Automatic centering clamp for disk sleeve parts

A technology of automatic centering and parts, which is applied to metal processing machinery parts, clamping, chucks, etc., can solve the problems that the workpiece cannot be clamped at one time, the geometric accuracy of the parts is difficult to guarantee, and the workpiece cannot be automatically positioned, and the structure is simple. , the effect of high versatility and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

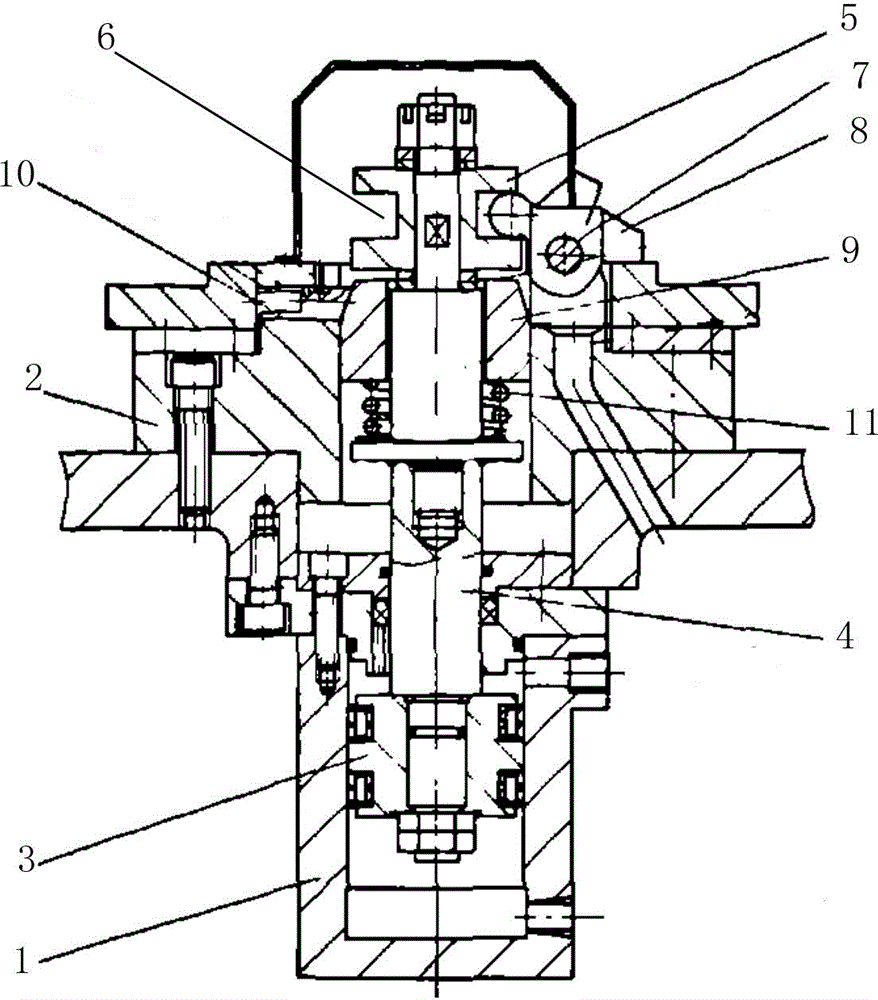

[0010] The automatic centering fixture for disc sleeve parts of the present invention includes a hydraulic cylinder 1 and a clamping body 2. A piston 3 is arranged in the hydraulic cylinder 1, and the piston 3 is connected to a hinge 5 through a piston rod 4 fixedly connected thereto. , the hinge 5 is provided with three grooves 6 distributed at 120°, the openings of the three grooves 6 are all away from the center of the hinge 5, and the three grooves 6 are arranged on the clamp body 2 corresponding to it. The protrusions of the three shift forks 7 are connected with the claws 8, and the hydraulic cylinder block 1 on the upper and lower sides of the piston 3 has small holes. The upper end of the piston rod 3 is covered with a taper sleeve 9, and the taper sleeve 9 is connected to the boss on the piston rod 4 through a spring 11. The clamp body 2 is horizontally provided with three pins 10 equally divided by 120°. Three bearing pins 10 all offset with taper sleeve 9. The shif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com