Water-dispersion-resistant slurry with controllable initial setting time for shield synchronous grouting and preparation method

A technology of anti-water dispersion and initial setting time, applied in the field of shield tunnel construction building materials, can solve the problems of low late strength and long initial setting time, and achieve the effects of improving late strength, good water retention and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preferred embodiment of the present invention provides a shield water-resistant dispersion synchronous grouting slurry with controllable initial setting time. The specific preparation steps are as follows:

[0033] First, take each raw material component according to the following mixing ratio, and the dosage per unit volume (kg / m3) is as follows: cement 240, fly ash 300, water 432, sand 775, hydroxyethyl methylcellulose 0.33, calcium formate 75.5, except Materials other than water are in powder or granular form.

[0034] Among them, the cement used is ordinary Portland cement with the label P.O 42.5 produced by Sichuan Lanfeng Cement Co., Ltd.; ) 20%-45%, water content ≤ 5%; the sand is river sand in Chengdu area, fineness modulus 2.2-2.8, particle size <5mm; the hydroxyethyl methylcellulose used is Shandong Youso Chemical Technology Co., Ltd. The parameters produced by the company are hydroxyethyl methylcellulose with a viscosity of 10W and a purity greater than 98...

Embodiment 2

[0037] A preferred embodiment of the present invention provides a shield water-resistant dispersion synchronous grouting slurry with controllable initial setting time. The specific preparation steps are as follows:

[0038]First, weigh each raw material component according to the following mixing ratio, and the dosage per unit volume (kg / m3) is as follows: cement 240, fly ash 300, water 432, sand 775, hydroxyethyl methylcellulose 0.33, other materials except water All in powder or granular form.

[0039] Among them, the cement used is ordinary Portland cement with the label P.O 42.5 produced by Sichuan Lanfeng Cement Co., Ltd.; ) 20%-45%, water content ≤ 5%; the sand is river sand in Chengdu area, fineness modulus 2.2-2.8, particle size <5mm; the hydroxyethyl methylcellulose used is Shandong Youso Chemical Technology Co., Ltd. The parameters produced by the company are hydroxyethyl methylcellulose with a viscosity of 10W and a purity of more than 98%, which is white or off-wh...

Embodiment 3

[0042] A preferred embodiment of the present invention provides a shield water-resistant dispersion synchronous grouting slurry with controllable initial setting time. The specific preparation steps are as follows:

[0043] First, take each raw material component according to the following mixing ratio, and the dosage per unit volume (kg / m3) is as follows: cement 240, fly ash 300, water 432, sand 775, hydroxyethyl methylcellulose 0.33, calcium formate 55, except Materials other than water are in powder or granular form.

[0044] Among them, the cement used is ordinary Portland cement with the label P.O 42.5 produced by Sichuan Lanfeng Cement Co., Ltd.; ) 20%-45%, water content ≤ 5%; the sand is river sand in Chengdu area, fineness modulus 2.2-2.8, particle size <5mm; the hydroxyethyl methylcellulose used is Shandong Youso Chemical Technology Co., Ltd. The parameters produced by the company are hydroxyethyl methylcellulose with a viscosity of 10W and a purity greater than 98%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Liquidity | aaaaa | aaaaa |

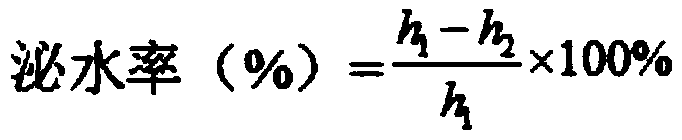

| Bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com