Organic acid reinforced steel slag fuel gas desulfurization method

An organic acid and steel strengthening technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of affecting the desulfurization rate, slow dissolution of alkaline substances, etc. The effect of reducing the cost of desulfurization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

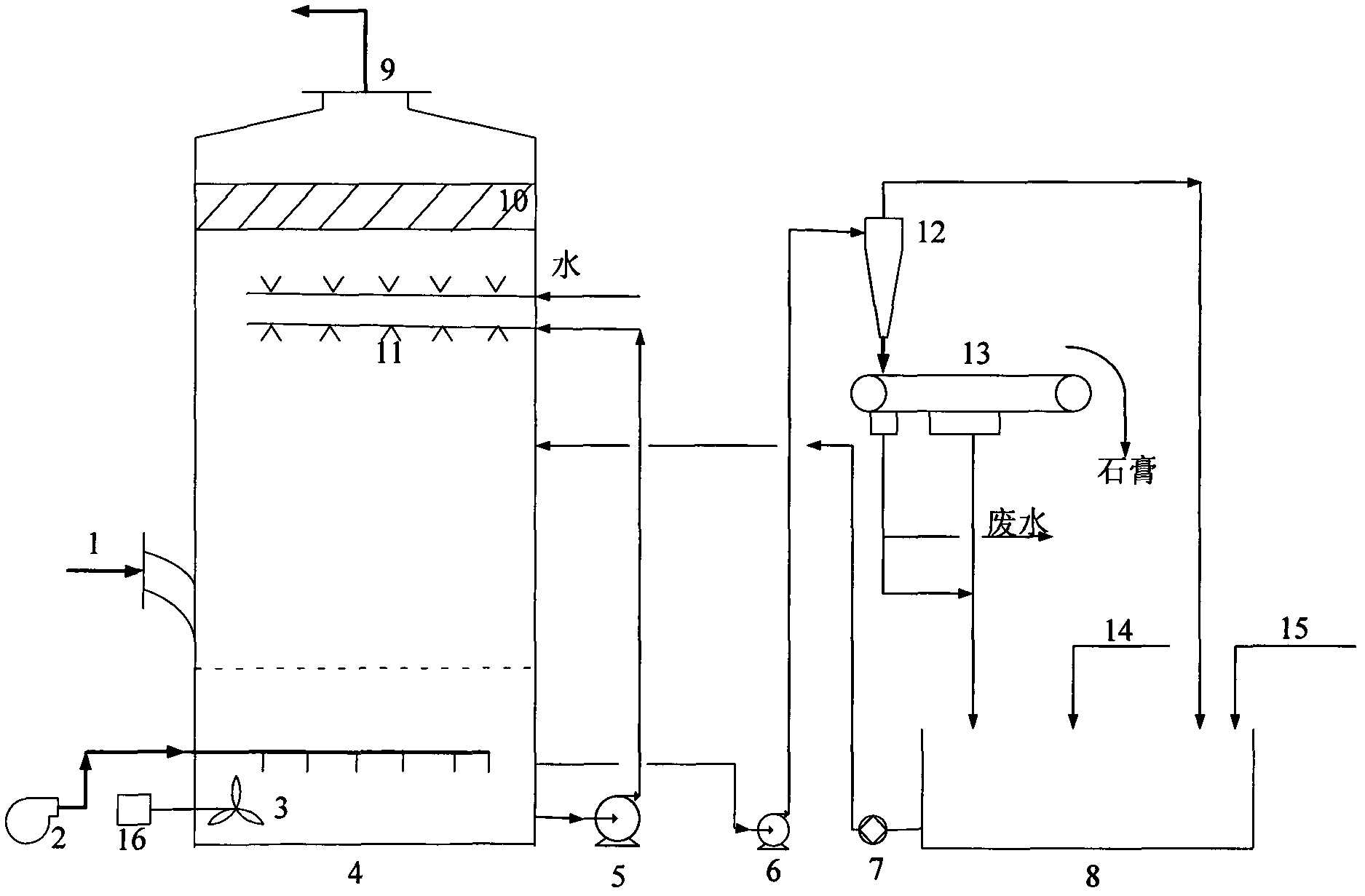

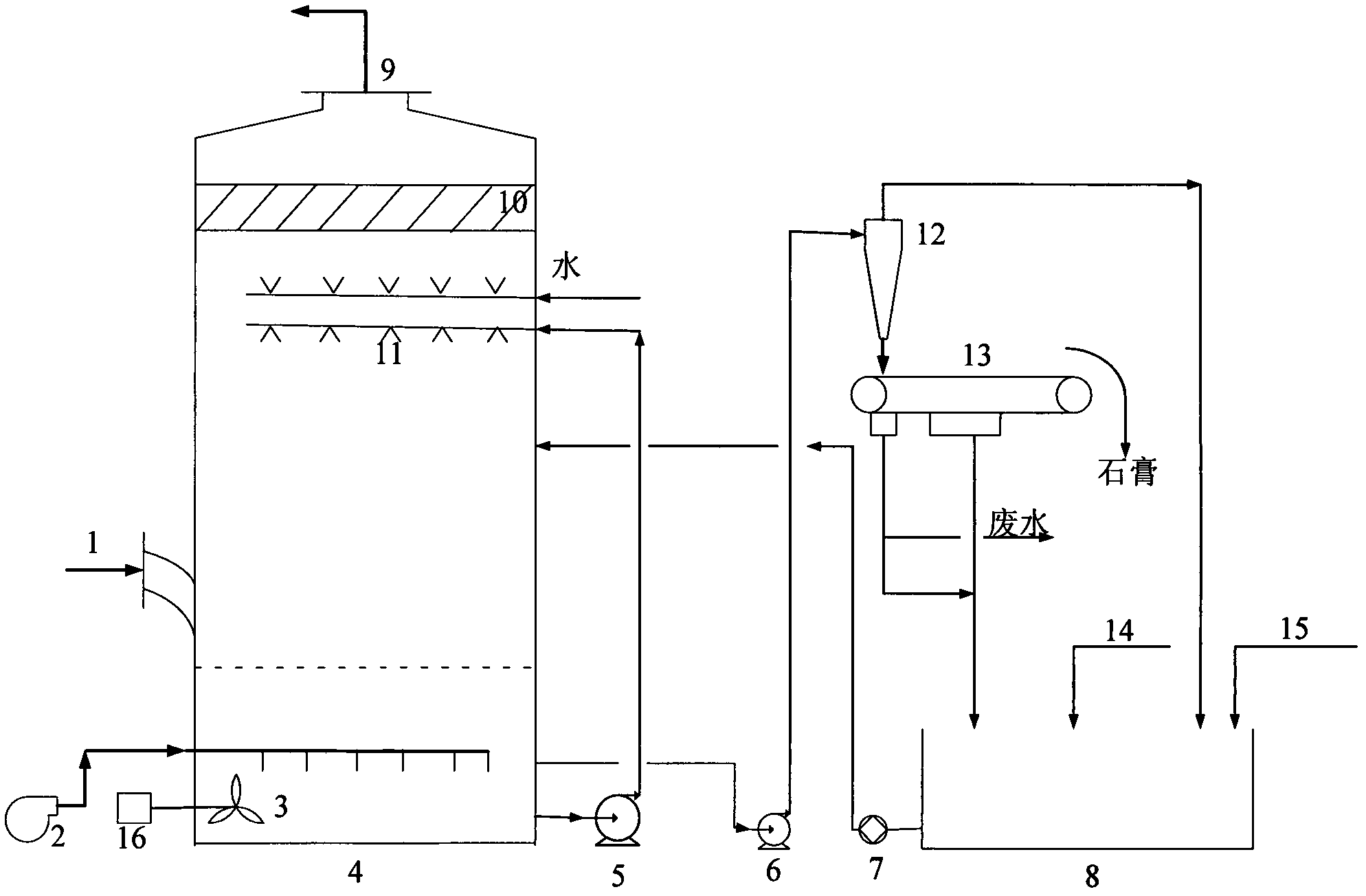

[0031] Referring to accompanying drawing 1, steel slag is directly added in the steel slag dissolving tank 8 through 15, and the organic acid that replenishes simultaneously joins in the steel slag dissolving tank 8 from organic acid supply port 14, and after steel slag and organic acid react for 5-6 hours, the supernatant It is transported into the desulfurization tower 4 through the absorption slurry feed pump 7 and contacts with the flue gas entering from the flue gas inlet 1, and the absorption desulfurization reaction occurs, and the purified flue gas is discharged from the top 9 of the desulfurization tower 4 through the demister 10, absorbing SO 2 The absorption slurry is transported to the nozzle 11 through the slurry circulation pump 5 at the bottom of the desulfurization tower 4 to continue spraying and absorbing SO 2 , the sulfite and bisulfite generated at the bottom of the desulfurization tower 4 are forcibly oxidized into hemihydrate gypsum by the air blown in by...

Embodiment 2

[0035] According to the technological process described in embodiment 1, carry out the supporting flue gas desulfurization of 170t / h boiler, boiler outlet SO 2 The concentration is 1800mg / Nm 3 , the temperature is 152°C, the pH of the tower is 6.0, the organic acid in the steel slag slurry tank is acetic acid, the concentration is 10%, and the liquid-gas ratio is 5.0L / m 3 , the desulfurization rate is 96.2%, and the steel slag utilization rate is 98.6%.

Embodiment 3

[0037] The coal quality used in Example 2 is adjusted according to the process described in Example 1, and part of sulfur is added to increase the boiler flue gas outlet SO 2 The concentration is 9690mg / Nm 3 , the organic acid in the steel slag dissolving tank is citric acid, the concentration is 10%, and the liquid-gas ratio is 7.0L / m 3 , all the other conditions are the same as in Example 2, the desulfurization rate is 95.8%, and the steel slag utilization rate is 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com