Biocompatible and temperature-sensitive nano composite hydrogel and preparation method thereof

A biocompatible and nanocomposite technology, applied in the field of biocompatibility and temperature-sensitive nanocomposite hydrogel and its preparation, can solve the problems of difficult to meet tissue engineering, poor mechanical comprehensive performance, poor biocompatibility, etc. , to achieve the effects of low cost, high biocompatibility and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

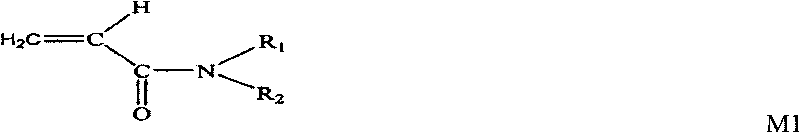

Method used

Image

Examples

Embodiment 1

[0039] Add 1.20g of isopropylacrylamide, 0.25g of laponite, and 0.05g of polyhydroxybutyrate into 10mL of deionized water in sequence, and in a sealed container at 20°C, pass nitrogen gas, ultrasonically disperse for 30min, and stir for 45min until complete Disperse to form a homogeneous solution; cool the above mixed solution to 3°C with ice cubes, add 0.01 g of ammonium persulfate after 30 minutes, and inject 20 μL of N,N,N'N'-tetramethylethylenediamine after 10 minutes, under nitrogen protection, Continue to stir for 10 minutes until the mixed solution begins to appear viscous; immediately pour the viscous mixed solution into a glass mold with a thickness of 2mm, and stand at 20°C for in-situ free radical polymerization for 24 hours, and then the reaction product Soak in deionized water for 2 weeks to obtain the biocompatibility and temperature-sensitive nanocomposite hydrogel.

[0040] The obtained nanocomposite hydrogel: the volume phase transition temperature is 33.2°C, ...

Embodiment 2

[0042] Add 1.0g of isopropylacrylamide, 0.2g of lithium magnesium silicate, and 0.3g of poly(hydroxybutyrate-hydroxyvalerate) into 10mL of deionized water in sequence, and in a sealed container at 20°C, blow nitrogen into it, and ultrasonically disperse 30min, stirred for 60min, until completely dispersed to form a uniform solution; the above mixed solution was cooled to 2°C with ice cubes, 0.02g ammonium persulfate was added after 30min, and 40μL of N,N,N'N'-tetramethylethane was injected after 10min. Diamine, under the protection of nitrogen, continue to stir for 10 minutes until the mixed solution begins to appear viscous; immediately pour the viscous mixed solution into a glass mold with a thickness of 2mm, and stand at 25°C for in-situ free radical polymerization After reacting for 20 h, the reaction product was soaked in deionized water for 2 weeks to obtain the biocompatible and temperature-sensitive nanocomposite hydrogel.

[0043] The obtained nanocomposite hydrogel: ...

Embodiment 3

[0045] Add 1.3g of diethylacrylamide, 0.15g of laponite, and 0.05g of poly-3-hydroxybutyrate-3-hydroxyhexanoate (PHBHHx) into 10mL of deionized water in sequence, and pass it into a sealed container at 20°C Nitrogen, ultrasonically disperse for 30 minutes, stir for 30 minutes until completely dispersed to form a uniform solution; cool the above mixed solution to 3°C with ice cubes, add 0.015g ammonium persulfate after 30 minutes, and inject 30 μL after 10 minutes N, N, N'N'- Tetramethylethylenediamine, under the protection of nitrogen, continue to stir for 10 minutes until the mixed solution begins to appear viscous; immediately pour the viscous mixed solution into a glass mold with a thickness of 2mm, and stand at 25°C for the original Then, the reaction product was soaked in deionized water for 2 weeks to obtain the biocompatible and temperature-sensitive nanocomposite hydrogel.

[0046] The obtained nanocomposite hydrogel: the volume phase transition temperature is 33.9°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com