Biodegradable multilayer co-extrusion material and preparation method thereof

A biodegradation and co-extrusion technology, applied in the direction of chemical instruments and methods, layered products, flat products, etc., can solve the problems of preparing different properties and high film costs, and achieve the effect of improving performance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

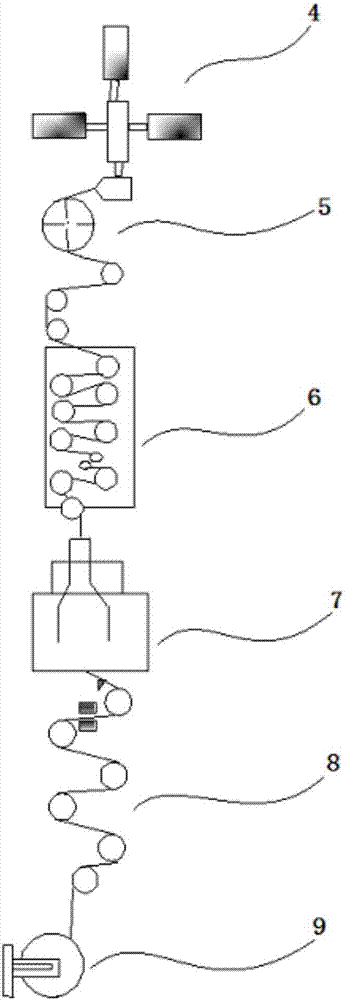

[0056]The preparation method of biodegradable three-layer co-extrusion material comprises the following steps:

[0057] (1) Weigh the component raw materials of the two surface layer functional layers, enter the respective mixing hoppers according to the set ratio, mix and stir evenly, and then enter the respective single-screw extrusion with exhaust function In the machine, it is melted and plasticized at a temperature of 140-230°C and exhausted, and then extruded into the first and third flow channels of the die head;

[0058] (2) Weigh the component raw materials of the middle layer, enter them into the mixing hopper according to the set ratio, mix and stir evenly, and then enter into the twin-screw extruder with exhaust function, at 140-230°C After melting and plasticizing at high temperature and exhausting, it is extruded into the middle layer flow channel of the die;

[0059] (3) The raw materials in the above three layers are melted and extruded to a die head with a te...

Embodiment 1

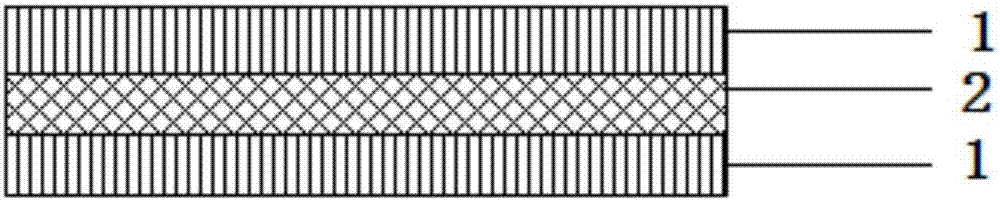

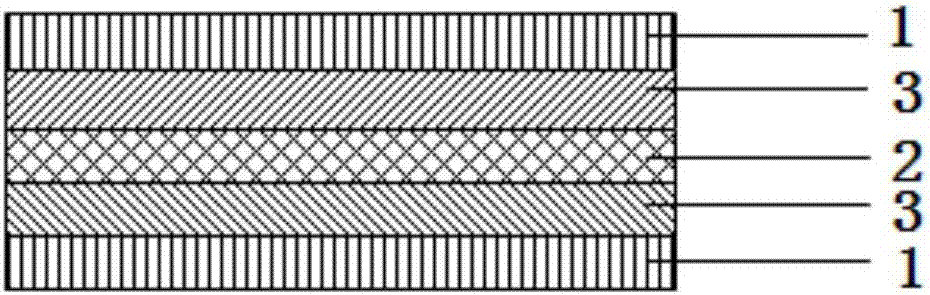

[0073] In this example, a biodegradable three-layer co-extruded biaxially oriented synthetic paper with a thickness of 35 μm is used as an example product.

[0074] see figure 1 and 3 As shown, the upper surface functional layer is a resin layer, and its components are: polylactic acid resin PLA (MFI (melt flow index): 3.5) 79.0% (wt%), polybutylene adipate-terephthalate Butylene glycol formate PBAT (MFI: 3.0) 20% (wt%), antioxidant 1.0% (wt%). After the raw materials in the upper surface functional layer are mixed evenly according to the above ratio, they enter the single-screw extruder 4 with exhaust function, melt and plasticize at a temperature of 160-200°C, and then extrude into the into the first flow channel of the die head.

[0075] The middle layer 2 is a foam layer, and its components are: polylactic acid resin (MFI: 3.5) 40% (wt%), polylactic acid degradable composite masterbatch containing 70% calcium carbonate (average particle size 3.0μm) 58% (wt%), antistati...

Embodiment 2

[0082] In this embodiment, a biodegradable three-layer co-extruded biaxially oriented film with a thickness of 19 μm for printing and lamination is used as an example product.

[0083] see figure 1 As shown, the upper surface functional layer is a resin layer, and its components are: polybutylene succinate (PBS) (MFI: 3.0) 98.0% (wt%), anti-blocking agent 2.0% (wt%). After the raw materials in the functional layer on the upper surface are mixed evenly according to the above ratio, they enter the single-screw extruder with exhaust function, melt and plasticize at a temperature of 170-200°C and exhaust, and then extrude into the mold. In the first layer of the flow channel of the head.

[0084] The middle layer 2 is a resin layer, and its components are: polybutylene succinate (PBS) (MFI: 3.0) 98% (wt%), antistatic agent 2.0% (wt%). After the raw materials in the middle layer are mixed evenly according to the above ratio, they enter the twin-screw extruder with exhaust functio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com