Treatment device and method for odor generated in butter melting

A treatment device and odor technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of heavy odor in the workshop, poor working environment, etc., and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

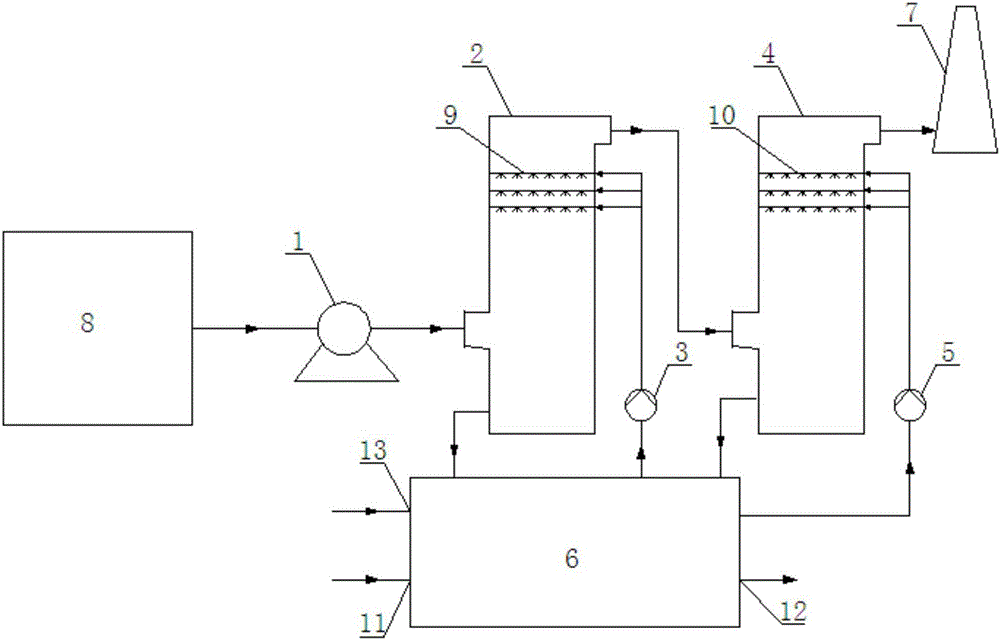

[0020] like figure 1 As shown, a tallow smelting odor treatment device includes a vacuum pump 1, a first spray scrubber 2, a first spray pump 3, a second spray scrubber 4, a second spray pump 5, and a circulating water pool 6 and chimney 7; the gas inlet at the bottom of the first spray scrubber 2 is communicated with the smelting device 8 through the vacuum pump 1, and the gas outlet at the top of the first spray scrubber 2 is connected with the gas at the bottom of the second spray scrubber 4 The inlet is communicated, and the gas outlet on the top of the second spray scrubber 4 is communicated with the chimney 7; the first spray scrubber 2 is provided with a spray layer I9, and the second spray scrubber 4 is provided with Spray layer II10, the spray layer I9 communicates with the circulating water pool 6 through the first spray pump 3, the spray layer II10 communicates with the circulating water pool 6 through the second spray pump 5, and the first spray washing The bottom...

Embodiment 2

[0022] A method of using the tallow smelting odor treatment device described in embodiment 1 to process tallow smelting odor, comprising the following steps:

[0023] (1) add water and edible alkali in circulating pool 6, be mixed with lye;

[0024] (2) Use the vacuum pump 1 to suck the odor generated by the smelting device 8 to the first spray washing tower 2, and at the same time, the first spray pump 3 pumps the lye in the circulating water pool 6 into the spray layer I9 to spray and wash the odor gas;

[0025] (3) The odor after step (2) spraying and washing enters the second spraying and washing tower 4, while the second spraying pump 5 pumps the lye in the circulating pool 6 into the spray layer II10 to spray and wash the odor again. gas;

[0026] (4) the tail gas after step (3) spraying and washing again is discharged through the chimney 7;

[0027] (5) The lye at the bottom of the first spray scrubber 2 and the second spray scrubber 4 is discharged into the circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com