Leather manufacturing method with hair saving and hair removing functions

A hair-preserving, hair-removing, and hair-filtering technology, which is applied in the field of tanning, can solve problems such as high production costs and environmental pollution of tanning pollutants, and achieve the effects of good compactness, improved leather yield, and moderate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

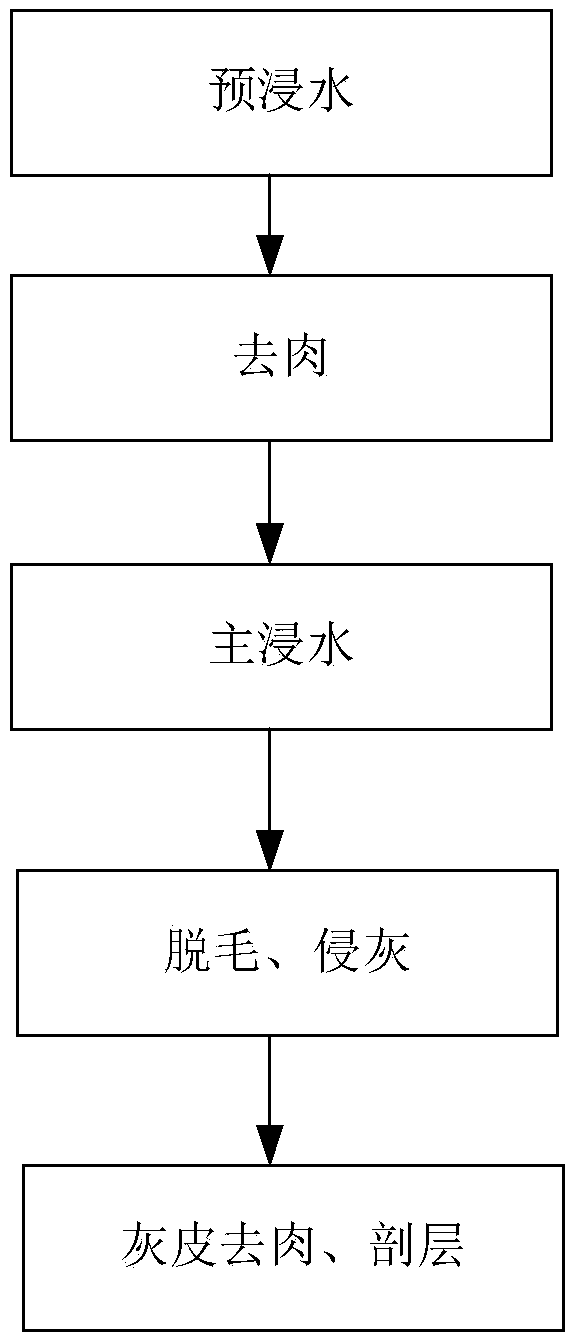

[0040] The whole process of leather production mainly includes the process plan and process: batching of raw cowhide→head and tail removal→weighing→presoaking→washing→fleshing→main soaking→washing→fleshing→hair preservation and depilation→filtering→ Liming→fleshing→washing→weighing→ammonium-free deliming→softening→washing→pickling→less chromium or no tanning→resting on a horse→grading→squeezing and stretching→split (top layer and second layer leather) (Sold))--Trim trimming→shaving→weighing→retanning→washing→neutralization→dyeing and fatliquoring→over-dyeing→washing→horse riding→squeezing and stretching→resurfacing→softening→pressing plate→grinding Leather→clean surface→grinding leather→back cover→stand still→roller oiled→stand still (4 hours)→press plate→feel layer→trimming→measure ruler storage.

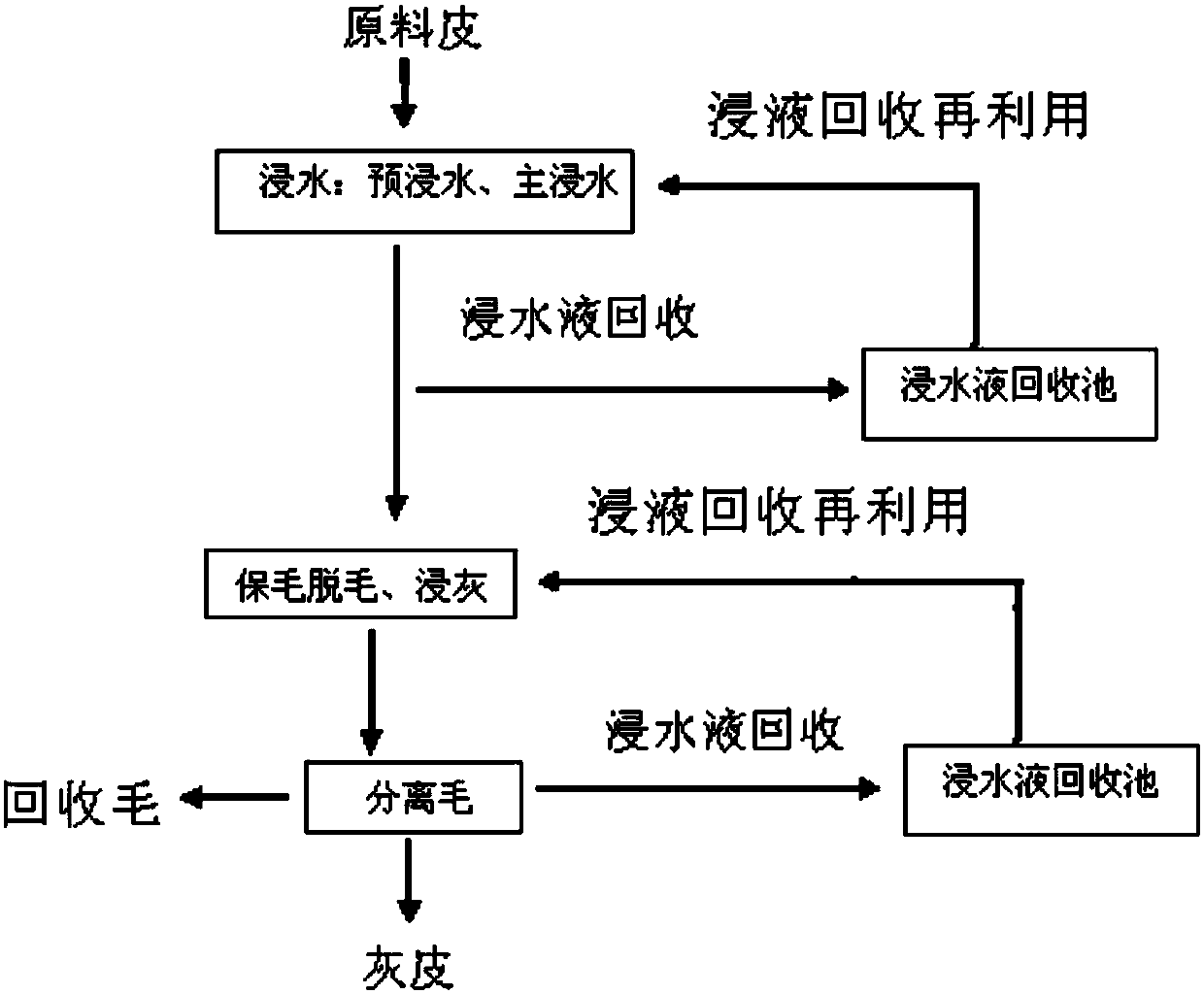

[0041] Among them, such as figure 1 and figure 2As shown, the present embodiment provides a kind of tanning method for hair preservation and depilation, which mainly includes th...

Embodiment 2

[0062] On the basis of Example 1, this example mainly describes the analysis of experimental data using SINOBEAMLM and SINOBEAM LS in the above-mentioned tanning method for hair preservation and depilation.

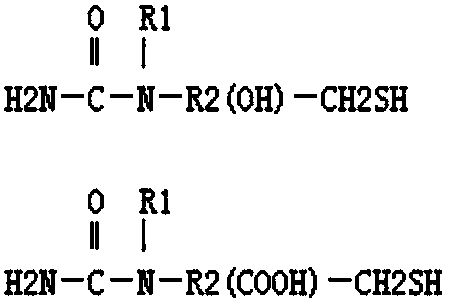

[0063] The chemical structure of described mercaptourea is:

[0064]

[0065] wherein R1 = H, -CH3, -CH2-CH3; R2 = -CH2-, -CH2-CH2- and so on.

[0066] This kind of compound molecule contains -SH and -NH2 active groups at the same time, which can depilate and disperse collagen fibers at the same time. This innovative product can simplify and improve the depilation and liming process in the process of tanning.

[0067] In particular, the general properties of the mercaptourea LM:

[0068] (1) Appearance: light brown transparent liquid with sulfide smell;

[0069] (2), solid content: 25%;

[0070] (3), pH value: 4.5.

[0071] 1), mercaptourea hair removal effect

[0072] According to the experimental procedure in Example 1, select triethanolamine, thioglycolic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com