A welding smoke collection device and method capable of automatically tracking and positioning welding points

An automatic tracking and collection device technology, which is applied to chemical instruments and methods, cleaning methods and appliances, and dust removal, etc., can solve the problems of high cost and complicated tracking control system of welding smoke automatic tracking arm, and achieve the effect of efficient collection and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

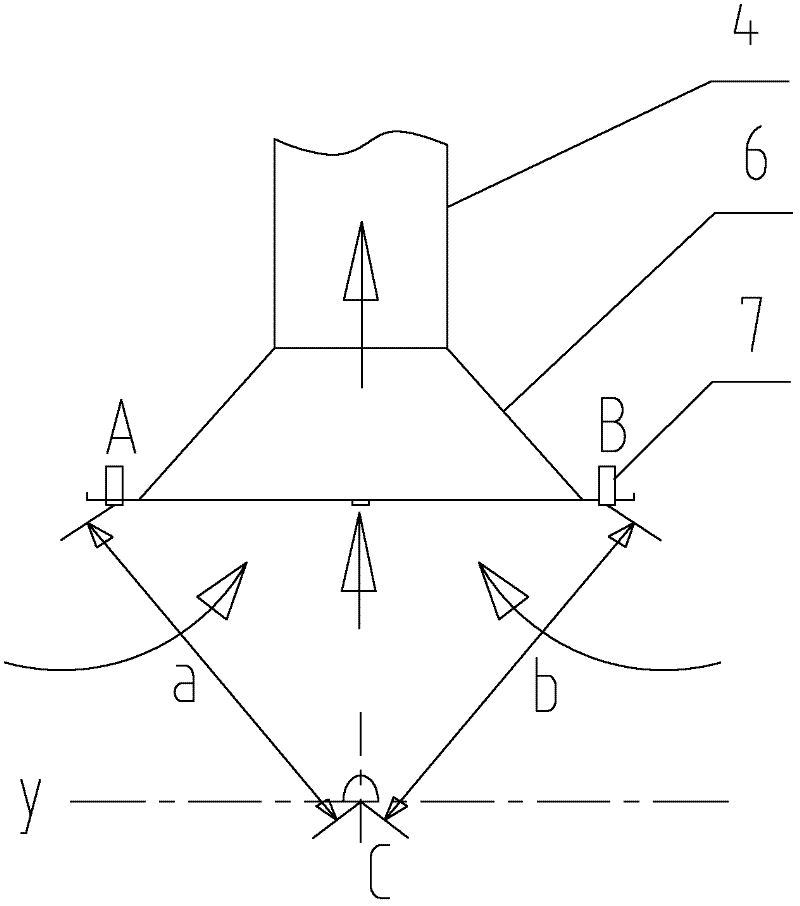

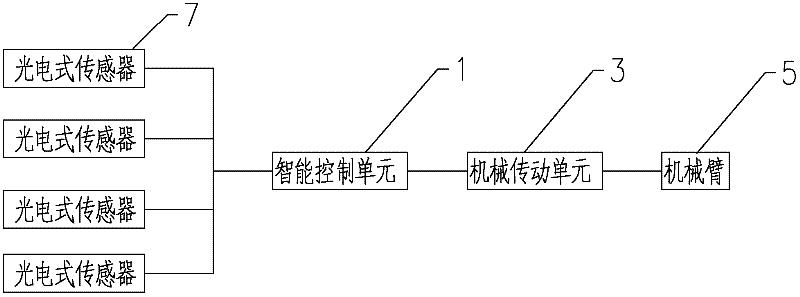

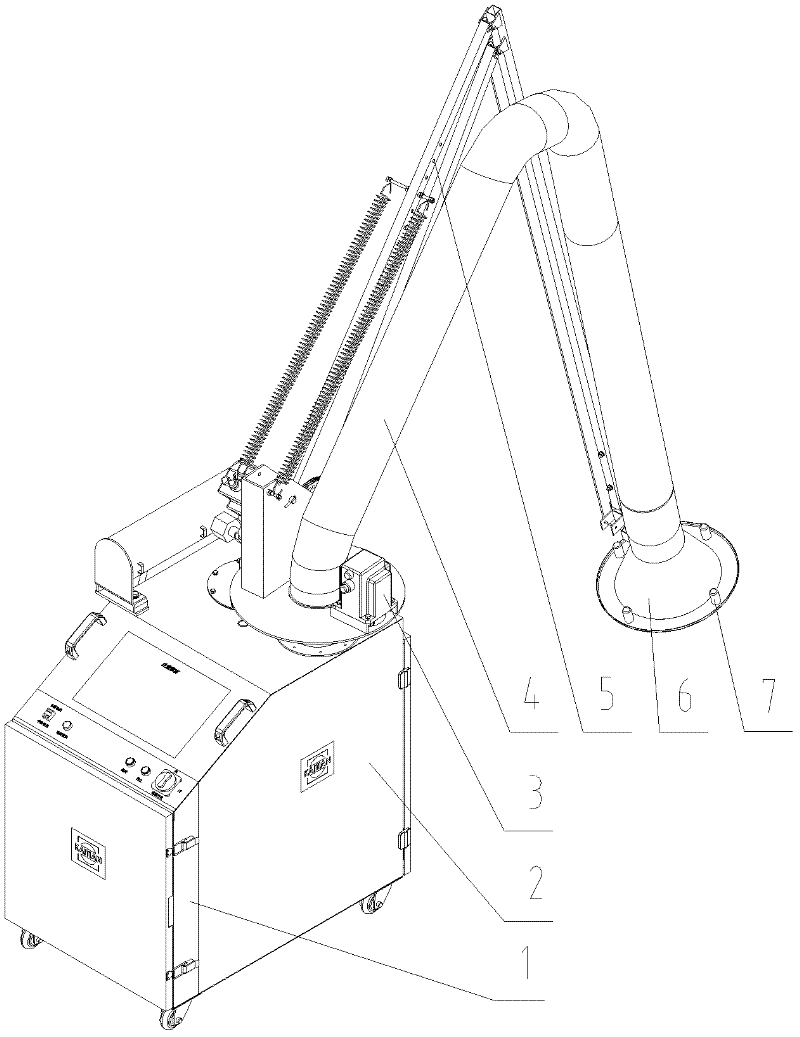

[0021] see Figure 1 to Figure 3 , the present invention includes a tracking control system and a welding fume exhaust duct, the tracking control system is composed of an intelligent control unit 1, a mechanical transmission unit 3, a mechanical arm 5 and a group of four independent and identical photoelectric sensors 7 in total. The four photoelectric sensors 7 are connected to the intelligent control unit 1, the intelligent control unit 1 is connected to the mechanical transmission unit 3, the mechanical transmission unit 3 is connected to the mechanical arm 5, the welding fume exhaust pipe 4 is fixed on the mechanical arm 5, and the welding fume extraction One end of the air duct 4 is connected to the air inlet of the welding fume purifier 2, and the other end is connected to the exhaust mask 6. The exhaust mask 6 is installed at the end of the mechanical arm 5. Each of the four photoelectric sensors 7 is installed in pairs on the exhaust mask. 6 and evenly distributed arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com