Steel wire rope clamping device

The technology of a clamping device and a wire rope clip is applied in the field of elevators, which can solve the problems of unusability, low cost and high cost, and achieve the effects of convenient installation and disassembly, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

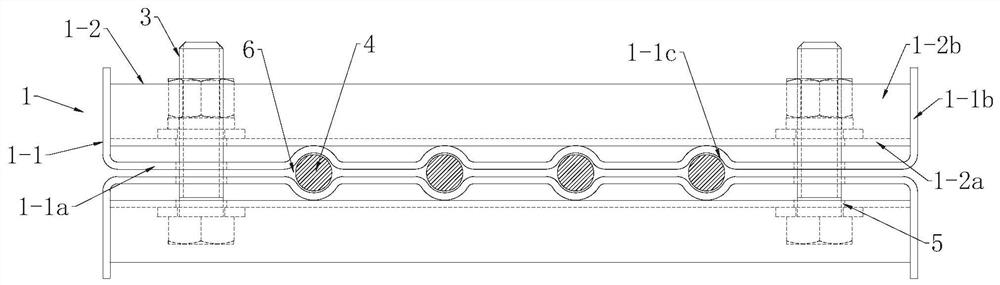

[0045] see Figure 1-3 , which is a structural schematic diagram of Embodiment 1 of the present invention, provides a wire rope clamping device, including two first rope clamps 1 symmetrically arranged, and the two first rope clamps 1 are detachably connected through fasteners 3, and are connected between the two A plurality of wire rope jaws 6 are formed between the first rope clamps 1, and the wire rope 4 is clamped in the wire rope jaws 6.

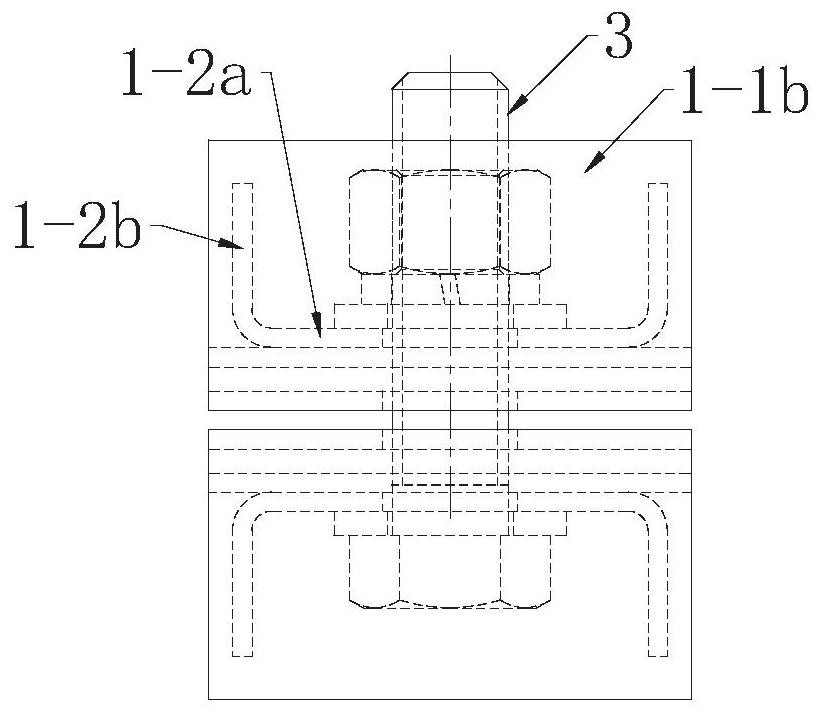

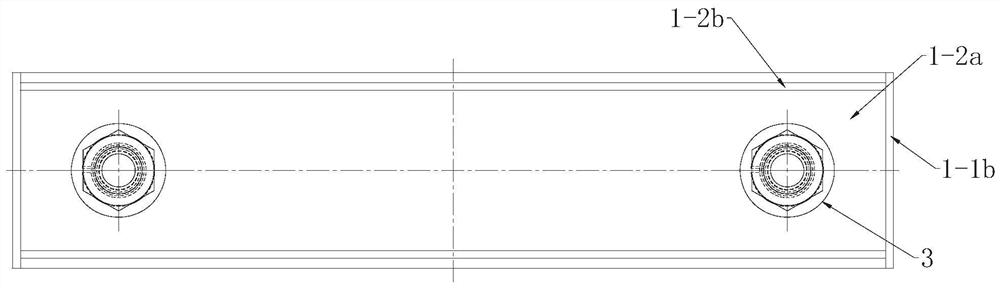

[0046] Among them, see Figure 4-6 , the first rope clip 1 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com