Low NOx coal dust combustion method and device based on underfire air and overfire air

A technology of pulverized coal combustion and burn-out wind, which is applied in the combustion method, combustion using lump fuel and liquid fuel, combustion using lump fuel and gaseous fuel, etc. Large investment and other problems, to achieve the effect of prolonging the stay time and implementing convenient and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

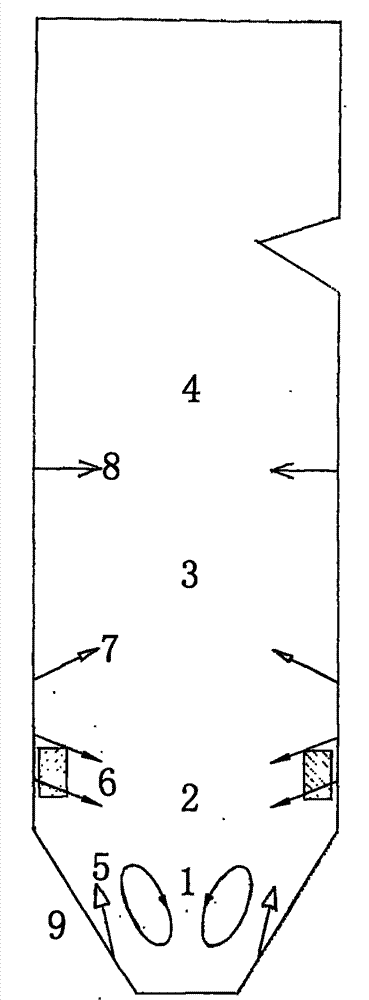

[0021] The low NOx pulverized coal combustion method based on downfire wind and overfire air is implemented on the main burner of industrial boilers in power plants, such as figure 1 shown. The improved boiler divides the furnace from bottom to top into four parts: low-temperature oxidation zone 1, reduction zone 2 at the initial stage of ignition, late reduction zone 3 and burnout zone 4.

[0022] During the application process, the following methods for reducing nitrogen oxides are adopted:

[0023] (1) The main fuel 6, which accounts for 70% to 80% of the total fuel calorific value, is sprayed obliquely downward into the furnace, and the fuel is pyrolyzed under the reducing atmosphere of the reduction zone 2 at the initial stage of ignition, and the volatile NO x Formation;

[0024] (2) 20% to 40% of the hot air is used as the downwind o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com