Patents

Literature

870 results about "Hydroxy fatty acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

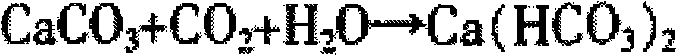

The polymer cutin is formed by inter-esterification of omega hydroxy acids and derivatives of them that are substituted in mid-chain, such as 10,16-dihydroxy palmitic acid. Only the epidermal cells of plants synthesize cutin. Omega hydroxy fatty acids also occur in animals.

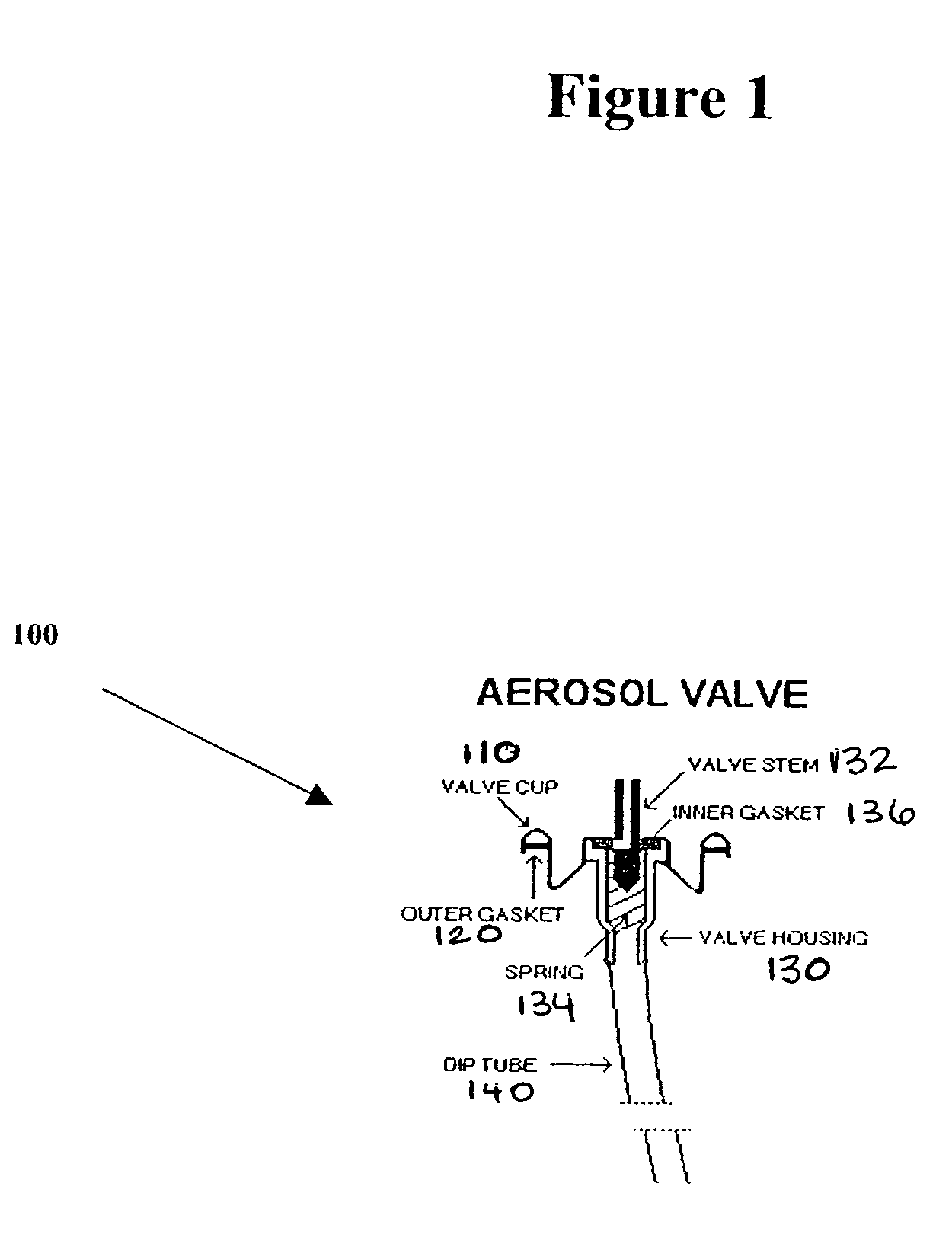

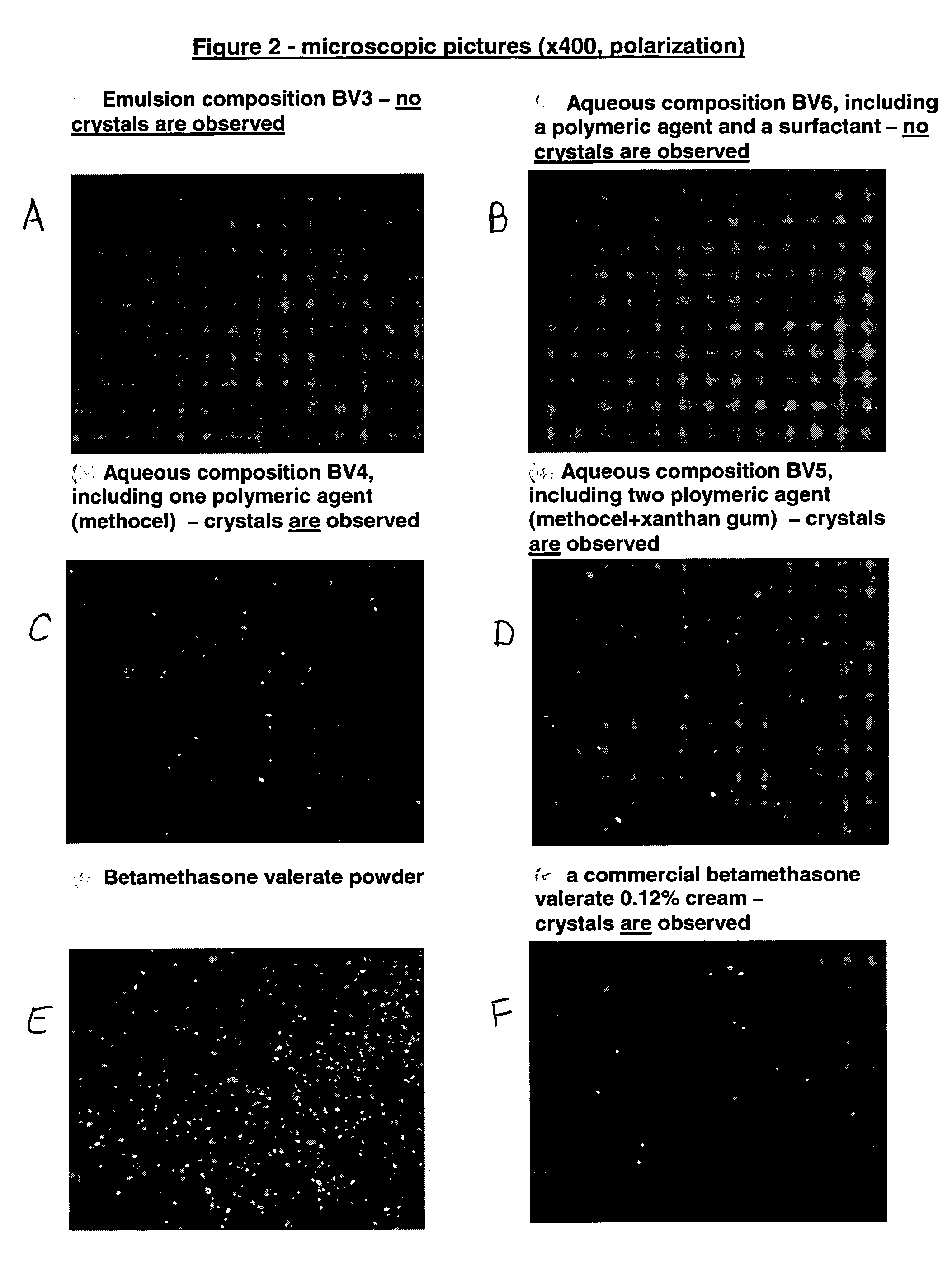

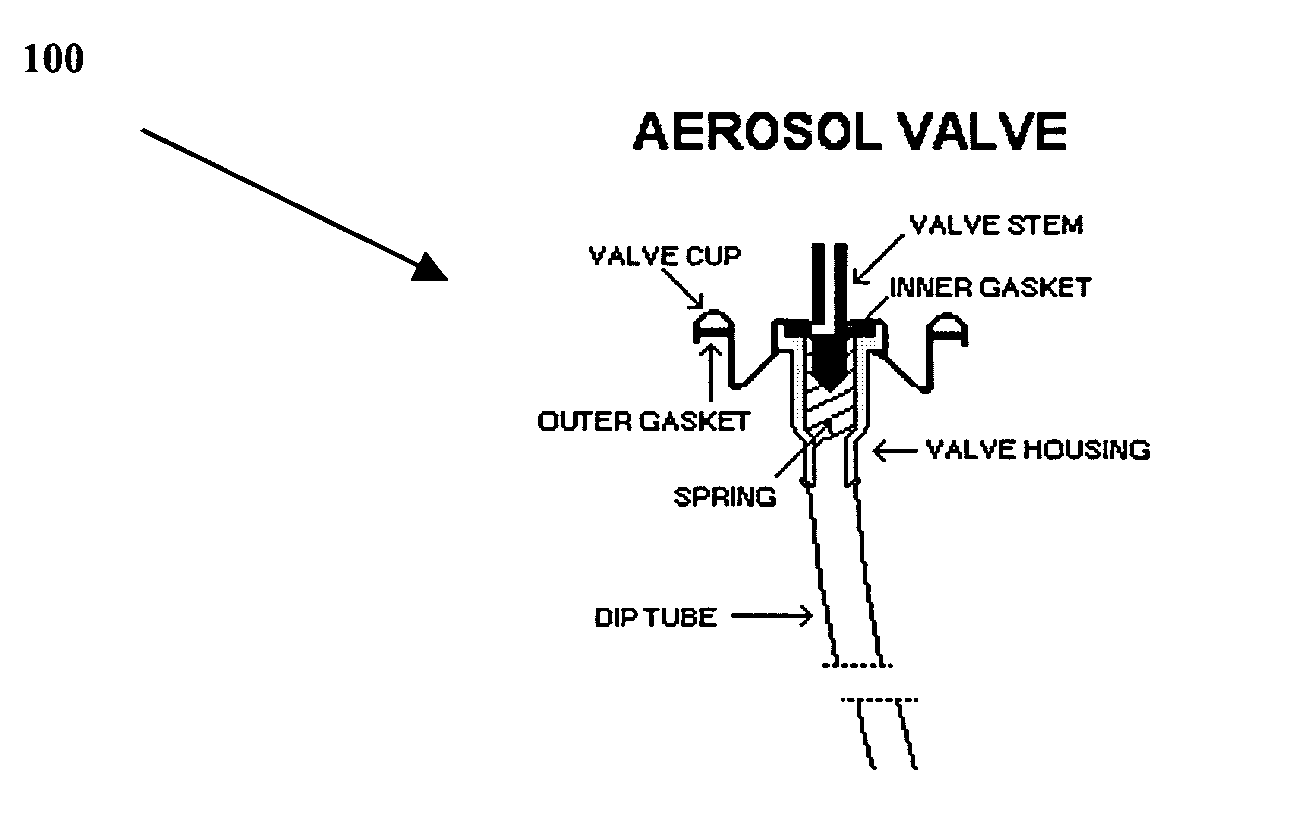

Steroid kit and foamable composition and uses thereof

InactiveUS20060018937A1Preventing and alleviatingCosmetic preparationsSenses disorderActive agentFilm-forming agent

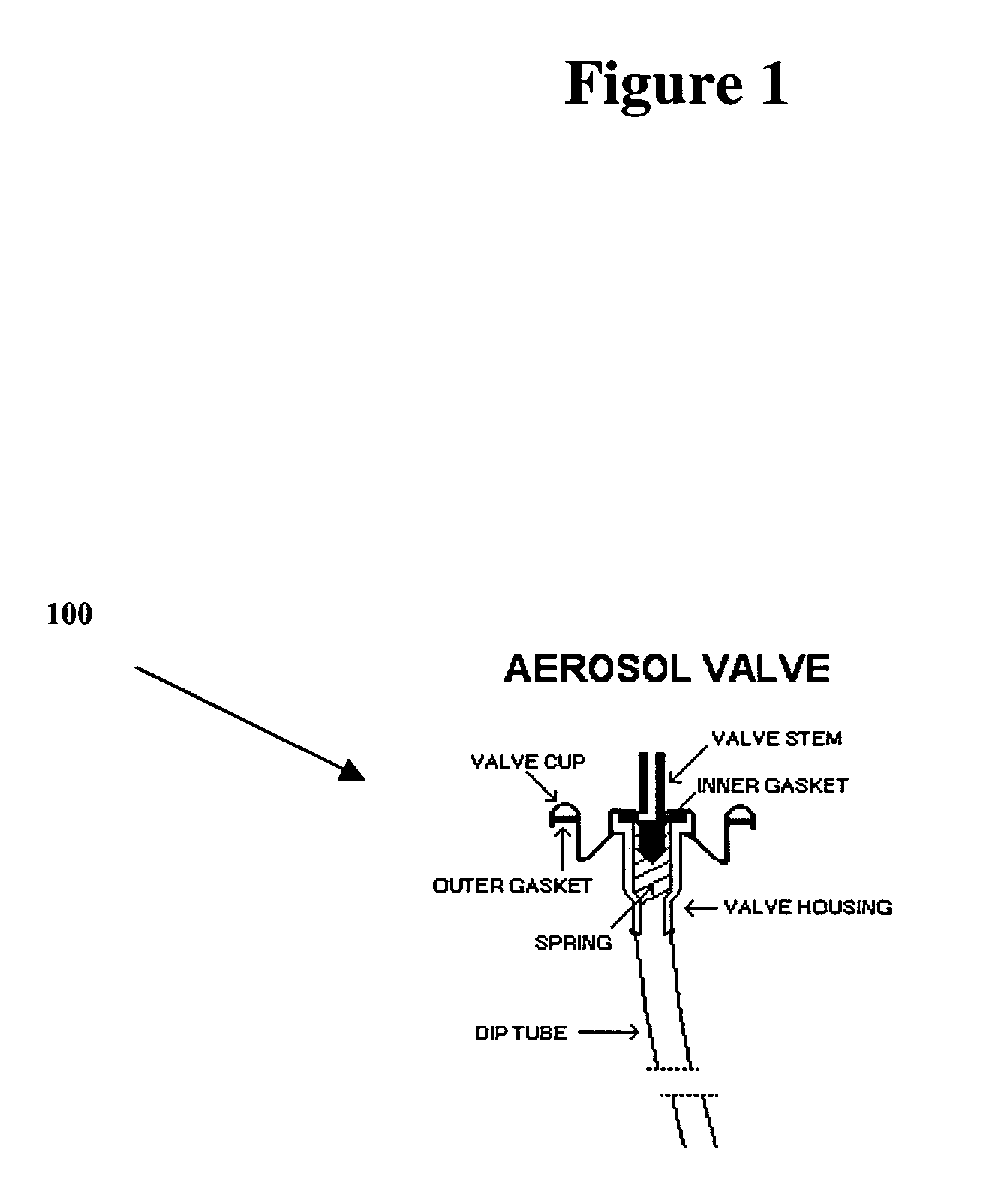

A composition and therapeutic kit including an aerosol packaging assembly including a container accommodating a pressurized product and an outlet capable of releasing a foamable composition, including a steroid as a foam. The pressurized product includes a foamable composition including: a container accommodating a pressurized product; and an outlet capable of releasing the pressurized product as a foam; wherein the pressurized product comprises a foamable composition including: i. a steroid; ii. at least one organic carrier selected from the group consisting of a hydrophobic organic carrier, a polar solvent, an emollient and mixtures thereof, at a concentration of about 2% to about 50% by weight; iii. a surface-active agent; iv. about 0.01% to about 5% by weight of at least one polymeric additive selected from the group consisting of a bioadhesive agent, a gelling agent, a film forming agent and a phase change agent; v. water; and vi. liquefied or compressed gas propellant at a concentration of about 3% to about 25% by weight of the total composition. The composition further may include a therapeutically active foam adjuvant, selected from the group consisting of a fatty alcohol, a fatty acid, a hydroxyl fatty acid; and mixtures thereof.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Retinoid immunomodulating kit and composition and uses thereof

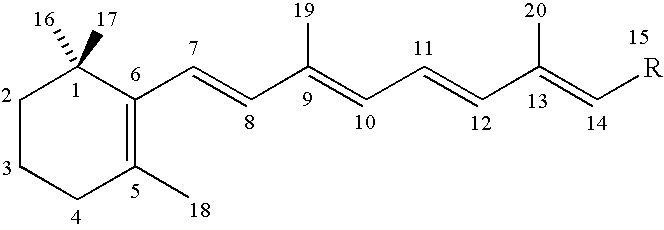

A composition and therapeutic kit including an aerosol packaging assembly including a container accommodating a pressurized product and an outlet capable of releasing a foamable composition, including a retinoid as a foam. The pressurized product includes a foamable composition including: a container accommodating a pressurized product; and an outlet capable of releasing the pressurized product as a foam; wherein the pressurized product comprises a foamable composition including: i. a retinoid; ii. at least one organic carrier selected from the group consisting of a hydrophobic organic carrier, a polar solvent, an emollient and mixtures thereof, at a concentration of about 2% to about 50% by weight; iii. a surface-active agent; iv. about 0.01% to about 5% by weight of at least one polymeric additive selected from the group consisting of a bioadhesive agent, a gelling agent, a film forming agent and a phase change agent; v. water; and vi. liquefied or compressed gas propellant at a concentration of about 3% to about 25% by weight of the total composition. The composition further may include a therapeutically active foam adjuvant, selected from the group consisting of a fatty alcohol, a fatty acid, a hydroxyl fatty acid; and mixtures thereof.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Thermoreversible pharmaceutical formulation for anti-microbial agents comprising poloxamer polymers and hydroxy fatty acid ester of polyethylene glycol

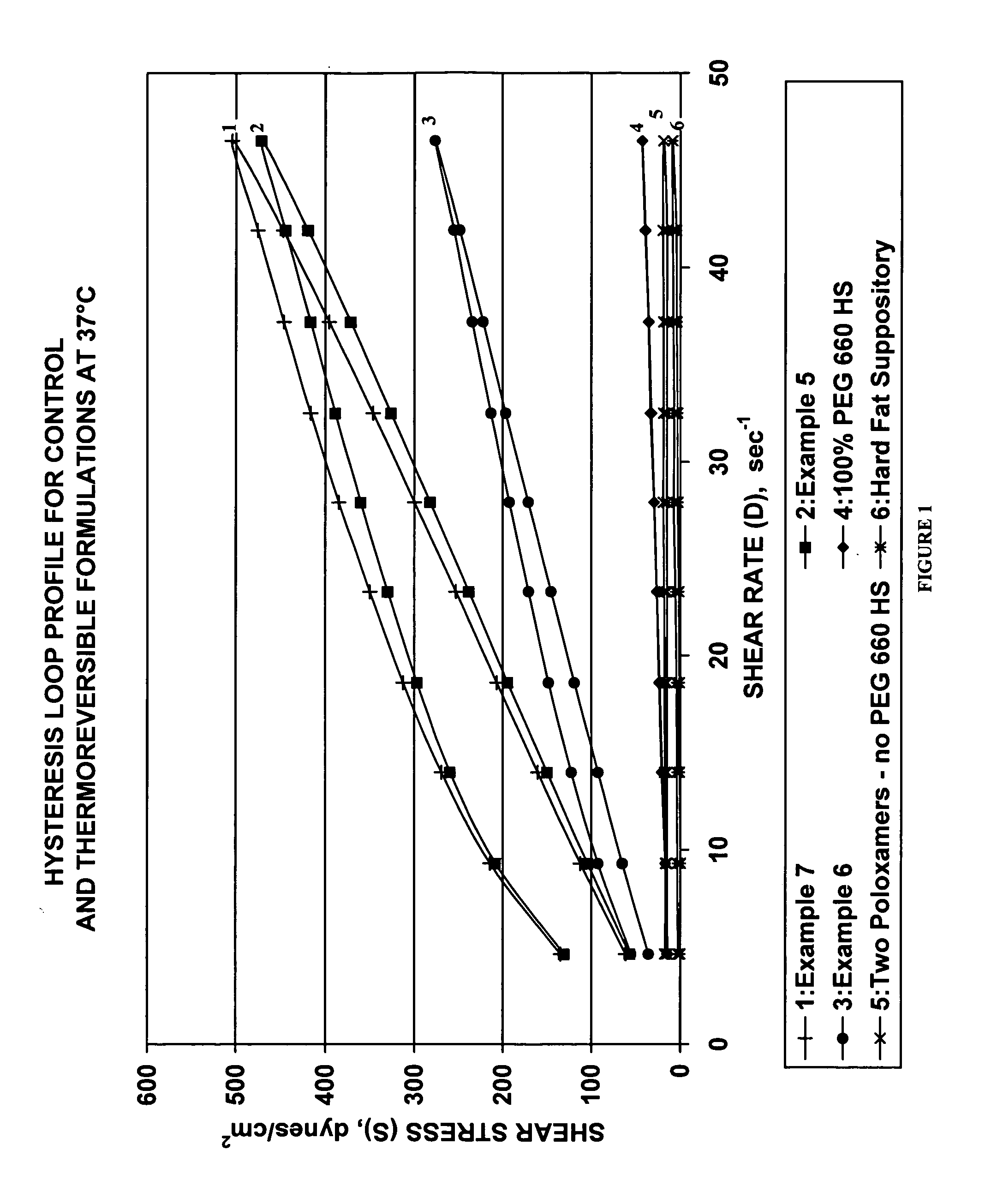

The present invention provides a pharmaceutical formulation having thermoreversible properties, comprising: a) an anti-microbial agent; b) a poloxamer mixture containing at least two poloxamer polymers; and c) a hydroxy fatty acid ester of polyethylene glycol, wherein the formulation is a solid at room temperature and is a liquid-gel at body temperature. The thermoreversible pharmaceutical formulation has a viscosity of about 8,500 cP to about 400,000 cP at room temperature, and a viscosity of about 1,000 cP to about 8,000 cP at body temperature and exhibits a hysteresis loop behavior. The present invention further provides a process of preparing as well as a method of treating a microbial infection in a mammal using the same.

Owner:TARO PHARMA INDS

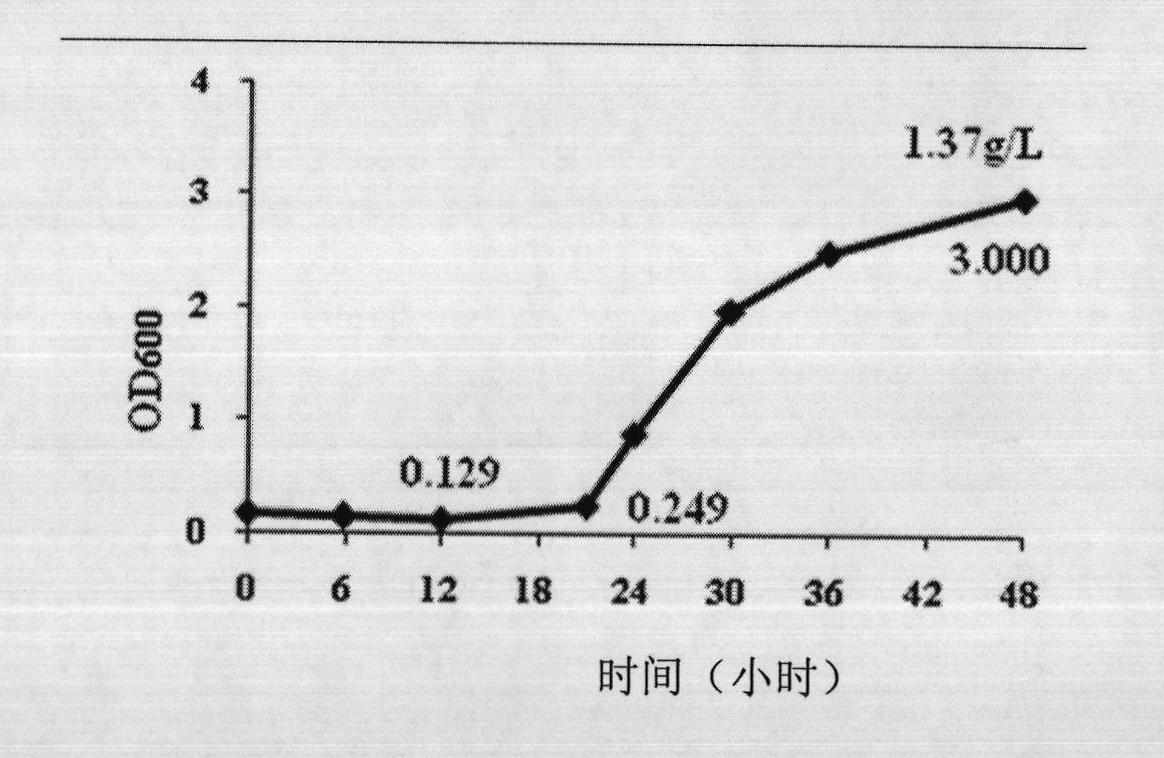

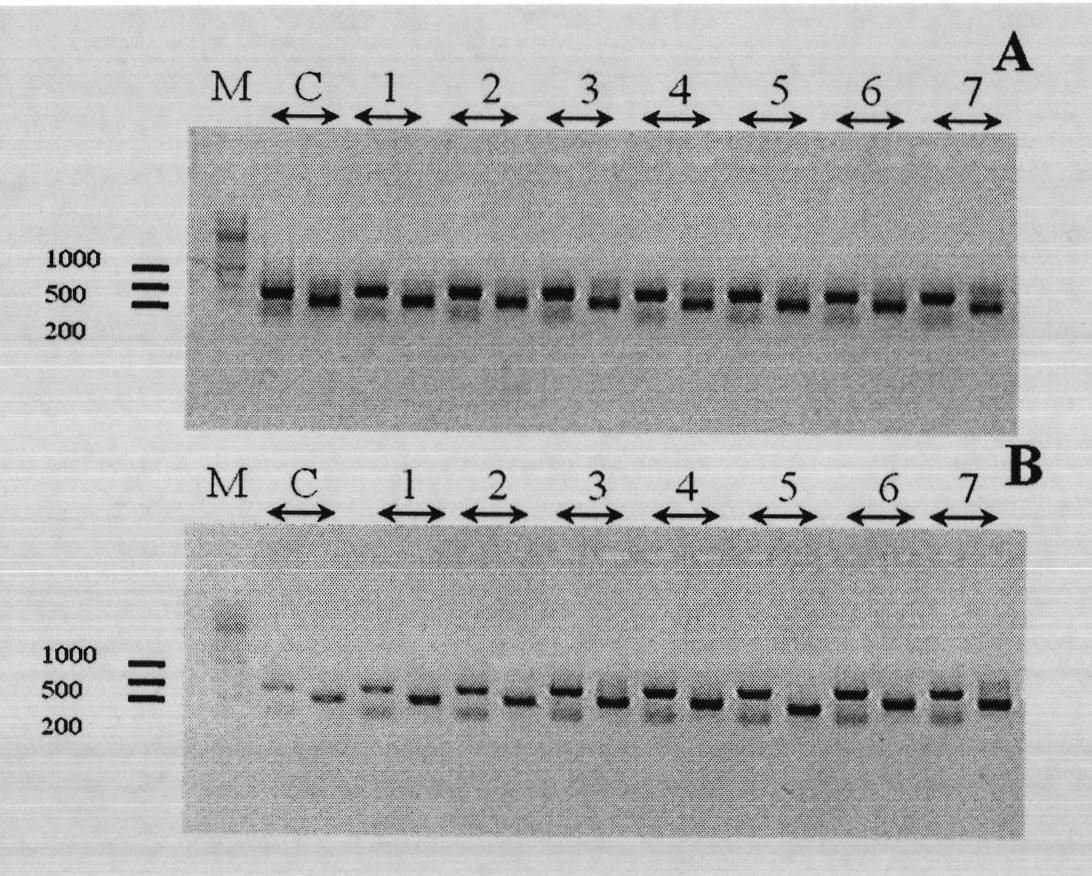

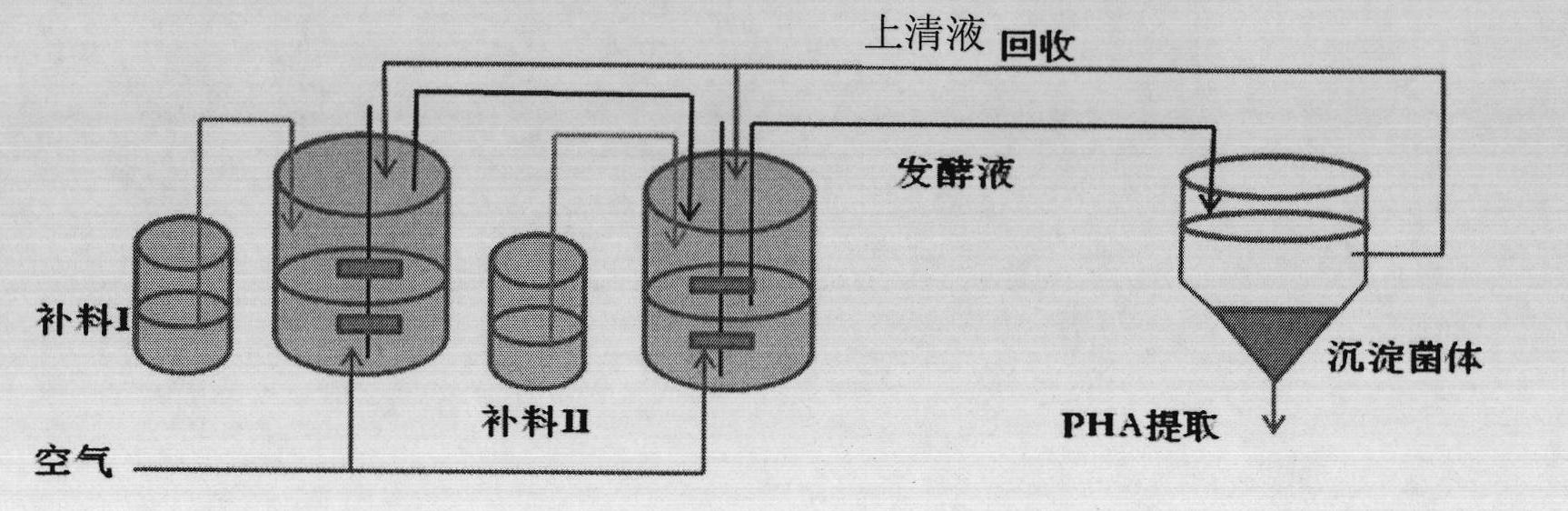

Halomonas strain and application thereof

ActiveCN102120973AIncrease productionReduce manufacturing costBacteriaFermentationBiotechnologyNutrient

The invention discloses a halomonas strain and application thereof. The halomonas strain is a halomonas sp. TD01 with a preservation number of CGMCC NO.4353. Experiments indicate that the halomonas sp. TD01 can effectively accumulate polyhydroxyalkanoates (PHA) in a mineral medium (MM) and provides a better guarantee for the biosynthesis of the PHA and PHBV (poly(hydroxybutyrate-hydroxyvalerate)). The halomonas strain has the advantages of simple nutrient requirement, no need of sterilization in a fermenting process, capability of continuous implantation and simpleness and easiness in control. Methods for preparing the PHA by using the halomonas sp. TD01 all lower the production cost from varying degrees and increase the yield of the PHA; and the obtained PHA has the molecular weight of above 500kDa and has an industrial application value.

Owner:BLUEPHA CO LTD

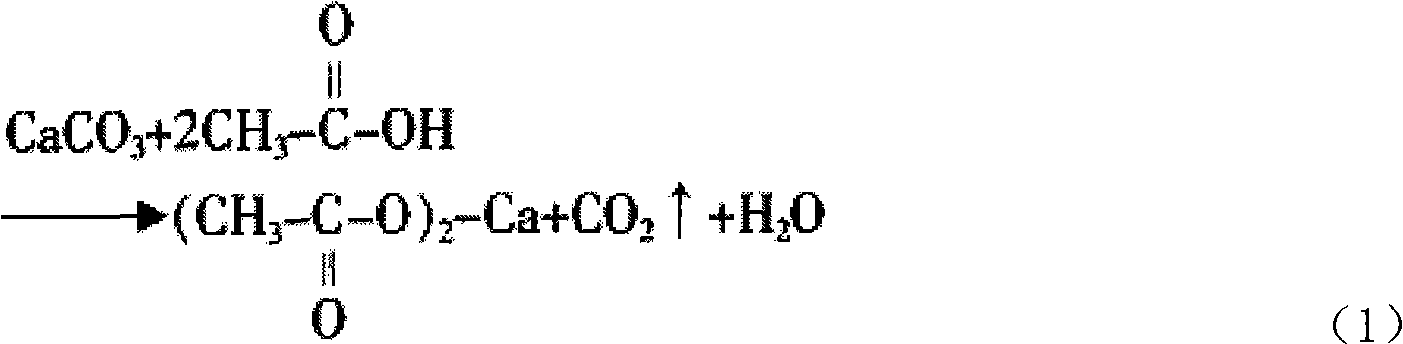

High base number composite calcium sulfonate lubricating grease and its preparation method

A composite lubricating grease contains high-basicity petroleum calcium sulfonate or synthetic calcium sulfonate, acetic acid, C12-C22 hydroxy fatty acid, boric acid, arylamine-type antioxidizing agent and basic lubricating oil. Its advantages are excellent extreme-pressure resistance to friction, water, salt fog and corrosion, high drop point and thermal stability, good viscosity and long service life.

Owner:SINOPEC LUBRICANTS TIANJIN

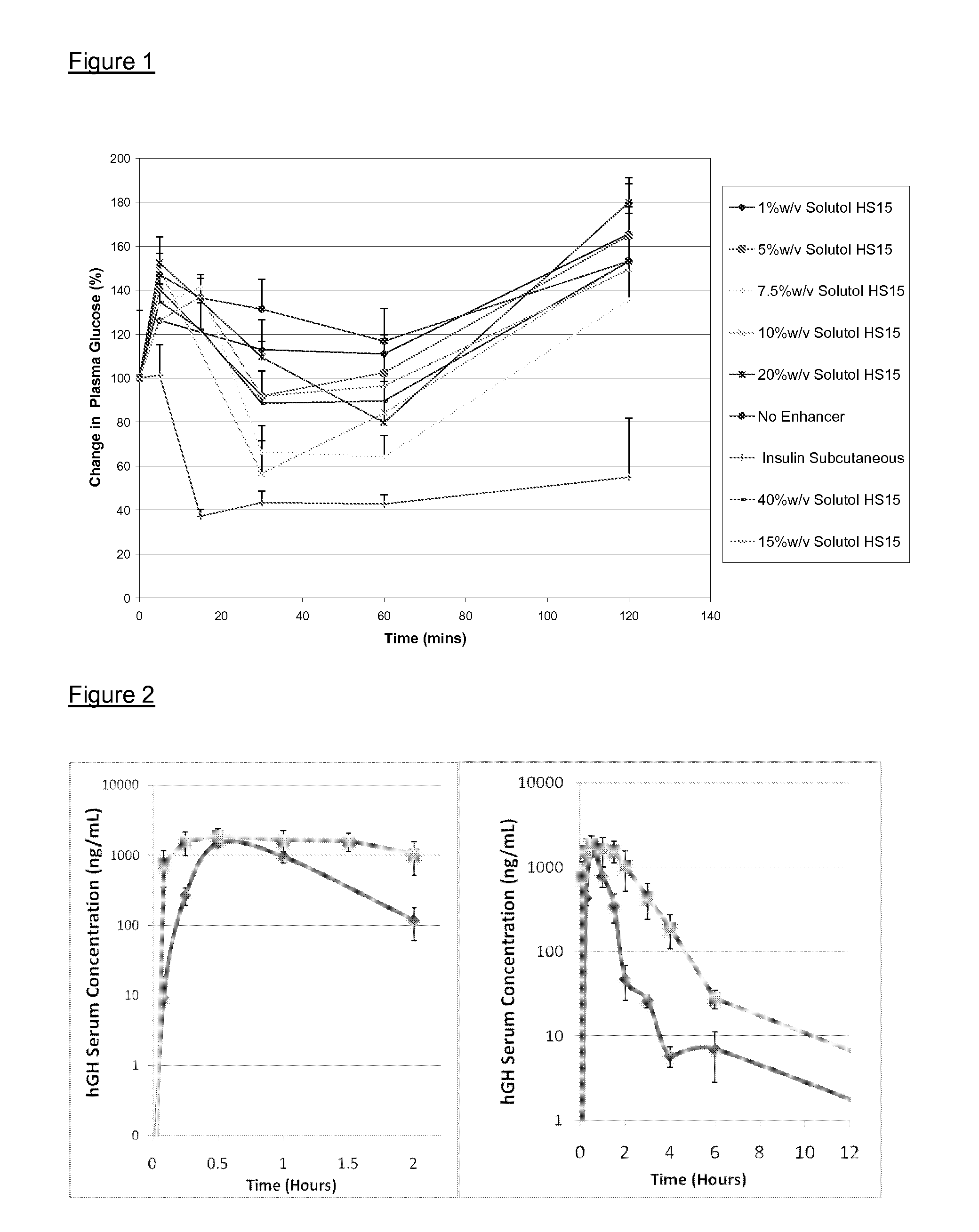

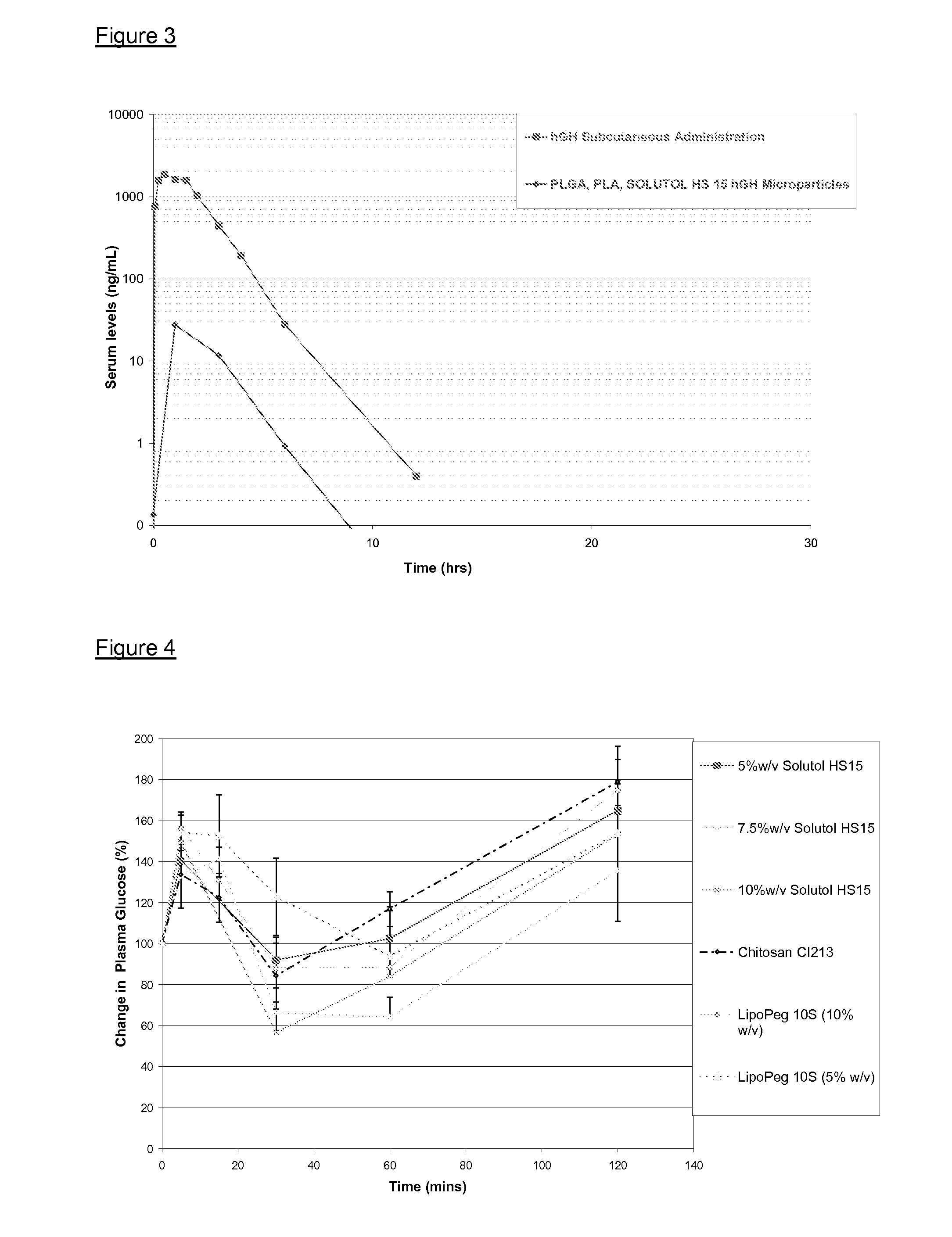

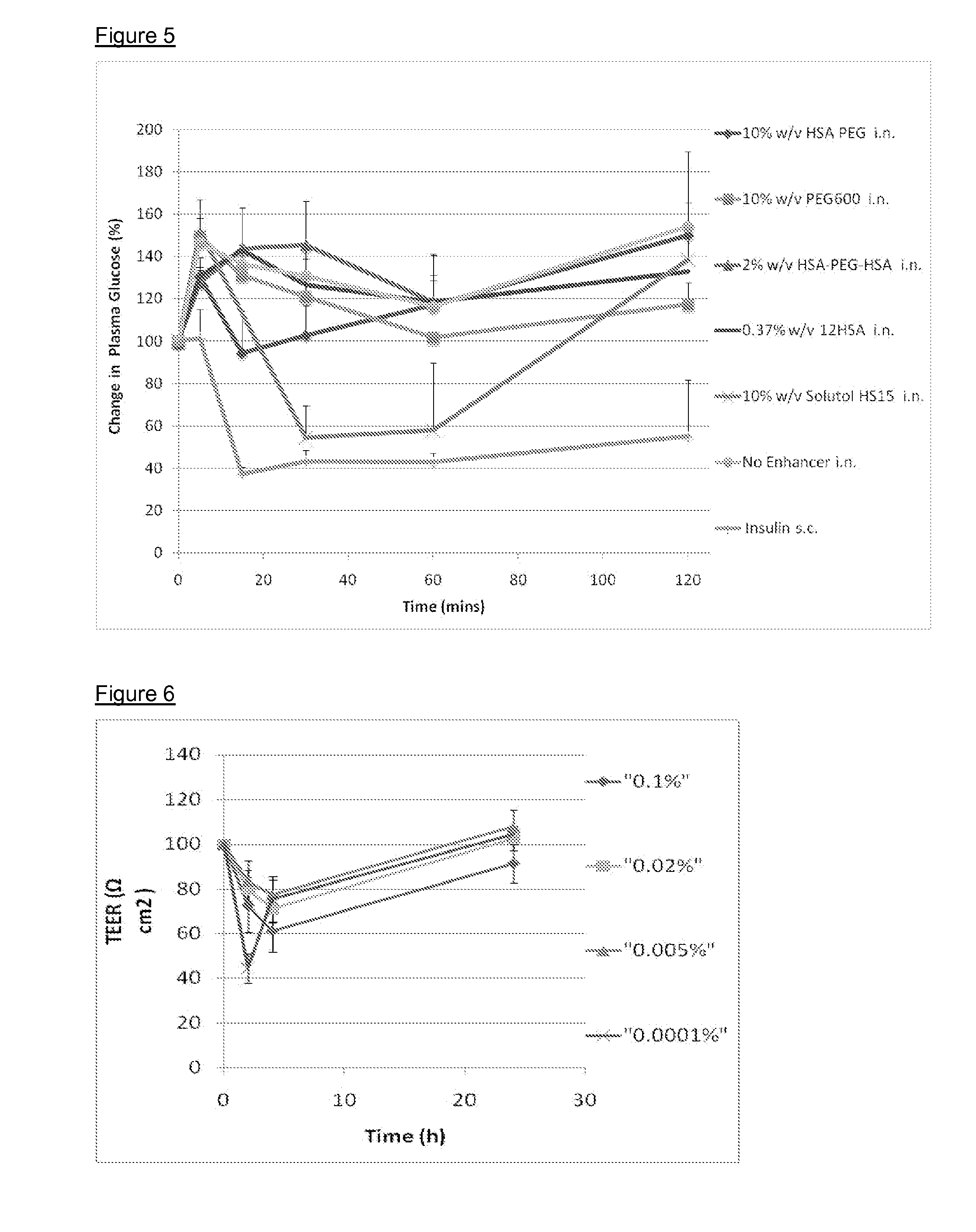

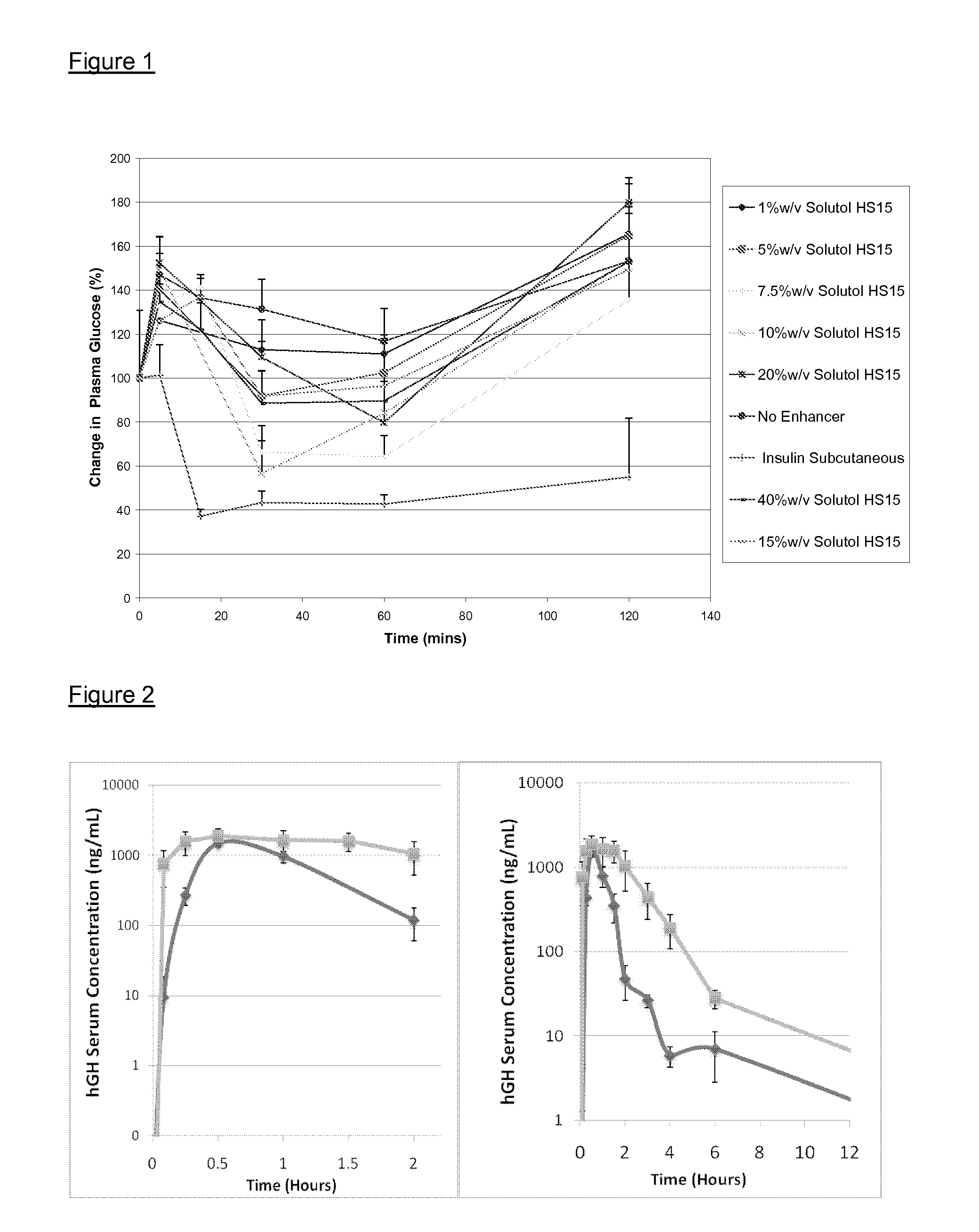

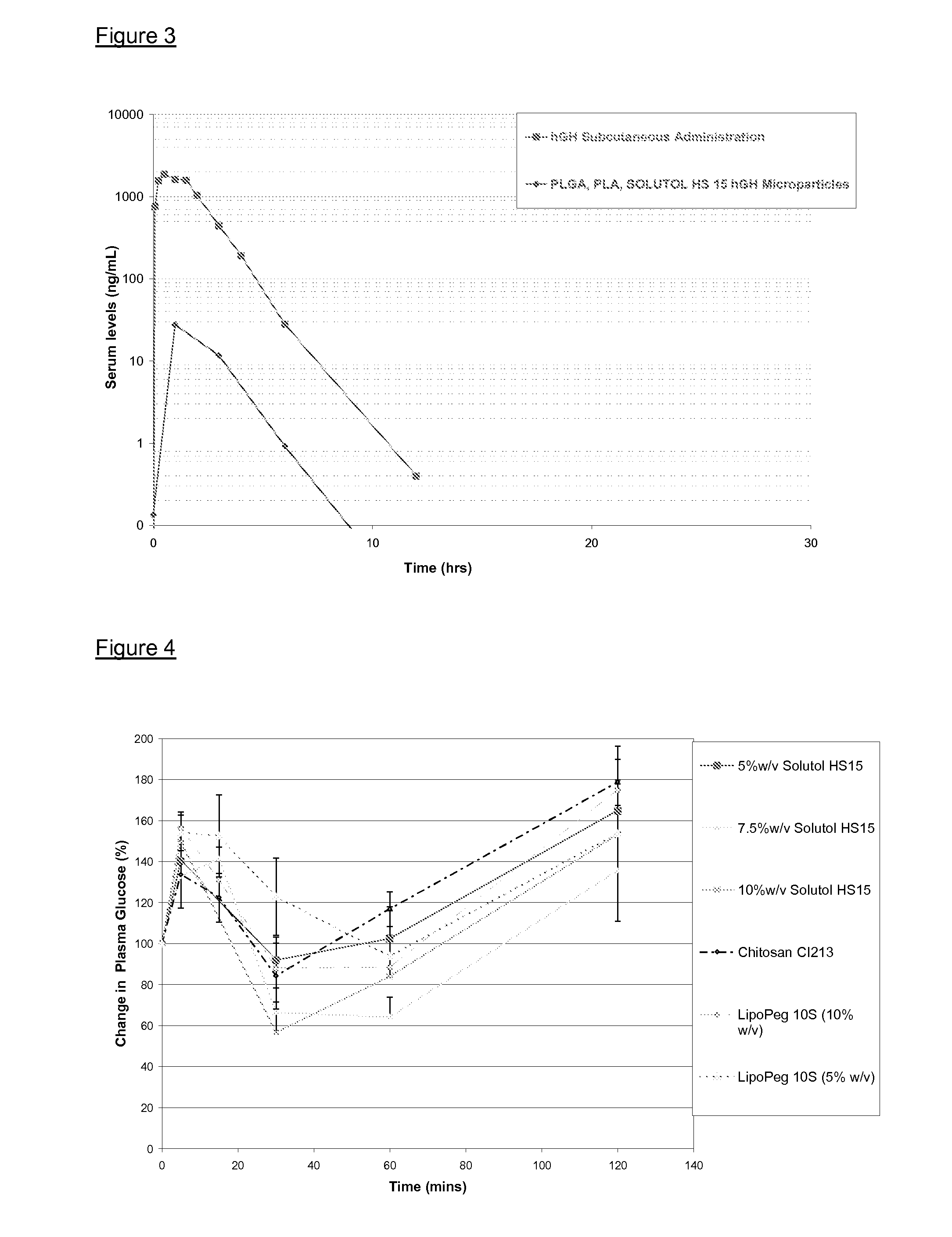

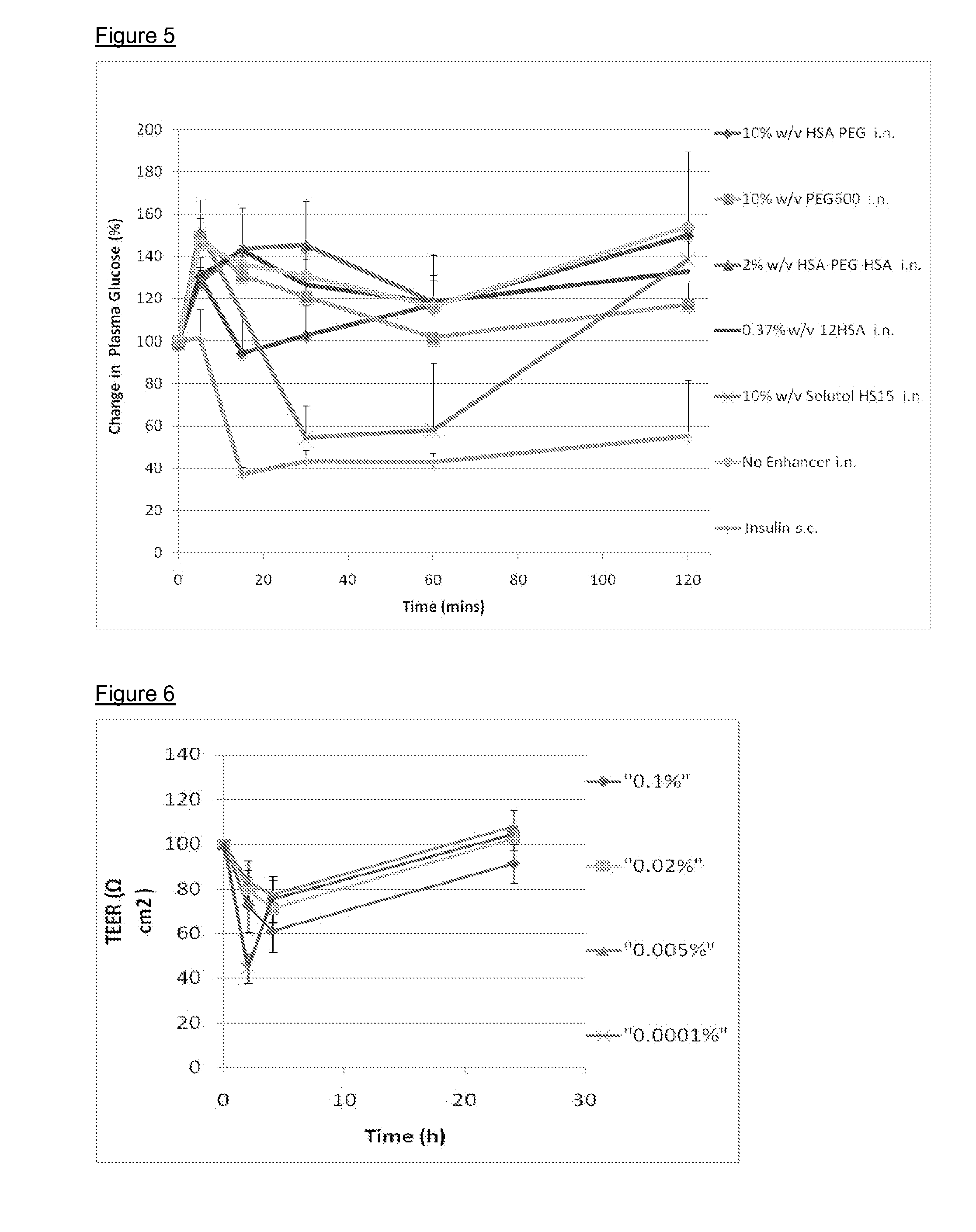

Absorption of therapeutic agents across mucosal membranes or the skin

InactiveUS20110171140A1Prevent degradationKeep it workingPowder deliveryBiocideMedicinePolyethylene glycol

Absorption of a therapeutic agent across a mucosal membrane or the skin can be enhanced using an absorption enhancer comprising a hydroxy fatty acid ester of polyethylene glycol.

Owner:CRITICAL PHARMA LTD

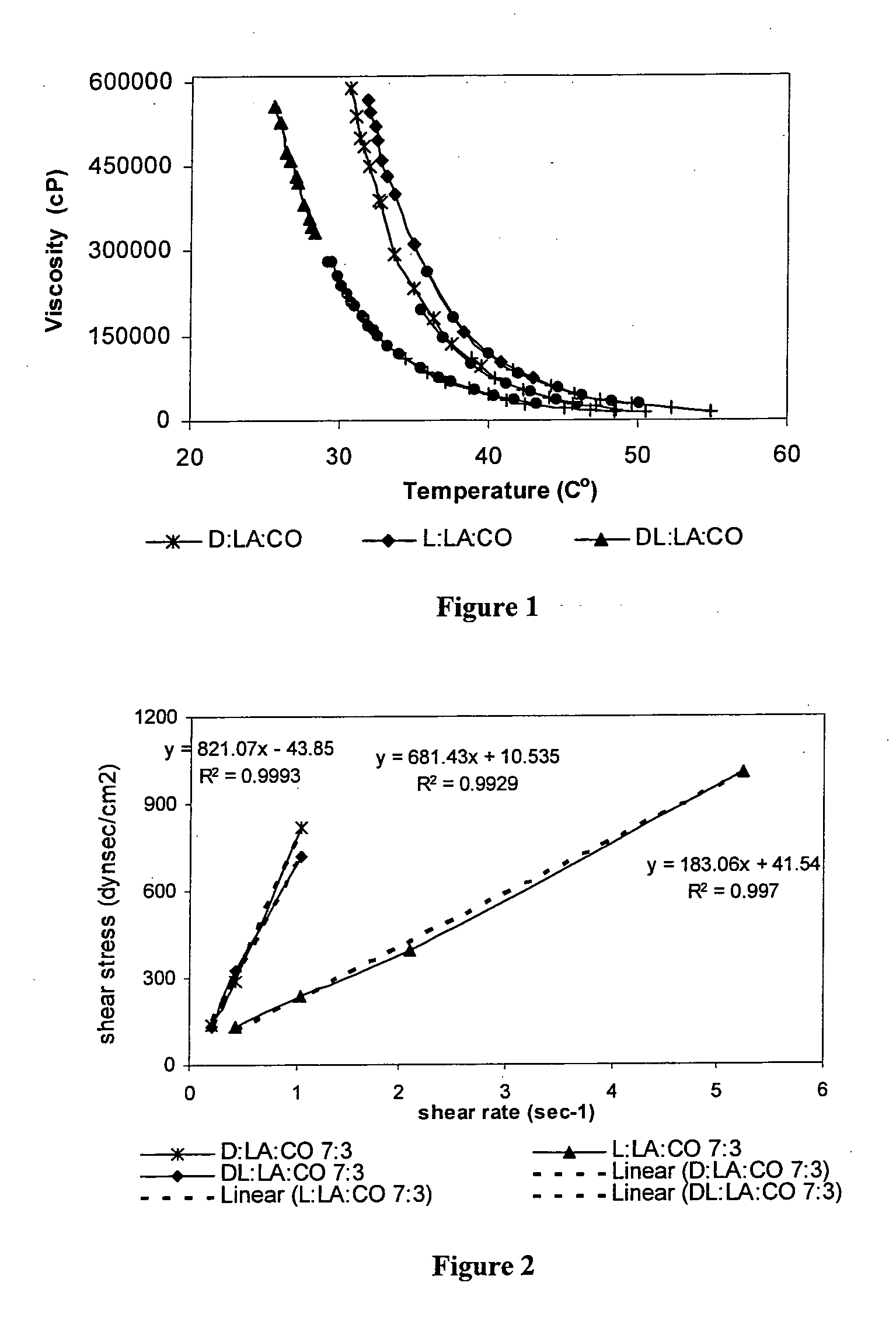

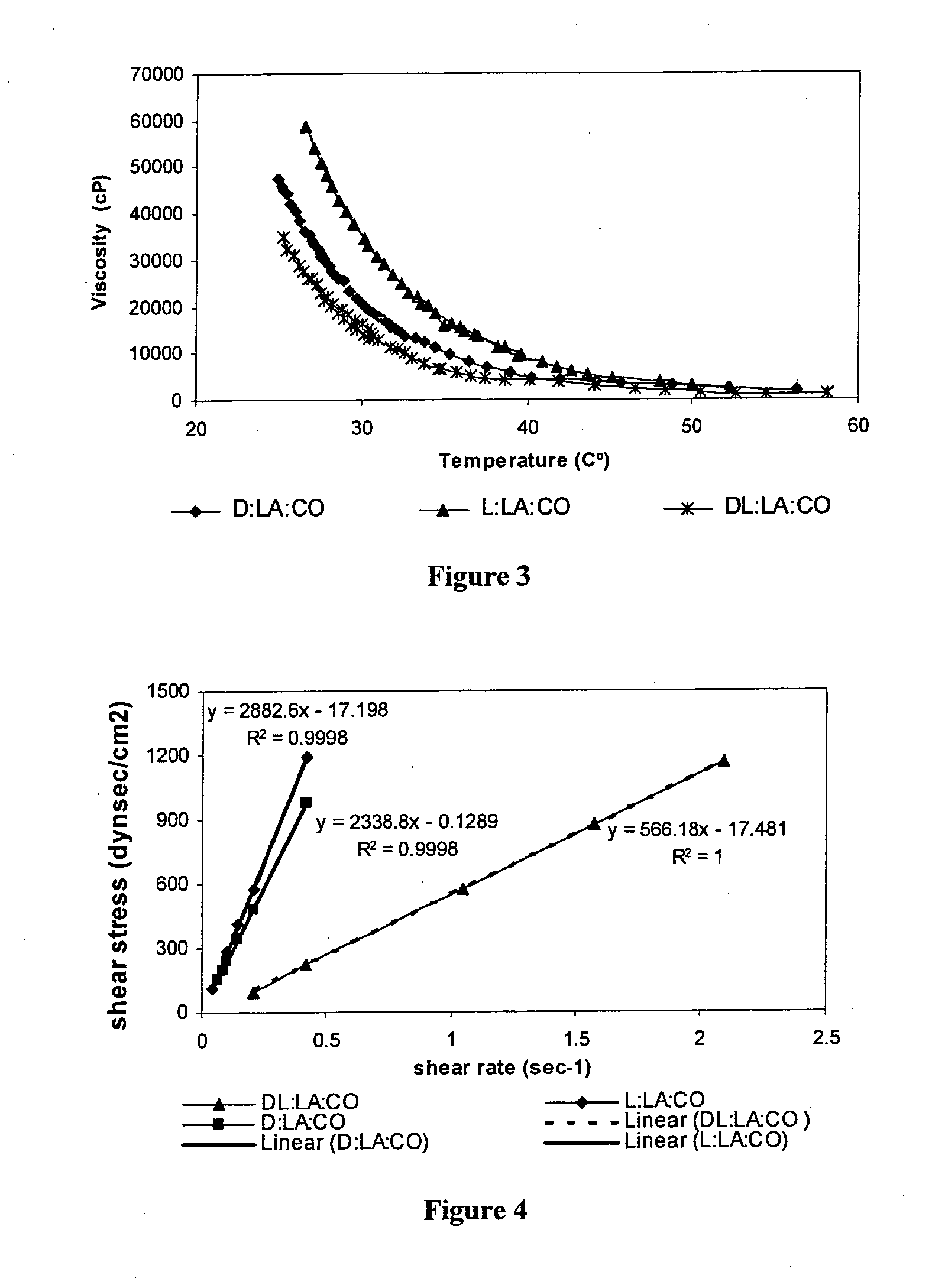

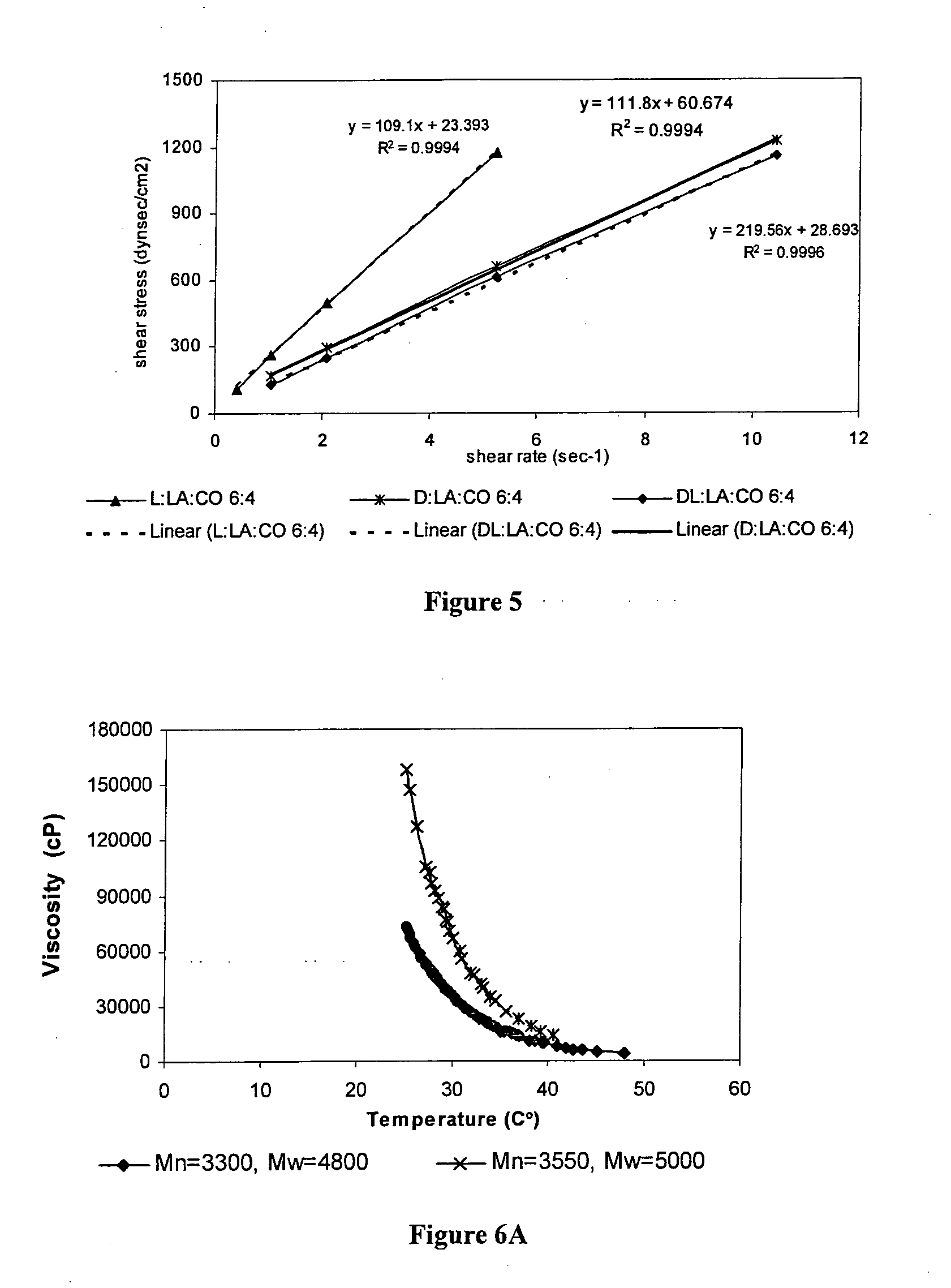

Injectable biodegradable polymer compositions for soft tissue repair and augmentation

InactiveUS20100260703A1Pharmaceutical delivery mechanismUrinary disorderInjectable polymersActive agent

Methods for soft tissue repair and / or augmentation using injectable, biodegradable polymers are described herein. In one embodiment, the polymer compositions are liquid or pastes at room temperature. In a preferred embodiment, the polymer composition contains liquid or pasty hydroxy fatty acid-based copolyesters, polyester-anhydrides, or combinations thereof. The viscosity of the polymers increases upon contact with bodily fluid to form a solid or semisolid implant suitable for soft tissue repair and / or augmentation. In another embodiment, the polymer composition contains particles of a polymer stereocomplex. One or more active agents may be incorporated into the polymer compositions. Suitable classes of active agents include local anesthetics, anti-inflammatory agents, antibiotics, analgesics, growth factors and agents that induce and / or enhance growth of tissue within the filled cavity or control the growth of a certain type of tissue, and combinations thereof. The polymer compositions may also contain one or more additives or excipients that modify the physical and / or mechanical properties of the polymer. The polymer compositions are typically administered by injection. The injectable polymers can be used for a variety of soft tissue repair and augmentation procedures.

Owner:POLYGENE LTD

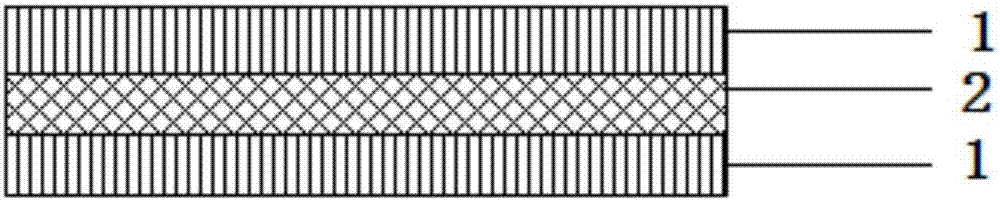

Low-pollution compound reverse osmosis membrane

ActiveCN101130444AOvercome the disadvantage of easy falling offImprove anti-pollution performanceGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisWide areaReverse osmosis

The invention discloses a low-pollution compound reverse osmosis film, which comprises the following parts: nonwoven layer, polysulfone support layer and polyamide layer on the polysulfone support layer, wherein the crosslinked PVA layer is set on the polyamide layer, which is crosslinked by one of aliphatic dialdehydes, hydroxy fatty acid, acid anhydride or polyvalent anion salt compound and PVA solution. The invention overcomes the defect of easy stripping of PVA layer to improve the anti-pollution property of composite osmosis reverse film to lengthen the using life, which is easy to prepare and operate with high desalinization rate and large water flux, therefore fitting for water disposing course in wider domain to expand the application of the reverse osmosis film.

Owner:VONTRON TECH CO LTD

Tissue induction biomedical material

InactiveCN106267341AConjugated cellulose/protein artificial filamentsTissue regenerationAcetic acidCollagen i

The invention discloses a tissue induction biomedical material, and particularly relates to a degradable active biological membrane / powder. The tissue induction biomedical material is prepared from, by weight, 0.1-99% of degradable medical polyurethane, 0-99.9% of polyhydroxyalkanoate, 0-99.9% of polylactic acid and 1-99.9% of collagen, wherein polyhydroxyalkanoate is one of PHA, PHB, PHBV, PHBHHx and P3HB4HB, polylactic acid is one of polyglycolic acid and polylactic acid-glycolic acid copolymer, and collagen is one or more of collagen I, collagen II, collagen VI, collagen IX, collagen X, collagen XI and other various in-vivo collagen. The ratio of all the components is adjusted according to the requirements of the implanting positions of different in-vivo tissue for material performance, degradation products and PH values, so better clinical service is provided.

Owner:YUANRONG BIOLOGICAL PHARMA WUXI CO LTD

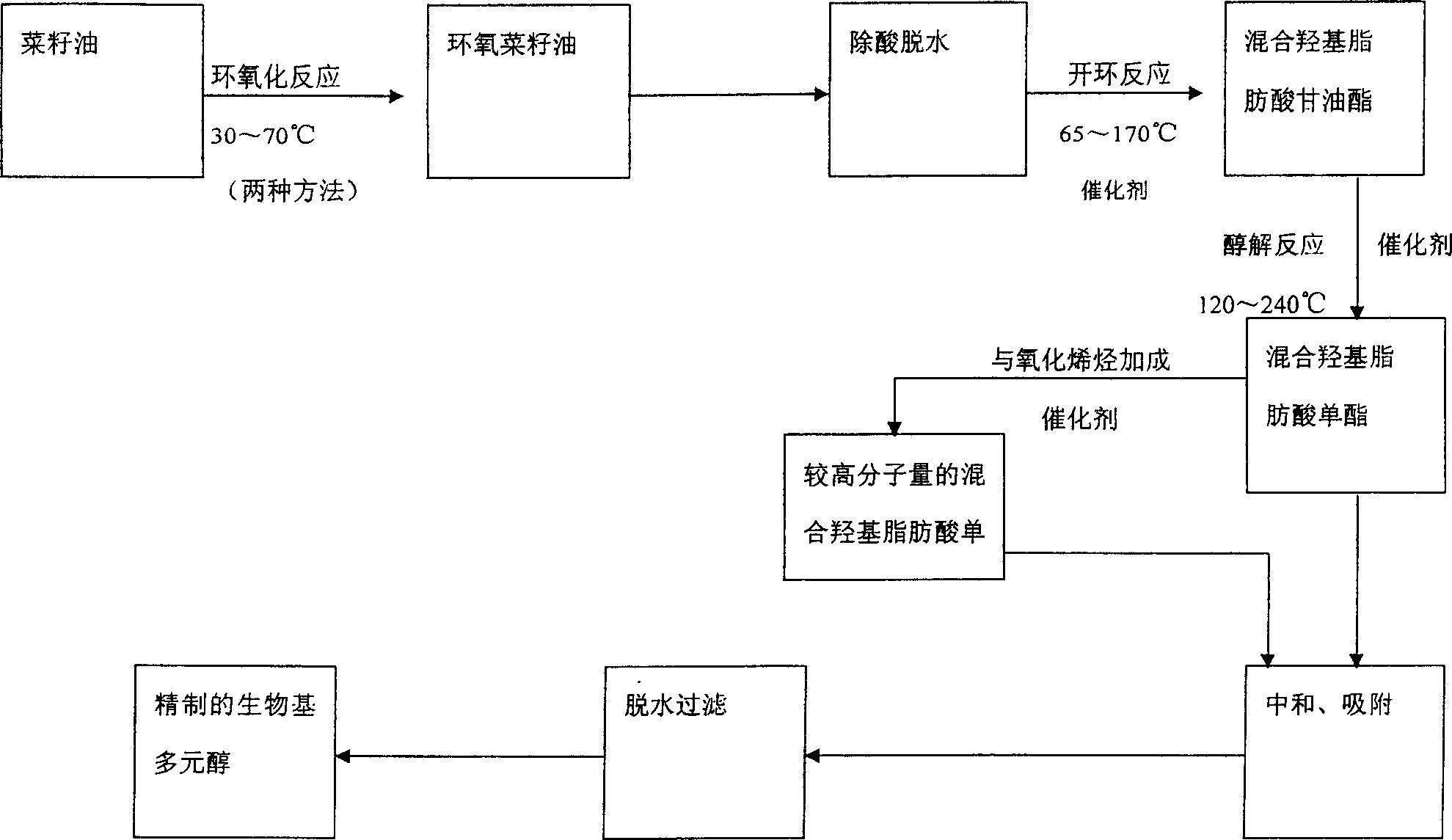

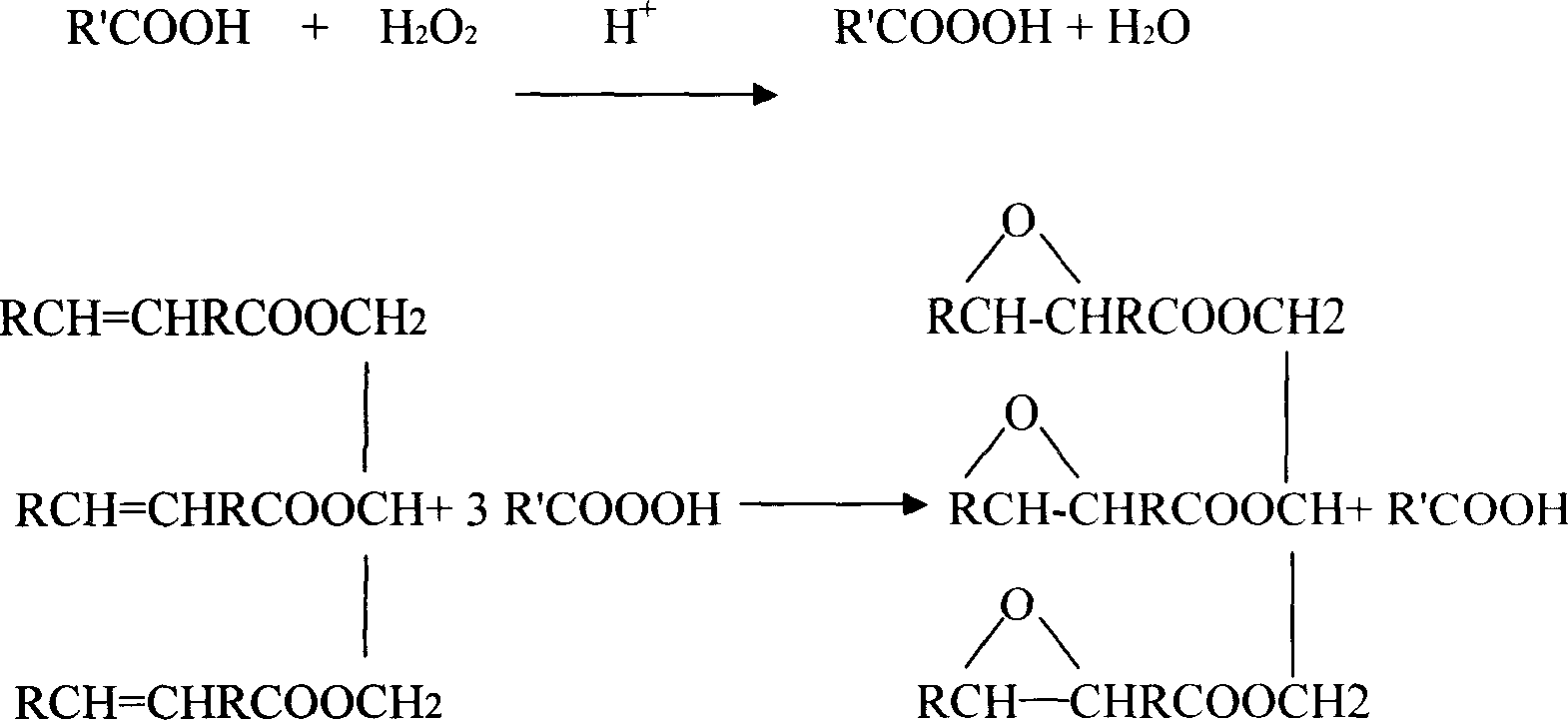

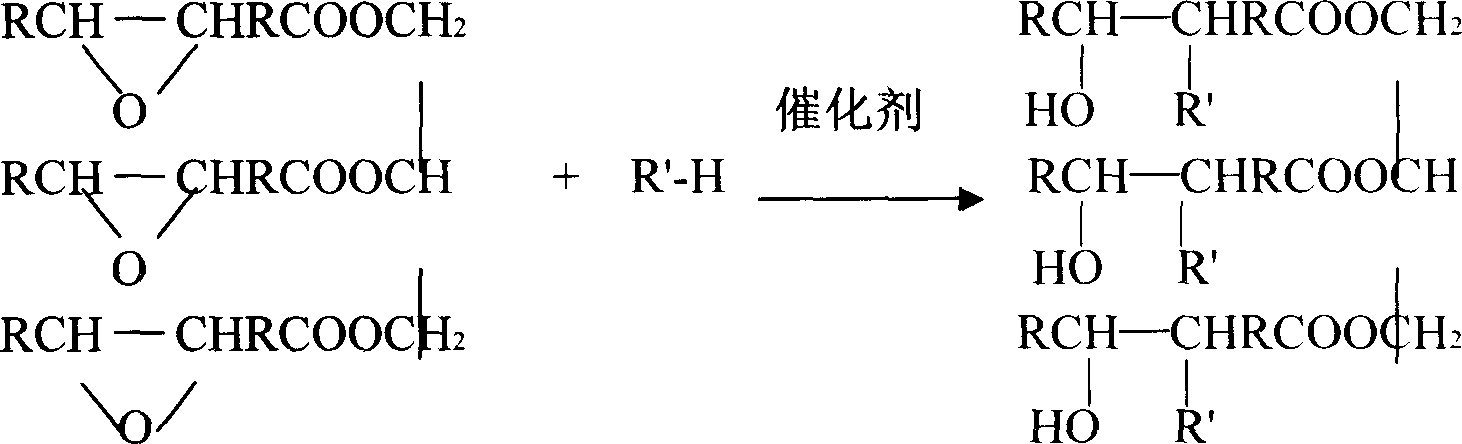

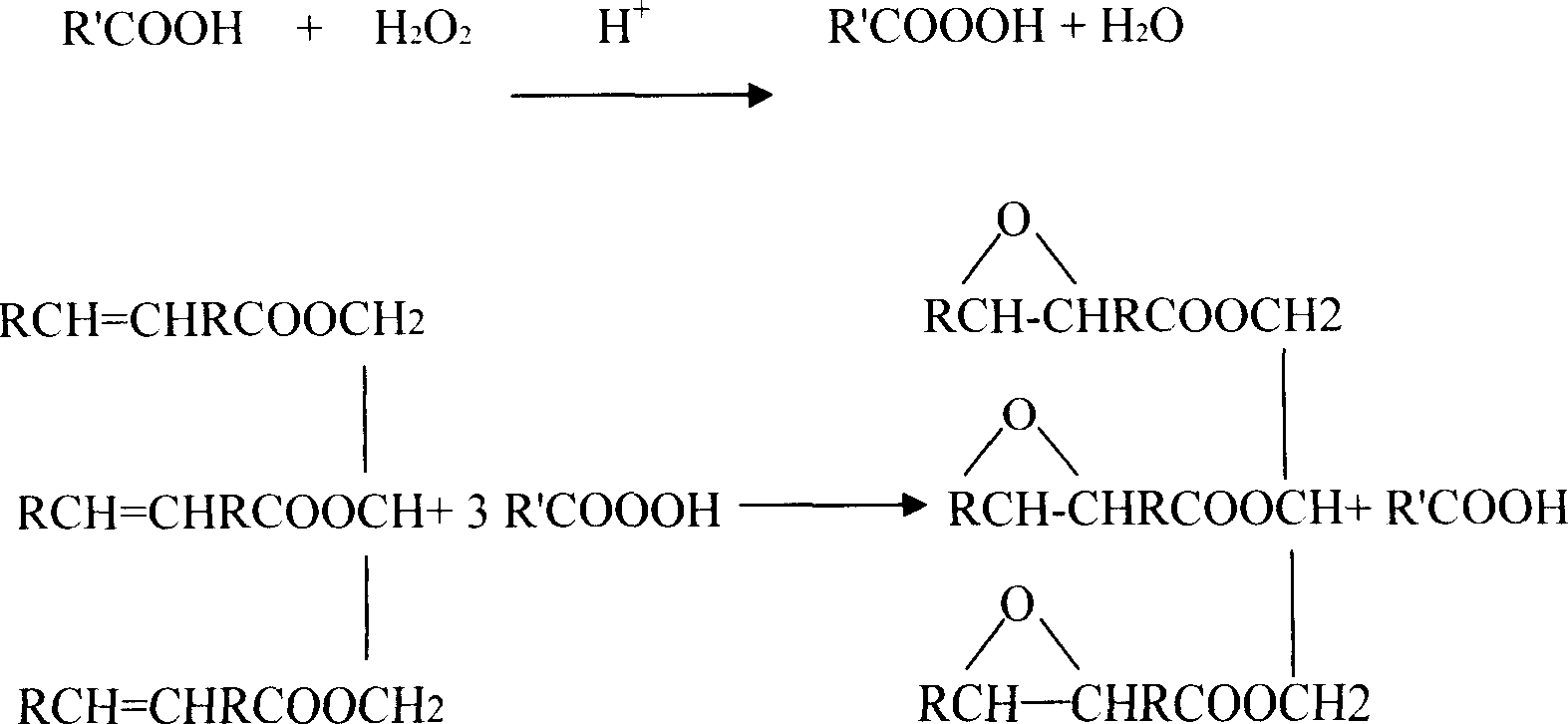

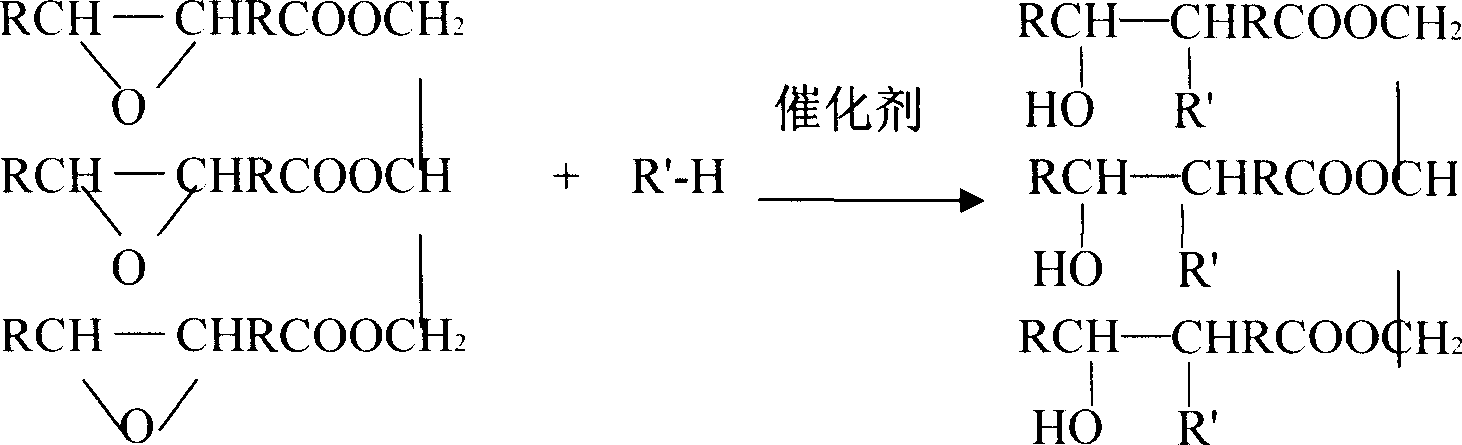

Bio-based polyhydric alcohol prepared by using rape seed oil

The invention discloses a rape oil preparing biological radical polyatomic alcohol method, which comprises the following steps: naking the rape oil and epoxidation agent to carry on epoxidation reaction; generating epoxy rape oil; proceeding epoxy key open cycle reaction with generated epoxy rape oil and nucleophilic reagent with reactive hydrogen; getting mixed hydroxy fatty acid glycerin fat; adding in amine or alcohol amine; heating-up to proceeding alcoholysis reaction; getting mixed hydroxy fatty acid monoesters-biological radical polyatomic alcohol. The invention has degree of functionality and high reaction active. The raw material is cheap and easy to get.

Owner:HONGBAOLI GRP CO LTD

Fuel blends

A fuel additive composition containing ethanol, n-propanol or mixtures thereof together with a non-hydroxy fatty acid and organic ester is described. A miscible fuel blend composition containing the fuel additive composition and diesel oil, gas oil or a mixture thereof, as well as a process for preparing the fuel blend composition is also described.

Owner:VICTORIAN CHEM INT

Biodegradable thermoplastic starch-polyethylene film

The invention discloses a biodegradable thermoplastic starch-polyethylene film and relates to the technical field of film production. The biodegradable thermoplastic starch-polyethylene film is prepared from the following raw materials by mass percent: 40-50 percent of thermoplastic starch (self-made), 20-30 percent of polyethylene, 0.5-3 percent of microcrystalline cellulose, 2-5 percent of calcium sulfate, 1-3 percent of oxidized polyethlene wax, 1-2 percent of zinc stearate, 1-2.5 percent of polyhydroxyalkanoate, 0.5-2 percent of ethylene-glycol, 0.5-2 percent of sorbitol, 0.5-3 percent of maleic anhydride and 0.2-1 percent of glutaraldehyde. The prepared thermoplastic starch-polyethylene film has a favorable mechanical property and excellent biodegradability, is wide in application range, and can be made into various plastic products in the market. Therefore, the thermoplastic starch-polyethylene film is a biodegradation plastic film with a broad market prospect.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

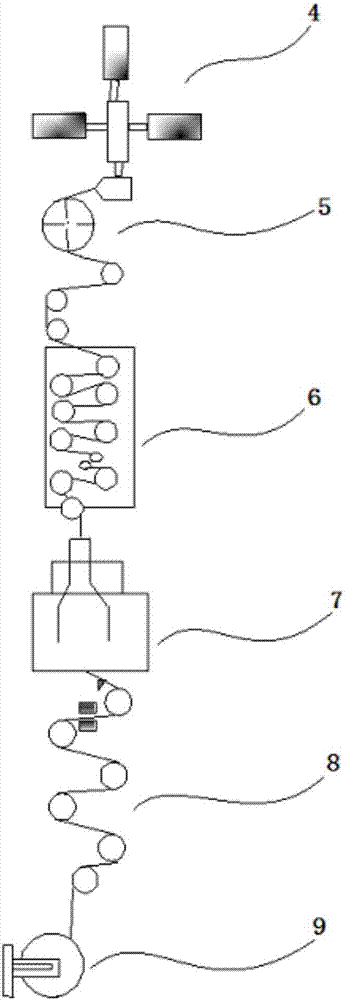

Polyhydroxyalkanoates fiber and preparation method thereof

InactiveCN101538750AArrange straight and neatHigh crystallinityMonocomponent copolyesters artificial filamentConjugated synthetic polymer artificial filamentsFiberBiocompatibility Testing

The invention relates to a fiber and a preparation method thereof, in particular to a degradable fiber and a preparation method thereof. The fiber contains polyhydroxyalkanoates, and the preparation method thereof comprises the steps of melting and extruding a base material, obtaining a sample band, cold-stretching or pre-stretching the sample band, quenching, performing isothermal crystallization and the like. The fiber disclosed by the invention has the advantages of good biocompatibility, biodegradability, high strength and / or good toughness.

Owner:TIANJIN GREENBIO MATERIAL CO LTD +1

Composite calcium sulphonic consistent grease and preparation method thereof

InactiveCN101319164AImprove water resistanceImprove corrosion resistanceThickenersAdditivesCalcium EDTABase Number

The invention relates to a composite calcium sulfonate grease and a preparation method thereof. The composite calcium sulfonate grease comprises: (A) base oil which accounts for 50-80 percent of the total weight of the grease; (B) calcium alkylbenzenesulfonate with a super high base number accounting for 10-30 percent of the total weight of the grease; (C) a composite thickener consisting of hydroxy fatty acid of C12-C22 accounting for 0.5-5 percent of the total weight of the grease, boric acid accounting for 0.5-3 percent of the total weight of the grease, and calcium hydroxide accounting for 0.5-2 percent of the total weight of the grease; (D) a disperser or similar matter accounting for 0.5-4 percent of the total weight of the grease; and (E) a transforming agent. The composite calcium sulfonate grease is prepared through the processes of mixing, stirring, heating up, homogenizing, degassing, etc. The grease not only has the advantages of high drop point, good thermal stability at a high temperature, good water resistance, good corrosion protection, excellent extreme pressure anti-wear properties, etc., but also is characterized by high drop point, good rust and corrosion resistance without additives, extreme pressure anti-wear properties, good mechanical stability, colloid stability, and nonhardening property for a long-period storage.

Owner:杭州得润宝油脂股份有限公司

High-performance complex calcium sulfonate grease and preparation method thereof

InactiveCN101824357AImprove high temperature resistanceGood mechanical stabilityLubricant compositionAntioxidantDioctyl sebacate

The invention discloses high-performance complex calcium sulfonate grease and a preparation method thereof. The complex calcium sulfonate grease comprises the following components: 35 to 80 percent of base oil, 10 to 40 percent of ultrahigh-base-number synthetic calcium sulfonate, 0.5 to 2 percent of antioxidant and 0.5 to 20 percent of transforming agent, wherein the base oil is dicarboxylic acid diester, dioctyl sebacate, dioctyl adipate and the like; the ultrahigh base number of the ultrahigh-base-number synthetic calcium sulfonate is between 380 and 420mgKOH / g; and the synthetic calcium sulfonate comprises the following complex components: 0.5 to 8 percent of C12 to C24 hydroxy fatty acid, 0.5 to 4 percent of boric acid and 0.5 to 2 percent of calcium hydroxide. The complex calcium sulfonate based grease has high-temperature resistance, high mechanical stability and high extreme-pressure abrasion resistance, reduces the using amount of the transforming agent such as alcohol, ether and the like and environmental pollution in the production process, and improves the efficiency of transforming Newtonian high-base-number calcium sulfonate into non-Newtonian high-base-number calcium sulfonate completely, so that the production technology is simpler.

Owner:李墨菊

Production of omega-amino fatty acids

The invention provides a whole cell catalyst which expresses a recombinant α-dioxygenase or the combination of a recombinant fatty acid reductase and a phosphopantetheinyl transferase phosphopantetheinylating the fatty acid reductase, and which in addition to the α-dioxygenase and / or the combination of fatty acid reductase and phosphopantetheinyl transferase expresses a transaminase, characterized in that the phosphopantetheinyl transferase and / or transaminase is preferably recombinant; and a method for the conversion of a fatty acid, ω-hydroxy fatty acid, ω-oxo fatty acid or a monoester thereof to an amine, comprising oxidation of the fatty acid, ω-hydroxy fatty acid, ω-oxo fatty acid or the monoester thereof to an oxidation product by contacting with an alkane hydroxylase and / or alcohol dehydrogenase, contacting the oxidation product with a phosphopantetheinylated fatty acid reductase or a α-dioxygenase to give an aldehyde, and contacting the aldehyde with a transaminase.

Owner:EVONIK OPERATIONS GMBH

Oily makeup cosmetics

The present invention is to provide oily makeup cosmetics which comprises an oligo ester obtained from (a) an aliphatic acid or a hydroxy aliphatic acid having 8 to 30 carbon atoms (straight or branched, saturated or unsaturated), (b) a straight or branched dibasic acid having 12 to 36 carbon atoms, and (c) glycerol or a glycerol condensate, and a hydrocarbon having a branched structure.

Owner:KANEBO COSMETICS INC +1

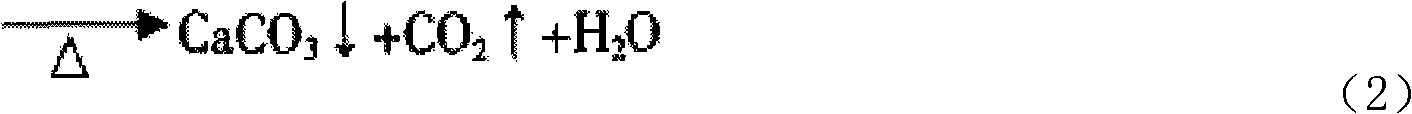

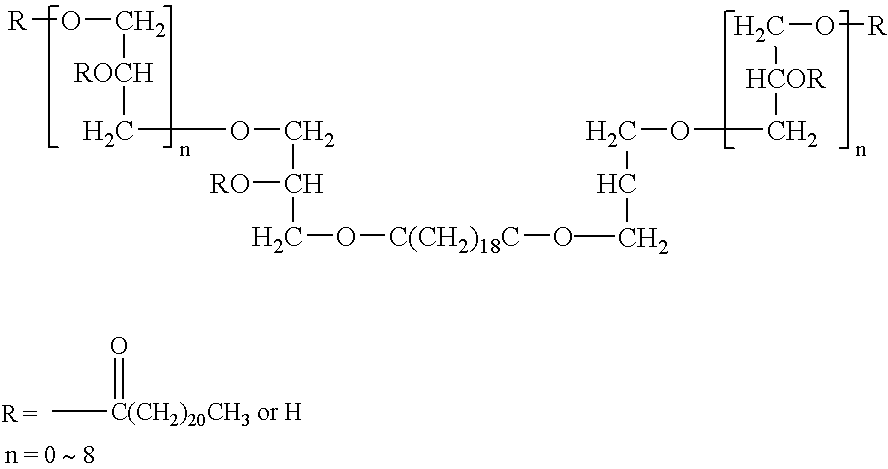

Biocompatible and temperature-sensitive nano composite hydrogel and preparation method thereof

InactiveCN101703805AGood biocompatibilityImprove mechanical propertiesTumor/cancer cellsProsthesisDesorptionBiocompatibility Testing

The invention relates to a biocompatible and temperature-sensitive nano composite hydrogel and a preparation method thereof. The hydrogel contains alkyl acrylamide M1 with temperature-sensitive property, inorganic nano-powder M2 and polyhydroxyalkanoate M3 with good biocompatibility, and the mass percentage of the three is 94-60: 1-20: 5-39. The preparation method comprises the steps that: the M1, the M2 and the M3 are subjected to in-situ free radical polymerization reaction in aqueous solution, and the nano composite hydrogel with biocompatibility and temperature-sensitive property is obtained after soaking and impurity removal. The method has simple and easily controlled preparation process, and can implement automatic desorption of cells by reducing the temperature; the biocompatibility and the temperature-sensitive property of the hydrogel can be adjusted by changing the density of a crosslinker, the dosage of the M3 and the component; and the method can be widely applied in the fields of tissue engineering and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing PHA (polyhydroxyalkanoate)

PendingCN109504715ASimple and safe production environmentLow priceMicroorganism based processesFermentationCell wallFermentation

The invention provides a method for preparing PHA (polyhydroxyalkanoate). The method comprises the following steps of (1) preparing halophilic bacterium fermentation liquid; performing solid-liquid separation to obtain concentration bacterium liquid; (2) washing the concentration bacterium liquid obtained in step (1); (3) performing cell wall breaking cracking on the washed bacterium liquid obtained in step (2) so as to obtain wall breaking liquid; (4) removing non-PHA substances in the wall breaking liquid obtained in step (3); collecting the PHA; (5) purifying the PHA; (6) drying the PHA. The method has the advantages that the process is mild; the cost is low; the requirement on the equipment is low; the large-scale industrialized production can be realized.

Owner:BLUEPHA CO LTD

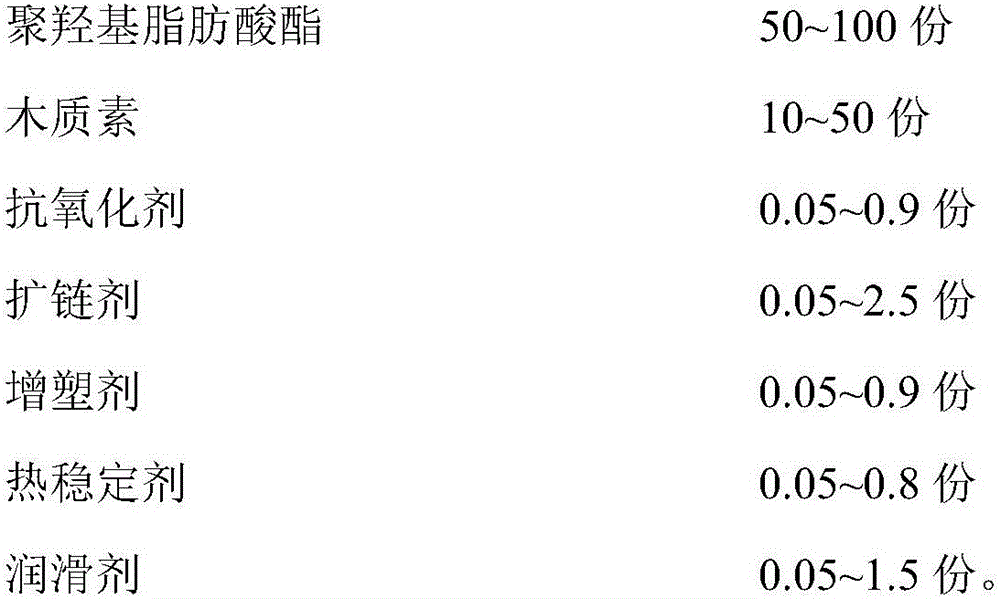

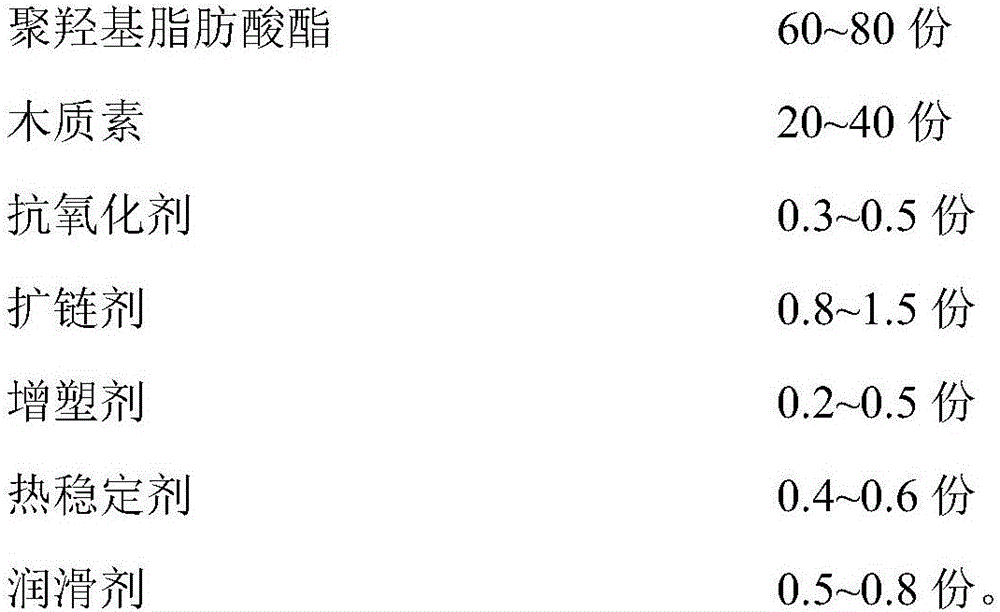

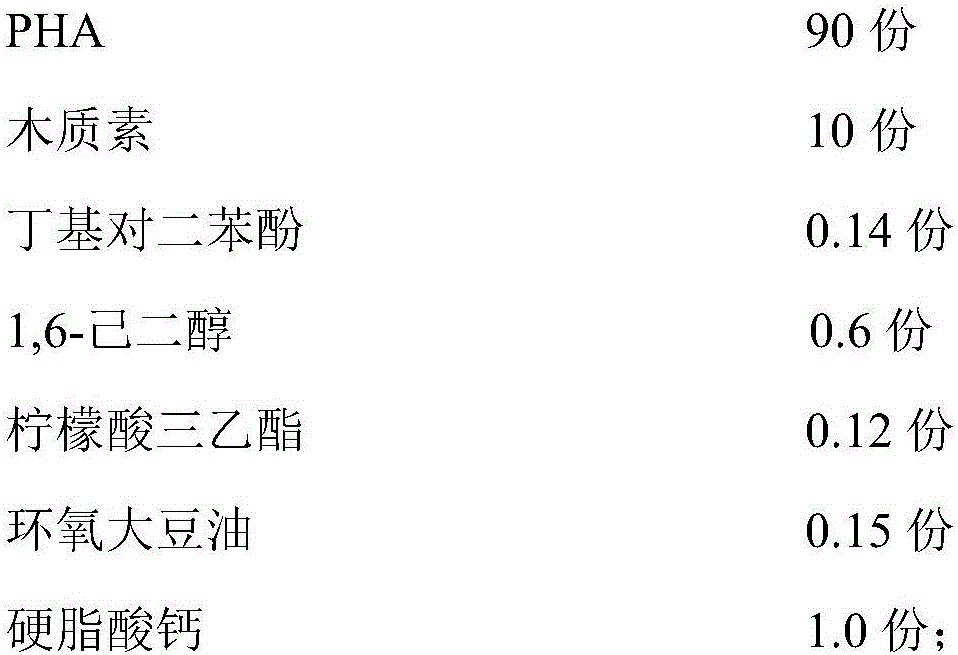

Lignin modified PHA biodegradable plastic and preparing method thereof

The invention discloses a preparing method of a lignin modified PHA biodegradable plastic. The preparing method comprises the steps of 1, conducting vacuum drying on a certain amount of polyhydroxyalkanoate and lignin for certain time; 2, adding dried polyhydroxyalkanoate, lignin, chain extender, antioxidant, plasticizer, lubricant and heat stabilizer in a high mixing machine, and conducting full mixing; 3, extruding the mixed materials into granules through a twin-screw extruder; 4, conducting membrane blowing on the obtained lignin-PHA composite plastic at certain temperature to prepare the lignin modified PHA biodegradable plastic. According to the preparing method of the lignin modified PHA biodegradable plastic, by introducing a biologic material lignin, the lignin-PHA composite plastic prepared through compound modification meets the demand for complete degradation, meanwhile, the mechanical property of pure PHA resin is strengthened, the cost of the plastic is effectively reduced, and the plastic is more beneficial to market popularization.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

Water-in-oil emulsion preparation for external use on skin

InactiveUS20050118210A1Reduce oxidationQuality improvementCosmetic preparationsBody powdersAdditive ingredientCarboxylic acid

A water-in-oil emulsion preparation for external use on the skin, characterized in that the oil phase comprises a mixture of an ester compound obtained by esterifying the following ingredients (A), (B) and (C); an ester oil; a surfactant; and an oil other than ester oil and that the aqueous phase comprises an aqueous solution of a water-soluble inorganic salt: (A) a polyhydric alcohol, (B) a fatty acid and / or hydroxy fatty acid each having 8 to 30 carbon atoms and (C) a dibasic carboxylic acid having 12 to 30 carbon atoms. This water-in-oil emulsion preparation for external use on the skin is excellent in moisture-confining properties, use touch and stability.

Owner:THE NISSHIN OILLIO GRP LTD

Rigid polyurethane foam prepared by using rape seed oil

Owner:HONGBAOLI GRP CO LTD

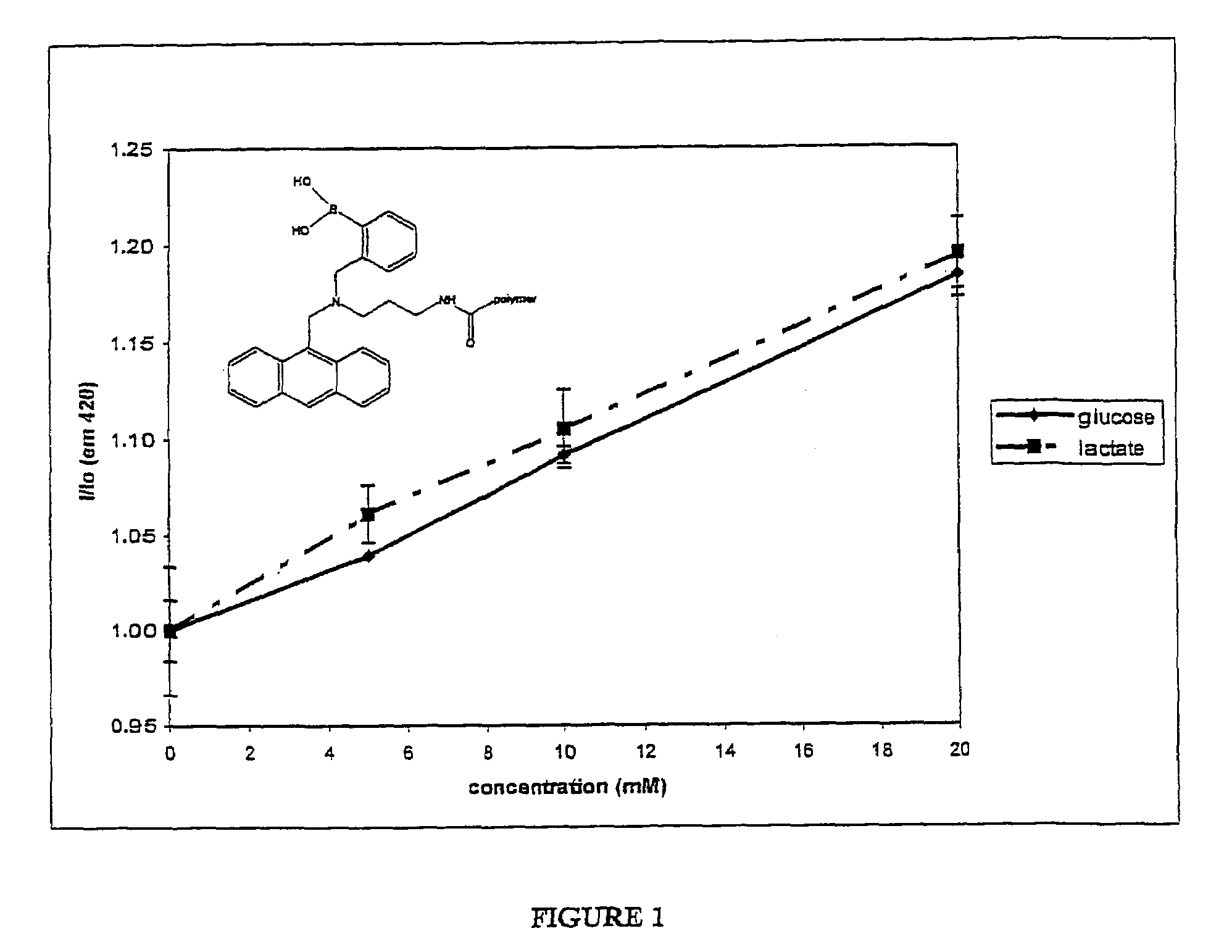

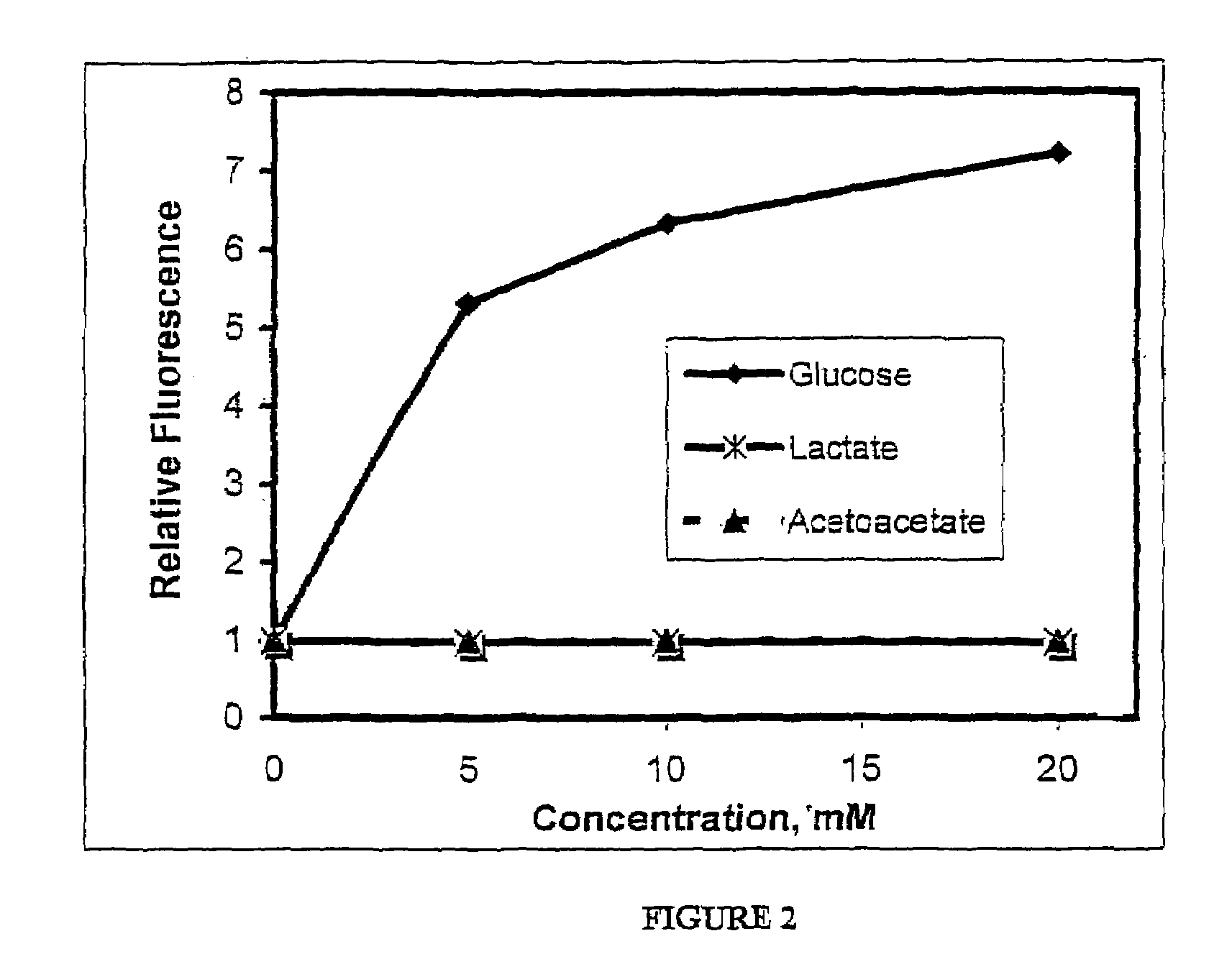

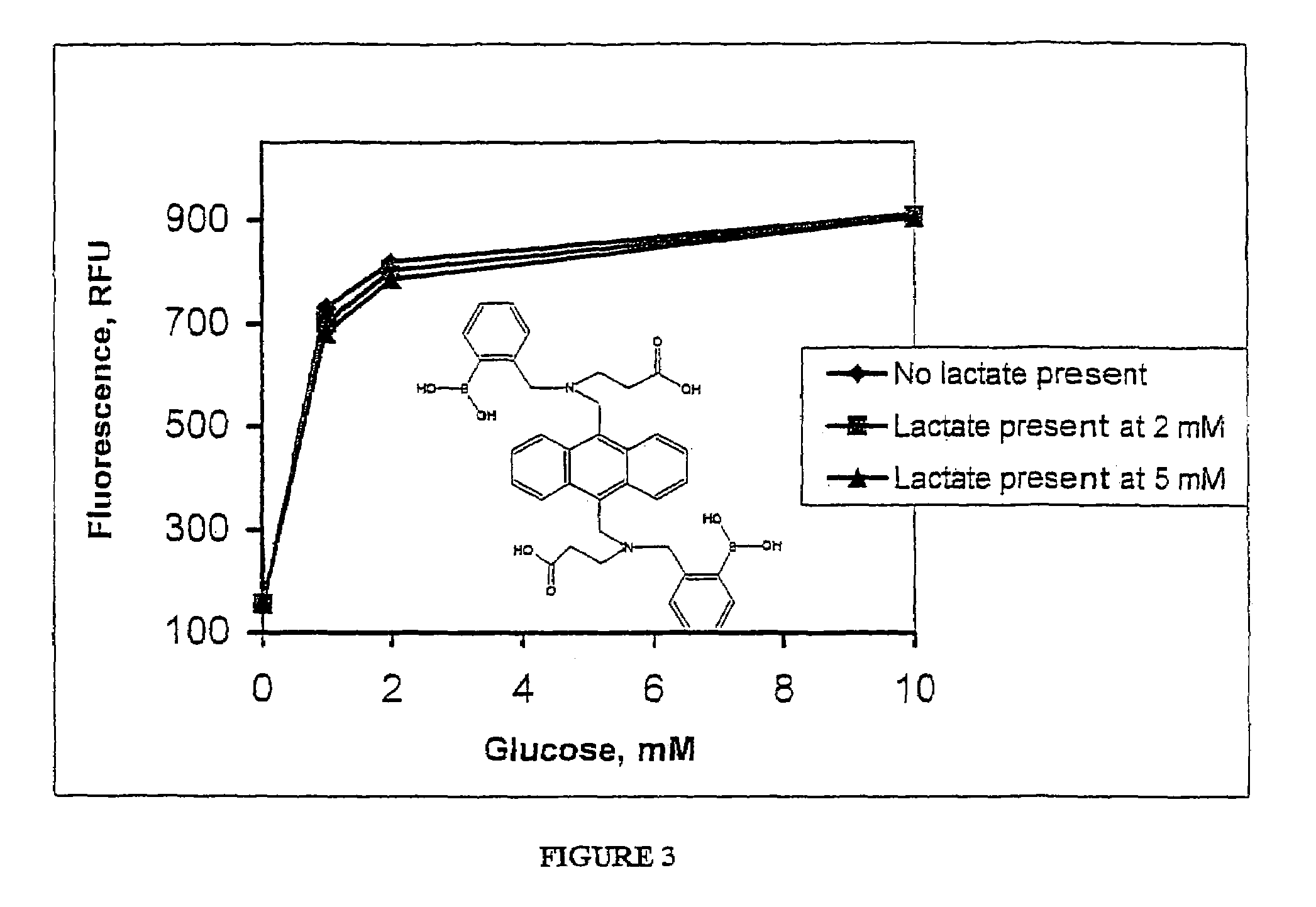

Detection of glucose in solutions also containing an alpha-hydroxy acid or a beta-diketone

InactiveUS7078554B2BiocideMaterial analysis by observing effect on chemical indicatorDiketoneGlucose polymers

Owner:SENSEONICS INC

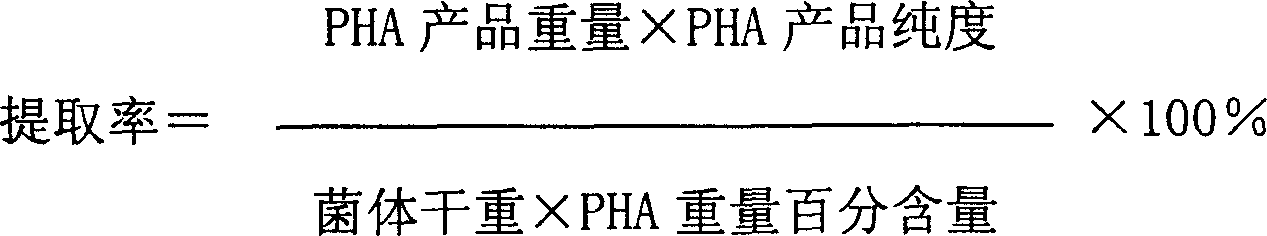

Method for extracting intracellular poly hydroxy fatty acid in microbe

This invention is extraction method of cellular hydroxy fatty acid esters from microorganism. The procedure is as followings: 1) ferment to get enough microorganisms, collect it. 2) Dry to powder, add esterlike organic solvents. React at 80-120deg C for 1-4hours. Extract hydroxy fatty acid esters. 3) Restore the organic phase. 4) Precipitate hydroxy fatty acid esters from the organic phase with esterlike organic solvents. 5) Separate, wash and precipitate. 6) dry to obtain hydroxy fatty acid esters. This invention could be used in high quality PHA industrialization. It's time-reduced, energy-saving, environment-friendly and highly-efficient. It has a large application scale.

Owner:TSINGHUA UNIV

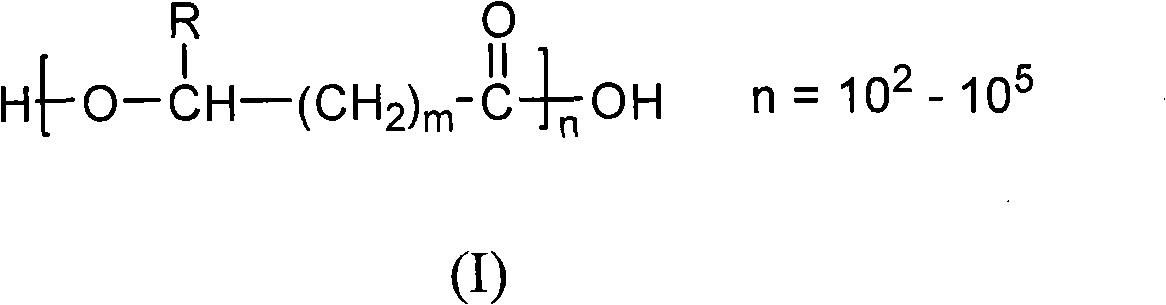

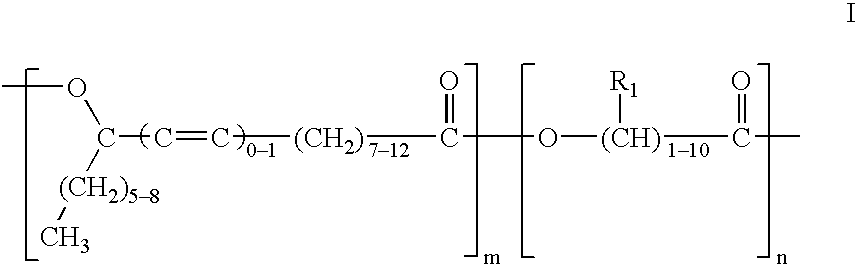

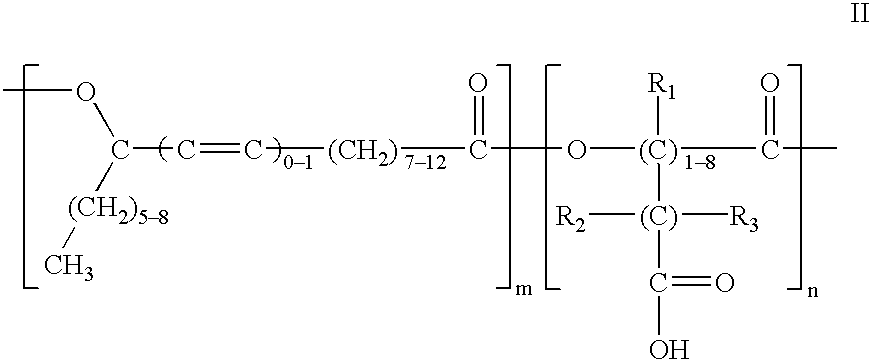

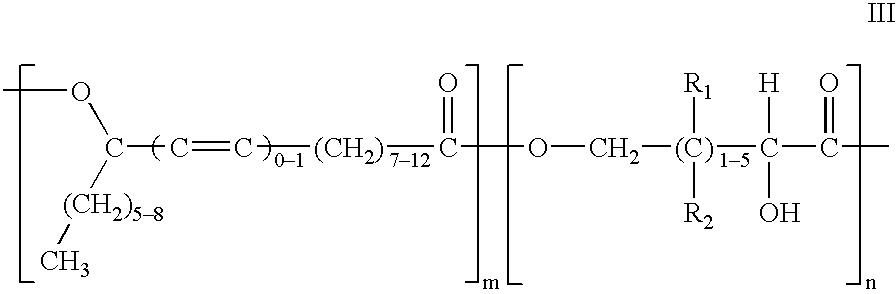

Polyesters based on hydroxy fatty acids and lower hydroxy alkyl acids and uses thereof

InactiveUS20020172646A1Low degree of irritationLow toxicityOrganic active ingredientsBiocideCosmetic vehicleCombinatorial chemistry

Owner:ETHOX CHEM LLC

Absorption of therapeutic agents across mucosal membranes or the skin

InactiveUS8795634B2Improve efficacyImproved profilePowder deliveryOrganic active ingredientsMedicinePolyethylene glycol

Absorption of a therapeutic agent across a mucosal membrane or the skin can be enhanced using an absorption enhancer comprising a hydroxy fatty acid ester of polyethylene glycol.

Owner:CRITICAL PHARMA LTD

Cigarette filter tow and preparation method thereof

ActiveCN102392316AImprove heat resistanceImprove thermal stabilityTobacco smoke filtersArtificial filament heat treatmentPolyesterFiber

The invention discloses a cigarette filter tow and a preparation method thereof. The cigarette filter tow comprises the main component of a blending modified polylactic acid material. The blending modified polylactic acid material comprises the following components in parts by weight: 100 parts of temperature resistant lactic acid polyester mixture, 0.5-1.2 parts of polyethylene glycol, 0.5-1.2 parts of polyhydroxyalkanoate, 2-2.75 parts of mixture of thermal stabilizer and antioxidant additive, 0.3-0.7 part of adsorbent and 0.3-0.7 part of titanium dioxide. The invention has the advantages that the thermal resistance and thermal stability of the polylactic acid material are improved because of the temperature resistant additive or a polylactic acid nucleater and the mixture of the thermal stabilizer and the antioxidant additive; in addition, the tension thermoforming is carried out on a thermal steam box at 97-103 DEG C through a stretched fiber tow, the fiber tow is sprayed by using cold water before entering a crimping machine to avoid nodositas and stiffness of the fiber tow; the curled tow is sprayed by using a spraying device which is placed behind a crimping knife, and an anti-toxic smoke solution is placed in the spraying device, therefore, the affinity and the adsorbability of the cigarette filter tow on a toxic substance can be improved.

Owner:浙江恩实生物科技有限公司

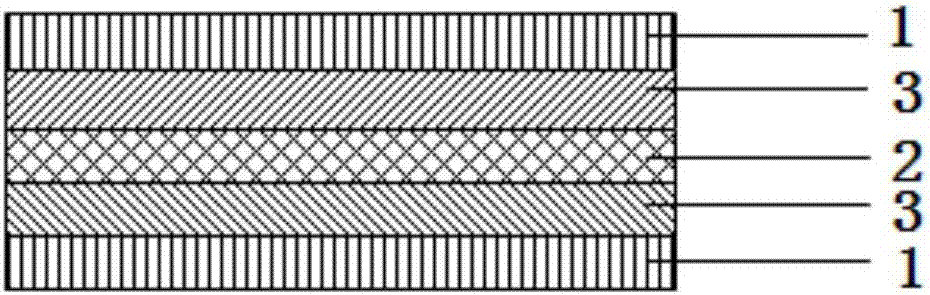

Biodegradable multilayer co-extrusion material and preparation method thereof

ActiveCN107031153APromote degradationWith natural propertiesSynthetic resin layered productsFlat articlesPolybutyleneMedical product

The invention provides a biodegradable multilayer co-extrusion material. The material is characterized by comprising two surface functional layers and a middle layer located between the two surface functional layers, components of the surface functional layers and the middle layer include biodegradable materials, and the biodegradable materials refer to one or more of polybutylene succinate, polylactic acid, polyhydroxyalkanoate and polybutylene adipate-polybutylene terephthalate. The invention further discloses a preparation method of the material. The biodegradablity of four selected master batches of the multilayer co-extrusion material is good, and adopted inorganic minerals are natural, so that the co-extrusion material has completely biodegradable properties and can be widely used in various types of food packages, medical products, environmental protection labels, advertisements and all kinds of environmental-protection products.

Owner:齐庆德

Polyurethane polymers comprising copolyester polyols having repeat units derived from biobased hydroxyfatty acids

Owner:SYNTHEZYME

Polypropylene surface modified additive resin and preparation method thereof

The invention relates to a polypropylene plastic surface modified additive resin with biocompatibility and hydrophily and a preparation method thereof. The surface modified additive resin is a block or graft copolymer consisting of a polypropylene segmer with matrix affinity and a segmer with water affinity and organism affinity; the molecular weight of the the polypropylene segmer with the matrix affinity and the segmer with the water affinity and the organism affinity are 100 to 20,000 respectively; the segmer with the water affinity and the organism affinity is any one of single-ended hydroxyl ploy methyl methacylate, single-ended polyethylene glycol, polydimethylsiloxane, terminal hydroxyl aliphatic polyester, single-ended hydroxyl polylactic acid and single-ended hydroxyl polyhydroxyalkanoates. The modified additive can be directly blended with the polypropylene and absorbed on the surface of the polypropylene during the molding, has excellent adhesion with the polypropylene and can improve surface anticoagulation property and other biocompatibility of the polypropylene.

Owner:SHANTOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com