Patents

Literature

34 results about "Industrial fire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An Industrial fire is a type of industrial disaster involving a conflagration which occurs in an industrial setting. Industrial fires often, but not always, occur together with explosions. They are most likely to occur in facilities where there is a lot of flammable material present. Such material can include petroleum, petroleum products such as petrochemicals, or natural gas. Processing flammable materials such as hydrocarbons in units at high temperature and/or high pressure makes the hazards more severe. Facilities with such combustible material include oil refineries, tank farms (oil depots), natural gas processing plants, and chemical plants, particularly petrochemical plants. Such facilities often have their own fire departments for firefighting. Sometimes large amounts of dust or powder are vulnerable to combustion and their ignition can cause dust explosions. Severe industrial fires have involved multiple injuries, loss of life, costly financial loss, and/or damage to the surrounding community or environment.

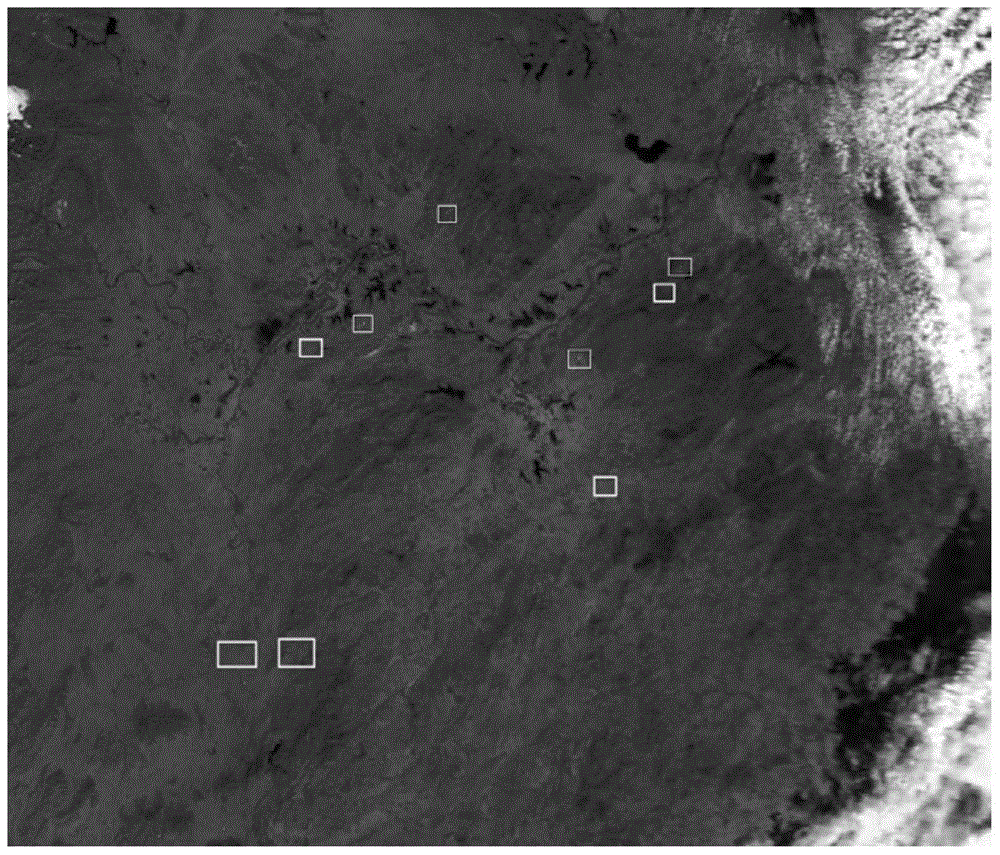

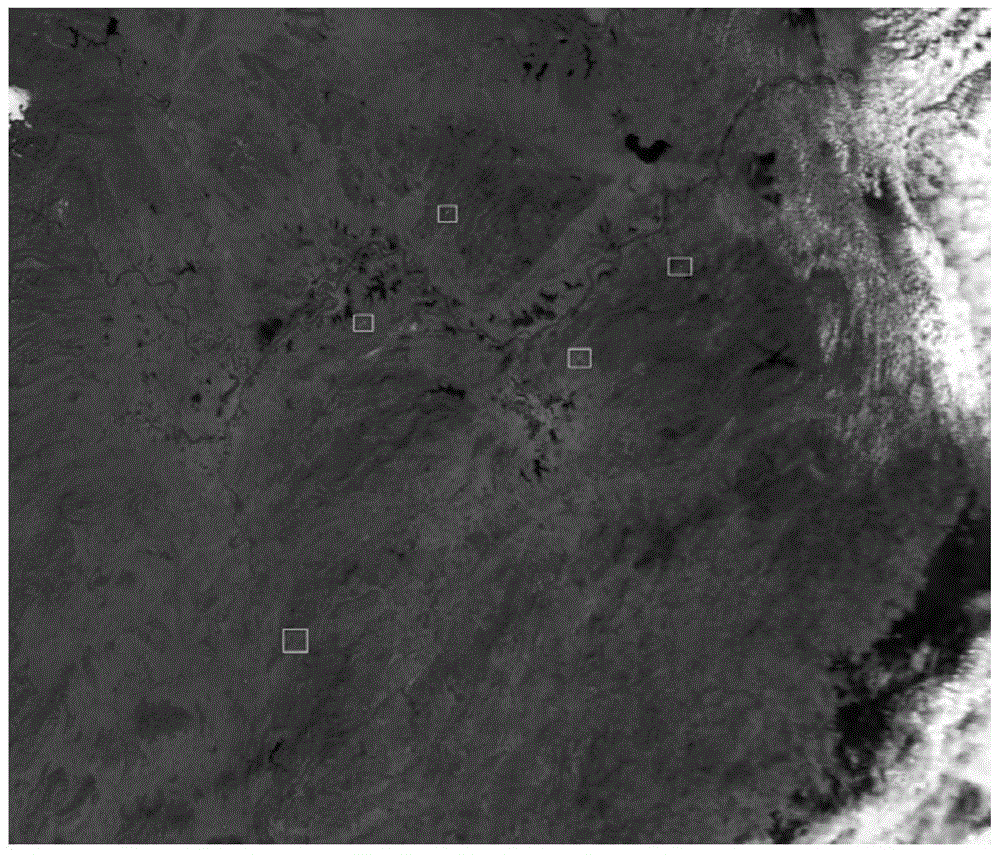

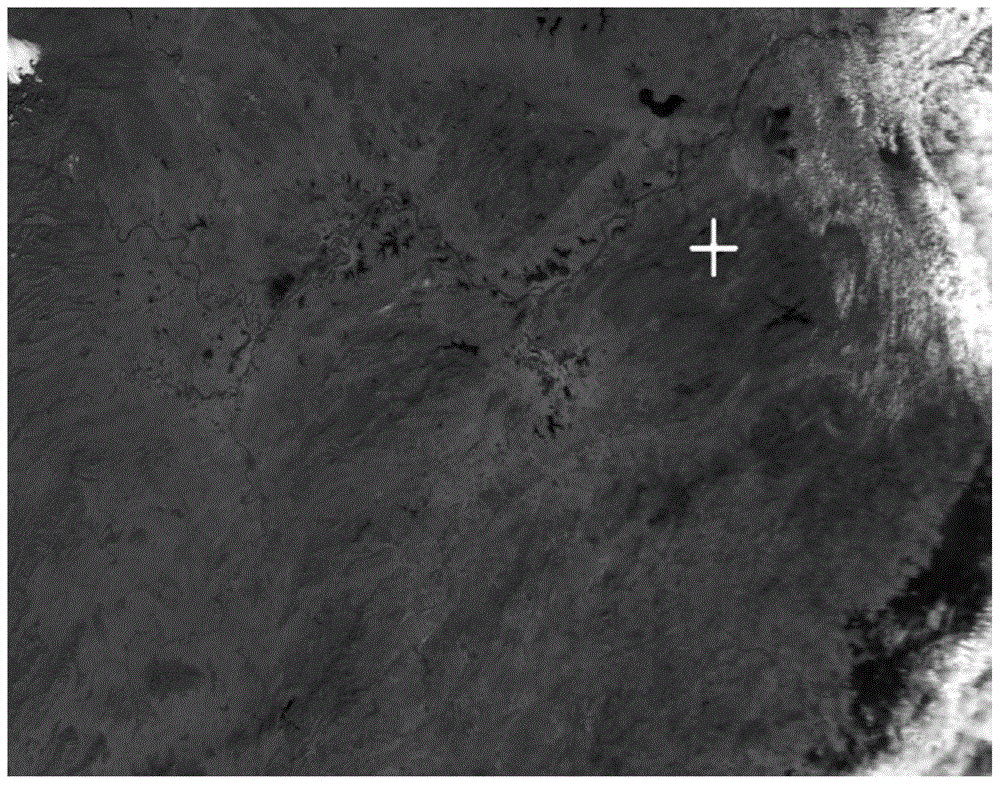

Method for monitoring mountain fire nearby electric transmission line based on MODIS data

ActiveCN104269012AWildfire monitoring fastMountain fire monitoring is accurateScene recognitionFire alarmsBackground informationSatellite image

The invention discloses a method for monitoring a mountain fire nearby an electric transmission line based on MODIS data. The method comprises the first step of obtaining satellite image data and preprocessing the satellite image data, the second step of recognizing and excluding pixels corresponding to water bodies and clouds, the third step of judging potential fire points, the fourth step of judging absolute fire points, the fifth step of judging the fire points according to background information, the sixth step of filtering out noise points, the seventh step of filtering out industrial fire points according to the NDVI, and the eighth step of judging the fire points having influences on the electric transmission line and outputting the positions of final fire points. The method has the advantages that the false report rate of abnormal high-temperature points is greatly lowered; the industrial fire points are recognized successfully; the recognition accuracy rate of the fire points nearby the electric transmission line is greatly increased.

Owner:ZHEJIANG UNIV

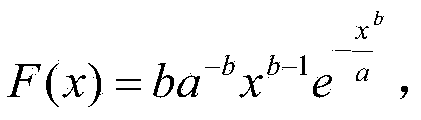

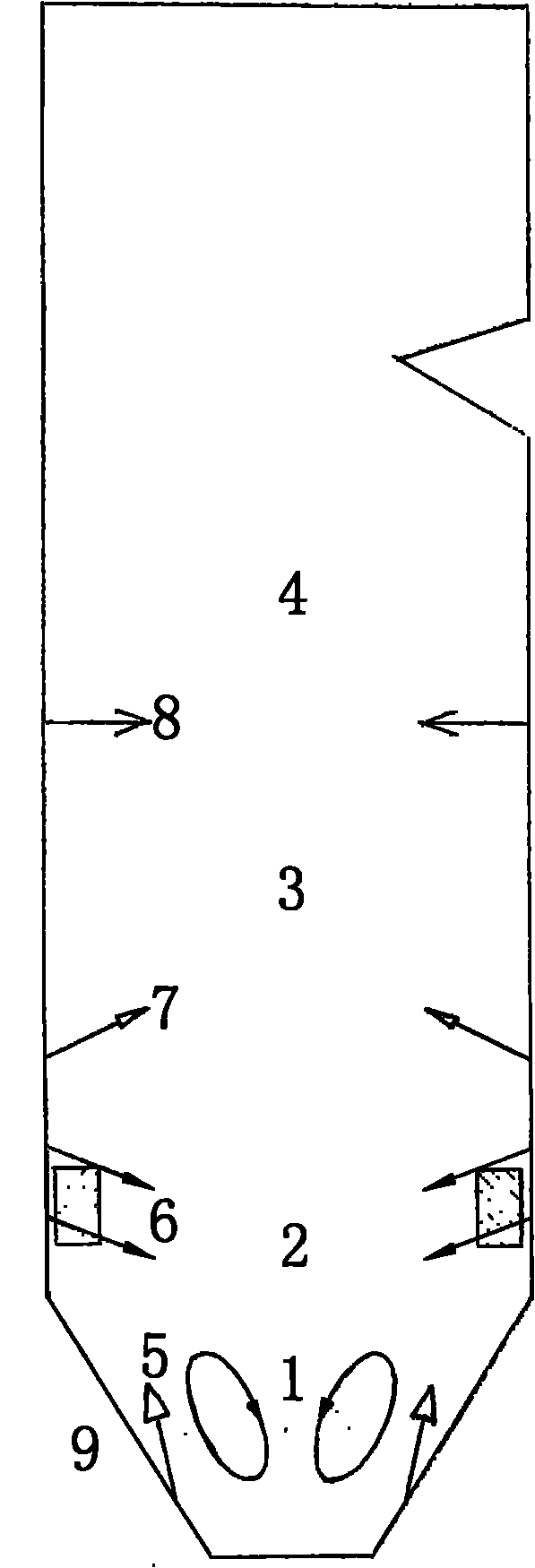

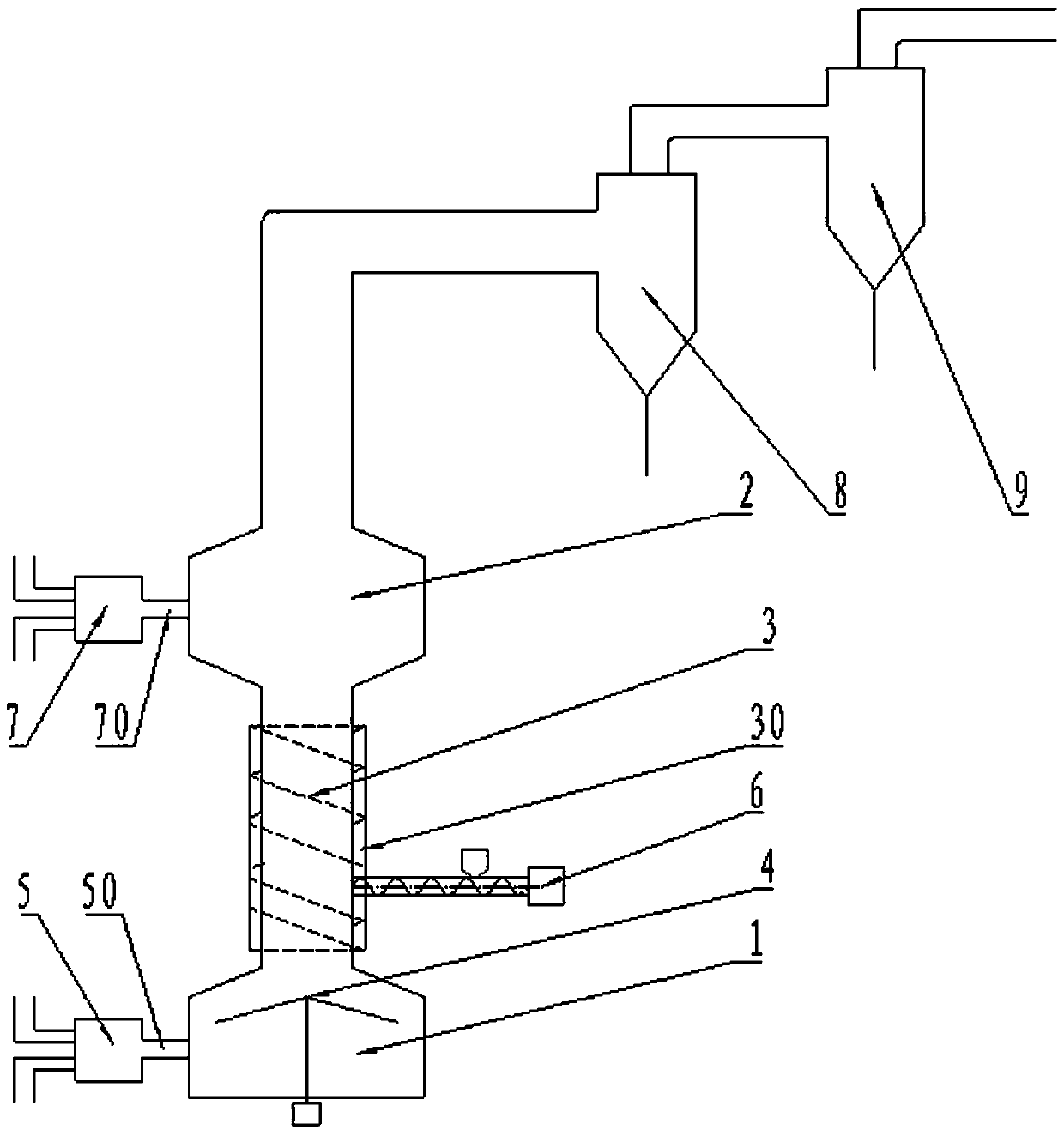

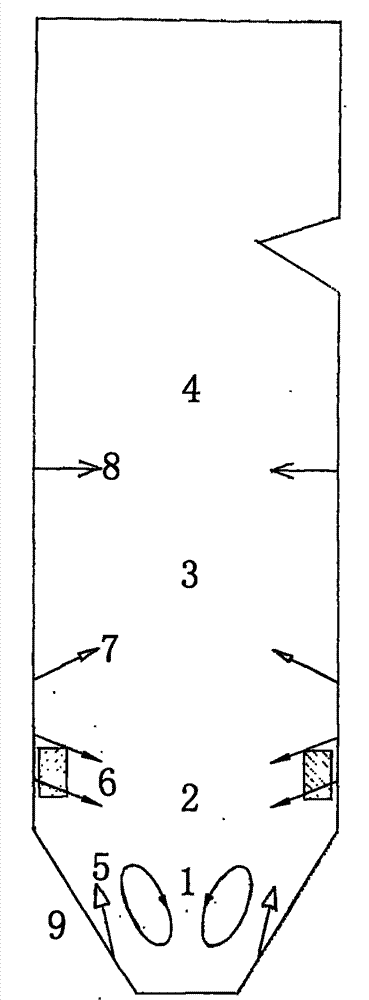

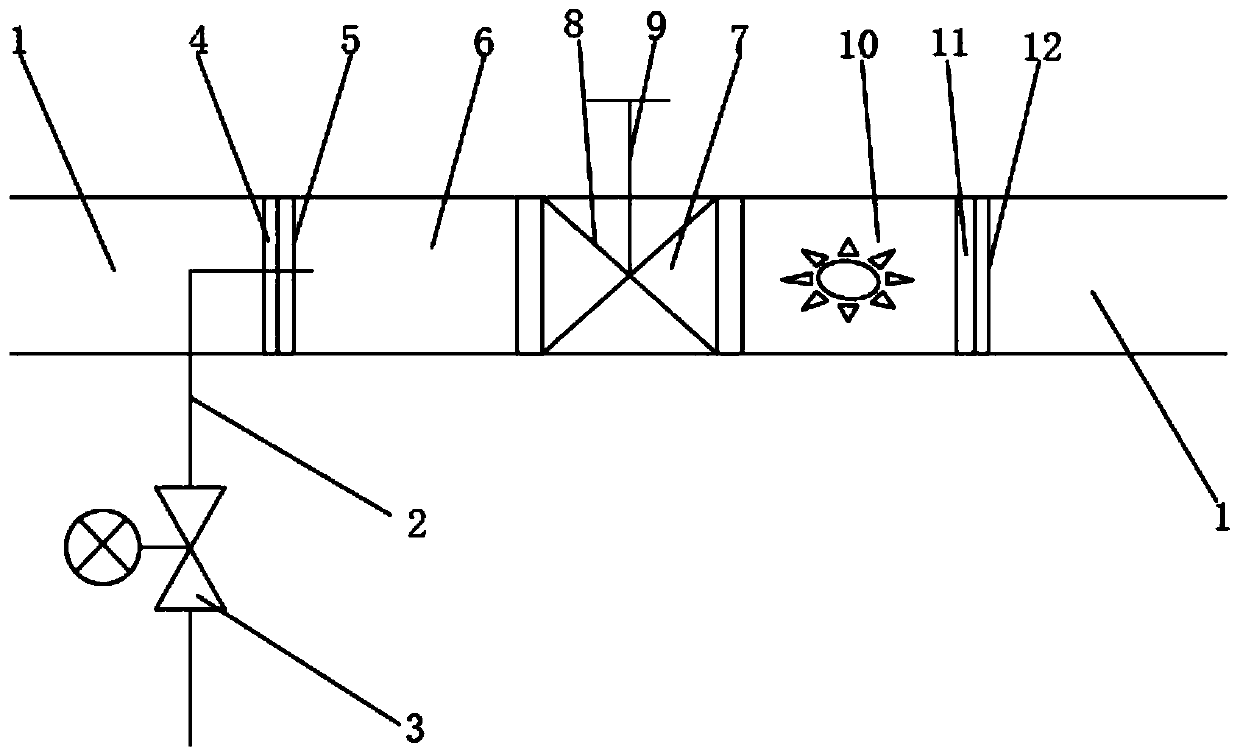

Low NOx coal dust combustion method and device based on underfire air and overfire air

InactiveCN102003701AEmission reductionReduce carbon content in fly ashCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBottom ashEngineering

The invention relates to a combustion improvement technology of an industrial fire coal boiler, aiming to provide a low NOx coal dust combustion method and device based on underfire air and overfire air. The method comprises: injecting parts of two-strand air required for combustion into a hearth from a boiler bottom ash hopper; strongly mixing with aslant downward injected fuel jet flow; fully utilizing the space of the bottom ash hopper to prolong smoke dwell time; burning fuel in a low-temperature oxidation zone; preventing volatile components from converting to nitric oxide; upwards and aslant injecting upper-layer fuel to form a reducing zone, so as to reduce generated nitric oxide into N2; and lowering nitric oxide emission amount. The invention also provides a boiler device for realizing the method. Under the condition that the original combustion condition is not influenced essentially, the invention effectively lowers the emission of nitric oxide and is easy to reform the existing boiler.

Owner:ZHEJIANG UNIV

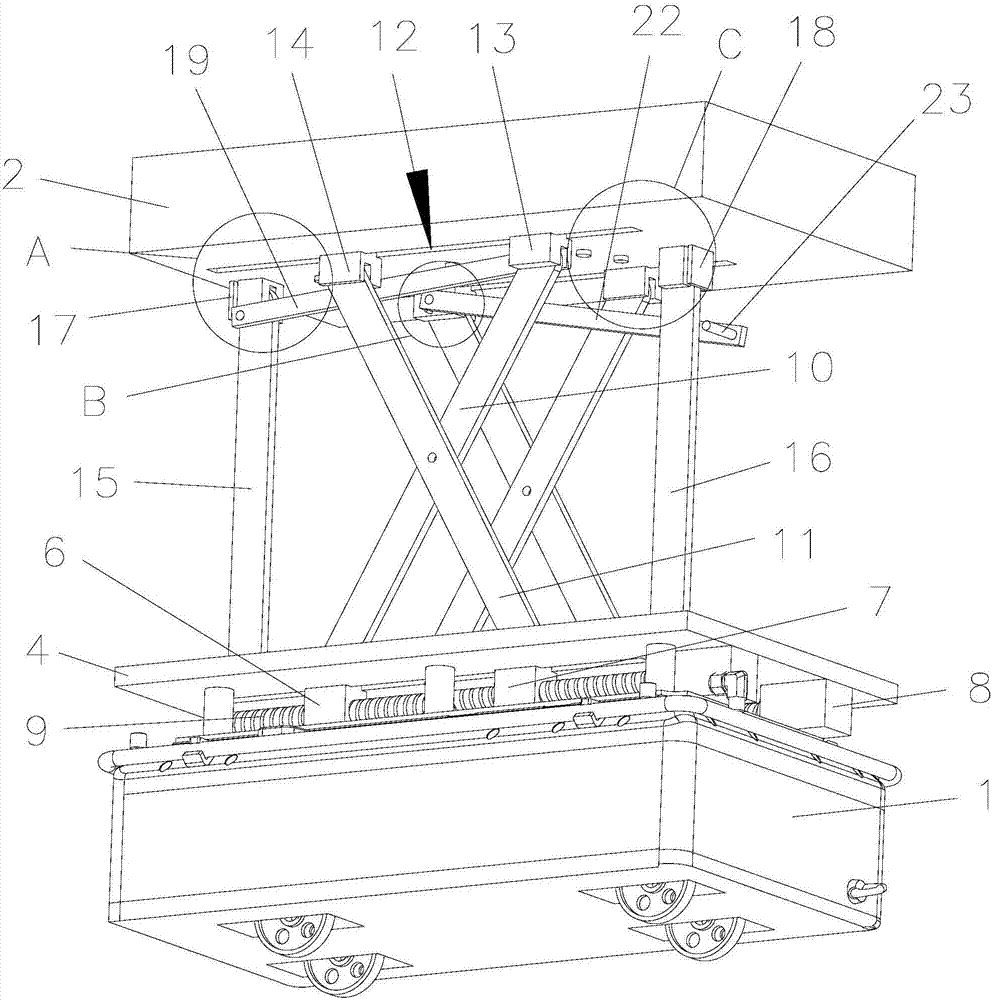

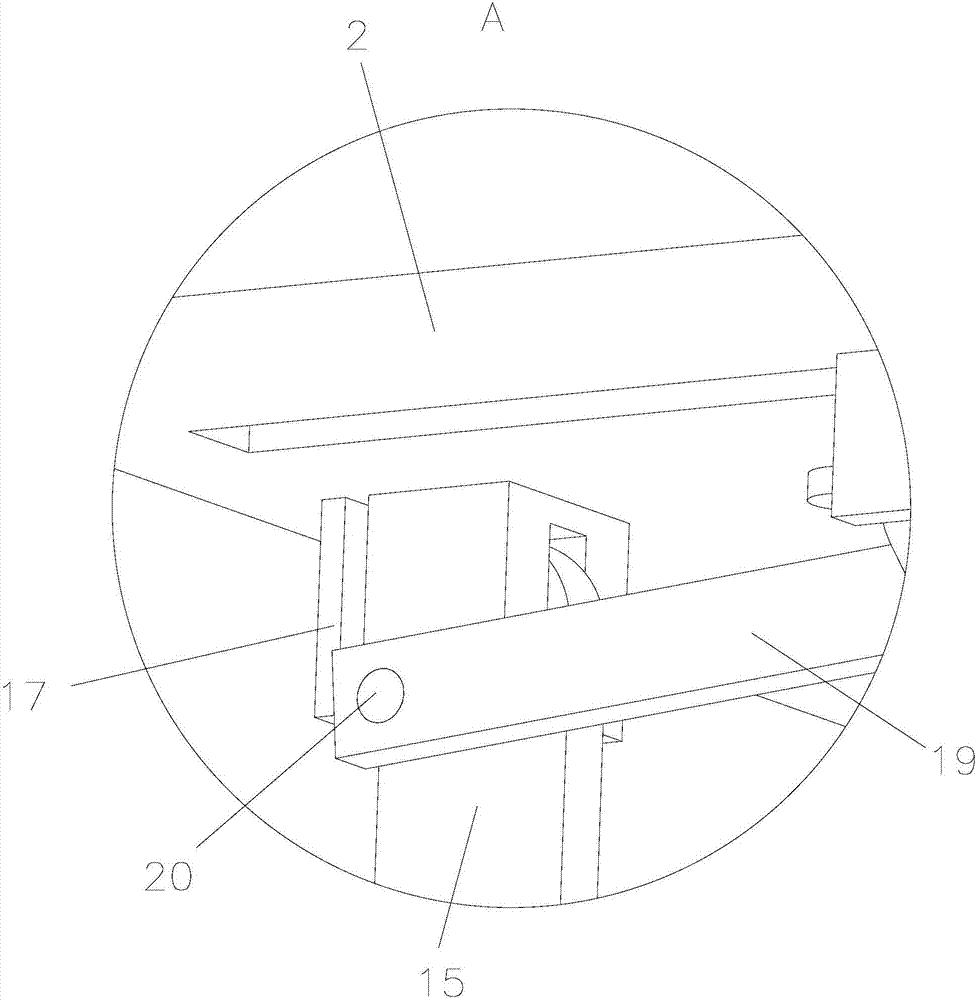

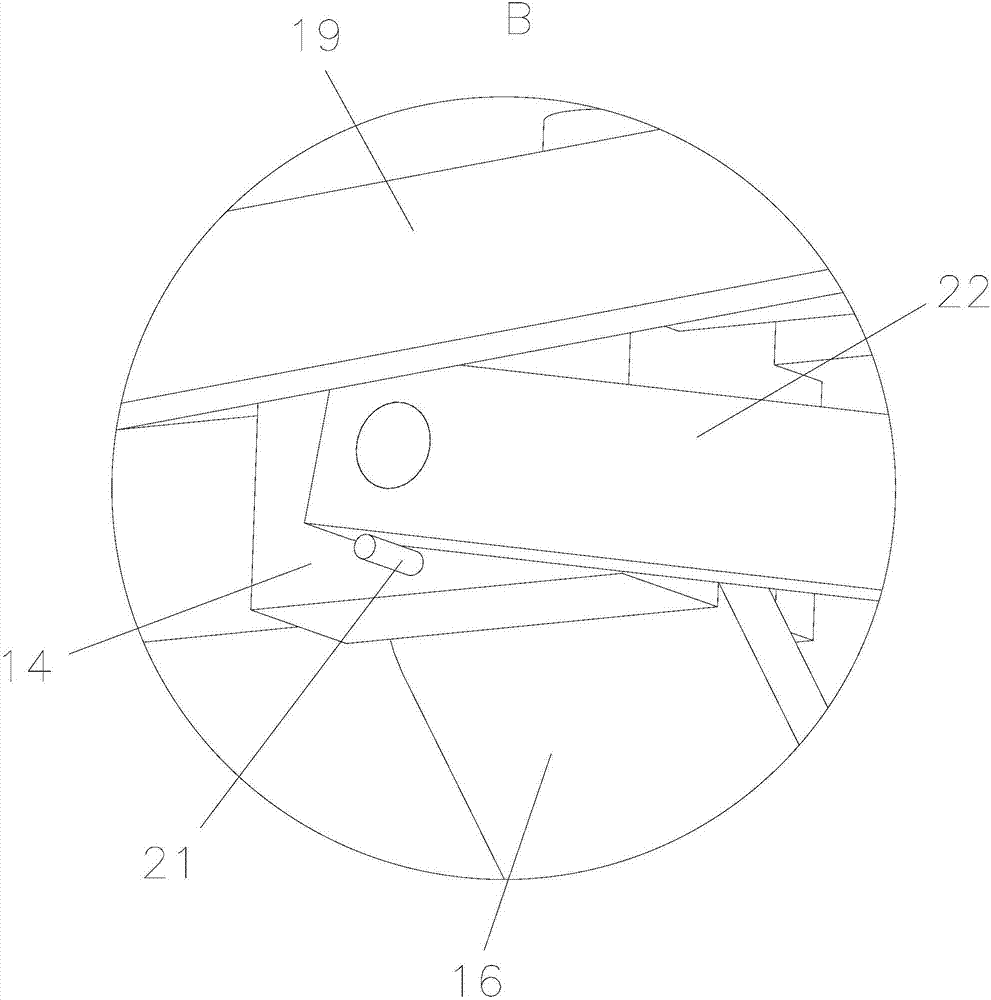

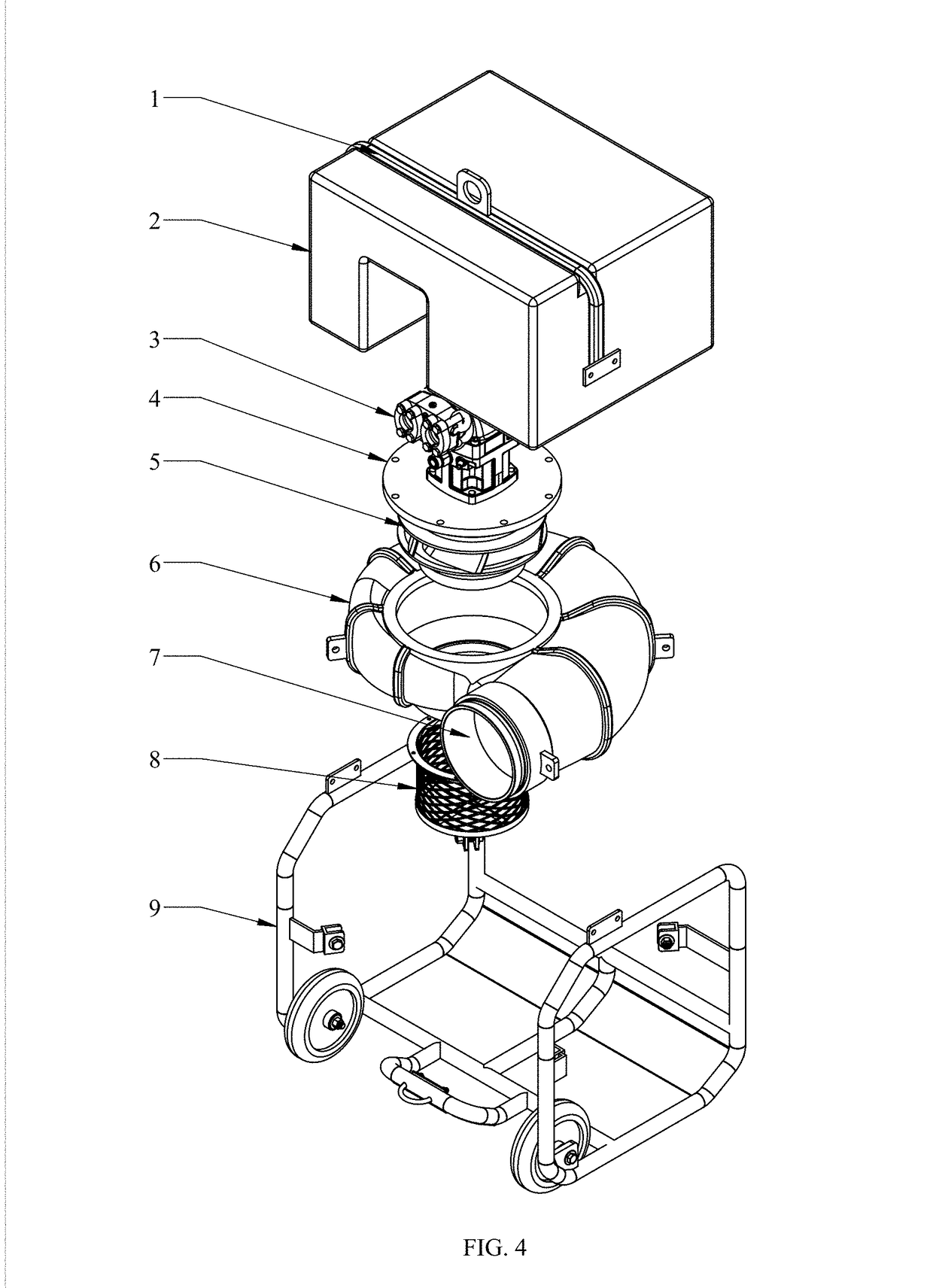

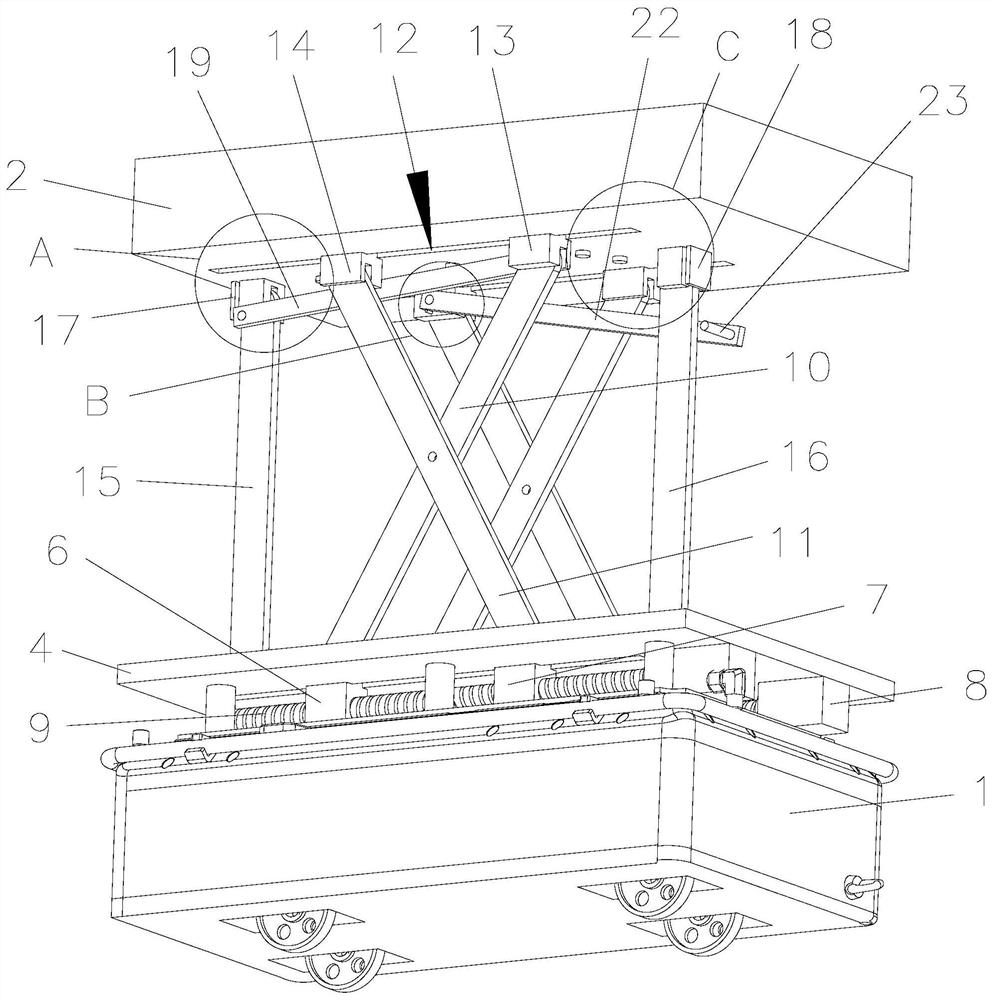

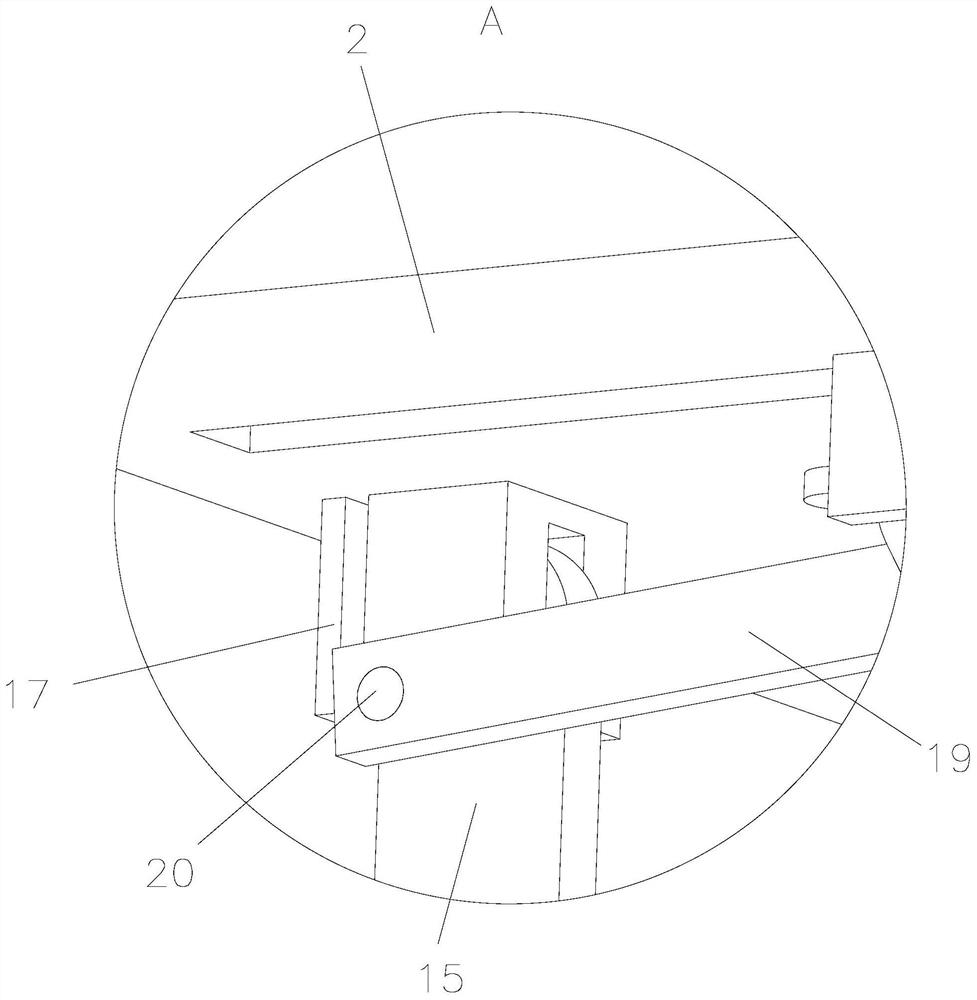

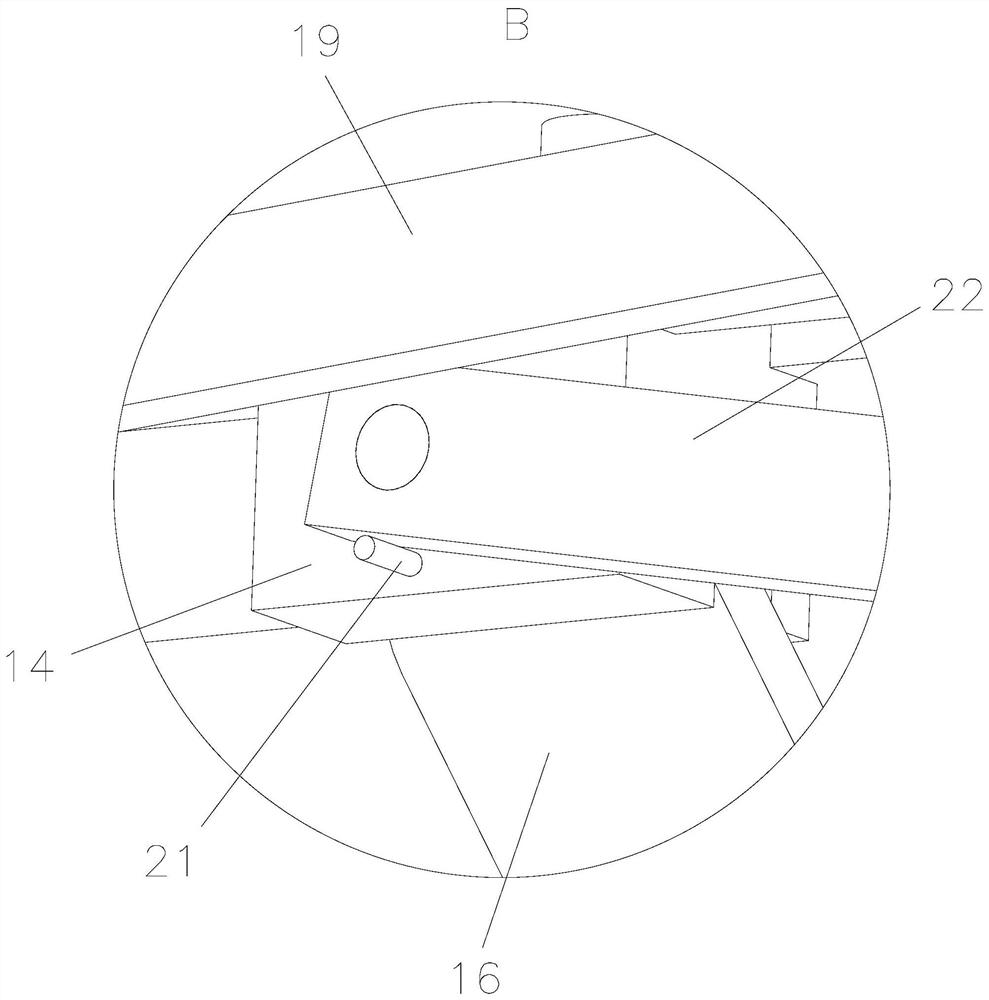

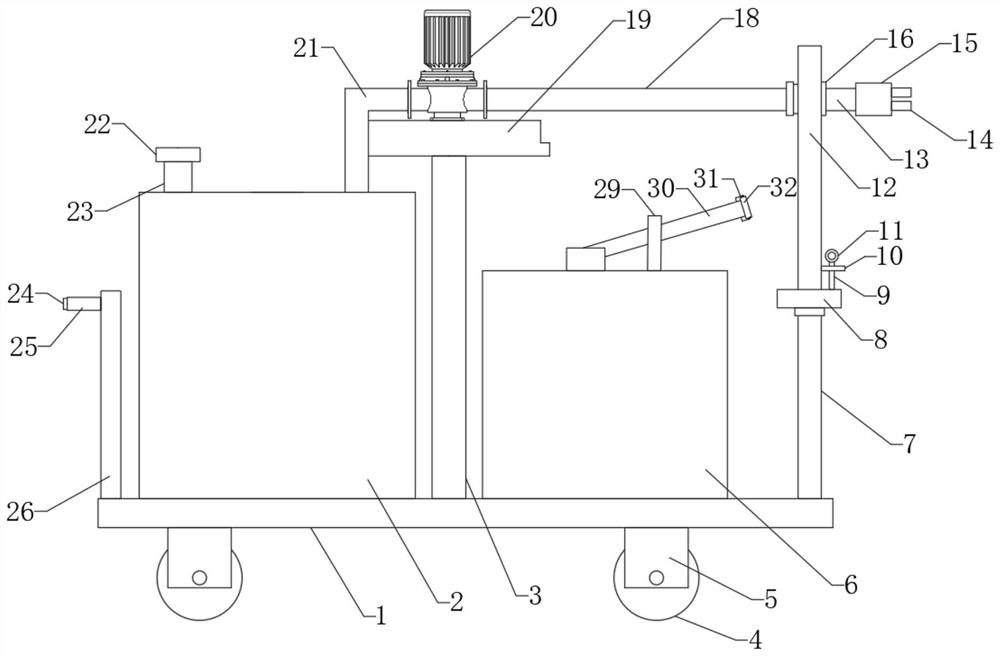

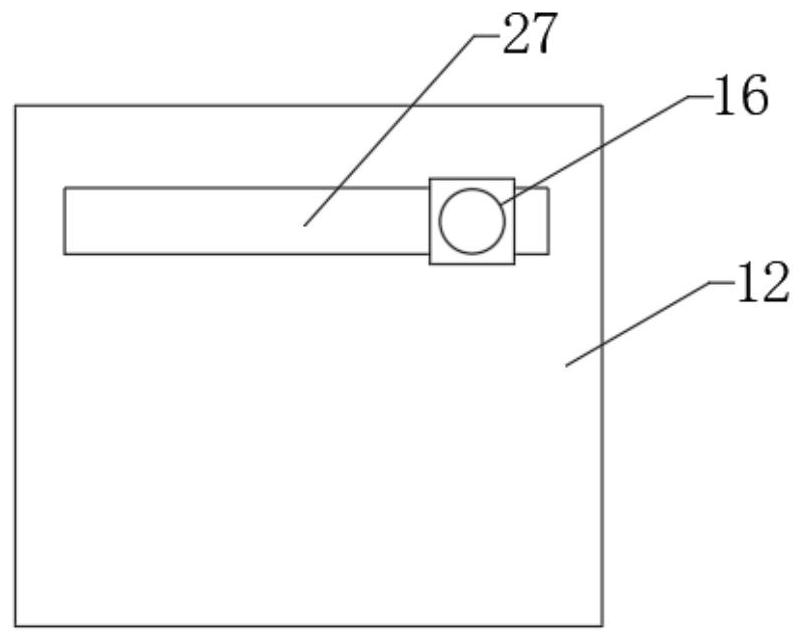

Industrial fire-fighting robot with lifting object table

ActiveCN107412982AAchieve riseAchieve declineFire rescueLifting framesIndustrial fireIndustrial engineering

The invention relates to an industrial fire-fighting robot with a lifting object table. A first lifting rod arranged on a first sliding block and a second lifting rod arranged on a second sliding block are adopted and hinged to each other, the first lifting rod is hinged to a third sliding block slidably arranged on the object table, the second lifting rod is hinged to a fourth sliding block slidably arranged on the object table, and the first sliding block and the second sliding block are pushed by a motor and a two-way screw rod to move back to back or face to face, so that the object table ascends or descends, and by adopting the motor and the screw rod for driving, the driving force is high. A first supporting rod and a second supporting rod are supported at the two ends of the object table correspondingly and achieve the dual supporting effect together with the first lifting rod and the second lifting rod, and accordingly the object table can bear heavy fire-fighting tools. The first supporting rod and the second supporting rod can be taken up through cooperation of a first suction cup and a first knocking rod and cooperation of the first suction cup and a second knocking rod correspondingly. The object table can ascend and descend, so that a firefighter does not need to bend to take the fire-fighting tools in the use process, the labor intensity of the firefighter is relieved, and the fire-fighting efficiency is improved.

Owner:CHANGZHOU INST OF LIGHT IND TECH

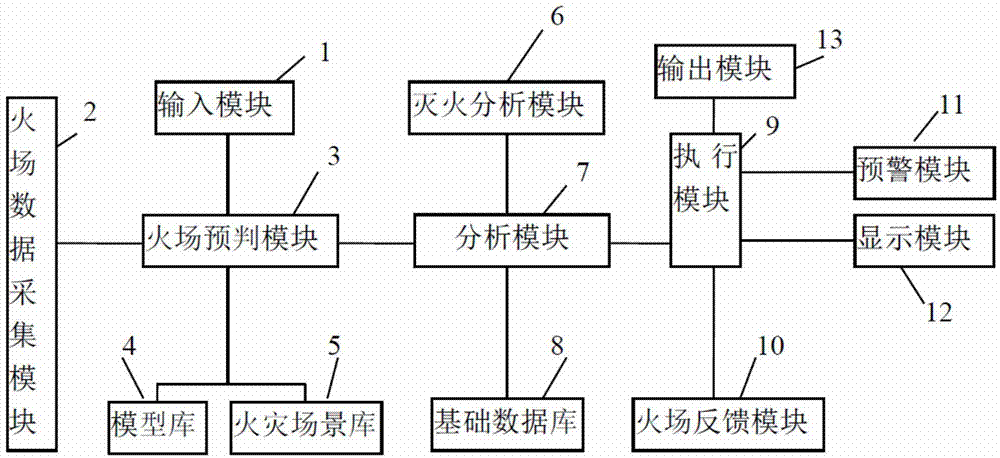

Industrial fire scene rapid determining and auxiliary deciding device

InactiveCN103679609ARestore accuratelyAvoid the disadvantage of not being able to restore the entire accident sceneData processing applicationsDecision takingData acquisition module

The invention relates to an industrial fire scene rapid determining and auxiliary deciding device which is suitable for rapid determination and auxiliary decision for a fire scene. Input data together with data collected by a fire scene data collection module is input into a fire scene pre-determination module for pre-determination, formed fire scene information is sent to a fire extinguishing analysis module, calculated disposal information is input into an analysis module, an analysis result is distributed to an execution module, the execution module forms a scheme for dealing with the accident, and the scheme is output by an output module, wherein if it is determined that the fire hazard is further expanded, fire-fighting supply is insufficient and the like, an early warning module carries out early warning, and the fire scene parameters and required fire fighting supply are displayed by a display module in real time. The device of the invention can be applied to rapid determination and auxiliary decision for the fire scene during fire hazard.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for extracting iron by utilizing nickel slag and preparing fibers

The invention provides a method for extracting iron by utilizing nickel slag and preparing fibers. The method comprises the following steps of: adding a reducing agent and auxiliary materials to nickel slag discharged in a nickel smelting process to reduce oxides of iron in the nickel slag into iron; after the iron is separated, adding an additive to the remaining molten nickel slag; and blowing or throwing the molten mixture with the additive through high-speed air or a centrifugation throwing machine to prepare inorganic fibers. According to the method, on the basis of melting and reducing the thermal nickel slag for refining the iron, the remaining slag is used as a main raw material to prepare the inorganic slag fibers, and the waste nickel slag is changed into valuable materials and recycled, so that the sensible heat of the thermal nickel slag is sufficiently utilized, and the energy consumption in the processes of refining the iron from the nickel slag and producing the fibers is reduced. The main components of the prepared inorganic nickel slag fibers are SiO2, Al2O3 and the like, and the prepared inorganic nickel slag fibers belong to high-temperature inorganic fibers andcan be widely applied to the fields of pipe warm preservation, industrial fire resistance and warm preservation and the like.

Owner:PEKING UNIV

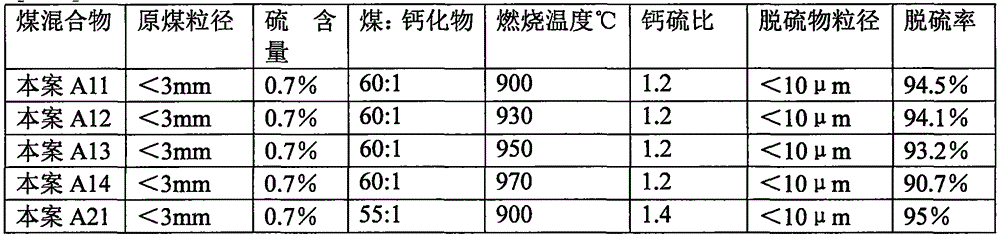

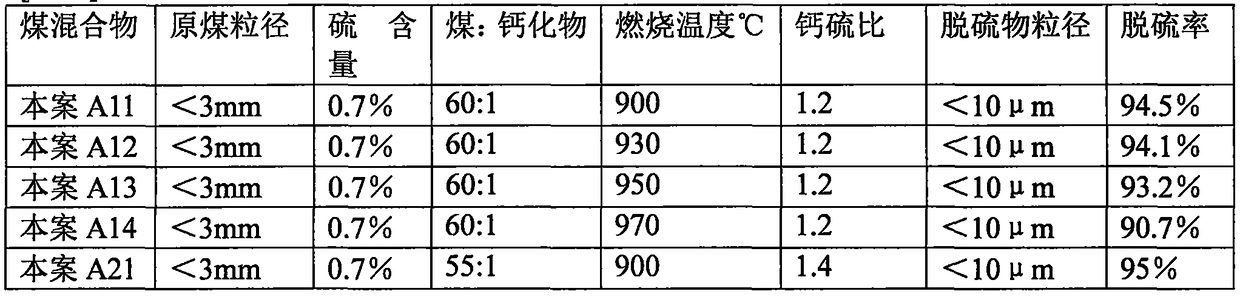

Sulfur-fixation efficiently combusted clean coal with desulfuration effect and preparation method

ActiveCN105733724AImprove self-desulfurization efficiencyIncrease contact areaSolid fuelsCalcium hydroxideCombustion

The invention discloses sulfur-fixation efficiently combusted clean coal with a desulfuration effect and a preparation method used in industries and families. Nano active calcium hydroxide and nano active magnesium hydroxide are prepared and added into raw coal, so that on the basis of the prior art, the sulfur removal efficiency of fire coal and the combustion efficiency of coal are further improved, and emission of SO2 in air is reduced. The sulfur-fixation efficiently combusted clean coal has the main application that firstly, emission of SO2 of industrial fire coal into air is reduced; secondly, the operation cost of sulfur removal is lowered; thirdly, due to direct use of the clean coal in arcola and families, the emission amount of SO2 in air can be effectively reduced, air pollution can be alleviated, and the probability of haze can be reduced; fourthly, the use amount of a calcium desulfurizer is reduced, and the utilization efficiency of the calcium desulfurizer is improved; fifthly, the effective utilization rate of raw coal can be increased.

Owner:韩秀峰 +1

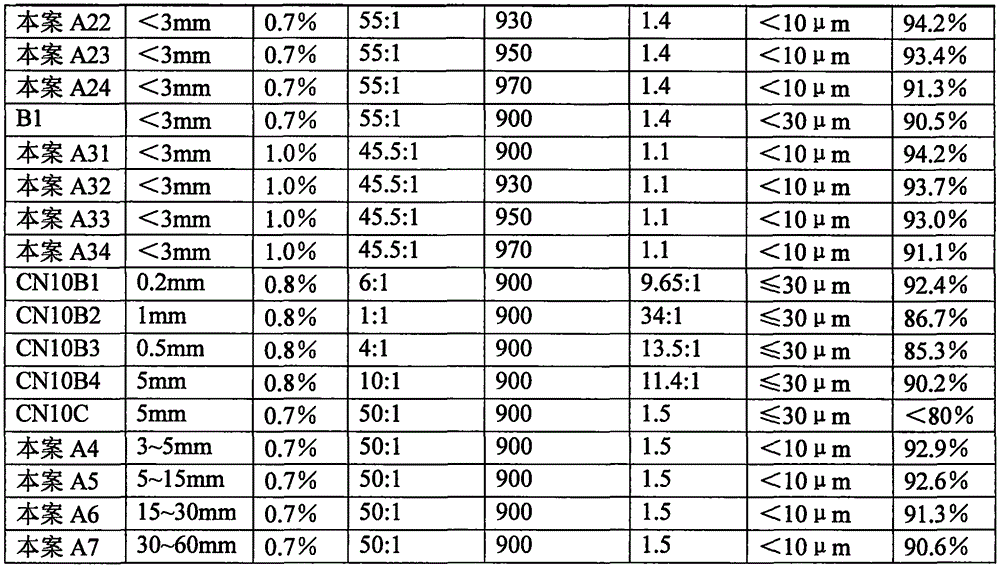

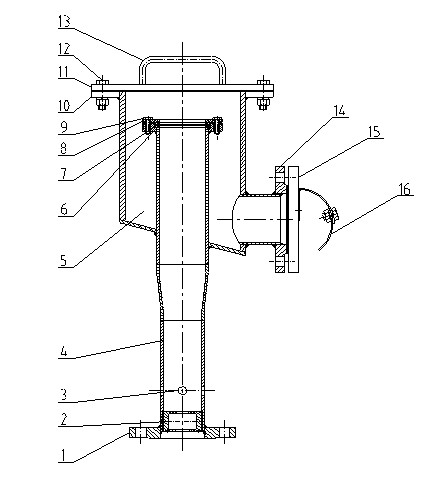

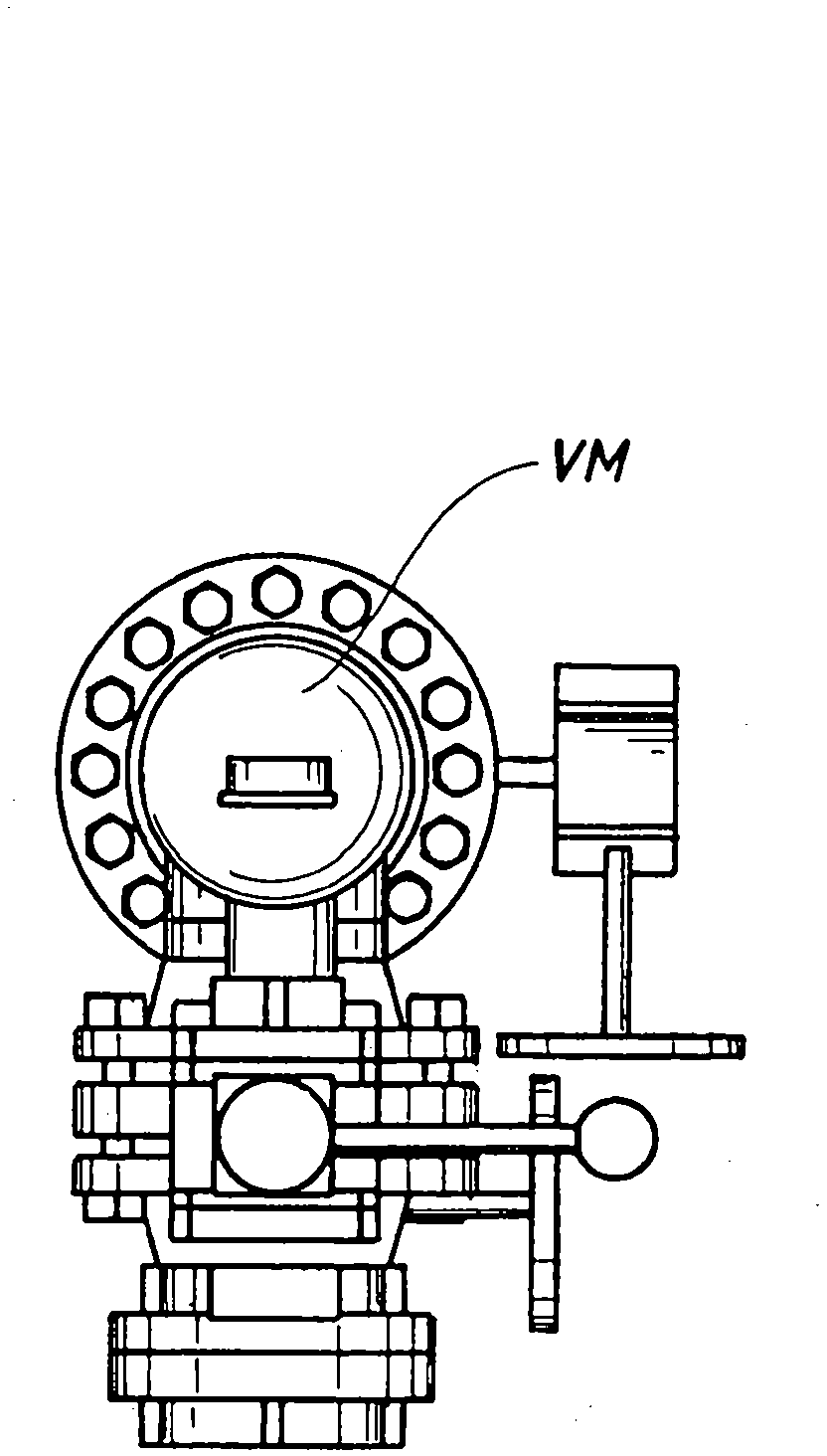

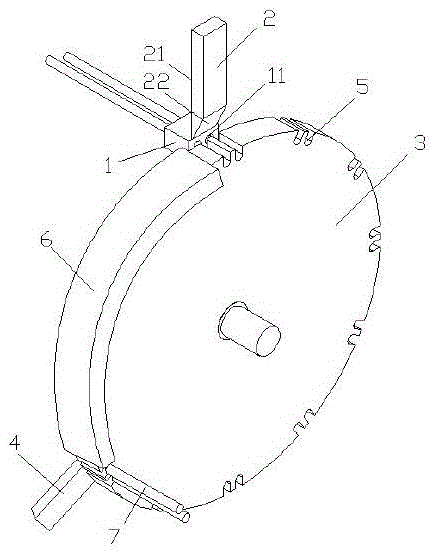

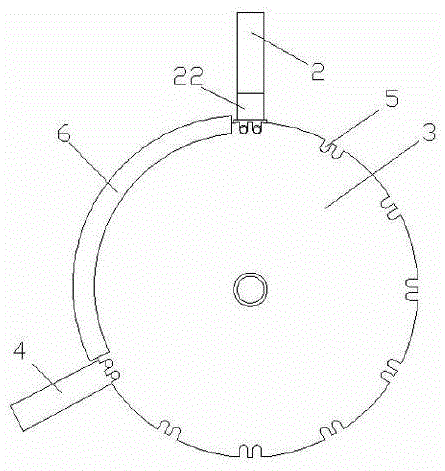

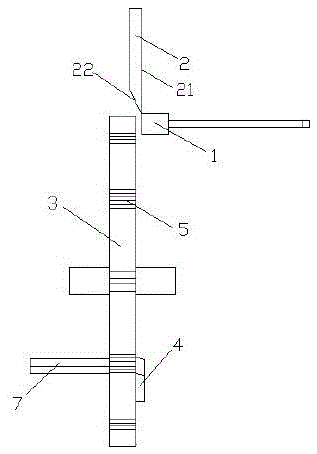

Universal adjustable pipeline welding tool for vertical type foam generator

InactiveCN102764947AReduce labor intensityReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention relates to a universal adjustable pipeline welding tool for a vertical type foam generator and belongs to the field of industrial fire control. The welding tool is simple in structure, low in production cost, universal, adjustable, convenient to operate and adjust and suitable to the processing of non-standard products. The tool comprises a positioning bolt, a left side positioning plate I, a pressing block, a positioning volume, an adjustable sliding frame I, a V-shaped positioning block, a right side positioning plate, a positioning sleeve, an adjustable sliding frame II and a base. Compared with the prior art, the tool has the advantages of being capable of reducing the labor strength and production cost, simple in structure, universal, adjustable and convenient to adjust.

Owner:JIANGXI RONGHE SPECIAL FIRE EQUIP MFG

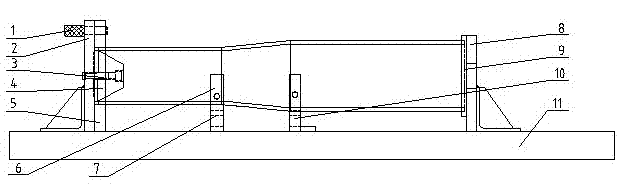

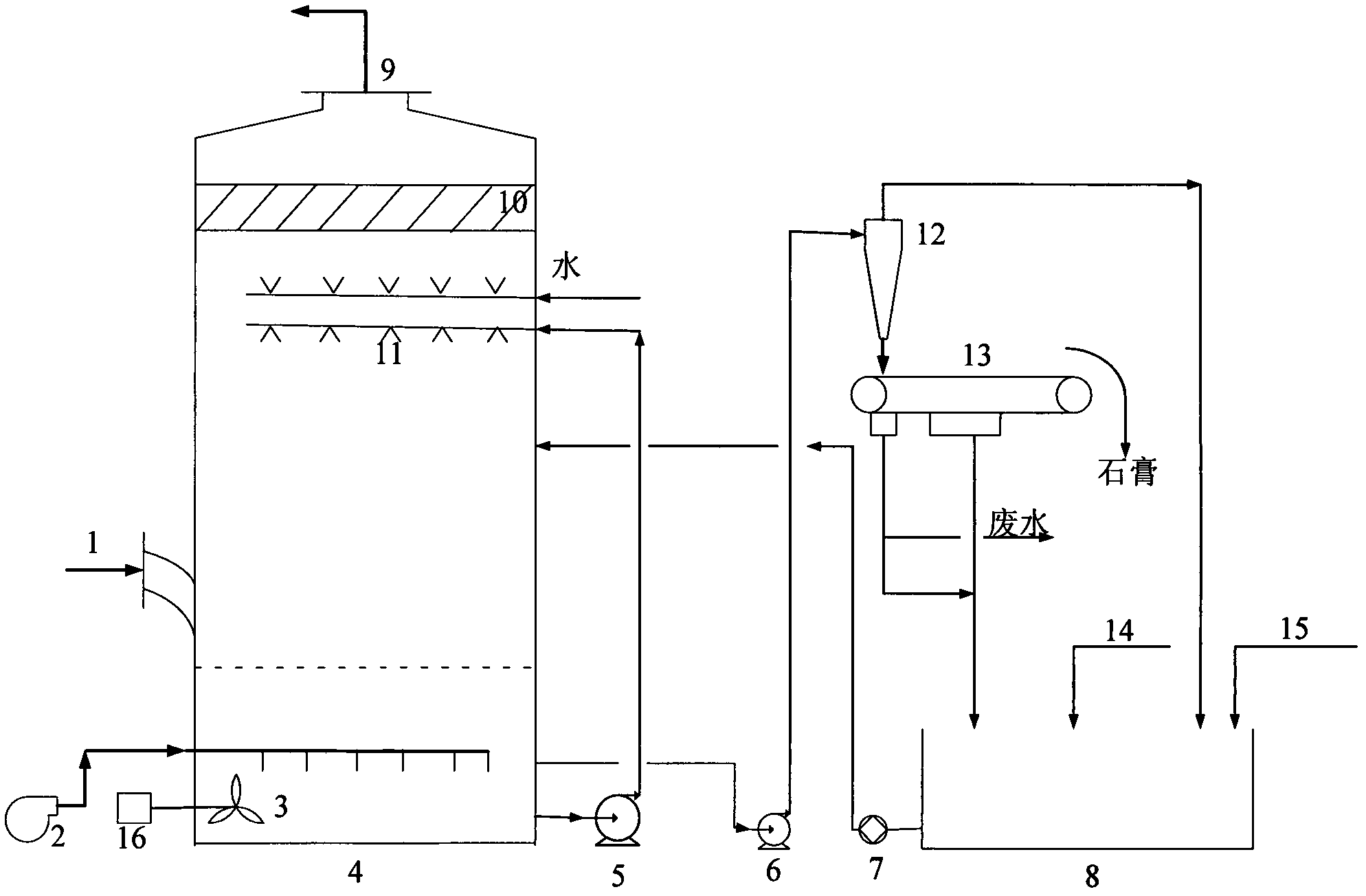

Organic acid reinforced steel slag fuel gas desulfurization method

InactiveCN102614772AIncrease profitIncrease pH buffer valueDispersed particle separationOrganic acidSinter Plant

The invention discloses an organic acid reinforced steel slag fuel gas desulfurization method, which is mainly applied to sintering plants, thermal power plants, industrial fire coal boilers and other flue gas desulfurization (FGD) containing sulfur dioxide, and particularly has a good prospect specific to sintering flue gas desulfurization. Due to the adoption of the method, low investment and low running cost of flue gas desulfurization can be realized, and a desulfurization technology is applied more widely. A process adopted by the invention has the advantages of low investment, running and managing costs, realization of steel slag recycling, realization of treatment of waste with waste. The method has superior cost performance and a wide market prospect.

Owner:CHENGDU UNIV OF INFORMATION TECH

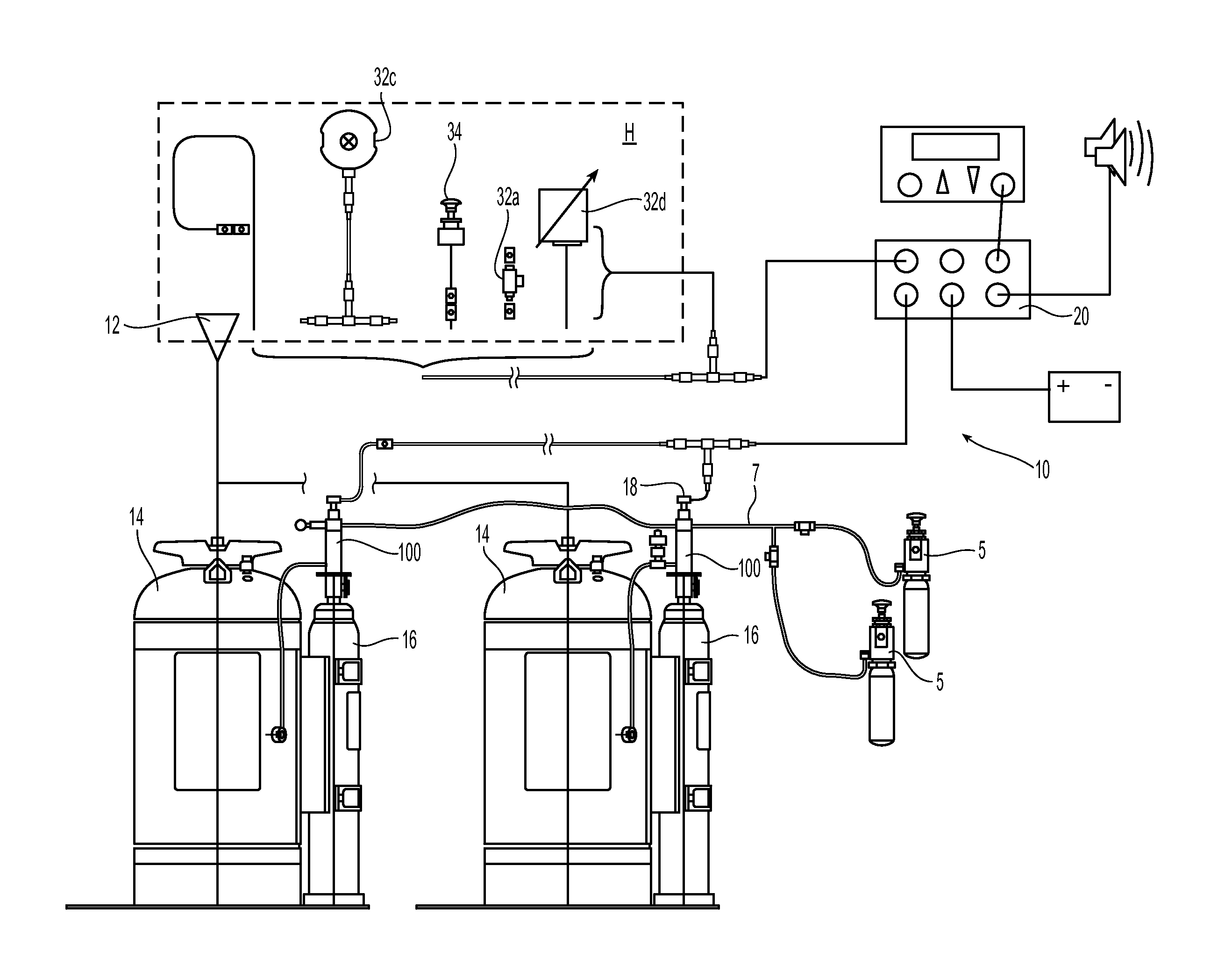

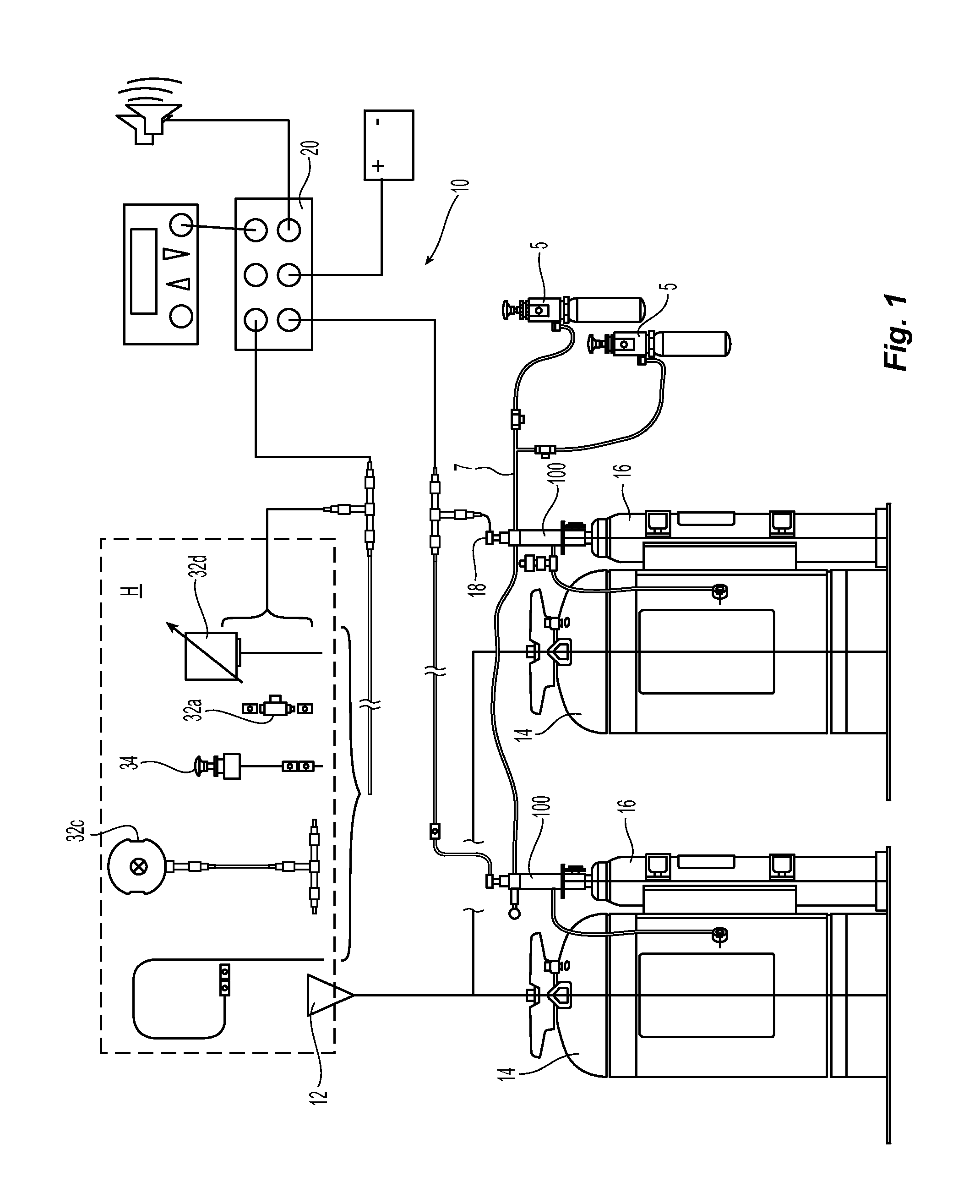

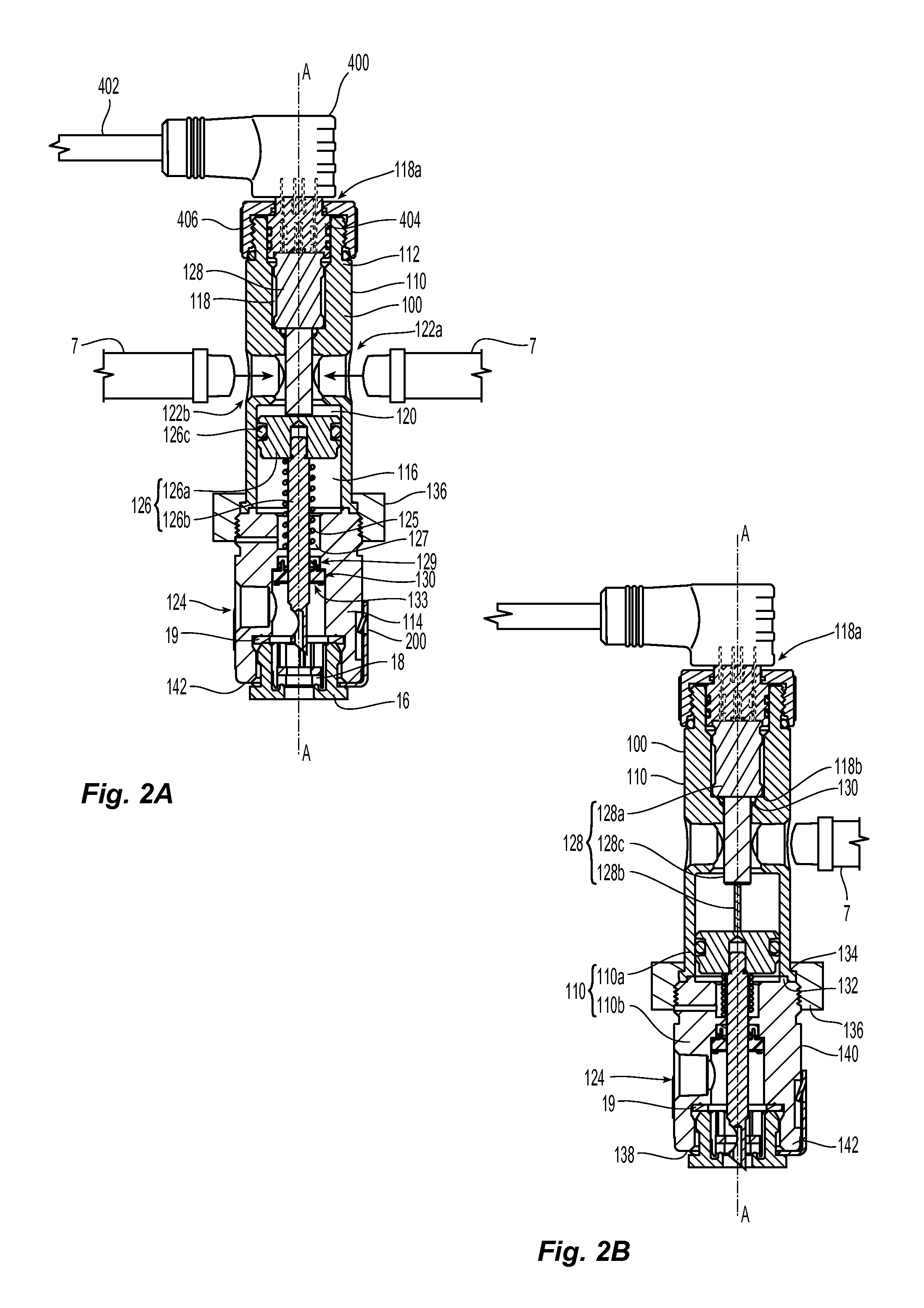

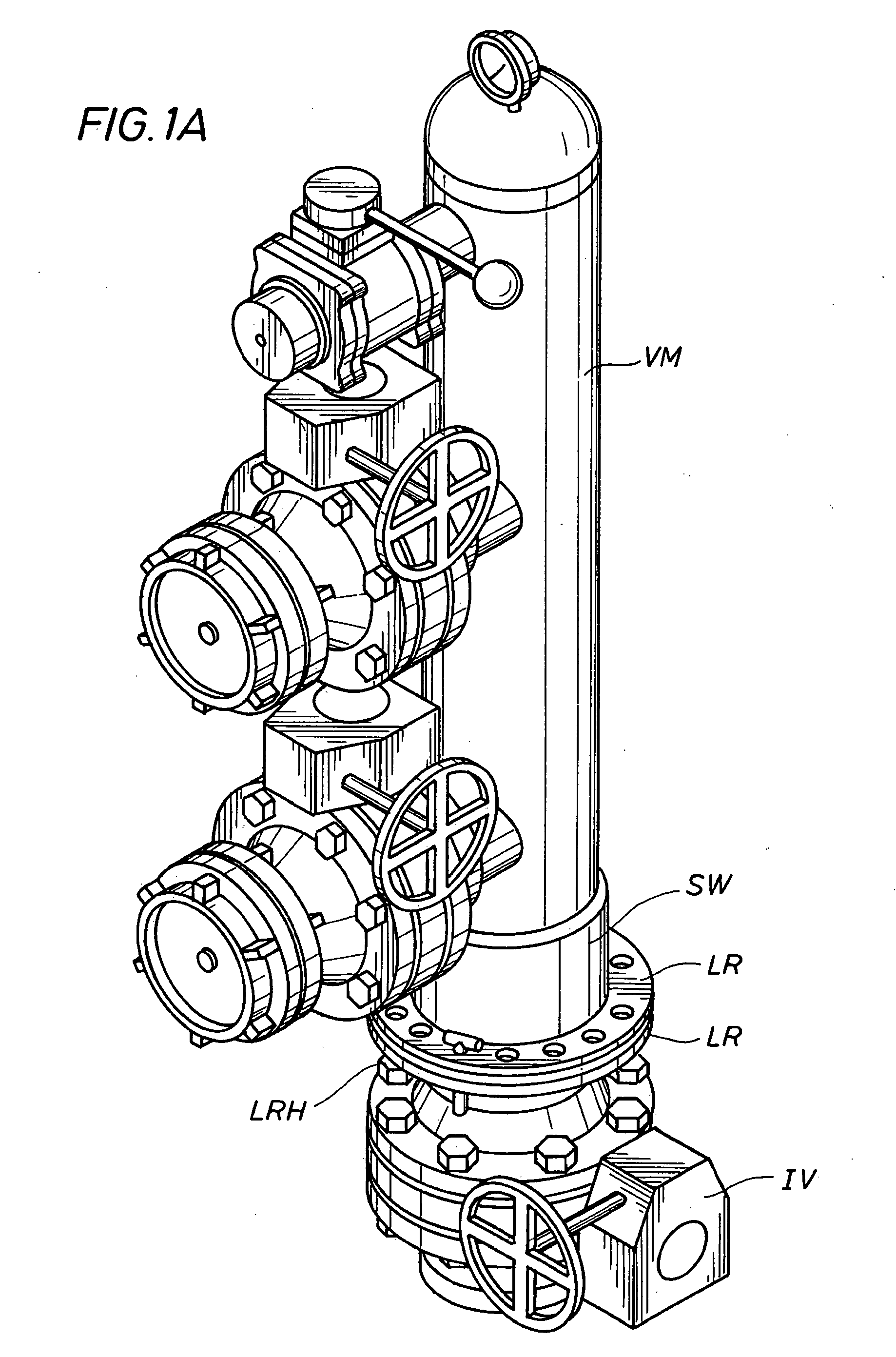

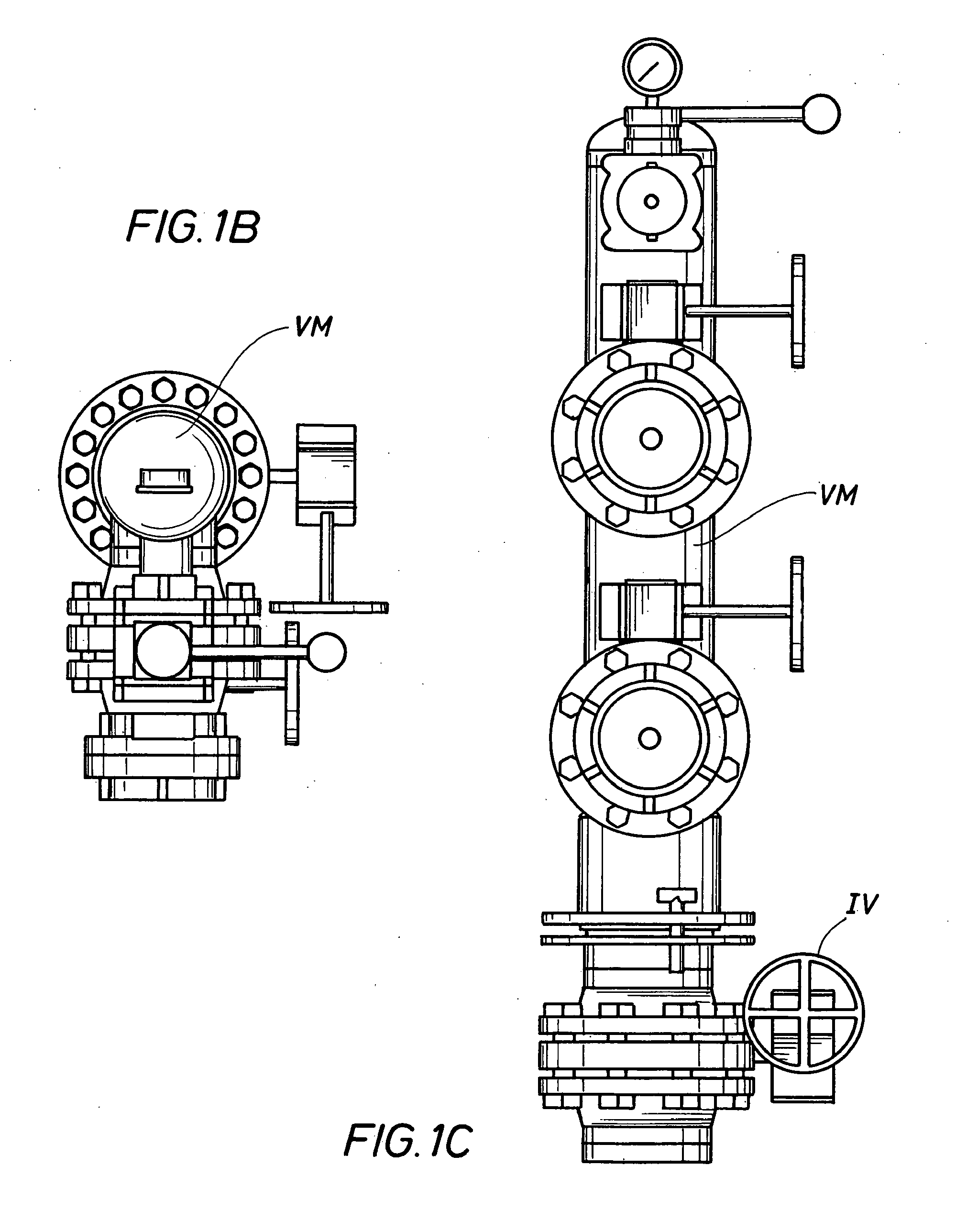

Electric-pneumatic actuator assembly

An actuator assembly for use in fire suppression systems for use in vehicle and industrial fire protection systems. The actuator assembly engages a cartridge of pressurized gas and releases the gas contained therein with a puncturing assembly. The actuator assembly includes a receptacle that controls the manner in which the actuator assembly and cartridge engage one another. The actuator assembly is configured for electrical and pneumatic actuation for rupturing the seal of the cartridge of pressurized gas. The actuator assembly has a housing that includes at least one inlet port that is coupled to a pressurized gas source, which is formed between a first chamber for electrical components sealed from the operative environment of the actuator assembly and a second chambers for the puncturing assembly. The actuator assembly allows for serial interconnection of multiple actuator assemblies for operation by a as single source of pressurized gas.

Owner:TYCO FIRE PRODS LP

Vertical foam generator

The invention relates to a vertical foam generator and belongs to the field of industrial fire control. The invention aims to provide the vertical foam generator. The installation of the foam conduit part of the vertical foam generator is simplified. The vertical foam generator comprises a foam conduit, a buffer tube and a guide plate, wherein the foam conduit partially extends into the inner cavity of the buffer tube; the outer wall of the buffer tube and the outer wall of the foam conduit are welded, and the outer wall of the foam conduit and the outer wall of the buffer tube form a hollow cavity body; the side wall of the buffer tube is provided with a hole; the buffer tube is connected with a mounting flange fixedly arranged on a holed storage tank wall through a discharge flange; and the guide plate and the mounting flange are fixedly connected. Compared with the prior art, the vertical foam generator has the following advantages: 1-, the generator is smaller in size, lighter in weight and more convenient in installation after the inlet of the generator and the buffer tube are combined into a whole; 2-, the fire-fighting efficiency is higher; and 3-, the maintenance is simple.

Owner:JIANGXI RONGHE SPECIAL FIRE EQUIP MFG

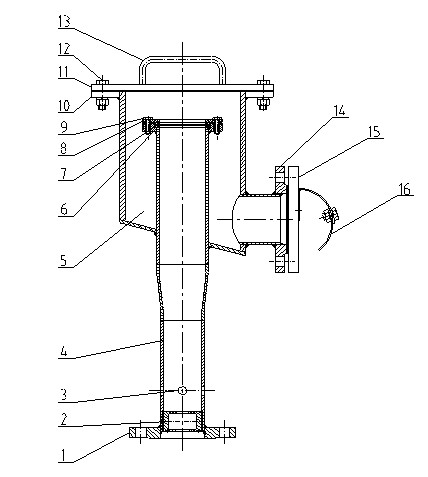

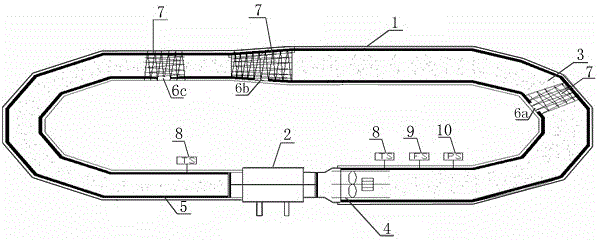

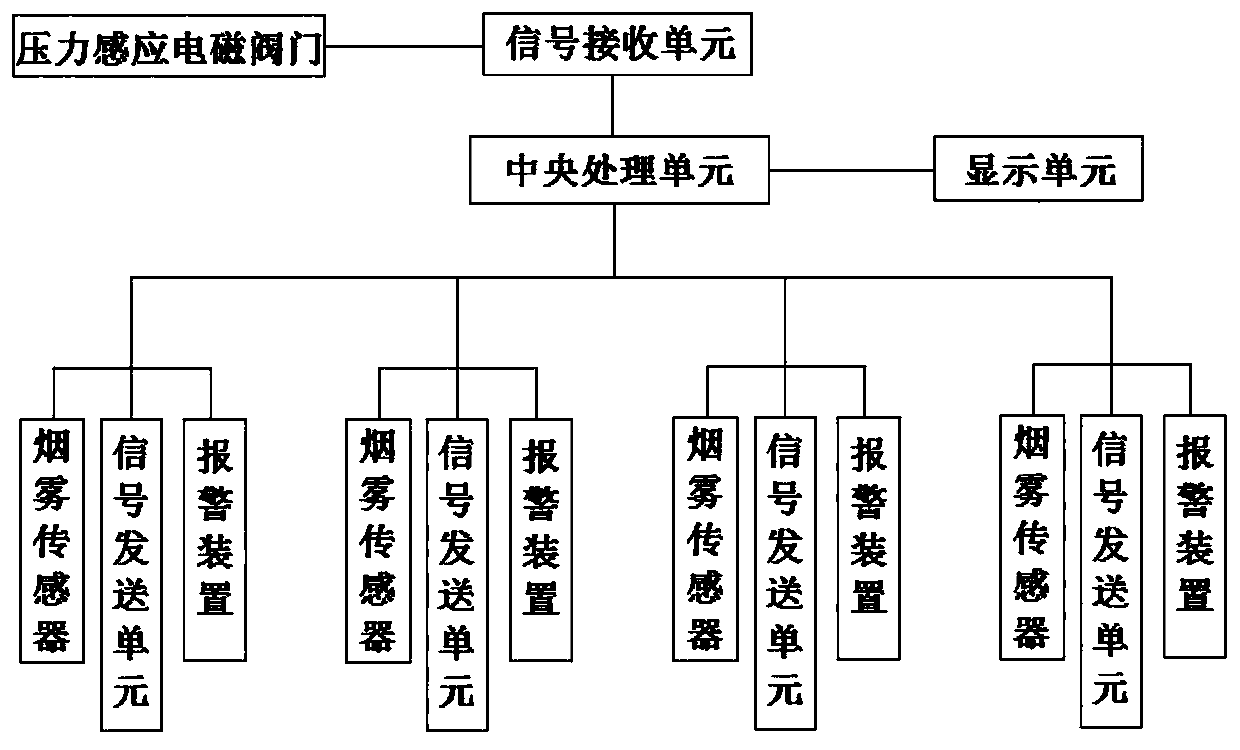

Automatic industrial fire-control system

ActiveCN107168178AEvacuation priorityEffective casualty controlProgramme controlComputer controlControl systemFire control

The invention discloses an automatic industrial fire-control system which includes a control module, a fire-control monitoring module, a positioning module, a water pressure control module and an alarm module. The control module includes a central processing unit and a display unit. The central processing unit acquires the coordinate of a place where fire occurs and generates a place map, computes the area of the place, transmits the place map to the display unit, and transmits the area of the place to the water pressure control module. The fire-control monitoring module divides an industrial factory district into a plurality of independent units, and each independent unit is provided with a smoke sensor therein. The positioning module includes a plurality of signal transmitting units. The water pressure control module includes a signal receiving unit and a plurality of pressure sensing electromagnetic valves. The invention also discloses an industrial fire-control monitoring alarm system, which can perform fire control in a targeted manner, can effectively control injuries and damages caused by the fire in the industrial factory district.

Owner:安徽瑞弋自动化科技有限公司

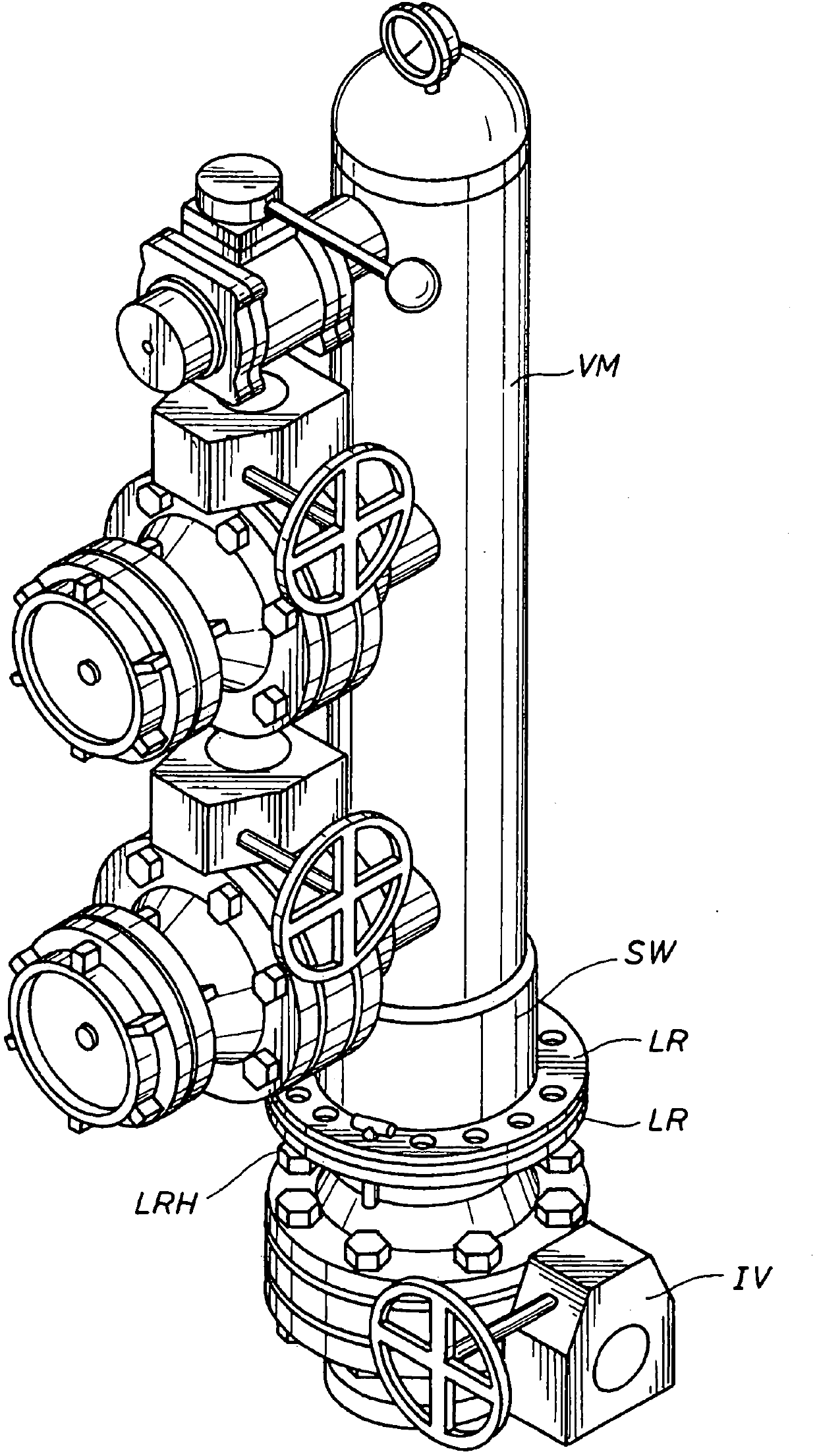

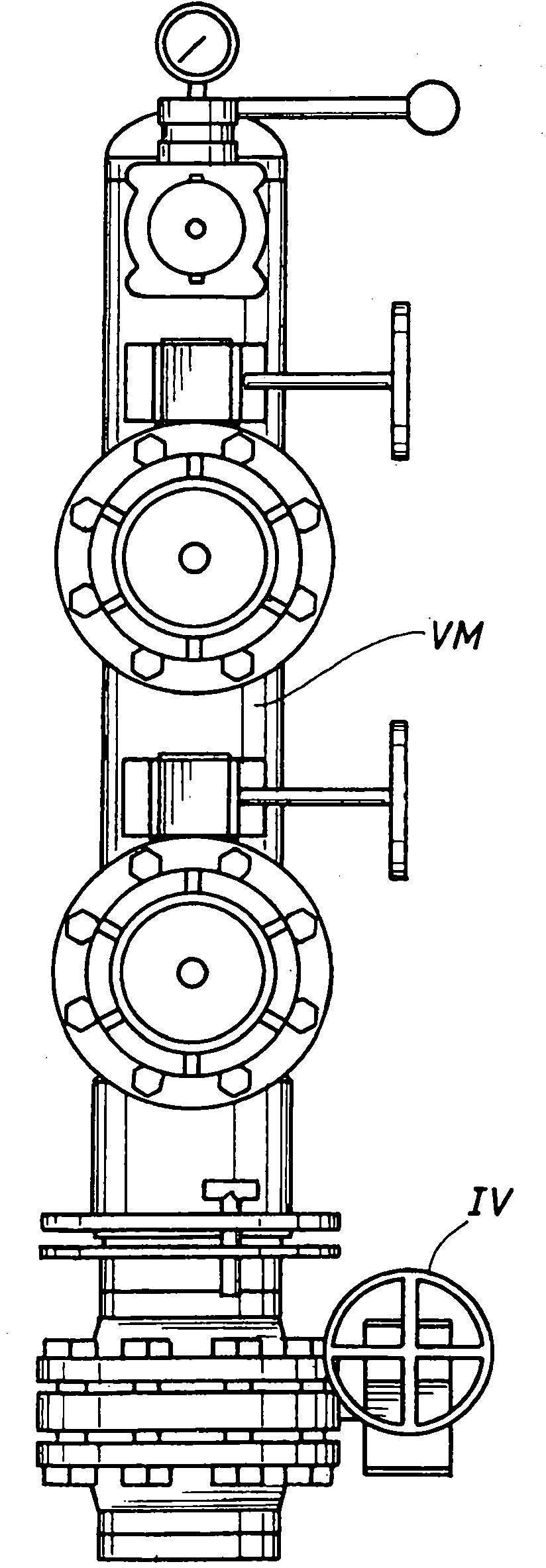

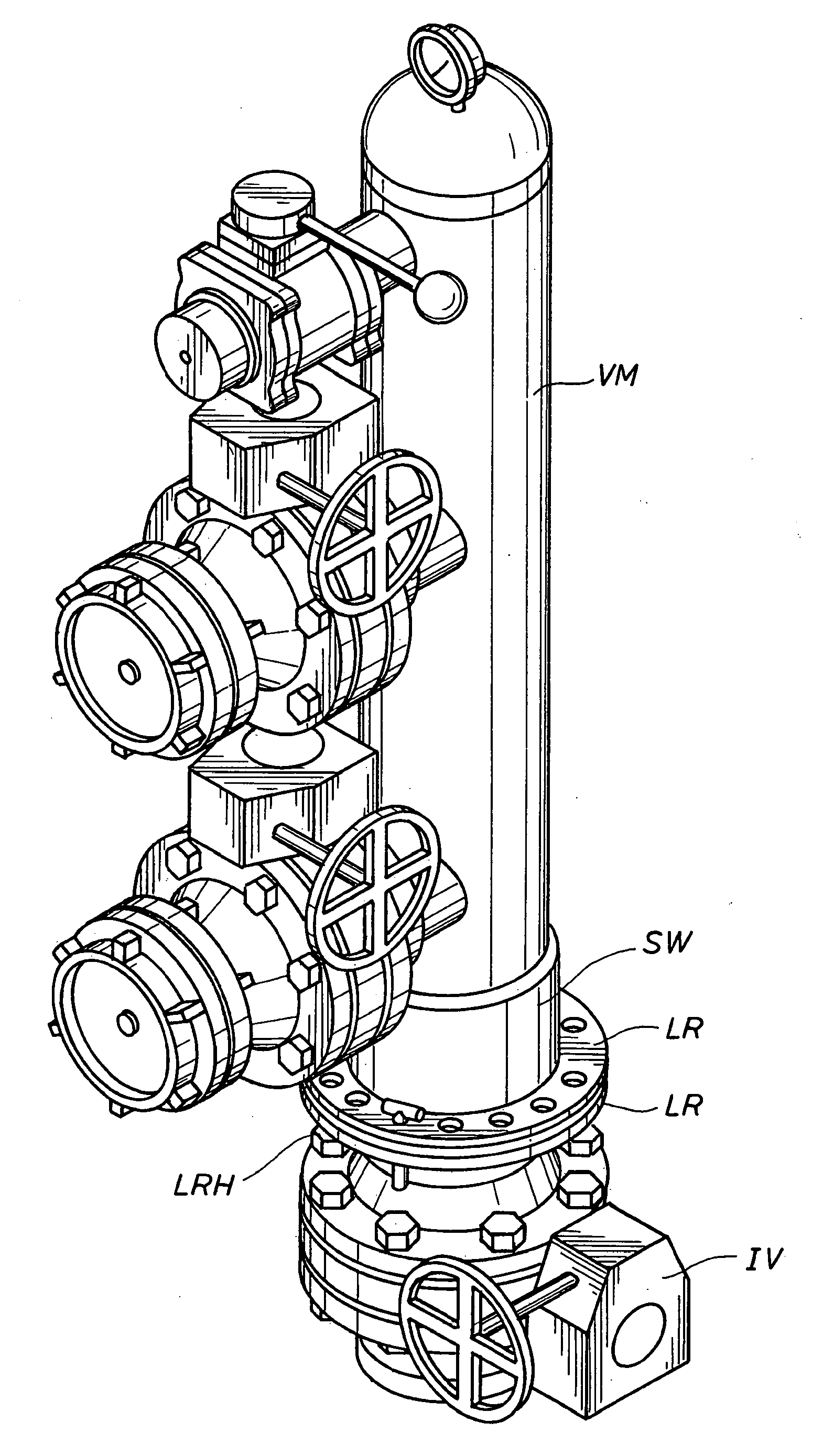

Swivel with or for hydrant manifold industrial fire fighting

A swivel with, or for, a hydrant manifold for industrial fire fighting comprising a swivel providing an at least 6 inch flow conduit and preferably including mating male and female sleeves of stainless steel and preferably having at least two rings of stainless steel ball bearings and a location for an interior water seal.

Owner:WILLFIRE HC

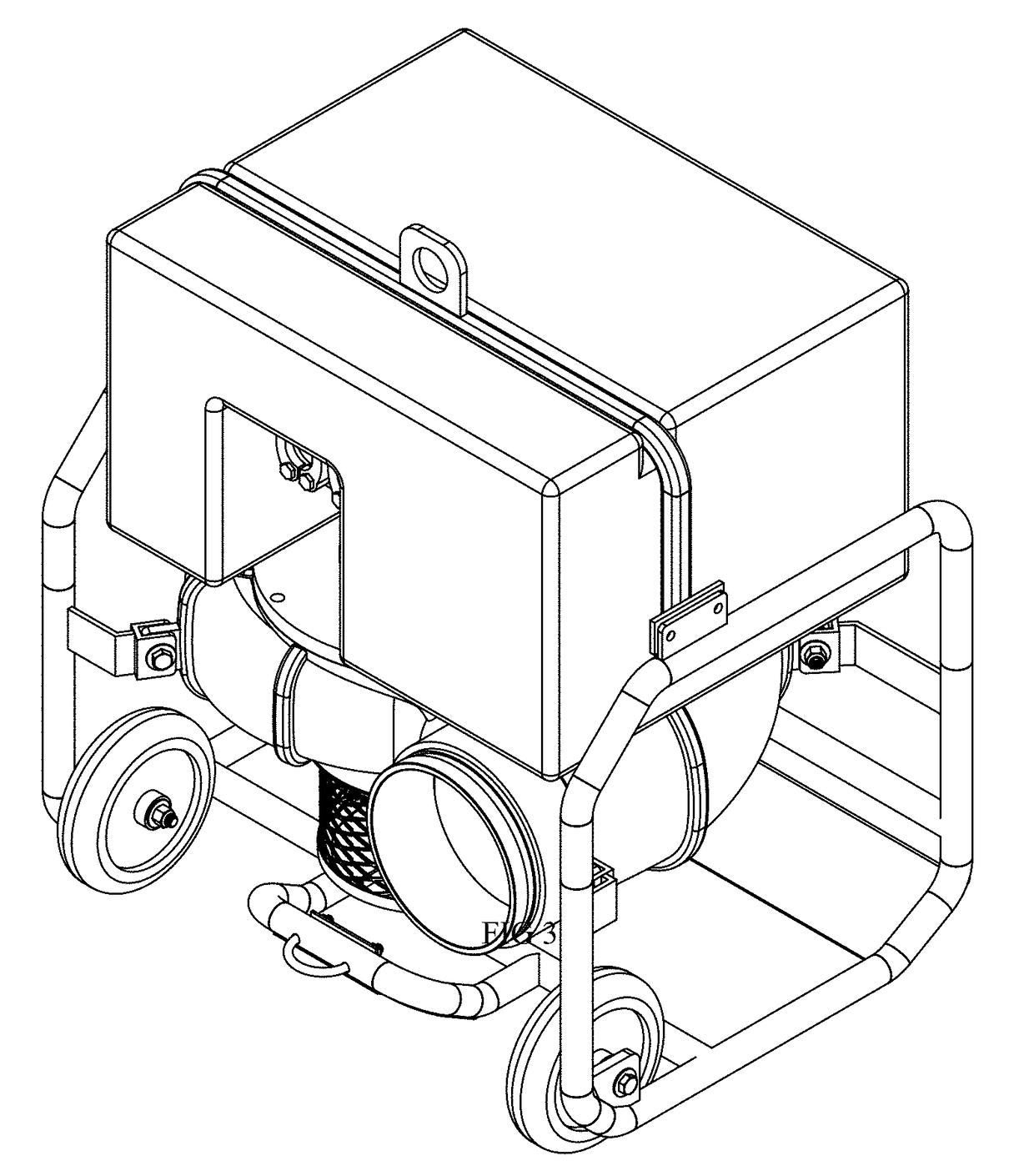

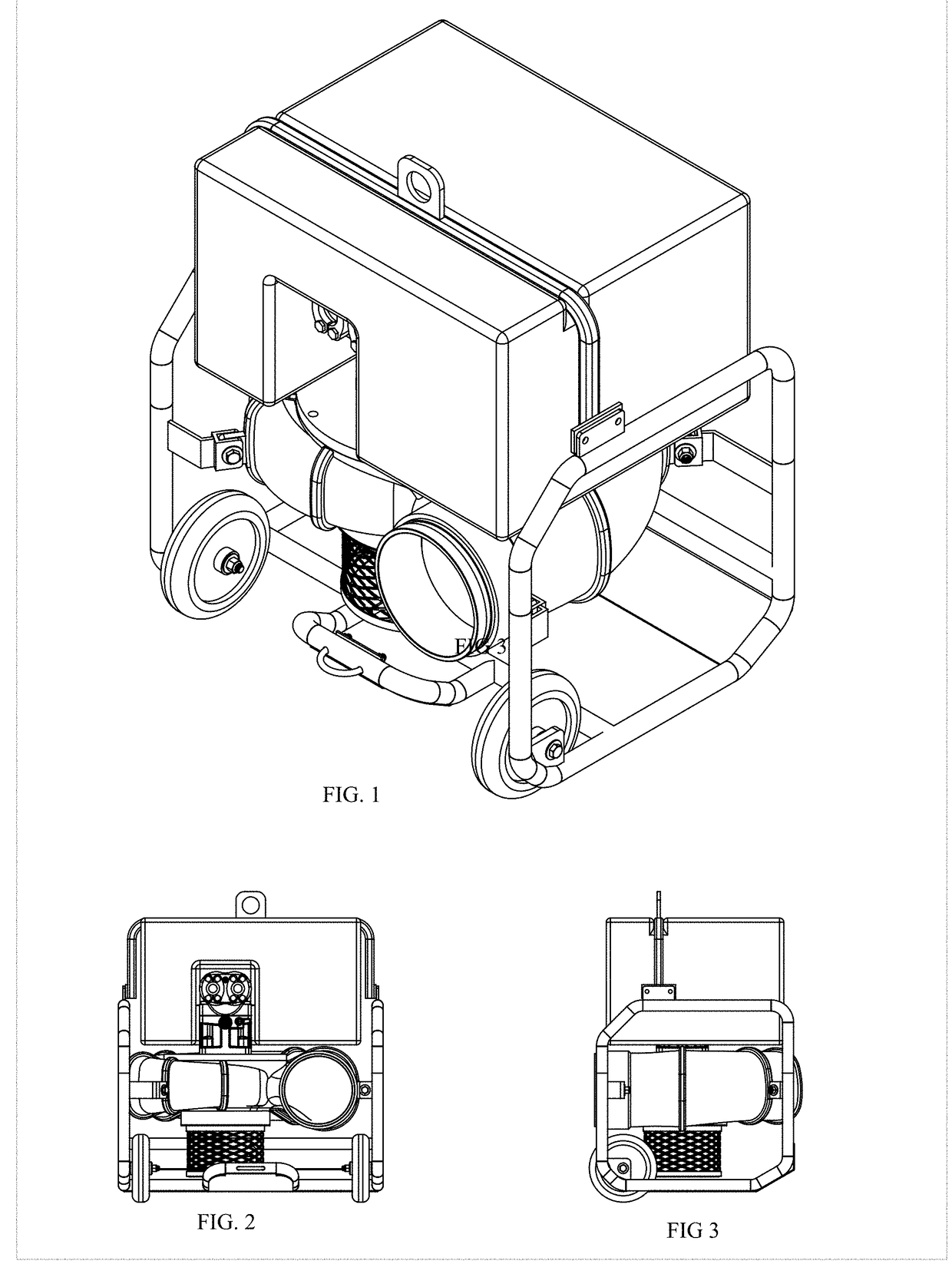

Composite constructed floating submersible water supply pump

InactiveUS20170268522A1Strong and durable and lightweightEliminating corrosion failureSpecific fluid pumpsPump componentsFiberSaline water

The disclosure describes the improvement of mobile floating submersible pump systems where such systems are used for rapid deployment water transfer. Such systems are deployed within industrial fire fighting, flood control operations (FIG. 7) and similar water transfer requirements. A floating submersible pump is designed to separate the power system (FIG. 7, item 11), such as a diesel engine, from the pump body (FIG. 7, item 16), which further enables the operator to deploy a pumping system where traditional ground based centrifugal pumps are unable to physically siphon the water. Floating submersible pump systems are cumbersome in nature, requiring heavy equipment and significant manpower to deploy them. The innovation disclosed uses advancements in structural fiber reinforced materials to drastically reduce the weight of such systems, which removes the need for heavy deployment equipment, with the added benefit of corrosion protection from saline environments through the use of chemically inert composites.

Owner:CHIEF TECH

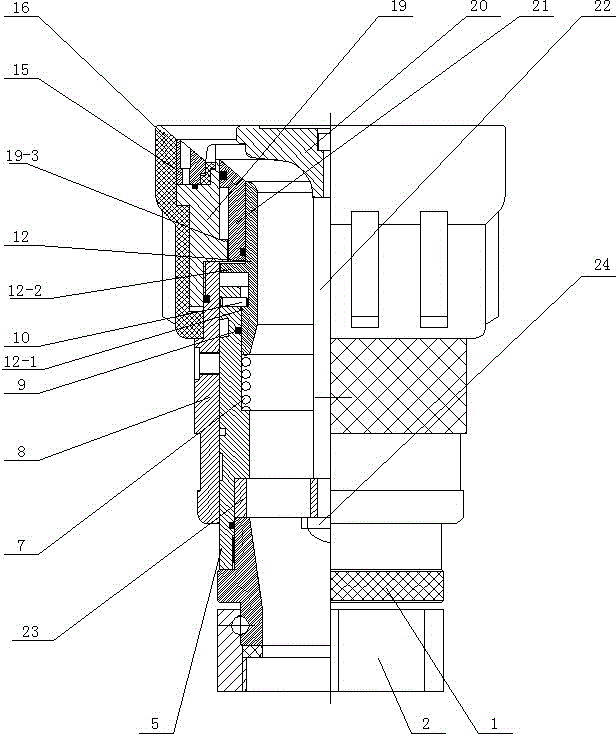

Monitor head of fire-fighting monitor

ActiveCN104147731AAdjust spray pressureDynamic adjustment of spray pressureFire rescueEngineeringIndustrial fire

The invention relates to a monitor head of a fire-fighting monitor and belongs to the technical field of industrial fire fighting. The monitor head comprises a rotating joint seat, a spiral body and a spiral cylinder, wherein the spiral body is mounted on the rotating joint seat, the spiral cylinder sleeves the outer side of the spiral body, is matched with the spiral body through a spiral groove and can move up and down along the spiral body, a nozzle seat which stretches upwards is fixedly connected to the outer circumferential wall of the upper part of the spiral cylinder, and a flow guiding cone which is inserted into the spiral cylinder is arranged on the circumferential wall of the spiral cylinder; a flow-stabilizing fixing ring is arranged at the top of the rotating joint seat, and a top cover which is fixedly connected with the flow-stabilizing fixing ring is arranged in the center of the nozzle seat; an oblique plane which shrink inwards is arranged the circumferential cycle of an outlet of the flow guiding cone, a step is arranged on the circumferential cycle of the inner circumferential wall of the spiral body, and a compression spring is arranged between the bottom of the flow guiding cone and the step. According to the monitor head of the fire-fighting monitor, water jetting capacity can be finely adjusted according to the pressure in the water jetting process, so that the relative stable water jetting pressure of the fire-fighting monitor can be guaranteed.

Owner:TAIZHOU XIANGDA FIRE EQUIP CO LTD

Wind tunnel testing method based on temperature sensing fiber positioning detection

The present invention discloses a wind tunnel testing method based on temperature sensing fiber positioning detection mainly applied to the field of pipeline leak detection. Through establishing a testing device in a powdered media pipeline transportation process, the environment of a powdered media transportation pipeline and various possible damage states of the transportation pipeline, various characteristics after pipeline damage are measured from the outer wall of the transportation pipeline by using a temperature sensing fiber, the data characteristics after pipeline damage are summed and are used as the judgment basis of early warning in actual monitoring, thus the damage of a pipeline lining can be effectively monitored in real time, the early warning of accident risks is realized, and the method has a huge significance for industrial fire safety.

Owner:VITALONG FIRE SAFETY GRP

Swivel with or for hydrant manifold for industrial fire fighting

A swivel with, or for, a hydrant manifold for industrial fire fighting comprising a swivel providing an at least 6 inch flow conduit and preferably including mating male and female sleeves of stainless steel and preferably having at least two rings of stainless steel ball bearings and a location for an interior water seal.

Owner:TYCO FIRE PRODS LP

Water intake engineering control system

InactiveCN110968026AEnsure safe implementationClosed circuit television systemsProgramme control in sequence/logic controllersControl systemProcess engineering

The invention discloses a water intake engineering control system. The system is arranged at a water intake point, the water intake point is provided with a water intake pump room, a water pump control box, a power distribution room, an industrial fire pool and a diesel generator room; a water pump and a water pump control box are arranged in the water taking pump room, a liquid level meter is arranged in the industrial fire pool and comprises a PLC control cabinet, a PLC operator station, a power module, a monitoring module, a communication module, accessories and a communication cable, and the PLC control cabinet is arranged in the water pump control box. The PLC operator station is arranged in the PLC control cabinet, the PLC operator station is a PLC upper computer, and the PLC upper computer comprises an Intel i7-2600 processor, an 8GB memory, a 1TB SATA hard disk and a 22-inch LCD; the power supply module is connected with the PLC control cabinet through a communication cable; the monitoring module is arranged on the site of a water intake project; the communication module is arranged between the monitoring module and the PLC control cabinet, under the power effect of the power module, the monitoring module and the communication module cooperate with each other to monitor the water taking work of the water taking point, and the safety of the electric power production process is guaranteed.

Owner:光大生物能源(六安)有限公司

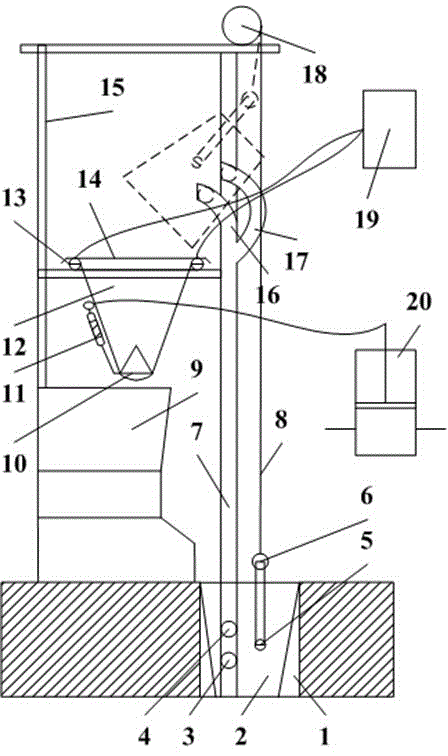

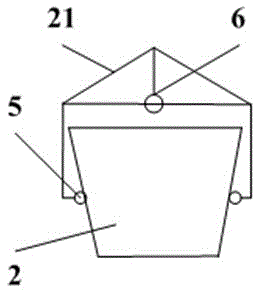

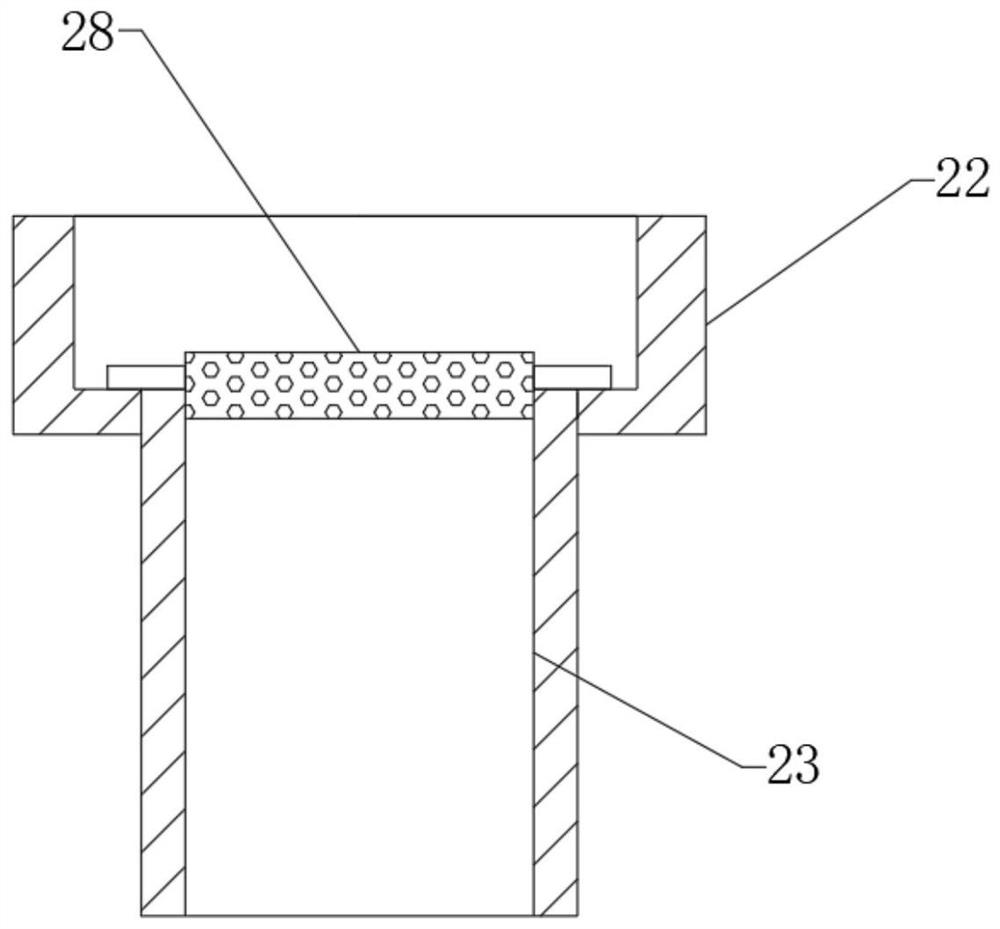

Bucket-type coal quantity weighing metering device for industrial fire coal chain-grate boiler

InactiveCN104792392AReduce labor burdenSolve problems such as measurement errorsWeighing apparatus with automatic feed/dischargeEngineeringLoad cell

The invention discloses a bucket-type coal quantity weighing metering device for an industrial fire coal chain-grate boiler. A coaling bucket is installed in a coal discharging pit. A lifting motor is installed above the coal discharging pit. Vertical guide rails are arranged on the two sides between the coal discharging pit and the lifting motor. Fixed pulleys and upper and lower pulleys are fixedly connected with the two sides of the coaling bucket, the upper and the lower pulleys are embedded in the vertical guide rails and move, and the fixed pulleys and support pulleys are in rigid connection through a pulley support. The lifting motor is fixed on a fixing support and connected with the support pulleys arranged on the coaling bucket through a steel wire rope and drives the coaling bucket to lift. The weighing coal bucket is horizontally installed on the fixing support and provided with a weighing sensor. The weighing sensor is connected with a measuring control cabinet. The bottom of the weighing coal bucket is provided with a gate which is used for discharging the coal, and the bottom of the gate is a boiler coal bucket. The bucket-type coal quantity weighing metering device for the industrial fire coal chain-grate boiler can automatically weigh, meter and discharge the coaling of each bucket, tries not to change the original bucket-type lifting structure and circuit, and is simple in structure and convenient to operate.

Owner:HANGZHOU SPECIAL EQUIP INSPECTION & RES INST

An industrial automatic fire protection system

The invention discloses an automatic industrial fire-control system which includes a control module, a fire-control monitoring module, a positioning module, a water pressure control module and an alarm module. The control module includes a central processing unit and a display unit. The central processing unit acquires the coordinate of a place where fire occurs and generates a place map, computes the area of the place, transmits the place map to the display unit, and transmits the area of the place to the water pressure control module. The fire-control monitoring module divides an industrial factory district into a plurality of independent units, and each independent unit is provided with a smoke sensor therein. The positioning module includes a plurality of signal transmitting units. The water pressure control module includes a signal receiving unit and a plurality of pressure sensing electromagnetic valves. The invention also discloses an industrial fire-control monitoring alarm system, which can perform fire control in a targeted manner, can effectively control injuries and damages caused by the fire in the industrial factory district.

Owner:安徽瑞弋自动化科技有限公司

Method for extracting iron by utilizing nickel slag and preparing fibers

The invention provides a method for extracting iron by utilizing nickel slag and preparing fibers. The method comprises the following steps of: adding a reducing agent and auxiliary materials to nickel slag discharged in a nickel smelting process to reduce oxides of iron in the nickel slag into iron; after the iron is separated, adding an additive to the remaining molten nickel slag; and blowing or throwing the molten mixture with the additive through high-speed air or a centrifugation throwing machine to prepare inorganic fibers. According to the method, on the basis of melting and reducing the thermal nickel slag for refining the iron, the remaining slag is used as a main raw material to prepare the inorganic slag fibers, and the waste nickel slag is changed into valuable materials and recycled, so that the sensible heat of the thermal nickel slag is sufficiently utilized, and the energy consumption in the processes of refining the iron from the nickel slag and producing the fibers is reduced. The main components of the prepared inorganic nickel slag fibers are SiO2, Al2O3 and the like, and the prepared inorganic nickel slag fibers belong to high-temperature inorganic fibers andcan be widely applied to the fields of pipe warm preservation, industrial fire resistance and warm preservation and the like.

Owner:PEKING UNIV

Industrial slag salt secondary calcination purification device and its use method

ActiveCN106145162BBurn fullyEasy to transportSolid waste disposalAlkali metal halide purificationSlagCyclonic separation

The invention provides a secondary calcination purification device for industrial salt slag. The secondary calcination purification device capable of purifying the industrial salt slat, removing organic impurities and realizing recycling of the salt slag, high in purification efficiency and capable of being produced in batch comprises a primary calcinator and a secondary calcinator which is arranged above the primary calcinator, and the first and second calcinators are connected through a temperature control pipe therebetween; a propeller connected with a power unit is arranged in the primary calcinator, and a primary gas mixing chamber is further connected to the primary calcinator and is connected with a natural gas pipeline as well as an air conduit; the temperature control unit is connected with a spiral conveyer; the secondary calcinator is connected with a secondary gas mixing chamber which is connected with the natural gas pipeline as well as the air conduit; a cyclone separator A is connected to the tail end of the secondary calcinator and is connected with a cyclone separator B; the temperature control pipeline is wrapped with a temperature control unit.

Owner:安徽今朝环保科技有限公司

Industrial fire fighting robot with lift stage

ActiveCN107412982BGreat driving forceAvoid bending over to takeFire rescueLifting framesElectric machineryStructural engineering

Owner:CHANGZHOU INST OF LIGHT IND TECH

Low NOx coal dust combustion method and device based on underfire air and overfire air

InactiveCN102003701BEmission reductionReduce carbon content in fly ashCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelBottom ashNitrogen oxides

The invention relates to a combustion improvement technology of an industrial fire coal boiler, aiming to provide a low NOx coal dust combustion method and device based on underfire air and overfire air. The method comprises: injecting parts of two-strand air required for combustion into a hearth from a boiler bottom ash hopper; strongly mixing with aslant downward injected fuel jet flow; fully utilizing the space of the bottom ash hopper to prolong smoke dwell time; burning fuel in a low-temperature oxidation zone; preventing volatile components from converting to nitric oxide; upwards and aslant injecting upper-layer fuel to form a reducing zone, so as to reduce generated nitric oxide into N2; and lowering nitric oxide emission amount. The invention also provides a boiler device for realizing the method. Under the condition that the original combustion condition is not influenced essentially, the invention effectively lowers the emission of nitric oxide and is easy to reform the existing boiler.

Owner:ZHEJIANG UNIV

Petroleum or industrial fireproof thermal insulation coating

InactiveCN107163696ASimple preparation processLow costChloropene polymer coatingsEmulsionPentaerythritol

The invention relates to a petroleum or industrial fireproof thermal insulation coating, and belongs to the field of industrial fire-fighting coating. The petroleum or industrial fireproof thermal insulation coating is prepared from, by weight, 400 to 500 parts of water, 280 to 400 parts of a flexible emulsion, 100 to 180 parts of melamine, 60 to 80 parts of pentaerythritol, and an appropriate amount of an aqueous thickening agent. The flexible emulsion in the petroleum or industrial fireproof thermal insulation coating is capable of prolonging flame retardant time of a base material; foaming is adopted so as to improve the flame retardant effect further and achieve thermal insulation performance. A preparation method of the petroleum or industrial fireproof thermal insulation coating is relatively simple; cost is relatively low; the finished product can be used in industrial buildings; and workability is improved further.

Owner:南通市乐佳涂料有限公司

Mountain fire monitoring method near transmission lines based on MODIS data

InactiveCN104269012BWildfire monitoring fastMountain fire monitoring is accurateScene recognitionFire alarmsSatellite imageBackground information

Owner:ZHEJIANG UNIV

Embedded true fire simulation valve control practical operation device

InactiveCN111091735AReal fire clean combustionAchieve environmental protectionCosmonautic condition simulationsFire rescueProcess engineeringLiquefied petroleum gas

The invention belongs to the field of fire drill. The invention discloses an embedded real fire simulation valve control practical operation device comprising an industrial pipeline facility applied to industrial fire drilling; the industrial pipeline facility is provided with a valve front pipe cavity, a practical operation valve and a leakage pipe cavity from left to right. The valve front pipecavity and the leakage pipe cavity are connected with the industrial pipeline facility through a first flange, a practical operation valve and a second flange respectively. The embedded real fire simulation valve control practical operation device also includes a gas inlet pipe and a gas inlet communication blind plate for drilling gas; the gas inlet communication blind plate is located on the left side of the first flange, and the gas outlet end of the gas inlet pipe penetrates through the gas inlet communication blind plate and the first flange to be communicated with the valve front pipe cavity. According to the scheme, liquefied petroleum gas or LNG is utilized, and the purposes of true fire clean combustion, energy conservation and environmental protection are achieved at the same time; the whole device is simplified and reasonable in process, forms a unit, and can be randomly combined with drilling facilities, so that comprehensive fire-fighting drilling is realized, and the win-win target of true fire and true fire extinguishing capability cultivation is realized.

Owner:XINXING CATHAY INT EMERGENCY EQUIP TECH

Industrial fire-retardant plastic plasticizer

The invention discloses an industrial fire-retardant plastic plasticizer, which is composed of the following components in parts by weight: 10 to 30 parts of polypropylene, 5 to 10 parts of manganese acetate, 6 to 8 parts of butadiene, 4 to 6 parts of acetalated polyvinyl alcohol, 3 to 8 parts of zinc borate, 8 to 12 parts of magnesium hydroxide, and 2 to 7 parts of epoxy plant oil. The plasticizer has a high plasticizing efficiency, and has the advantages of cold resistance, heat resistance, pollution resistance, extracting resistance, good mobility, good electric insulation property, and stability to light and heat. This novel plasticizer is prepared by compounding a plurality of plasticizers; this method enables the resin product to have a very good comprehensive property and achieve a satisfying plasticizing effect, so the method is accepted by more and more factories.

Owner:QINGDAO UWELL INFORMATION TECH

Precise Cutting Device for Soft Metal Delay Cords Used in Industrial Delay Detonators

The invention belongs to the field of civil blasting equipment, and discloses a precise cutting device for a soft metal delay cable used in an industrial delay detonator, which includes a guide fixed knife, a movable cutter matched with the guide fixed knife, an index feed tray, and an index feed tray Matching trimming knife and positioning rod, at least one feeding hole is arranged on the guiding fixed knife, and the head of the movable cutting knife is located above the outlet of the feeding hole, and is in contact with the outer wall of the guiding fixed knife; A material holding tank is arranged on the outer peripheral surface; the notch of the material holding tank is opposite to the outlet of the feeding hole, and is located on the extension line of the outlet of the feeding hole, and the positioning rod is arranged on the axial extension line of the material holding tank, The positioning rod extends into the material trough, and the present invention can realize the smoothness of both ends of the extension cable and the precise lengthening of the extension cable under the condition of maintaining the existing production efficiency, and reduce the deformation of the extension cable, so that the length of the finished extension cable is accurate , the drug surface is not loose, which greatly improves the delay time accuracy and firing reliability of industrial fire detonators.

Owner:ZHEIANG WUCHAN GUANGHUA EXPLOSIVE MATERIALS

Automatic industrial fire extinguishing device based on Internet of Things

InactiveCN112354121ASmall range of directionsSave energyFire rescueHand carts with multiple axesStructural engineeringWater spray

The invention discloses an automatic industrial fire extinguishing device based on Internet of Things. The automatic industrial fire extinguishing device based on Internet of Things comprises a bottomplate, wherein a supporting column a is welded to the upper surface of the bottom plate, a plate body c is welded to the upper surface of the supporting column a, a water pump is mounted on the uppersurface of the plate body c, a water tank is welded to the upper surface of the bottom plate, a water pipe b communicates to a water inlet of the water pump, one end of the water inlet pipe b penetrates through the inner top wall of the water tank and communicates within the water tank, a supporting column b is welded to the upper surface of the bottom plate, one end of the supporting column b isrotatably connected to a plate body a through a bearing, and a water pump transfers water in the water tank to a connecting pipe b. A water spraying angle for fire extinguishment can be adjusted, anddirections of the connecting pipe b and a nozzle can be changed without adjusting the direction of a vehicle body, so that the physical labor is saved. The direction range of spraying of dry powder in a dry powder storage tank is smaller and the dry powder is centralized to fire extinguishing pints, so that equipment can be extinguished better.

Owner:衡阳市华毅自动化科技有限公司

A kind of clean coal with desulfurization effect, high-efficiency combustion and preparation method

ActiveCN105733724BImprove self-desulfurization efficiencyIncrease contact areaSolid fuelsOperational costsIndustrial fire

The invention discloses sulfur-fixation efficiently combusted clean coal with a desulfuration effect and a preparation method used in industries and families. Nano active calcium hydroxide and nano active magnesium hydroxide are prepared and added into raw coal, so that on the basis of the prior art, the sulfur removal efficiency of fire coal and the combustion efficiency of coal are further improved, and emission of SO2 in air is reduced. The sulfur-fixation efficiently combusted clean coal has the main application that firstly, emission of SO2 of industrial fire coal into air is reduced; secondly, the operation cost of sulfur removal is lowered; thirdly, due to direct use of the clean coal in arcola and families, the emission amount of SO2 in air can be effectively reduced, air pollution can be alleviated, and the probability of haze can be reduced; fourthly, the use amount of a calcium desulfurizer is reduced, and the utilization efficiency of the calcium desulfurizer is improved; fifthly, the effective utilization rate of raw coal can be increased.

Owner:韩秀峰 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com