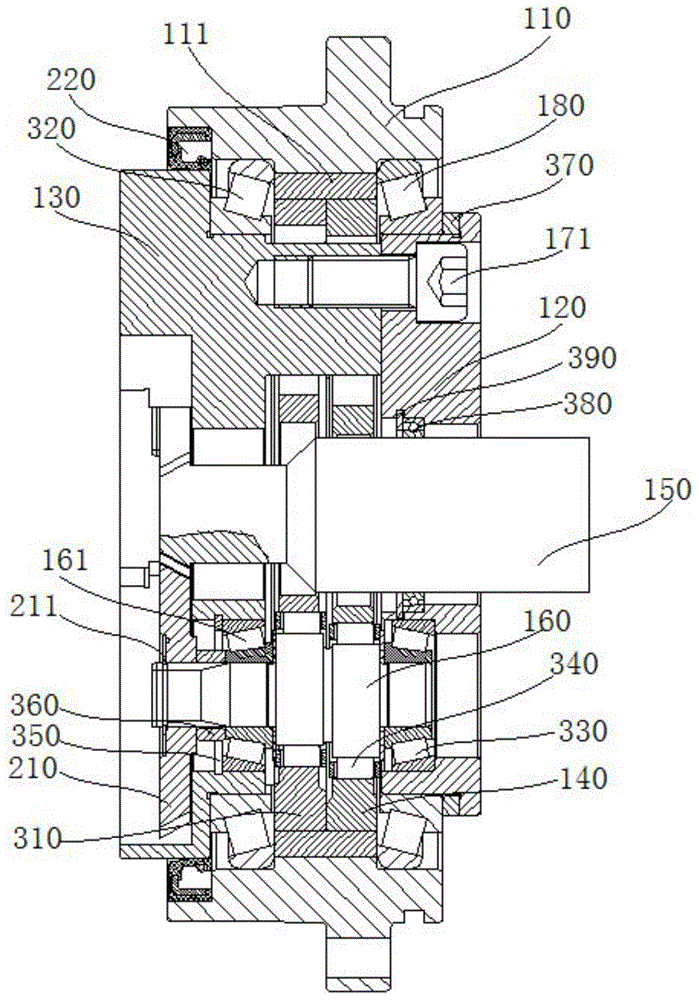

[0030] Such as figure 1 , 2 , 3, and 4 show an RV reducer with a contoured spiral bevel gear in this embodiment. The main body is marked with 100, which includes a pin gear housing 110, and one end of the pin gear housing 110 is provided with an input planet carrier The other end of 120 is provided with an output planetary carrier 130, and the input planetary carrier 120 and the output planetary carrier 130 are fixedly connected and configured to be able to rotate in the pin gear housing 110; the inner wall of the pin gear housing 110 is provided with a needle roller 111, and a pair of cycloidal wheels are provided Between the input planetary carrier 120 and the output planetary carrier 130 and configured to mesh with the needle roller 111; the output planetary carrier 130 is provided with a planetary gear 210, and the center of the output planetary carrier 130 is provided with an input shaft 150 meshing with the planetary gear 210; The planetary gear 210 and the input shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com