Longitudinal and horizontal two-way band saw cutting machine for waste slag cement foamed slabs or building blocks

A saw cutting machine and horizontal cutting technology, which is applied in the field of vertical and horizontal two-way band saw cutting machines, can solve the problems of easy-to-break cutting, large power consumption, and difficult to grasp cutting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

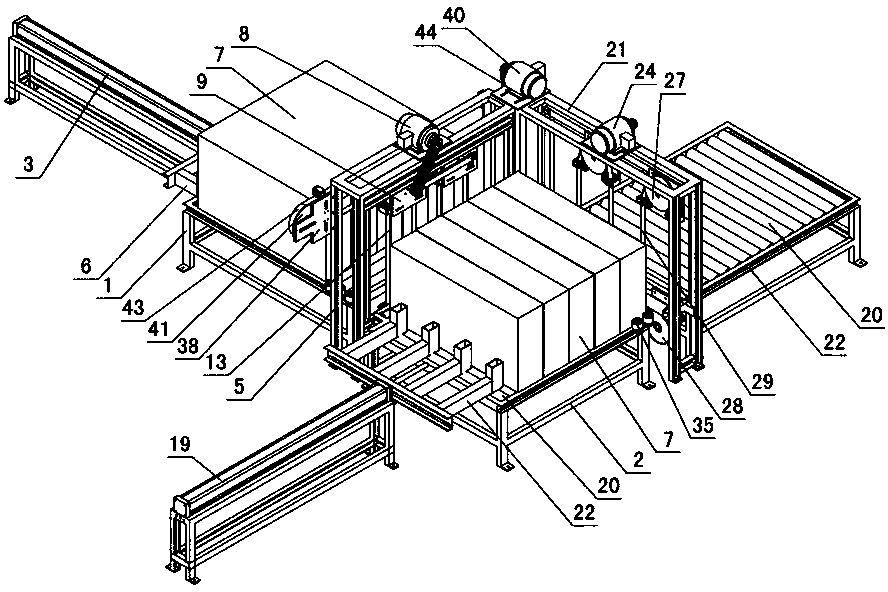

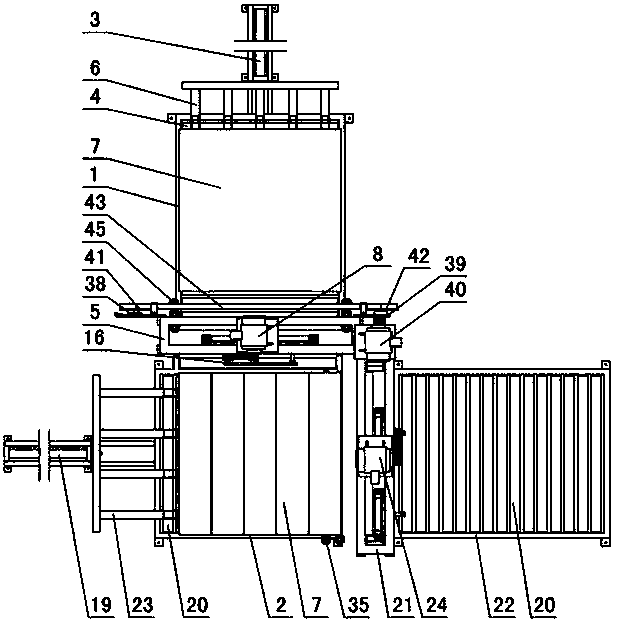

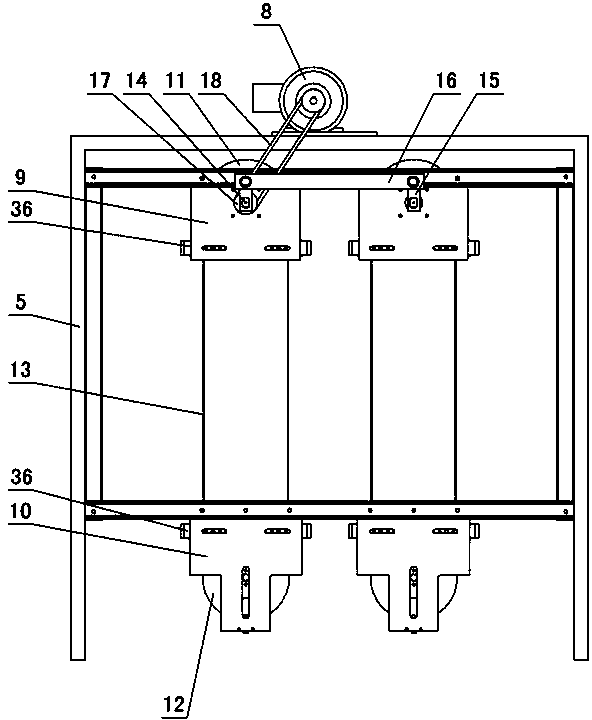

[0015] The invention relates to a vertical and horizontal two-way band saw cutting machine for waste slag cement foam strips or blocks, such as figure 1 — Figure 8As shown, it is characterized in that: it includes a transverse frame 1 and a longitudinal frame 2, and a transverse push cylinder 3, a transverse roller 4, and a transverse cutting frame 5 are installed on the transverse frame, and the piston rod of the transverse push cylinder is connected with a transverse push claw 6, and the transverse push claw Cooperate with the embryo body 7 on the horizontal drum, the first motor 8 is installed on the horizontal cutting frame 5, and the horizontal upper fixed plate 9 and the horizontal lower fixed plate 10 are installed in the horizontal cutting frame, and the horizontal upper fixed plate and the horizontal lower fixed plate are two More than one group, horizontally upper power wheel 11 is set in the horizontally upper fixed plate, horizontally lower power wheel 12 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com