Patents

Literature

100results about How to "Effective collection and processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

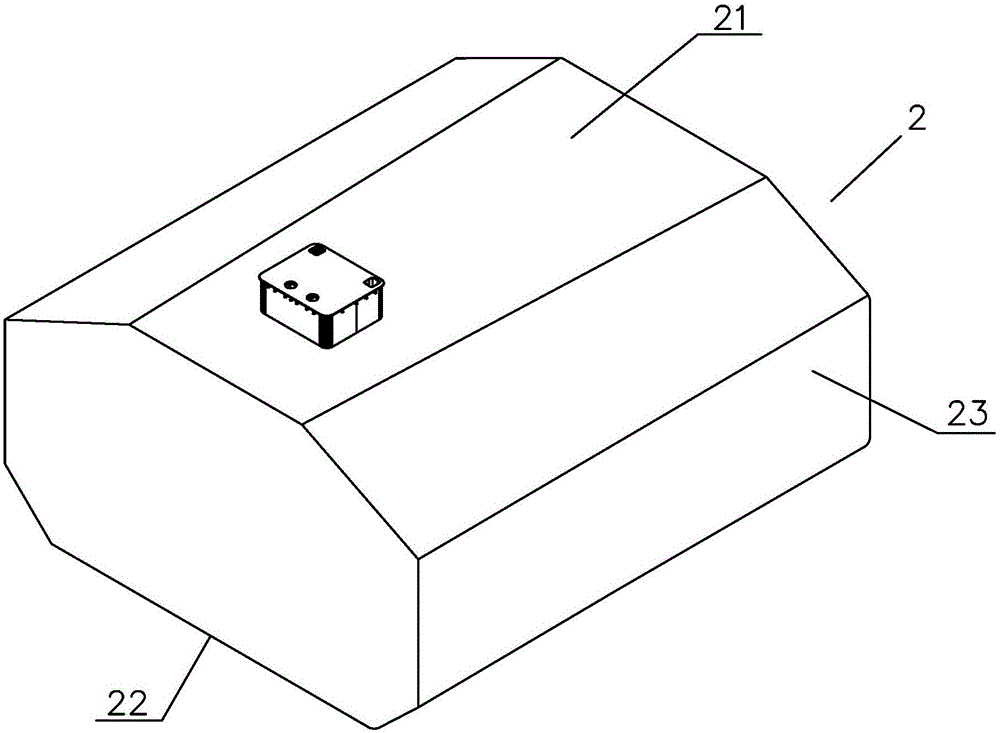

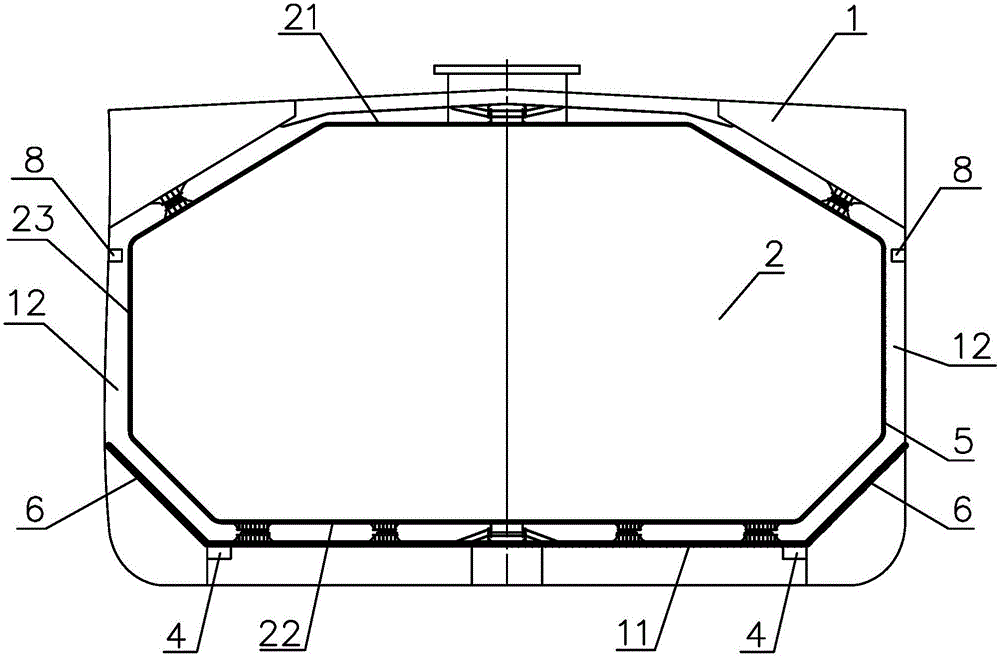

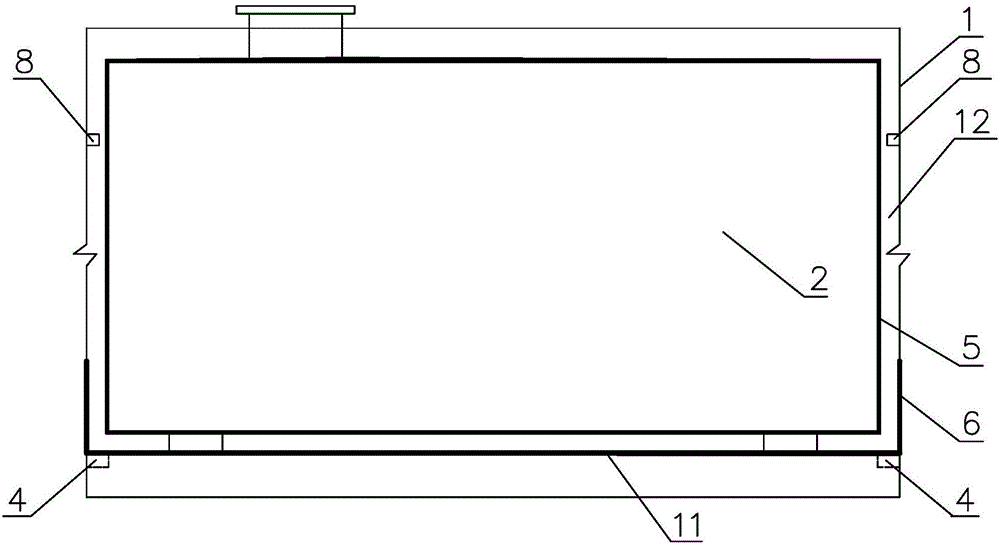

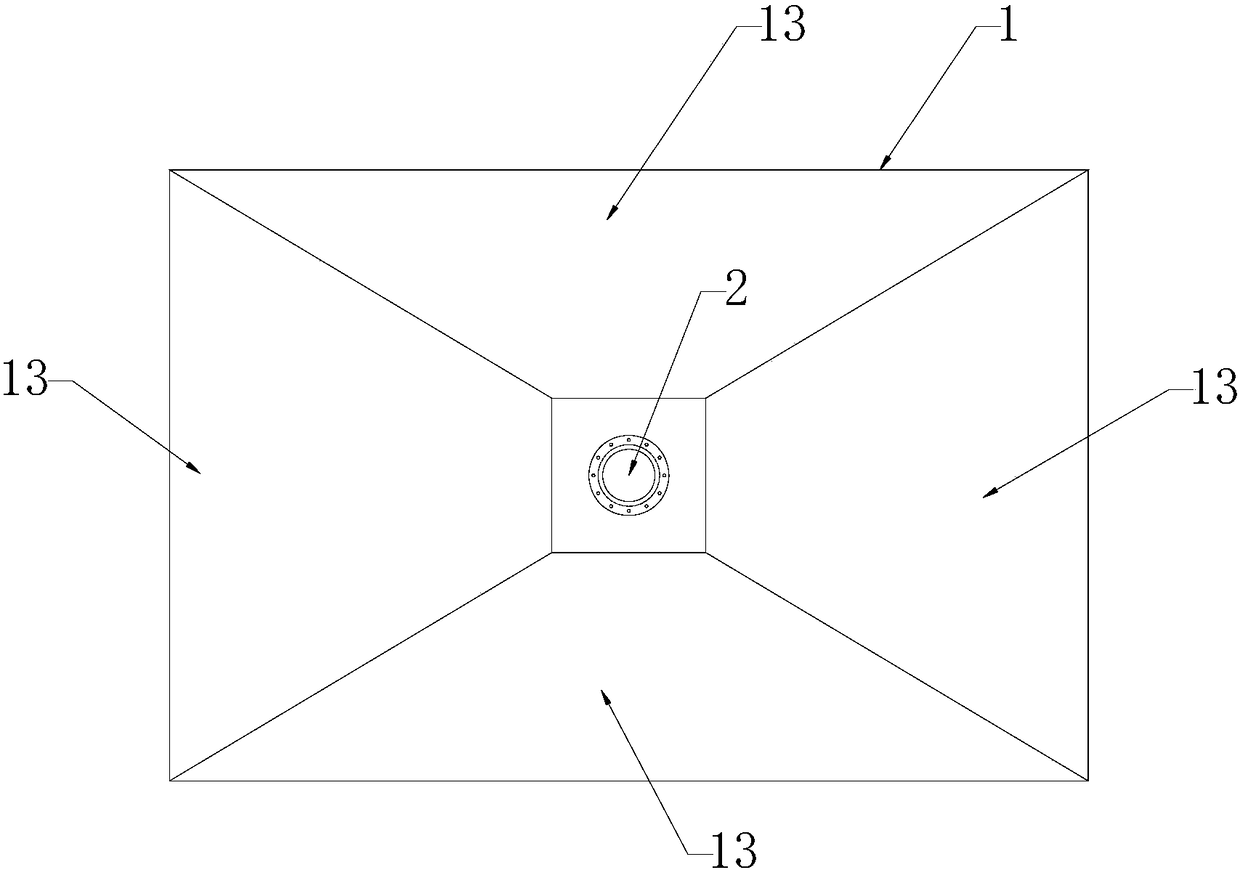

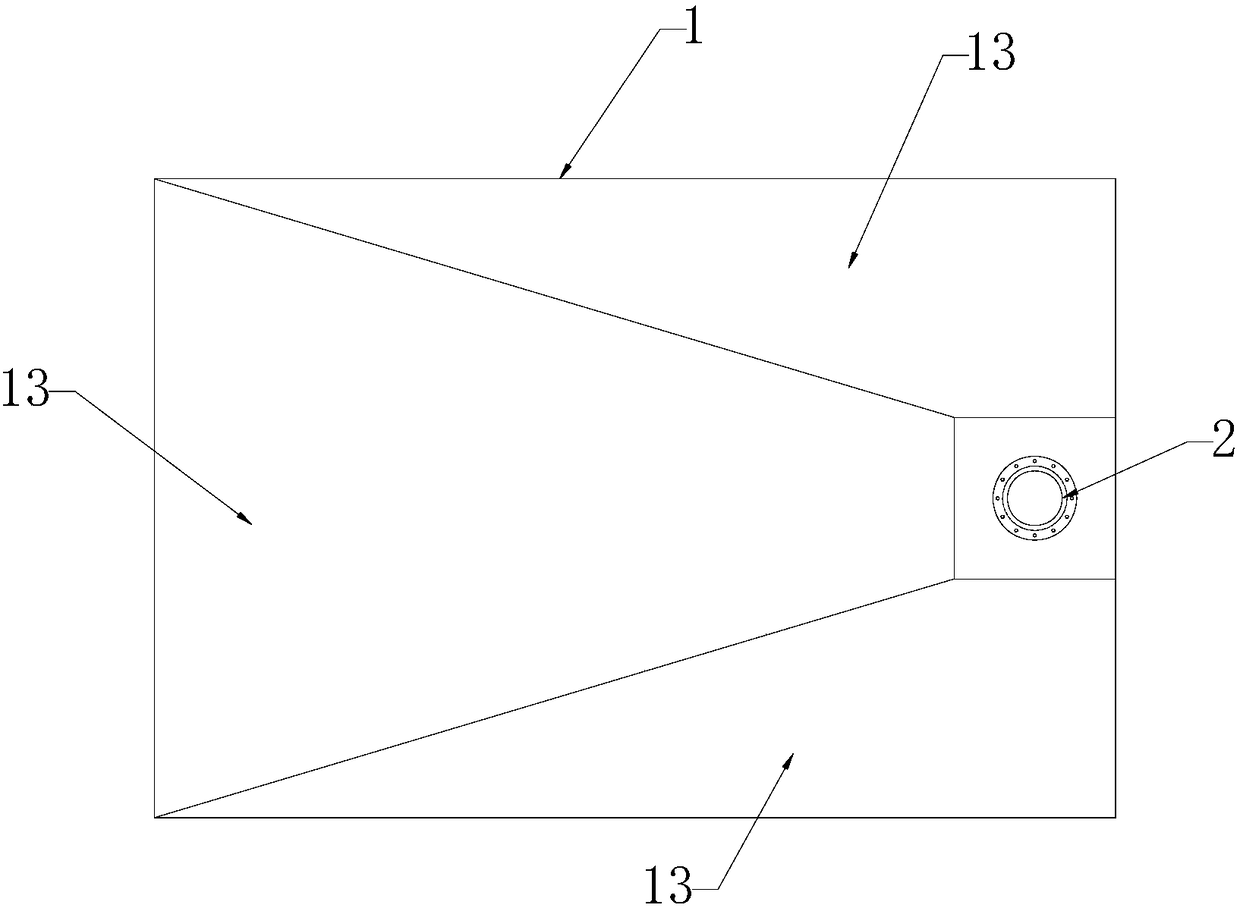

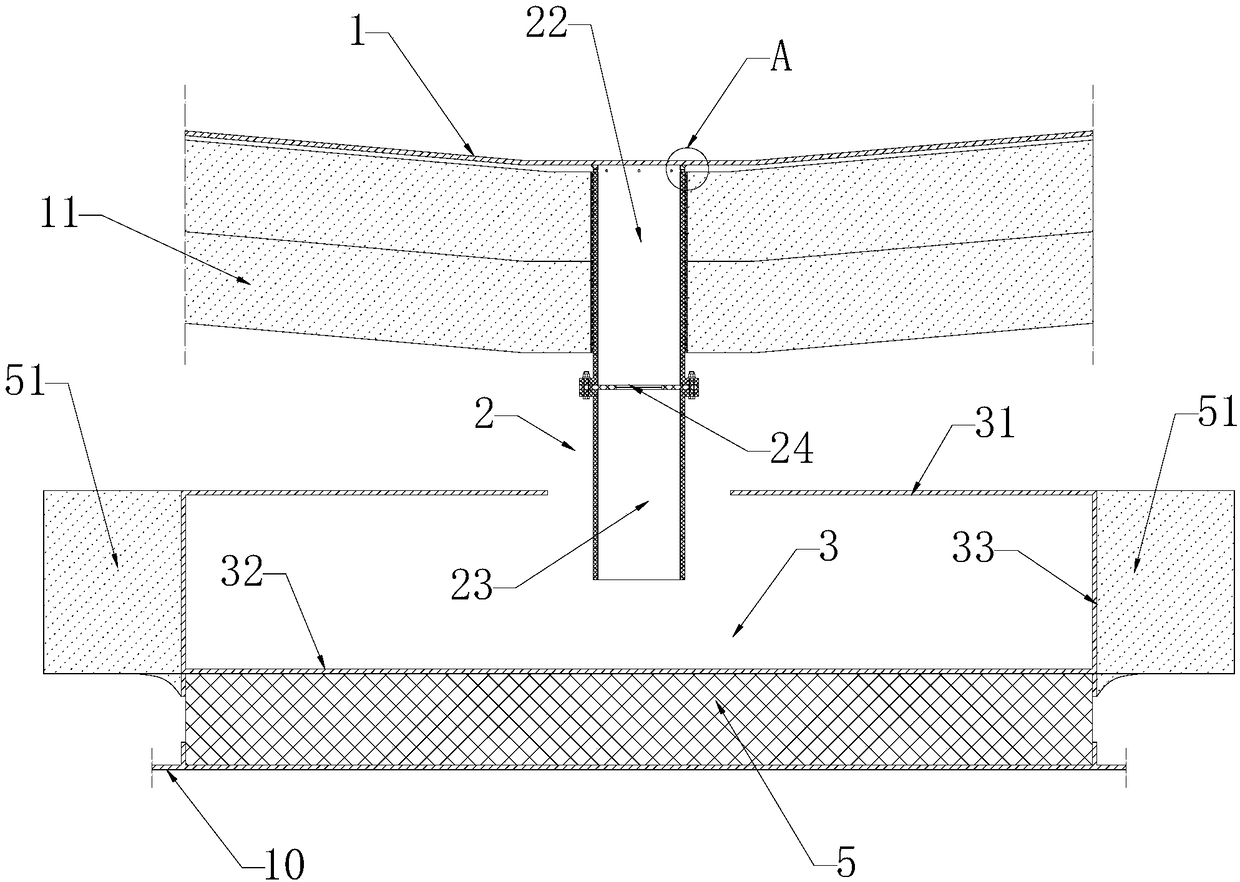

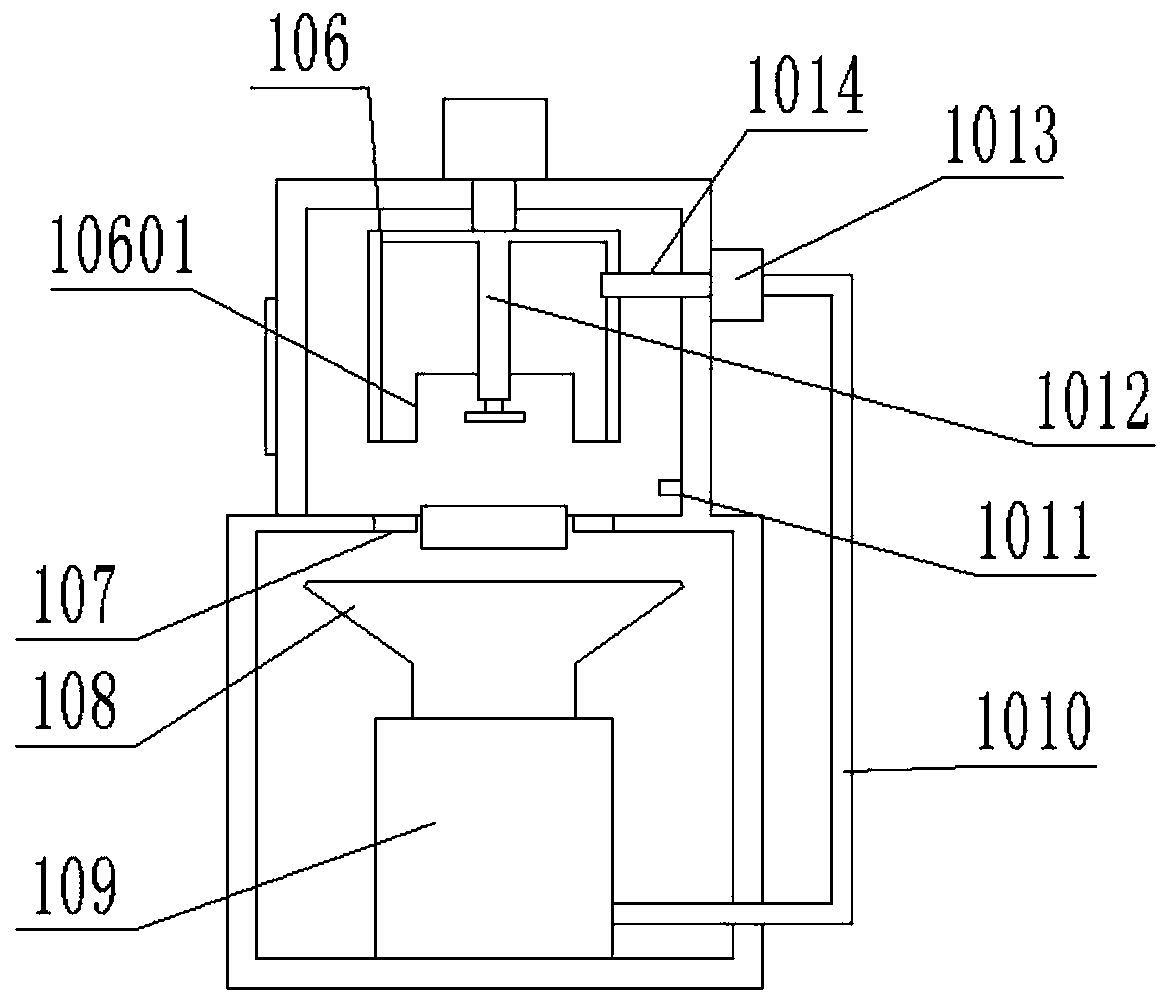

Containment system for type B independent liquid cargo tank

ActiveCN106516016AEffective collection and processingEnsure safetyFor bulk goodsHull structureEngineering

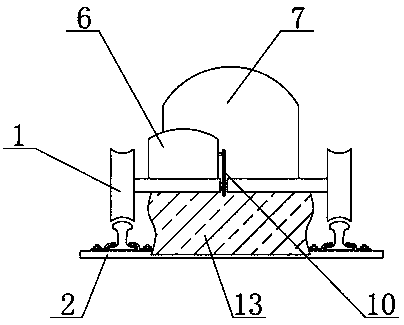

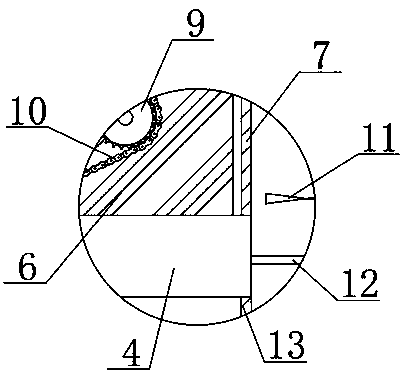

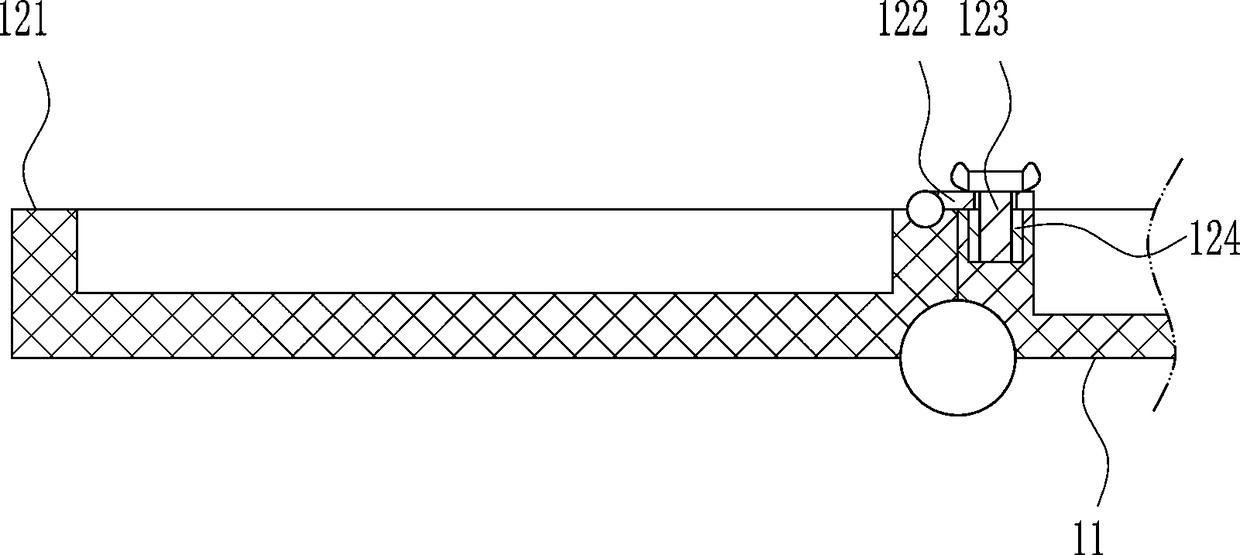

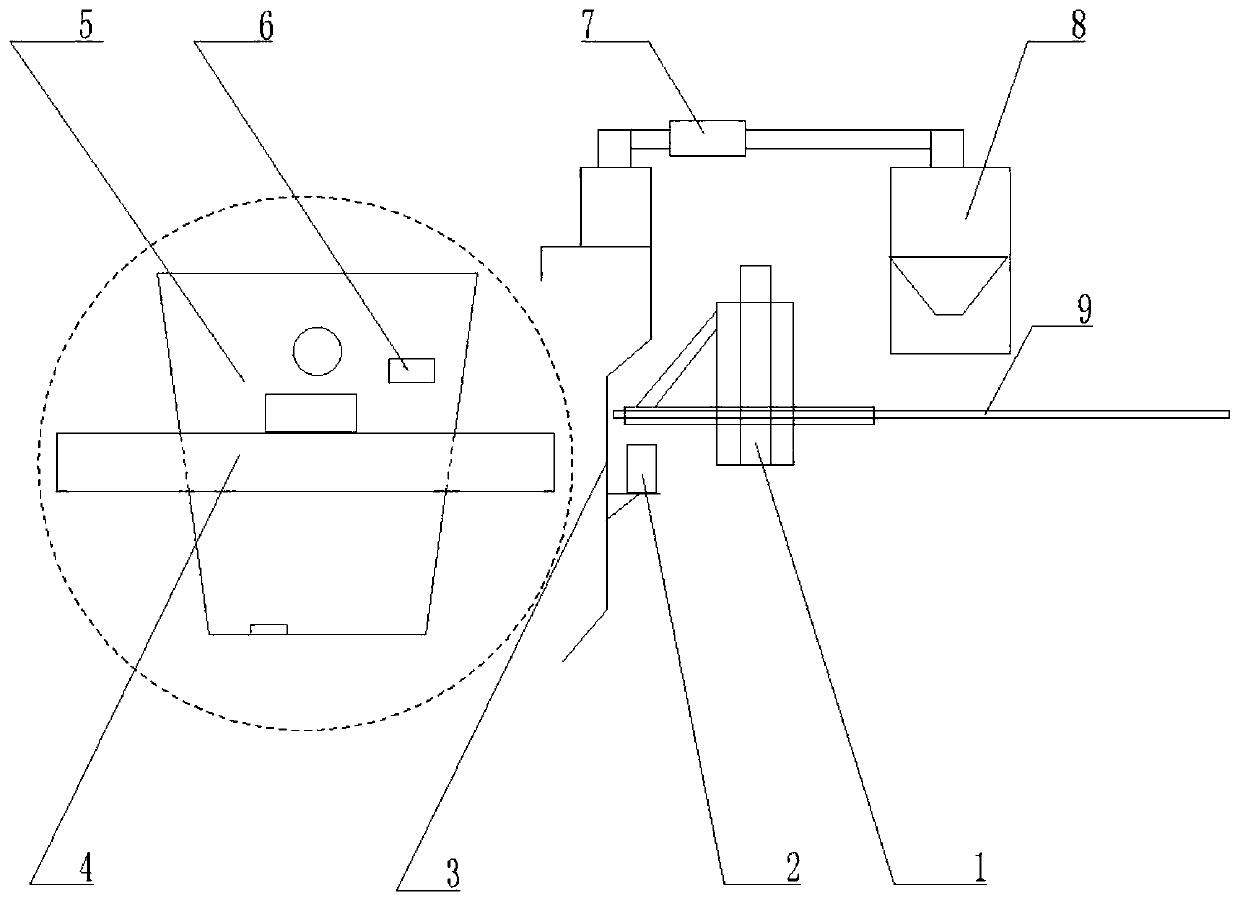

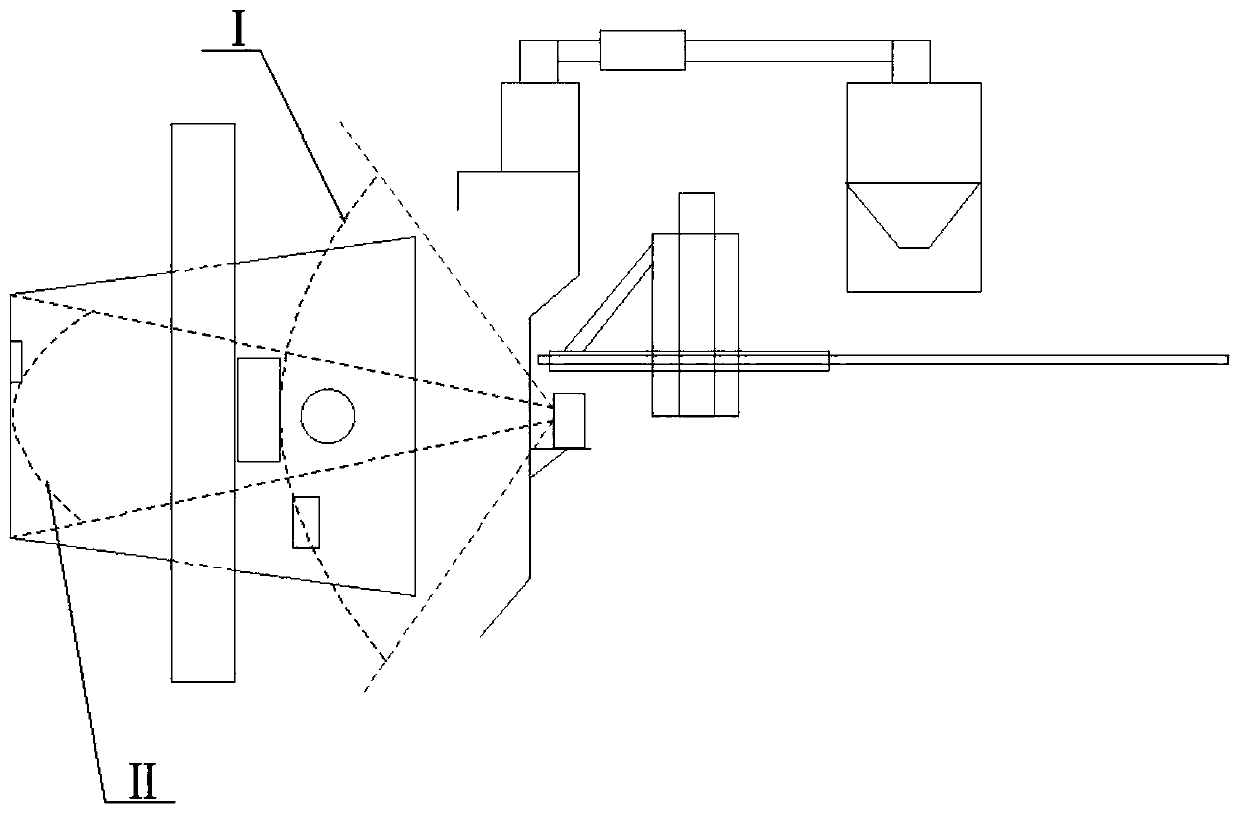

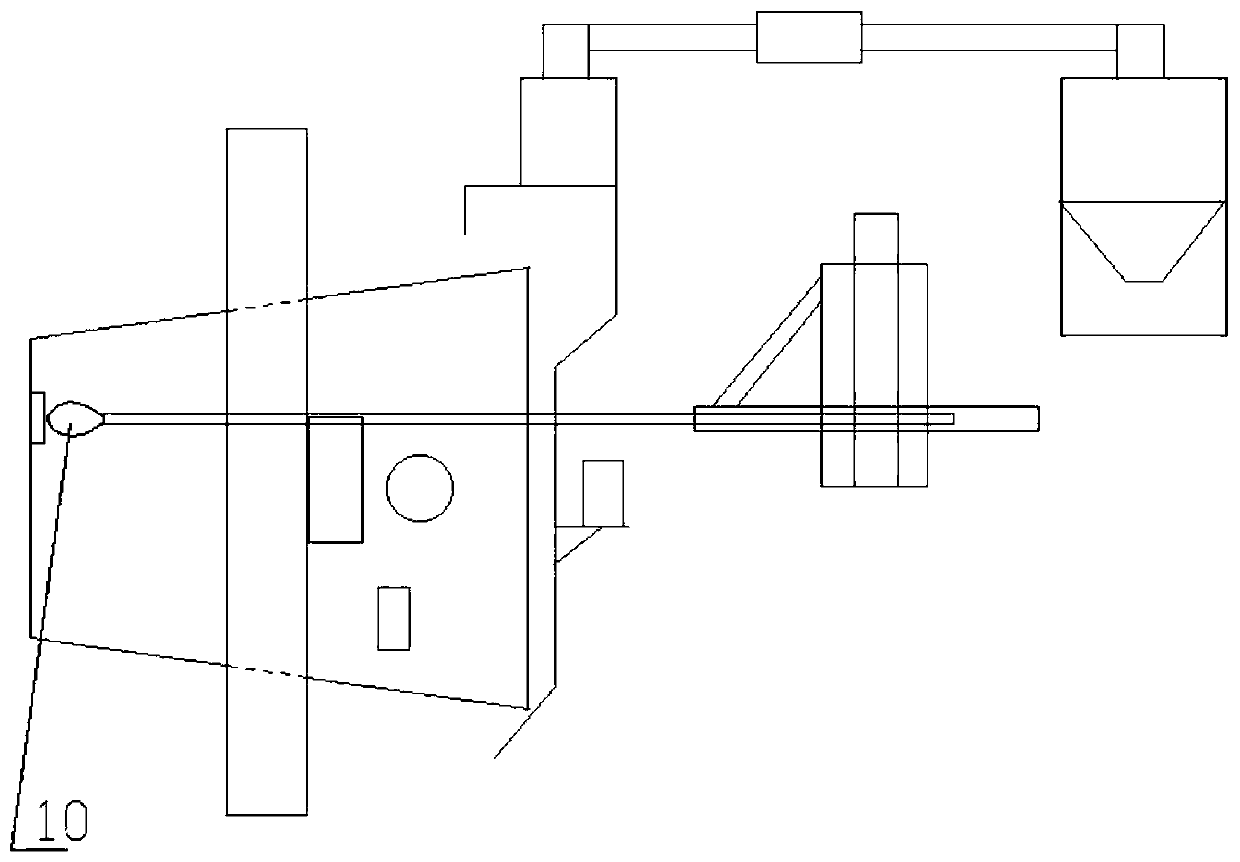

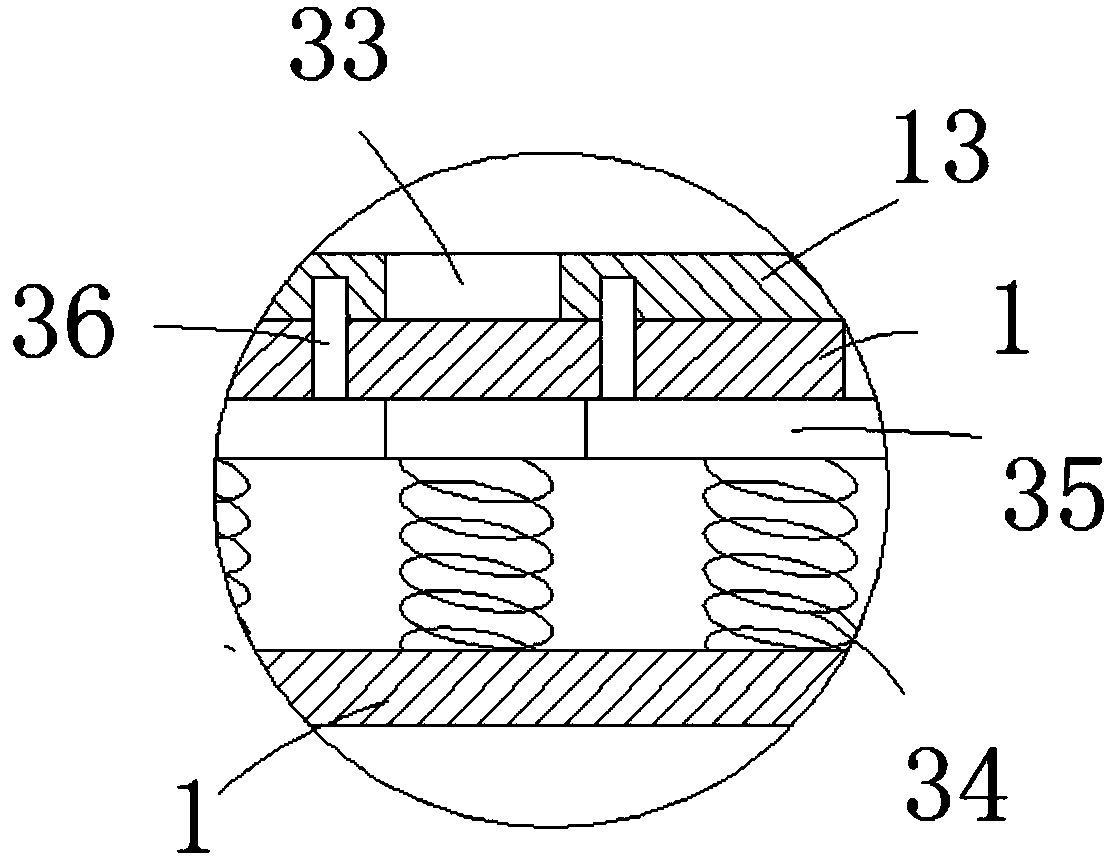

The invention provides a containment system for type B independent liquid cargo tank. The liquid cargo tank comprises a top surface, a bottom surface and a side wall, wherein the top surface, the bottom surface and the side wall are formed by welding a plurality of outer plates; the containment system comprises leakage slots and liquid collecting wells; the leakage slots respectively cover all the weld seams among the outer plates on the top surface and the side wall; the liquid leaking from the weld seams can flow down along the leakage slots to an inner bottom plate of a hull; one or more liquid collecting wells are respectively arranged at both ends of the inner bottom plate in the length direction of the hull; insulating layers are laid on the top surface, the bottom surface and the side wall; the containment system also comprises a baffle plate; the baffle plate is arranged around the liquid cargo tank; and the upper end of the baffle plate is connected with the wall plate of the hull, and the lower end of the baffle plate is connected with the inner bottom plate. According to the containment system disclosed by the invention, the cost is reduced in the aspect of materials by reasonable design of the containment system, and the containment system can guarantee the safety of the hull structure in the case of liquid cargo leakage in the liquid cargo tank.

Owner:JIANGNAN SHIPYARD GRP CO LTD

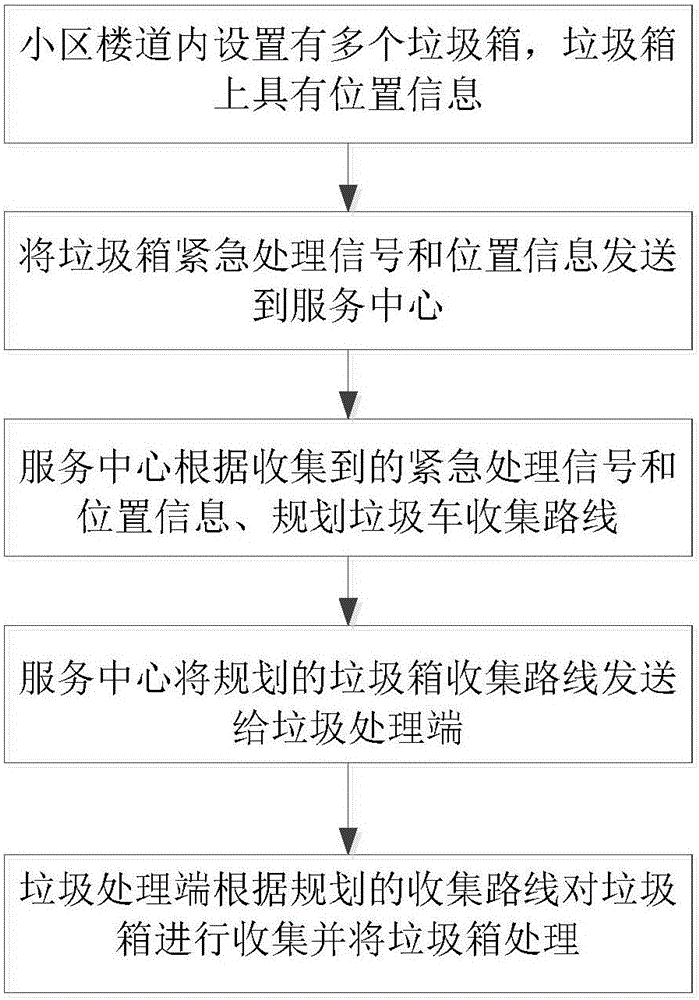

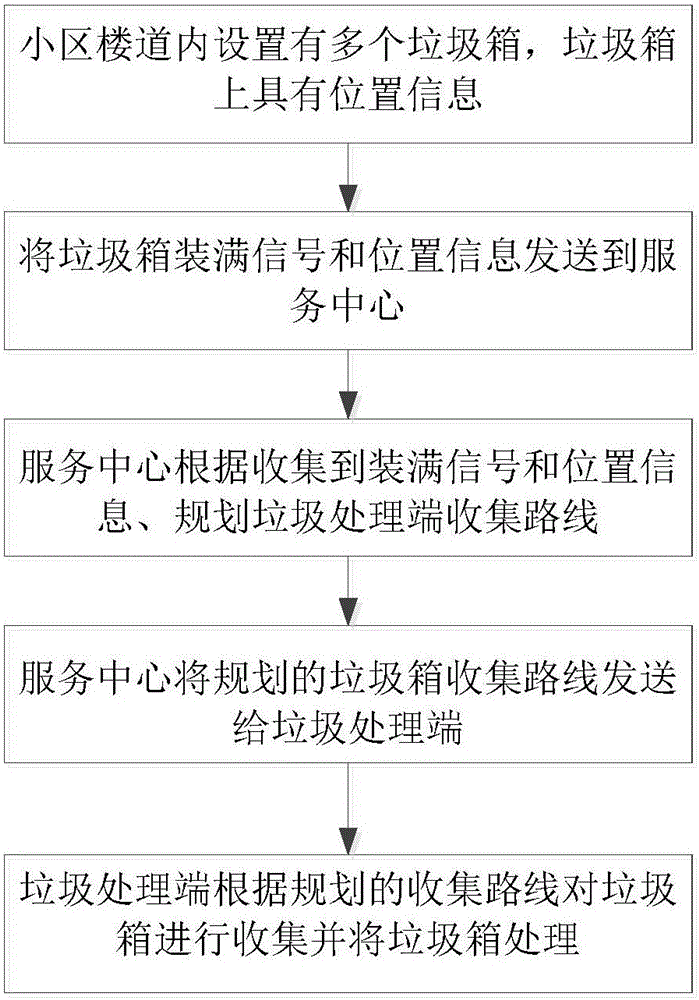

Community garbage disposal method

InactiveCN106115119AImprove processing efficiencyEffective collection and processingRefuse receptaclesLitterComputer science

The invention discloses a garbage treatment method in a residential area, which comprises the following steps: a plurality of garbage bins are arranged in the corridor of the residential area, and the garbage bins have position information; Put the garbage to a certain extent and set the sending signal; the garbage in the garbage bin will send the signal to the service center when the garbage in the garbage bin meets the requirements of sending the signal; the service center will plan the collection route of the garbage disposal terminal according to the collected full signal and location information; The center sends the planned collection route of the garbage disposal terminal to the garbage disposal terminal; the garbage disposal terminal collects the garbage bins according to the planned collection route and processes the garbage bins. The invention provides a more effective community garbage treatment method.

Owner:SHENZHEN ZHIHUISHIFANG TECH

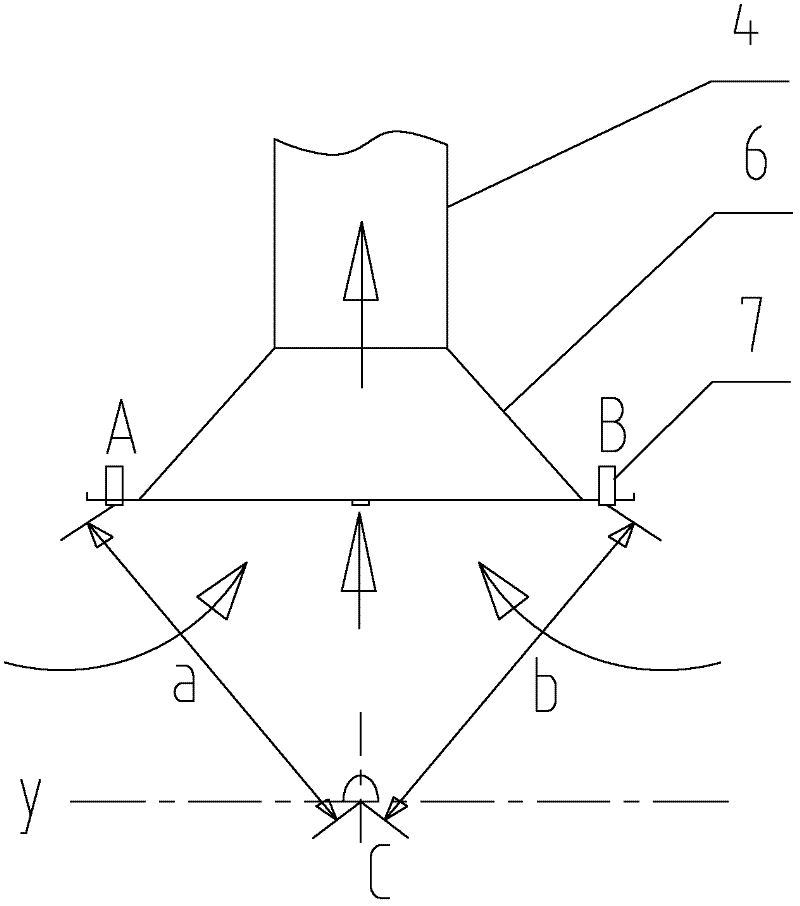

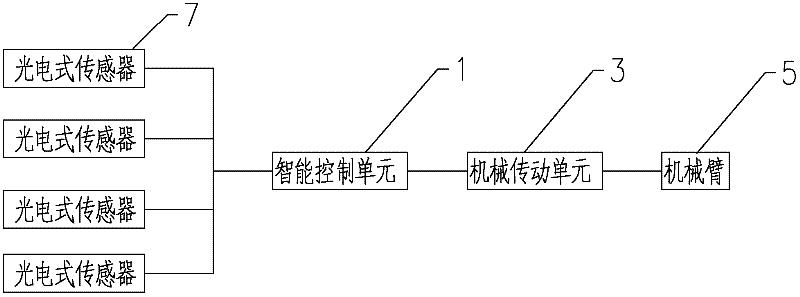

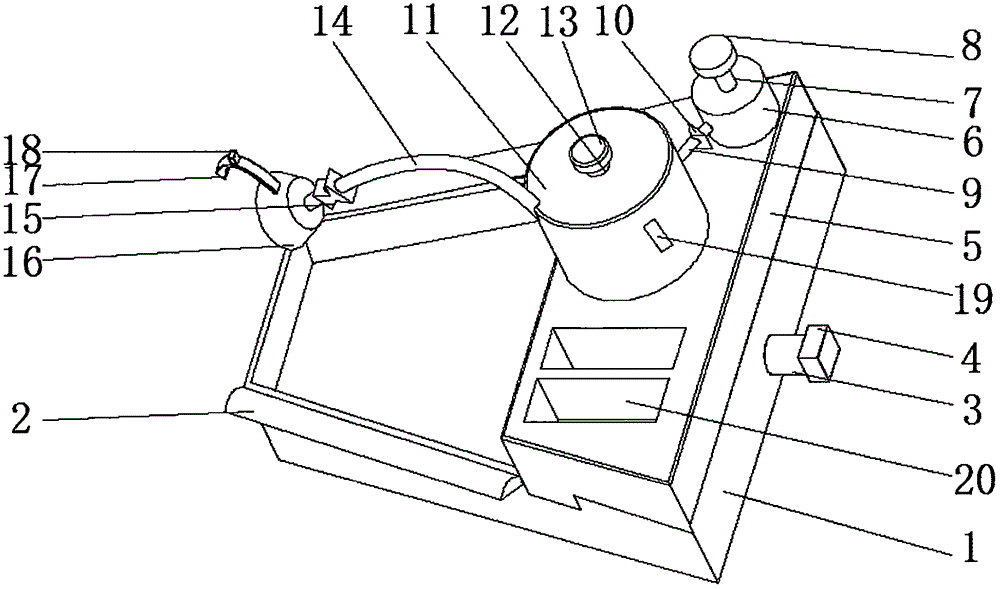

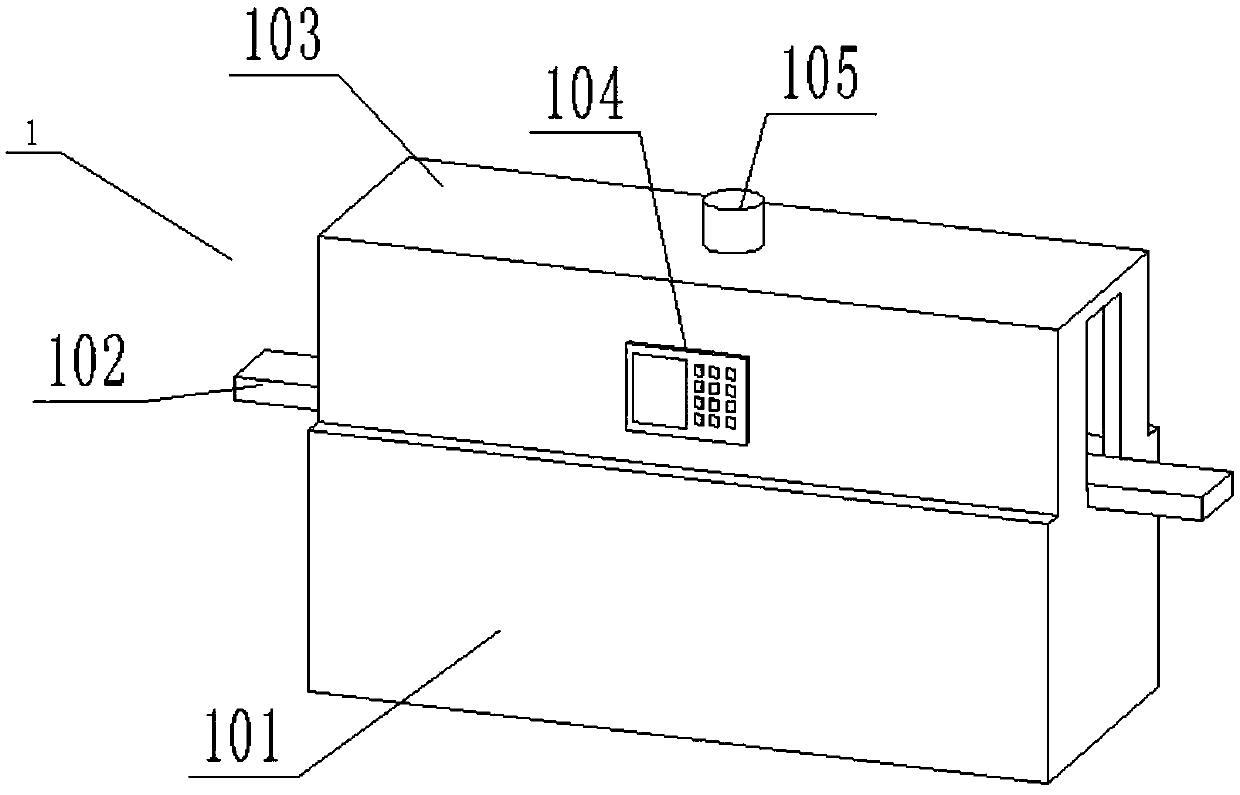

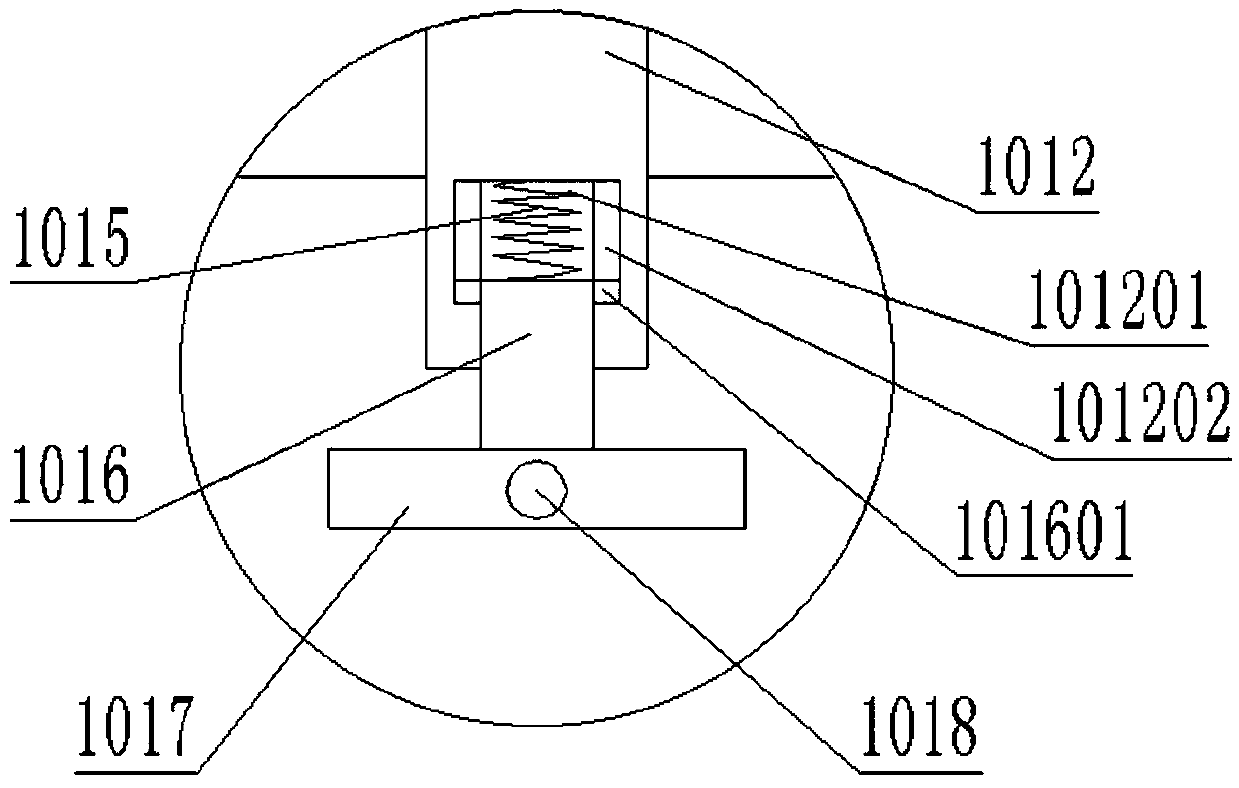

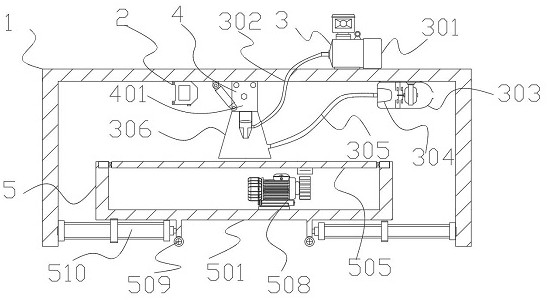

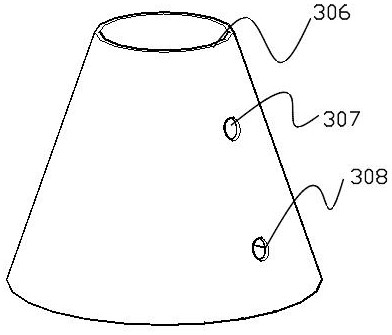

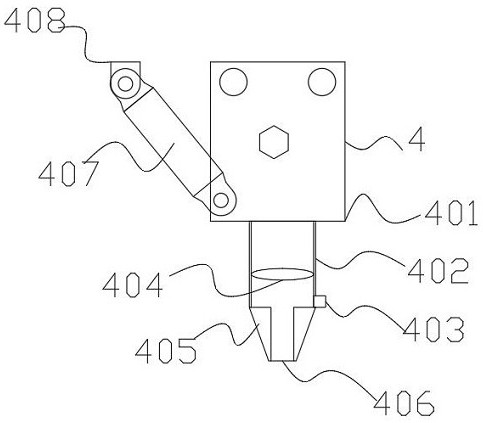

A welding smoke collection device and method capable of automatically tracking and positioning welding points

InactiveCN102266862AImplement trackingEffective collection and processingDirt cleaningEngineeringDistance sensors

A welding fume collection device and method capable of automatically tracking and positioning welding points. The welding fume collection device includes a tracking control system and a welding fume exhaust pipe. The tracking control system includes a group of photoelectric sensors, an intelligent control unit, and a mechanical drive. The welding smoke collection method of the unit and the mechanical arm is to use the photoelectric sensors installed at different positions on the exhaust mask to sense the visible light, infrared rays or ultraviolet rays emitted by the solder joints, and the distance between the solder joint movement and the photoelectric sensors can be changed. The strength of the welding spot arc sensed by each photoelectric sensor changes, and each photoelectric sensor outputs an electrical signal to the intelligent control unit according to the sensed welding spot arc light intensity, and calculates the direction and direction of the welding spot movement. The distance is controlled by the mechanical transmission unit to drive the mechanical arm to move. The invention has high working efficiency, low energy consumption, low equipment cost, and can automatically realize the tracking of solder joints.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

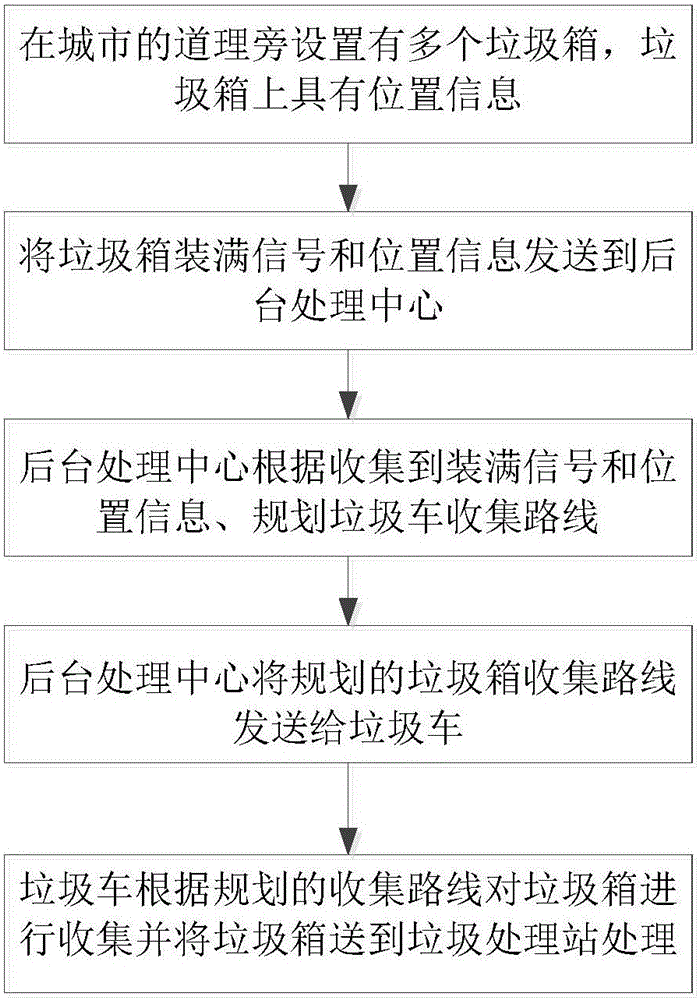

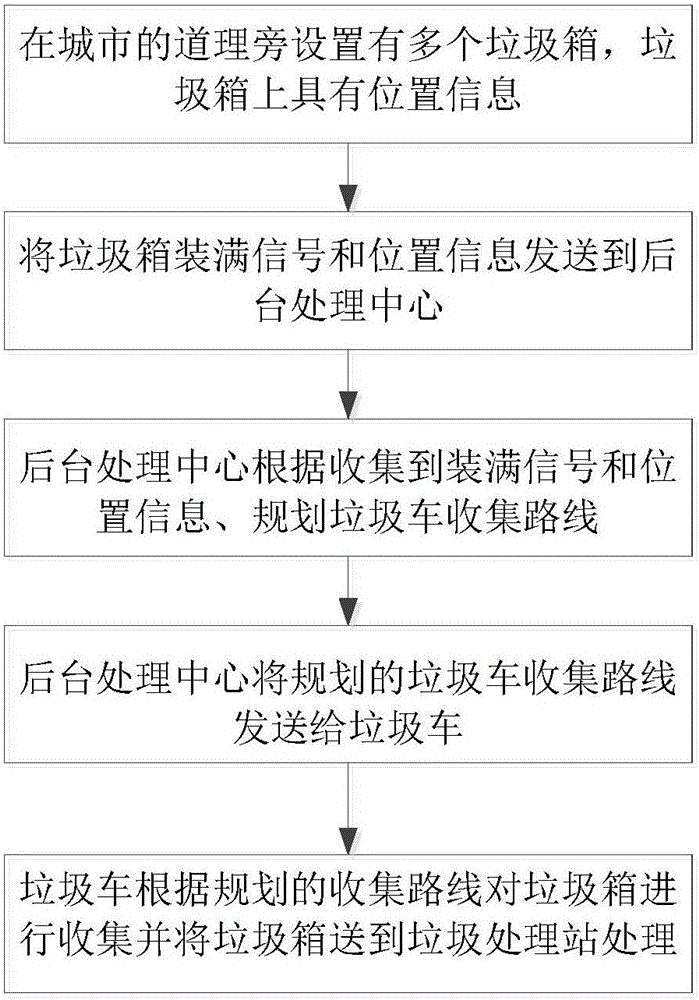

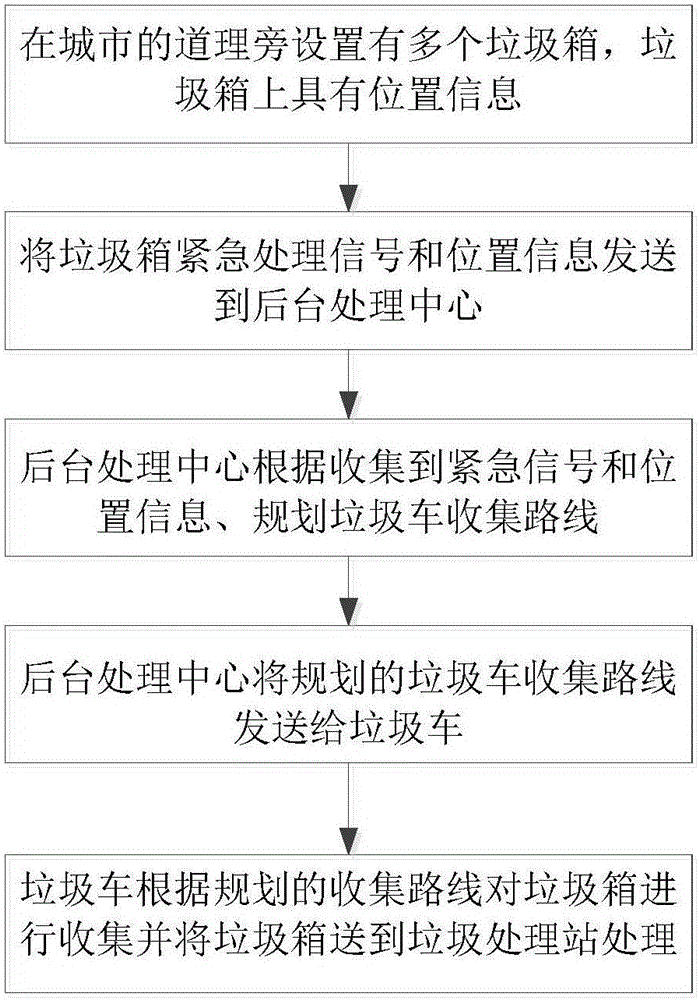

City garbage treatment method

InactiveCN106005833AImprove collection efficiencyImprove waste disposal efficiencyRefuse receptaclesRefuse transferringReal-time computingCommunication unit

The invention discloses a city garbage treatment method. The method includes the following steps that multiple garbage cans are arranged beside a road of a city., the garbage cans are marked with different labels, and position information of the garbage cans is shown on the labels; signals indicating that the garbage cans are filled and position information of the filled garbage cans are transmitted to a backstage processing center, an infrared sensor, a microprocessor and a communication unit are arranged on each garbage can, the infrared sensors are used for monitoring entering of garbage in real time, when the infrared sensors detect that the blocking time of the garbage reaches the threshold value, the microprocessors judge that the garbage cans are filled, and the signals indicating that the garbage cans are filled are sent to a garbage vehicle through the communication units; the backstage processing center plans the collecting route of the garbage vehicle according to the collected signals that the garbage cans are filled and the position information. The backstage processing center sends the planned collecting route of the garbage vehicle to the garbage vehicle; and the garbage vehicle collects the garbage cans according to the planned collecting route and sends the garbage cans to a garbage can treatment station for treatment. The invention provides a more effective city garbage treatment method.

Owner:SHENZHEN ZHIHUISHIFANG TECH

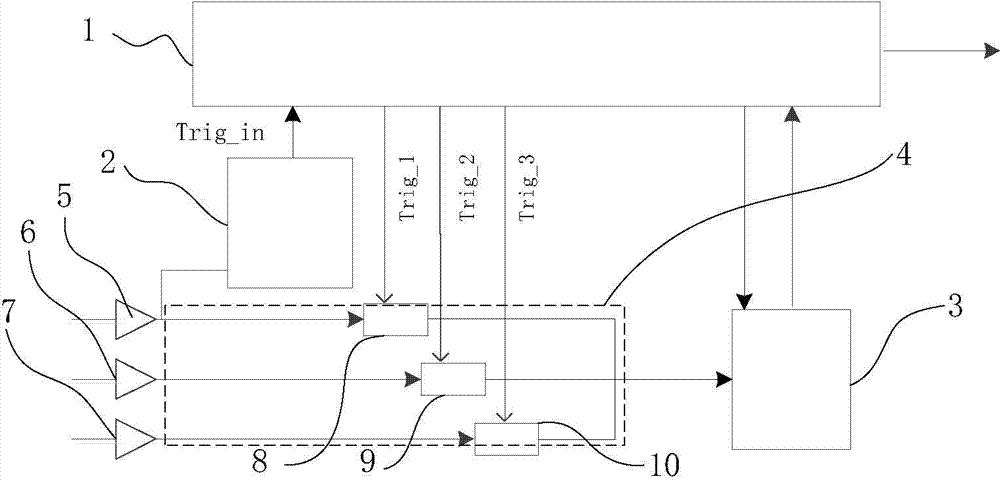

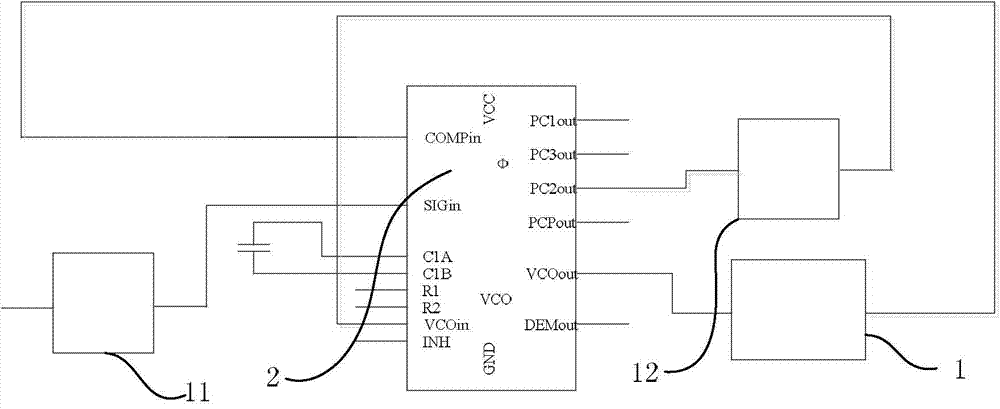

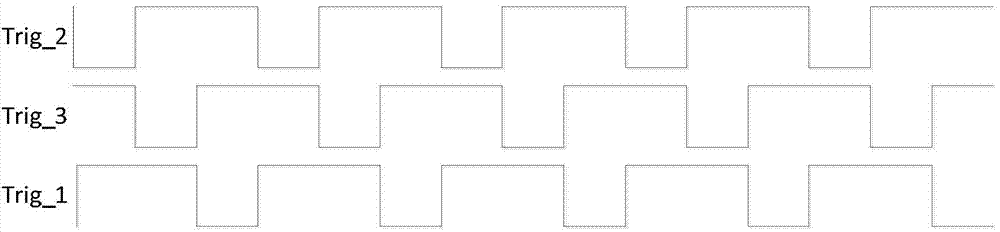

Intermediate frequency processing system of vector network analyzer and method for intermediate frequency processing

InactiveCN103618569ASimple structureTroubleshoot technical issues with difficult layoutsTransmission monitoring/testing/fault-measurement systemsPropogation channels monitoringPhase locked loop circuitIntermediate frequency

The invention discloses an intermediate frequency processing system of a vector network analyzer and a method for intermediate frequency processing. The intermediate frequency processing system comprises a field programmable gate array. The FPGA is respectively connected with a logic phase-locked loop circuit unit and an analog-digital conversion unit, the logic phase-locked loop circuit unit is connected with an intermediate unit, the intermediate unit is connected with the analog-digital conversion unit, the intermediate unit comprises an intermediate reference signal end, a first reflected signal end and a second reflected signal end, and the intermediate reference signal end is connected with the logic phase-locked loop circuit unit. The technical mode of the FPGA, the logic phase-locked loop circuit unit, the analog-digital conversion unit and the intermediate unit is adopted, so that the technical problem that due to the fact that the size of a circuit board is limited, the local arrangement of a multi-pin connector is difficult is solved, the number of devices and pins of the connector is effectively reduced, the size of the product is reduced, power consumption is reduced, and cost is reduced.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

City trash treatment method

InactiveCN106005834AEasy to handleImprove processing efficiencyRefuse receptaclesRefuse transferringEngineeringUrban waste

The invention discloses a method for treating urban garbage, which comprises the following steps: setting a plurality of garbage bins beside roads in the city, and the garbage bins have position information; sending the garbage bin full signal and the position information to a background processing center; background processing The center plans the garbage truck collection route according to the collected full signal and location information; the background processing center sends the planned garbage truck collection route to the garbage truck; the garbage truck collects the garbage bins according to the planned collection route and sends the garbage bins to Dispose of at the garbage disposal station. The invention provides a more effective urban garbage treatment method.

Owner:SHENZHEN ZHIHUISHIFANG TECH

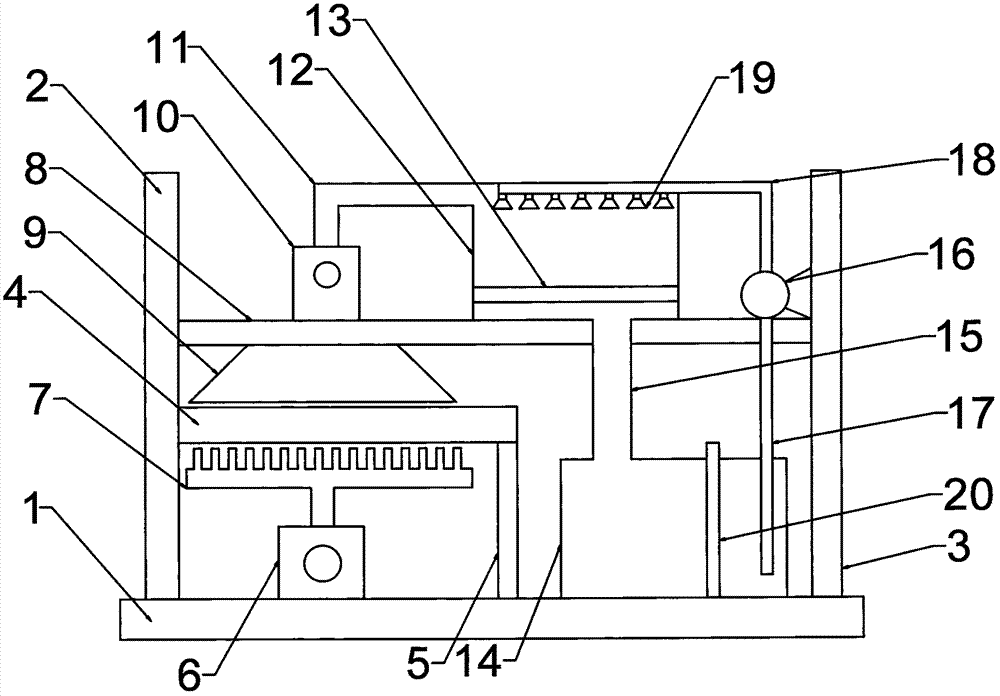

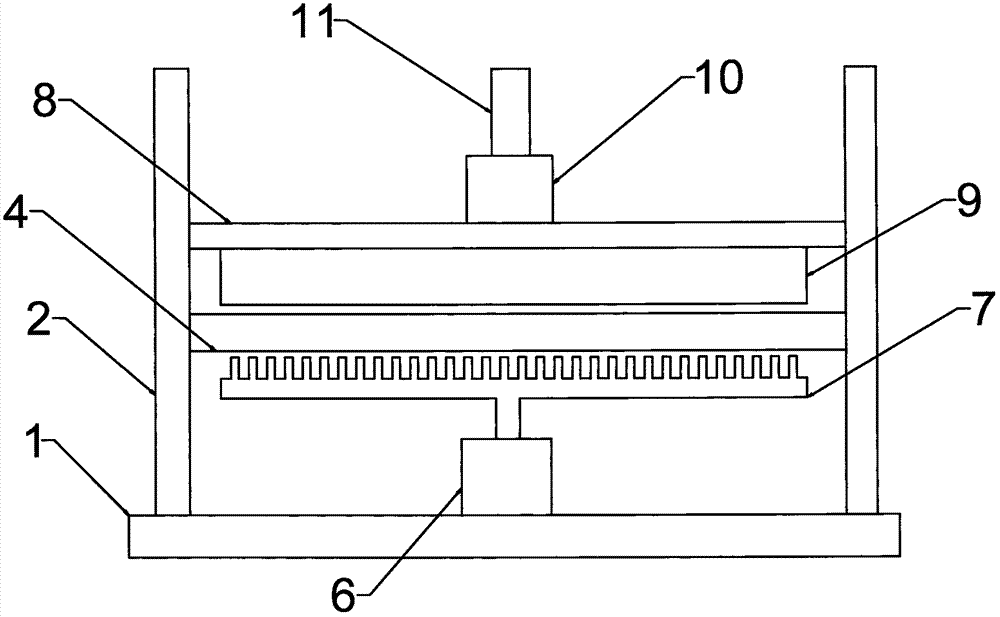

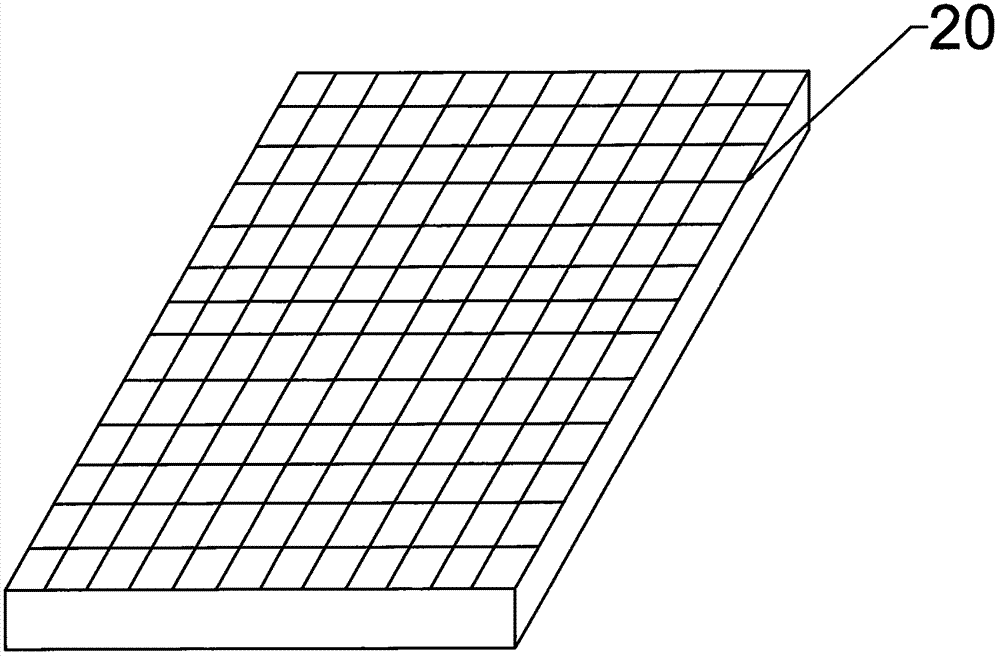

Textile mechanical dust removal device

InactiveCN106994275AImprove production qualityGood for collection and cleaningGas treatmentUsing liquid separation agentAerospace engineeringWater tanks

The invention discloses a textile mechanical dust removal device which comprises a base, a left upright column, a right upright column, a textile workbench, a horizontal platform and a water pump; a supporting column is arranged at the lower part of the right end of the textile workbench; an air blower is arranged on the left side of the upper part of the base; a blowhole platform is arranged at the upper part of the air blower; an air suction opening is formed in the left side of the lower end of the horizontal platform; an exhaust fan is arranged on the left side of the upper end of the horizontal platform; a ventilation pipe is arranged at the air outlet end of the upper end of the exhaust fan; the right end of the ventilation pipe is provided with a dust accumulation tank in a connecting manner; a filter screen is arranged at the lower part in the dust accumulation tank; a water tank is arranged on the right side of the upper part of the base; and a double-layer filter plate is vertically arranged in the water tank. According to the textile mechanical dust removal device, by matching densely distributed air blowing pipelines with the exhaust fan at the upper end, thread ends, fluffs and dust generated in the textile process can be rapidly and effectively eliminated, and the quality of production can be effectively improved.

Owner:杨露萍

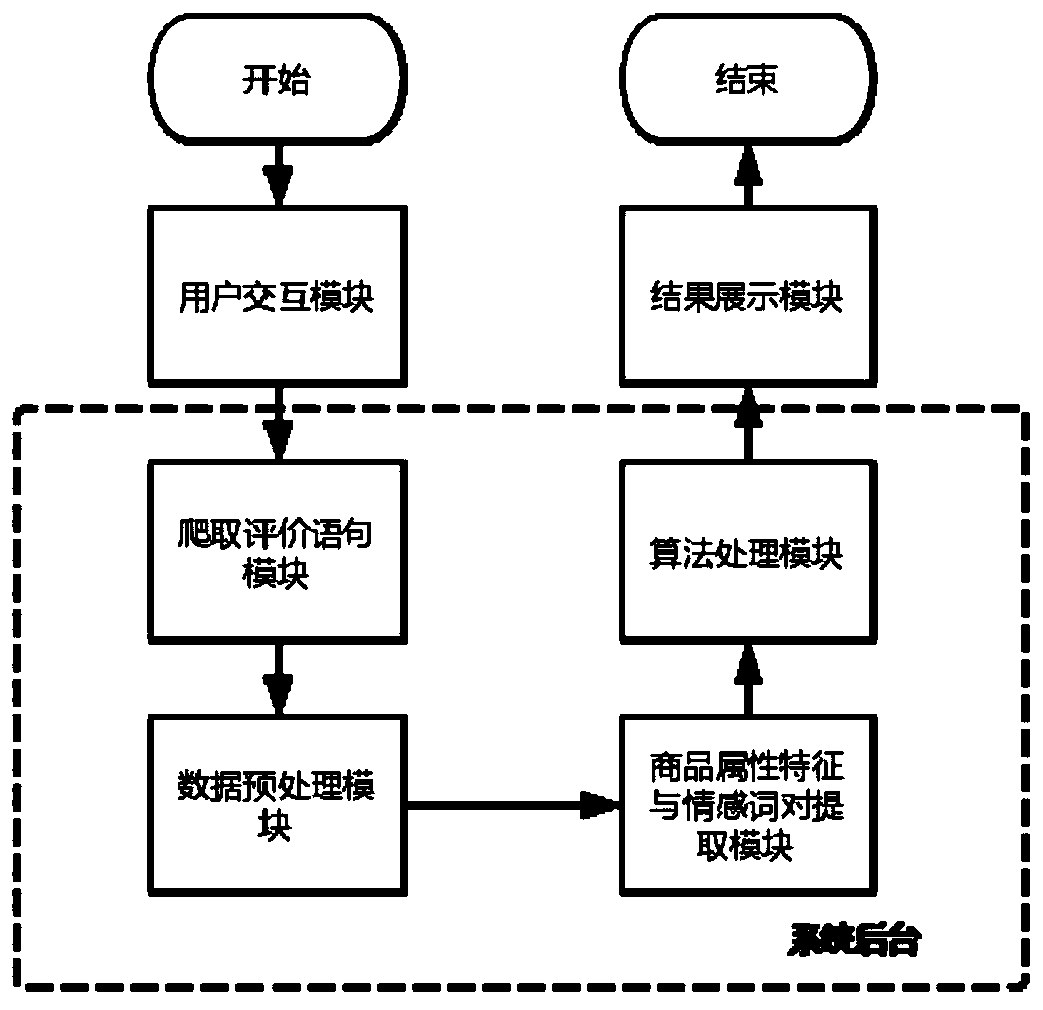

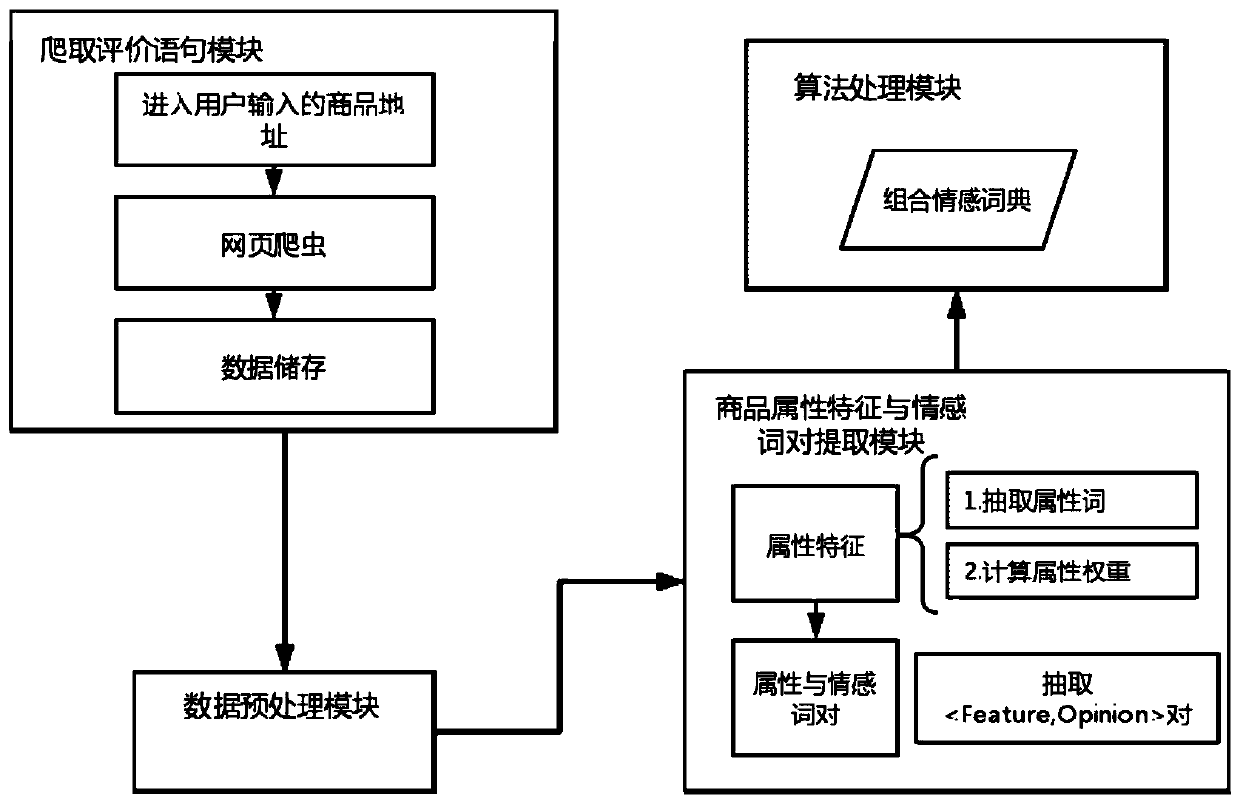

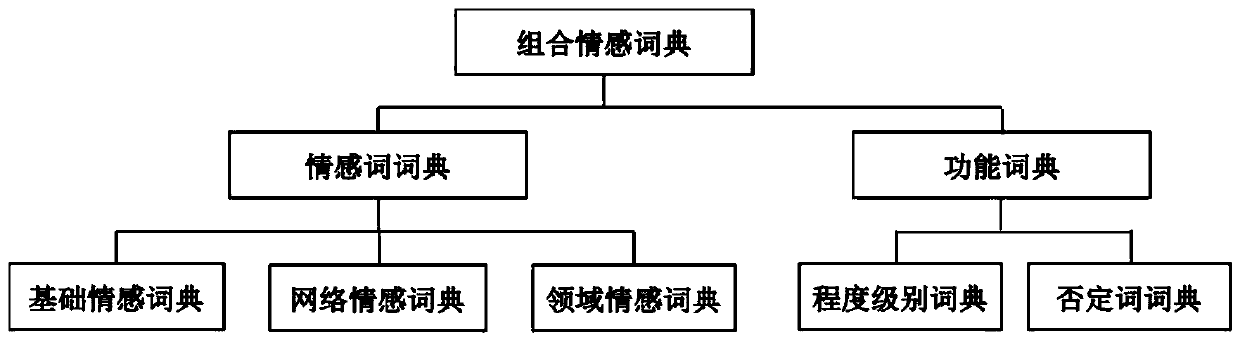

Commodity evaluation sentiment analysis system based on attributive characteristics

InactiveCN110706028AEfficient collection and processingFast and extensive use experienceWeb data indexingSpecial data processing applicationsEngineeringEvaluation data

The invention relates to the technical field of big data, and discloses a commodity evaluation sentiment analysis system based on attribute characteristics. The system is used for obtaining sentimenttendencies of consumers for specific commodities and different attributes of the commodities so as to facilitate purchase evaluation and provide reference for subsequent product research and development and sales. The system comprises a user interaction module used for authenticating the identity of a user and receiving the website of a target commodity input by the user; an evaluation statement acquisition module used for capturing consumer evaluation data; a data preprocessing module used for preprocessing the data; an extraction module used for extracting attribute features and attribute weights of the commodities from the preprocessed data to obtain attribute feature-sentiment word pairs; an algorithm processing module used for inputting the extracted attribute feature-sentiment word pairs into an algorithm model for calculation and analysis, realizing an attribute feature-based sentiment analysis algorithm and outputting a commodity evaluation sentiment quantized value; and a result display module used for displaying the analysis result. The system is suitable for commodity evaluation sentiment analysis.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

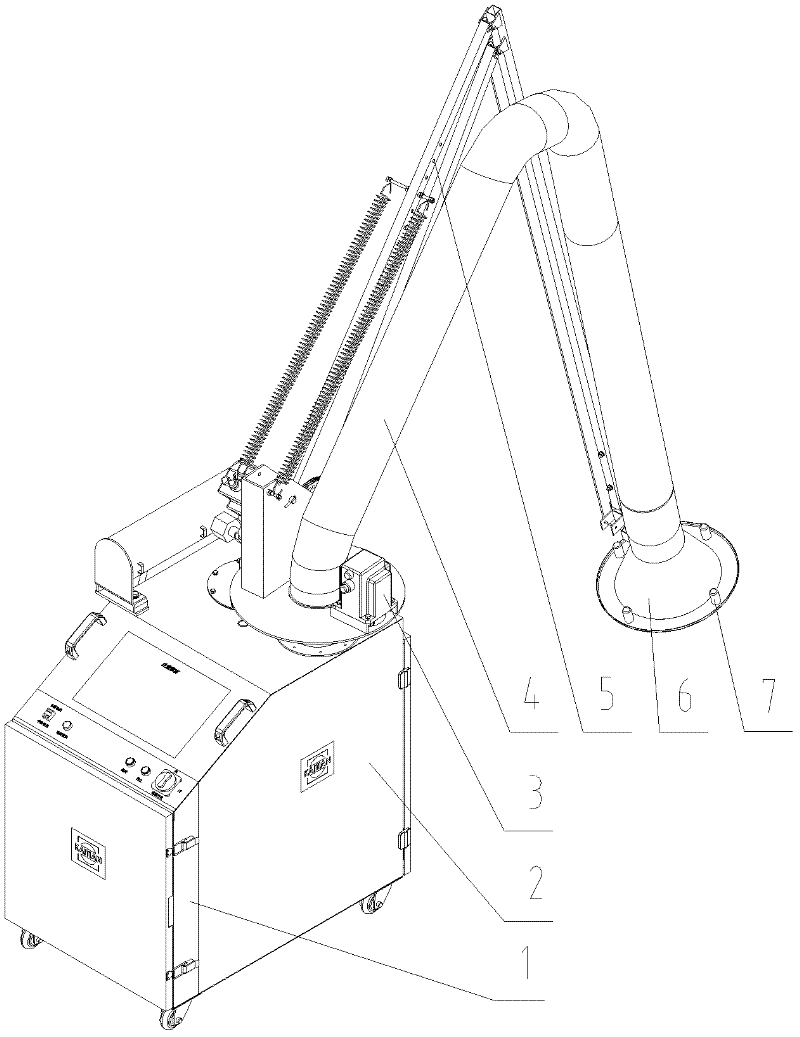

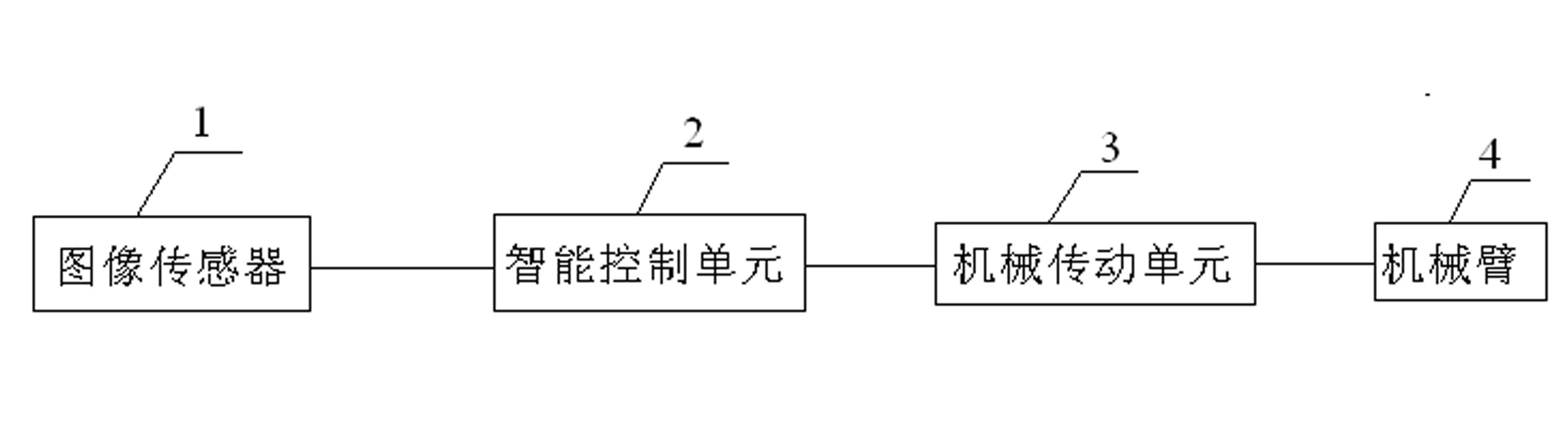

Welding fume collecting device and method capable of automatically tracking and positioning welding point

InactiveCN101829870AImplement trackingEffective collection and processingWelding/cutting auxillary devicesDirt cleaningInfraredControl system

The invention discloses a welding fume collecting device and a welding fume collecting method capable of automatically tracking and positioning a welding point. The welding fume collecting device comprises a tracking control system and a welding fume exhaust tube, wherein the tracking control system comprises an image sensor, an intelligent control unit, a mechanical transmission unit and a mechanical arm; the image sensor is connected with the intelligent control unit; the intelligent control unit is connected with the mechanical transmission unit; the mechanical transmission unit is connected with the mechanical arm; and the image sensor is arranged at the end part of the mechanical arm. The welding fume collecting method comprises the following steps of: sensing visible light or infrared rays emitted by the welding point by using the image sensor, wherein the welding point is a light spot in a sensed image; transmitting image information to the intelligent control unit through the image sensor, analyzing and processing the image information through the intelligent control unit, calculating the change direction and distance of a light spot coordinate, and controlling the mechanical transmission unit to drive the mechanical arm to move; and when the light spot coordinate value is the same as the preset point coordinate value, stopping the movement of the mechanical arm. The device and the method have high working efficiency and low energy consumption, and can automatically realize the tracking of the welding point.

Owner:欧朝旭

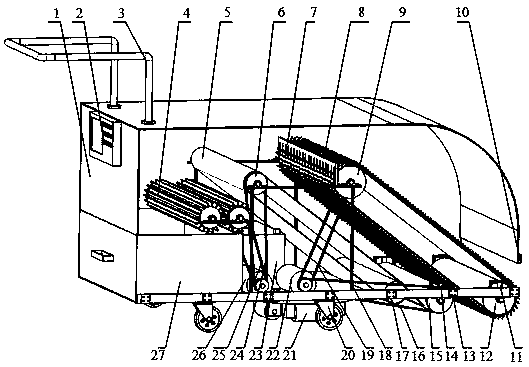

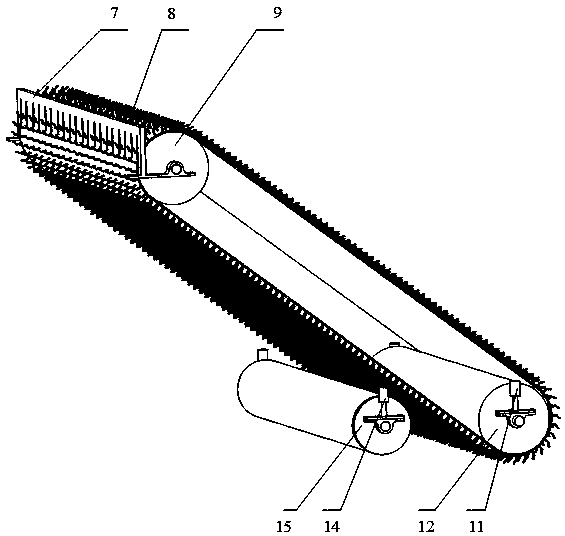

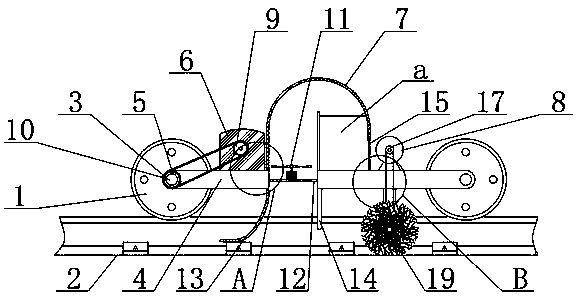

Road fallen leaf sweeping and collecting machine vehicle

InactiveCN108425330AEffective collection and processingRoad cleaningGrain treatmentsSteering wheelCollection system

The invention discloses a road fallen leaf sweeping and collecting machine vehicle. The road fallen leaf sweeping and collecting machine vehicle comprises a vehicle body, a fallen leaf collecting device, a fallen leaf conveying device, a fallen leaf smashing device, a fallen leaf storage device, an automatic traveling and steering device and an intelligent distance recognizing device. Two power motors, a battery, an automatic traveling and steering wheel assembly, four universal powerless supporting wheels, an electric broom shaft, a nail belt driven shaft, a fallen leaf conveying belt drivenshaft and a bearing bracket are fixed on a chassis of the vehicle body. A nail belt driving shaft, a fallen leaf conveying belt driving shaft and two fallen leaf smashing shafts are fixed on the bearing bracket. Three rows of position sensors are separately fixed on the front plate and two side plates of the vehicle body, and are used for judging the distances from the vehicle body to the ground and a barrier. A fallen leaf collecting box, a function operation panel and a sweeping vehicle digital electronic control processing system are fixed on a rear plate of a compartment. By the automaticsweeping, processing and collecting system, the purpose of treating fallen leaves effectively and conveniently in an unmanned manner is achieved.

Owner:邢志平

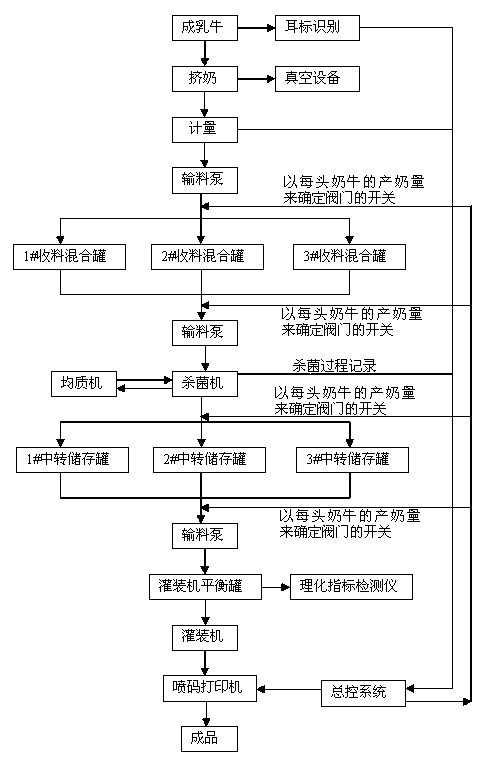

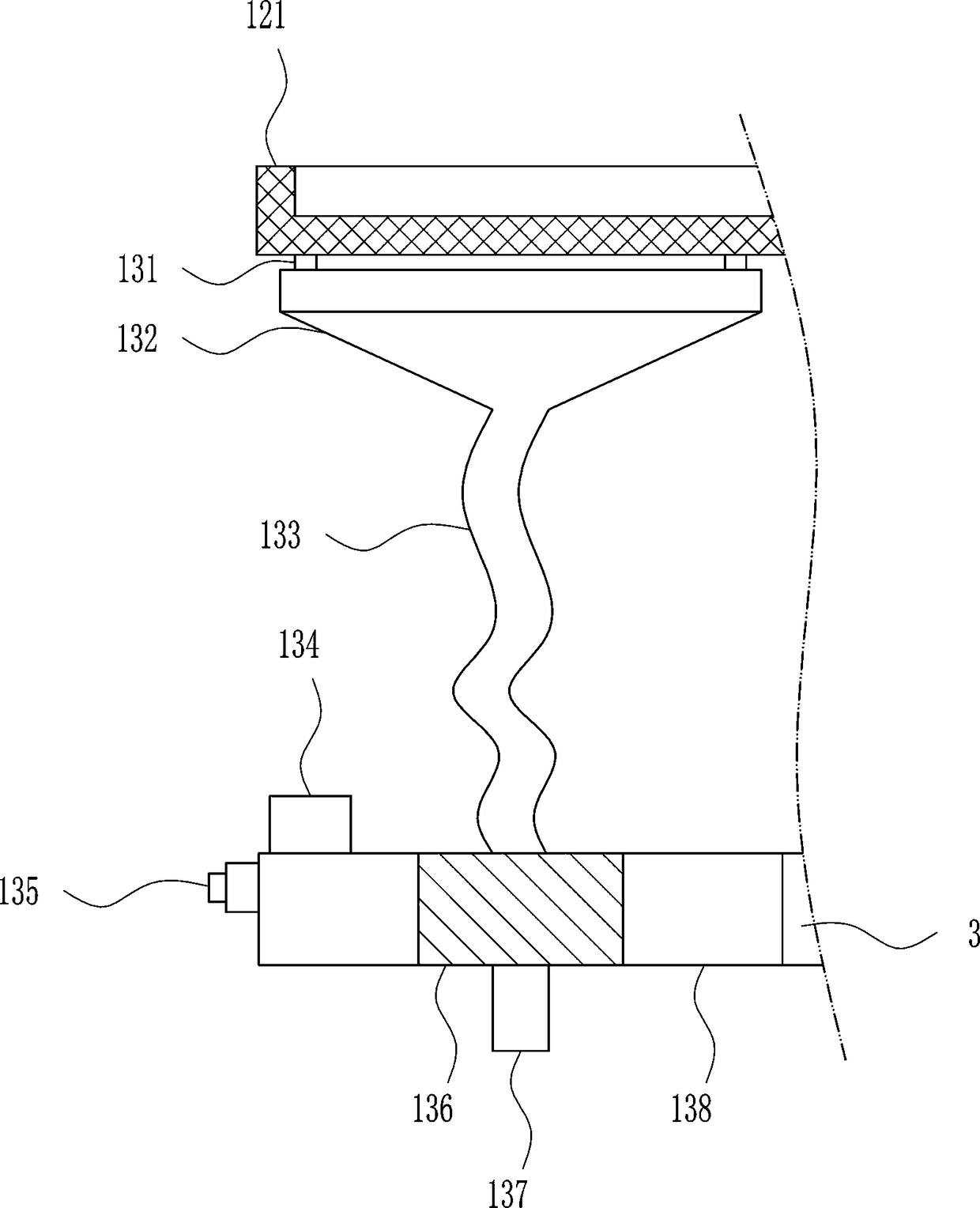

Method for amount-distribution corresponding collection and processing of milk

InactiveCN104170750ARealize collection and processingAchieving Portable SupplyLiquid fillingMilking devicesControl systemEngineering

The invention discloses a method for amount-distribution corresponding collection and processing of milk, in order to realize amount-distribution supply of the milk from each dairy cow. The method comprises the steps of milking, amount-distribution corresponding, sterilizing, transferring storage, and filling and code spraying, wherein a plurality of received material mixing tanks are arranged in the amount-distribution corresponding step, a plurality of transferring storage tanks are arranged in the transferring storage step, and a master control system is used for controlling the whole production process, so that the milk produced by each dairy cow can realize filling production separately, amount-distribution corresponding collection and processing of the milk can be conveniently, accurately and efficiently realized, and amount-distribution supply of the milk from each dairy cow is realized finally. According to the invention, independent selection needs to drinkable dairy products by consumers are met, and precise customizing in the true sense is realized.

Owner:MY FAMILY RANCH NANJING DAIRY

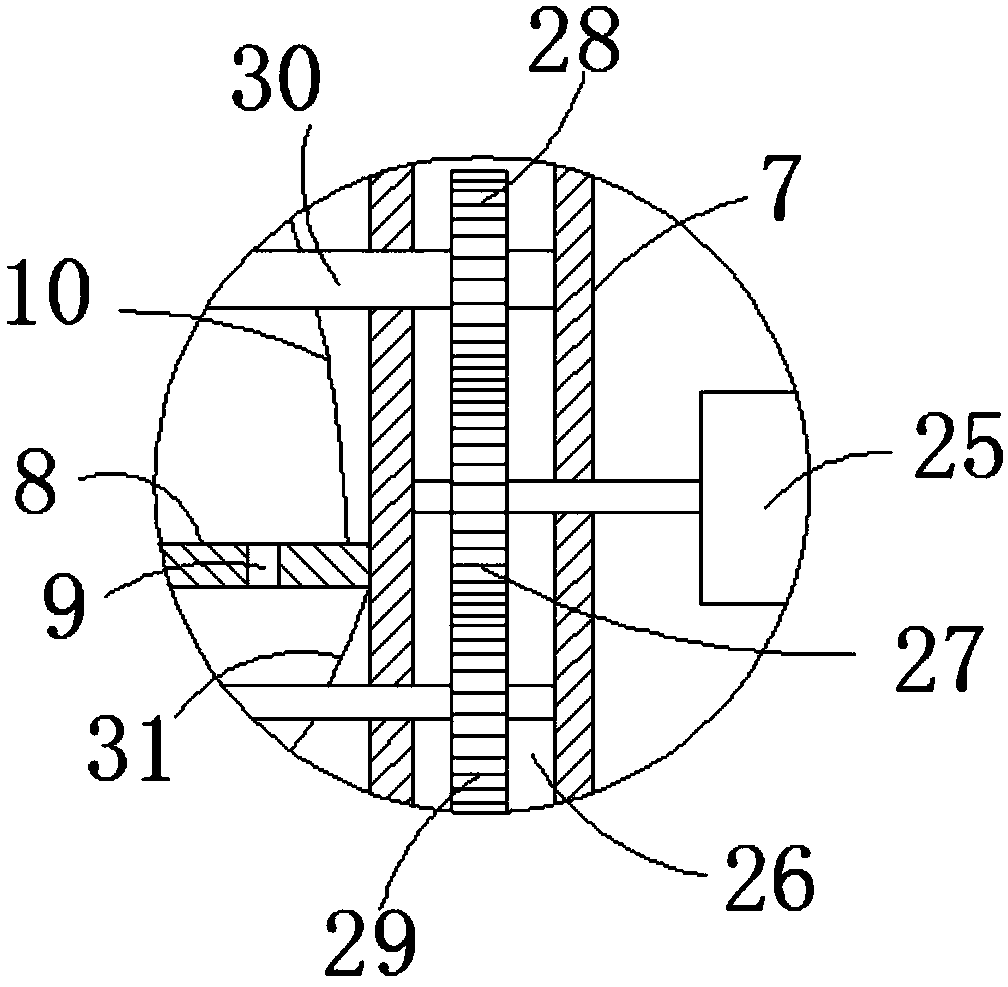

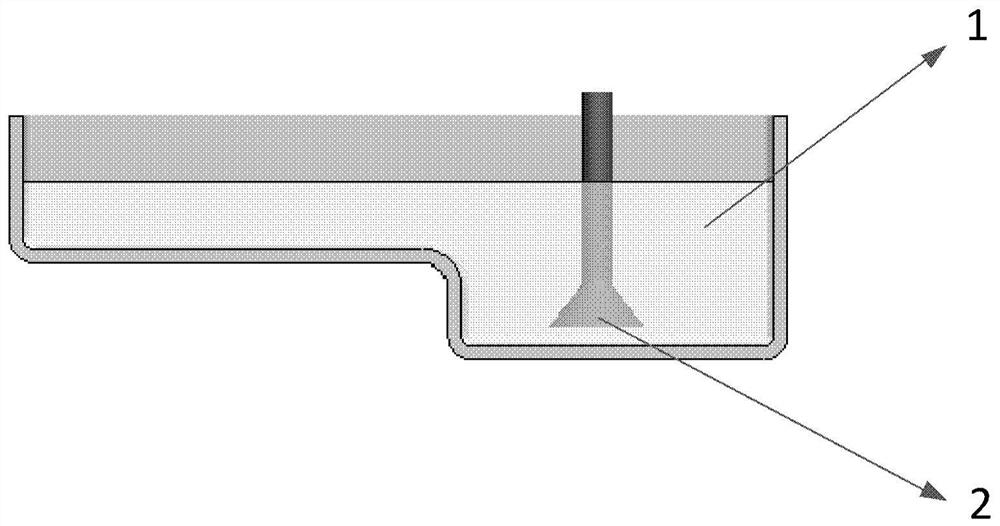

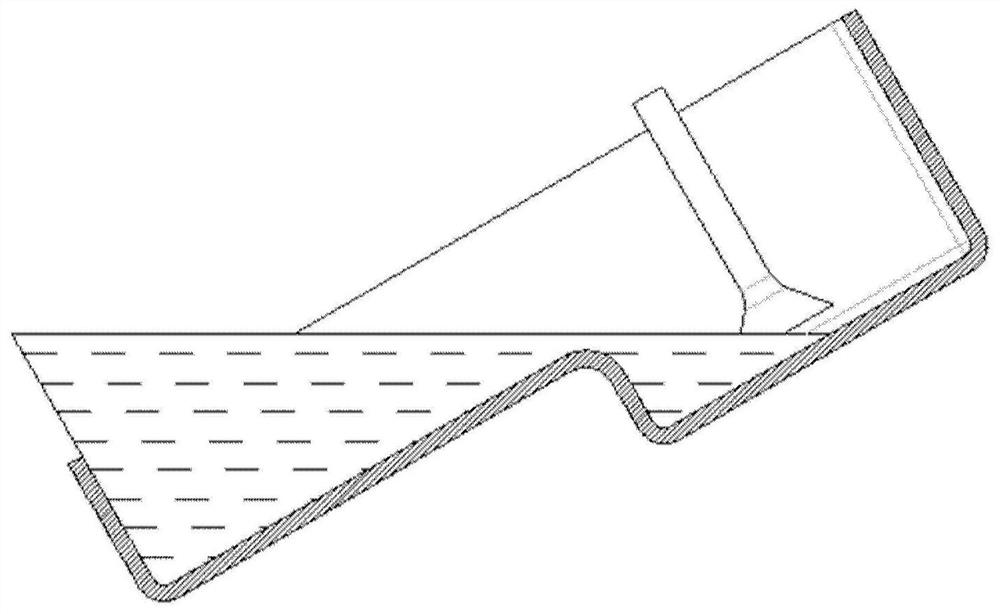

B-type independent liquid cargo compartment leakage liquid cargo leading-out structure

The invention provides a B-type independent liquid cargo compartment leakage liquid cargo leading-out structure. A liquid cargo compartment exists in the ship body. The lowest point of the bottom surface of the liquid cargo compartment is provided with a vertical flow guiding pipe. The upper part of the flow guiding pipe is provided with a plurality of flow guiding holes along the circumferentialdirection of the flow guiding pipe. Leakage liquid cargo flows into the flow guiding pipe through the flow guiding holes. The inner bottom of the ship body is provided with a liquid collecting trap. The flow guiding pipe extends into the liquid collecting trap. The flow guiding pipe is divided into an upper pipe and a lower pipe. An explosion plate is arranged between the upper pipe and the lowerpipe. The leakage liquid cargo leading-out structure according to the invention can ensure safety of the ship body structure on the condition of liquid cargo leakage in the liquid cargo compartment, thereby preventing direct contact between the liquid cargo and the ship body structure, and furthermore effectively collecting and processing the leaked liquid cargo.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Self-walking cleaning device of railway track

ActiveCN108360446ASave human effortImprove work efficiencyRailway cleaningFiltrationEconomic benefits

The invention relates to the technical field of environment-friendly cleaning, in particular to a self-walking cleaning device of a railway track. The self-walking cleaning device comprises wheels andthe track, wherein rotary shafts are fixedly connected to the inner sides of the wheels, a fixing plate is rotatably connected to the outer side of the rotary shafts, a generator, a ventilation pipeand a motor are sequentially arranged on the fixing plate from left to right, a suction ventilator and a rubbish bin which are bilaterally arranged are located in the ventilation pipe, a fixing rod isfixedly connected to the bottom end of the suction ventilator, a rubber blocking piece and an air blocking plate which are bilaterally arranged are arranged at the bottom end of the suction ventilator, and a filtration plate is arranged on the right side of the rubbish bin. In the self-walking cleaning device, by arranging the rubber blocking piece, the air blocking plate, the suction ventilatorand a passing pipe, rubbish collected after cleaning can be effectively collected and treated. The self-walking cleaning device is novel and scientific in design concept, has huge economic benefit andwide market prospect and is worthy of popularization and use.

Owner:泰兴市东城水处理工程有限公司

Community garbage treatment method

InactiveCN106203690AImprove collection efficiencyImprove processing efficiencyForecastingComputer scienceCollection Time

The invention discloses a community garbage treatment method. The method comprises the following steps of: setting a plurality of garbage cans in corridors of a community, wherein the garbage cans are provided with position information; sending garbage can full signals and the position information to a service center; programming a collection path of a garbage treatment end by the service center according to the collected full signals and the position information, determining a collection time period of receiving the full signals through the programmed collection path, and programming a path according to the full signals and the position collected in the collection time period; sending the programmed collection path of the garbage treatment end to the garbage treatment end by the service center; and collecting the garbage cans by the garbage treatment end according to the programmed collection path, and sending the garbage cans to a garbage treatment station to treat. The invention provides a more effective community garbage treatment method.

Owner:SHENZHEN ZHIHUISHIFANG TECH

Portable disinfecting device applied after urological operations

InactiveCN105854168AEasy to observeReduce workloadMedical applicatorsChemicalsLiquid tankEngineering

The invention discloses a portable disinfecting device applied after urological operations. The disinfecting device comprises a waste liquid groove, wherein contact plates are fixedly arranged on openings at the upper ends of the front and back sides of the waste liquid groove; a drainage pipe is arranged on the right side face of the waste liquid groove; a pipe plug is arranged on the nozzle of the drainage pip; and a supporting plate is fixedly arranged at the right end of the upper part of the waste liquid groove. The device is practical in appearance; the contact plates, which get into contact with a body, are represented as rounded and smooth faces which fit to the human body; by virtue of a transparent viewing window, which is provided with scales, on a washing liquid tank, the residual amount of cleaning liquid can viewed conveniently, so that the cleaning liquid can be conveniently added timely; a check valve which is arranged on a connecting pipe of an air compressor, the back flow of medicine liquid is prevented; by virtue of an LED lamp, medical personnel can conveniently view a disinfected region; the device is small in structure, free from occupation of a space and convenient to store and carry; disinfected waste liquid can be collected and processed effectively, so that the workload of the medical personnel is reduced; and the disinfecting device is applicable to disinfection after most urological operations.

Owner:黄智龙

Sorting system after molding of fine ceramic product

ActiveCN110524708ARealize processingAchieve recyclingGrinding carriagesGrinding drivesMetalMaterials science

The invention discloses a sorting system after the molding of a fine ceramic product. The system comprises a rapid cooling device after the fine ceramic molding, a drying device for producing the fineceramic sealed with the metal, a fine ceramic grinding device witha dust collection function, a fine ceramic polishing device, a storing, taking and placing device for producing the fine ceramic sealed with the metal and a conveying device for producing and machining the fine ceramic. Through the reasonable arrangement and cooperation of the above several processes, the finished ceramic productsare sorted, and the percent of pass of the products is increased.

Owner:湖南福易达电子科技有限公司

Multifunctional sun-withering equipment for tea process

InactiveCN108244278AEasy to pushPlay a guiding rolePre-extraction tea treatmentEngineeringMultiple function

The invention relates to sun-withering equipment, in particular to multifunctional sun-withering equipment for a tea process and aims to provide the multifunctional sun-withering equipment which facilitates tea recovery and is used for the tea process to solve the technical problems. In order to solve the technical problems, the multifunctional sun-withering equipment for the tea process comprisesa wheel, a pillar, a mounting plate, a mounting frame, a first slider, a first slide rail, a handle, a drawer, a second slider, a second slide rail, a first storage net frame and a storage mechanism.The pillar is fixedly connected to the bottom of the mounting plate, the wheel is fixedly connected to the bottom of the pillar, the mounting frame is fixedly connected to the top of the mounting plate, and the second slide rail is fixedly connected to one side in the mounting frame. The equipment realizes the effects of facilitating tea recovery and multiple functions.

Owner:刘治国

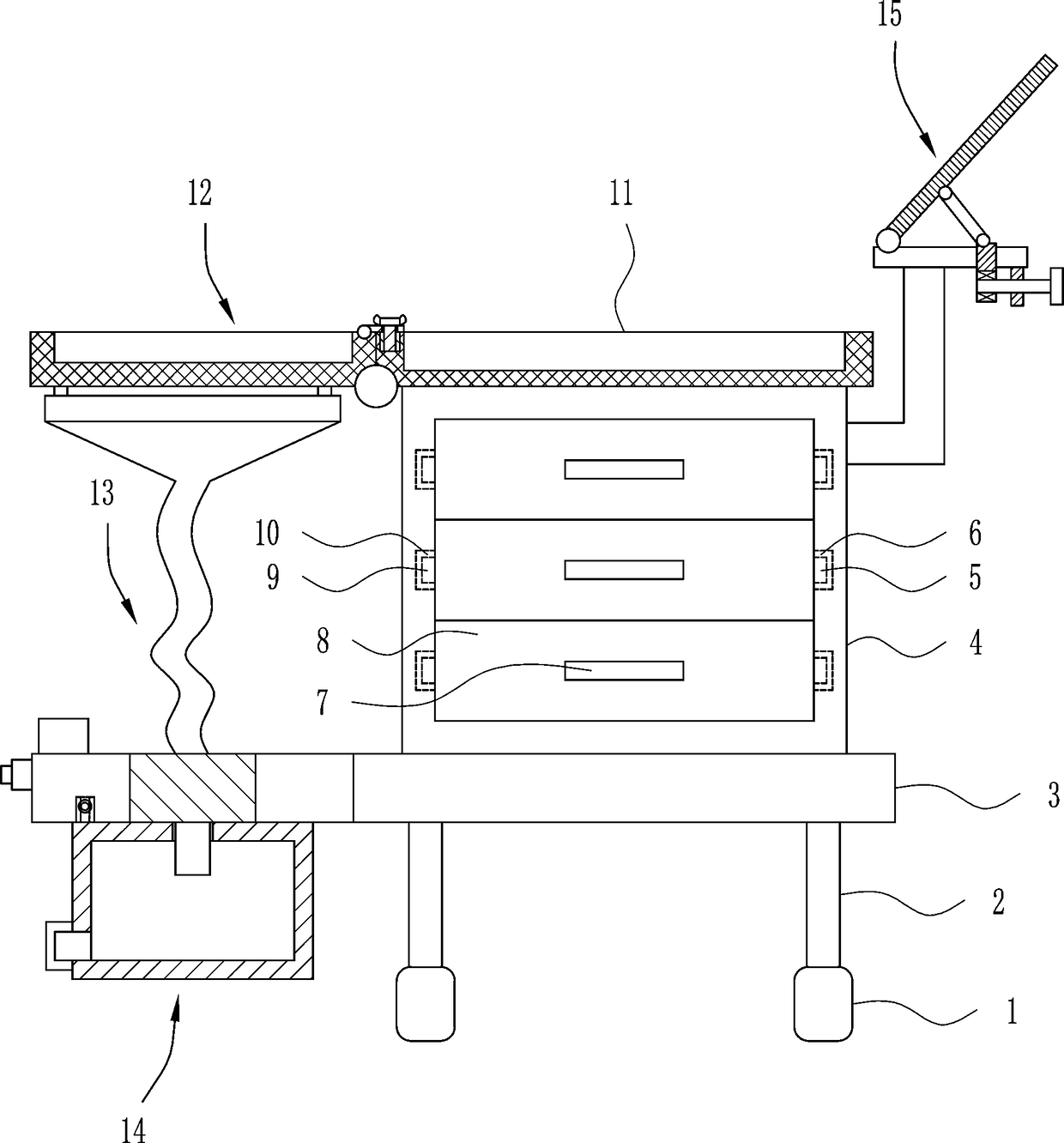

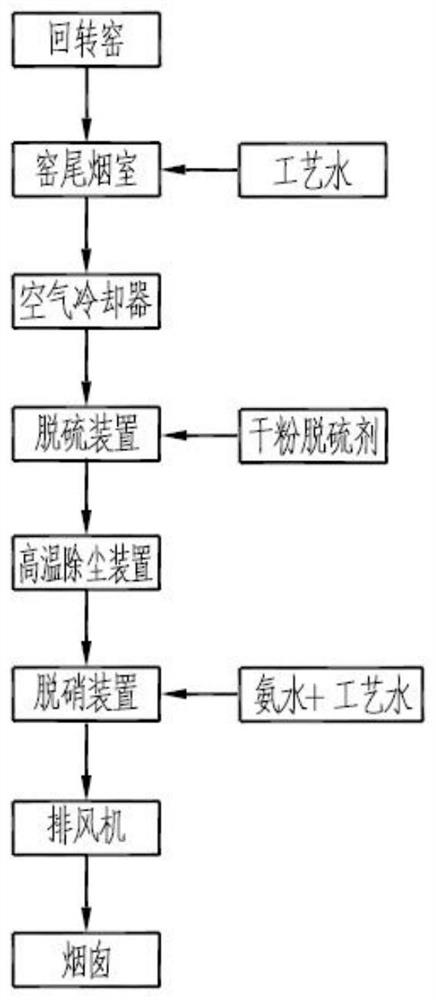

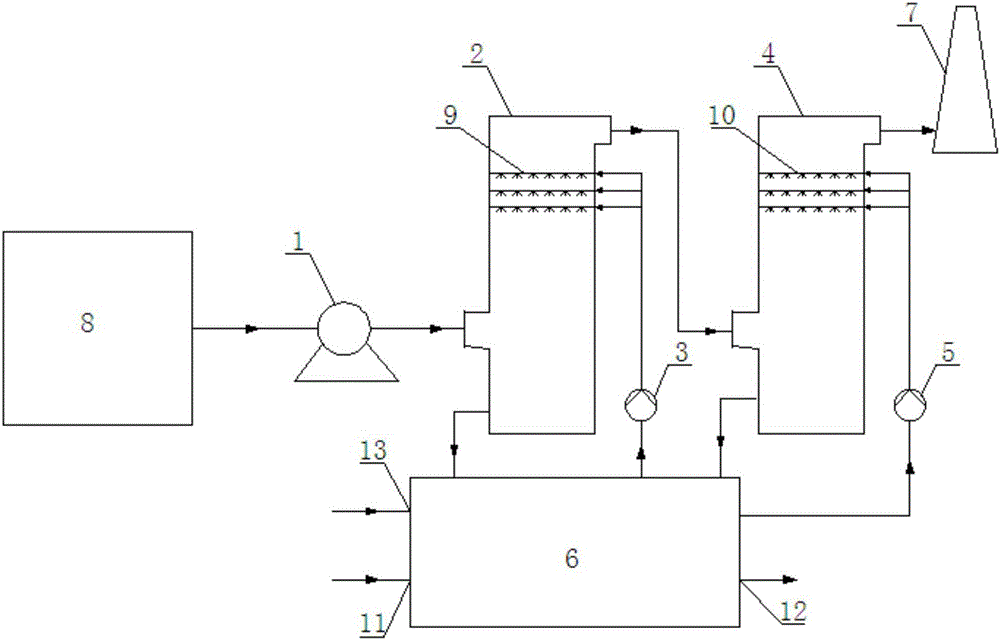

Waste gas treatment system for dolomite sand calcination rotary kiln

PendingCN111912242AReduce dust concentrationEasy to collectDispersed particle separationIncreasing energy efficiencyDolomiteCalcination

The invention discloses a waste gas treatment system for a dolomite sand calcination rotary kiln. The waste gas treatment system comprises a kiln tail smoke chamber, an air cooler, a desulfurization device, a high-temperature dust collection device, a denitration device, an exhaust fan and a chimney which are connected in sequence. According to the waste gas treatment system for the dolomite sandcalcination rotary kiln, after high-temperature flue gas calcined by the rotary kiln is cooled, dry desulfurization is firstly adopted, then high-temperature dust removal is carried out, and then denitration is carried out through a selective catalytic reduction method, so that desulfurization, dust removal and denitration of waste gas discharged from the rotary kiln are realized, and the waste gas is discharged through the exhaust fan and the chimney after the concentration of pollutants in the waste gas reaches the standard; and the pollutant emission concentration of the waste heat flue gaspurified by the system disclosed by the invention can meet the most strictest atmospheric pollutant special emission limit value requirement in Inorganic Chemical Industry Pollutant Emission Standard(GB31573-2015).

Owner:新疆凯盛建材设计研究院(有限公司)

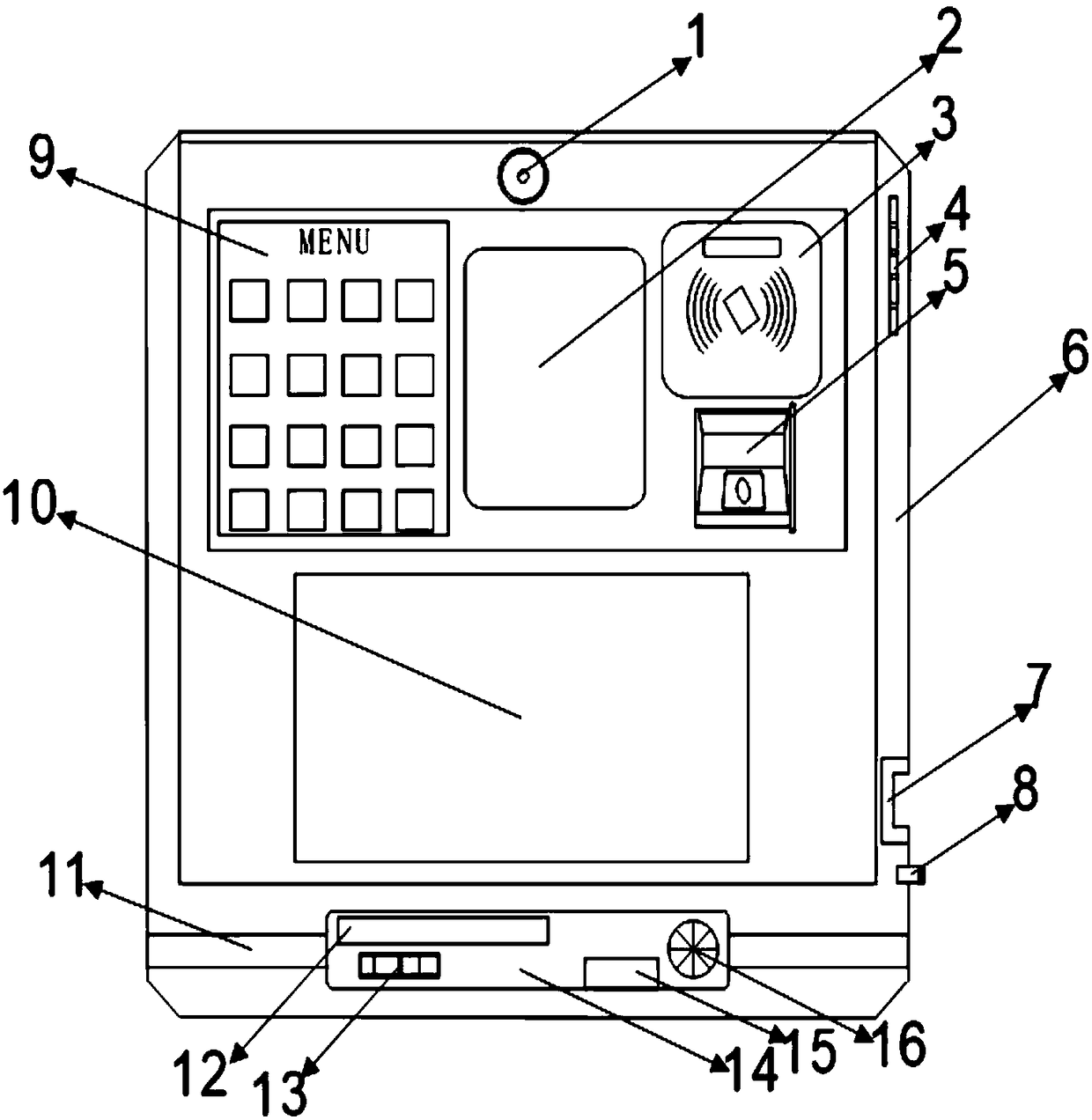

Attendance machine allowing free change of attendance range and adjusting method of attendance machine

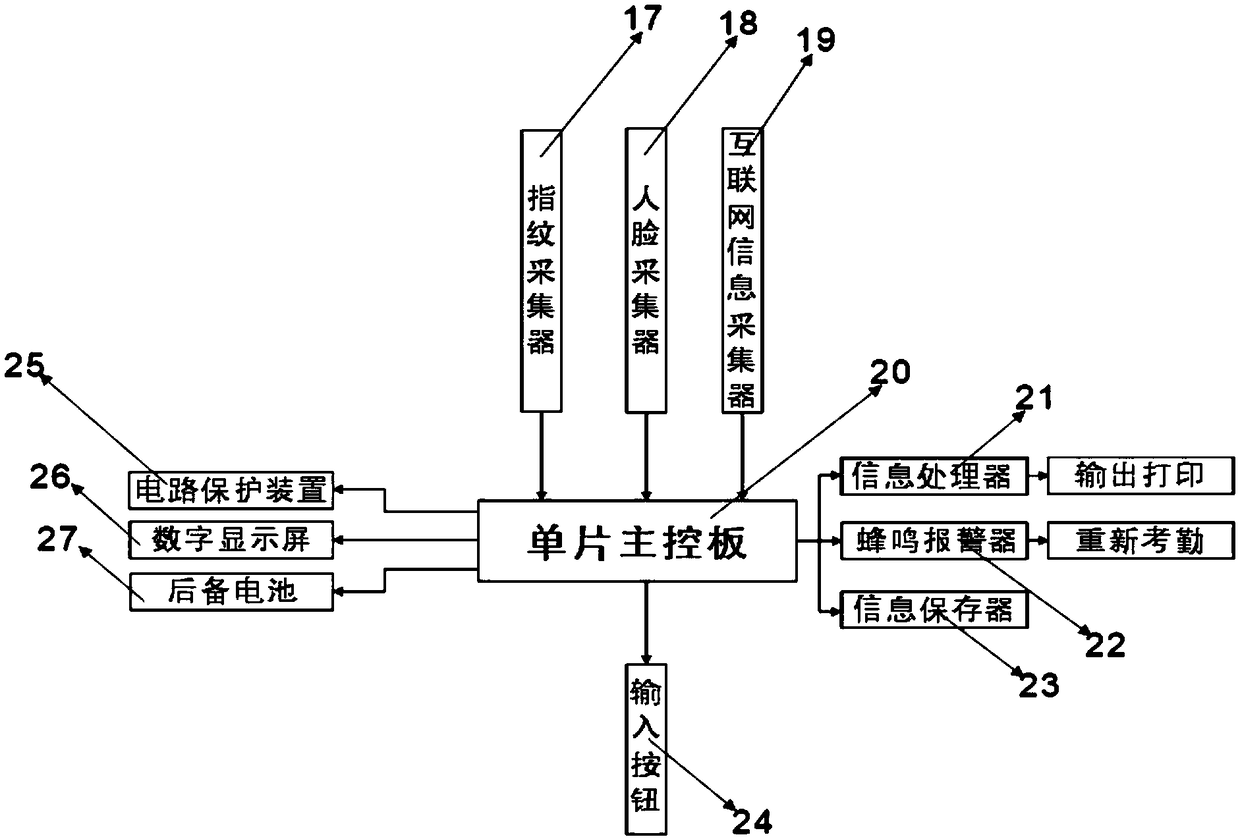

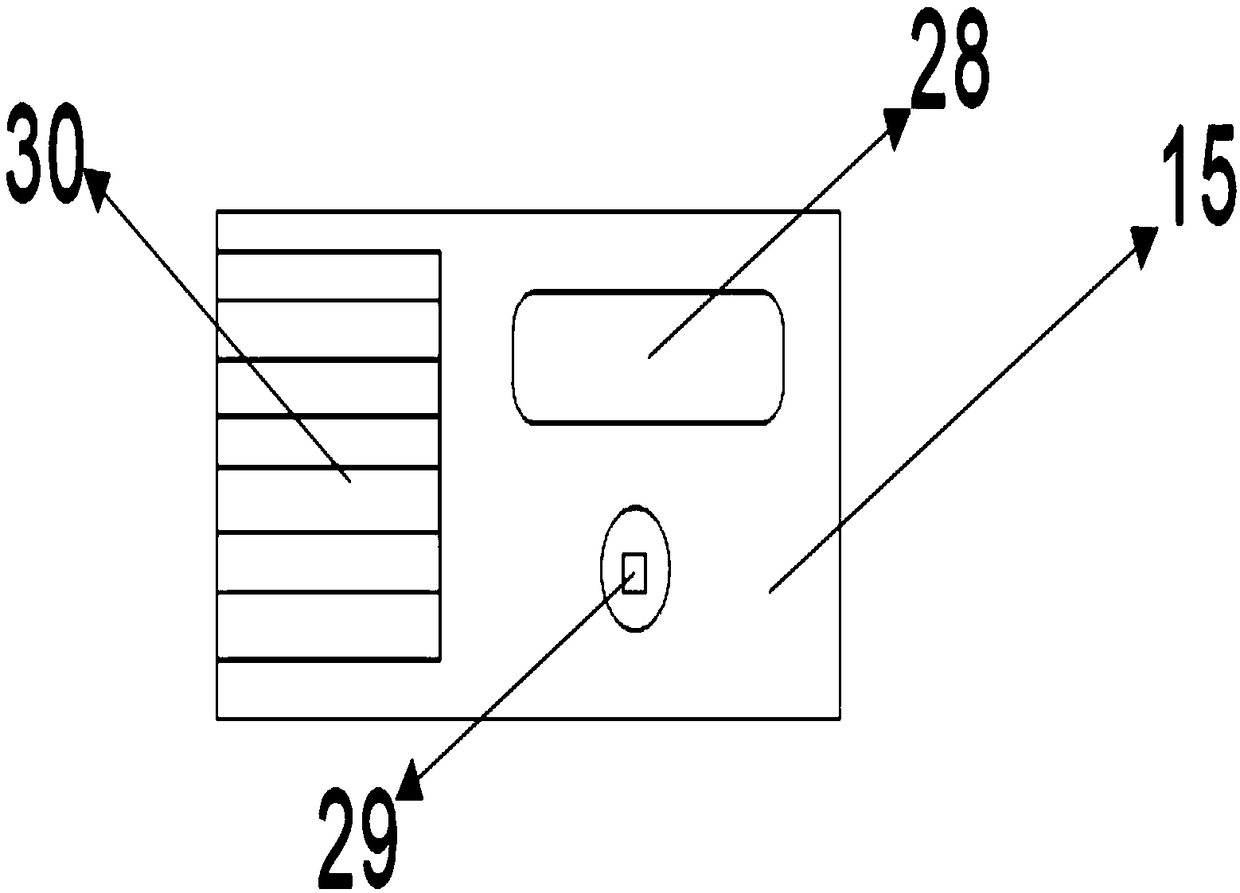

InactiveCN108765614AFreely switch attendance timeDiversified attendance methodsRegistering/indicating time of eventsKey pressingDisplay device

The invention discloses an attendance machine allowing free change of the attendance range and an adjusting method of the attendance machine. The attendance machine comprises a high-definition camera,a photo display, a mobile phone code scanning area, a loudspeaker, a fingerprint acquisition area, a machine body, a charging jack, a USB jack, a menu key area, a main board module, a fixing band, atemperature display screen, a regulating switch, a radiator, an exhaust device, a cooling fan, a fingerprint acquisition device, a human face acquisition device, an internet information acquisition device, a single-chip main control panel, an information processor, a buzzer alarm, an information conservator, an input button, a circuit protection device, a digital display screen, a backup battery,a heat-sensitive sensor, an LED lamp and an exhaust fan, wherein the mobile phone code scanning area, the fingerprint acquisition area, the menu key area and the main board module are arranged at theupper part of the machine body, and the radiator is arranged at the lower part of the machine body. The attendance range can be changed freely through a setting program of the menu key area, and the attendance machine has a cooling function and high practicability.

Owner:广东麦贝科技有限公司

Hot repairing method of molten steel cylinder

The invention relates to a hot repairing method of a molten steel cylinder. The method comprises the following steps: 1) positioning the molten steel cylinder; 2) recognizing the number of the moltensteel cylinder; 3) overturning the molten steel cylinder; 4) detecting a cylinder lining; 5) positioning a dust collecting cover; 6) starting a dust removing device; 7) positioning a hot repairing spraying gun; 8) treating residual steel; and 9) washing a machine. According to the method, an intelligent system replaces traditional manual operation, so that the working efficiency and the residual steel treating effect are improved; in addition, automatic cylinder lining diagnosing and automatic cleaning functions are provided; and moreover, state pre-warning and defect alarming are realized, sothat major and extraordinarily serious accident can be avoided.

Owner:ANGANG STEEL CO LTD

Treatment device and method for odor generated in butter melting

InactiveCN106237816AGuarantee product qualityEasy to handleGas treatmentDispersed particle separationChemistryWorking environment

The invention discloses a treatment device and method for odor generated in butter melting. The treatment device for odor generated in butter melting comprises a vacuum pump, a first spray washing tower, a first spray pump, a second spray washing tower, a second spray pump, a circulating water pool and a chimney. The treatment method for the odor generated in butter melting comprises the steps of alkali liquor preparing, spray washing, secondary spray washing, exhaust gas emission and the like. The odor generated in the butter melting process is pumped into the spray washing towers through the vacuum pump and effectively treated through spray washing of alkali liquor in the two stages of spray washing towers, and then remaining exhaust gas can be emitted on standard. Accordingly, the odor generated in the butter melting process can be effectively collected and treated, a good working environment of a whole workshop is guaranteed, products achieve the grease fragrance, and the product quality is guaranteed.

Owner:GUANGHAN MAIDELE FOOD CO LTD

City garbage processing method

InactiveCN106447153AImprove collection efficiencyImprove waste disposal efficiencyCo-operative working arrangementsResourcesTruckReliability engineering

The invention discloses a city garbage processing method. The method is characterized by comprising the following steps: arranging multiple garbage bins at the roadside of a city, wherein the garbage bins are provided with position information, the garbage bins comprise GPS, and when garbage bin emergency signals are sent, the position information is sent at the same time; emitting garbage bin emergency processing signals and the position information to a background processing center, wherein the emergency signals comprise garbage full-load signals and garbage bin body damage signals; the background processing center, according to the received emergency processing signals and the position information, planning a garbage truck collection route; the background processing center sending the planed garbage truck collection route to a garbage truck; and the garbage bin collection truck, according to the planed collection route, collecting the garbage bins and sending the garbage bins to a garbage processing station for processing. The city garbage processing method provided by the invention is more effective.

Owner:SHENZHEN ZHIHUISHIFANG TECH

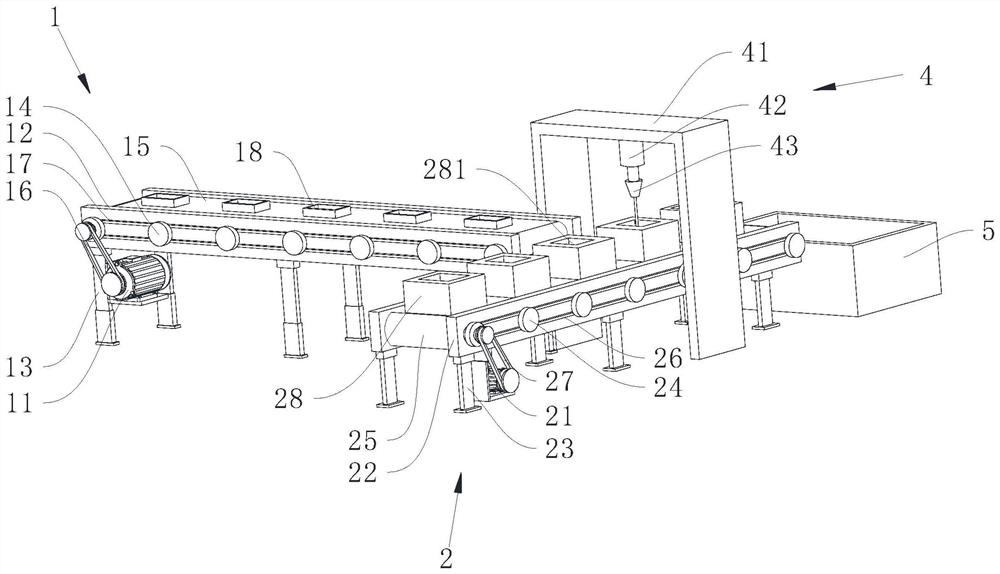

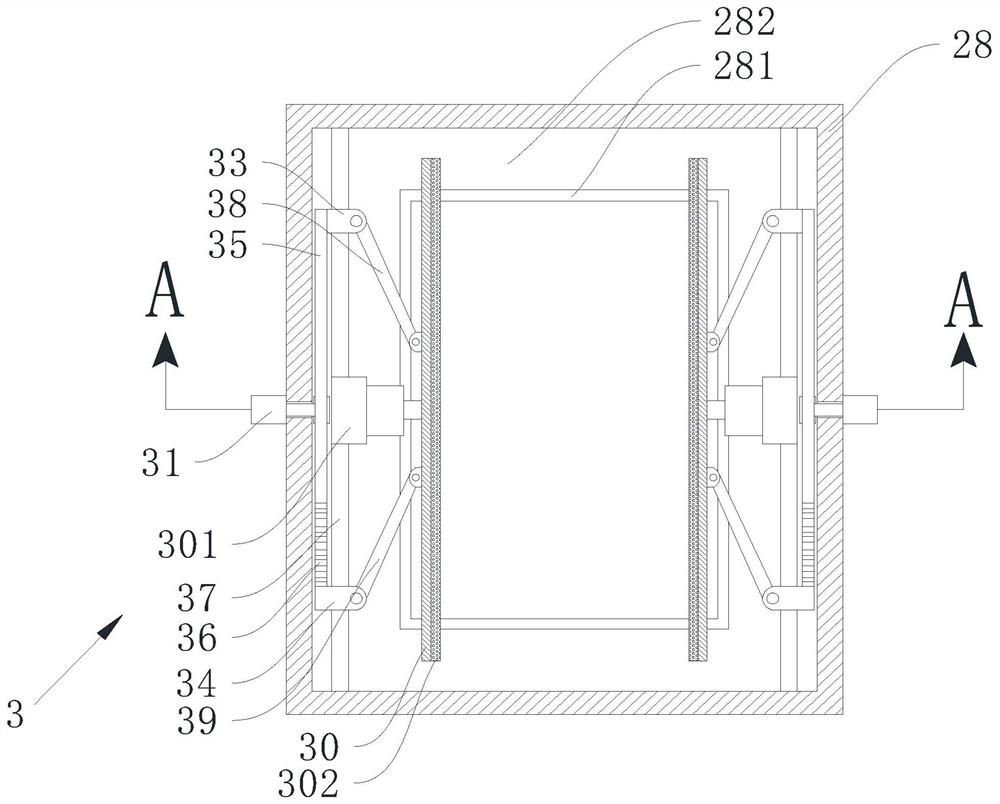

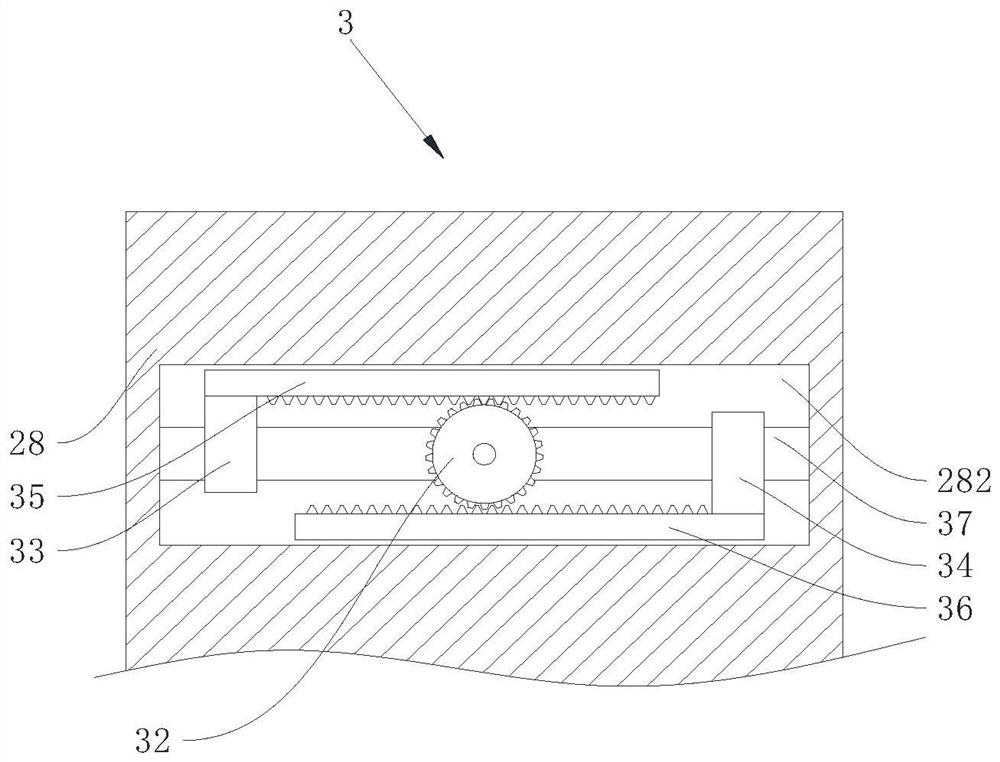

Fresh food cold-chain logistics automatic sealing and packaging system

ActiveCN112918799AMeet the needs of mass productionFast packingClimate change adaptationPackaging by pressurising/gasifyingBiotechnologyCold chain

The invention relates to the technical field of fresh food packaging processing, in particular to a fresh food cold-chain logistics automatic sealing and packaging system which comprises a first conveying mechanism, a second conveying mechanism, an extrusion device and an extraction device. The second conveying mechanism comprises a second driving motor, a second supporting frame, second supporting legs, second transmission rollers, a second conveying belt, a second main transmission belt, a second auxiliary transmission belt and a packaging box. The extrusion device comprises a rotating motor, a driving gear, a first sliding block, a second sliding block, a first rack, a second rack, a sliding rod, a first supporting rod, a second supporting rod, an extrusion plate, a telescopic rod, a sponge plate and a heat sealing cutter. The extraction device comprises a [-shaped frame, an electric lifting cylinder and a vacuum extractor. In the vacuumizing and sealing packaging process of fresh food, the requirement for large-batch production is met, and the fresh food cold-chain logistics automatic sealing and packaging system has the effects of being high in packaging speed, good in packaging quality and high in packaging continuity.

Owner:金乡县万兴蒜业有限公司

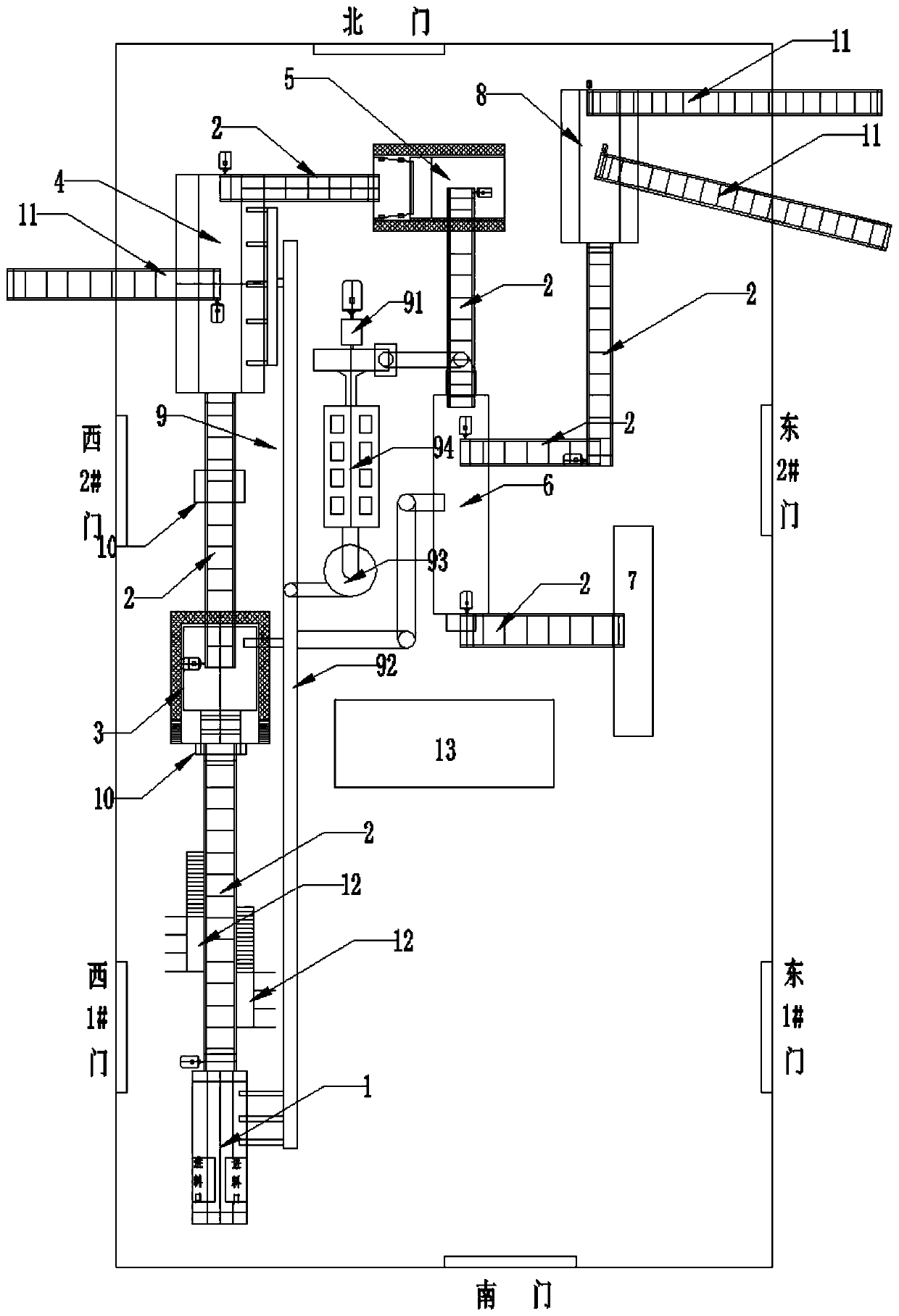

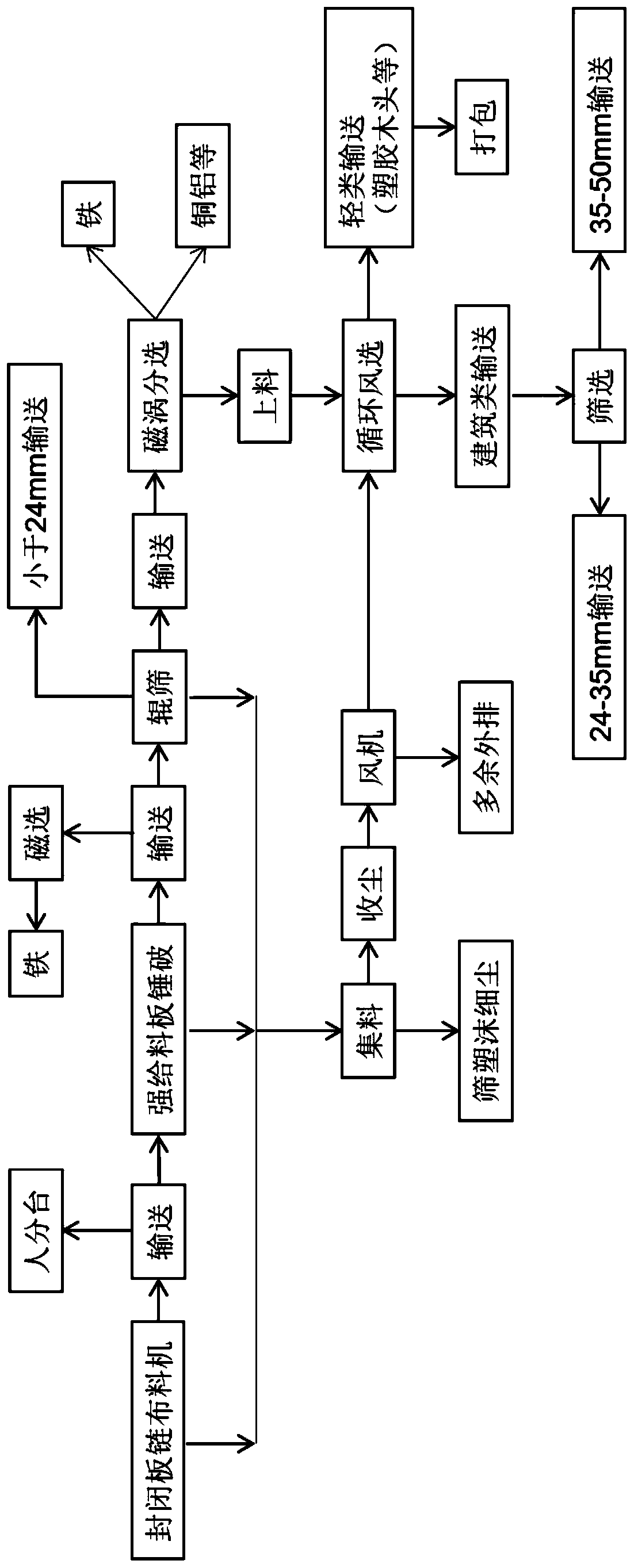

Construction waste classification treatment system and process

PendingCN110899309AAchieve recyclingEfficient collectionConstruction waste recoverySolid waste disposalMagnetic vortexDust control

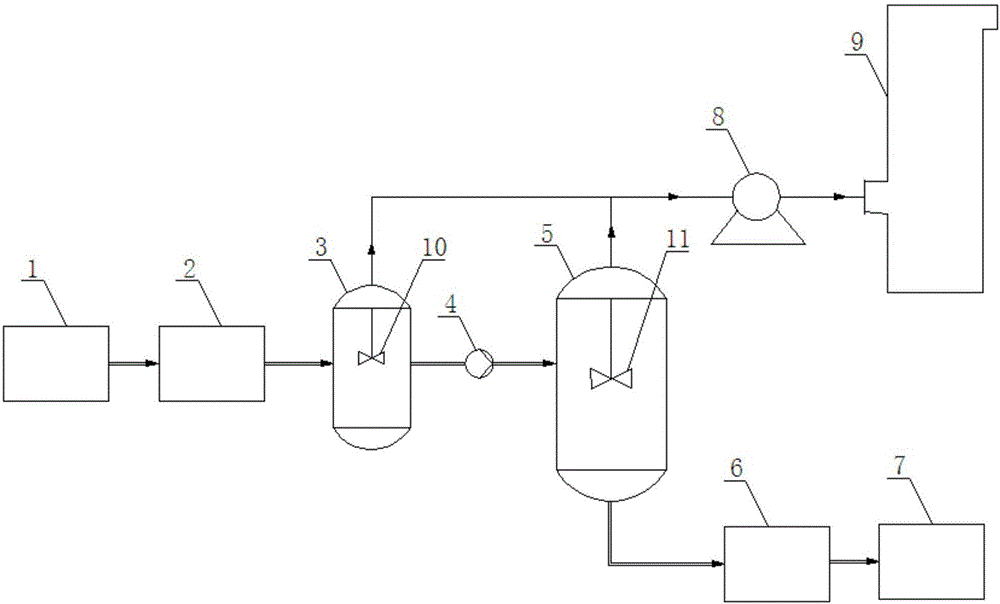

The invention discloses a construction waste classification treatment system and process. The classified treatment system is characterized by comprising a closed chain plate distributing machine (1),strong feeding plate hammering equipment (3), a first roller screen (4), magnetic vortex sorting equipment (5) and circulating winnowing equipment (6) which are sequentially connected through conveying equipment (2); the circulating winnowing equipment (6) is connected with the packaging equipment (7) and a second roller screen (8) through the conveying equipment (2); the system also comprises dust removing equipment (9) which is connected with the closed chain plate distributing machine (1), the strong feeding plate hammering equipment (3), the first roller screen (4) and the circulating winnowing equipment (6) to remove dust. According to the construction waste treatment system, the processes of crushing, screening, magnetic separation, winnowing, packaging and the like can be effectively carried out on construction waste, recycling of the construction waste is achieved, and particularly dust and the like generated in the production process can be effectively collected through the dust collection system. An environment-friendly, effective and economical construction waste recycling and classifying treatment system is realized.

Owner:HUBEI XINXINLAN ENVIRONMENTAL PROTECTION TECH CO LTD

Method and device for low-temperature refining of beef tallow

InactiveCN106350213AImprove working environmentEffective collection and processingFatty-oils/fats refiningFatty-oils/fats productionWorking environmentEngineering

The invention discloses a method and a device for low-temperature refining of beef tallow. The device comprises a feeding machine, a mincing machine, a preheating tank, a mince pump, a melting kettle, a suspension tank, a centrifuge, a vacuum pump and a washing device. The method includes: feeding, mincing, preheating, low-temperature melting, suspension, centrifugal separation and the like. By combination of preheating and low-temperature melting for refining, less odor is generated in a refining process, discharged odor can be effectively collected for treatment due to a vacuum state of the whole refining process, a favorable work environment of a workshop is kept, and a product has a grease aroma; further, by the aid of the feeding machine and the mincing machine, procedures of manual cutting and feeding are saved, so that labor intensity is relieved; in addition, high automation degree, high operation efficiency, time saving and labor saving are realized, and product safety and sanitation are guaranteed.

Owner:GUANGHAN MAIDELE FOOD CO LTD

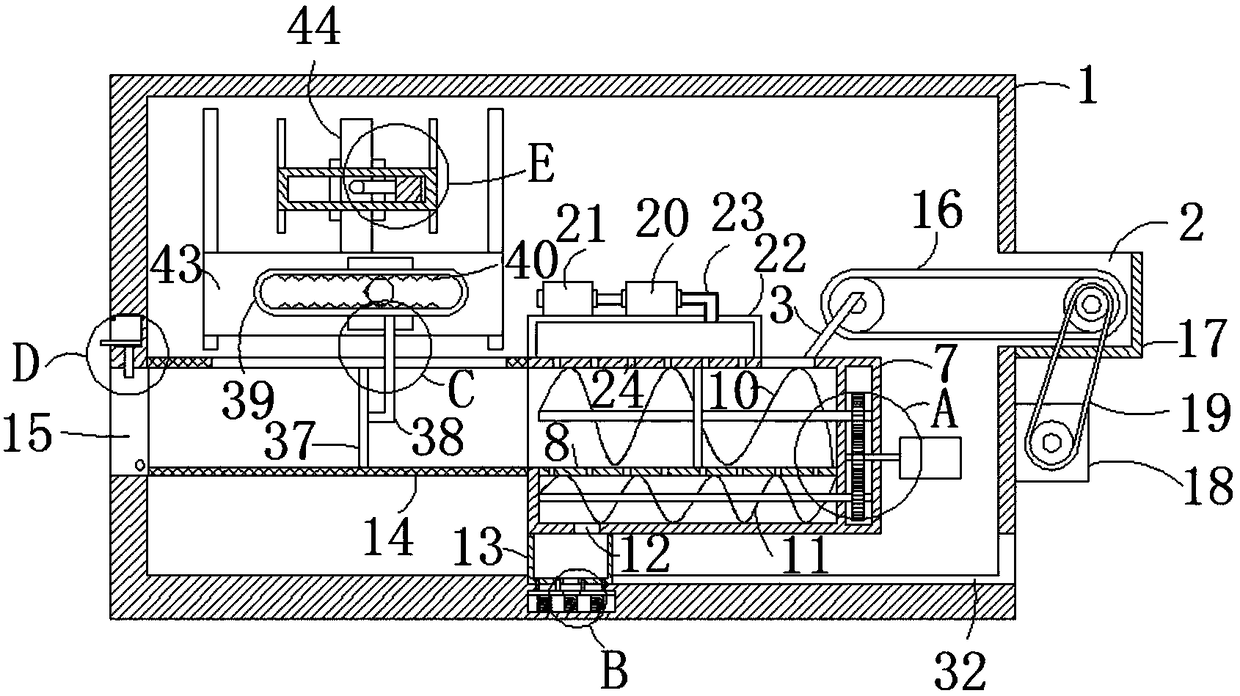

Corn straw bundling machine

ActiveCN108076856AEase of baling operationAchieve entryBalingAgricultural engineeringMaterial transfer

The invention belongs to the technical field of agricultural machinery, and particularly relates to a corn straw bundling machine. The corn straw bundling machine comprises a box body, wherein a material feeding inlet is formed in the sidewall of the box body, a material feeding mechanism is arranged on the inner side of the box body, and an inclined plate is fixedly connected to the inner sidewall of the box body, two baffles are fixedly connected to the sidewall of one side of the inclined plate, and a plurality of intermediate shafts are fixedly connected between the two baffles; each intermediate shaft is sleeved by a roller, and a material transferring box is fixedly connected with the inner sidewall of the box body; a straw mouth which corresponds to the position of the inclined plate is formed in the material transferring box, and an intermediate board is fixedly connected with the inner sidewall of the material transferring box. The corn straw bundling machine has the advantages that through the corn straw bundling machine, drying treatment on straw can be performed effectively, and meanwhile effective separation of impurities in the straw can be achieved, so that straw bundling operation of farmers is facilitated through the corn straw bundling machine.

Owner:TONGLING HUIYU IND CO LTD

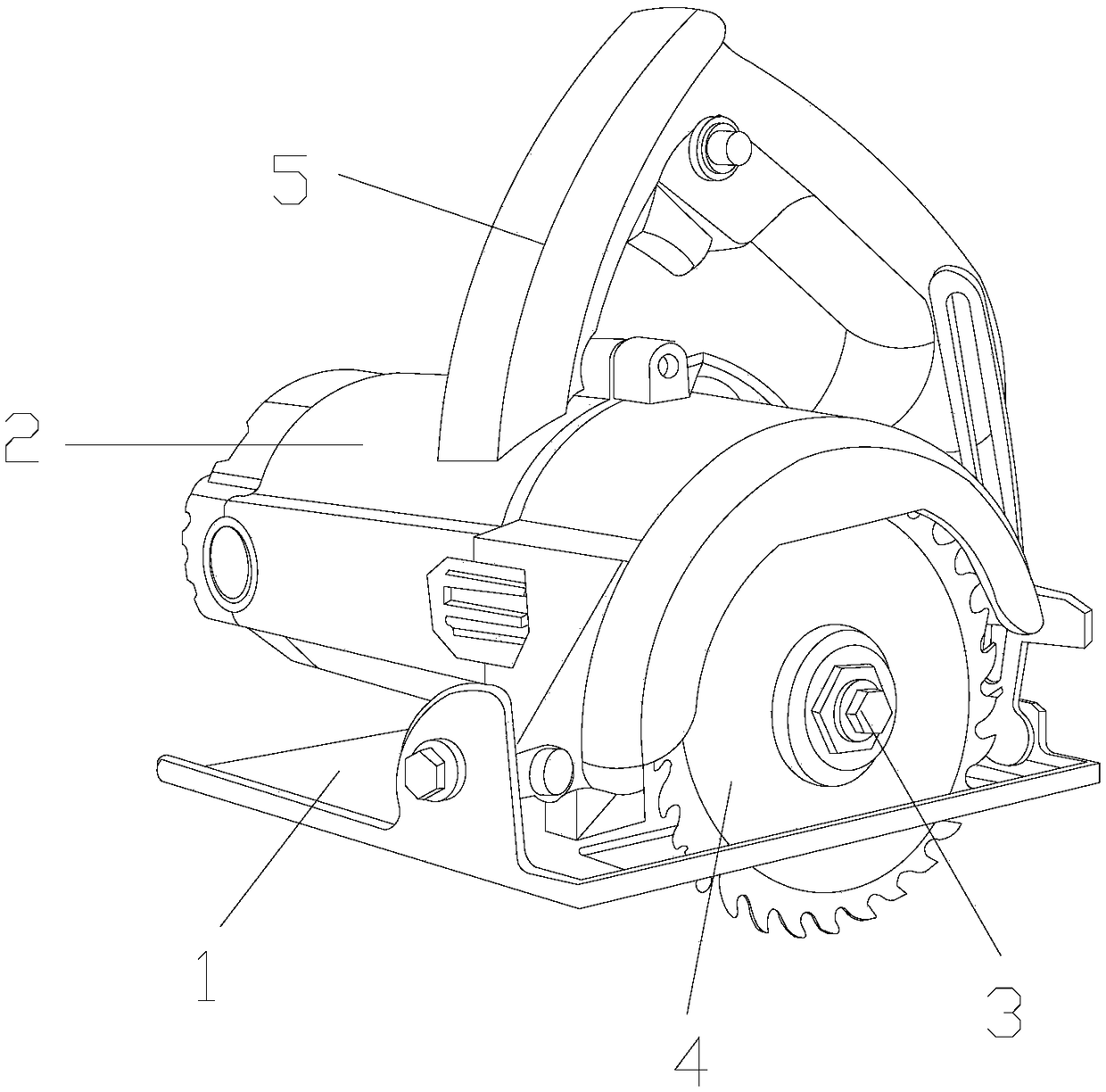

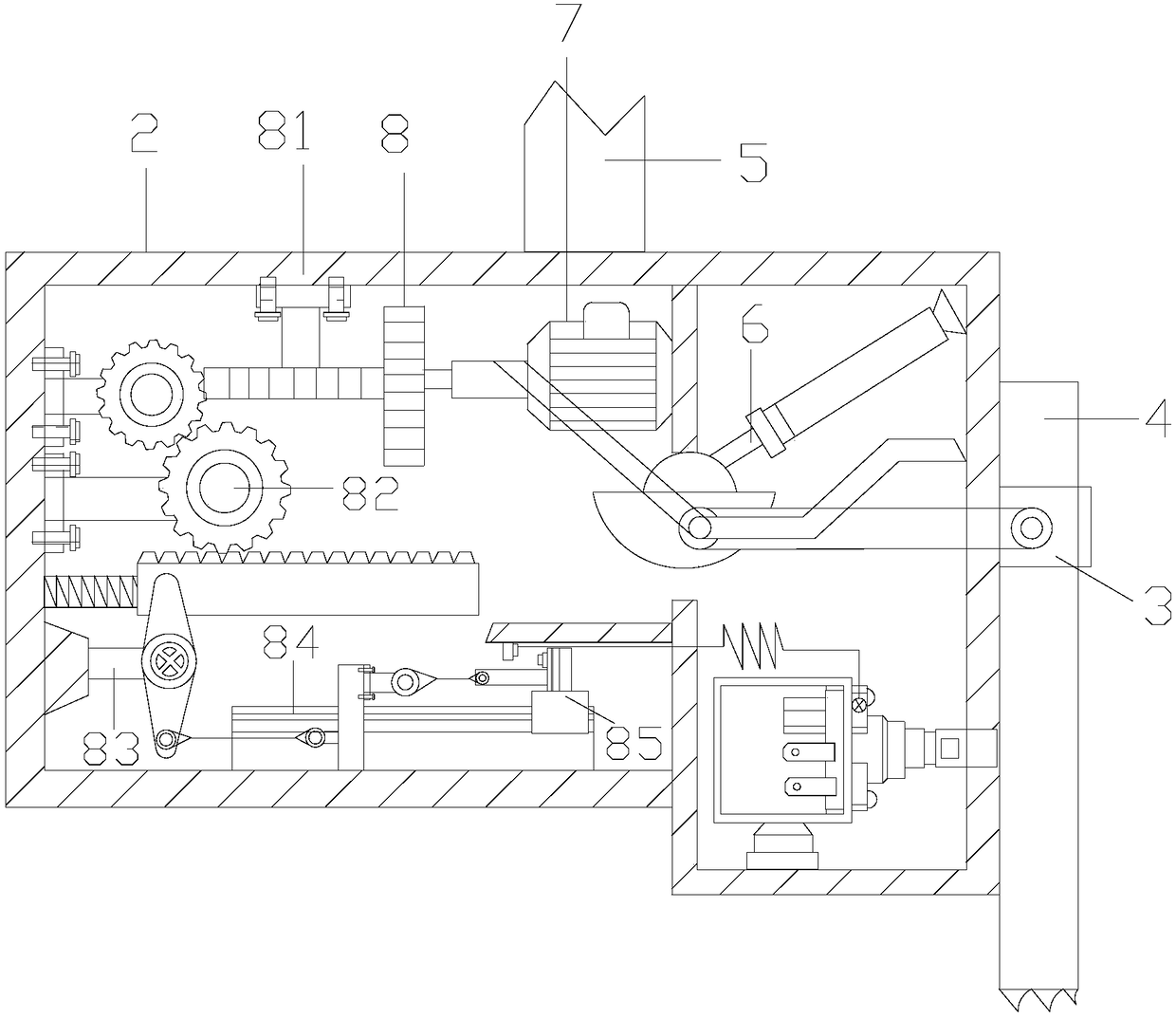

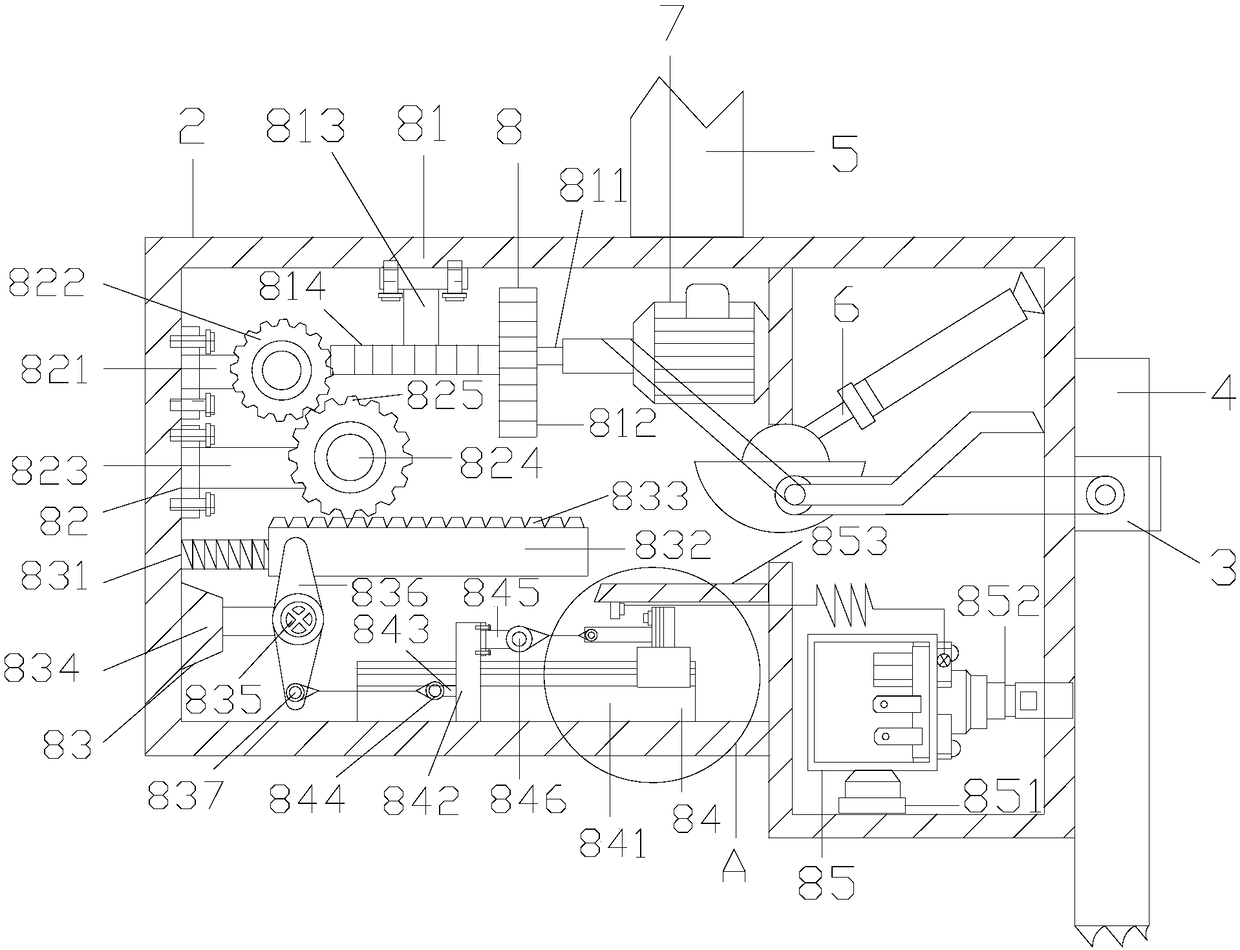

Flying scrap preventing household wood cutting machine

InactiveCN108162104AEffective collection and processingAvoid health effectsCircular sawsBark-zones/chip/dust/waste removalPulp and paper industryWood cutting

The invention discloses a flying scrap preventing household wood cutting machine. The flying scrap preventing household wood cutting machine structurally comprises a base, a power source box, a cutting machine shaft, a cutting blade, a movable handle, a telescopic connecting rod device, a motor and a real-time wood scrap collecting device. The power source box is fixedly welded to the surface of the upper end of the base. The cutting machine shaft is mechanically connected to the middle upper position of the surface of the right end of the power source box and penetrates into the power sourcebox. The telescopic connecting rod device is movably connected to the upper right position of a cavity in the power source box. The motor is fixedly connected to the middle part of the uppermost position of the cavity in the power source box. The real-time wood scrap collecting device is movably connected to the left portion of the cavity in the power source box. In the wood cutting operation process, wood scraps generated through cutting can be effectively collected and treated in time, and the phenomenon of scrap flying in the work process is prevented; and the situation that users inhale the wood scraps and other objects into the bodies, and the body health of the users is influenced is prevented, it is guaranteed that the cutting work is smoothly conducted, and the reliability performance of the equipment is effectively improved.

Owner:惠安闽神石材加工设备开发有限公司

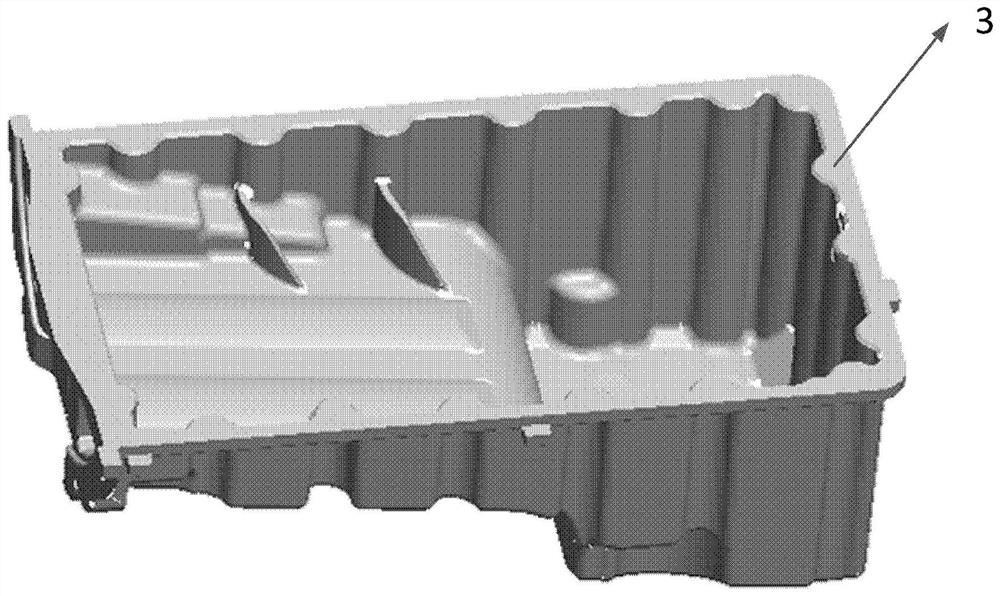

Engine oil pan

PendingCN112523834AReduce fill volumeLow costOilsumpsMachines/enginesThermodynamicsMechanical engineering

The invention provides an engine oil pan. The engine oil pan comprises an oil baffle and a guide pipe, wherein the oil baffle is fixed to an inner cavity of a shell body of the engine oil pan, dividesthe inner cavity of the shell body into a shell body large end area and a shell body small end area and can block most lubricating oil in the shell body large end area, so that the engine oil pan isin an inclined state, an oil suction port can suck the oil, a first guide pipe end of the guide pipe is fixedly connected to a through hole formed in the oil baffle, in addition, the first guide pipeend is provided with a one-way valve allowing the lubricating oil to pass through in a one-way mode, and a second guide pipe end of the guide pipe extends to the bottom of the shell body large end area, so that the guide pipe can guide the lubricating oil in the shell body small end area into the shell body large end area through the one-way valve.

Owner:天津特瑞捷动力科技有限公司

Laser cutting device with protective structure

InactiveCN111673293AEffective collection and processingEasy to installLaser beam welding apparatusDust controlStructural engineering

The invention discloses a laser cutting device with a protective structure. The laser cutting device comprises a rack, a convection module, a cutting module and a station module. An air blower is arranged above the right side of the convection module, and the convection module is located at the right side of the rack. The convection module comprises the air blower, an air shower pipe, a dust removal fan, a dust collection chamber, an air suction pipe, a protective cover, an air inlet and an air suction inlet. The air blower is arranged above the right side of the rack. The air shower pipe is connected to the output end of the air blower. The dust removal fan is installed on the right side inside the rack. The air suction pipe is connected to the left side of the dust removal fan, and the left end of the air suction pipe is connected with the air suction inlet. A laser generator is arranged above the cutting module, and the cutting module is located at the top of the inner side of the rack. A base plate is installed in the middle of the station module, and the station module is located at the bottom of the inner side of the rack. According to the laser cutting device with the protective structure, a user can effectively protect device operators through the convection module.

Owner:东莞市奇趣机器人科技有限公司

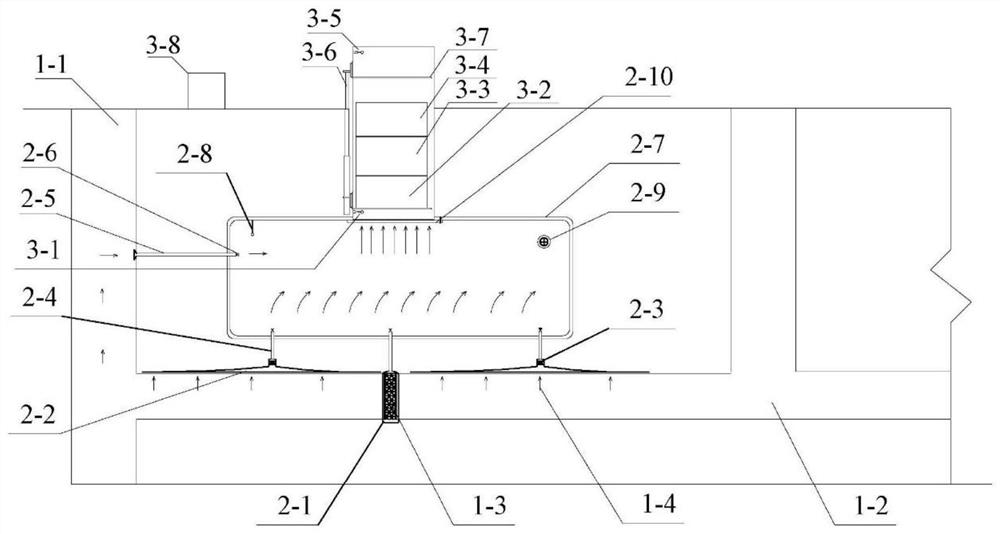

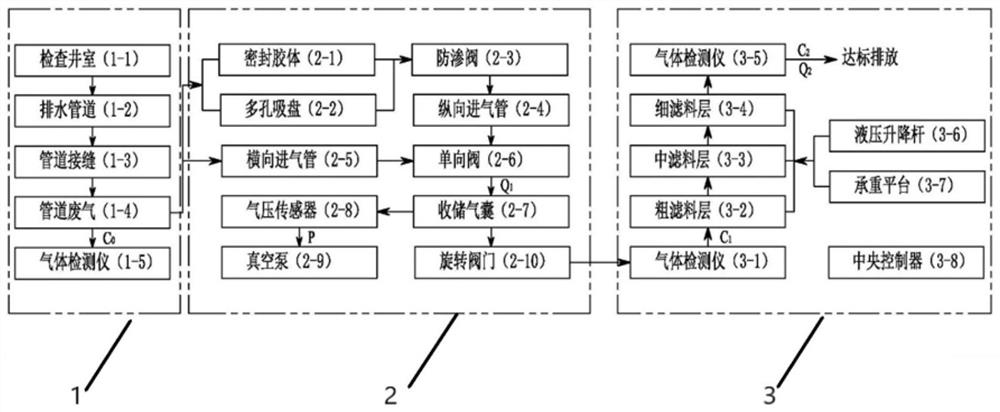

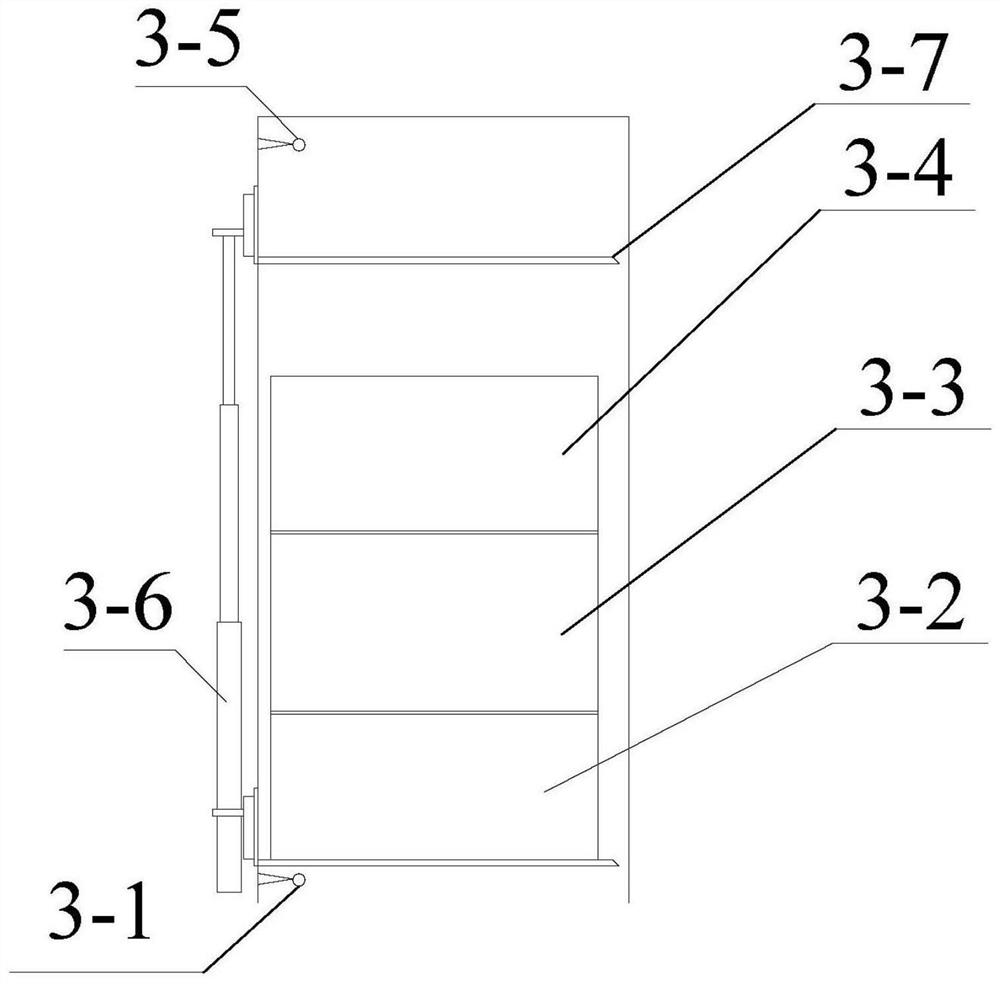

Underground pipeline waste gas leakage early warning and treatment system and method

PendingCN113864663AImprove the accuracy of early warningImprove collection efficiencyMeasurement of fluid loss/gain rateDispersed particle filtrationUnderground pipelineRotary valve

The invention discloses an underground pipeline waste gas leakage early warning and treatment system and method. The system comprises three subsystems including an underground pipeline waste gas leakage early warning system (1), a waste gas collection system (2) and a waste gas treatment system (3). The waste gas collection system is located above a drainage pipeline and is in communication with the drainage pipeline through a longitudinal gas inlet pipe and a transverse gas inlet pipe, and the waste gas treatment system is arranged above the waste gas collection system and is in communication with the waste gas collection system through a rotary valve; and waste gas generated in the underground pipeline system is collected through internal pressure control of the waste gas collection system, enters a gas treatment device of the waste gas treatment system and is adsorbed and degraded layer by layer, and finally, the waste gas is harmlessly discharged in a standard reaching manner. According to the underground pipeline waste gas leakage early warning and treatment system, a system solution for underground pipeline waste gas leakage early warning, collection treatment and up-to-standard emission is constructed, and precise detection, comprehensive collection and efficient treatment are achieved by combining aerodynamics and environmental engineering principles. The system has the advantages of high early warning precision, high collection efficiency, good treatment effect, low investment and operation cost and convenience in operation and management.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com