Duplex fuel/lubricating oil filter

A technology of fuel lubricating oil and filter, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc. It can solve the problems of increasing shipbuilding costs, temporary use, and not worth advocating, so as to reduce the occupied space and reduce the cost of shipbuilding. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

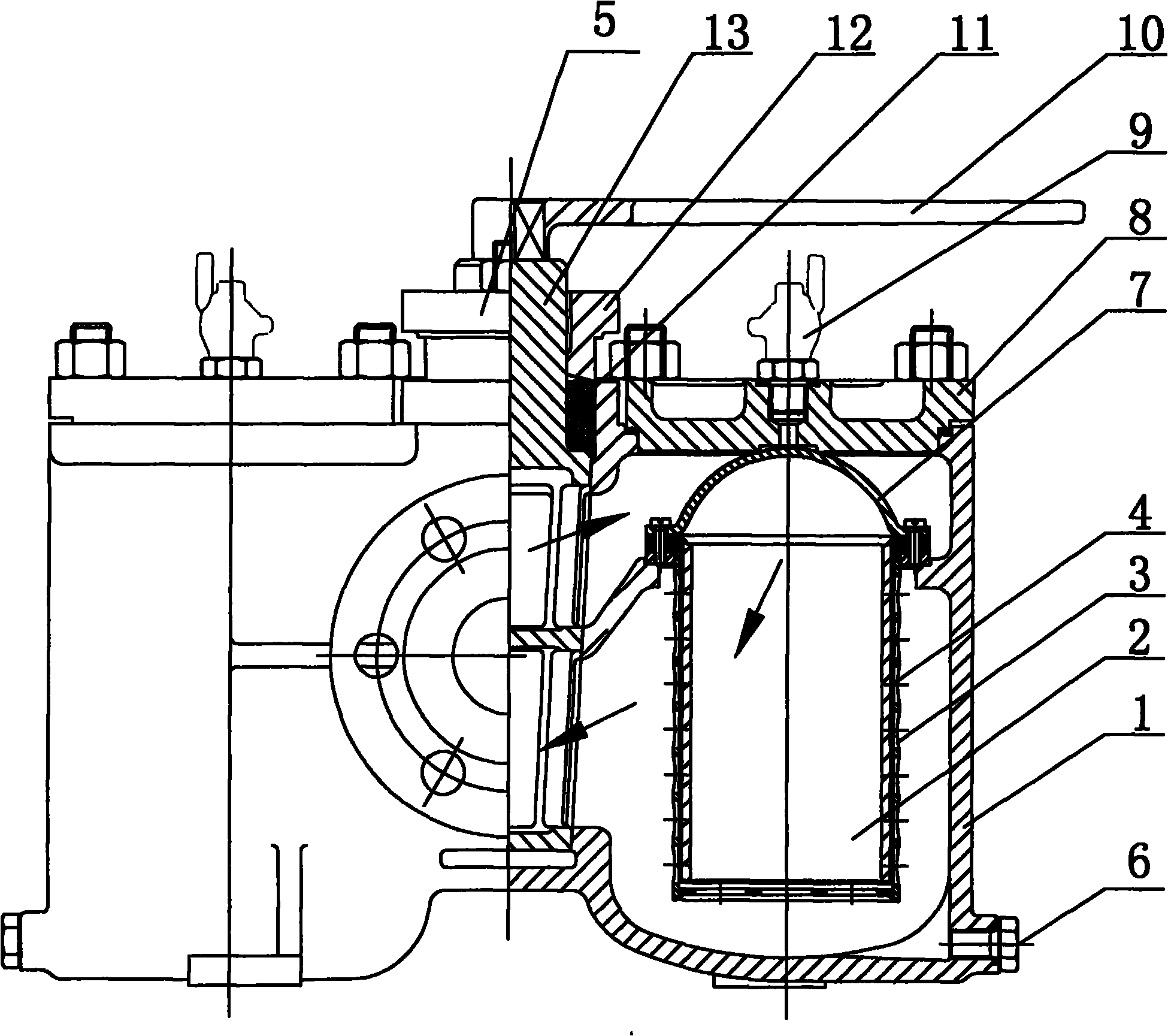

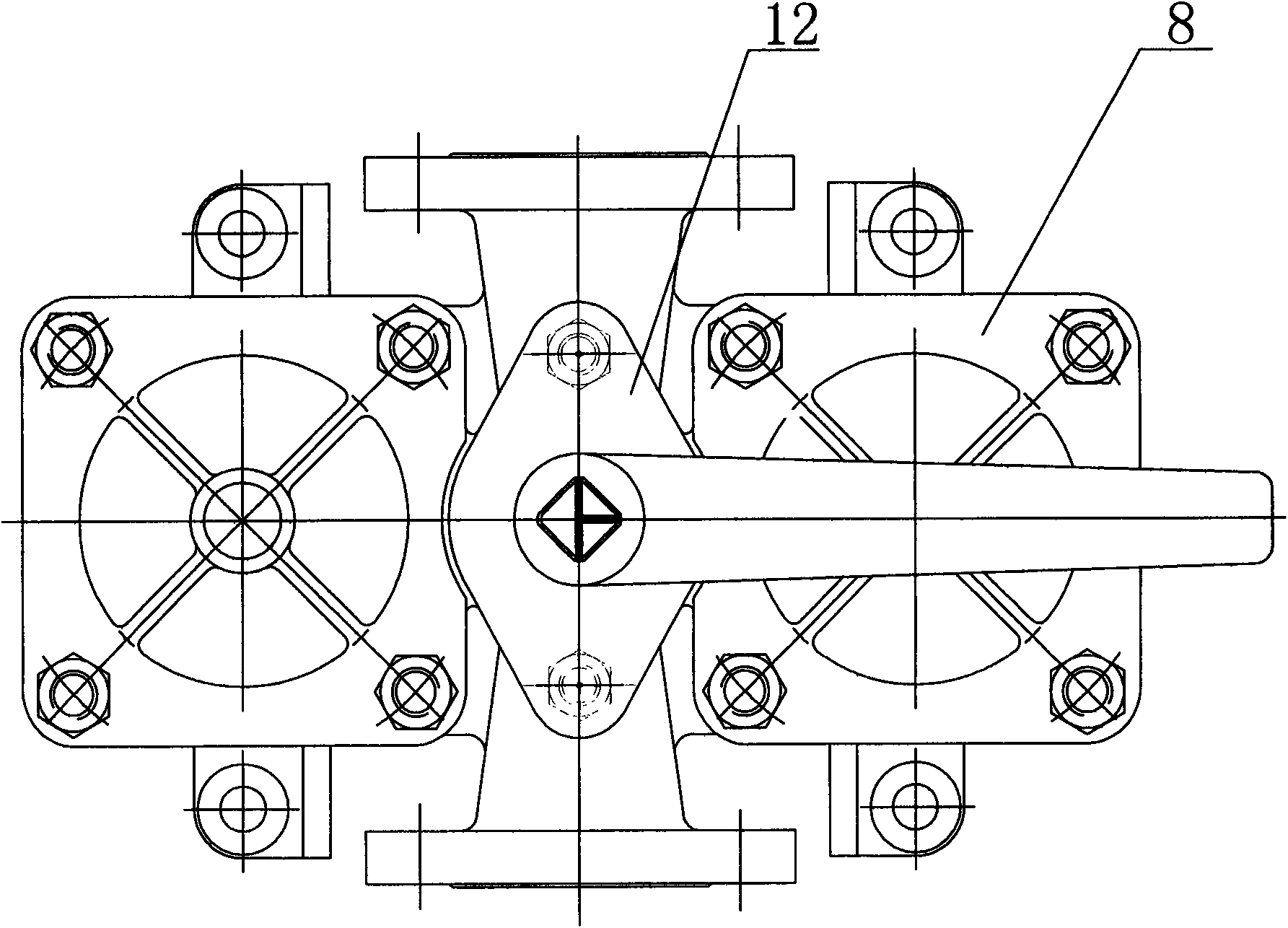

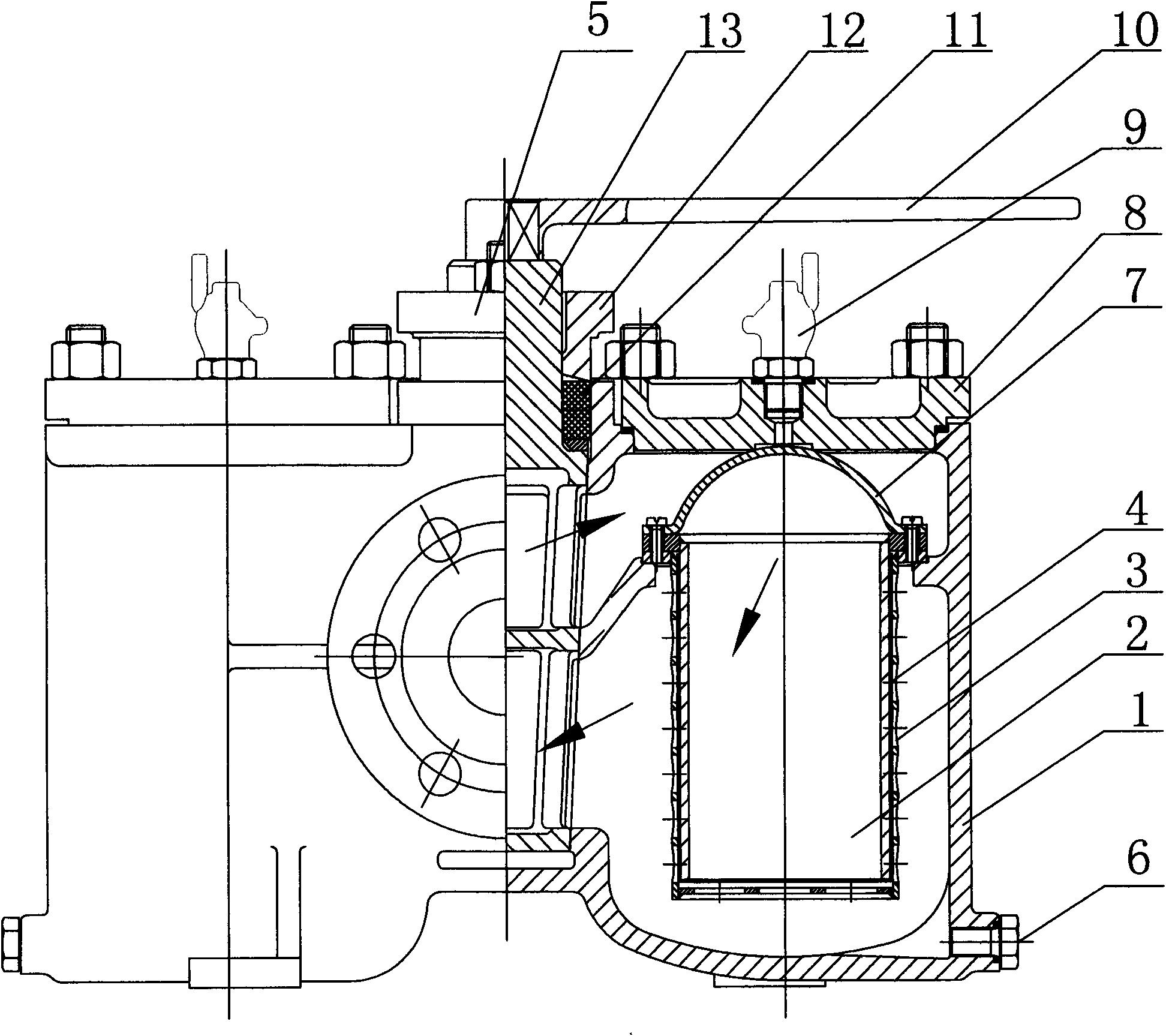

[0009] Such as figure 1 and figure 2 As shown, a duplex fuel oil filter, which includes a body 1, is provided with two left and right filter chambers in the body 1, and a cover plate 8 is provided on the top of the filter chamber, and an air release valve is provided on the cover plate 8 9. There is a drain screw plug 6 at the bottom of the filter chamber. A cork seat 5 is arranged between the two filter chambers, and a cork 13 is arranged in the cork seat 5, and a packing gland 12 is provided between the cork seat 5 and the cork 13, and the packing gland 12 will soak the oil filler 11 is filled between the cork seat 5 and the cork 13, and a handle 10 connected with the cork 13 is provided outside the cork seat 5, and the rotation of the cork 13 can be controlled by the handle 10. The plug core 13 is provided with upper and lower chambers, the upper chamber communicates with the inlet of the pipeline, the lower chamber communicates with the outlet of the pipeline, one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com