Roller repairing surfacing machine

A technology for surfacing welding machines and rolls, which is applied to welding equipment, welding equipment, welding accessories, etc., which can solve the problems of low trolley running accuracy, difficulty in expanding, and insufficient arc stabilization ability, etc., and achieve fast and convenient installation process, clamping Less stress and less labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

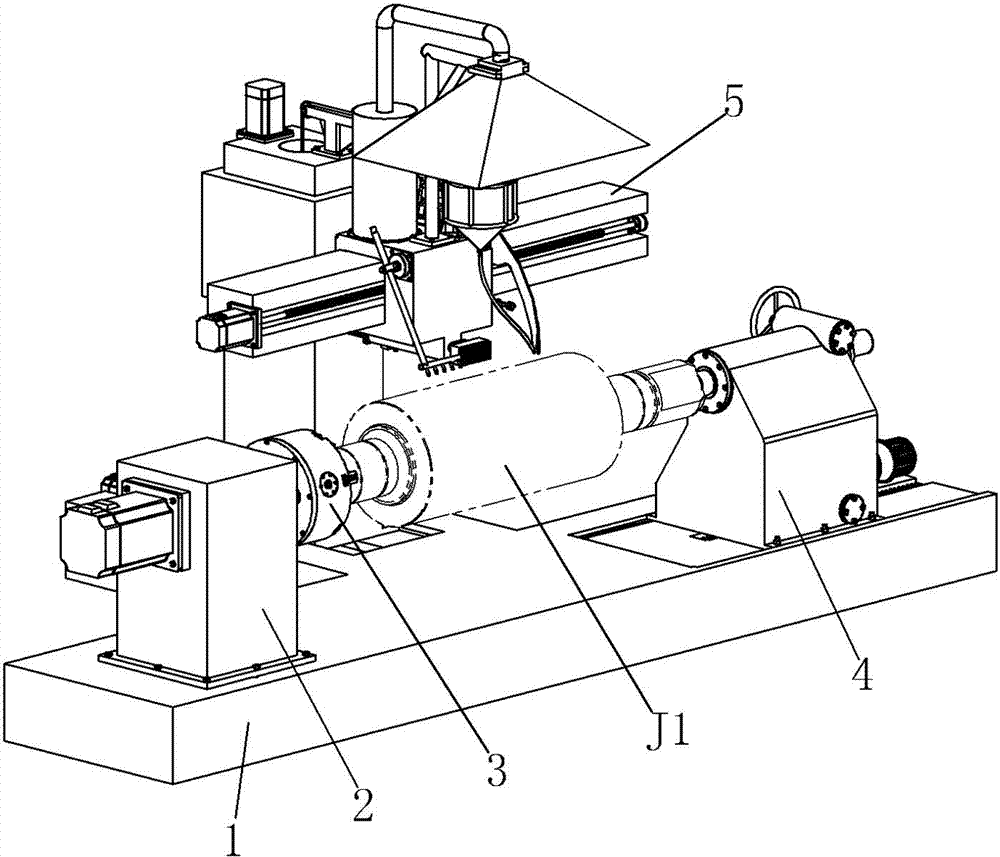

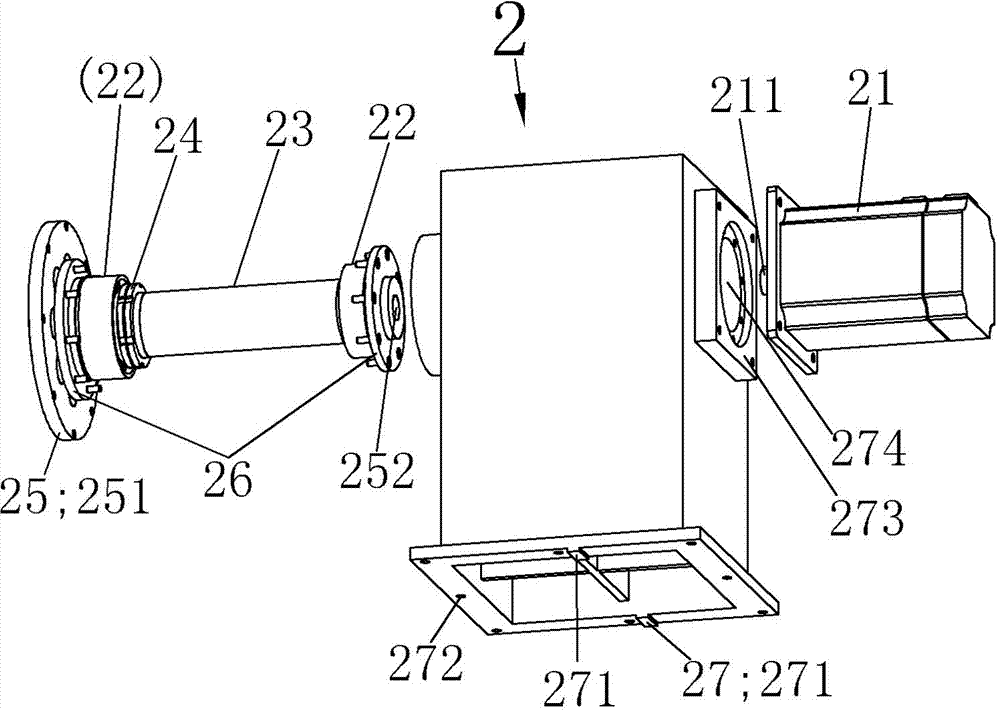

[0039] Example 1: See figure 1 As shown, the present invention is made up of base seat 1, headstock 2, six-jaw chuck 3, tailstock top device 4, and working device 5, and bedside box 2, tailstock top 4, and working device 5 are all arranged on the foundation On the seat 1, the six-jaw chuck 3 is arranged on the headstock; the surfacing roll J1 is arranged between the six-jaw chuck and the top device of the tailstock.

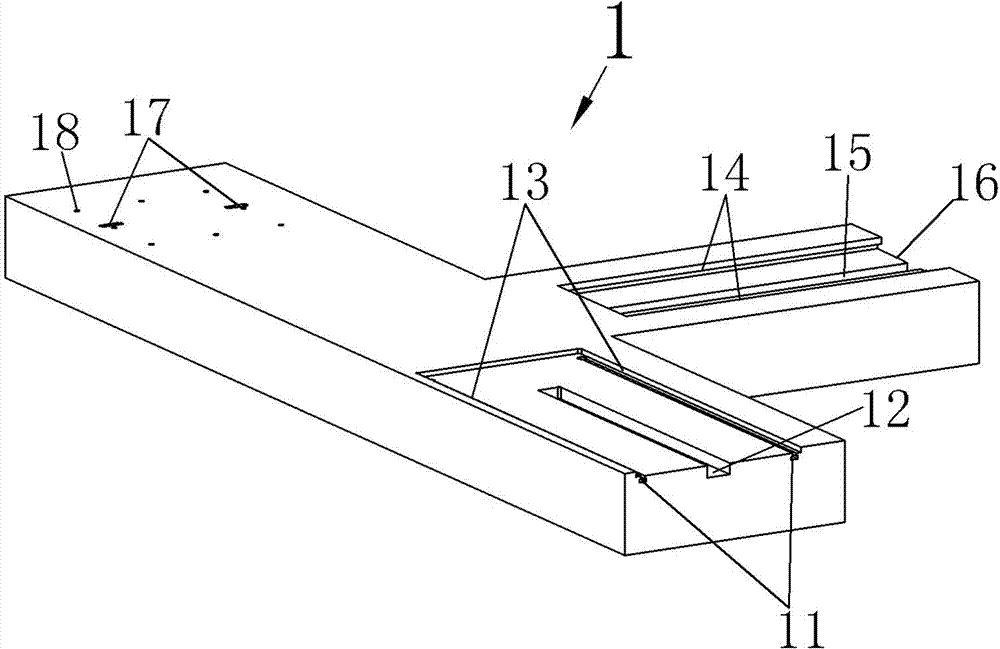

[0040] see figure 2 As shown, the base 1 is a "T"-shaped member as a whole; two T-shaped slots 11 are arranged at one end of the transverse section of the "T"-shaped member, and at the center of the two T-shaped slots 11 The position is provided with a first rectangular groove 12, two first rectangular guide rails 13 are provided on the outside of the two T-shaped grooves 11, and two key grooves 17 and a Combining hole group 18; two rectangular guide rails 14 are provided on the vertical section of the "T" shape member, and a joint surface 16 is provided at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com