Patents

Literature

55results about How to "Increase calcium ion concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

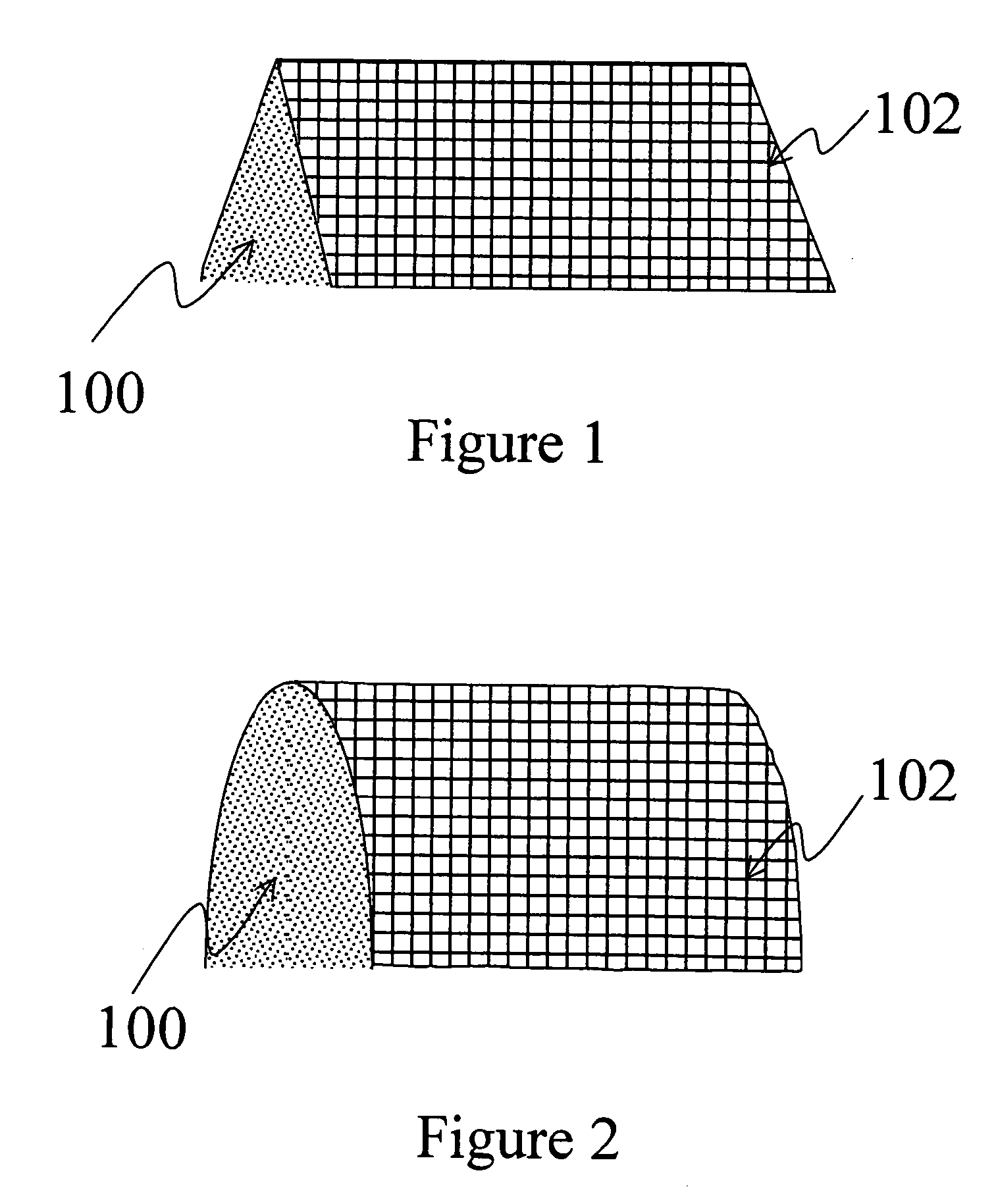

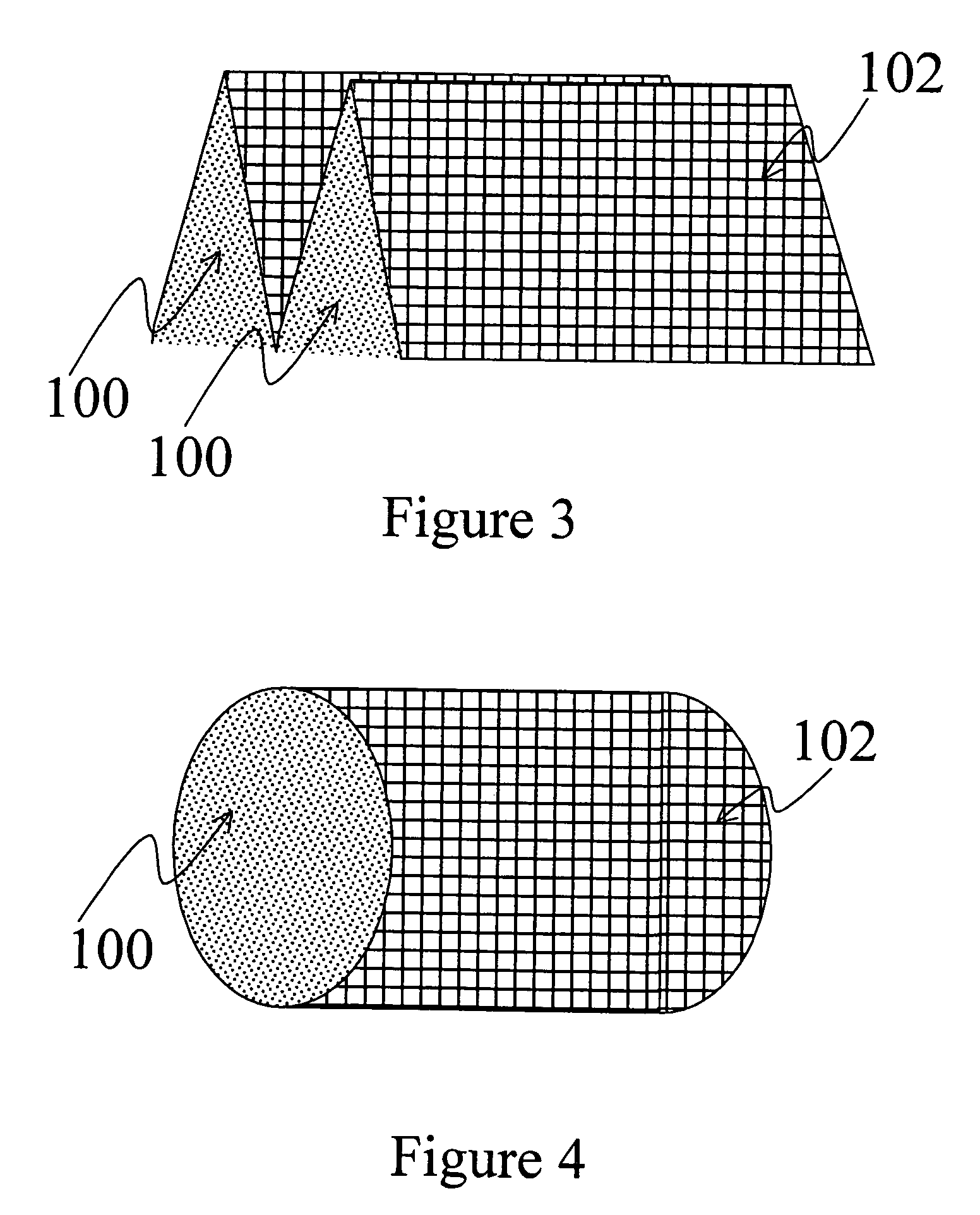

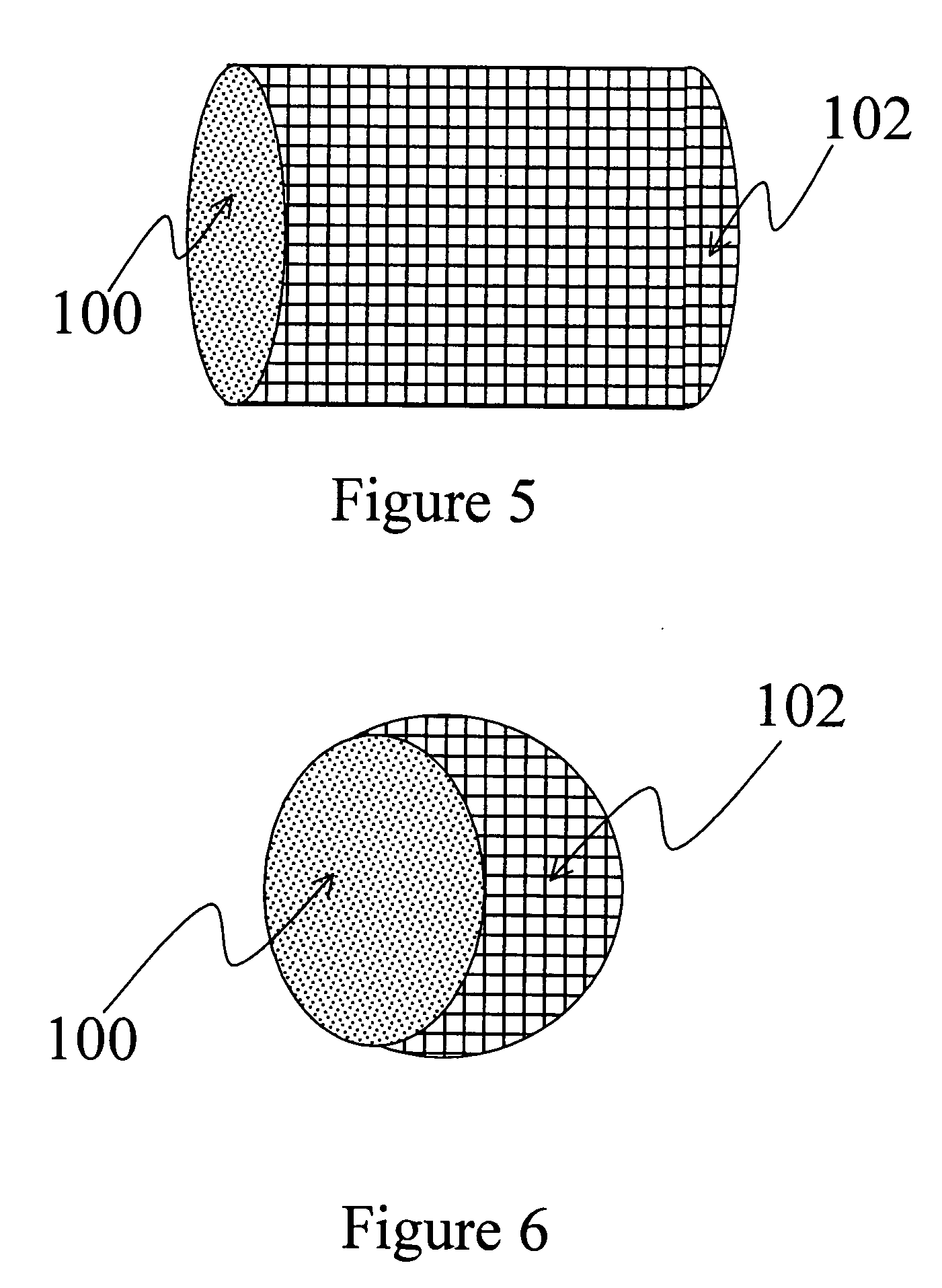

Method of making cell growth surface

InactiveUS20060292690A1Cell density be limitedReduced viabilityCell culture supports/coatingTissue/virus culture apparatusCell adhesionCell growth

The present invention discloses a three-dimensional porous growth surface made from polysaccharide material, especially the alginic acid, to enhance cell growth surface, promote cell adherence, immobilization and propagation, maintain surface structure integrity, enable programmable degradation, and thus increase cellular production. The present invention teaches several methods: a method to enhance the integrity of the growth surface by protecting the growth surface in a rigid solid support; a method of use for enhancing the performance of the surface; and a method of modifying a growth surface for eukaryotic and / or prokaryotic cells comprising the steps of increasing surface area by creating porous and 3-D structure, treating a surface to encourage cell attachment, promoting cell growth and proliferation, and disposing the growth surface in any conventional cell cultivating device. The growth surface is able to program degradation and release the cell / tissue mass after the culture is completed.

Owner:CESCO BIOENGINEERING CO LTD

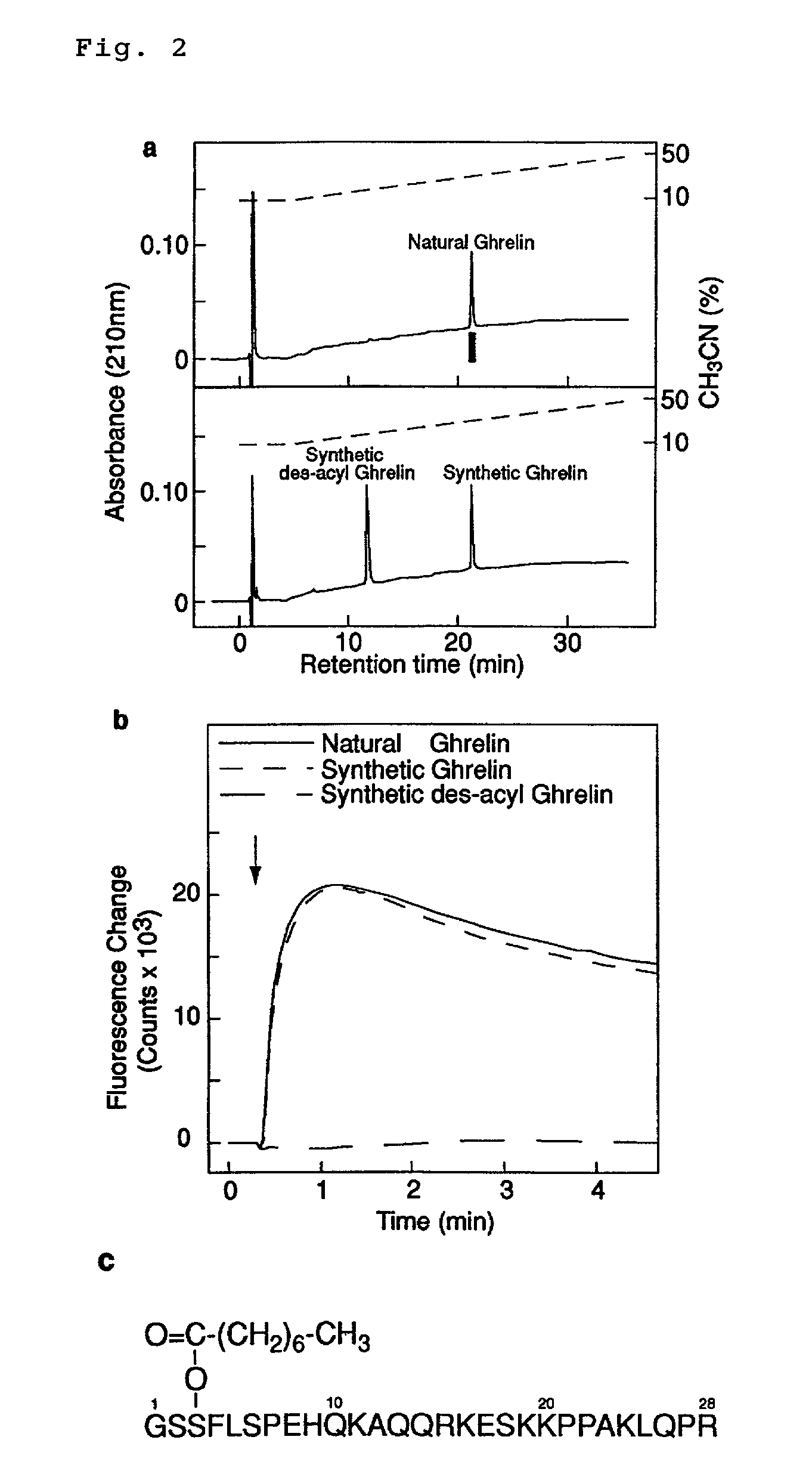

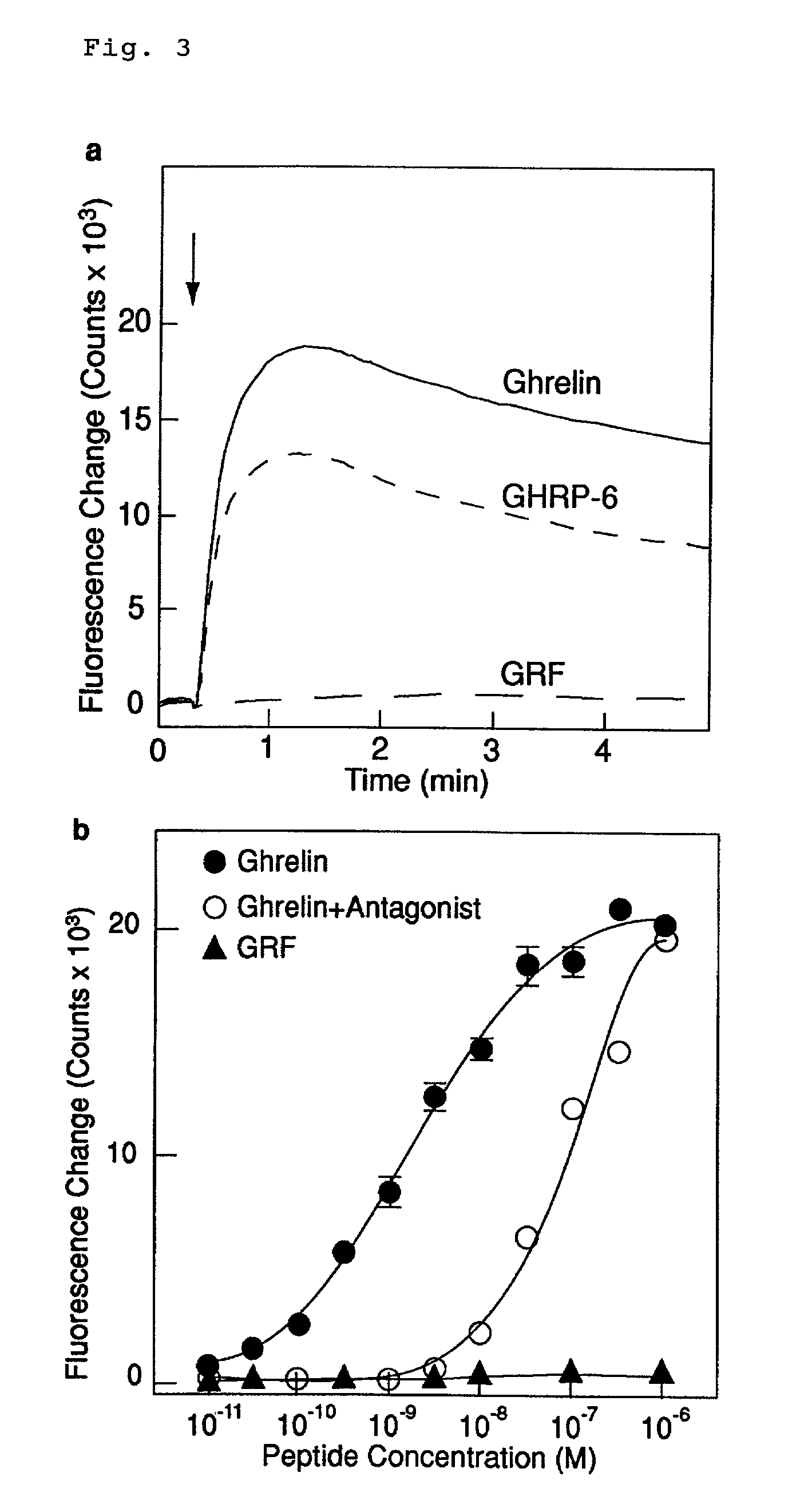

Modified ghrelin polypeptides

InactiveUS7385026B1Increasing intracellular calcium ion concentrationIncrease calcium ion concentrationFungiBacteriaSomatotropin secretionIntracellular calcium ion

The present invention provides a peptide-type compound which induces secretion of growth hormone and which has the activity of increasing the intracellular calcium ion concentration, wherein at least one amino acid is replaced by a modified amino acid and / or a non-amino acid compound, or a pharmaceutically acceptable salt thereof.

Owner:KANGAWA KENJI

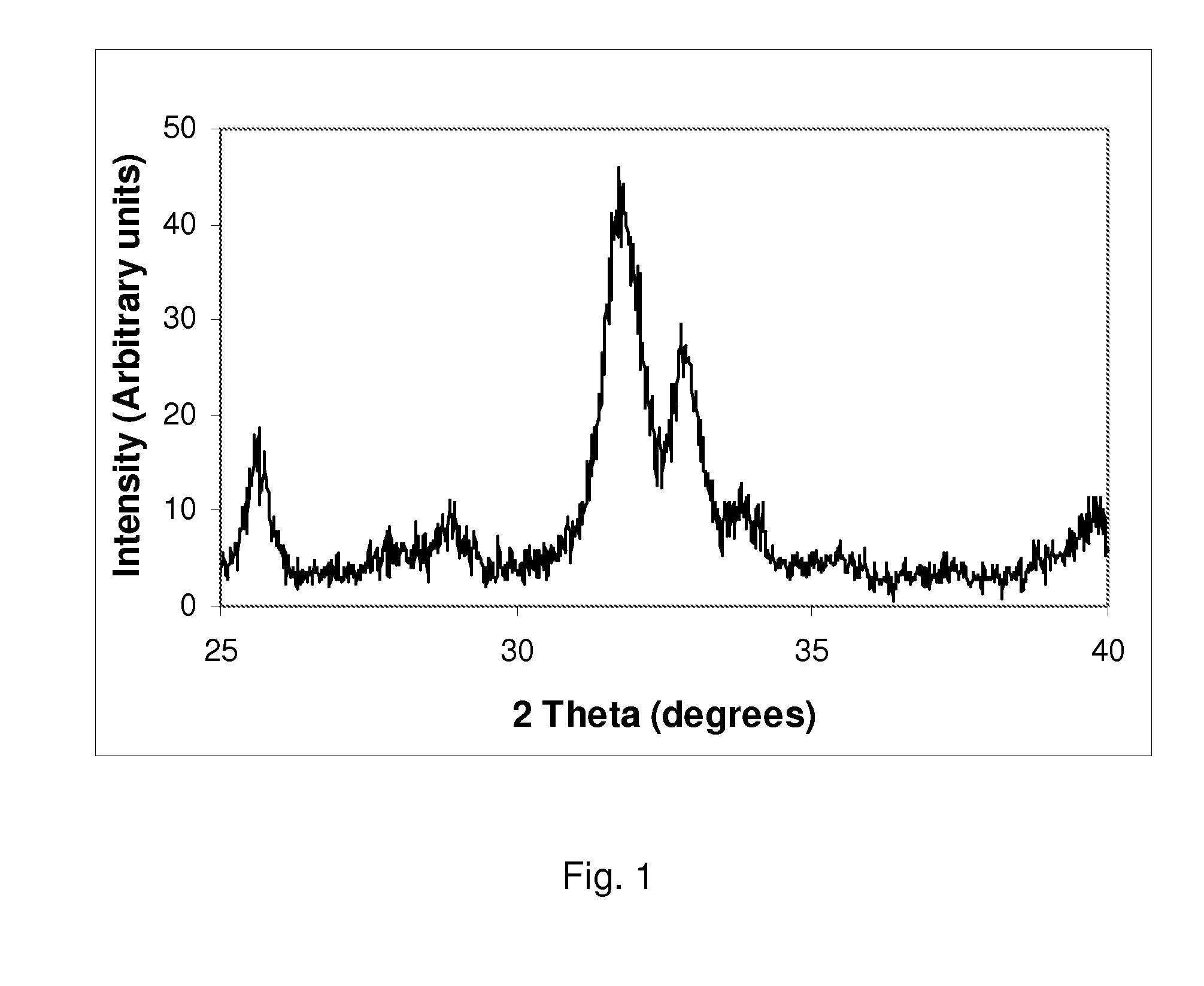

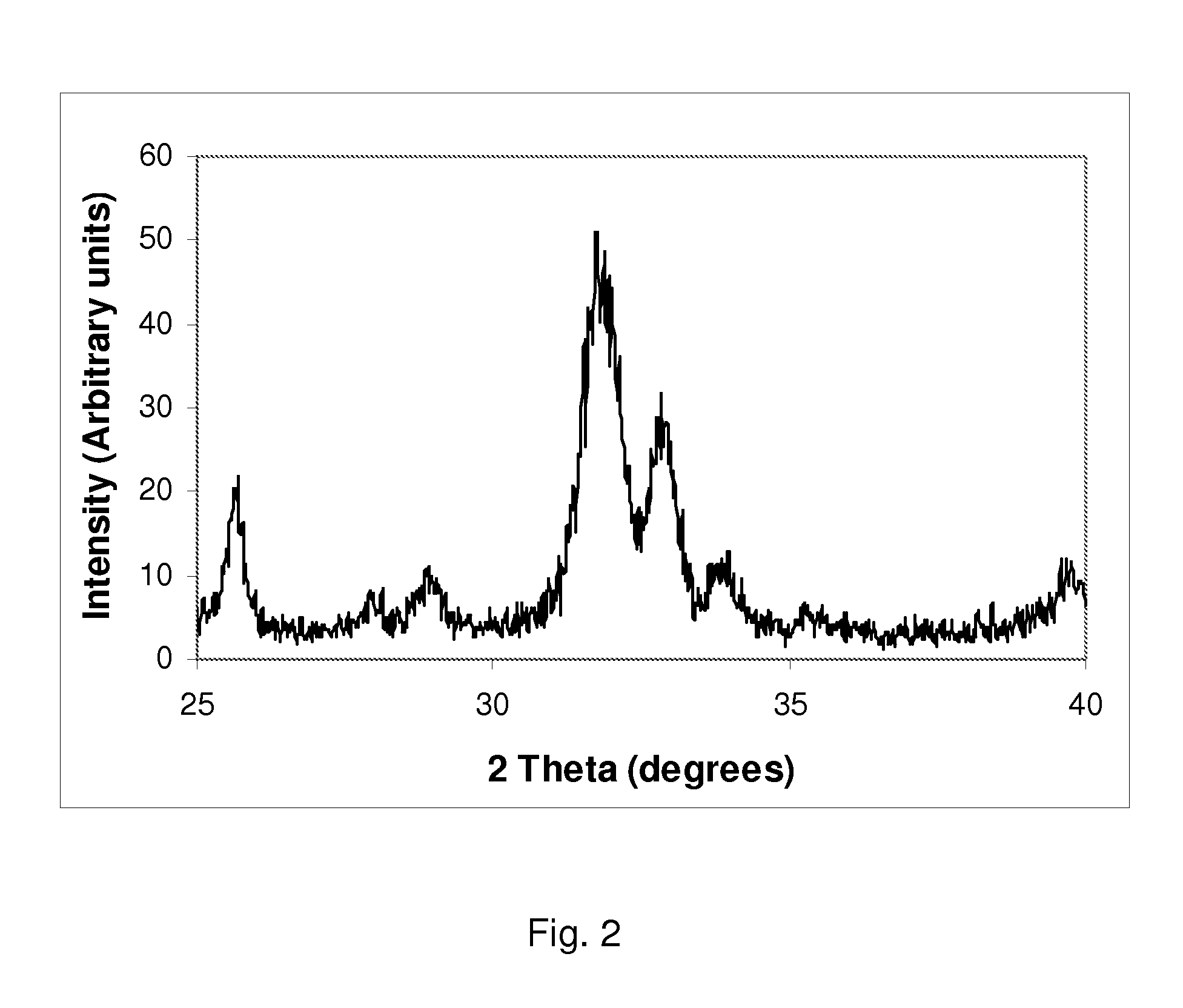

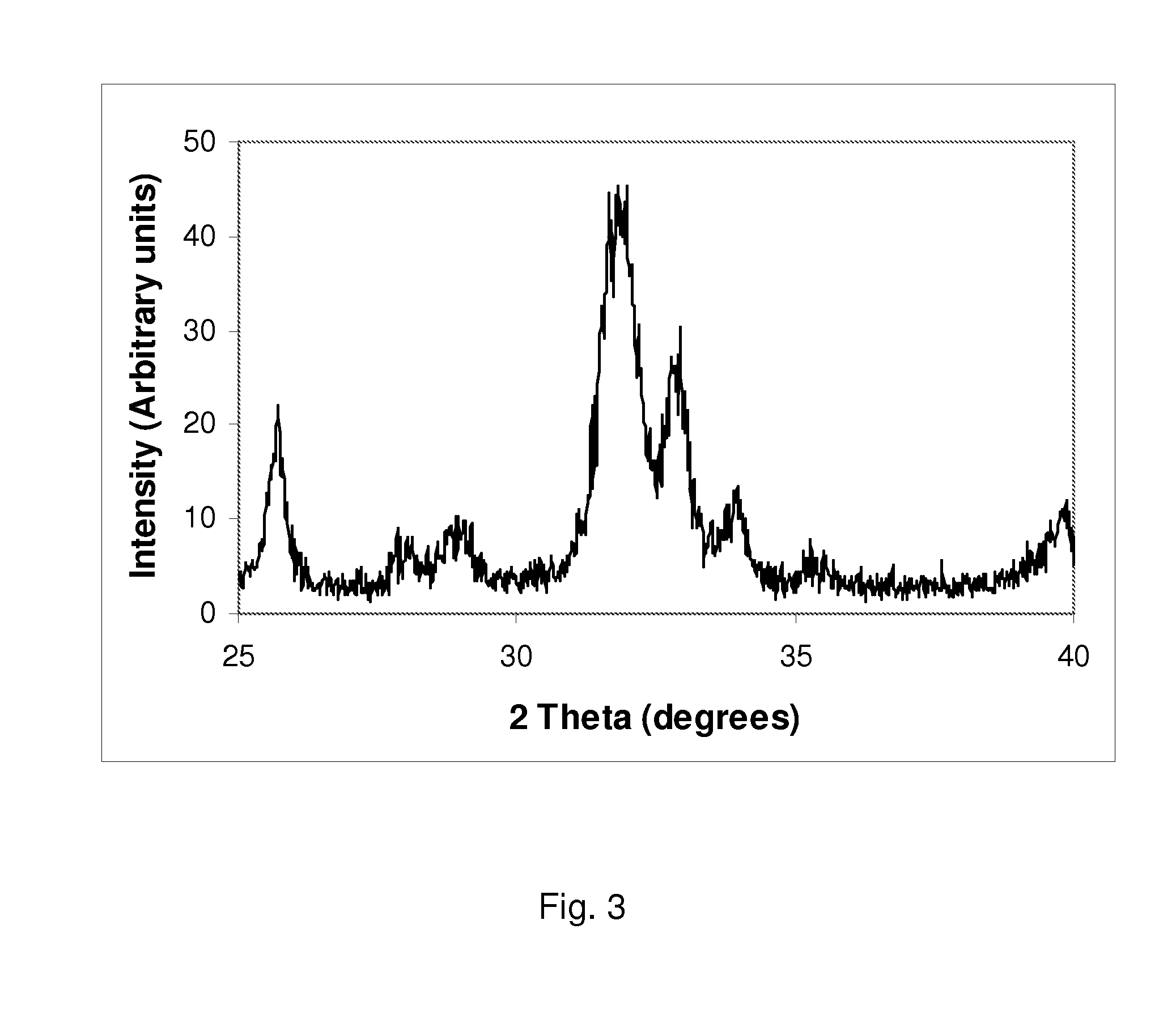

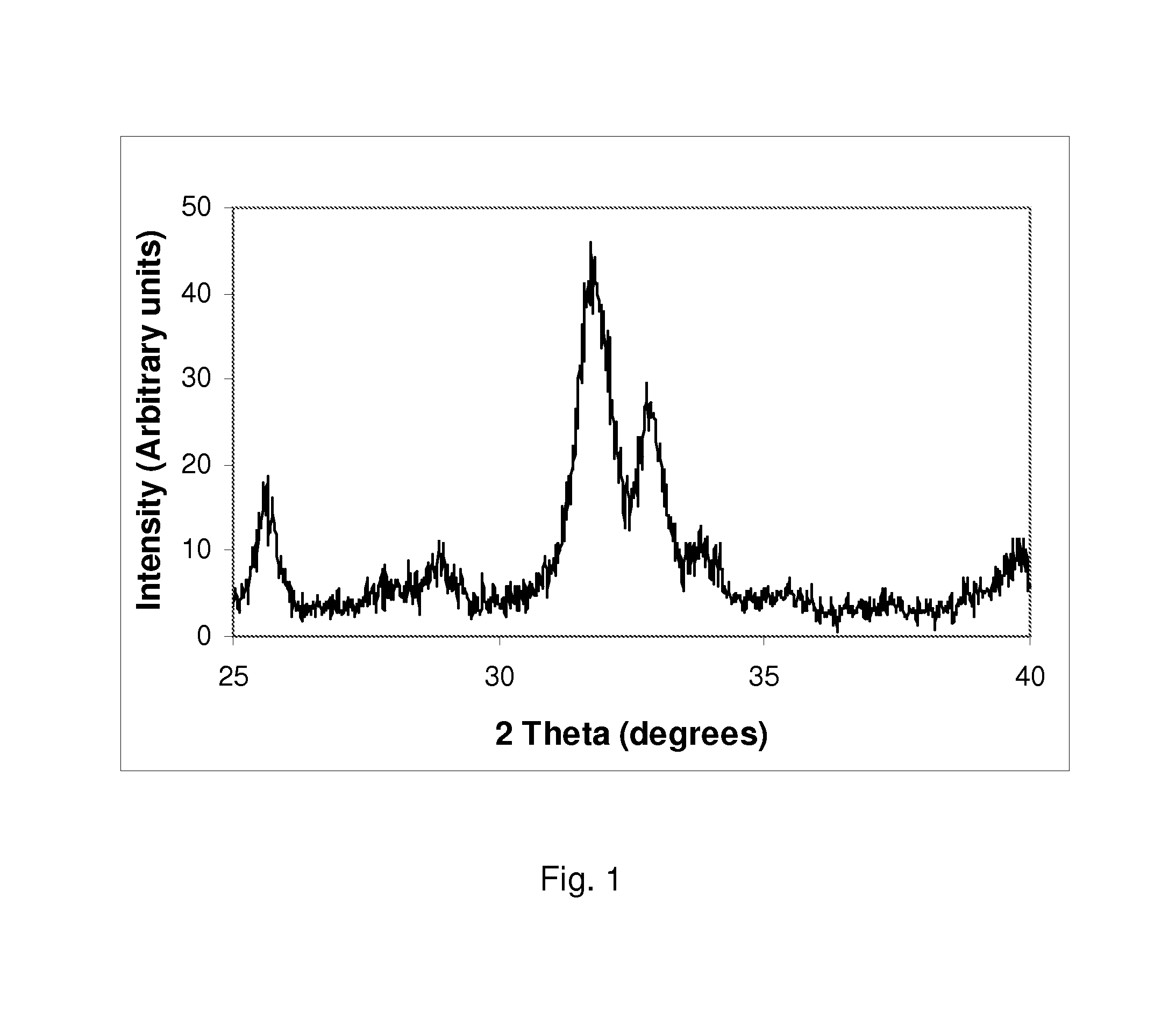

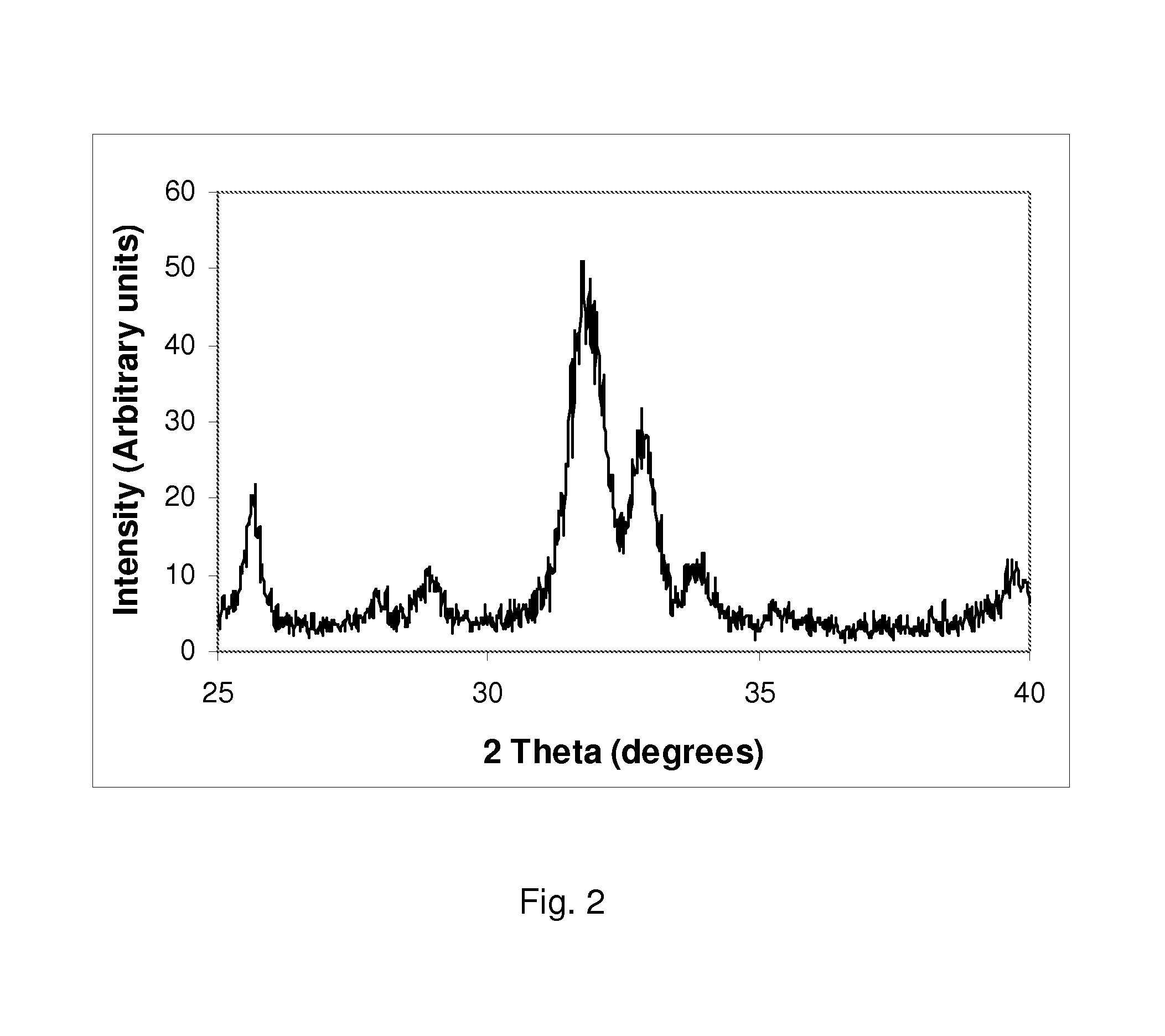

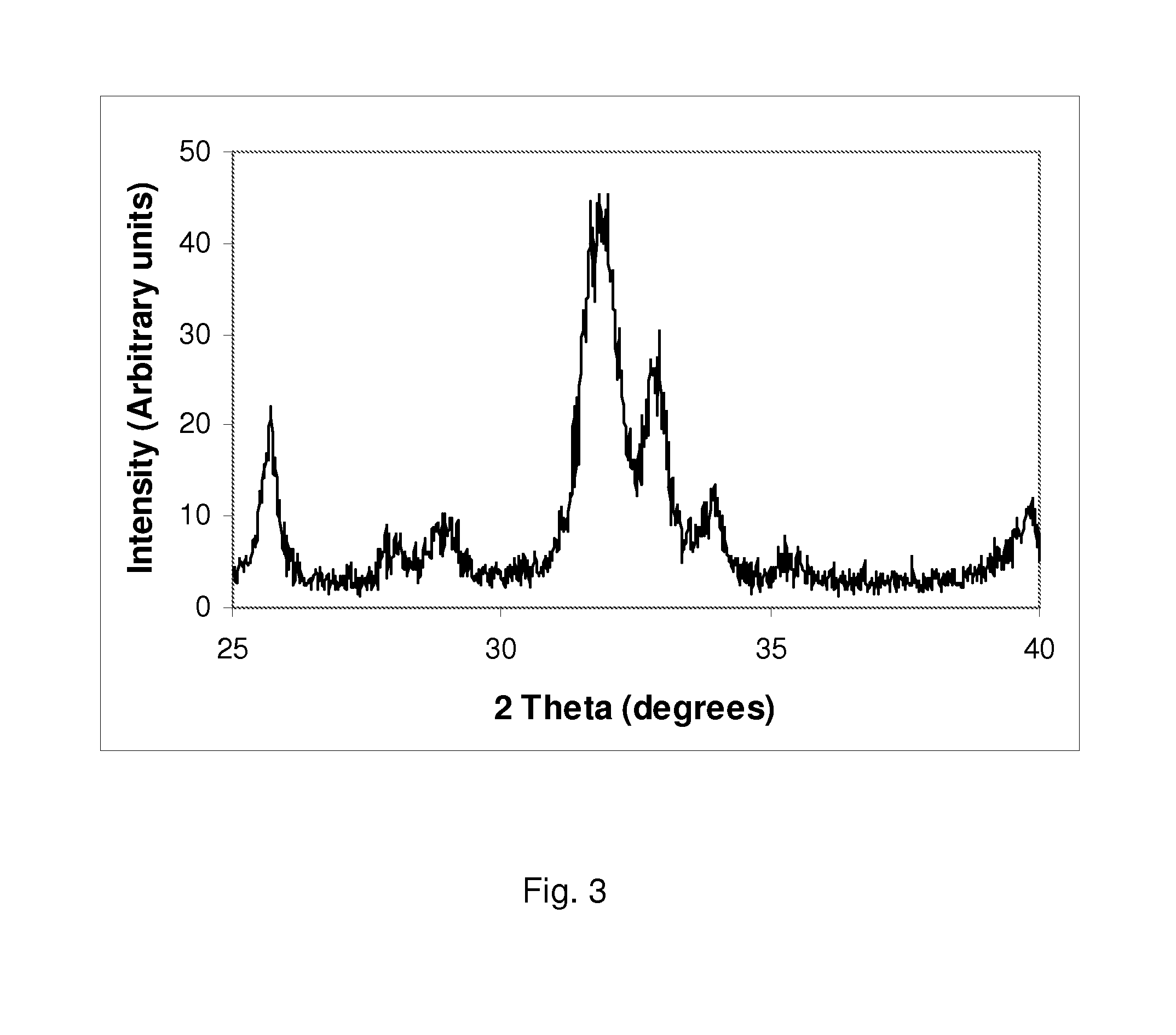

Silicate-substituted hydroxyapatite

ActiveUS20100173009A1Ease of mass productionImprove the level ofBiocideImpression capsCalcium biphosphateSolubility

An inorganic silicate-substituted calcium phosphate hydroxyapatite, useful as a biomaterial, has a Ca / P molar ratio in the range 2.05 to 2.55 and a Ca / (P+Si) molar ratio less than 1.66. The hydroxyapatite can be substantially free of carbonate ions. The material has relatively high solubility and is able to release silicon into solution.

Owner:SIRAKOSS

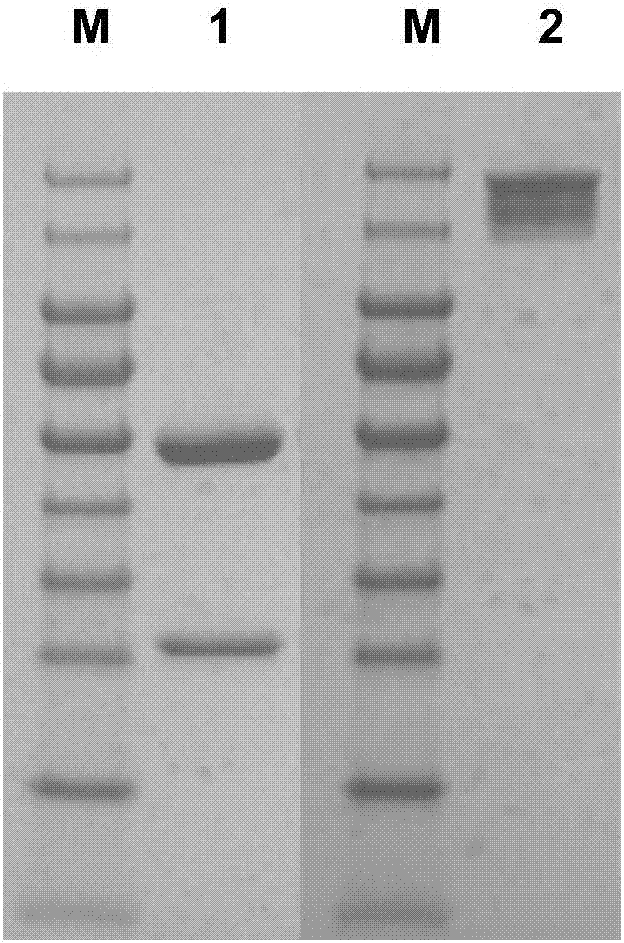

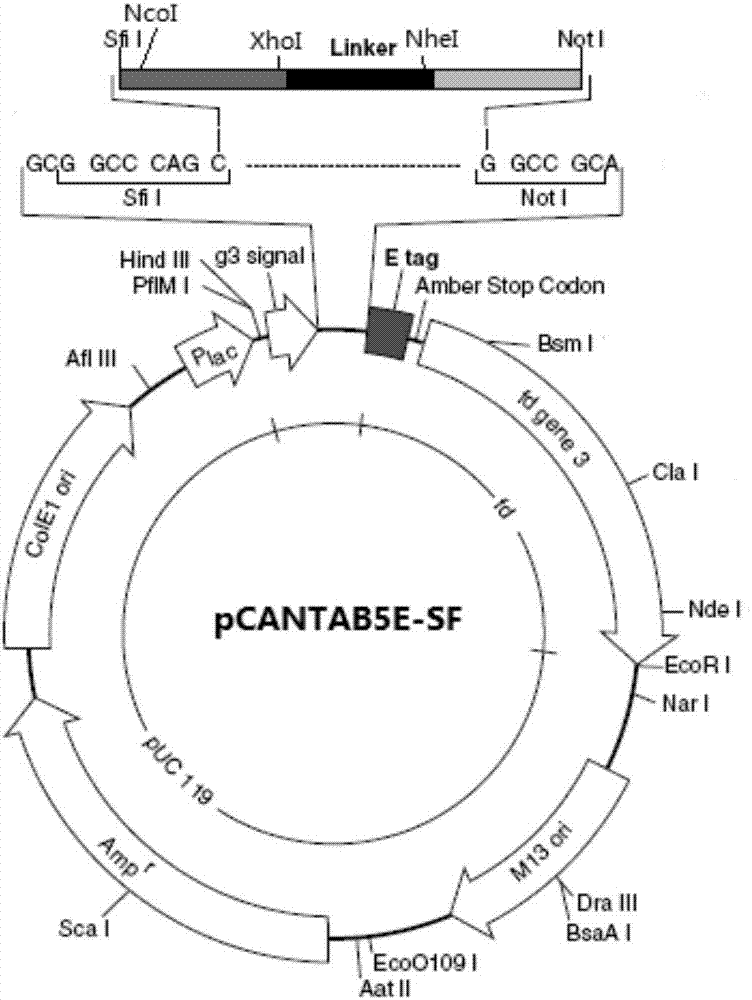

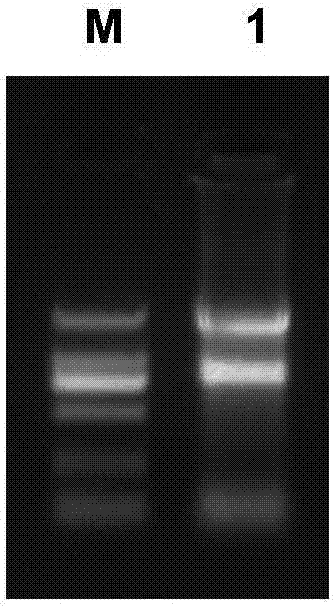

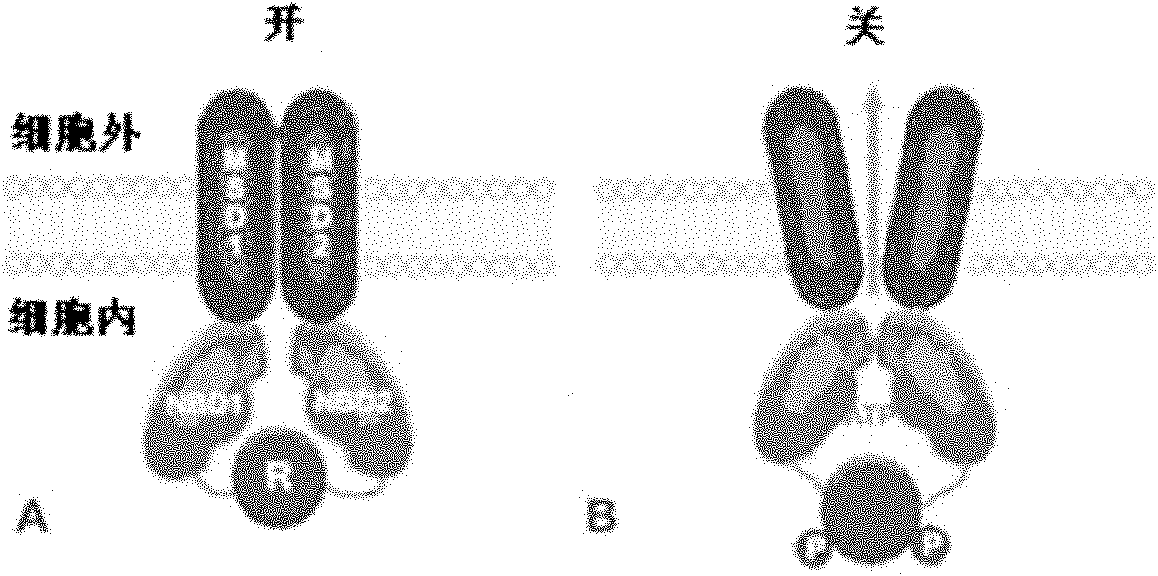

Anti-VEGFR (vascular endothelial growth factor receptor) 2 monoclonal antibody and application thereof

ActiveCN106892980AIncrease calcium ion concentrationImmunoglobulins against cell receptors/antigens/surface-determinantsAntibody ingredientsAntiendomysial antibodiesVascular proliferation

The invention belongs to the field of antibody drug, and discloses a full human-derived anti-human VEGFR2 monoclonal antibody screened by a phage antibody base technology and prepared by a gene engineering method, and further discloses a carrier including polynucleotide for encoding the monoclonal antibody, a host cell and an application. Through combining with VEGFR2, the monoclonal antibody stops the combination of VEGF with VEGR2, and does not induce receptor dimerization, cause the following tyrosine residue phosphorylation in intracellular tyrosine kinase structure and activate downstream signal access including activation of phospholipase C and increase of calcium ion concentration in the cell and others; the antibody drug triggers endothelial proliferation, survival, cytoskeleton rearrangement, cell migration, gene expression and others, and finally stops the vascular proliferation caused by combination of VEGF and VEGFR2 and induction of dimerization. The monoclonal antibody can be used for treating diseases caused by tumor angiogenesis.

Owner:CHANGCHUN GENESCIENCE PHARM CO LTD

Fertilizer for preventing bacterial wilt and promoting growth special for tomatoes

InactiveCN106242843AReduce the severity of the diseaseImprove disease resistanceSuperphosphatesMagnesium fertilisersPhosphorous acidMetasilicate

The invention discloses a fertilizer for preventing bacterial wilt and promoting growth special for tomatoes. The fertilizer is prepared from pig manure, chicken manure, earthworm manure, bagasse, crucifer, urea, superphosphate, potassium sulphate, manganese sulfate, magnesium sulfate, ferrous sulfate, ammonium molybdate, borax, prohexadione-calcium, calcium metasilicate, calcium carbonate, phosphorous acid, heteroauxin, humic acid, attapulgite, bentonite, microbial flora, alkyl glycoside, oligosaccharins and polyaspartic acid. The fertilizer for preventing bacterial wilt and promoting growth special for the tomatoes is reasonable in formula, comprehensive in nutrition and capable of promoting growth of the tomatoes, the disease resistance of tomato plants is improved, and bacterial wilt can be effectively prevented and controlled.

Owner:ANHUI SIERTE FERTILIZER IND

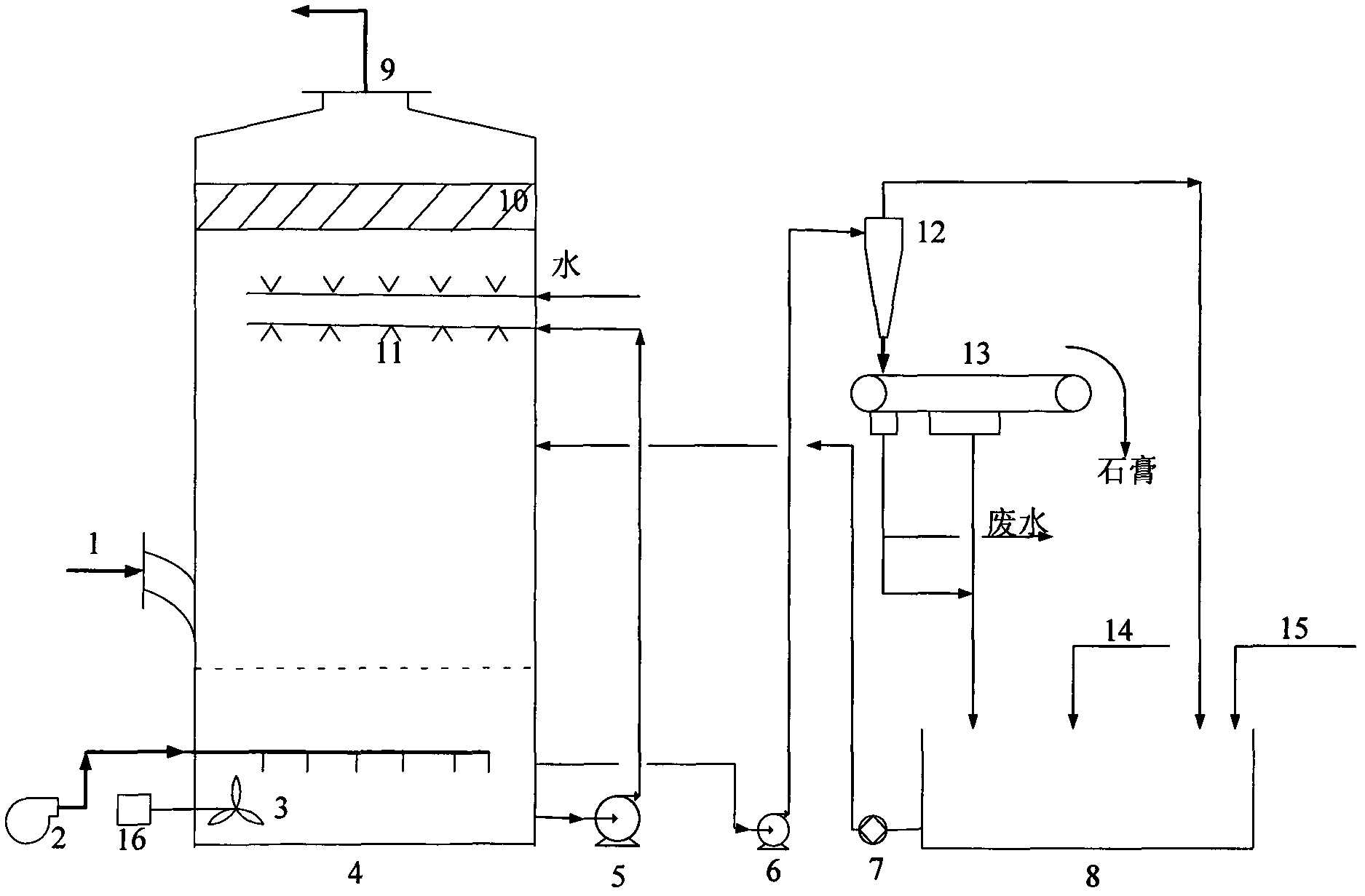

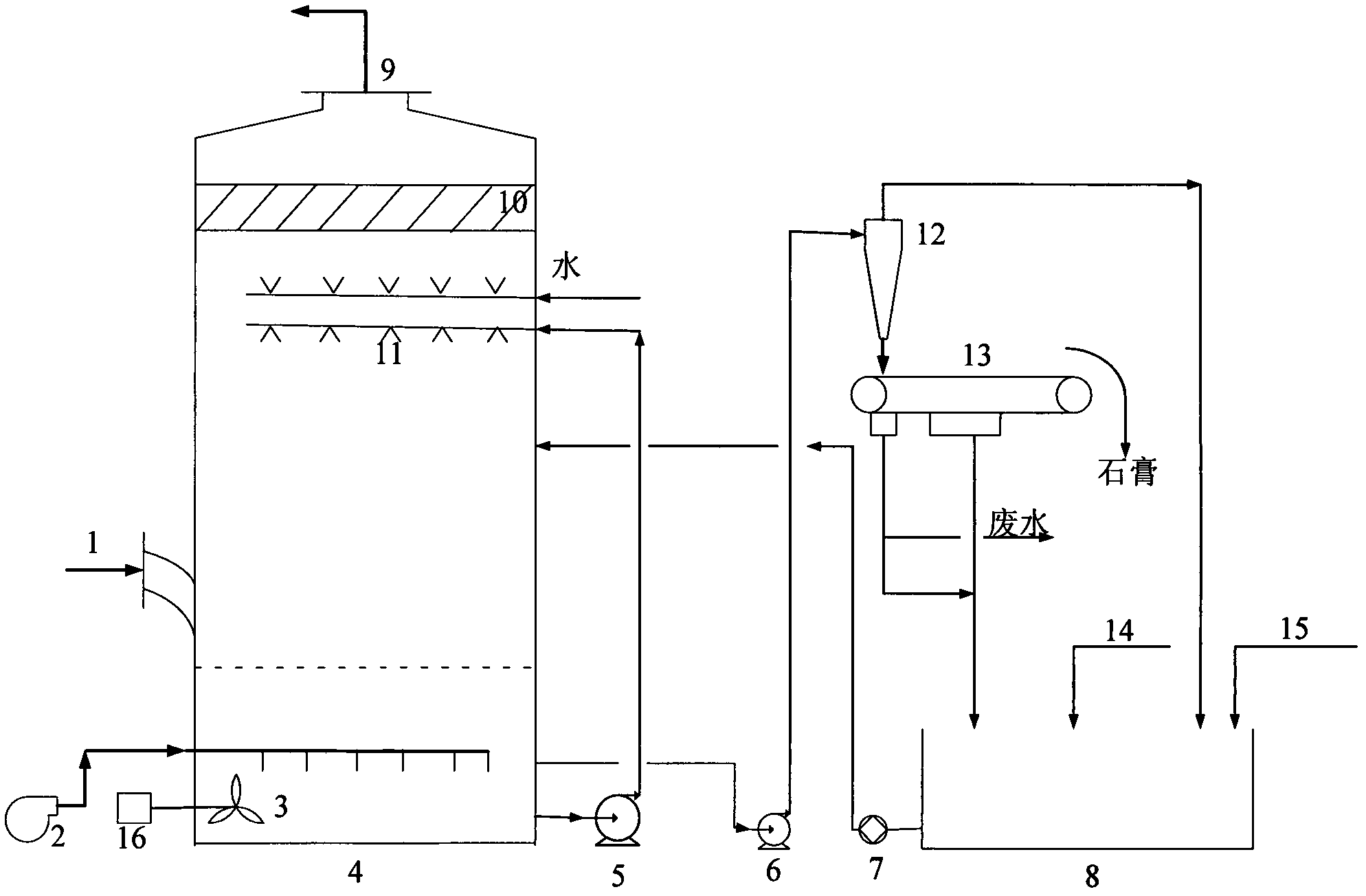

Synergist for assisting wet-process desulphurization of thermal power plant, and application method of synergist

InactiveCN103432894AReduce surface tensionIncrease the speed of diffusionDispersed particle separationOrganic acidGas to liquids

The invention discloses a synergist for assisting wet-process desulphurization of a thermal power plant. The synergist comprises the following components in percentage by mass: 55%-60% of organic acid, 15%-20% of organic acid salt, 10%-15% of oxidized catalyst, and 10%-15% of chelating dispersing agent. The acidity of the organic acid is stronger than that of carbonic acid and weaker than that of sulphurous acid, and the organic acid salt is used for providing organic acid groups. The synergist can reduce the surface tension between gas and liquid and improve the dispersion speed of gas to liquid; the concentration of calcium ions in the liquid solution can be increased, the crystallization speed of sulfate ions can be accelerated, and the desulfurization efficiency of the system and the utilization rate of lime stone can be improved; in addition, the characteristics of calcium sulfate crystals can be changed, so that muddy crystals can be produced, the crystals can be prevented from being deposited at parts, such as a spray nozzle.

Owner:杨子江

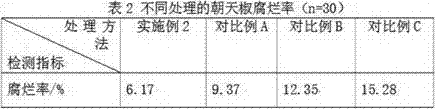

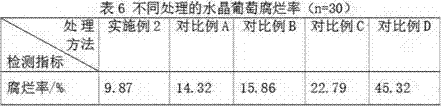

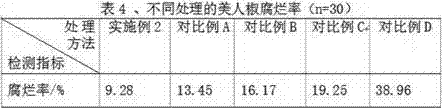

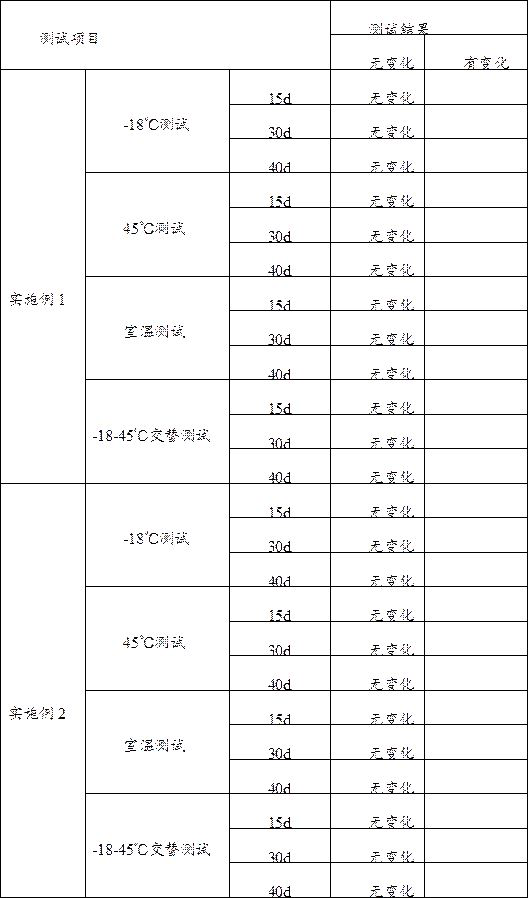

Fresh keeping method for fresh chillis or grapes

InactiveCN107047752AGuaranteed concentrationIncrease calcium ion concentrationFruit and vegetables preservationPlant protectionTrichoderma harzianumChemistry

The invention discloses a fresh keeping method for fresh chillis or grapes. The method comprises the following steps of: spraying chillis or grapes with trichoderma harzianum in a certain concentration one week before harvesting, impregnating the chillis or grapes with calcium salt cooling water in a certain concentration after harvesting, then airing the impregnated chillis or grapes in ventilating cold storage while maintaining the ventilating cold storage with a certain ozone concentration, subsequently putting the treated chillis or grapes into a spontaneous modified atmosphere package and performing sealing with 1-methylcyclopropene or 1-methylcyclopropene and a SO2 sustained release preservative in an airtight condition, tying the package, and then storing the chillis or grapes at low temperature while maintaining the indoor humidity of a fresh-keeping storehouse to be equal to or greater than 90%. According to the fresh keeping method for the fresh chillis or grapes, the previous steps of spraying calcium before harvesting and permeating calcium at normal temperature after harvesting are moved into the pre-cooling step by using the calcium salt cooling water so that the pre-cooling speed is accelerated, the efficiency is improved and the fresh keeping effect is achieved and improved. The method is particularly applicable to storing and fresh keeping the chillis and grapes harvested in a rainy season.

Owner:GUIYANG UNIV

Hyaluronic acid injection

PendingCN112294668AImprove water retentionSoft textureCosmetic preparationsToilet preparationsHyaluronate InjectionCollagenan

The present invention provides a hyaluronic acid injection, which comprises hyaluronic acid or sodium hyaluronate, amino acids, propylene glycol, vitamins and minerals. According to the hyaluronic acid injection, regeneration and reconstruction of collagen in a body are filled and promoted, so that the skin problems of dryness, fine wrinkles and aging are improved.

Owner:西安博和医疗科技有限公司

Treatment solution for sliced fruit

InactiveUS20120269942A1Growth inhibitionIncrease calcium ion concentrationPre-baking dough/flour preservationFruits/vegetable preservation using acidsChemical compositionCa lactate

A treatment for peeled or sliced produce, particularly sliced apples, comprises the steps of placing the sliced produce in a preferred solution for approximately 20 seconds and storing the treated produce at approximately 40 degrees F. One chemical composition for the treatment of peeled or sliced produce, particularly sliced apples, is a treatment solution composed of water plus the following chemicals by weight %:Lactic Acid0.51%Ca-Lactate0.34%CaCl21.13%CaCO31.07%Ascorbic Acid3.95%Total7.00%

Owner:HEKAL IHAB

Organic acid reinforced steel slag fuel gas desulfurization method

InactiveCN102614772AIncrease profitIncrease pH buffer valueDispersed particle separationOrganic acidSinter Plant

The invention discloses an organic acid reinforced steel slag fuel gas desulfurization method, which is mainly applied to sintering plants, thermal power plants, industrial fire coal boilers and other flue gas desulfurization (FGD) containing sulfur dioxide, and particularly has a good prospect specific to sintering flue gas desulfurization. Due to the adoption of the method, low investment and low running cost of flue gas desulfurization can be realized, and a desulfurization technology is applied more widely. A process adopted by the invention has the advantages of low investment, running and managing costs, realization of steel slag recycling, realization of treatment of waste with waste. The method has superior cost performance and a wide market prospect.

Owner:CHENGDU UNIV OF INFORMATION TECH

Silicate-substituted hydroxyapatite

Owner:SIRAKOSS

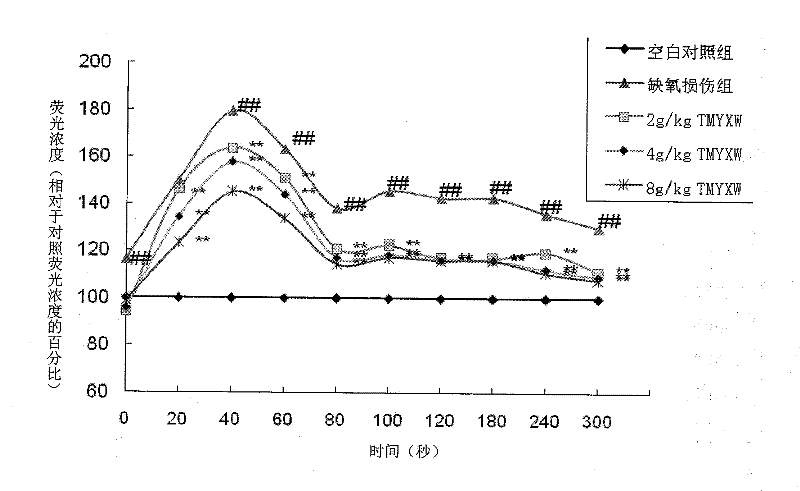

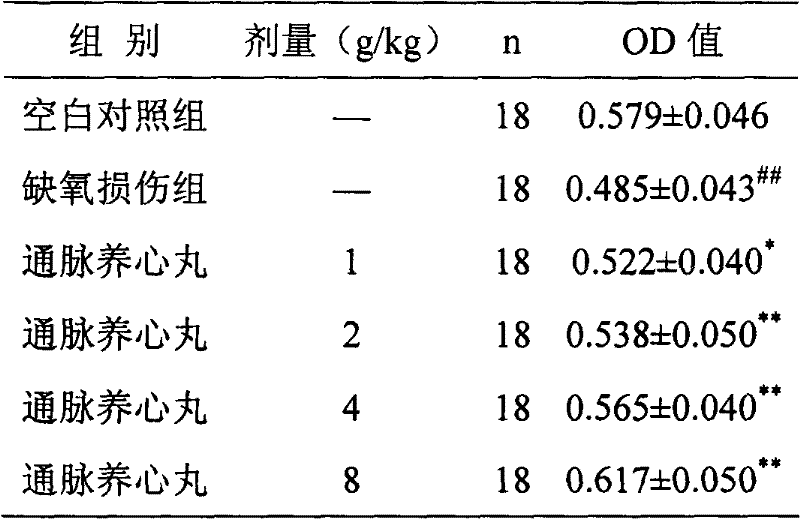

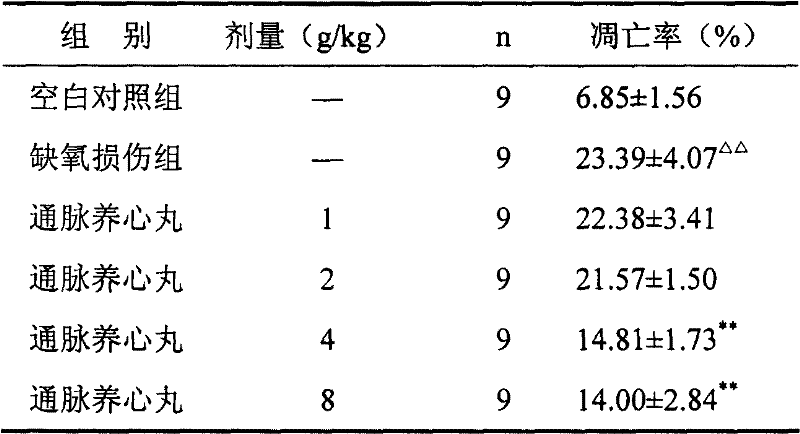

Application of Chinese medicinal composition to preparation of anti-myocardial cell apoptosis and/or anti-myocardial cell apoptosis related disease drug

ActiveCN102670956AAlleviate Calcium OverloadReduce the incidence of apoptosisUnknown materialsCardiovascular disorderDiseaseGLYCYRRHIZA EXTRACT

The invention discloses an application of a Chinese medicinal composition to preparation of an anti-myocardial cell apoptosis and / or anti-myocardial cell apoptosis related disease drug. The Chinese medicinal composition is prepared by, by weight, 1-10 parts of rehmannia roots, 1-10 parts of caulis spatholobi, 1-7 parts of dwarf lilyturf tuber, 1-7 parts of liquorice roots, 1-7 parts of prepared fleeceflower roots, 1-7 parts of donkey-hide gelatin, 1-7 parts of Chinese magnoliavine fruits, 1-7 parts of pilose asiabell roots, 1-5 parts of tortoise shells, 1-5 parts of Chinese dates and 0,1-2 parts of cassia twig.

Owner:津药达仁堂集团股份有限公司乐仁堂制药厂

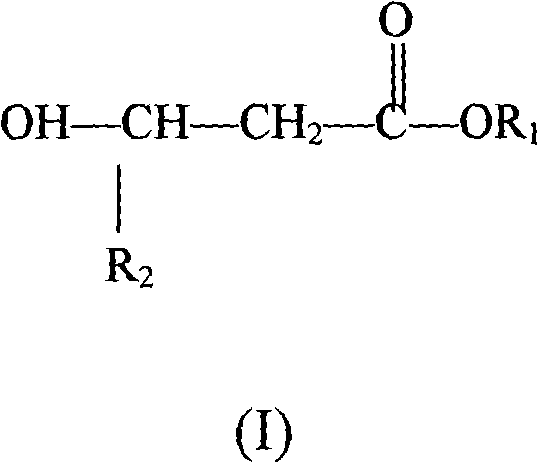

Uses of 3-hydroxy fatty acid and its derivative in preparing calcium ion duct modifying agent

InactiveCN101293831APromote proliferationIncrease calcium ion concentrationNervous disorderOrganic chemistryDiseaseIn vitro test

The invention provides an application of 3-hydroxy fatty acid and derivatives thereof in the preparation of calcium ion channel regulator. An in vitro test indicates that the calcium ion channel regulator promotes neuroglia cell growth and activates cell calcium ion channel; and can be used for treating disease correlated to insufficient activation of the calcium ion channel, and used for culturing cell in vitro, particularly neuroglia cell.

Owner:SHANTOU UNIV

Application of cystic fibrosis transmembrane transduction regulating factor inhibitor to preparation of medicaments for treating diabetes

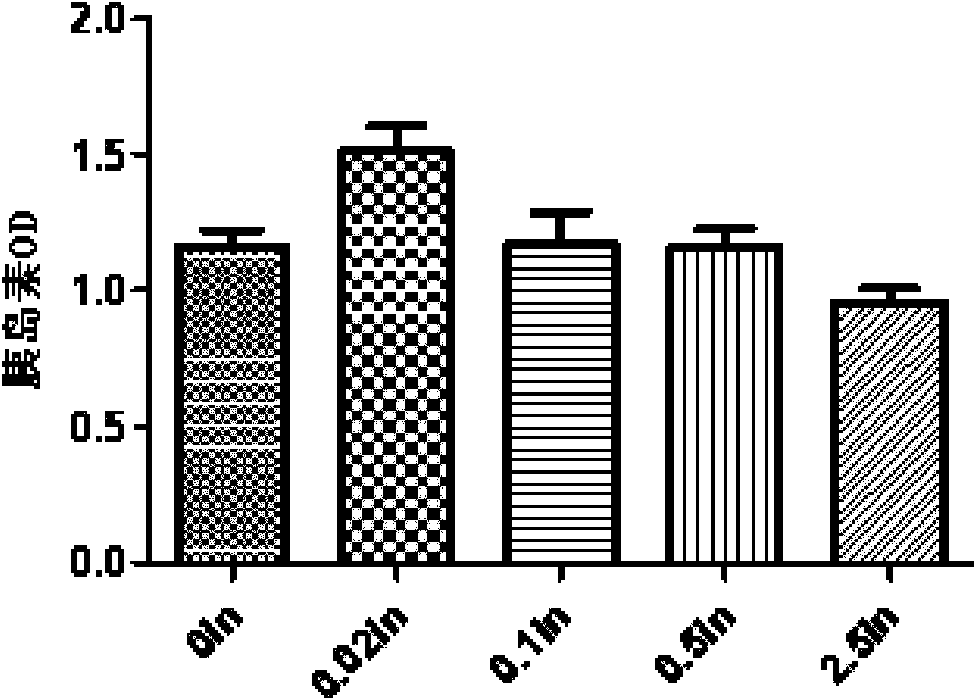

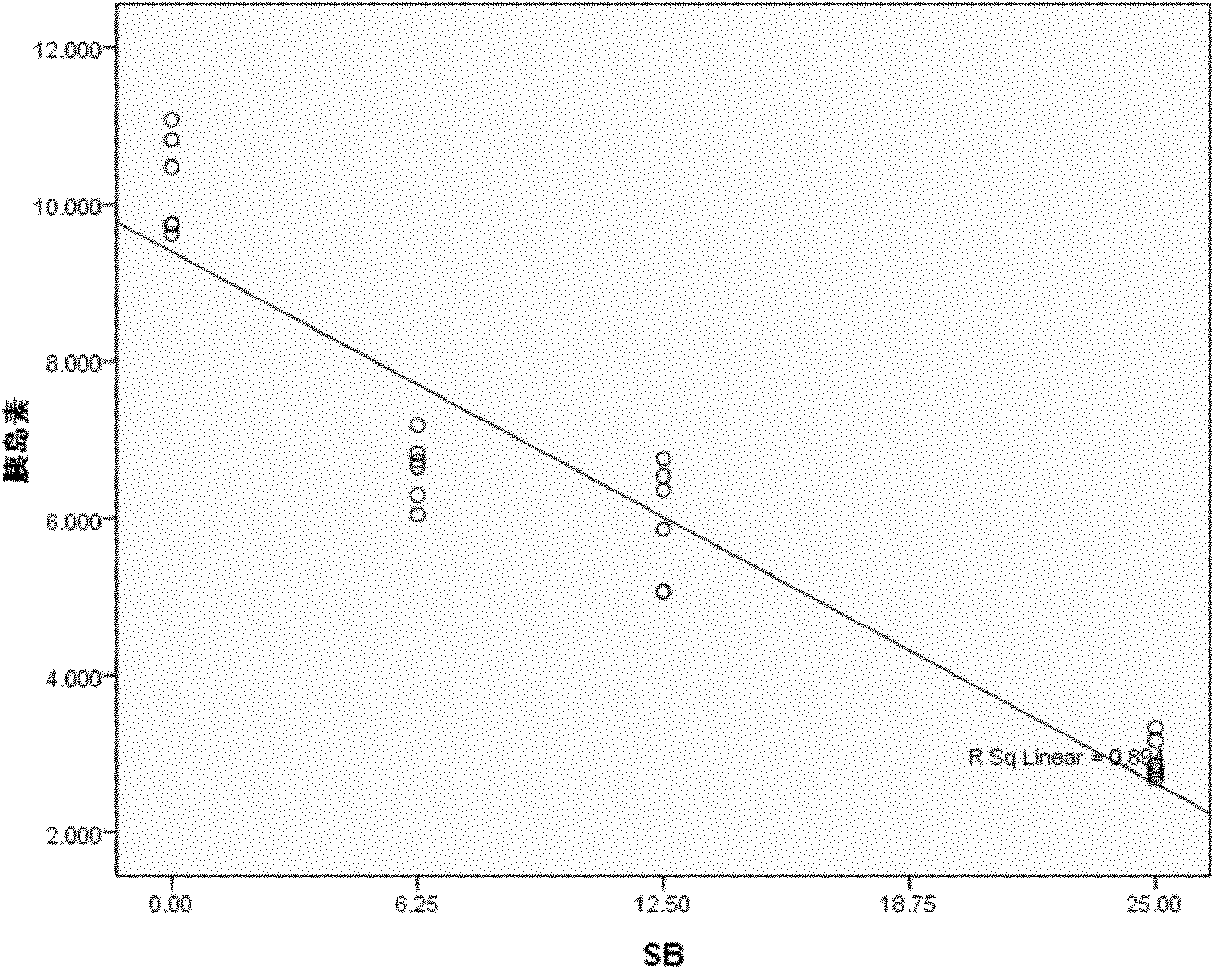

InactiveCN102133402AIncrease secretion levelStimulus releaseOrganic active ingredientsMetabolism disorderGlycosidase inhibitorSulfonylurea

The invention relates to application of cystic fibrosis transmembrane transduction regulating factor inhibitor to the preparation of medicaments for treating diabetes, and application of thiazolidone compounds or derivatives thereof to the preparation of medicaments for treating diabetes. The cystic fibrosis transmembrane transduction regulating factor inhibitor can be subjected to compatibility with medicaments of sulfonylurea, glinides, biguanides, insulin sensitizers and glycosidase inhibitors.

Owner:BEIJING TONGREN HOSPITAL AFFILIATED TO CAPITAL MEDICAL UNIV

Water-dispersion-resistant slurry with controllable initial setting time for shield synchronous grouting and preparation method

The invention discloses water-dispersion-resistant slurry with controllable initial setting time for shield synchronous grouting and a preparation method. The slurry is prepared from the following rawmaterials in parts by mass: 400-500 parts of water, 200-300 parts of cement, 200-500 parts of coal ash, 600-900 parts of sand, 0.1-2.0 parts of hydroxyethyl methyl cellulose and 0-100 parts of calcium formate. According to the water-dispersion-resistant slurry with controllable initial setting time for shield synchronous grouting and the preparation method, the requirement of water dispersion resistance of synchronous grouting in a high-permeability water-rich stratum can be realized, and particularly the slurry initial setting time and compressive strength in a shield synchronous grouting process can be controlled, so that the slurry initial setting time requirements matched with aspects of different stratum conditions, shield excavation, duct piece assembling speed, grouting equipment performance and the like in engineering practice are met.

Owner:SOUTHWEST JIAOTONG UNIV

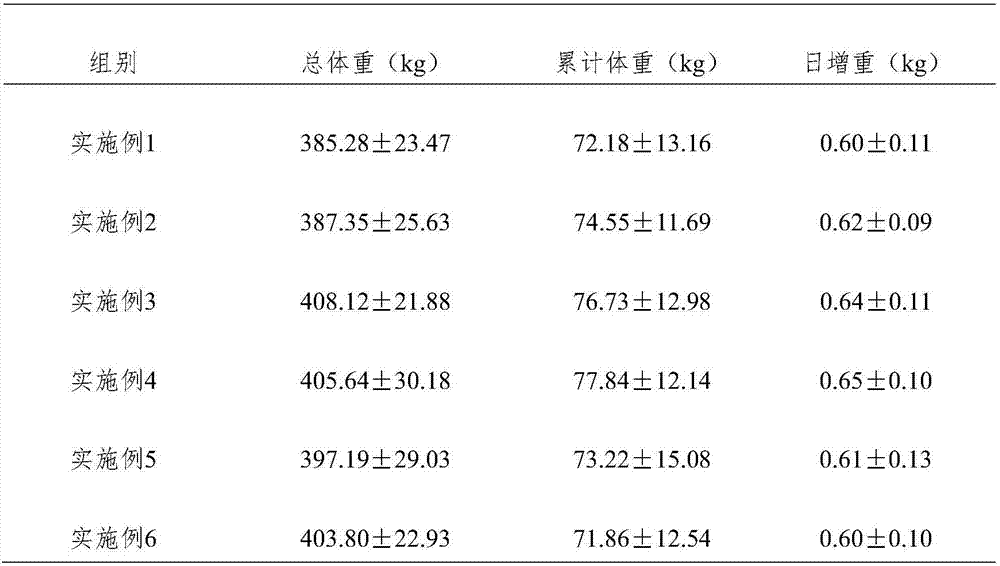

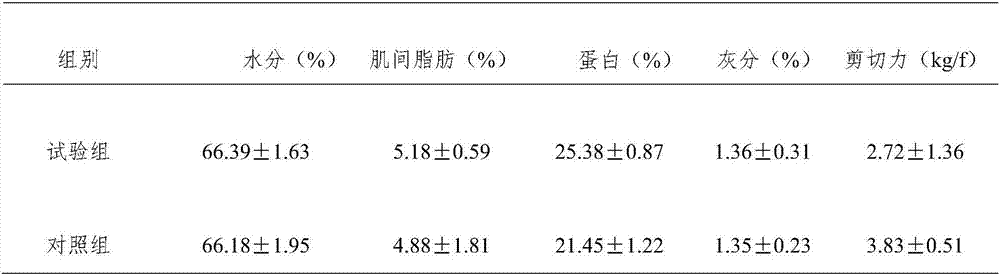

Special feed for beef cattle and preparation method of special feed for beef cattle

InactiveCN106858081AFunction increaseGrow fastFood processingAnimal feeding stuffMagnesium saltImmunocompetence

The invention belongs to the technical field of livestock culture, and particularly relates to a special feed for beef cattle and a preparation method of the special feed for the beef cattle. The special feed for the beef cattle is prepared by taking corn meal, tea leaf residues, wheat bran, a cottonseed cake, calcium hydrogen phosphate, a traditional Chinese medicine additive, a vitamin mixture, a sweetener and a magnesium salt as raw materials. The special feed has the characteristics of good palatability, complete nutrition and easiness in absorption, can improve the quality of beef and immunocompetence of the cattle.

Owner:NANNING UNIV

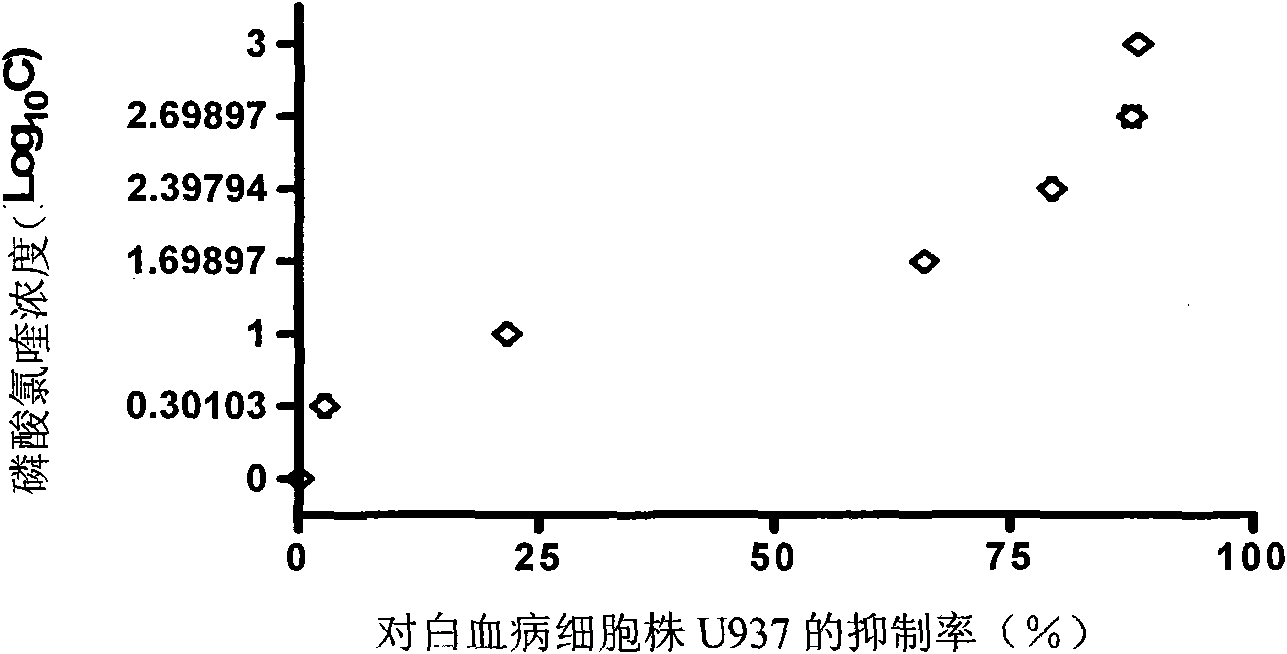

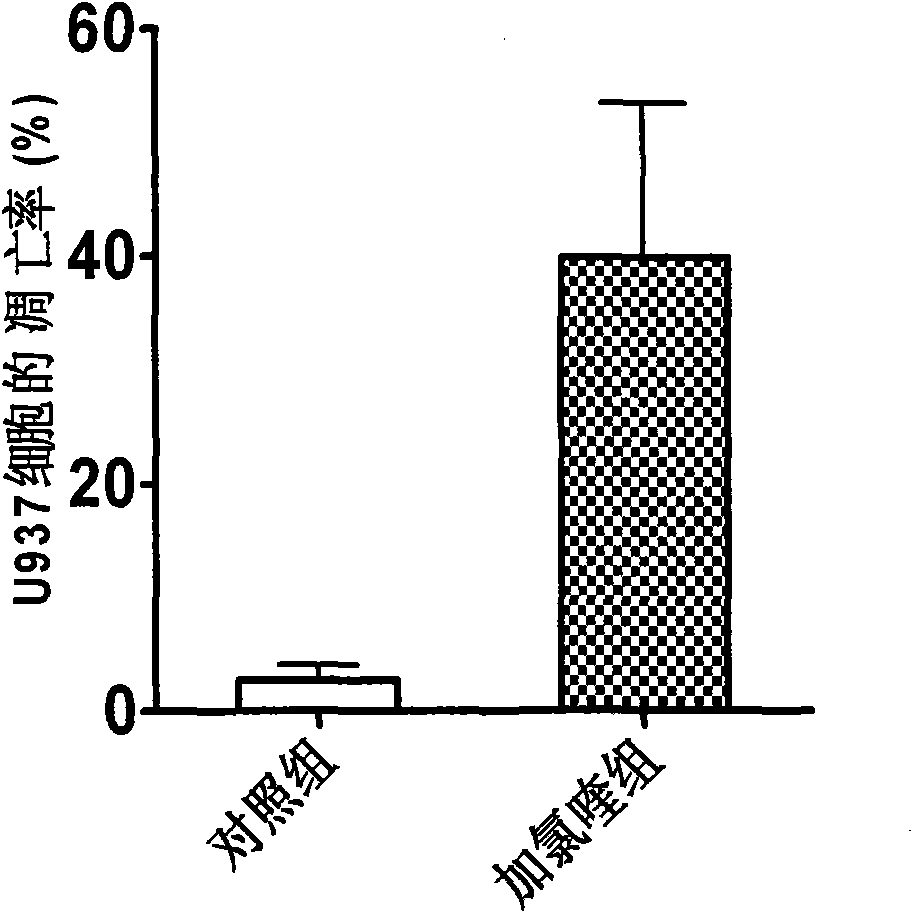

Application of chloroquine compound or salt thereof in preparation of medicament for treating acute leukemia

InactiveCN101829115APrevent seepagePro-apoptoticOrganic active ingredientsAntineoplastic agentsHydroxychloroquineApoptosis

Owner:RENJI HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

A kind of fruit and vegetable tissue solidifying agent and its preparation method and application

ActiveCN102273574AGood flexibilityIncreases tendernessFood preparationBiotechnologyCalcium hydroxide

The invention discloses a curing agent for fruit and vegetable tissues and a preparation method and application thereof, and belongs to the field of fine and deep processing of fruits and vegetables. The curing agent for the fruit and vegetable tissues consists of water, citric acid and a calcium-containing compound, wherein the mass ratio of the citric acid to the water is (1-3):100; the mass ratio of calcium ions in the curing agent to the curing agent is (0.3-2):1000; and the calcium-containing compound is calcium oxide or calcium hydroxide. The application of the curing agent comprises the following steps of: putting the fruits and vegetables into the curing agent for the fruit and vegetable tissues, pre-vacuumizing under reduced pressure or soaking under normal pressure, and then preboiling by using boiling water and rinsing by using clear water so as to fulfill the aims of curing the fruit and vegetable tissues and improving the processability of the fruits and vegetables; meanwhile, the bitterness or peculiar smell of the fruits and vegetables caused by the use of calcium chloride, calcium acetate and the like are avoided.

Owner:甘肃省农业科学院农产品贮藏加工研究所

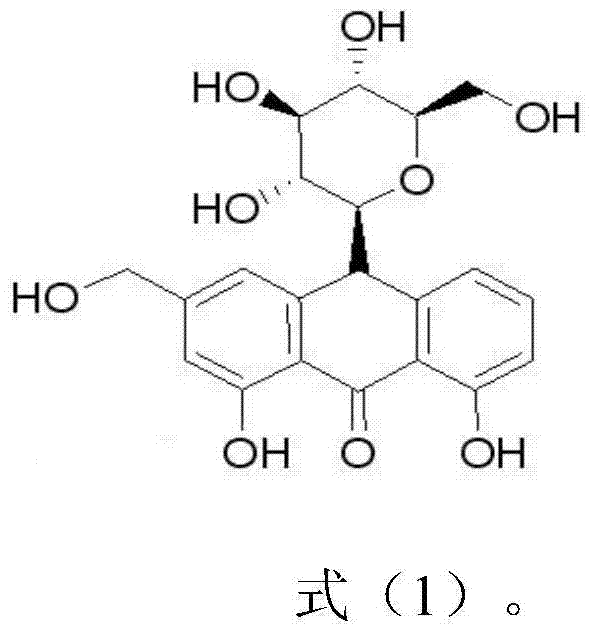

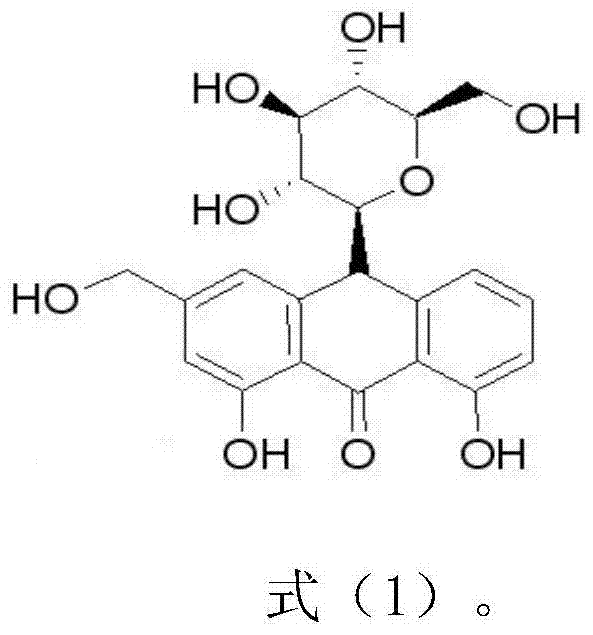

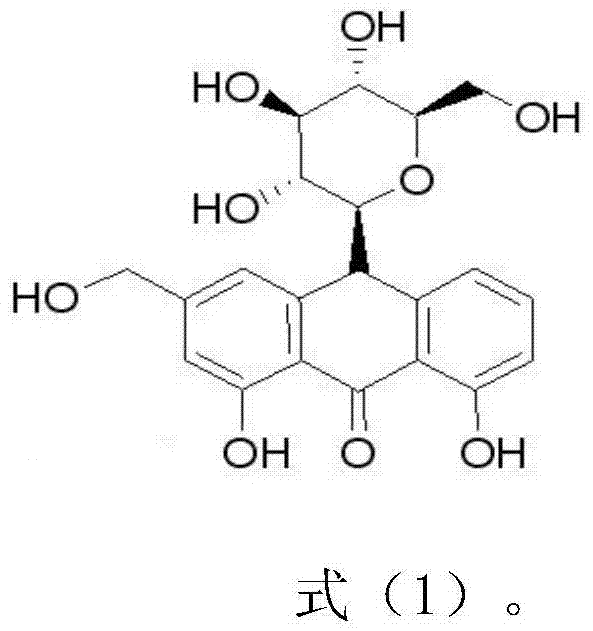

Uses of aloin as medicines for treating cerebral arterial thrombosis

ActiveCN104758278AReduce apoptosis rateIncrease calcium ion concentrationOrganic active ingredientsCardiovascular disorderIschemic injuryOxygen

Uses of aloin as medicines for treating cerebral arterial thrombosis are disclosed. By building an oxygen-glucose deprivation model, protective functions of the aloin for oxygen-glucose deprived PC-12 cells and possible mechanisms are researched. Experiment results show that: after oxygen-glucose deprivation reperfusion, the protective functions of the aloin are related to antioxidation, the aloin reduces contents of active oxygen and malonaldehyde in cells and increases the content of superoxide dismutase, the aloin can stabilize the mitochondrial membrane potential, and the aloin can reduce the apoptosis rate of the PC-12 cells and the concentration of calcium ions, and therefore the aloin is proved to have a protective function for ischemic injury.

Owner:NINGXIA MEDICAL UNIV

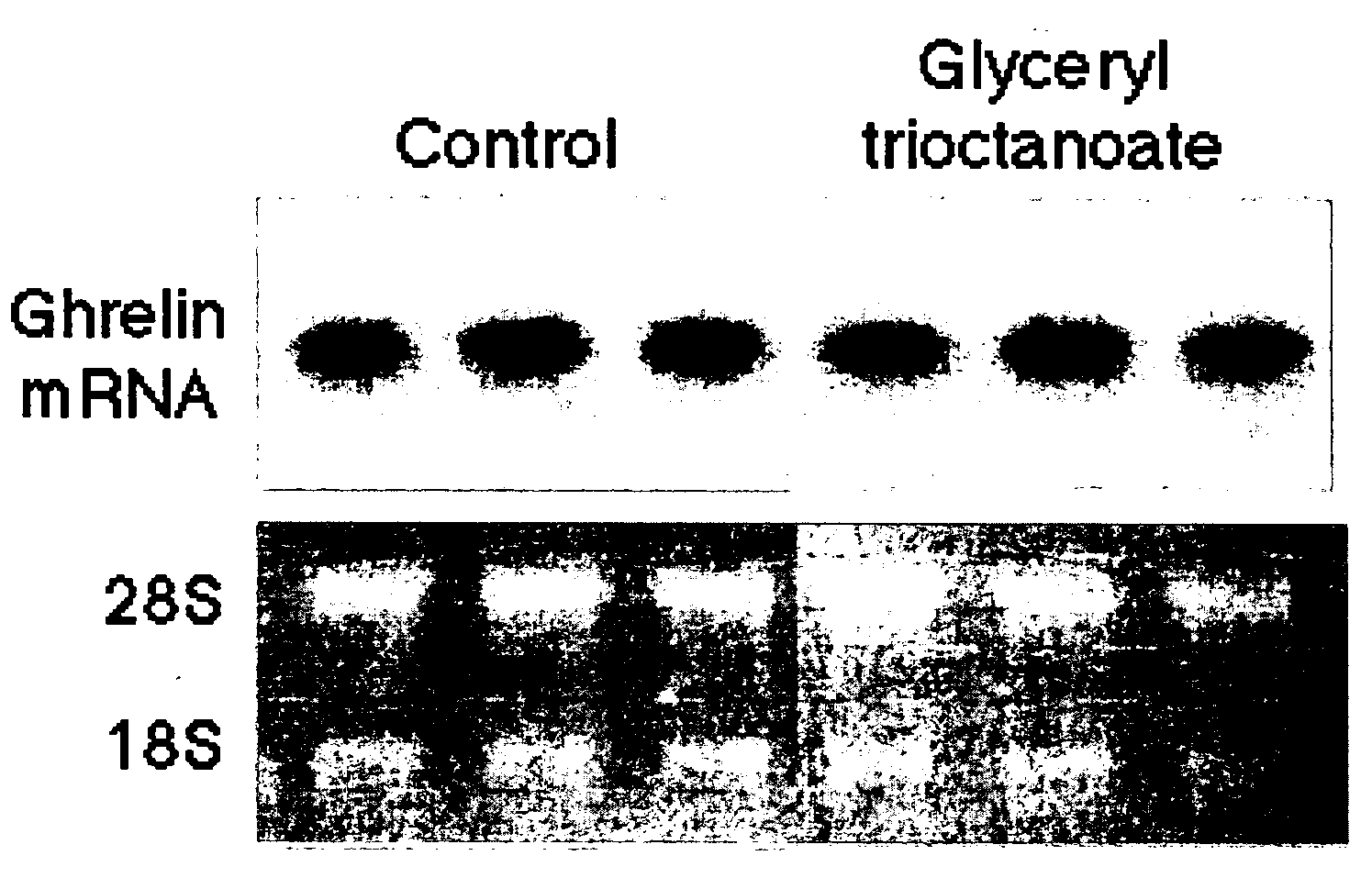

Regulator of Physiological Function of Ghrelin and Use Thereof

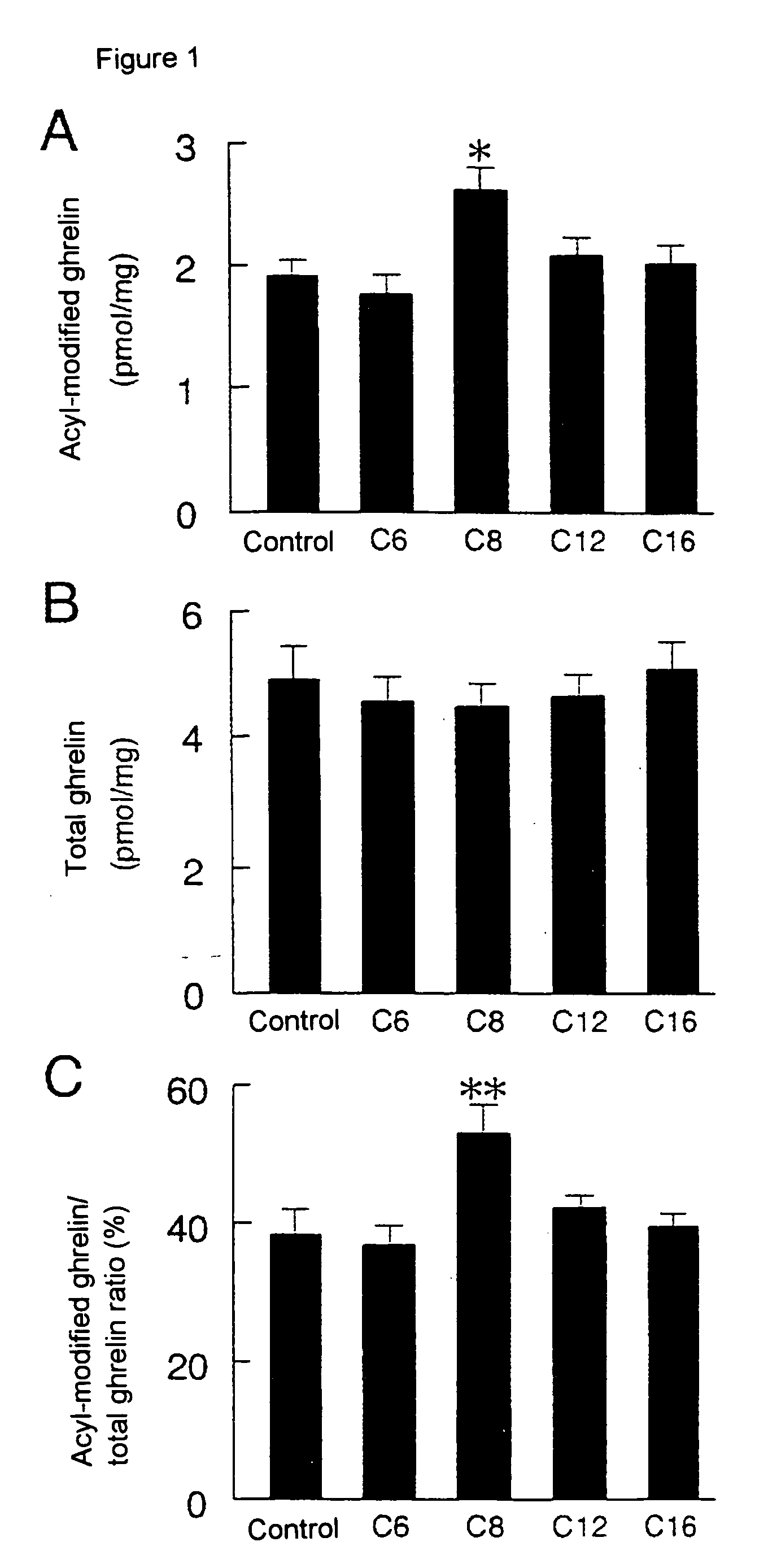

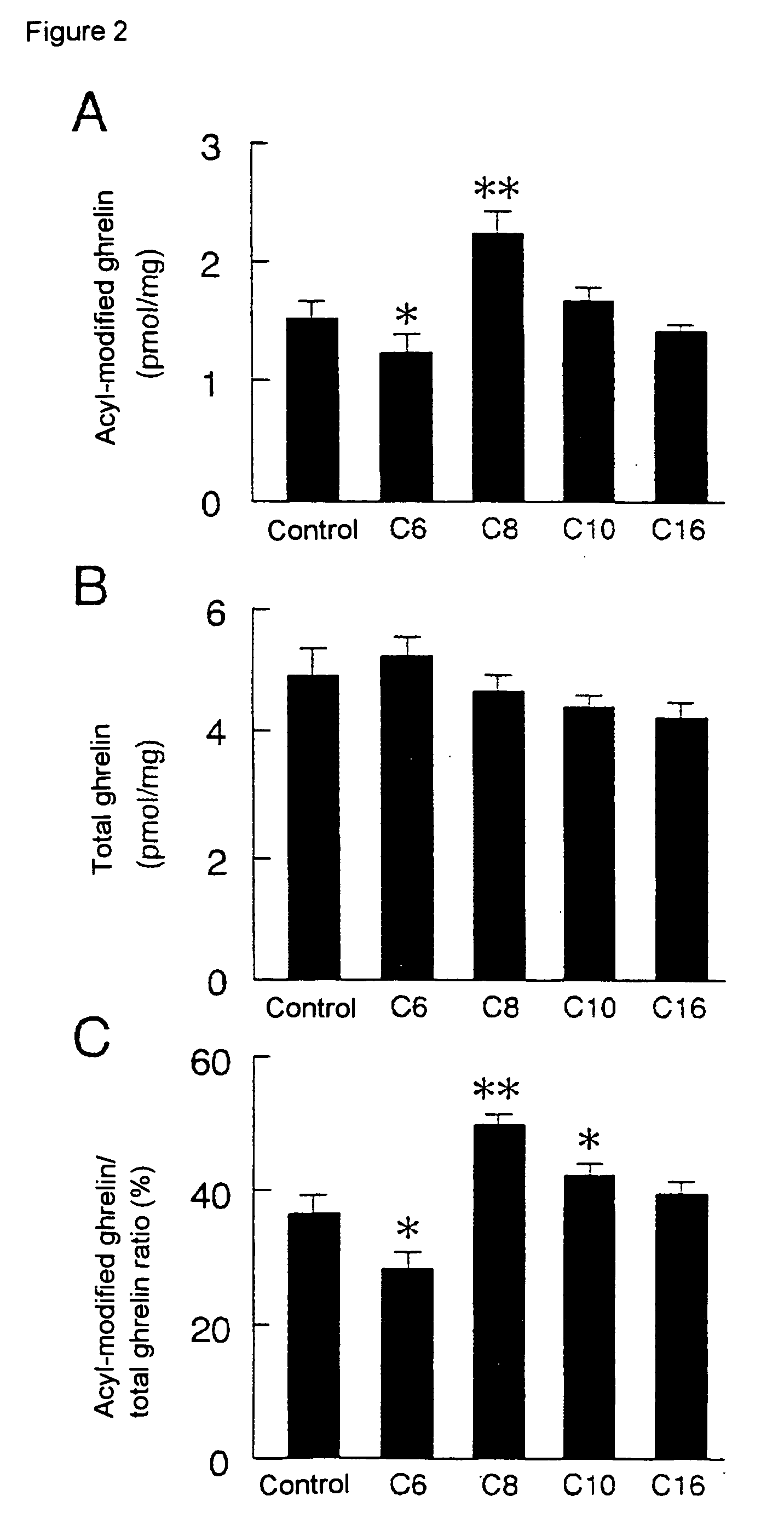

InactiveUS20080293818A1Increasing and decreasing ratioImprove scalabilityBiocideAntipyreticCarbon numberGrowth hormone secretion

A regulator for regulating physiological functions, such as activity of increasing an intracellular calcium ion concentration, activity of promoting growth hormone secretion, activity of promoting eating, regulatory activity relating to fat accumulation, activity of ameliorating heart function and activity of stimulating gastric acid secretion, of ghrelin, which regulator comprises a fatty acid of carbon number 2-35 or its derivative, and use thereof.

Owner:KURUME UNIVERSITY +1

Folium mori lung clearing compound blueberry fruit juice and preparation method thereof

InactiveCN106071532AIncrease calcium ion concentrationDrop TSSNatural extract food ingredientsFood ingredient functionsHerb medicinePectinase

The present invention discloses folium mori lung clearing compound blueberry fruit juice. The compound blueberry fruit juice is prepared from the following raw materials in parts by weight: 200-250 parts of blueberry fruits, an appropriate amount of folium mori, 6-7 parts of coconut meat, 6-8 parts of fresh pea grains, 2-3 parts of sanchi flowers, 1-2 parts of radish seeds, 3-5 parts of poria cocos, an appropriate amount of pectinase, an appropriate amount of calcium chloride, 8-10 parts of white granulated sugar, 0.8-1 part of maltodextrin, 1.2-1.5 parts of citric acids, and an appropriate amount of water. The added coconut meat has efficacies of supplementing deficiency and strengthening body, and benefiting qi and dispelling wind, and the added poria cocos and the other various Chinese herbal medicines have efficacies of strengthening spleen and harmonizing stomach, and calming heart and soothing nerves.

Owner:ANHUI HUI KING FOOD

Leather manufacturing method with hair saving and hair removing functions

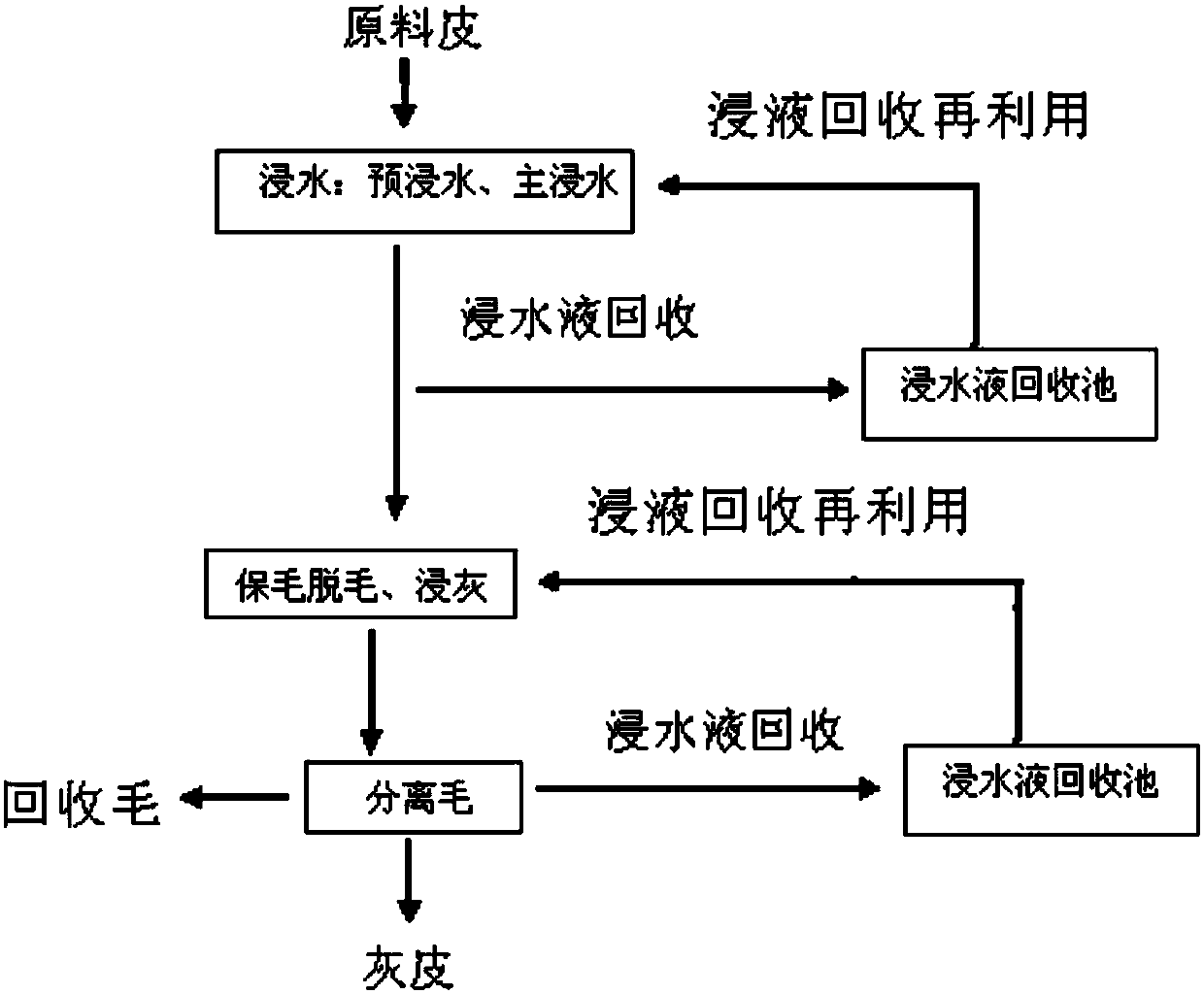

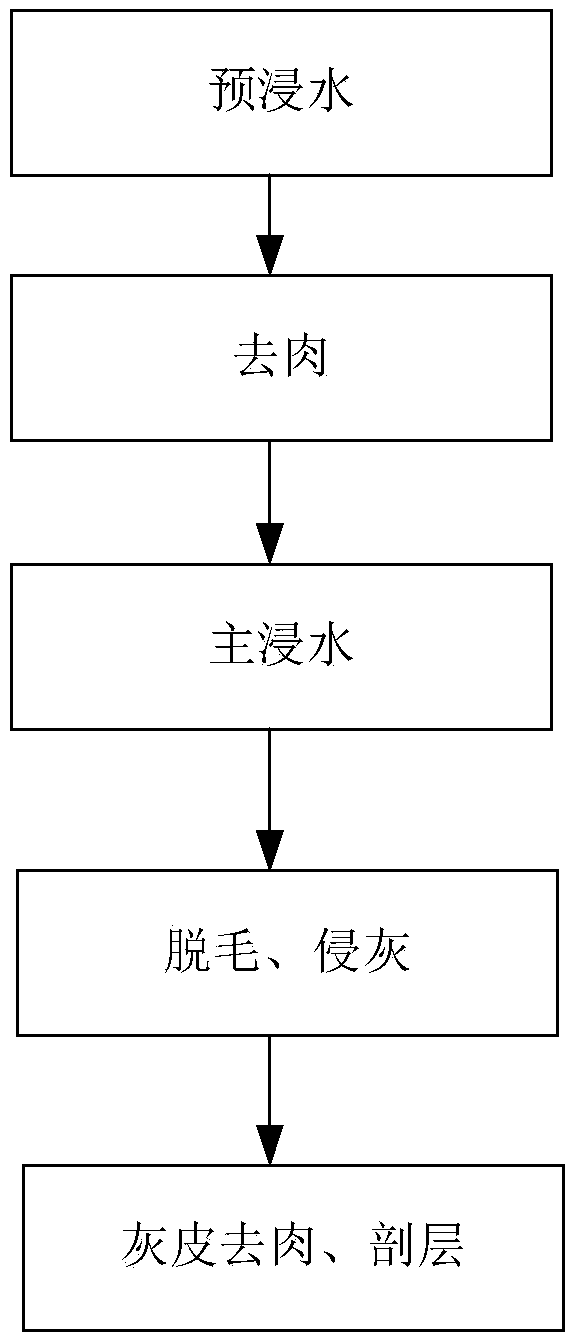

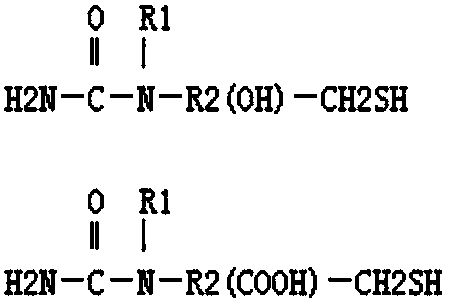

InactiveCN107619887AReduce dosageReduce removalLeather manufacturingPre-tanning chemical treatmentSulfideChemistry

The invention relates to the technical field of leather manufacturing, in particular to a leather manufacturing method with the hair saving and hair removing functions. The leather manufacturing method comprises the following steps: pre-soaking in water; flesh removing; main soaking in water; unhairing and liming; and flesh removing on limed skin and splitting. According to the leather manufacturing method provided by the invention, a sulfydryl urea compound LM and an expanding agent LS, namely an organic chelate alkali, are utilized in the hair saving and liming process, so that the sulfide consumption in the lime-soda liming process can be reduced by 66.6%, the lime consumption can be reduced by 74.3%, and the COD emission in the liming process can be reduced by 80%. However, the properties of finished leather are still good.

Owner:NINGXIA JINHAI LEATHER IND

Heat-clearing compound honeysuckle flower-blueberry juice and preparation method thereof

InactiveCN106107329ASimple structureIncrease calcium ion concentrationNatural extract food ingredientsFood ingredient functionsFruit juiceThirst

The invention discloses a heat-clearing compound honeysuckle flower-blueberry juice. The heat-clearing compound honeysuckle flower-blueberry juice is prepared from the following raw materials in parts by weight: 200-250 parts of blueberry fruits, 7-9 parts of bayberry fruits, 3-4 parts of choerospondias axillaris fruit paste, 2-4 parts of honeysuckle flowers, 3-4 parts of cortex acanthopanacis radicis, 1-2 parts of amomum fruits, 1-2 parts of lindernia ruelloides, an appropriate amount of pectase, an appropriate amount of calcium chloride, 8-10 parts of white granulated sugar, 0.8-1 part of maltodextrin, 1.2-1.5 parts of citric acid and an appropriate amount of water. The bayberry fruits added in the raw materials of the heat-clearing compound honeysuckle flower-blueberry juice have the functions of harmonizing the stomach, arresting vomiting, increasing the body fluid and quenching thirst; moreover, the added multiple Chinese herbal medicines, including the honeysuckle flowers and the like, have the functions of clearing away heat, detoxifying, dispelling wind-heat, relieving summer-heat and relieving restlessness.

Owner:ANHUI HUI KING FOOD

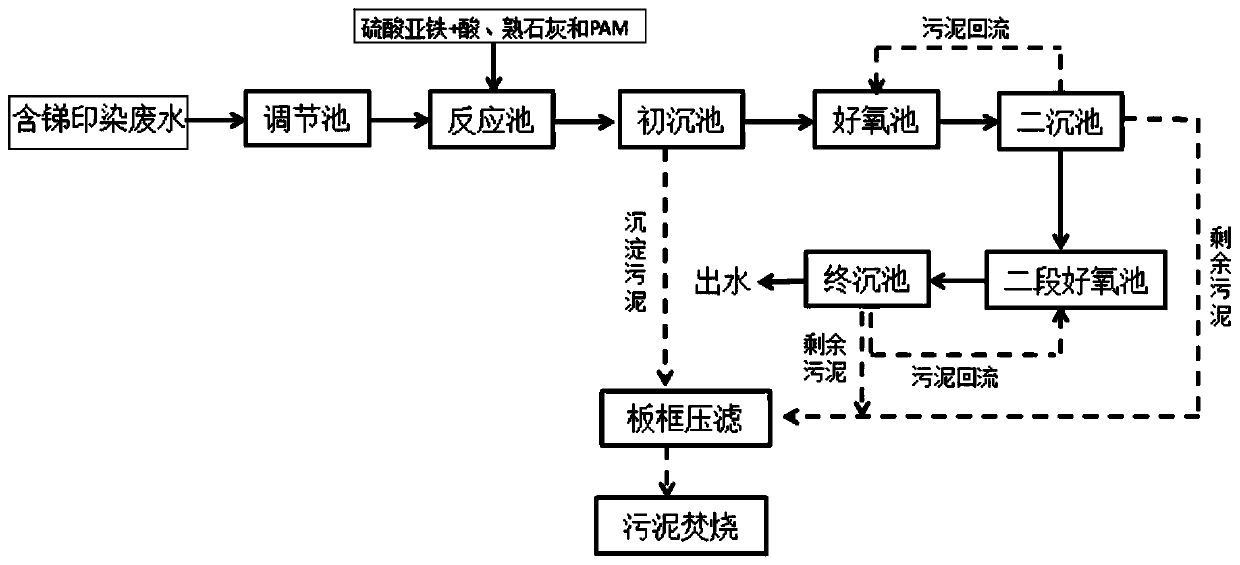

Method and device for efficiently and economically removing antimony in printing and dyeing wastewater

ActiveCN109970278AEnhance the antimony removal effect of coagulationEfficient Antimony RemovalSludge treatmentTreatment using aerobic processesFiltrationSludge

The invention discloses a method and device for efficiently and economically removing antimony in printing and dyeing wastewater. The wastewater enters a reaction tank through an adjusting tank, aciddissolving ferrous sulfate, slaked lime and anionic polyacrylamide are sequentially put into the reaction tank and subjected to a coagu-flocculation reaction; the mixture enters a primary settling tank after reacting, settled sludge is subjected to plate-frame pressure filtration, and separated wastewater enters an aerobic biochemical tank; the obtained product after biochemical treatment enters asecondary settling tank, separated sludge back flows to the biochemical tank, and the wastewater is introduced into a secondary biochemical tank; the wastewater after treatment enters a final settling tank, the separated wastewater is contained in tubes if reaching a standard or is further treated and reused to a workshop, and surplus sludge is subjected to plate-frame pressure filtration to be incinerated. The method is easy and convenient to operate, low in medicament cost and obvious in antimony removing effect, and the final antimony concentration of the wastewater can be stably reduced to 100 micrograms / L or below; aeration of the aerobic sludge tank is fully used, it is promoted that ferrous in the wastewater is oxidized to ferric iron, and a complexing effect and the settling performance between the iron oxide and antimonite are enhanced.

Owner:ZHEJIANG UNIV

Water-retention fertilizer special for tobaccos and used for preventing and controlling Ralstonia solanacearum

InactiveCN106396898AIncrease calcium ion concentrationChange pHCalcareous fertilisersAlkali orthophosphate fertiliserDiseasePhosphorous acid

The present invention discloses a water-retention fertilizer special for tobaccos and used for preventing and controlling Ralstonia solanacearum. The fertilizer comprises the following raw materials: maize straws, yeast residue, seaweed residue, cruciferae plants, Auricuralia auricular fermented bran, urea, ammonium dihydrogen phosphate, potassium chloride, manganese sulfate, EDTA-chelated magnesium, EDTA-chelated iron, phosphomolybdic acid, borax, EDTA-chelated calcium, calcium beta-methyl-beta-hydroxybutyrate, sodium silicate, calcium carbonate, phosphorous acid, benzothiadiazole, beta-aminobutyric acid, black mica, quartz, potassium feldspar, chitosan, bacillus, salicylic acid, jasmonic acid methyl ester, vanillin and a water-retaining agent. The prepared water-retention fertilizer special for tobaccos and used for preventing and controlling Ralstonia solanacearum is reasonable in formula, comprehensive in nutrition, and good in water retention effect. Meanwhile, the growth of tobaccos is facilitated. Both the drought resistance and the disease resistance of tobaccos are improved. The occurrence of Ralstonia solanacearum is effectively prevented. Meanwhile, the quality of tobaccos is improved.

Owner:ANHUI SIERTE FERTILIZER IND

Functional complemental feed for Danish high-yield sows at perinatal period and feeding method of functional complemental feed

InactiveCN110226679APromote feed intakeIncrease feed intakeFood processingAnimal feeding stuffChemistrySupply energy

The invention discloses a functional complemental feed for Danish high-yield sows at the perinatal period. The functional complemental feed comprises beet pulp, oat bran, puffed linseed meal, chocolate powder, calcium chloride, calcium hydrogen phosphate, table salt, N-carbamylglutamic acid, a composite premix feed for lactation sows, amino acids, a radix astragali extract, a radix codonopsis extract, radix angelica sinensis and dried orange peel. According to the functional complemental feed disclosed by the invention, through organic combination of dietary fibers, quick energy supply and Chinese herbal medicines, through cooperation of the usage of a feed for the lactation sows, and through blood sugar concentration adjustment, the functional complemental feed can nourish qi and blood, enhance immunity, clear heat, remove toxicity, prevent miscarriage, adjust intestinal tracts, promote postnatal womb contraction and restoration, shorten lochia discharging time, control postnatal infection, increase the birth weight of piglets, increase the vitality of the piglets, reduce the number of dead fetuses and increase the food consumption of the sows at the lactation period.

Owner:湖南佳智生物科技有限公司 +1

Medicine for raising body temperature

ActiveCN103223035AIncrease temperatureRestore nervous system functionOrganic active ingredientsDrug compositionsAxillary temperatureOyster

A medicine for raising body temperature is invented and is characterized by comprising the following mixed medicines according to the following weight ratio: by weight, 1.4-4.2 parts of cherokee rose-hip powder, 0.8-2.4 parts of oyster granules, 0.3-1 part of Chinese cassia tree powder and 0.5-2 parts of calcium gluconate powder. The medicine provided by the invention has reasonable compatibility of medicines, is convenient to take, and has effects of sterilizing, diminishing inflammation, astringing gland, minimizing secretion, raising concentration of calcium ion and raising temperature. The medicine provided by the invention is used to treat patients with various cold syndromes and with body axillary temperature of being below 36.9 DEG C. Used along with another invention of a dehydrated detumescence external application medicinal plaster for external application of focus, the medicine provided by the invention has a good curative effect of treating patients with cough, stomachache, rheumatoid joint pain, cervical and lumbar vertebra, slipped disc, hypertension, tumor and the like and with the body axillary temperature of being below 36.9 DEG C. After the medicine is used to treat more than 20 patients with fever, focus of more than 80% of the patients completely disappears.

Owner:刘红梅

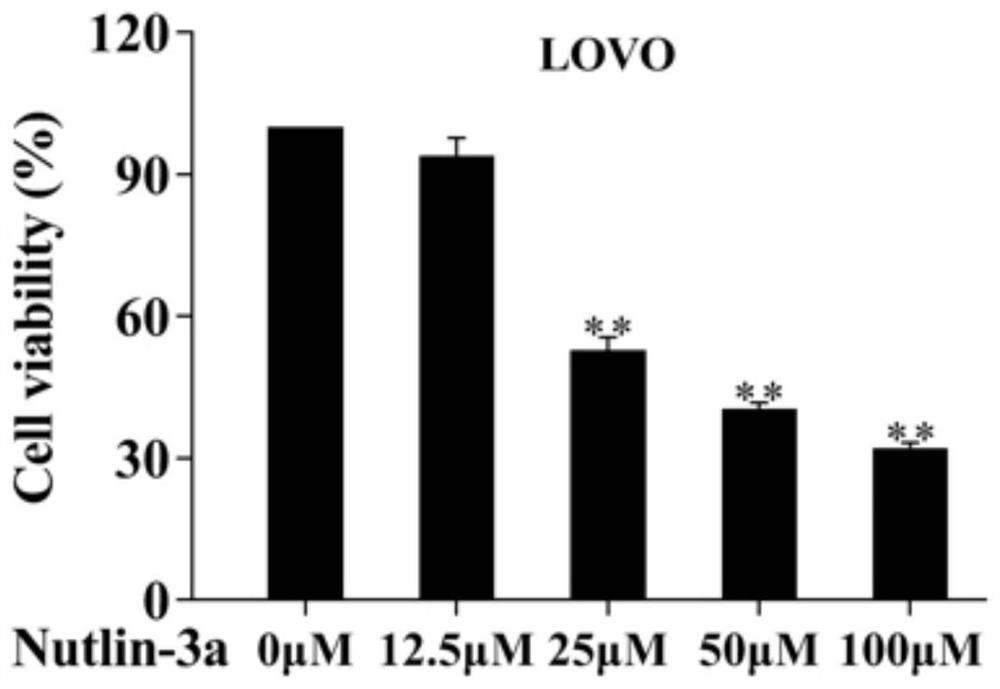

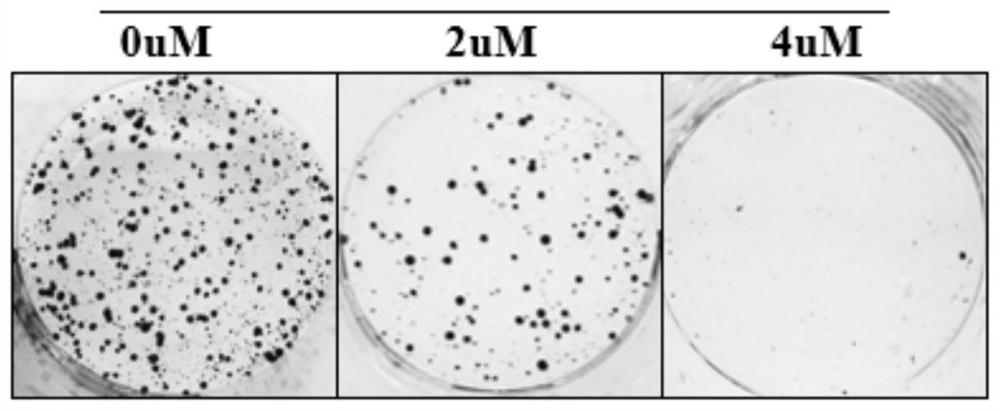

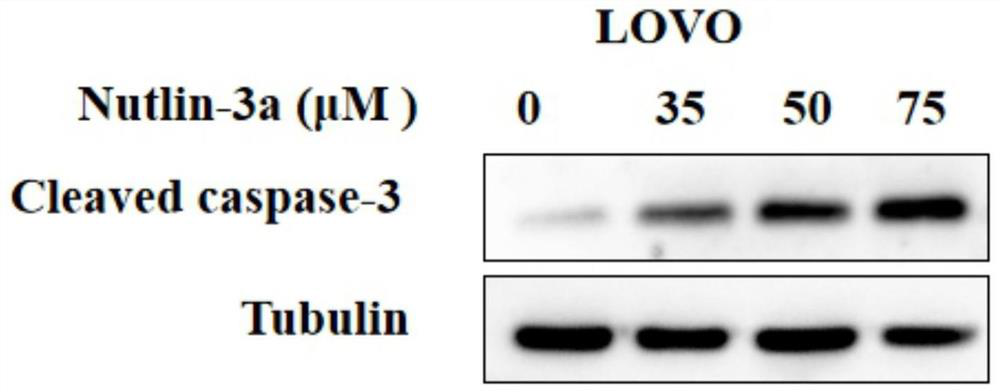

Use of MDM2 inhibitor Nutlin-3a in preparing medicine for apoptosis of cancer cells induced by activating endoplasmic reticulum stress

ActiveCN112891354APromote apoptosisIncrease calcium ion concentrationOrganic active ingredientsDigestive systemReticulum cellDeath Receptors

The invention discloses use of an MDM2 inhibitor Nutlin-3a in preparing a medicine for apoptosis of cancer cells induced by activating endoplasmic reticulum stress. Experiments prove that the MDM2 inhibitor Nutlin-3a can induce the occurrence of endoplasmic reticulum stress by increasing the concentration of calcium ions in cytoplasm, so as to activate a death receptor pathway to induce apoptosis of colon cancer cells. The invention further discloses an anti-tumor pharmaceutical composition of the MDM2 inhibitor Nutlin-3a and an endoplasmic reticulum stress activator. Both in-vivo and in-vitro experiments prove that the pharmaceutical composition has a remarkable synergistic effect and a good anti-tumor effect in the aspect of colon cancer treatment.

Owner:XINXIANG MEDICAL UNIV

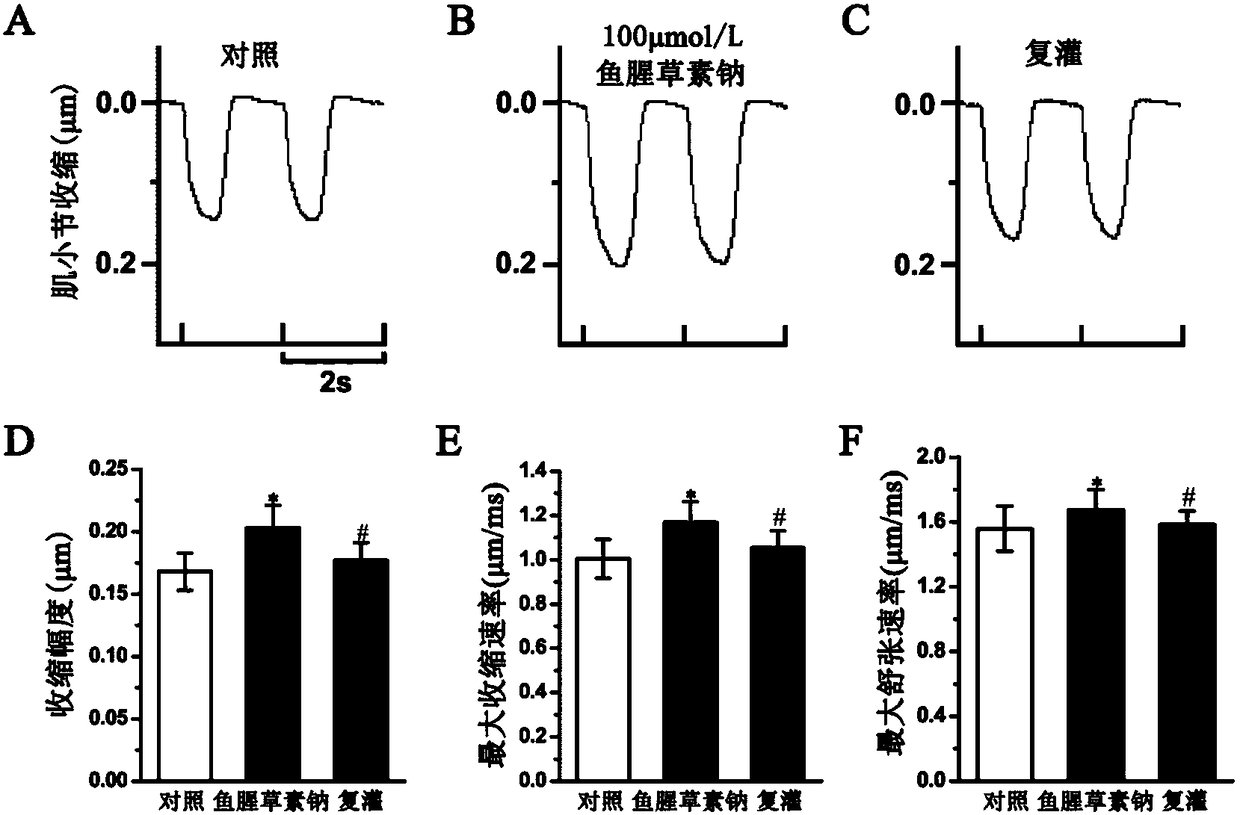

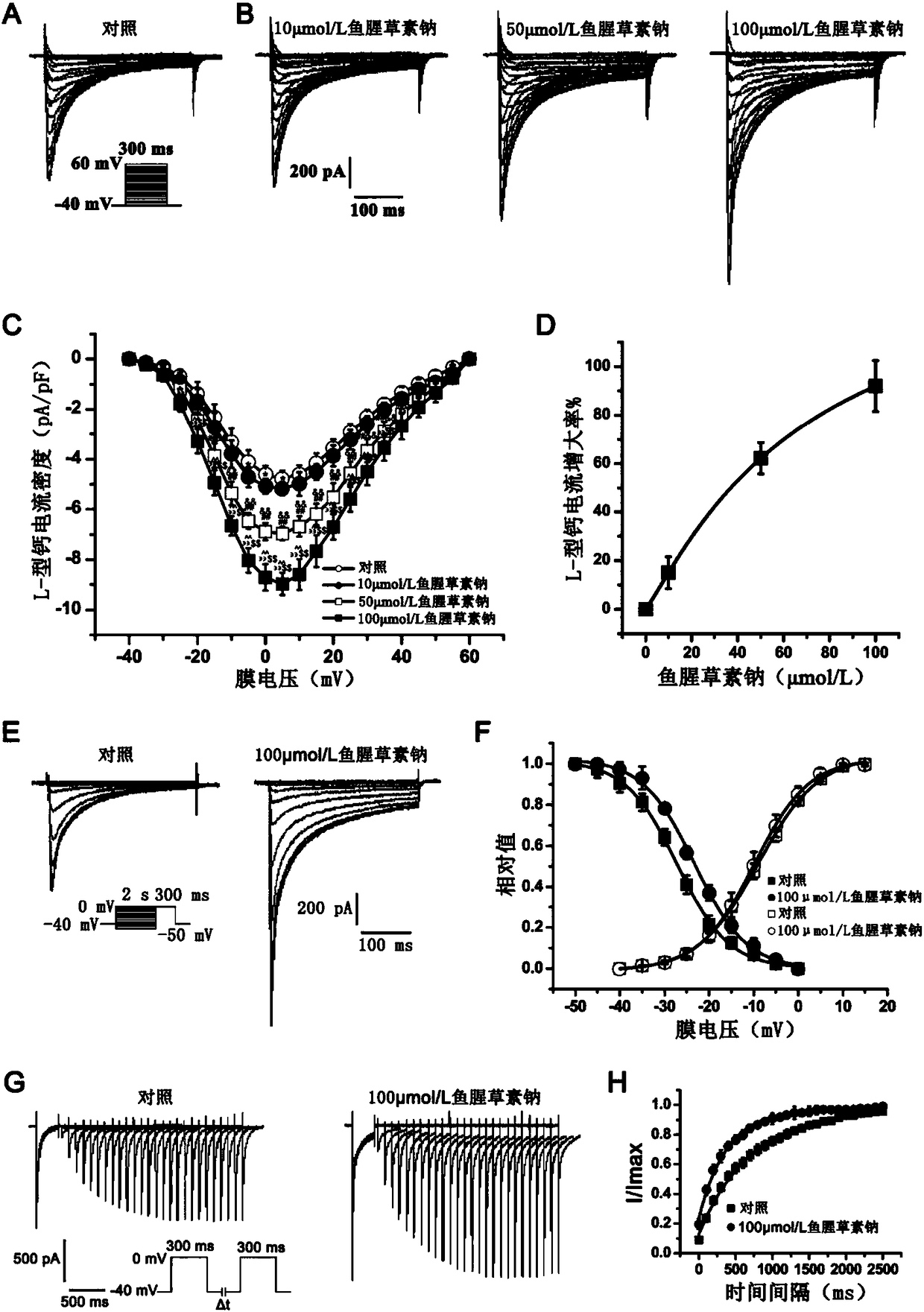

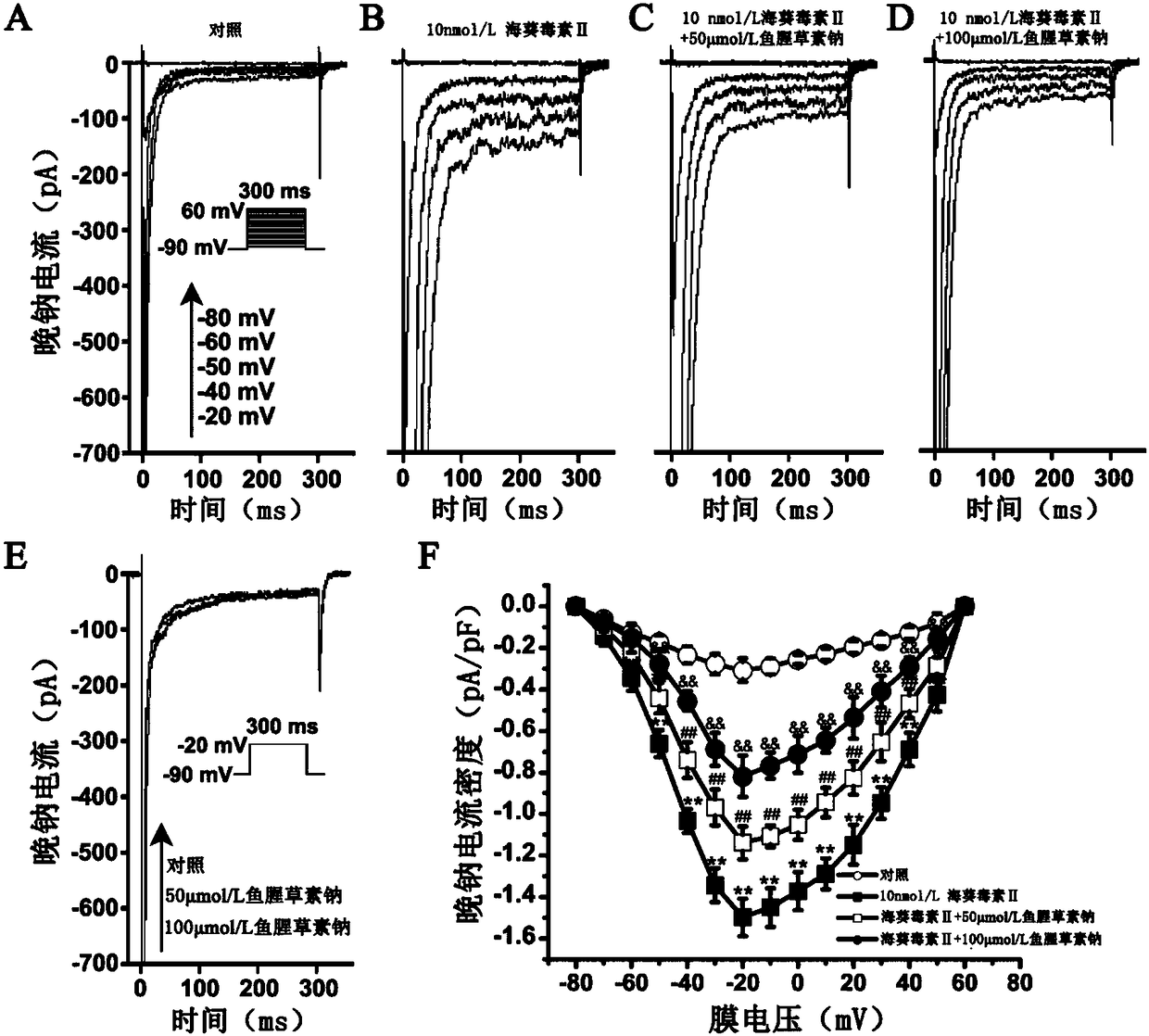

Application of sodium houttuyfonate to preparation of medicament for treating heart failure and/or arrhythmia

PendingCN108210487ALittle side effectsImprove myocardial systolic dysfunctionAnhydride/acid/halide active ingredientsCardiovascular disorderMedicineCardiac muscle

The invention provides application of sodium houttuyfonate to preparation of a medicament for treating heart failure and / or arrhythmia. The invention also provides application of the sodium houttuyfonate to preparation of a medicament for enhancing contractile force of ventricular myocytes. The sodium houttuyfonate increases L-type calcium current (Ica.L), and can improve myocardial systolic dysfunction caused by the reduction of sarcoplasmic reticulum Ca release when the heart failure is occurred. The sodium houttuyfonate blocks peak sodium current (Ina.p) and has the characteristics of class-I antiarrhythmic medicaments, and can also block late sodium current (INa.L) increased by the induction of congestin II (ATX-II) and has the potential of inhibiting the arrhythmia caused by the increment of the INa.L.

Owner:WUHAN UNIV OF SCI & TECH

Water-resistant and dispersed synchronous grouting slurry for shield tunneling with controllable initial setting time and its preparation method

ActiveCN110183189BImprove water retentionImprove water dispersion resistanceCalcium formatePhysical chemistry

The invention discloses a shield water-resistant dispersion synchronous grouting slurry with controllable initial setting time and a preparation method, which comprises the following raw materials in parts by mass: 400-500 parts of water, 200-300 parts of cement, and 200-parts of fly ash 500 parts, 600-900 parts of sand, 0.1-2.0 parts of hydroxyethyl methylcellulose, 0-100 parts of calcium formate. The invention can realize the anti-water dispersion performance requirements of synchronous grouting in high-permeability water-rich formations, especially the control of initial setting time and compressive strength of grout in the process of synchronous grouting of shield tunneling can be realized through the invention, so as to solve the problem of different formations in engineering practice The initial setting time requirements of grout are adapted to the conditions, shield tunneling and segment assembly speed, and performance of grouting equipment.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com