Polyhydroxyalkanoates fiber and preparation method thereof

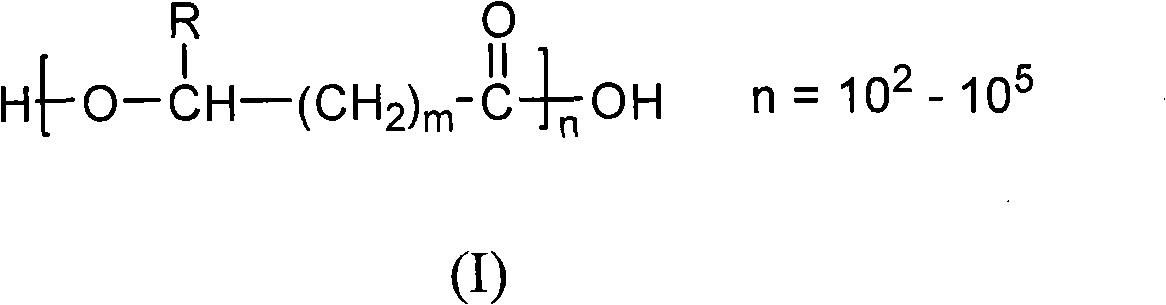

A technology of polyhydroxyalkanoate and hydroxybutyric acid, which is applied in the field of degradable fiber and its preparation, and can solve the problem of low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 2.5g of P(3HB-4HB)(4HB 10%) polymer (Tianjin Guoyun Biotechnology Co., Ltd.) with a weight average molecular weight Mw=300,000, put it into the melt extruder, and heat it to 170°C to the maximum Load extruded circular spline. After the sample is slowly cooled at room temperature, it is dried to remove water, and then cold stretched at a speed of 40mm / min to obtain oriented P(3HB-4HB) fibers with different stretching ratios. After standing at room temperature for a period of time, the strength test is performed . P(3HB-4HB) fibers with diameters ranging from 400μm to 800μm and strengths ranging from 200MPa to 300MPa were obtained.

Embodiment 2

[0038]Weigh 3.5g of P(3HB-4HB) (4HB is 10%) polymer (Tianjin Guoyun Biotechnology Co., Ltd.) with a weight average molecular weight Mw=300,000, put it into the melt extruder, and heat it to 160°C. Extrude round splines with maximum load. The extruded spline is pre-stretched and put into ice water for quenching treatment to obtain amorphous fiber. After the amorphous fiber is kept in ice water for isothermal crystallization for 24 hours, it is dried to remove water, and then cold-stretched at a speed of 40mm / min to obtain a 6-fold stretched oriented P(3HB-4HB) fiber. After leaving it at room temperature for a period of time, Conduct a strength test. A P(3HB-4HB) fiber with a diameter of 200 μm, a strength of 302 MPa, and an elongation of 117% was obtained.

Embodiment 3

[0040] The implementation method is the same as that in Example 2. The obtained 6-fold stretched oriented P(3HB-4HB) fiber was annealed at 76°C for 60 minutes under a stress of 100MPa, and then placed at room temperature for a period of time, and then tested for strength. . A P(3HB-4HB) fiber with a diameter of 150 μm, a strength of 559 MPa, and an elongation of 58% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com