Method for extracting iron by utilizing nickel slag and preparing fibers

A technology of nickel slag and fiber, which is applied in the field of iron extraction and fiber preparation by using nickel slag, can solve the problems that have not yet been achieved, it is difficult to achieve iron oxide enrichment, and there are not many methods, so as to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The thermal nickel slag produced in the nickel smelting process is analyzed by XRF (X-ray fluorescence spectrometry) method, among which SiO 2 The content is 45.3%, Fe 2 o 3 39.1%, MgO content is 2.0%, CaO is 4.5%, Al 2 o 3 It is 6.4%, and the rest is a small amount of Cu, Ni, S, etc.

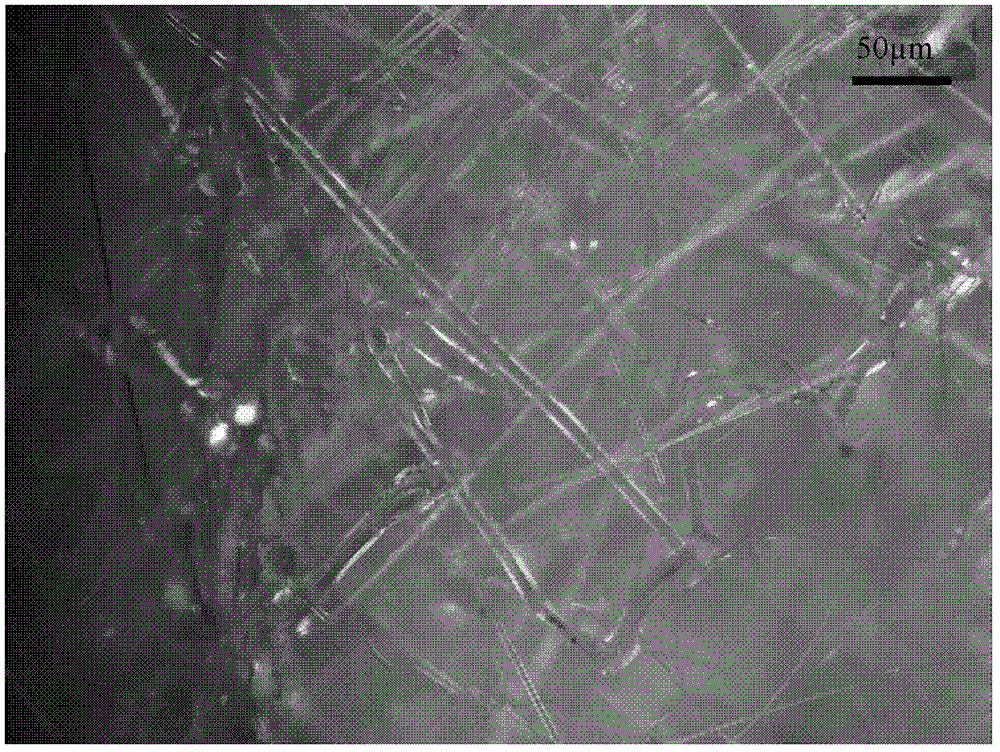

[0026] Put the newly discharged nickel slag in the slag bag for heat preservation. The slag bag transports the hot nickel slag to the production workshop and enters the electric furnace. Iron oxide, while adding 10% mass fraction of CaO and so on. The reduced molten iron is separated and cast into ingots. Add mass fraction 8% bauxite (containing Al 2 o 3 41%), the mixture is added to the temperature-adjusting furnace, and the temperature is controlled to 1300°C. Using the high-speed air injection method and spraying under the pressure of 1.5MPa, the inorganic nickel slag fiber is obtained. The average diameter of the fiber is 5.0μm, and the aspect ratio is 1000-2000. The microsco...

Embodiment 2

[0028] The thermal nickel slag produced in the nickel smelting process is analyzed by XRF (X-ray fluorescence spectrometry) method, among which SiO 2 The content is 44.3%, Fe 2 o 3 29.7%, MgO content is 9.7%, CaO is 5.0%, Al 2 o 3 It is 5.8%, and the rest is a small amount of Cu, Ni, S, etc.

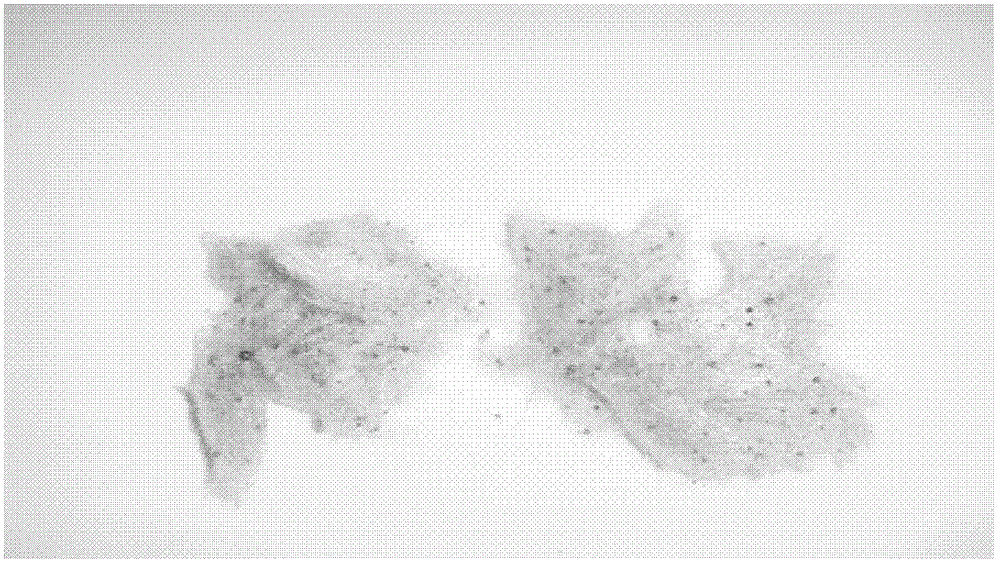

[0029] Put the hot nickel slag discharged from the nickel smelting process into the slag car for heat preservation. The slag car transports the hot nickel slag to the production workshop and enters the electric furnace. Reducing iron oxides in nickel slag and adding 30% CaO etc. at the same time. The reduced molten iron is separated and cast into ingots. Add 8% bauxite (containing Al 2 o 3 50%), the mixture is added into the tempering furnace, and the temperature is controlled to 1500°C. The inorganic nickel slag fiber is obtained by blowing under a pressure of 1.25 MPa by a high-speed air blowing method, the average diameter of the fiber is 5.4 μm, and the length-to-diameter rat...

Embodiment 3

[0031] The thermal nickel slag produced in the nickel smelting process is analyzed by XRF (X-ray fluorescence spectrometry) method, among which SiO 2 The content is 48.3%, Fe 2 o 3 39.7%, MgO content is 3.7%, CaO is 3.5%, Al 2 o 3 It is 2.8%, and the rest is a small amount of Cu, Ni, S.

[0032] The hot nickel slag discharged from the nickel smelting process is placed in a slag bag for heat preservation. The slag bag transports the hot nickel slag to the production workshop and enters the electric furnace. powder to reduce iron oxides in nickel slag, and at the same time add 20% CaO and so on. The reduced molten iron is separated and cast into ingots. Add 30% kaolinite (containing Al 2 o 3 30%, SiO 2 50%), the mixture is added into the tempering furnace, and the temperature is controlled to 1300°C. Fibers were obtained by centrifugal spinning method, and the spinning roll speed was 2000r / min. The obtained fiber has an average diameter of 5.9 μm and an aspect ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com