Patents

Literature

50results about How to "Reduce shipbuilding costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

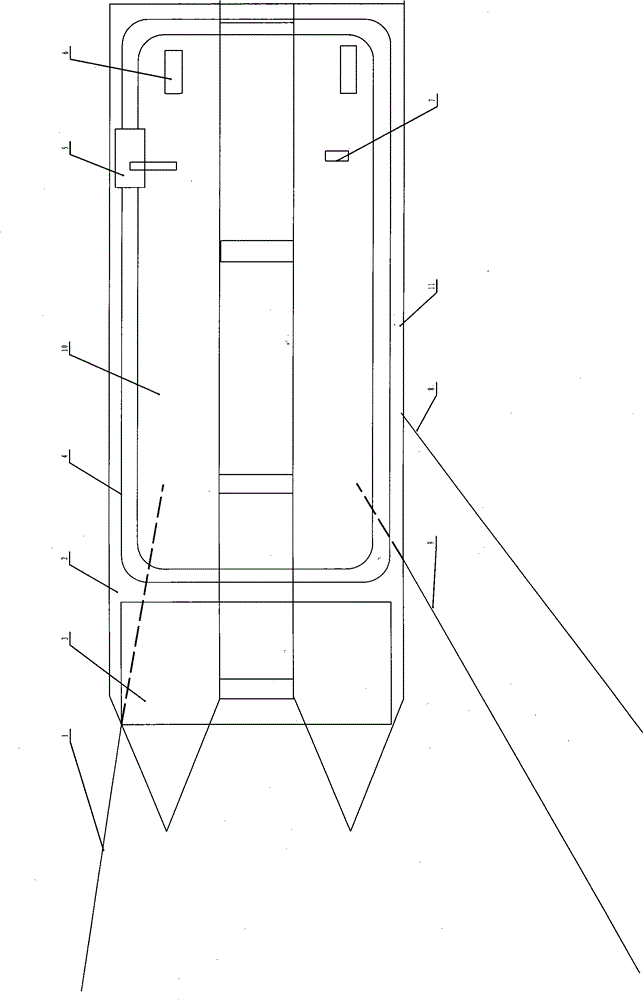

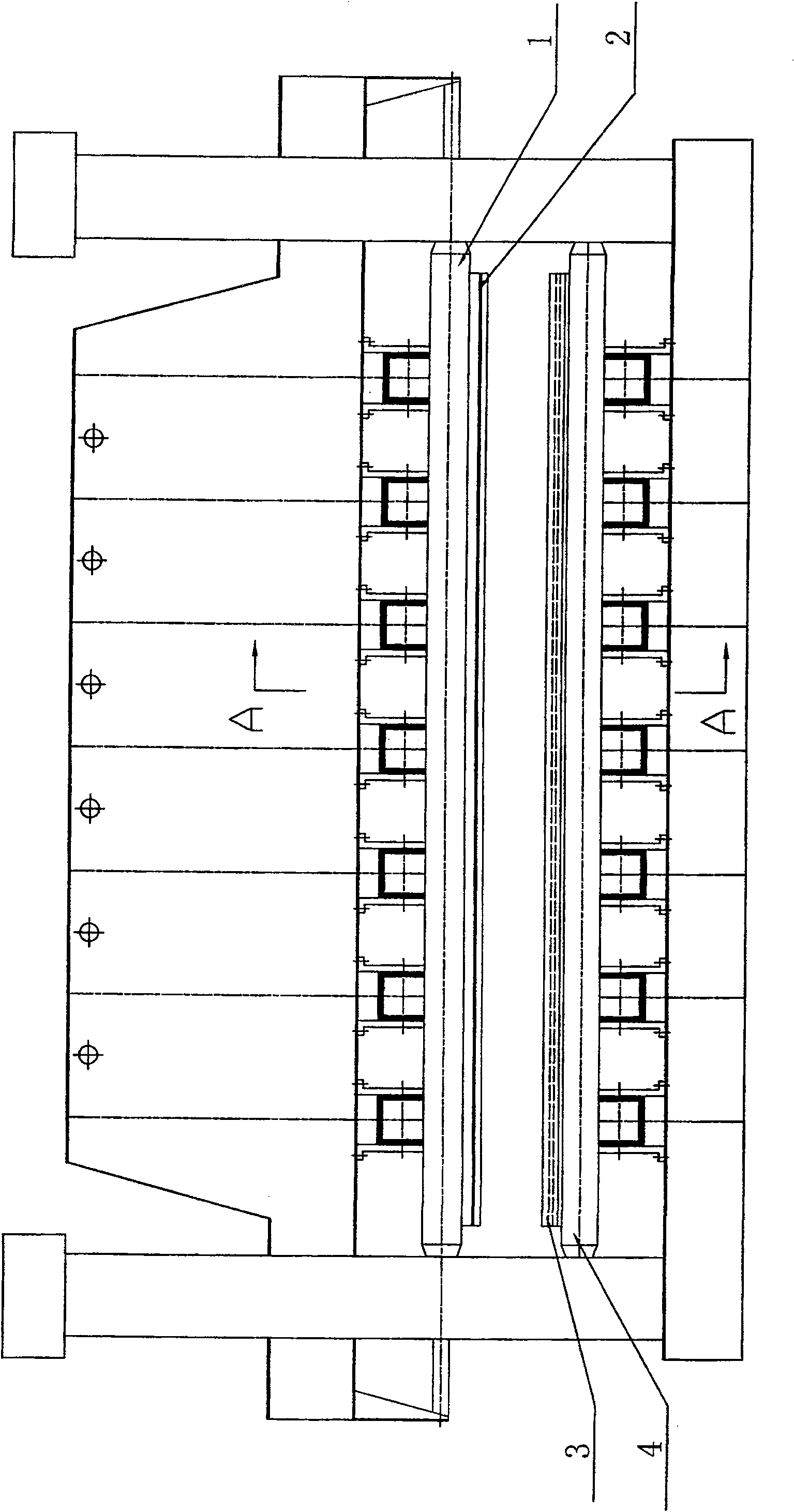

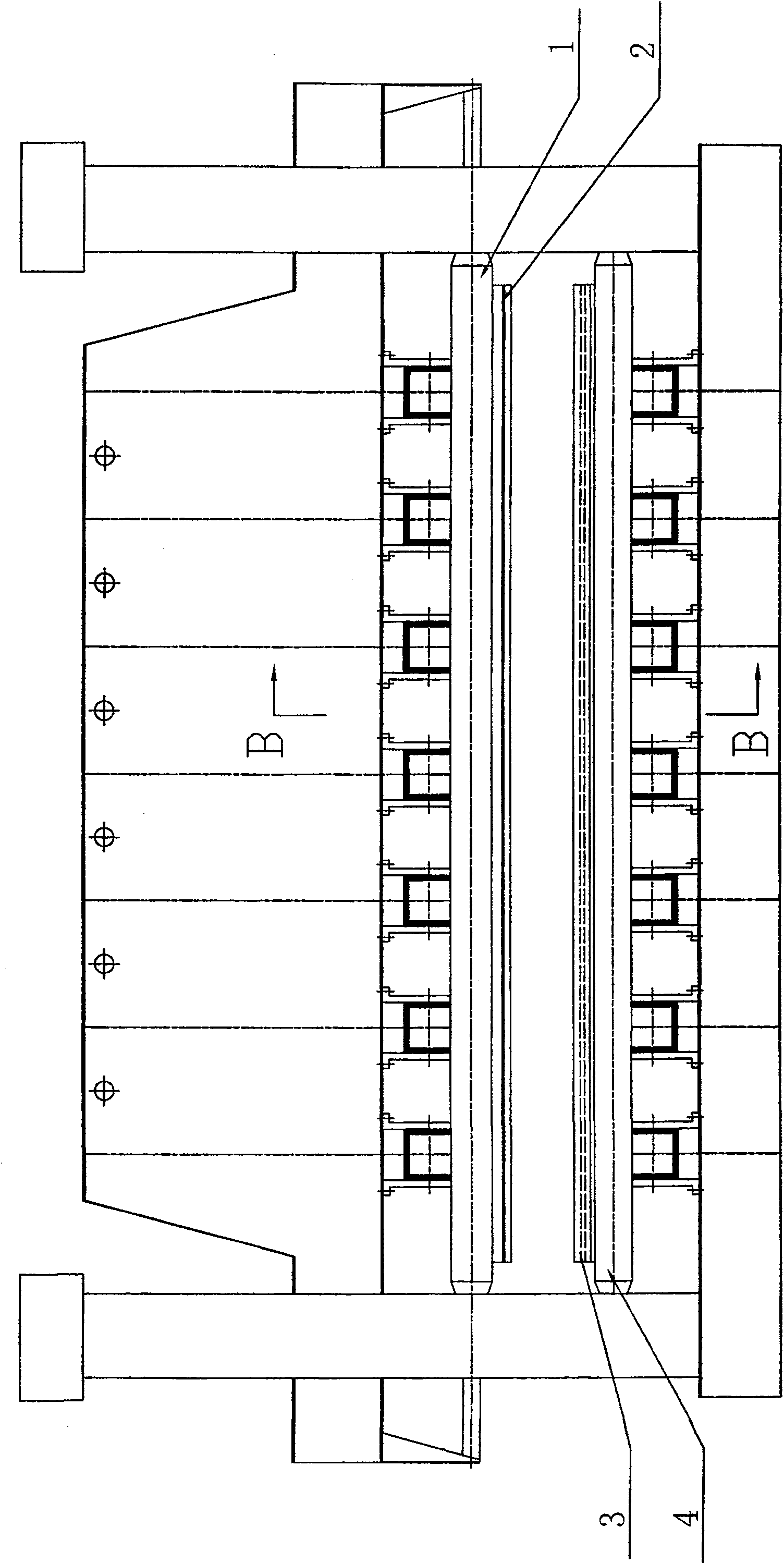

Containment system for type B independent liquid cargo tank

ActiveCN106516016AEffective collection and processingEnsure safetyFor bulk goodsHull structureEngineering

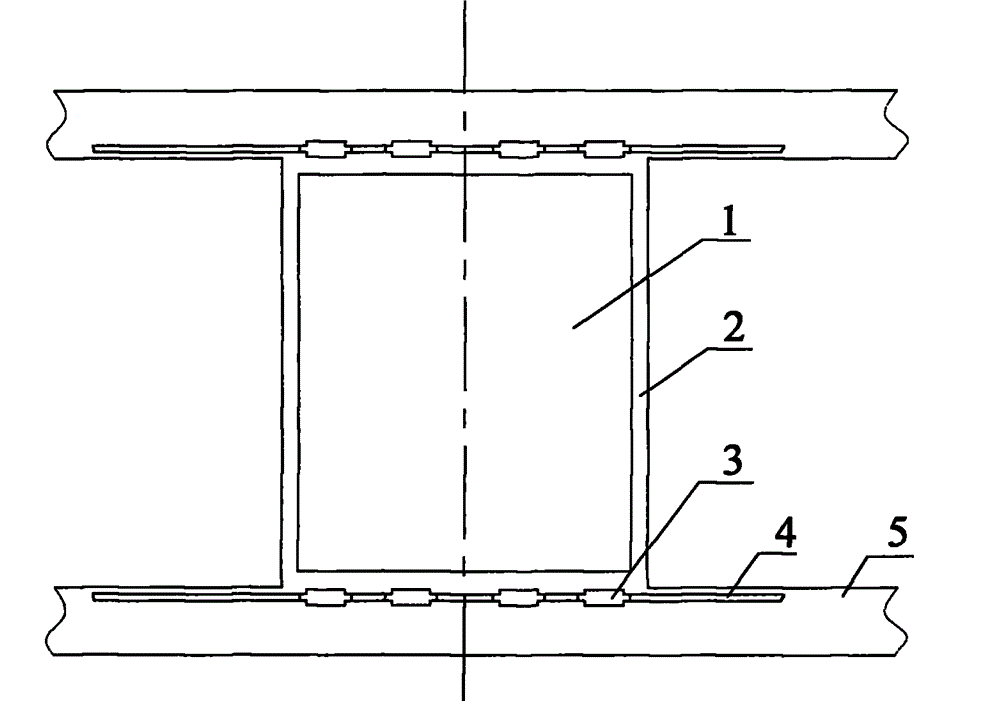

The invention provides a containment system for type B independent liquid cargo tank. The liquid cargo tank comprises a top surface, a bottom surface and a side wall, wherein the top surface, the bottom surface and the side wall are formed by welding a plurality of outer plates; the containment system comprises leakage slots and liquid collecting wells; the leakage slots respectively cover all the weld seams among the outer plates on the top surface and the side wall; the liquid leaking from the weld seams can flow down along the leakage slots to an inner bottom plate of a hull; one or more liquid collecting wells are respectively arranged at both ends of the inner bottom plate in the length direction of the hull; insulating layers are laid on the top surface, the bottom surface and the side wall; the containment system also comprises a baffle plate; the baffle plate is arranged around the liquid cargo tank; and the upper end of the baffle plate is connected with the wall plate of the hull, and the lower end of the baffle plate is connected with the inner bottom plate. According to the containment system disclosed by the invention, the cost is reduced in the aspect of materials by reasonable design of the containment system, and the containment system can guarantee the safety of the hull structure in the case of liquid cargo leakage in the liquid cargo tank.

Owner:JIANGNAN SHIPYARD GRP CO LTD

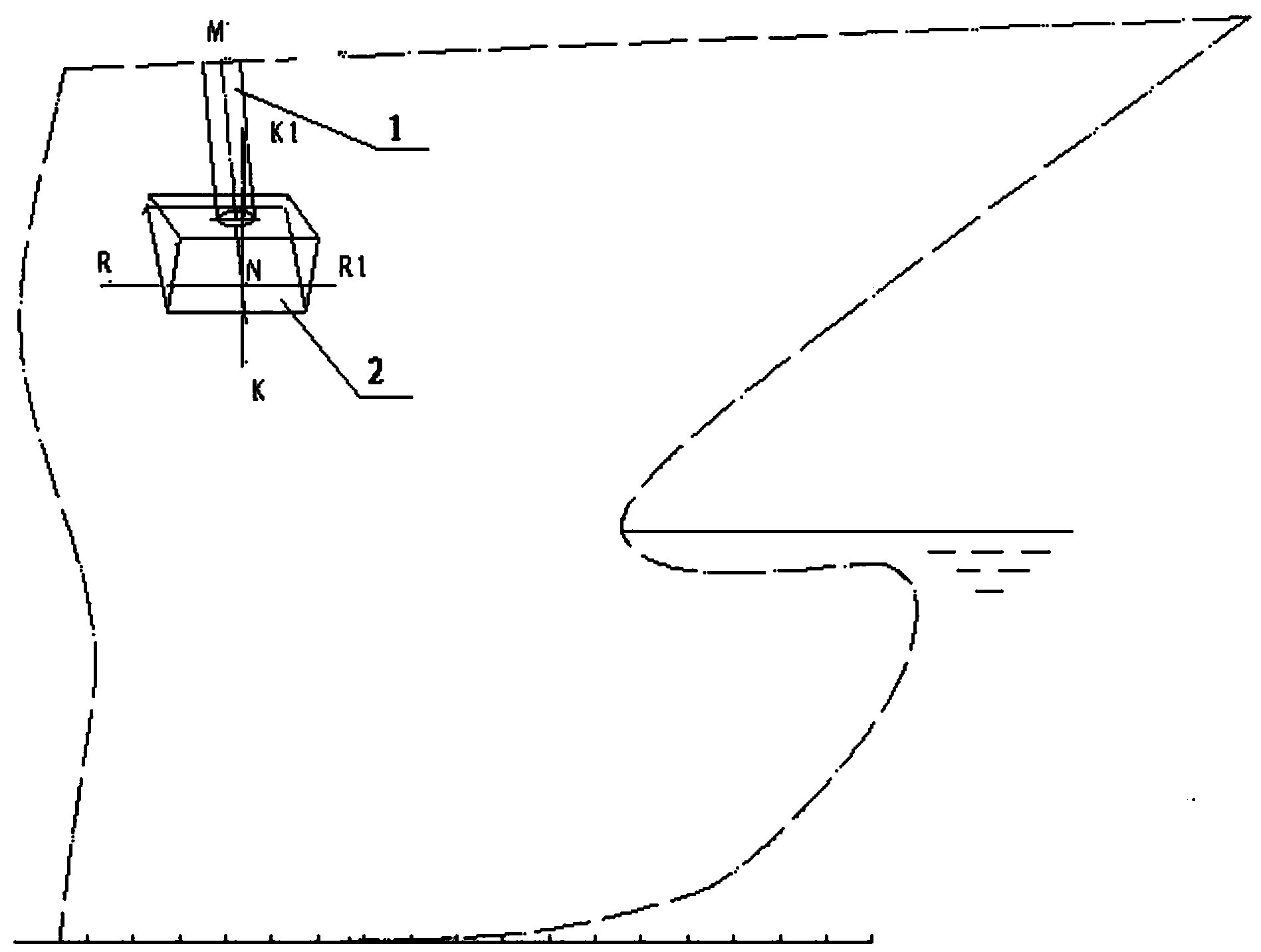

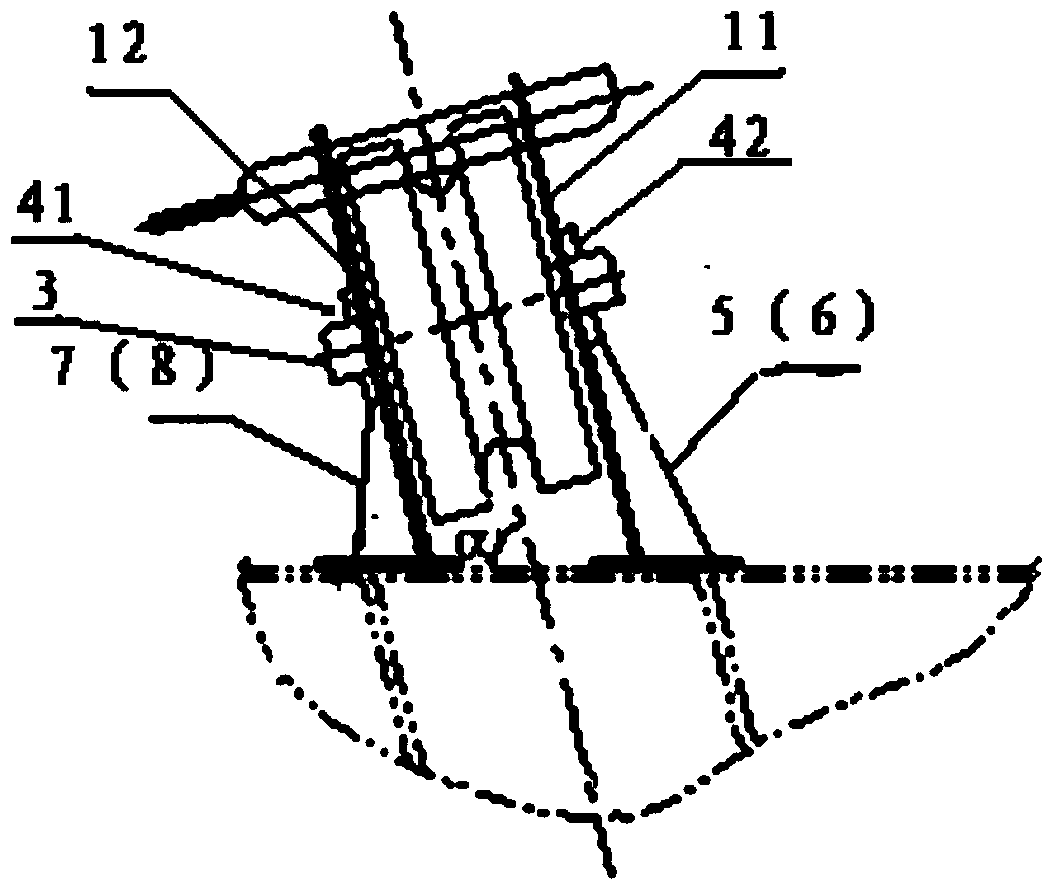

Hidden anchor recess and manufacturing installation technology

InactiveCN103523174ABreakthrough installation accuracy is not highHigh precisionVessel partsMarine engineeringReturned Amount

The invention relates to a hidden anchor recess. Sides of a first elbow plate and a second elbow plate are symmetrically welded at the two sides of an anchor recess side plate. Bottom plates of the first elbow plate and the second elbow plate are welded to an outer plate respectively. One side of a third elbow plate is welded to an anchor recess top plate and the other side of the third elbow plate is welded to the inner side of an anchor chain tube. The first side of a fourth elbow plate is welded to the outer side of the anchor chain tube, the second side of the fourth elbow plate is welded to the anchor recess top plate and the third side of the fourth elbow plate is welded to the outer plate. One side of a fifth elbow plate is welded to an anchor recess bottom plate and the other side of the fifth elbow plate is welded to the outer plate. In an inner field stage, all parts of the hidden anchor recess and the five elbow plates are welded and assembled and the hidden anchor recess is welded to the outer plate at one time in a slipway stage. According to the hidden anchor recess, a plurality of elbow plates are added on the outer side of the anchor recess and the included angles between the anchor recess and other devices are fixed, the sizes of parts are determined at one time and precision of manufacturing the parts is improved. Work of the anchor recess is completed in the inner field in advance instead of being performed in the slipway. Work loads and the waste and return amount of the slipway are reduced, the period of shipbuilding is shortened and shipbuilding cost is reduced.

Owner:WUCHANG SHIPBUILDING IND

Technology for reducing allowance cutting during ship building

The invention relates to a technology for reducing allowance cutting during ship building. In the technology, a hull is firstly divided into a plurality of general sections for building; and the general sections are gathered up. The invention is characterized in that in the step of lofting and baiting of parts, section allowance, slipway allowance, compensation dosage and material cutting are additionally and respectively placed once on a deck, a strake, a longitudinal bone, a rib, an enforced bone, a wall plate and other structures of each typical node according to section splicing or section butt joint and other different forms; in the step of the whole building of the general sections, when the joint of one of two general sections is provided with a transversal bulkhead, the two general sections adopt a splicing form, and the general section without the transversal bulkhead is inserted with the general section with the transversal bulkhead for carrying out sintered ceramsite liner welding; and when the joint of the two general sections are not provided with the transversal bulkhead, the two general sections adopt a sintered ceramsite liner welding butt joint form. The invention can determine the size of parts once, and improve the precision of parts manufacturing, thereby avoiding on-site secondary cutting quantity, and providing guarantee for general section construction; and the procedures are shifted forward, thus reducing slipway working capacity and waste backflow volume, shortening building ship period and reducing building ship cost.

Owner:WUCHANG SHIPBUILDING IND

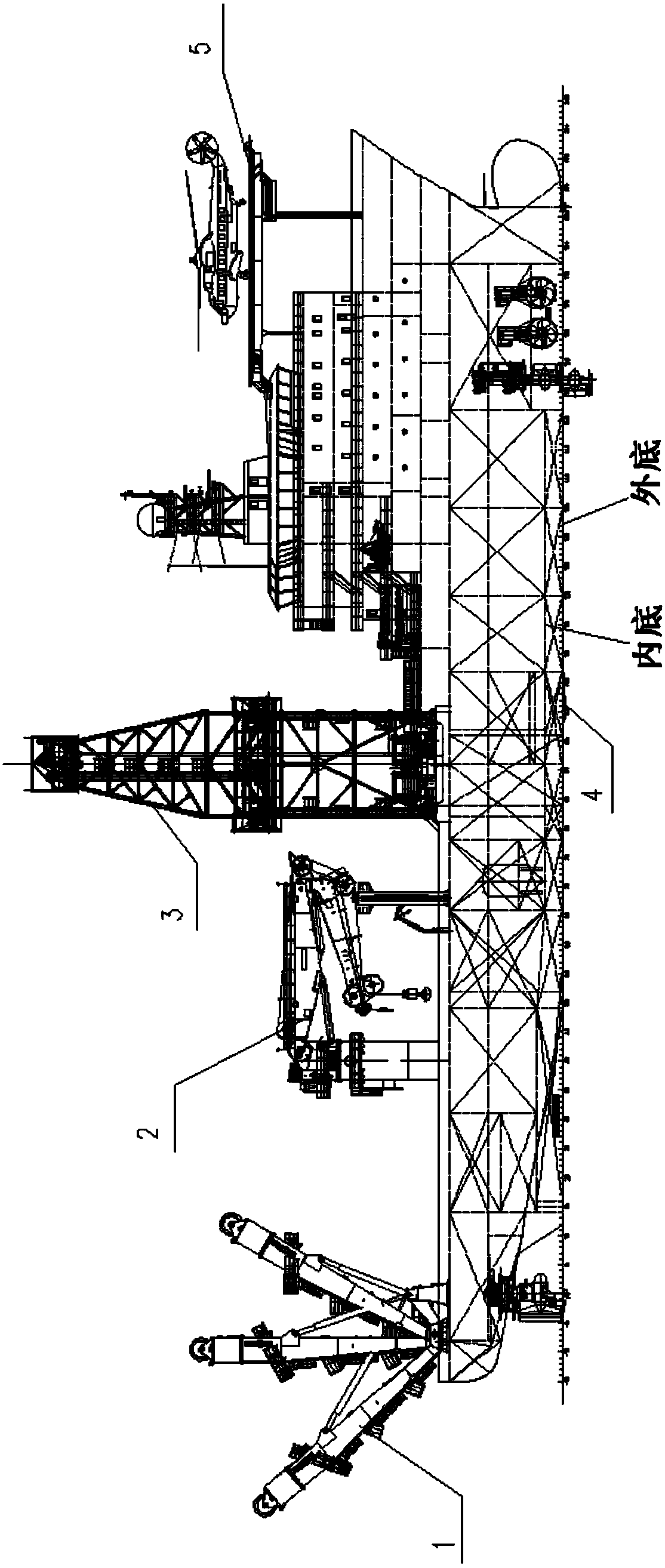

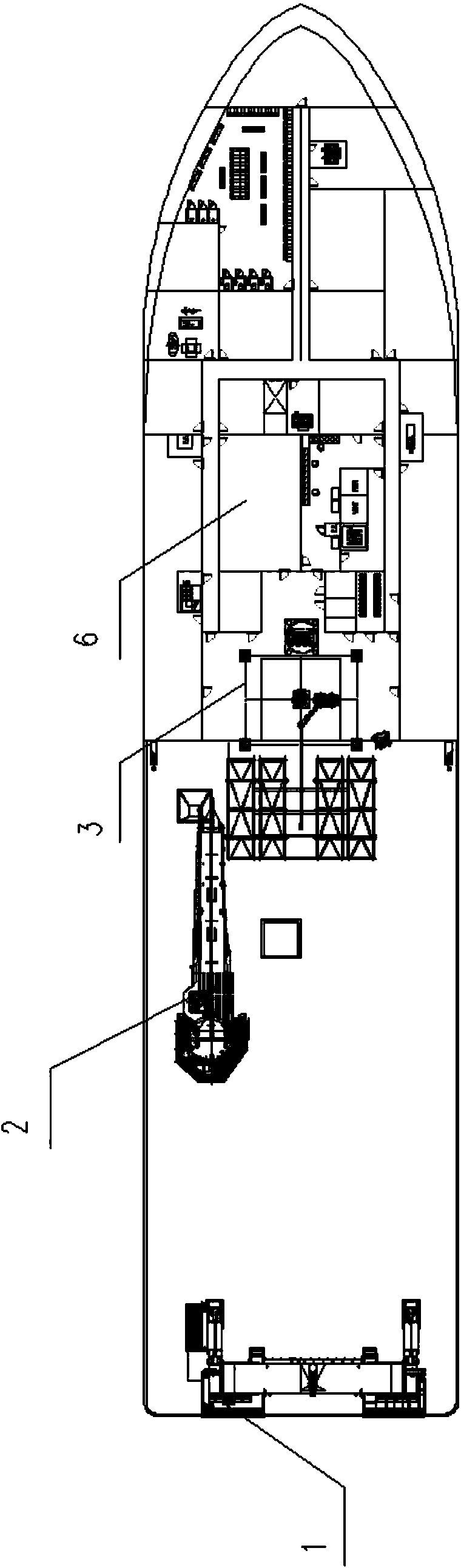

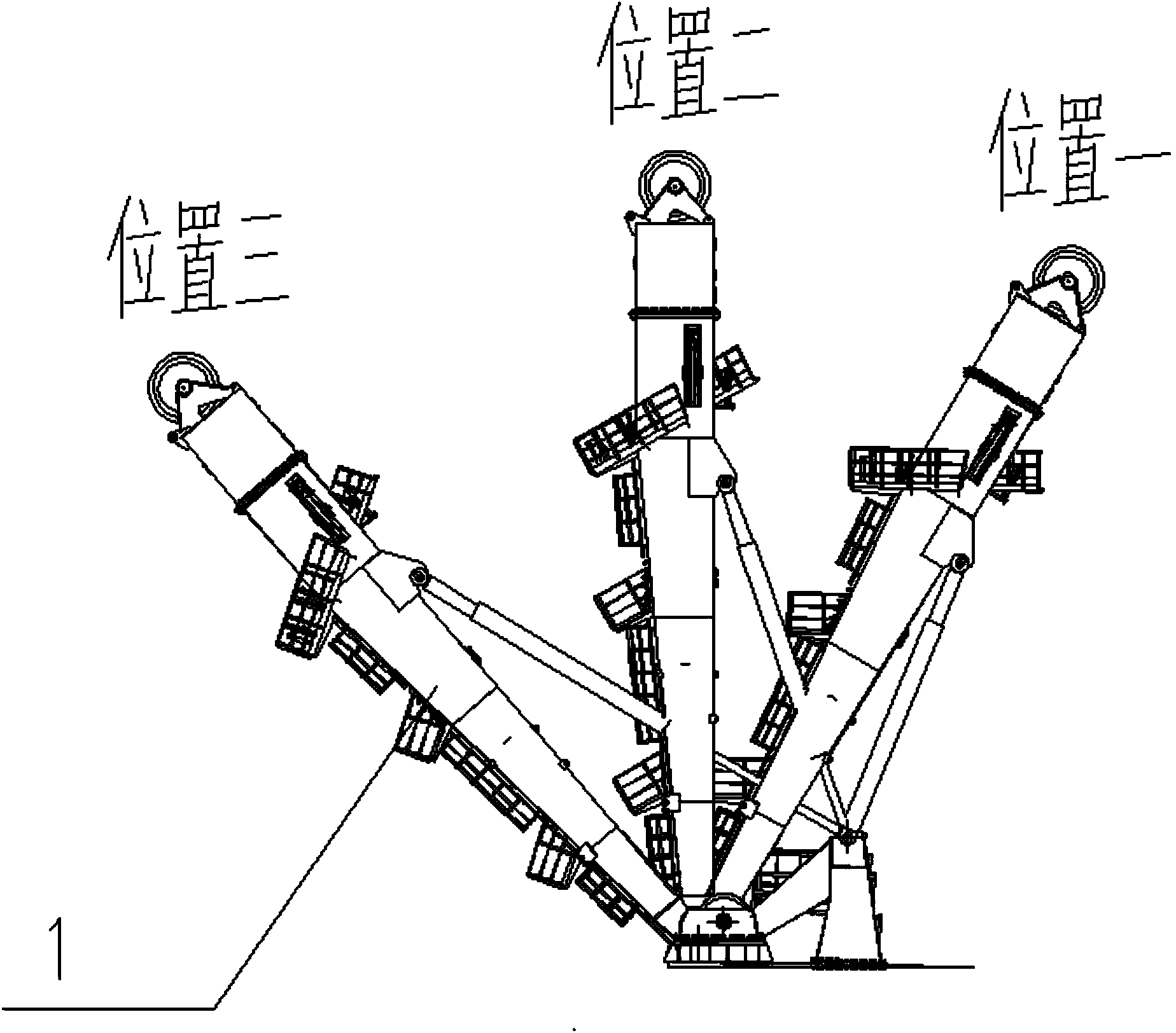

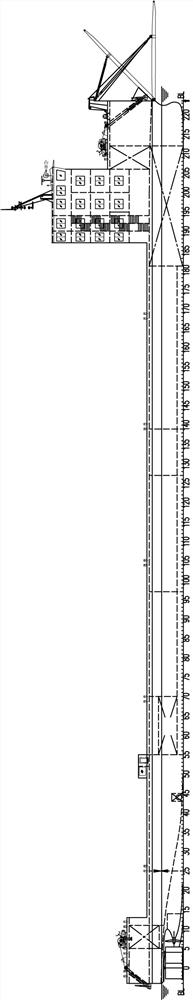

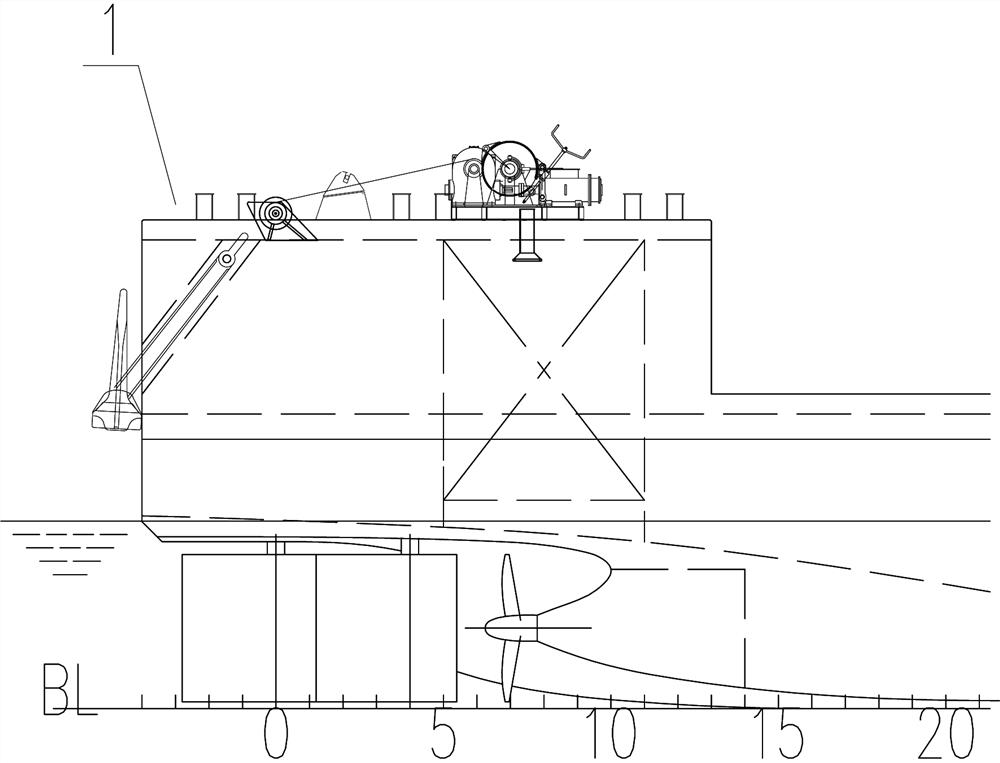

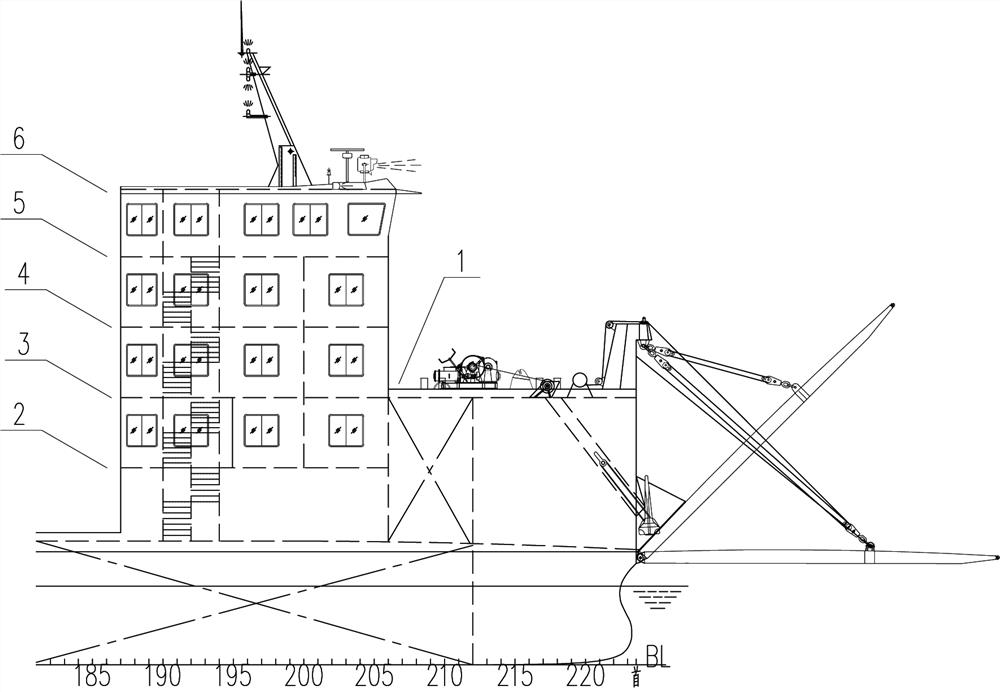

Multifunctional installation and investigation vessel

ActiveCN103395479AAchieve streamliningImprove efficiencyWaterborne vesselsSpecial purpose vesselsWinchEnergy converter

The invention relates to a multifunctional installation and investigation vessel, which comprises a vessel body and is characterized in that an A-type lifting frame, an oceanographic engineering crane and a derrick are sequentially arranged in the X direction on a main deck of the vessel body; a crane winch is arranged below the main deck, and a steel wire rope passes through the main deck; the crane and the crane winch are respectively arranged in positions on two sides of the vessel body; multiple empty tanks are arranged between the inner bottom and the outer bottom of the vessel body and in positions on two sides of the vessel body, and multiple lower water ballast tanks are arranged on the inner sides of the two sides of the vessel body; opposite tanks on the two sides of the vessel body are communicated via communication passages; an energy converter tank is also arranged at the bottom of the vessel body. When the tanks are damaged, water can enter the empty tanks uniformly, so that the stability is improved; when water in the empty tanks on one side of the vessel body is excessive, water can flow from one side to the other side of the vessel body via the communication passages, so that the transverse inclination after damage of the vessel can be reduced and the damaged stability is improved.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

Precision control method for container ship lashing system without real ship box test

ActiveCN110182312AWill not cause interferenceAvoid real ship lashing testsAccommodation for deck loadsVessel designingSimulation

The invention discloses a precision control method for a container ship binding system without a real ship box test. According to the method, after precision control production of hatch covers, a hatch coamings and lashing bridges according to the design drawing, the theoretical distance between box feet in the hatch covers and the lashing hole plates in the corresponding lashing bridges is compared with the measuring distance, actual allowance values of the lashing pieces in the real ship are obtained through calculation, and the actual allowance values of the lashing pieces are controlled tobe always larger than the allowable minimum allowance values, so that positions of all the lashing hole plates on the ship meet the requirements, the interference among the adjacent lashing pieces isavoided, and then the real ship lashing test can be effectively avoided, the shipbuilding cost can be reduced, and the shipbuilding period can be shortened.

Owner:DALIAN COSCO KHI SHIP ENG

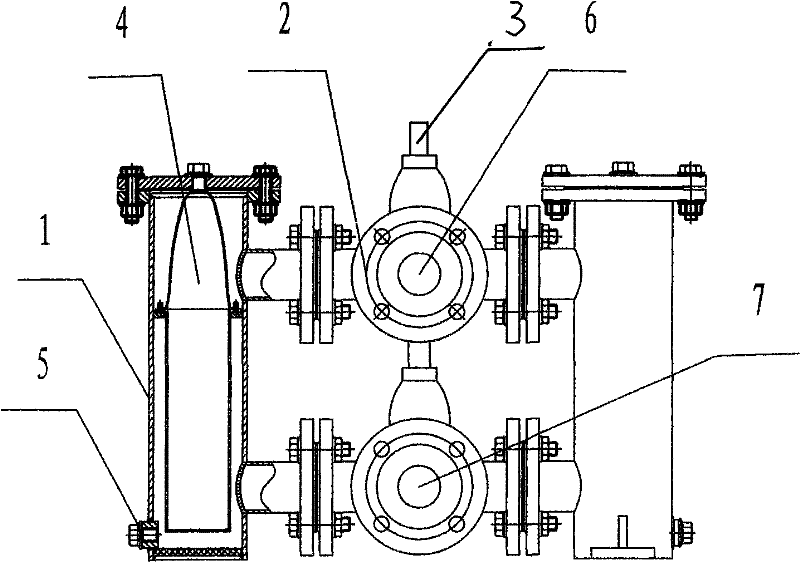

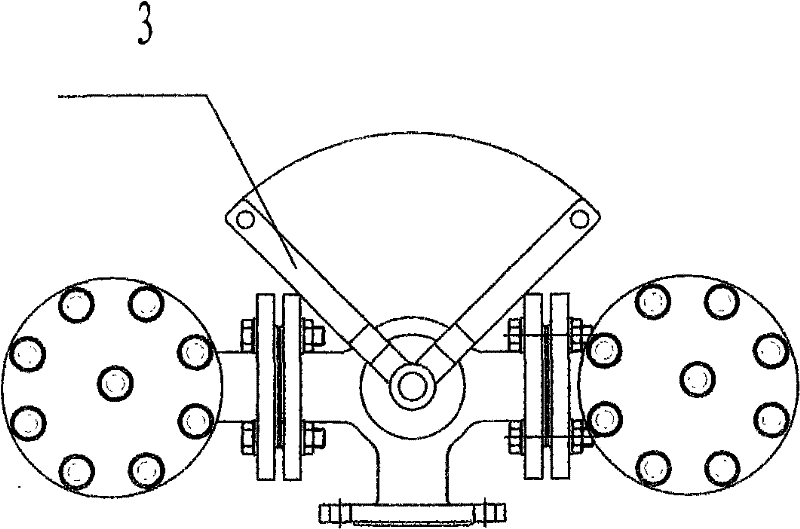

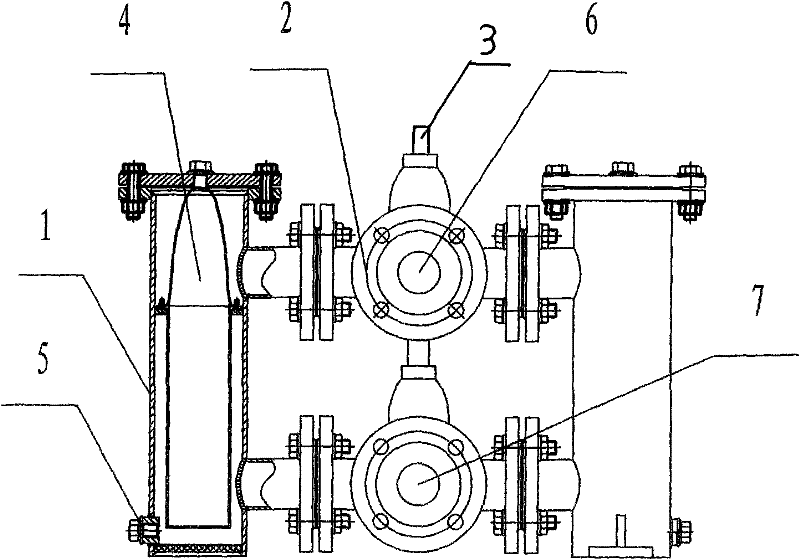

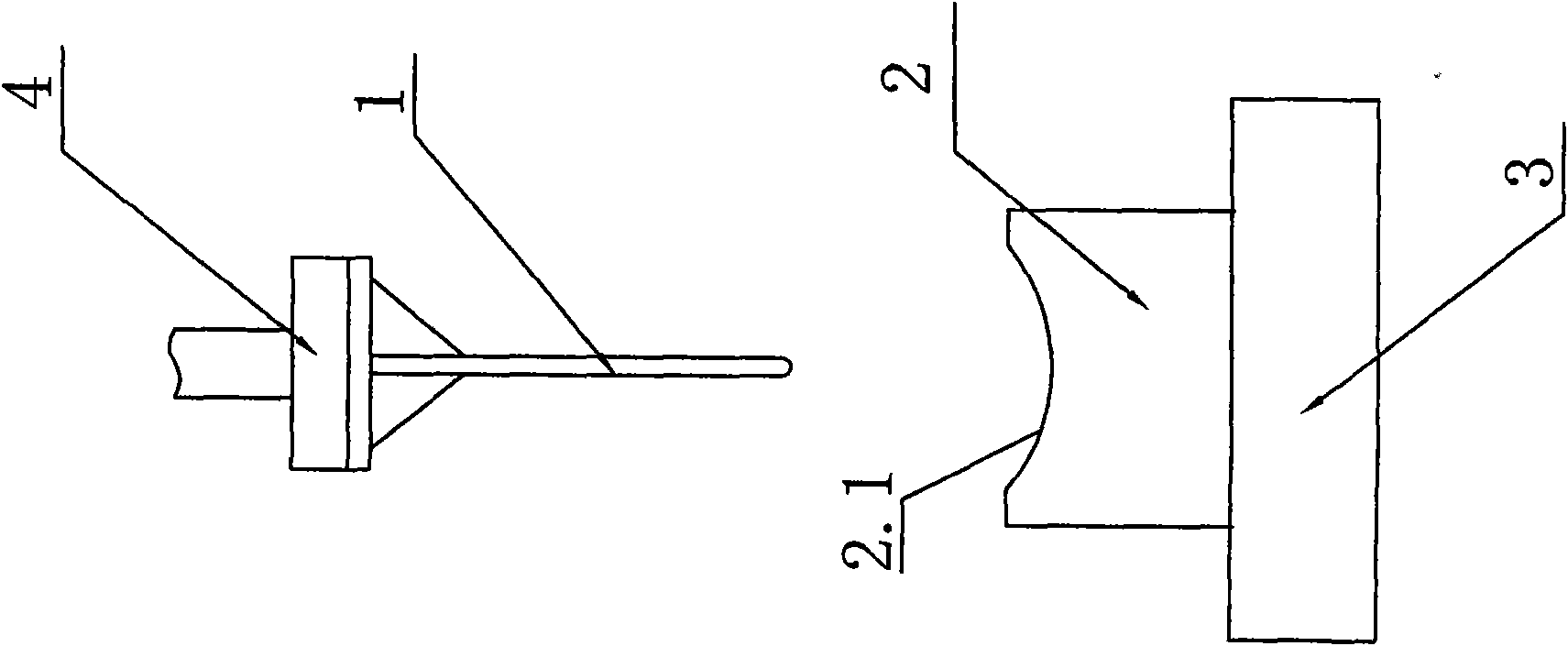

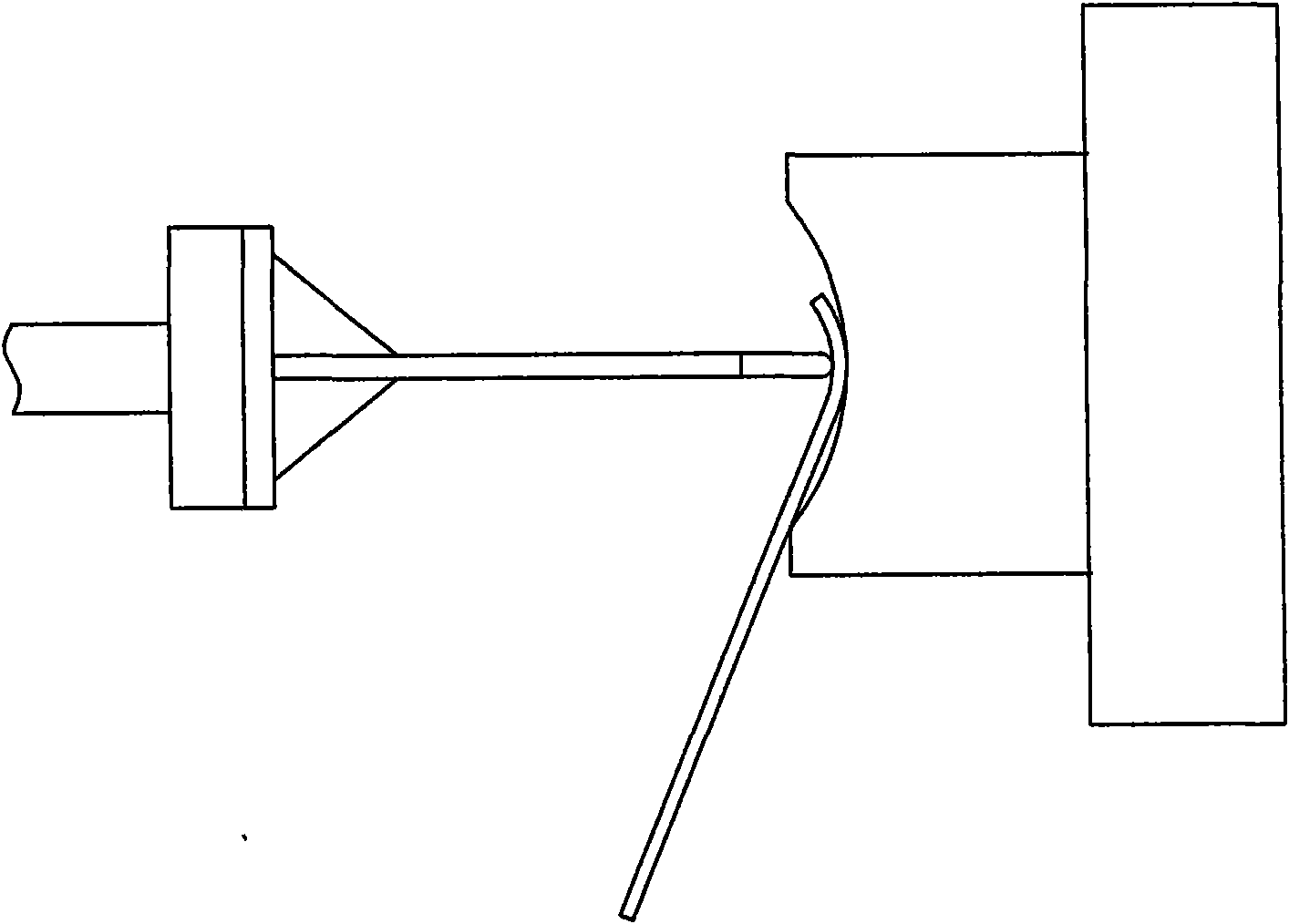

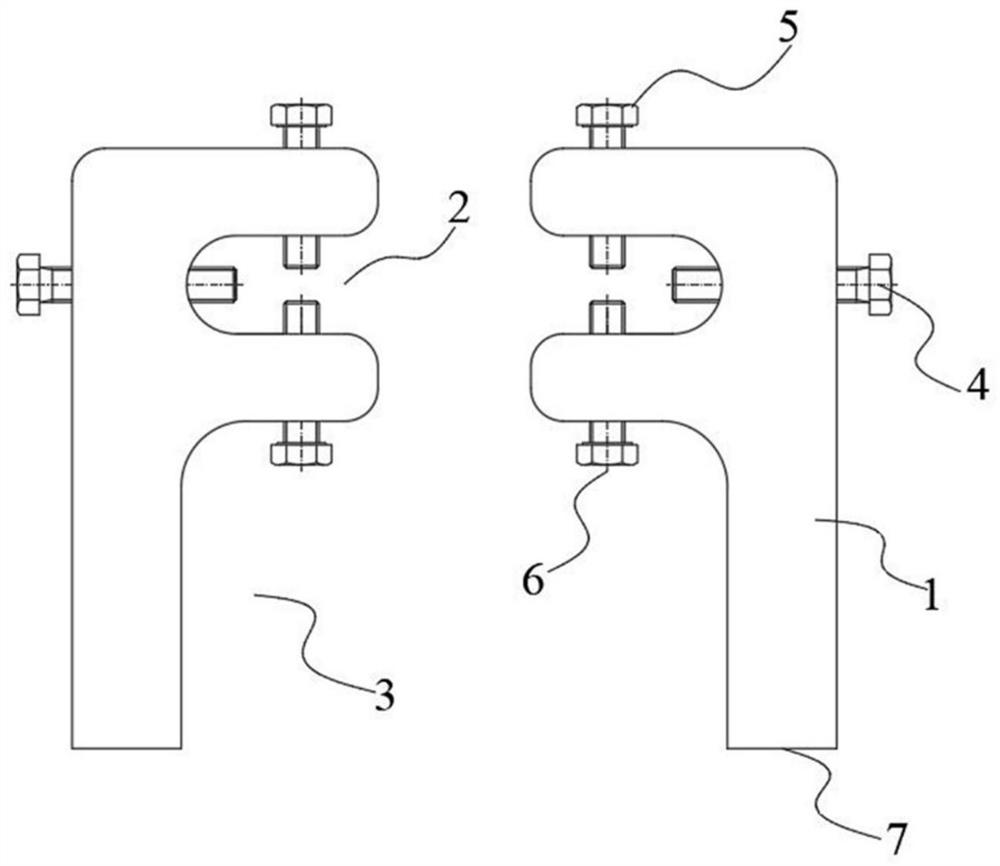

Seawater pipeline filter applicable to complex water areas

The invention discloses a seawater pipeline filter, consisting two filters (1) and two three-way valves (2) which are connected into a whole by flanges, wherein the two filters (1) are communicated with two valves of the two three-way valves (2); third valves of the two three-way valves (2) are respectively an inlet (6) and an outlet (7); the three-way valves (2) are also provided with spanners (3); and the spanners (3) are provided with valves in the three-way valves (2), and the valves are used for opening and closing the two valves of the three-way valves (2). The invention provides a seawater pipeline filter applicable to complex water areas and can clean obstructions under the condition that the water flow in the seawater pipeline is not cut off.

Owner:张晓荣

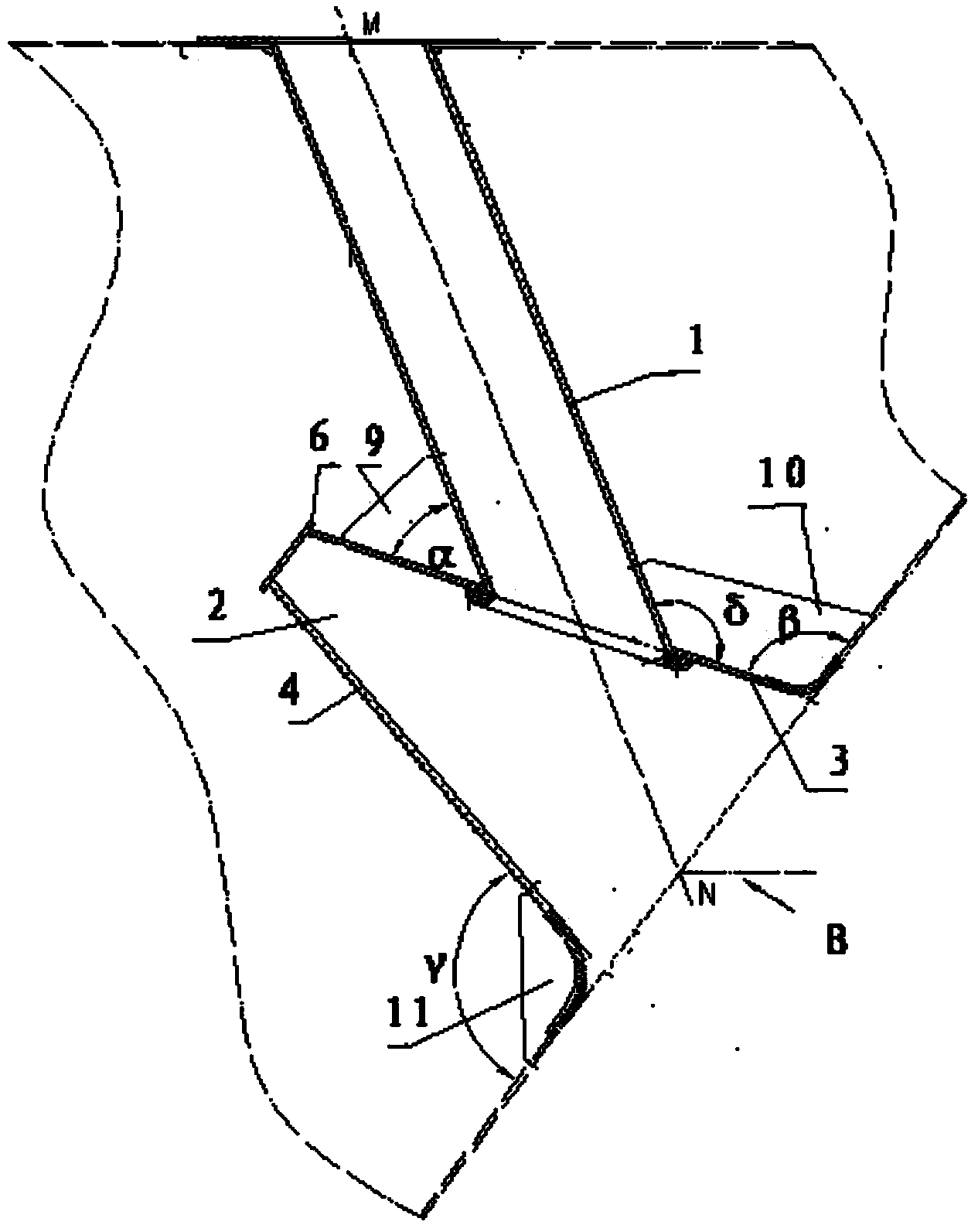

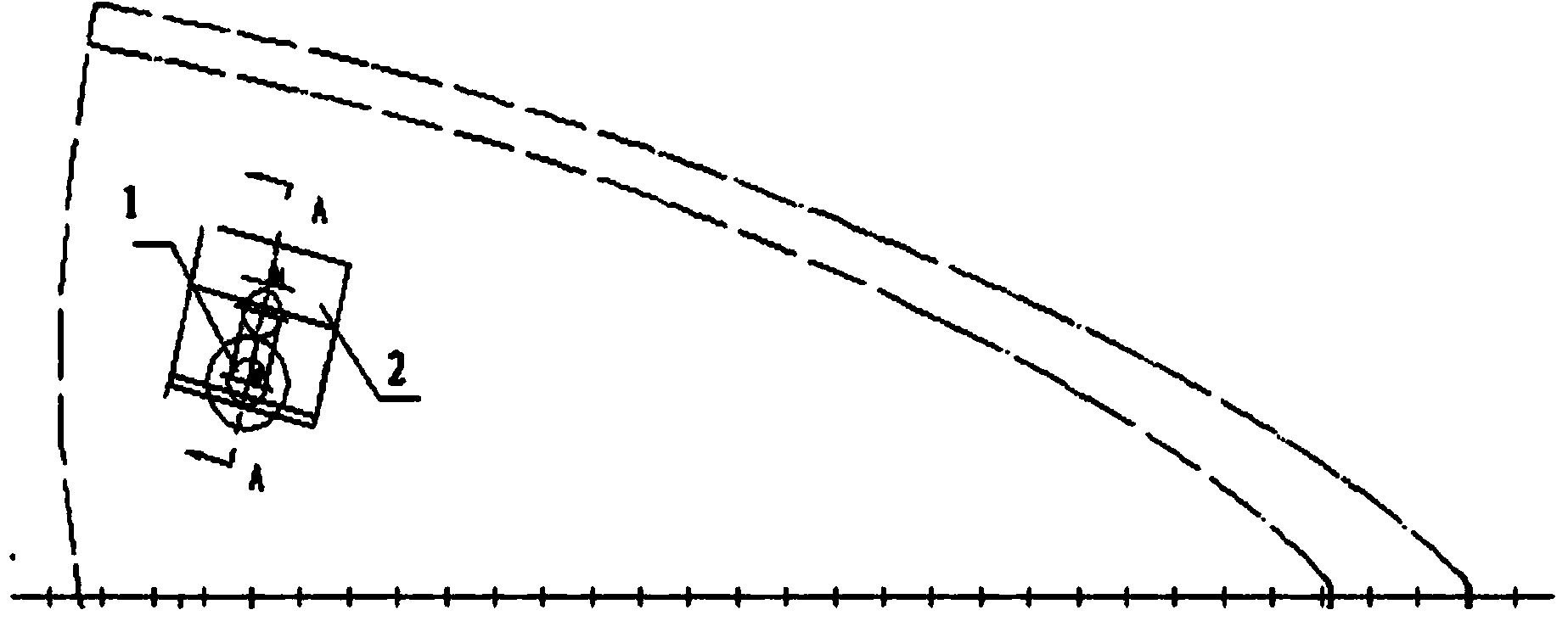

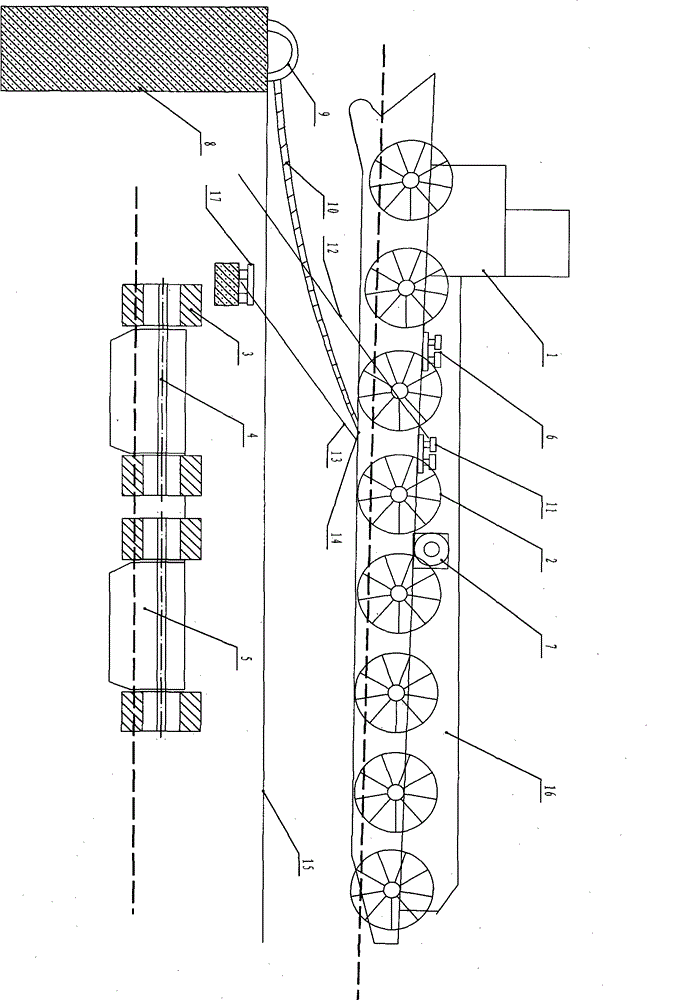

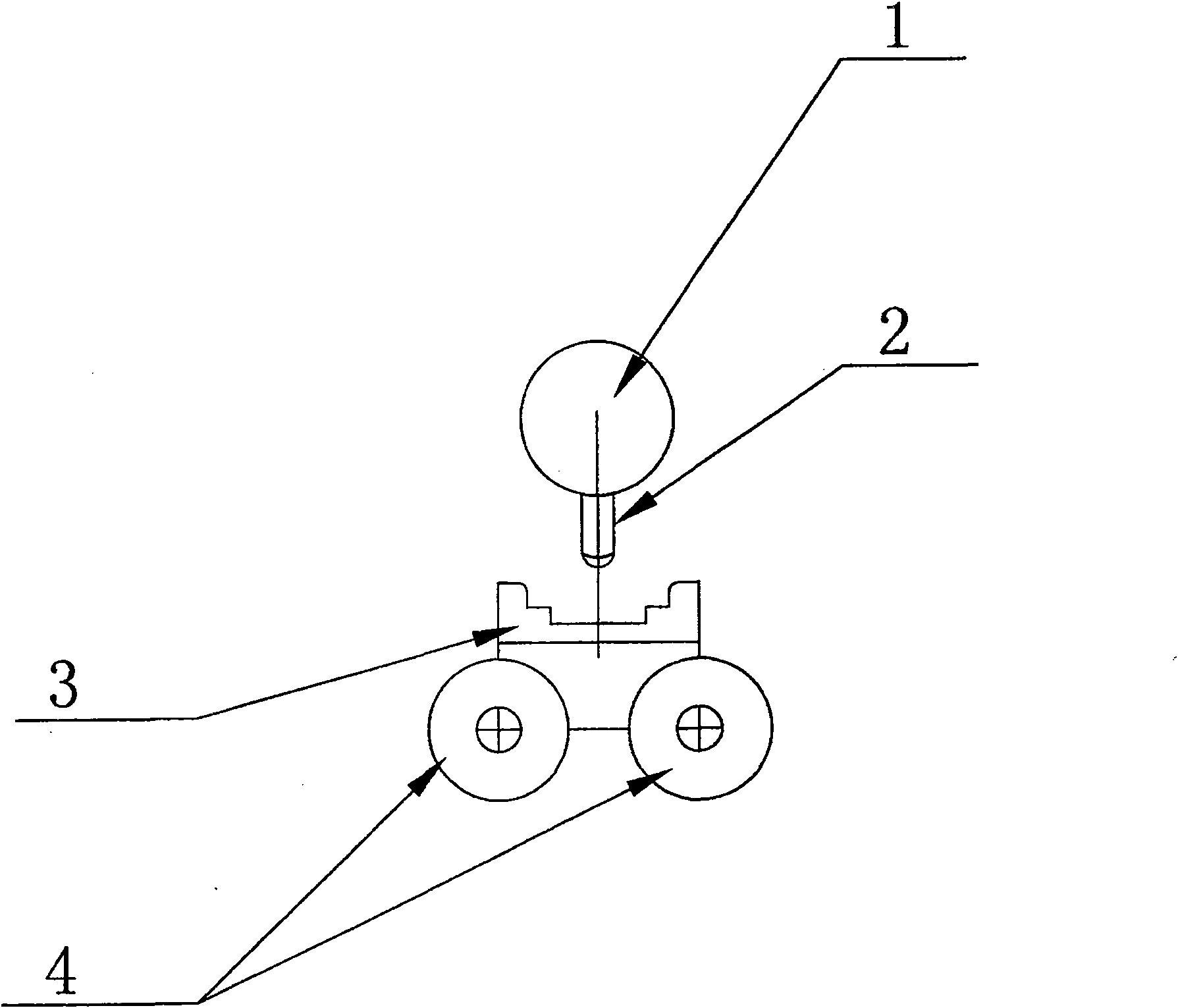

Idler wheel switch blade chain pulling device and manufacturing and installing technology of idler wheel switch blade chain pulling device

ActiveCN103523173AHigh precisionReduce workloadWaterborne vesselsWelding apparatusVertical planeIdler-wheel

The invention discloses an idler wheel switch blade chain pulling device. A first bracket and a second bracket of the idler wheel switch blade chain pulling device are located on the vertical plane of the axial lead of an idler wheel, the upper end of the lateral side of a third bracket is located below a left lining, the upper end of the lateral side of a fourth bracket is located below a right lining, the lateral side of the first bracket and the lateral side of the third bracket are respectively connected with a left side plate of a body in a welded mode, and the lateral side of the second bracket and the lateral side of the fourth bracket are connected with a right side plate of the body in a welded mode. Parts of the idler wheel switch blade chain pulling device are assembled in place in an internal field according to designed sizes, the four brackets are welded on the body of the idler wheel switch blade chain pulling device, and one-step installation can be achieved when the idler wheel switch blade chain pulling device is installed on a slipway. According to the idler wheel switch blade chain pulling device, the four brackets are additionally installed, the dip angle alpha between the idler wheel switch blade chain pulling device and a deck is directly determined, the sizes of the parts of the idler wheel switch blade chain pulling device are directly determined at one time in the internal field, the manufacturing accuracy of the parts is improved, and the ship building cost is reduced.

Owner:WUCHANG SHIPBUILDING IND

Dual-body water conservancy power generation ship

InactiveCN104608882AAdaptableIncrease tractionWaterborne vesselsSpecial purpose vesselsKeelMechanical energy

The invention relates to a dual-body water conservancy power generation ship. Damming power generation is characterized in that the unit installed capacity is determined by the water flow fall. The dam-free water conservancy power generation ship is characterized in that the unit (ship) installed capacity is determined by traction positioning energy of a traction device. According to the dual-body water conservancy power generation ship, a large traction hanging pile (sunken anchor) and a shore hanging pile (shore anchor) are built at the river bottom to be combined with the power generation ship to form three-dimensional triangular traction positioning, and water flow attacks a unit paddle wheel to convert water flow power into mechanical energy for work doing power generation. In order to improve the installed capacity and effectively reduce dual-anchor loads, dual-anchor-chain hanging points are selectively arranged at the portions of dual-hull-bottom keels to form appropriate angles, so that water flow attacking is converted into upper floating force to reduce resistance. In order to keep the balance of the dual-body ship, the installing space is increased, and the ship building cost is reduced; the flat-bottom dual-body ship is selected. A control system is formed by three anchors and ship-load power so as to keep the transverse level and the longitudinal level of the dual-body ship, and the best water flow is selected through transverse movement positioning. The unit is suitable for working doing power generation in any water flow state through wheel propeller lifting operation.

Owner:兰淑娟

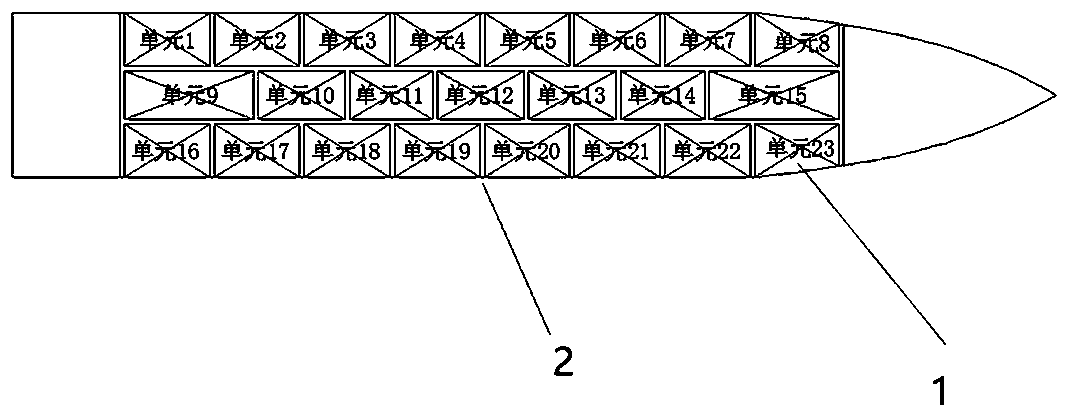

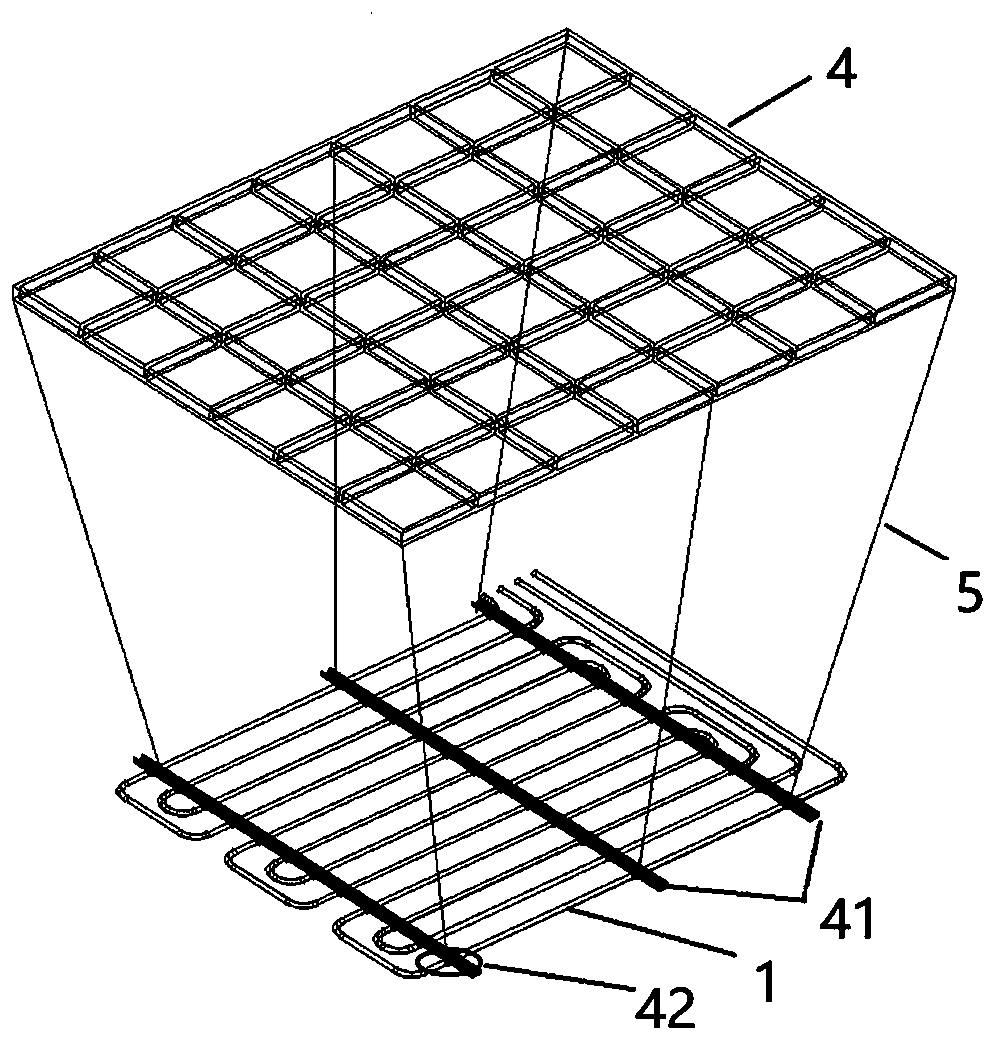

Method of installing heating coil used for liquid cargo tank of chemical cargo ship

The invention relates to a method of installing a heating coil used for a liquid cargo tank of a chemical cargo ship. The liquid cargo tank is divided first, corresponding heating coil unit modules ofeach liquid cargo tank unit are prepared separately and then are hoisted and installed according to an installation progress to achieve one cabin and one module in each liquid cargo tank. Heating coil pipe docking work of an original slipway is completed in advance on a platform, the mode that hoisting is conducted once in each cabin is achieved, the labor intensity is reduced, the working environment of construction personnel is improved, the working efficiency is improved, the slipway cycle is greatly shortened, and the construction cost of the chemical cargo ship is reduced.

Owner:上海船舶工艺研究所(中国船舶集团有限公司第十一研究所)

Method for pressing circular tubes by oil press

The invention relates to a method for pressing circular tubes by an oil press in the shipbuilding process, which comprises that: 1, an upper die and a lower die are designed, the upper end face of the upper die is provided with arc grooves corresponding to the diameter of a circular tube to be pressed, the upper die is fixed with a pressure head of the oil press, and the lower die is locked on a press platform of the oil press by a limit block; and 2, press lines of which the interval is 50mm are marked along the length direction of a plate, the plate which is prepared and marked with the press lines on the lower die is flatly placed, the pressure head of the oil press drives the upper die to run downwards and act on the press lines, the action is repeated to press the positions of various press lines, the plate is gradually pressed into a semi-finished product circular tube of which the middle is reserved with a gap of 20mm, the gap of 20mm of the semi-finished product circular tube is sealed, and fixed by welding, and the semi-finished product circular tube is welded and corrected to finally form the circular tube. The method only needs one oil press, and is matched with special dies to process the circular tubes, and not only reduces the dependency on a special tube-rolling machine, but also can improve the wall thickness of rolled tubes, reduce the requirements on equipment configuration of shipyards and shorten the shipbuilding period.

Owner:JIANGSU YANGZIJIANG SHIPBUILDING

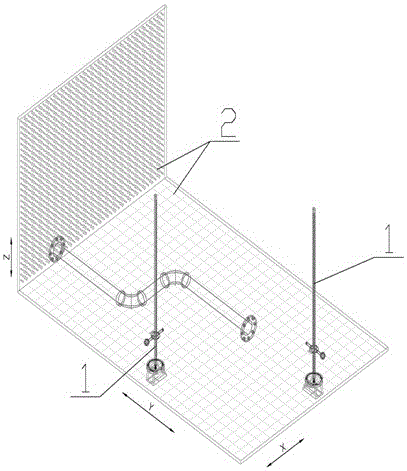

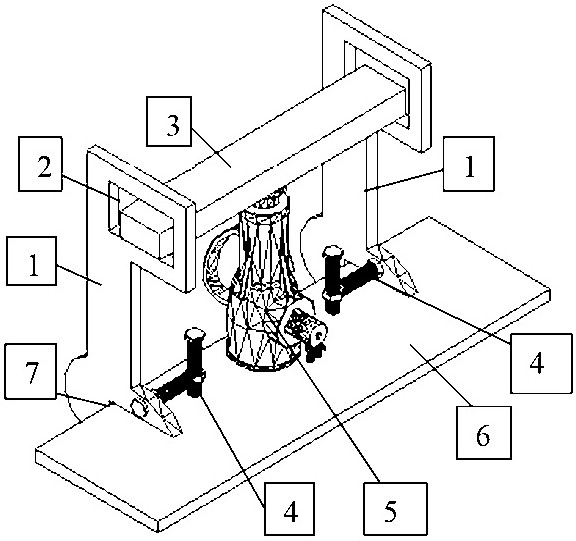

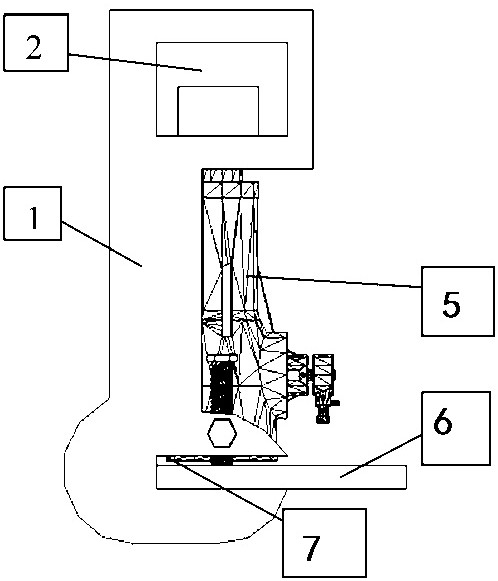

Pipe check platform instrument

ActiveCN105136032AReduce production errorsImprove working environmentUsing optical meansMeasurement deviceEngineering

The invention discloses a pipe check platform instrument, characterized by comprising a fixed mounting platform and a plurality of measurement mechanisms. The fixed mounting platform comprises a horizontal reference plate with an X graduation line and a Y graduation line, and a vertical reference plate perpendicular to the horizontal reference plate; the vertical plate is provided with connection apertures used for fixing installation flanges of a detected pipe. Each measurement mechanism comprises a scale column, and a base capable of being fixed to the horizontal reference plate; the base is provided with a panel; the scale column is provided with an infrared ray projector capable of sliding up and down along the scale column; the lower end of the scale column is fixedly provided with a rotary angle disc; the rotary angle disc is in connection with the panel, and can rotate relative to the panel.

Owner:GUANGXIN SHIPBUILDING & HEAVY IND

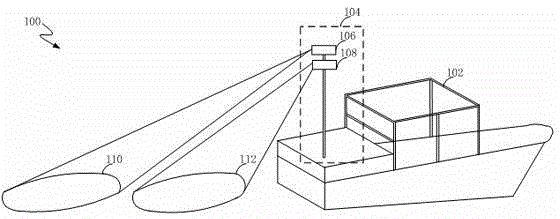

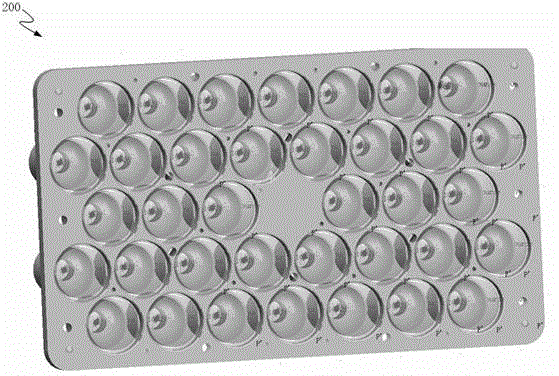

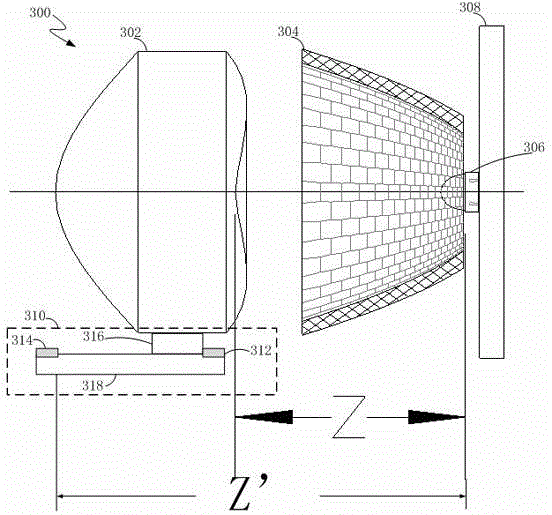

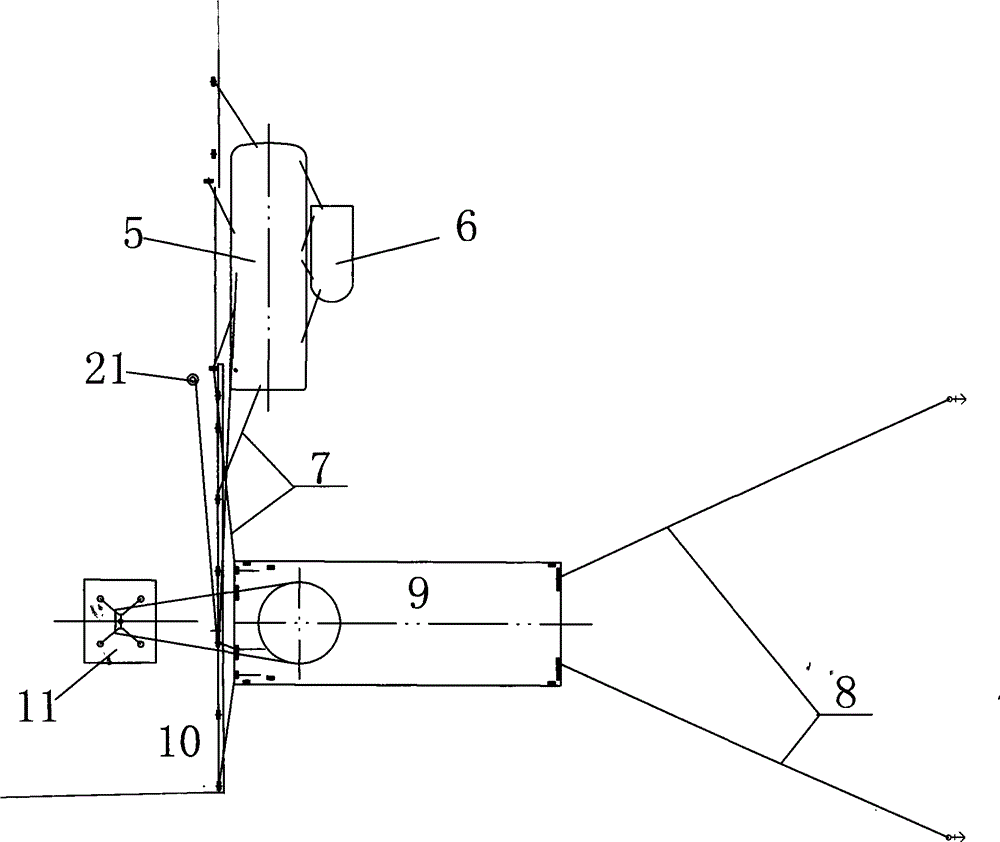

Focusable LED (light emitting diode) water surface fishing lamp and fishing ship with focusable LED water surface fishing lamp

InactiveCN104566081AExpand coverageEmission reductionPlanar light sourcesWaterborne vesselsSkyGreenhouse

The invention discloses a focusable LED (light emitting diode) water surface fishing lamp and a fishing ship with the focusable LED water surface fishing lamp. The focusable LED water surface fishing lamp comprises at least two fishing lamps, wherein each of the two fishing lamps comprises a plurality of LED assemblies, each of the LED assemblies comprises an LED light source, a reflective cup, a lens and a focusing device, each LED light source is arranged on a PCB (printed circuit board), each reflective cup is arranged at the reflecting surface of the corresponding LED source, each lens is arranged at the opening surface of the corresponding reflective cup, and each focusing device is arranged on the corresponding lens. Compared with the prior art, the focusable LED water surface fishing lamp and the fishing ship have the advantages that the energy loss is reduced, the shipbuilding cost is reduced, and the emission of greenhouse gases is reduced; by adjusting the focus, the irradiation distance of each lamp can be changed; the intensity of light rays which vertically irradiate to sky and ground is decreased, the utilization rate of the light rays is improved, and the energy loss is further reduced.

Owner:CHENGDU CRYSTAL LENS SCI & TECH

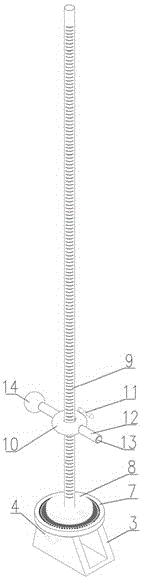

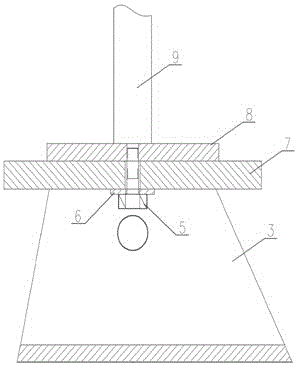

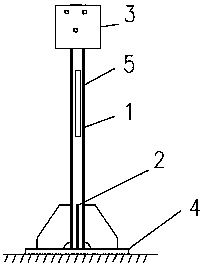

Mounting base of ship gyrocompass system azimuth repeater compass

InactiveCN107933848AEasy to manufactureEasy to operateNavigational aid arrangementsEngineeringRepeater

The invention discloses a mounting base of a ship gyrocompass system azimuth repeater compass. The mounting base comprises a first steel plate, a steel pipe is welded to the middle of the first steelplate, three second steel plates are arranged at the top of the first steel plate, and the bottoms of the multiple second steel plates are fixed to the top of the first steel plate. Flat iron is mounted in the middle of the side face of one side of the steel pipe, a third steel plate is arranged above the flat iron, and the third steel plate is fixed to the side face of one side, close to the flatiron, of the steel pipe. Each of the outer surface and the inner surface of the steel pipe is plated with a layer of zinc, the first steel plate, the second steel plates and the third steel plate alladopt 6 mm steel plates, and the steel pipe adopts a seamless steel pipe with the inner diameter being 3 inches. The mounting base is easy to operate, can be easily manufactured by a ship factory, isconvenient to mount, and saves the ship manufacturing cost.

Owner:GUANGXIN SHIPBUILDING & HEAVY IND

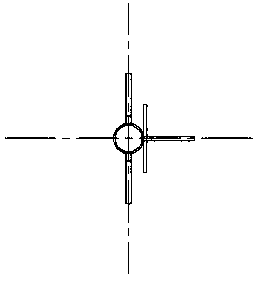

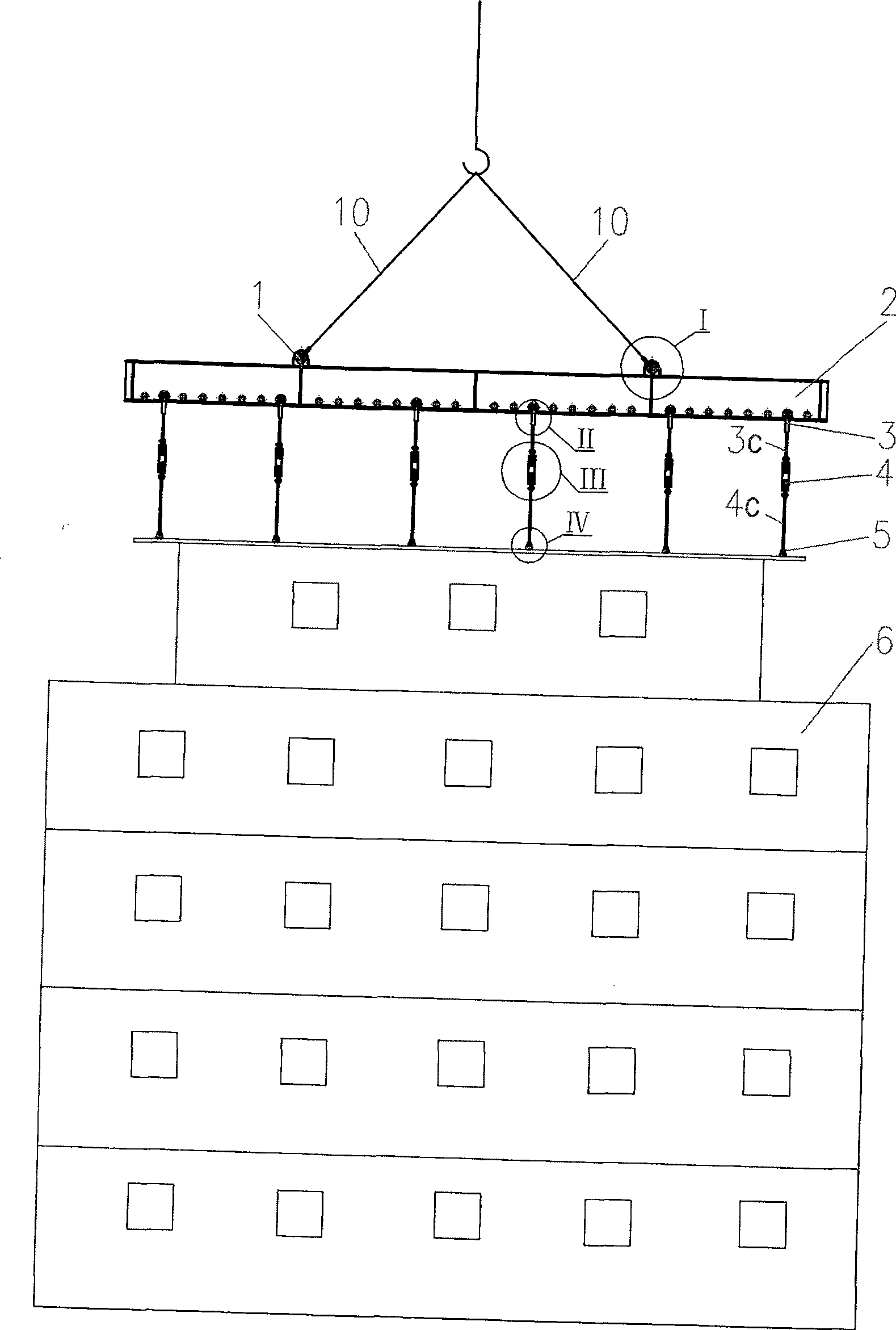

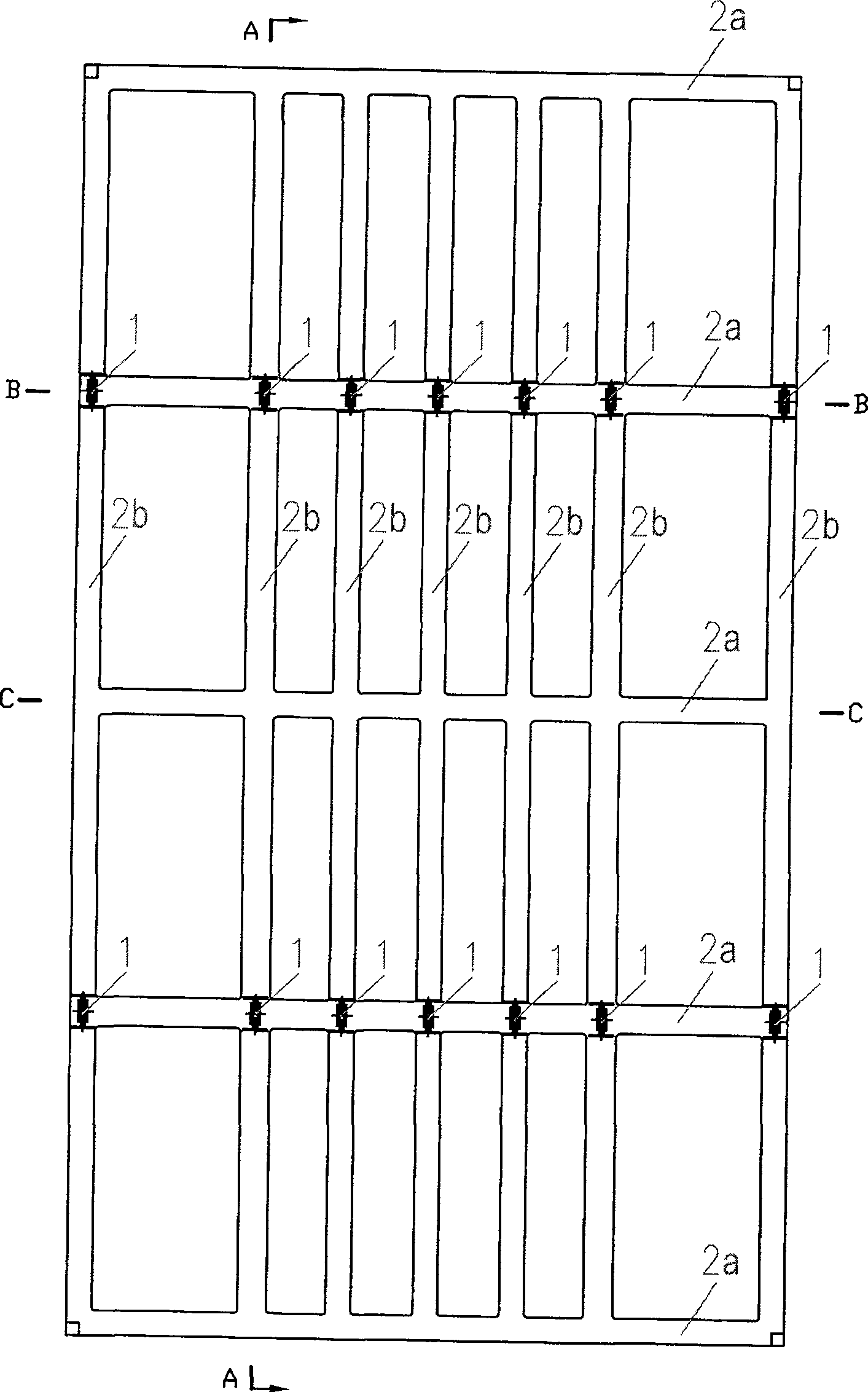

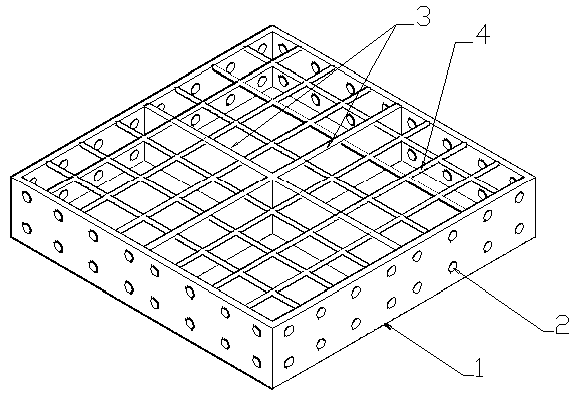

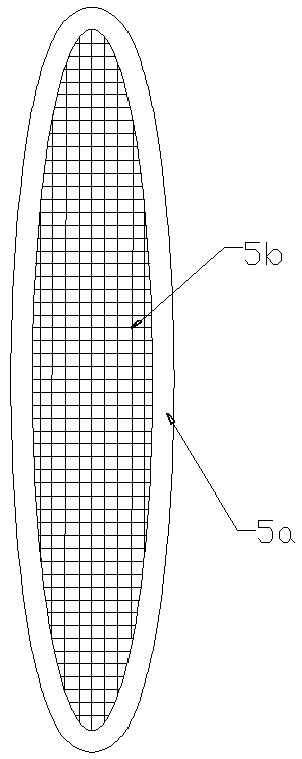

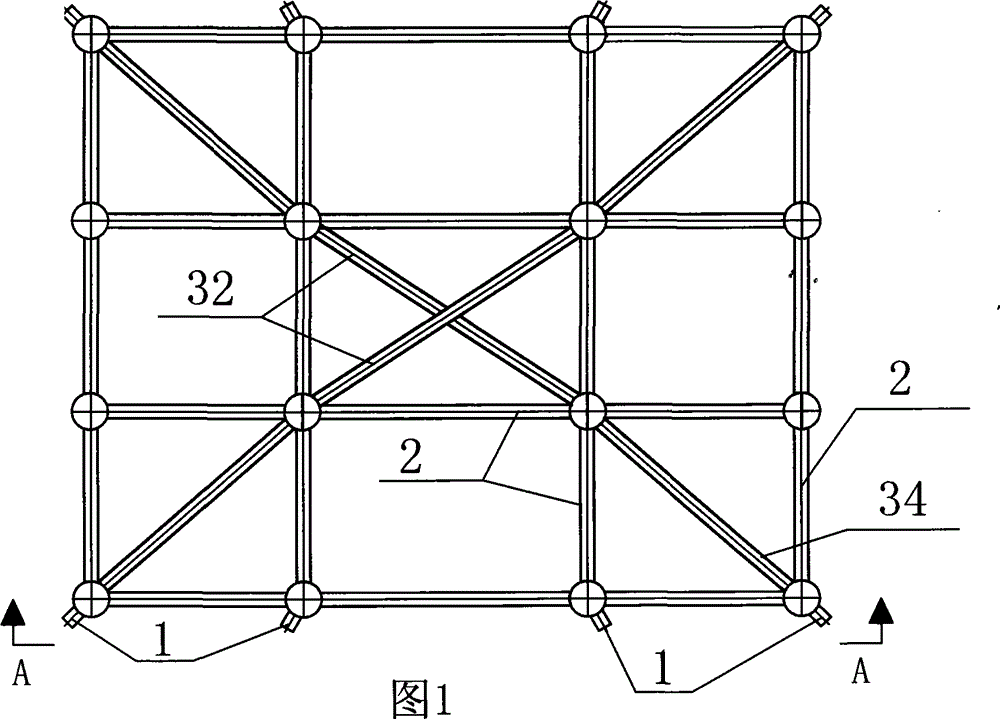

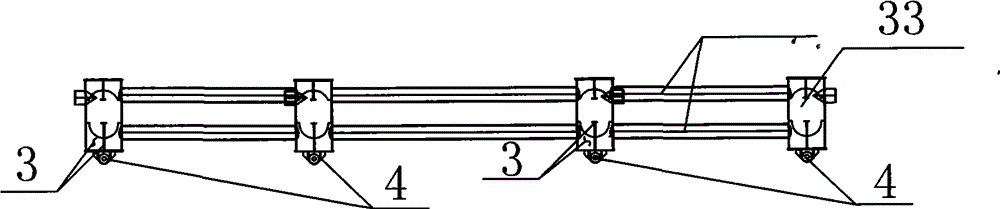

Hanging bracket for integral hoisting of ship superstructure and hoisting process

InactiveCN100542936CShorten the construction periodEffective control of deformationVessel partsLoad-engaging elementsProcess safetyUpper floor

The invention relates to a hanger for overall hoisting of a ship superstructure and a hoisting process, belonging to the field of ship and marine structure manufacturing and manufacturing technology. This kind of hanger for overall hoisting of ship superstructure adopts an integral frame structure, and the transverse and longitudinal members all adopt I-shaped cross-section beams composed of upper panel, vertical panel and lower panel, which have good rigidity and light weight; the lower part of the vertical panel is close to There is a row of lifting holes on the lower panel, which can be conveniently installed according to the optimally designed lifting points. The hanger can meet the needs of different ships. The hanger is conveniently connected to the superstructure of the ship, and the hoisting process is simple. The overall hoisting can be realized without changing the structure of the superstructure, effectively controlling the hoisting deformation, and significantly improving the safety of the process; the hanger is to realize various The effective guarantee of the overall hoisting process of the superstructure of similar ships; the overall hoisting of the superstructure will expand the scope of operations on land in the superstructure manufacturing, improve labor production efficiency, shorten the ship construction cycle, and reduce shipbuilding costs.

Owner:DALIAN UNIV OF TECH

Hull construction new process and new structure and application thereof

InactiveCN109760782AExtended service lifeReduce shipbuilding costsVessel partsHull shellsMarine engineeringKeel

The invention discloses a hull construction new process, a new structure and application thereof. The hull construction process at least comprises one of the following processes: a, assembling shell plates of a ship on an inflation tire to accomplish the shell construction of the ship, wherein the operation is not accomplished on the traditional keel system and a rib frame; b, constructing the whole shell on the entire deck of the ship, wherein the initially constructed hull is a floater with the deck at the lower side and the hull bottom at the upper side; and then filling water in partial cabin of the floater until the average volume weight of the whole floater is lightly less than the volume weight of the water and a top-heavy state is formed; entirely overturning in the water so that the deck is at the upper side and the hull bottom is at the lower side; c, enabling the entire deck of the ship to be the floater, and anchoring on a calm water surface, and accomplishing the construction procedure of the hull on the floater; d, avoiding the use of the entire heavy component on the whole hull, wherein the construction of the shell adopts the process of hoisting shell plates at multipoint by using the unmanned aerial vehicle to assemble, thereby reaching aims of improving the efficiency and shortening the days for construction.

Owner:徐林波

Oceanography engineering module integral hoisting method

ActiveCN101417693BShorten the lengthIncreased lifting capacityVessel partsLoading/unloadingFreeboardLightering

The invention discloses a method used for realizing the integral lifting of marine engineering modules in the marine engineering field. After the module is constructed integrally, the invention makes use of floating cranes, barges and special crane beams to realize the integral lifting of modules on water by regulating the sea gauge of a main hull. Compared with the similar technology, the invention has the following advantages that the preparation of special crane beams can reduce the length of lifting cables so as to enhance the effective lifting height of floating cranes; and the adopting of the floating crane to lift the modules to the barges can avoid the use of a plurality of fittings used for conveying so as to reduce the cost. Simultaneously, the deep water is adopted to moor the main ship so as to ballast the main hull and reduce the height of the freeboard and then the high lifting capability of the floating crane is enhanced and the shipbuilding cost is reduced finally.

Owner:DALIAN SHIPBUILDING IND

Method for pressing tank-type bulkhead using three rollers rolling machine

InactiveCN101249536BReduce in quantityReduce workloadShaping toolsIndustrial engineeringOil pressure

Owner:江苏新扬子造船有限公司

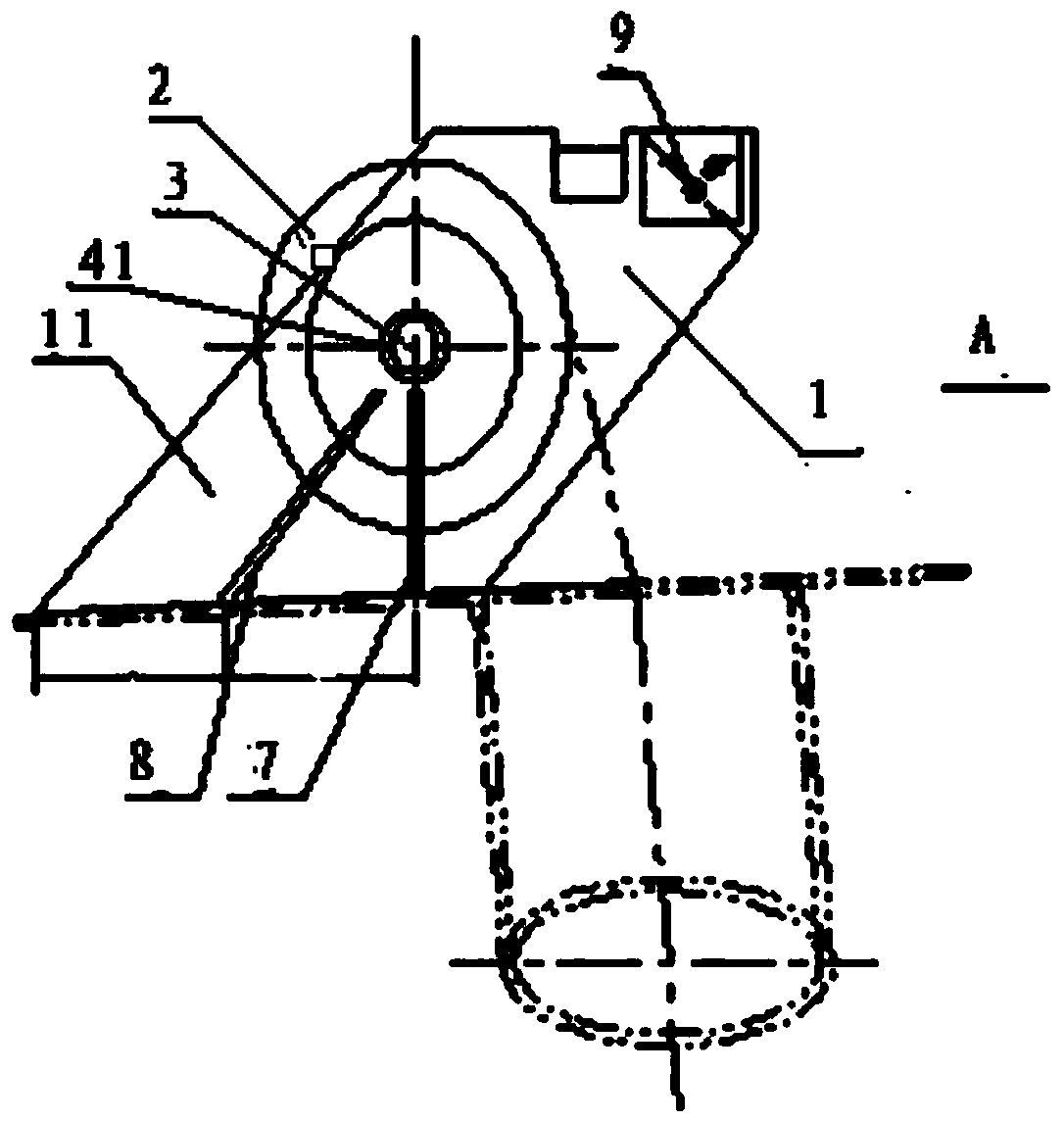

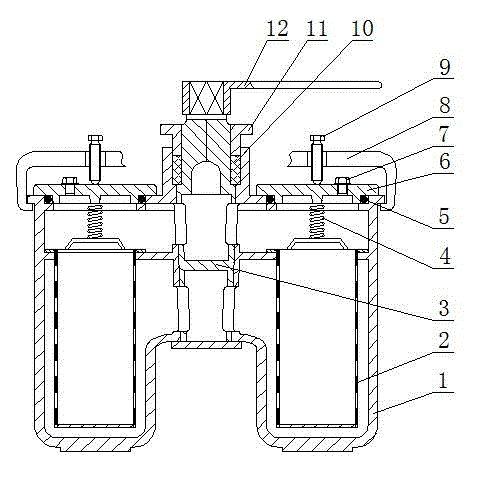

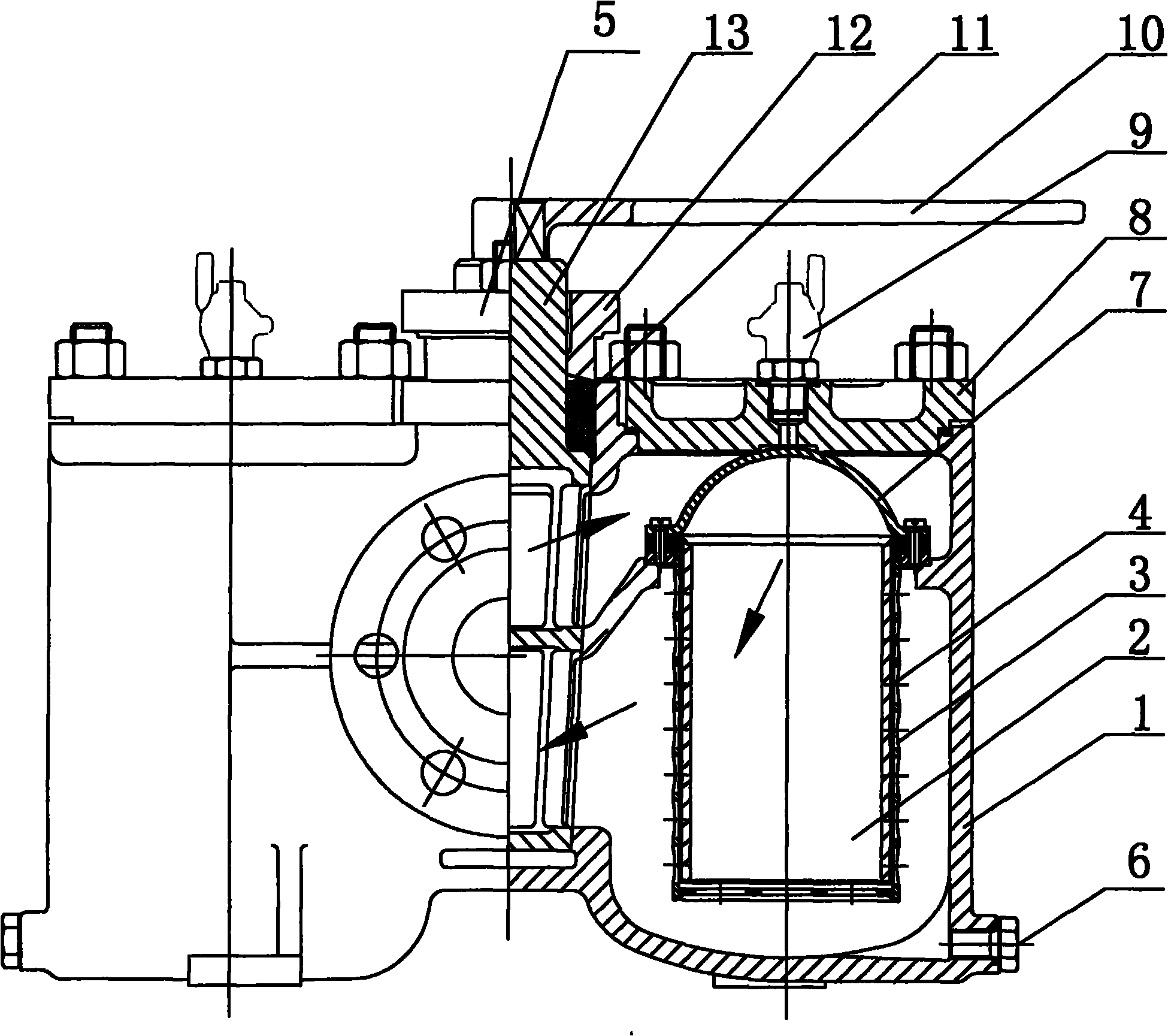

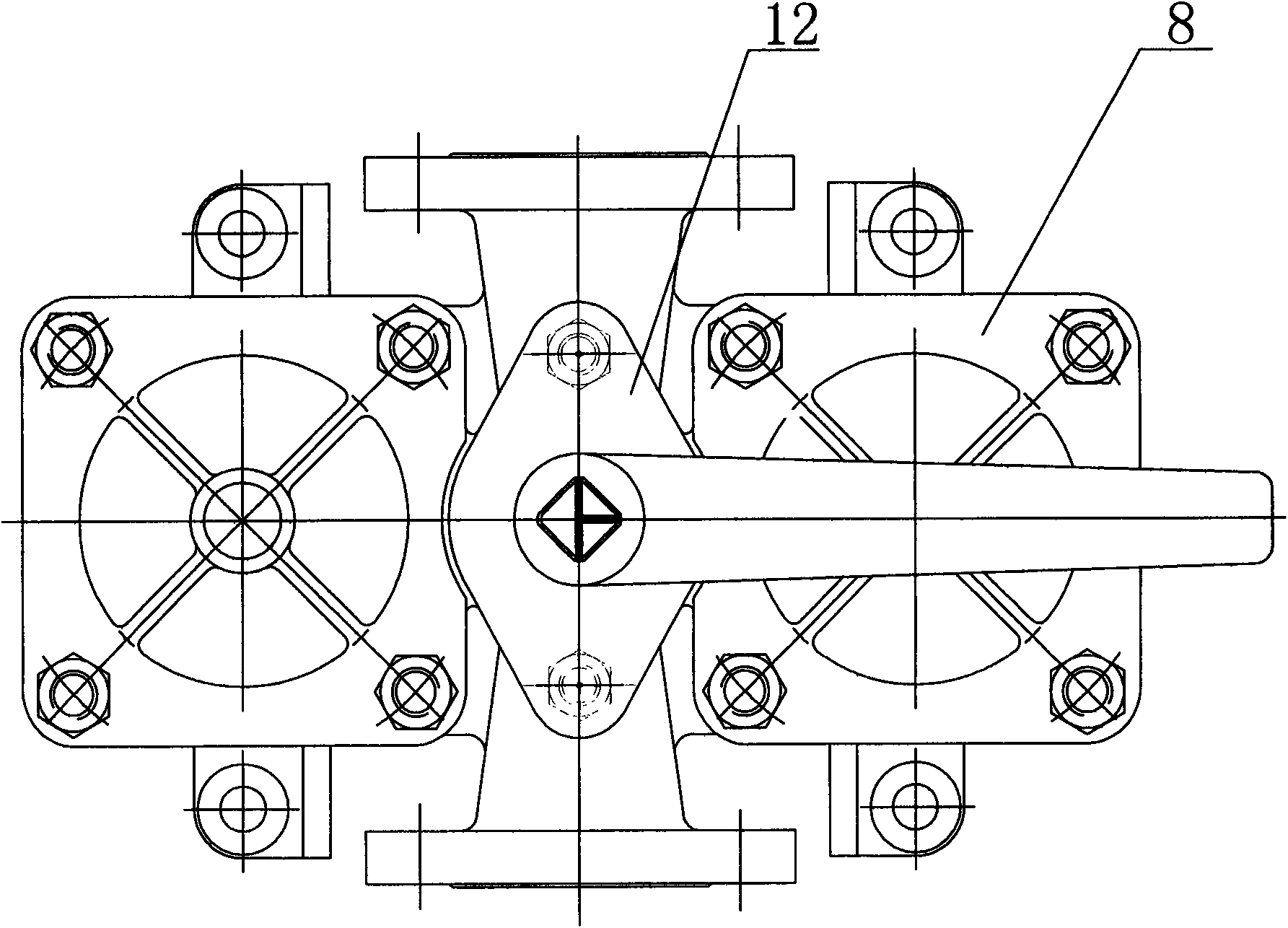

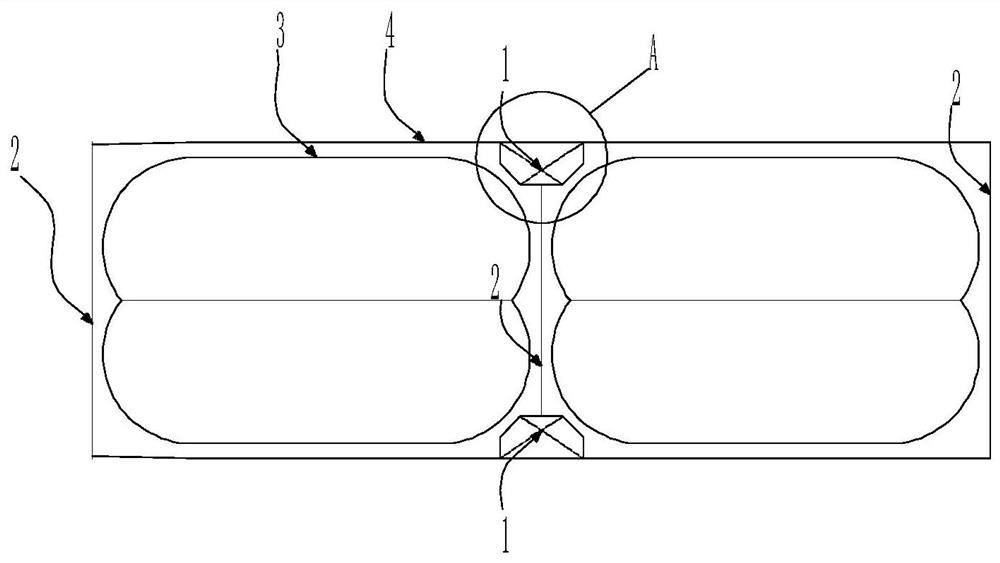

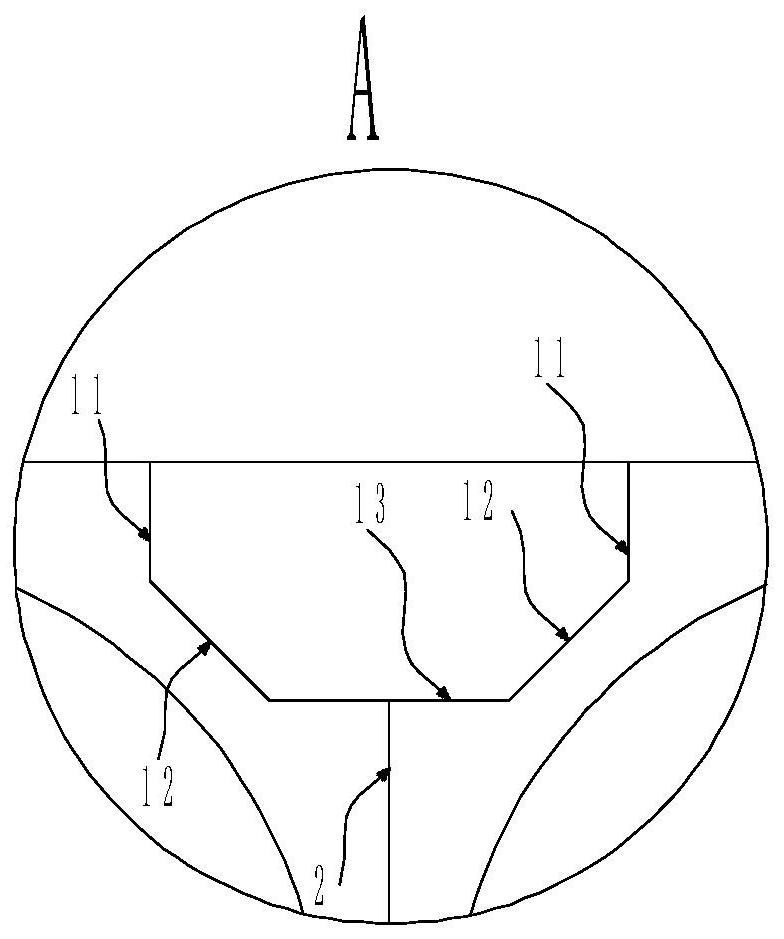

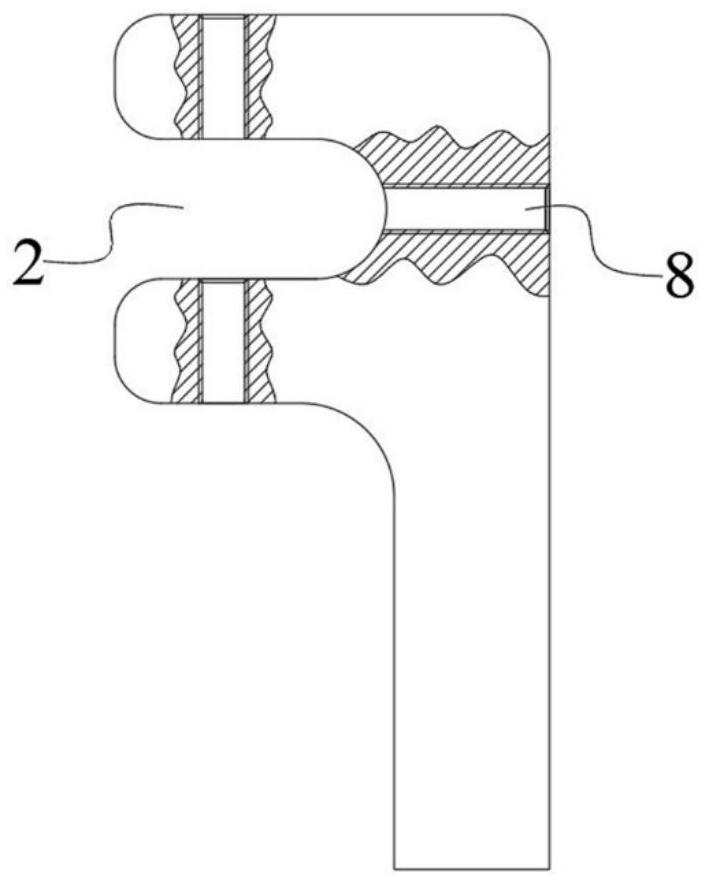

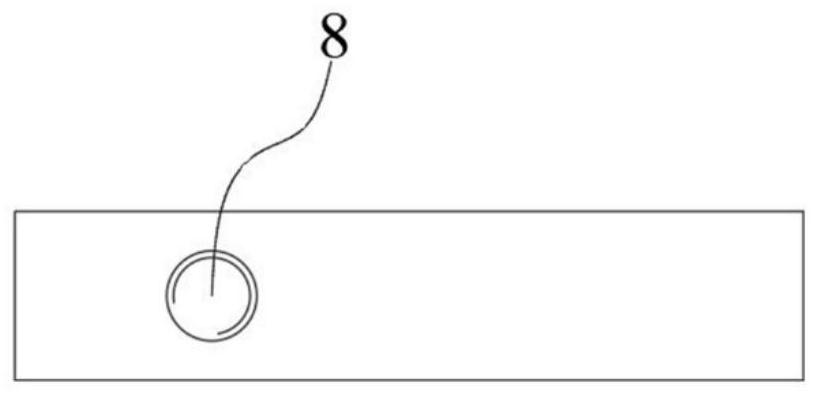

Duplex fuel oil filter

InactiveCN104083934AReduce shipbuilding costsSmall footprintMachines/enginesLiquid fuel feedersFuel oilBiochemical engineering

The invention discloses a duplex fuel oil filter which consists of a change-over valve core (3), a left cavity and a right cavity, wherein an operating handle (12) is arranged on the top of the change-over valve core (3); a filter body (1) and a filter cartridge (2) are arranged in each cavity; each filter cartridge (2) is sleeved with the corresponding filter body (1); a gland (6) is arranged at the upper end of each filter body (1); a pressing crossbar (8) is arranged on each gland (6); a compressed spring (4) is arranged in each filter body (1); the top end of each compressed spring (4) is fixed with the corresponding gland (6); each filter cartridge (2) is pressed on the corresponding filter body (1) through the bottom of the corresponding compressed spring. According to the duplex fuel oil filter provided by the invention, when one group of filters cannot work due to blockage, the other group of filters can be switched to work, so that the machine is not influenced by blockage of the filters, and the filters can be cleaned or replaced under the non-stop condition.

Owner:居国文

Leveling method for generating wave shapes on ship T-slipway panel and segmented free edge

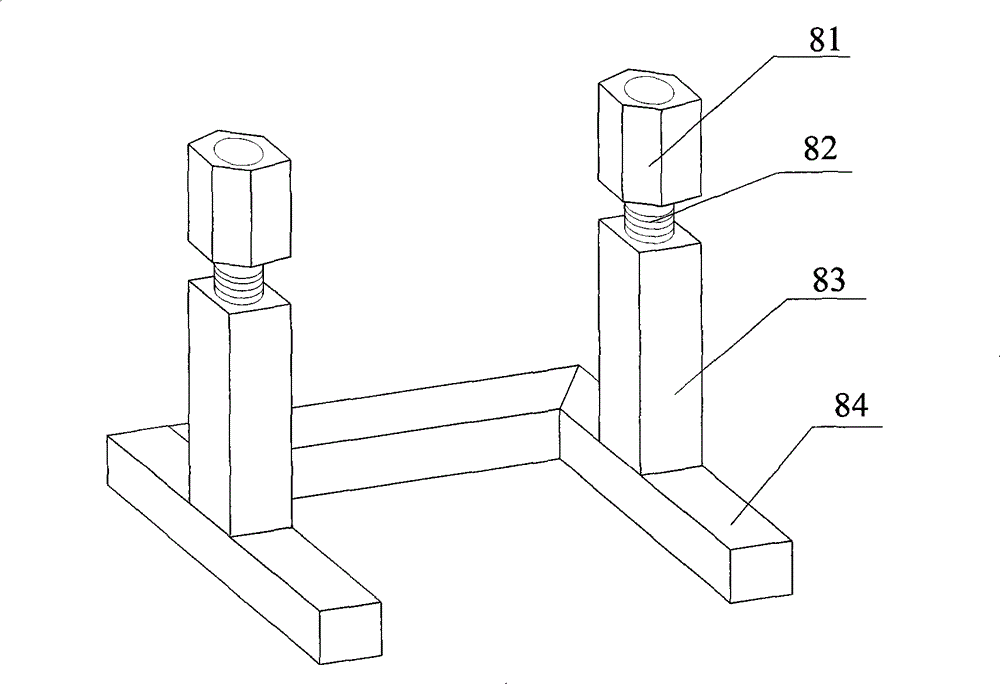

The invention discloses a leveling method for generating wave shapes on a ship T-slipway panel and a segmented free edge. The leveling method is based on a following device, and the device comprises two C-shaped portal main plates arranged in parallel, a cross beam, positioning screws and a jack; one end of each portal main plate is provided with a main plate inserting groove, and the other end of each portal main plate is provided with a cross beam hole; the two ends of the cross beam are arranged in the cross beam holes; and the positioning screw is in threaded connection with the portal main plates. The leveling method comprises the following steps that 1, the two portal main plates are inserted into the two sides of the position, needing to be leveled, of a product from the main plate inserting grooves, and the distance between the two portal main plates is determined according to the size of the wave shapes of the position, needing to be leveled, of the product; 2, positioning screws are tightened to fix the portal main plates; 3, the cross beam is inserted into the cross beam holes in the two portal main plates; and 4, the jack is placed between the cross beam and the leveling position.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

Welding method for stainless steel

ActiveCN107953016AShorten the shipbuilding cycleReduce shipbuilding costsArc welding apparatusWeld seamElectric arc

The invention belongs to the field of welding, and relates to a welding method for stainless steel. The welding method comprises the following steps of: step I, forming a groove which is a double-Y-shaped groove; step II, checking whether a gap between welding root parts meets 0 or not, and checking whether a stainless steel jointed board is staggered or not; step III, checking and cleaning a welding bead, and coating the two sides of the welding bead by saturated limewater, and grinding and clearing a welding seam; step IV, welding, wherein the root parts of the double-Y-shaped groove are firstly welded, welding current of the root parts is controlled to be 430-460 A, electric-arc voltage is 30-32V, welding speed is 28-30m / h, and heat input is 1.48-1.98 KJ / mm; and welding the groove; andstep V, checking reverse molding, and performing sealing run. The welding method can effectively shorten a ship building period, reduces ship building cost, and reduces energy consumption.

Owner:南通象屿海洋装备有限责任公司

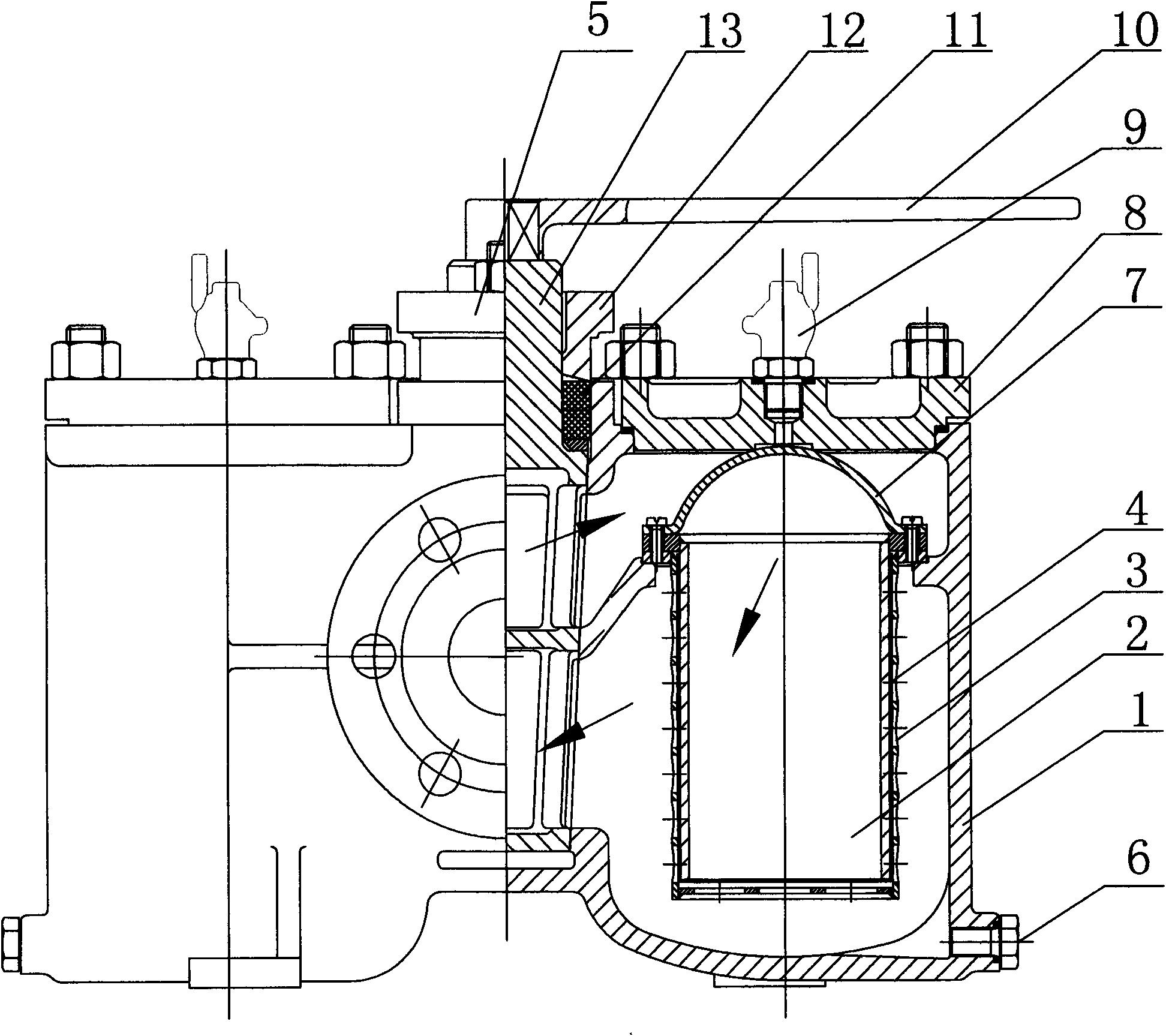

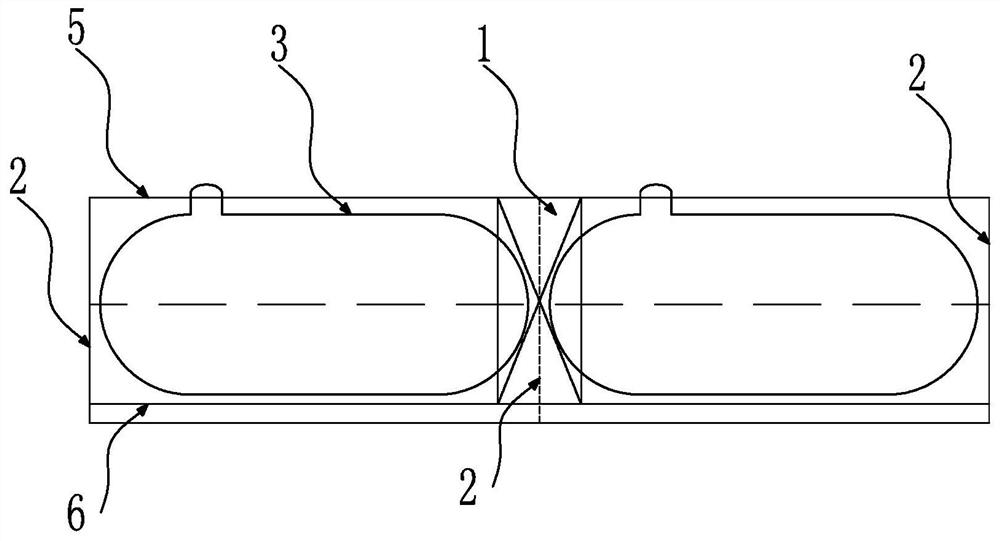

Duplex fuel/lubricating oil filter

InactiveCN102179100AAffect normal operationReduce shipbuilding costsStationary filtering element filtersOil filterWaste management

The invention discloses a duplex fuel / lubricating oil filter, which comprises a body (1). A left filter chamber and a right filter chamber are arranged in the body (1); a plug core seat (5) is arranged between the two filter chambers; a plug core (13) is arranged in the plug core seat (5); a handle (10) connected with the plug core (13) is arranged outside the plug core seat (5), and can control the rotation of the plug core (13); an upper chamber and a lower chamber are arranged in the plug core (13); the upper chamber is communicated with an inlet of a pipeline; the lower chamber is communicated with an outlet of the pipeline; one side of the upper chamber and one side of the lower chamber are sealed, and the other sides of the upper and lower chambers are provided with channels communicated with the filter chambers; a filter cartridge (2) is arranged in the filter chambers; the inlet port of the filter cartridge (2) is communicated with the upper chamber of the plug core (13); and the inflow port of the filter cartridge (2) is communicated with the lower chamber of the plug core (13). The invention provides a duplex fuel / lubricating oil filter, which can ensure that the filter is cleaned or replaced under the condition of no halt.

Owner:张晓荣

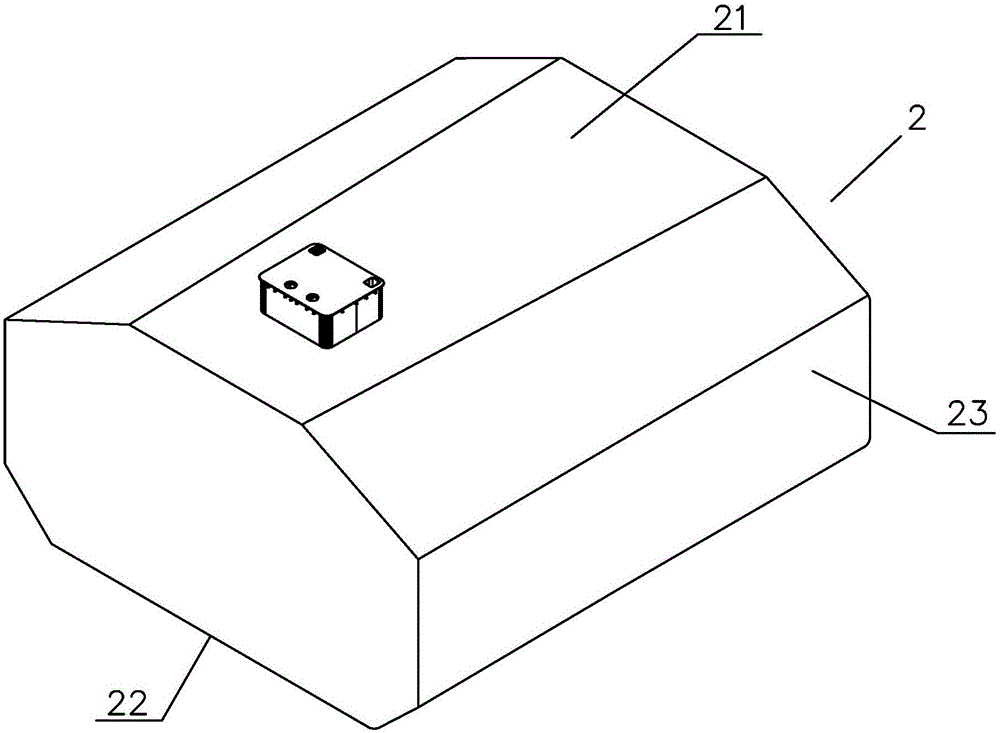

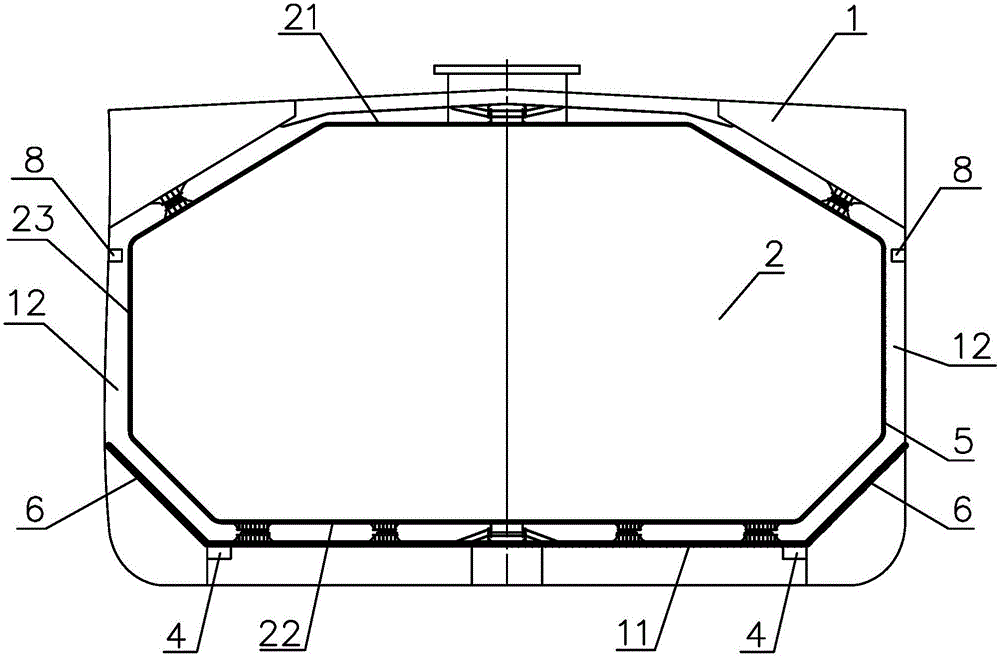

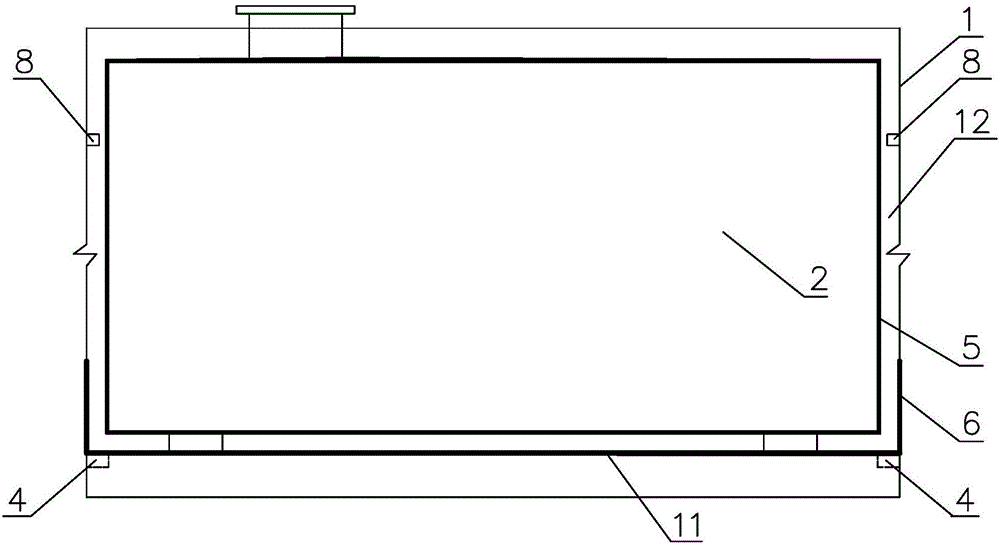

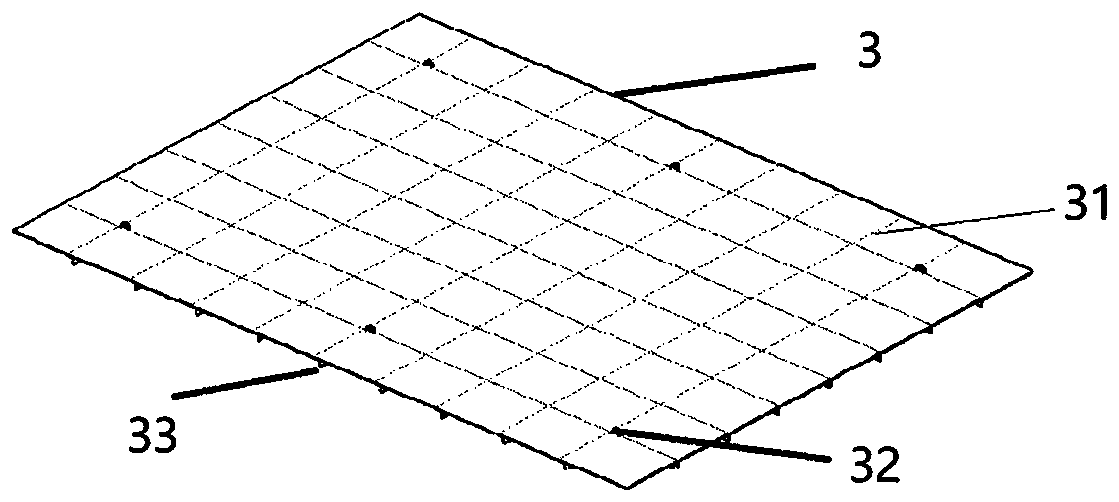

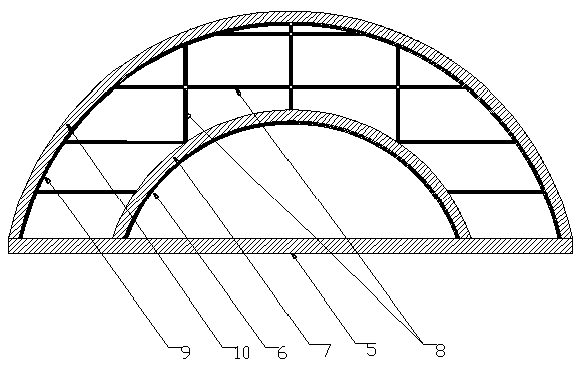

Rhombus-shaped isolated void compartment structure of liquefied gas ship

ActiveCN111409776BReduce damage and water ingressImproving residual capability of damage stabilityHull interior subdivisionFor bulk goodsCofferdamMechanical engineering

The invention belongs to an isolation void structure of a liquefied gas ship in the field of ship layout in the field of shipbuilding. The technical proposal is: the isolation void is arranged between two liquid cargo tanks, respectively located on both sides of the transverse bulkhead and outside the isolation void It is connected with the outer plate of the hull, so that the outer plate of the hull forms the outer wall of the isolation void; the upper part of the isolation void is connected with the main deck, so that the top of the main deck forms the isolation void, and the lower part of the isolation void is connected with the inner bottom, so that the inner bottom forms an isolation void. The bottom of the cabin; the inner wall of the cofferdam is enclosed by two transverse walls, two oblique walls and one longitudinal wall. One side of the wall is butted with the outer plating of the hull, and the longitudinal bulkhead is butted with the transverse bulkhead; there is a gap between the inner wall and the cargo tank. Adopting this technology can reduce the angle of inclination when the ship is damaged, and improve the safety of the ship. While improving the damage stability of the ship, it not only reduces the steel consumption but also improves the energy efficiency level of the ship.

Owner:JIANGNAN SHIPYARD GRP CO LTD

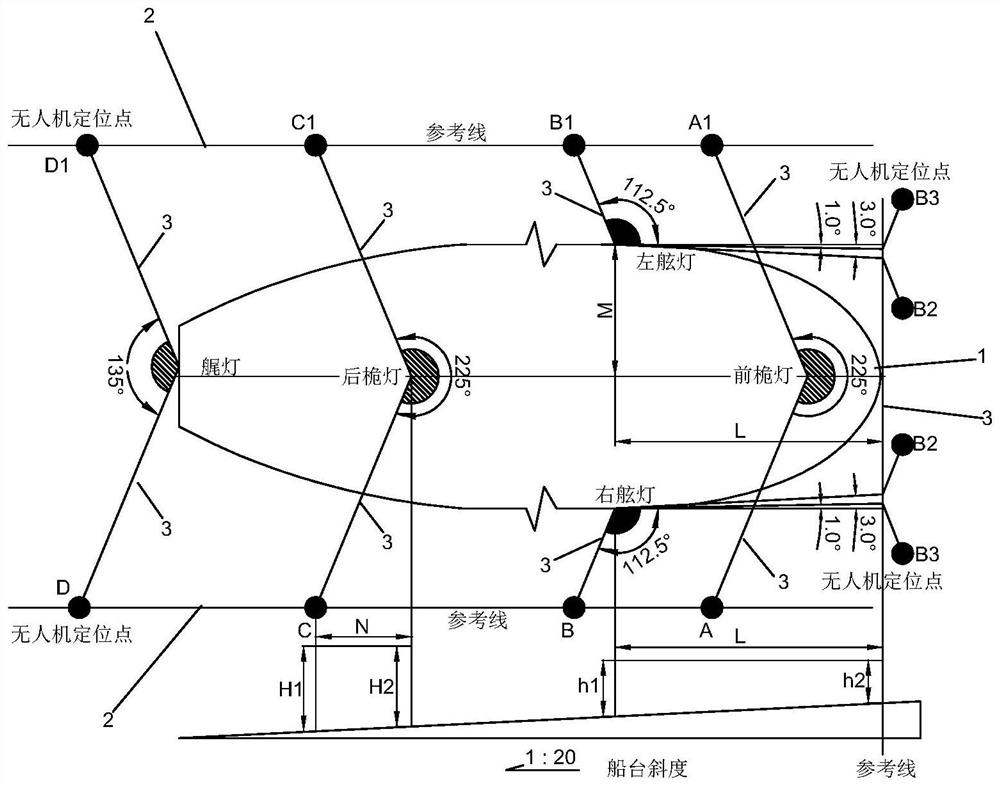

Ship navigation signal lamp inspection method based on unmanned aerial vehicle

PendingCN113848501AShorten the sea trial periodReduce security risksRemote controlled aircraftLamps testingUncrewed vehicleMechanical engineering

A ship navigation signal lamp inspection method based on an unmanned aerial vehicle comprises the steps that reference lines at the two sides of a ship are drawn at the specific position of the ship under construction; the intersection point of the angle line and the reference line is the horizontal projection position of the unmanned aerial vehicle, the intersection points are drawn on the corresponding ground according to on-site lofting, and the intersection points A, A1, B, B1, B2, B3, C, C1, D and D1 are determined; the height value of each intersection point is determined according to the actual height of the navigation signal lamp; the intersection point and the height value are the accurate position of the unmanned aerial vehicle in the signal lamp inspection process; and a ship navigation signal lamp is turned on, the unmanned aerial vehicle is operated by a remote controller and flies to a pointed position, the angle adjustment position of the navigation signal lamp is determined through a video, the angle of the navigation signal lamp is adjusted according to the position of the unmanned aerial vehicle until the critical irradiation angle line of the navigation signal lamp coincides with the unmanned aerial vehicle, and the standard of qualified inspection is met. The unmanned aerial vehicle is used for inspection, and the method has the advantages of being high in efficiency, easy to operate, low in cost and high in safety.

Owner:COSCO ZHOUSHAN SHIPYARD

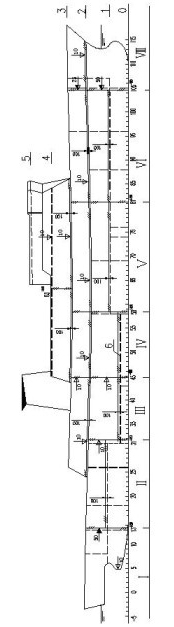

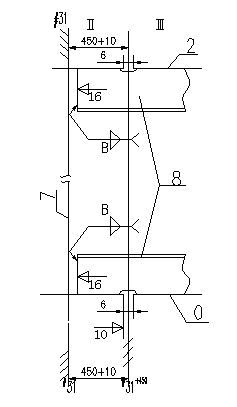

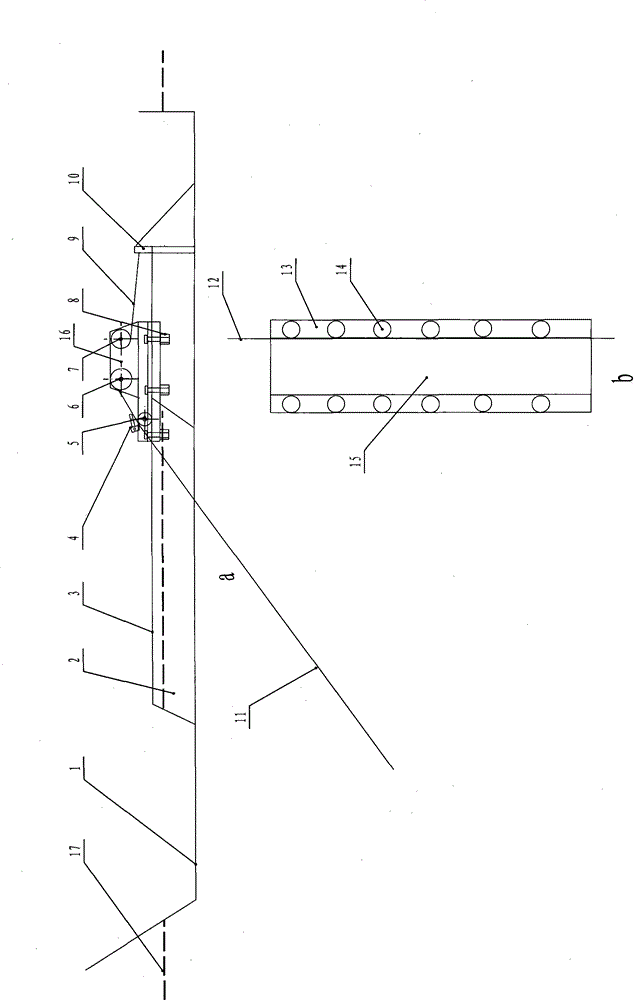

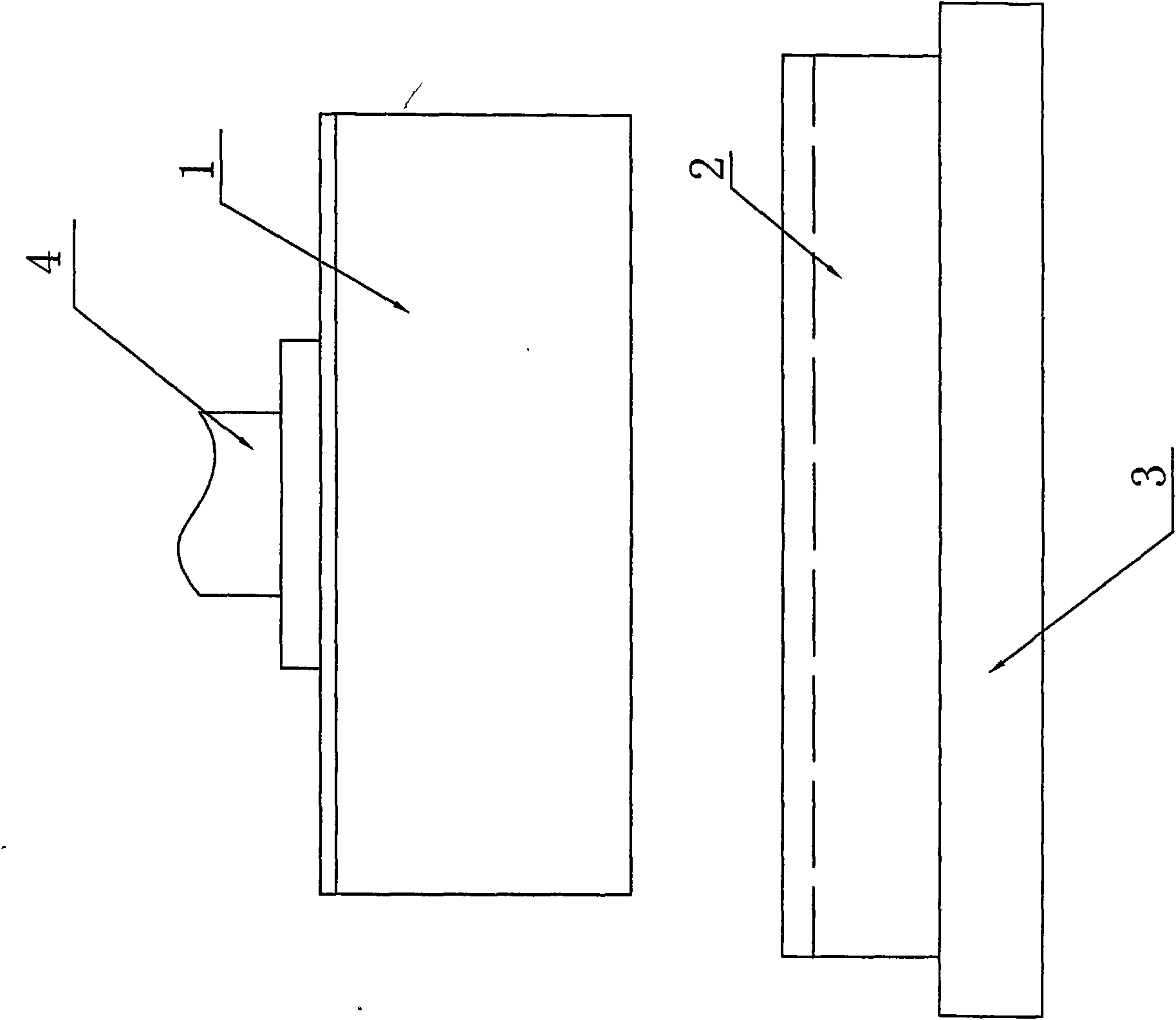

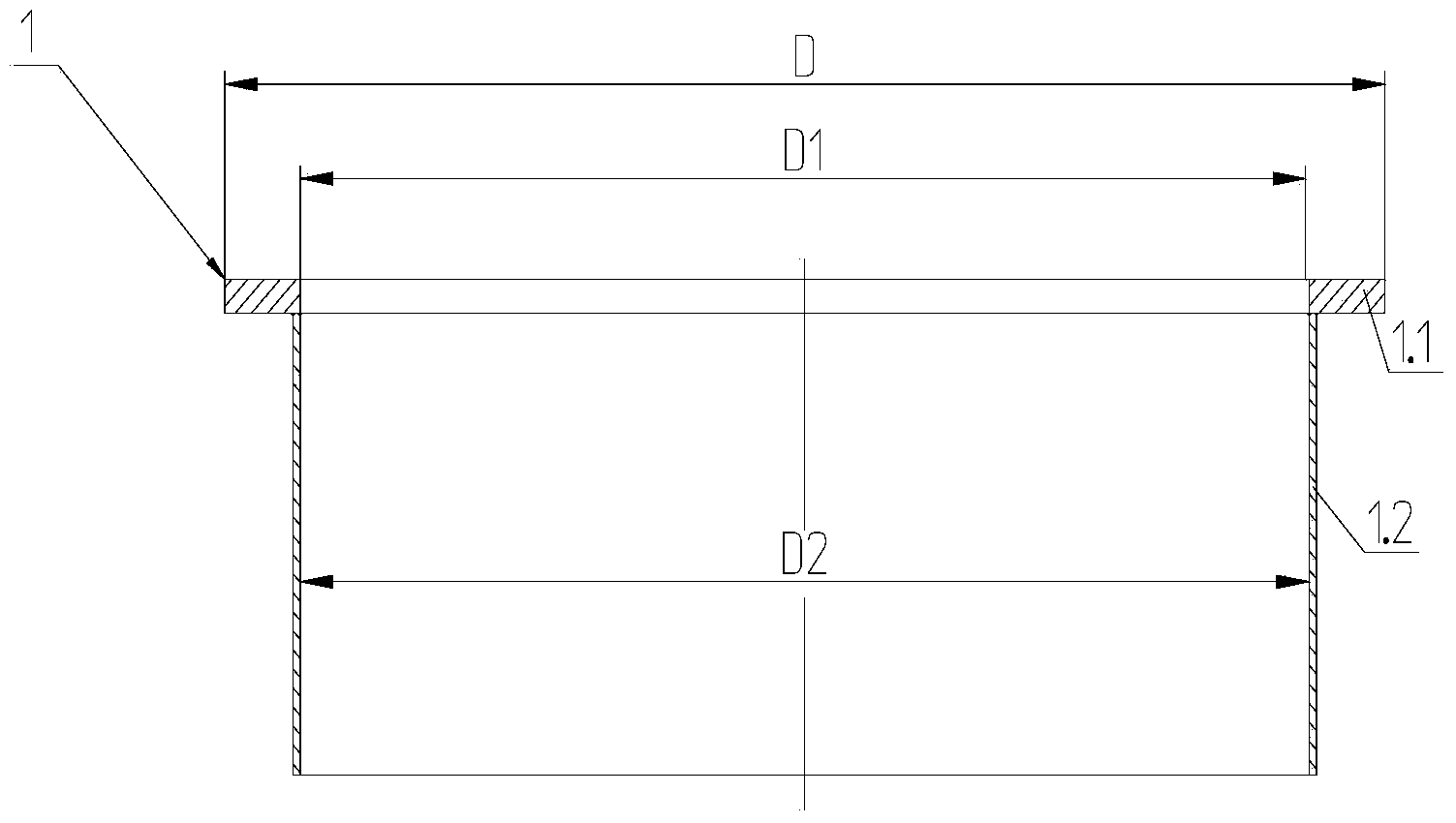

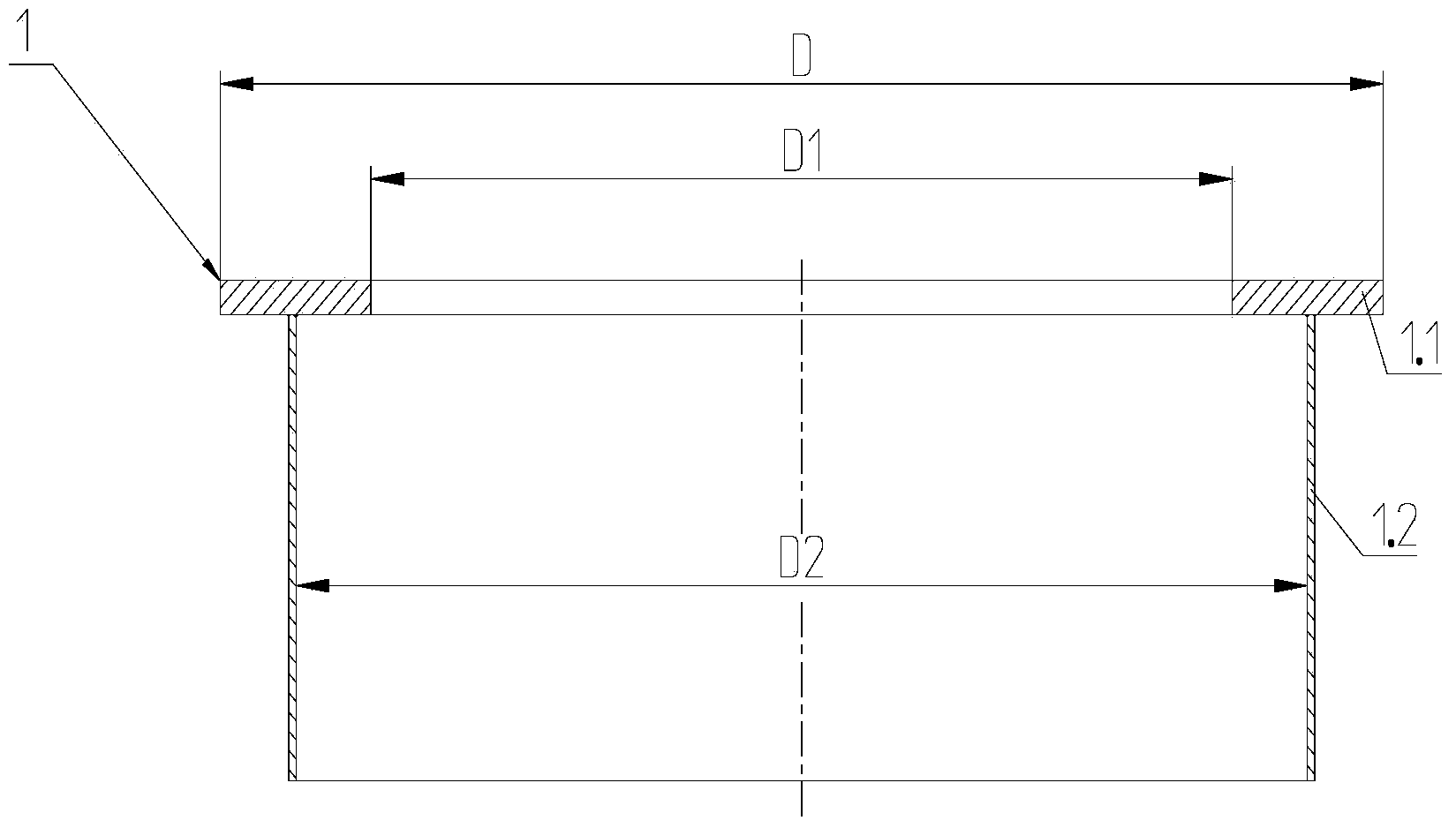

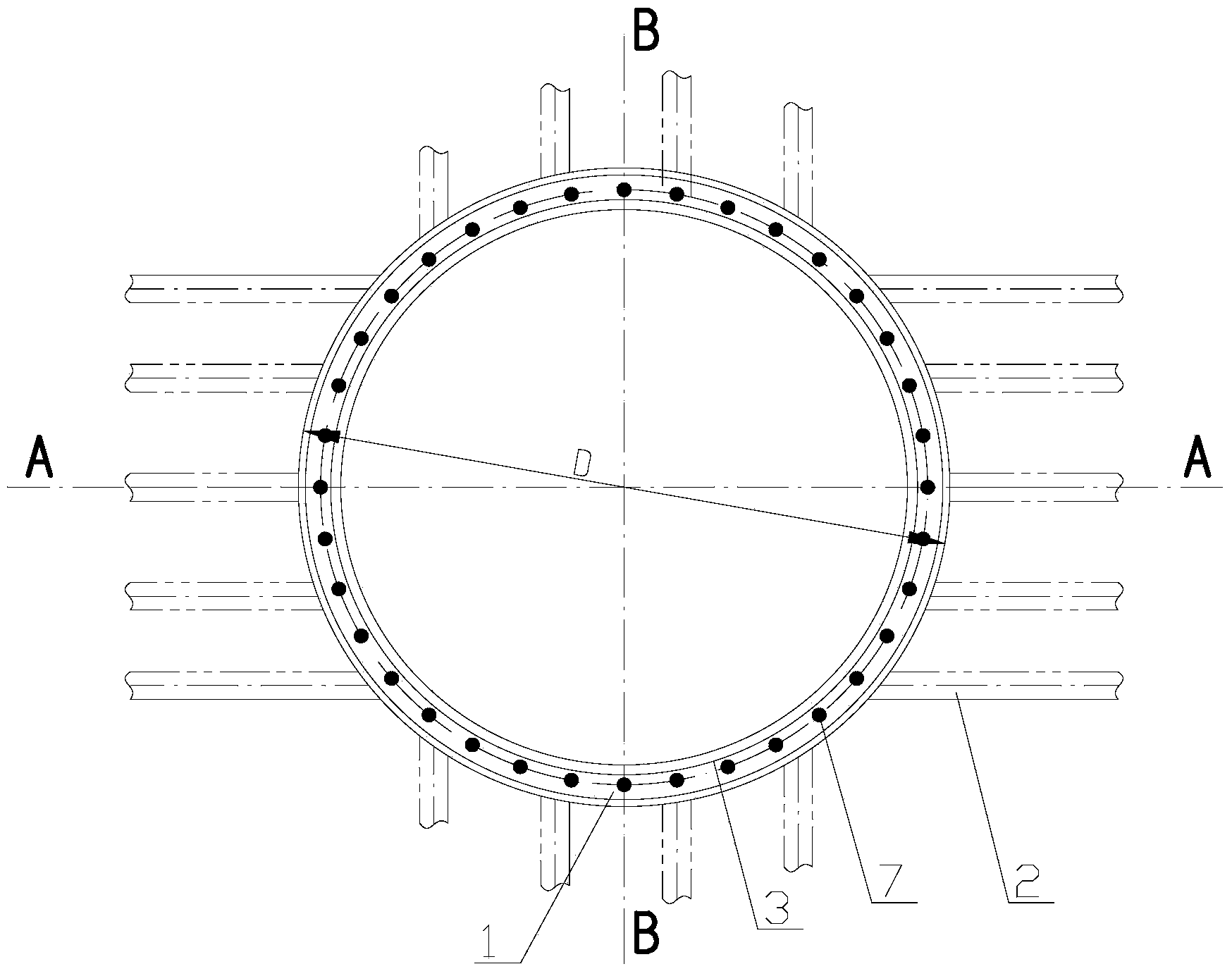

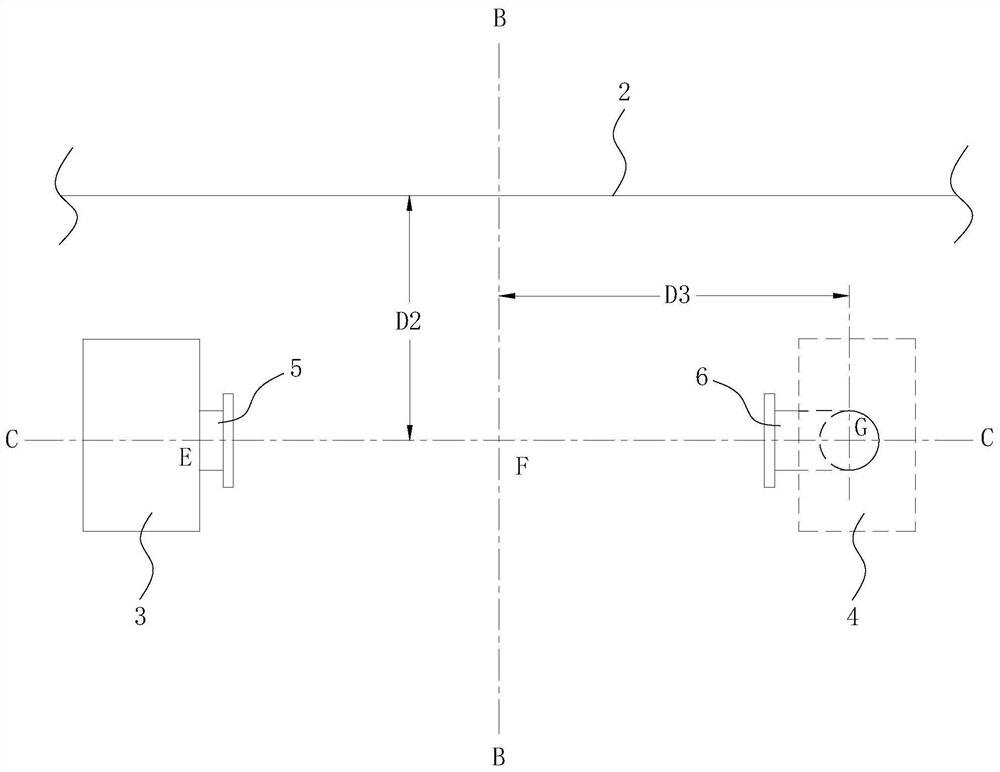

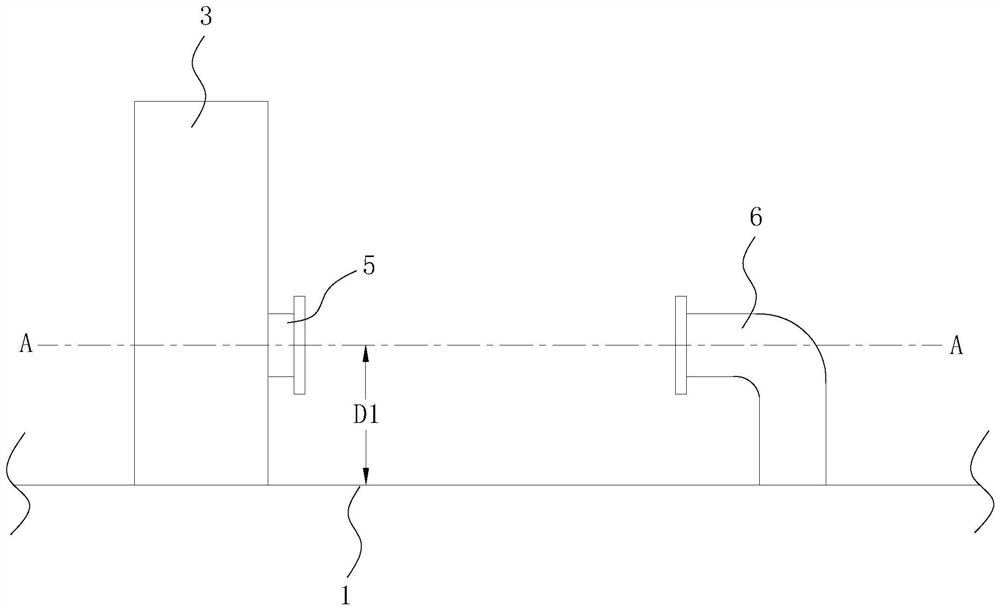

Full rotation steering oar device installation method

ActiveCN102923252BImprove installation qualityImprove ergonomicsVessel partsMarine engineeringFlange

The invention discloses a full rotation steering oar device installation method. A hull base of a full rotation steering oar which is installed in a trunk flange mode is cut into tapered unit bodies (indicated as the figure). The tapered unit bodies are transported to a workshop and high-precision mounting matching surfaces, screw holes and seal ring grooves are machined on the tapered unit bodies through a large vertical lathe. Next, the machined tapered unit bodies are lifted on a ship and replaced according to cutting steel marks and then the steering oar is installed so as to meet the requirement for shafting layout design, installation quality of the steering oar and sealing reliability. The full rotation steering oar device installation method abandons a traditional construction method, is labor-saving and effort-saving, improves work efficiency, and saves expensive tooling equipment investment. Secondly, the machined tapered unit bodies can be assembled with the steering oar, and then lifted on the ship and carries out replacement and installation. Installation quality and work efficiency of the steering oar are further improved and requirements of modern shipbuilding are met.

Owner:湖南湘船重工有限公司

Transformation method for transforming roll-on-roll-off ship into inland river large-piece transport ship

The invention discloses a transformation method for transforming a roll-on-roll-off ship into an inland river large-piece transport ship. The method comprises the following steps: assembling a forecastle of a left board piece body and a right board piece body at the bow end or the stern end, wherein the height of the forecastle is larger than or equal to 8 m, the distance between the forecastle and the outer edge of the bow end or the stern end is L1, and the forecastle is of a door type structure; disassembling the middle driving building of the roll-on-roll-off ship in a segmented mode; hoisting the detached middle driving building section to the forecastle, and performing mounting to form a side driving building; and arranging an anchoring platform and a mooring platform on the bow and the stern respectively, and keeping enough height between the mooring platform and a main deck so as to meet the requirement for arranging a bow chain locker, wherein an anchor chain can enter and exit from the chain locker smoothly during anchoring and weighing. An existing roll-on-roll-off ship is transformed into the inland river large-piece transport ship, an inland river large-piece transport ship berthing wharf does not need to be built again, large-piece transport can be completed through an existing roll-on-roll-off ship wharf, the problem of inland river large-piece transport is solved, and the shipbuilding cost is effectively reduced.

Owner:宜昌一凡船舶设计有限公司

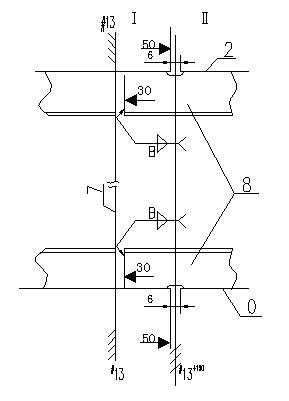

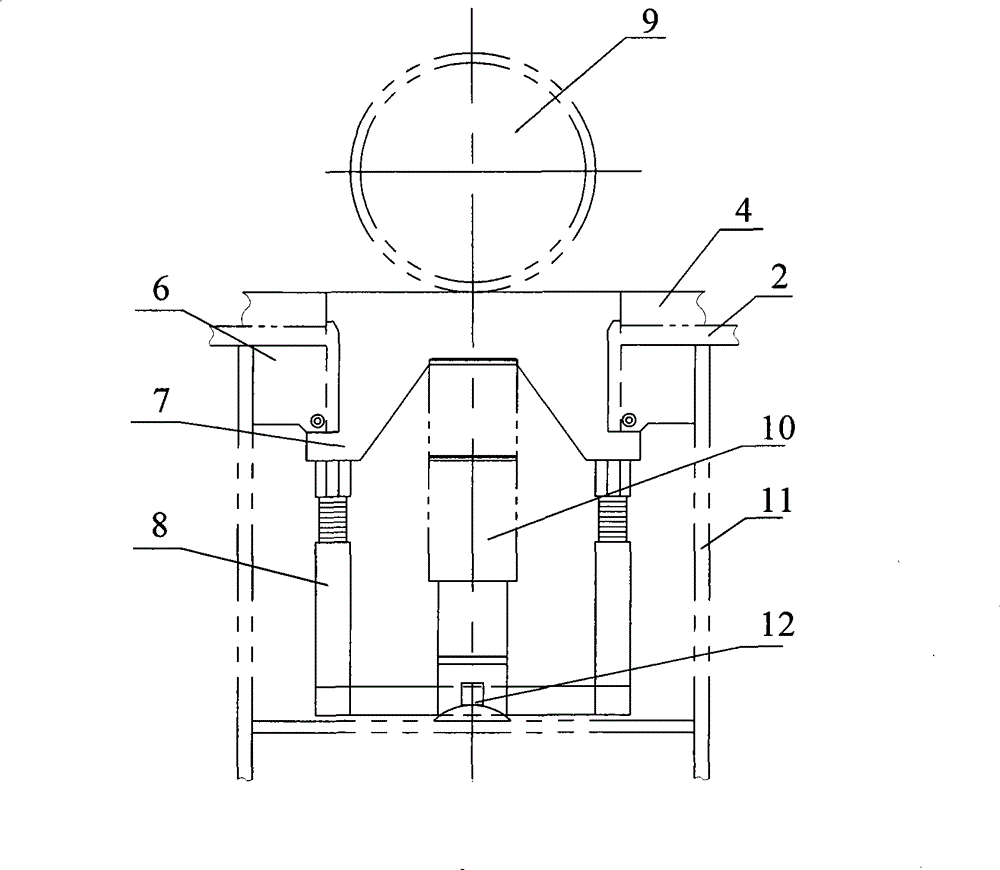

Deck track positioning tool and deck track laying method

ActiveCN110576943BReduce lossShorten the timeCargo handling apparatusPassenger handling apparatusMarine engineeringOrbit

The invention relates to a deck track positioning tool and a deck track laying method. The method includes the following steps: determining the positioning reference line and determining the center line of the track; marking the position of each adjustment pad on the positioning reference line; respectively fixing a plurality of positioning tooling along both sides of the positioning reference line; and adjust the track centerline of the deck track to be parallel to the positioning reference line through each positioning bolt; measure the distance between the bottom of the deck track and the deck at the position of each adjustment pad, and make corresponding distances according to the measured distances. Adjust the spacers; fix the produced spacers in the corresponding positions of the spacers, and fix the spacers with the deck rails; remove the positioning fixtures. The laying method of the present invention avoids the need to use thicker deck steel, reduces the loss of the deck plate, and does not need to carry out pyrotechnic correction on the deck steel, saves time and cost, and improves the laying efficiency.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Seawater tank flange short pipe installation method

ActiveCN110371241BImprove outfitting integrityImprove pre-outfitting rateVessel designingMarine engineeringStructural engineering

The invention discloses a method for installing short flange pipes of seawater tanks, which comprises the following steps: firstly, providing a general section of a ship, including an inner bottom plate, a transverse bulkhead perpendicular to the inner bottom plate, a high-level seawater tank, a low-level seawater tank, and a high-level seawater tank. blue short pipe and low flange short pipe, the high seawater tank is located above the inner bottom plate, and the low seawater tank is located below the inner bottom plate; then, the first opening for the high flange short pipe to communicate with the high seawater tank is opened on the high seawater tank , open a second opening on the inner bottom plate for the short flange tube to pass through and communicate with the low sea tank, adjust the short flange tube and the short flange tube to the preset installation position, and then weld and fix the high flange The short pipe and the low flange short pipe complete the installation. The invention completes the installation of the short flange pipe of the seawater tank in the construction stage of the general section through high-precision positioning of the short flange pipe. The construction difficulty is small and the efficiency is high, which provides a strong guarantee for shortening the dock cycle and saves shipbuilding costs.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Special support tooling for installing translational hatch cover of bulk carrier and installation method thereof

ActiveCN101857067BGuaranteed installation qualityReasonable useVessel partsProcess engineeringIndustrial engineering

Owner:JIANGNAN SHIPYARD GRP CO LTD

Accuracy control method for container ship lashing system free from actual ship test

ActiveCN110182312BWill not cause interferenceAvoid real ship lashing testsAccommodation for deck loadsVessel designingMarine engineeringClassical mechanics

The invention discloses a precision control method for the lashing system of a container ship which is free from actual ship test. The theoretical distance between the foot and the lashing eye plate in the corresponding lashing bridge is compared with the measured distance, and the actual margin value of the lashing parts in the real ship is calculated, and the actual margin value of the lashing parts is always greater than the allowable minimum margin value by controlling , to realize that all the lashing eye panels on the ship meet the requirements, and will not cause interference between adjacent lashing parts, thereby effectively avoiding actual ship lashing tests, reducing shipbuilding costs, and shortening the shipbuilding cycle.

Owner:DALIAN COSCO KHI SHIP ENG

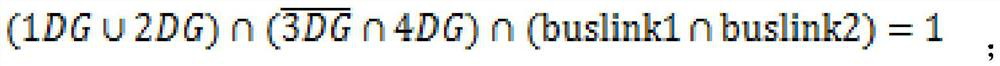

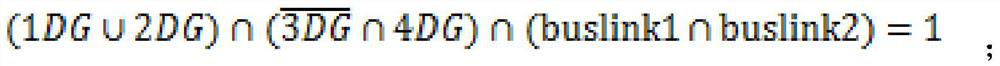

Low-voltage power supply and distribution method under ship critical power station capacity

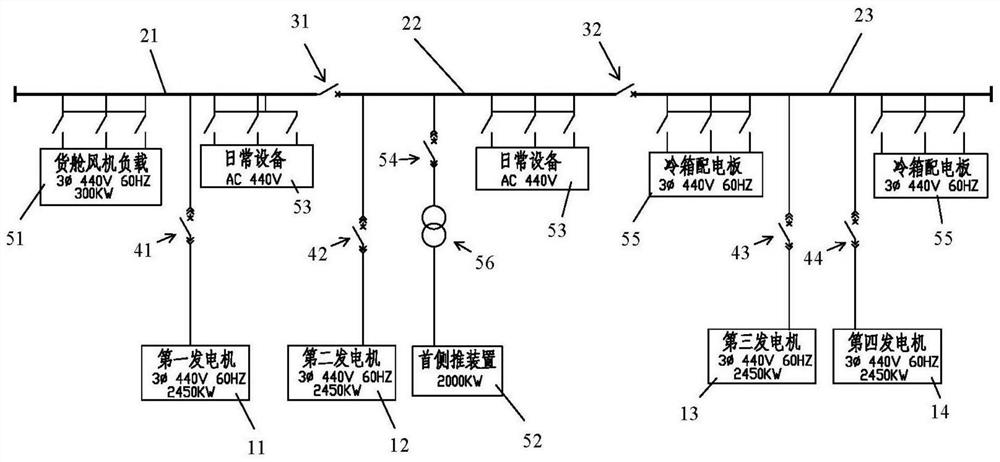

PendingCN113162036AEasy to operateGuaranteed continuityAuxillariesVessel ventillation/heating/coolingPower stationBusbar

The invention discloses a low-voltage power supply and distribution method under a ship critical power station capacity. Four generators are arranged in a power station, a first busbar, a second busbar and a third busbar are arranged in the power station, the first busbar and the second busbar are respectively connected with one generator, and the third busbar is connected with two generators; the first busbar and the second busbar are connected through a first interconnection switch, and the second busbar and the third busbar are connected through a second interconnection switch; the power station supplies power to a plurality of conventional loads and specific loads; the conventional loads are connected to the first busbar or the second busbar; the specific load is connected to the third busbar; and the first interconnection switch is switched on, and the second interconnection switch is switched off. The maximum short-circuit capacity of the system can be effectively reduced, regional power supply is carried out on the load, and the power supply continuity of the power system is ensured.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com