Sulfur-fixation efficiently combusted clean coal with desulfuration effect and preparation method

An efficient and clean technology, applied in the direction of solid fuel, fuel, petroleum industry, etc., can solve the problems of large investment in equipment and operation, low utilization rate of desulfurization agent, environmental air pollution, etc., achieve high utilization rate of calcium and magnesium, improve self-desulfurization The effect of high efficiency and desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

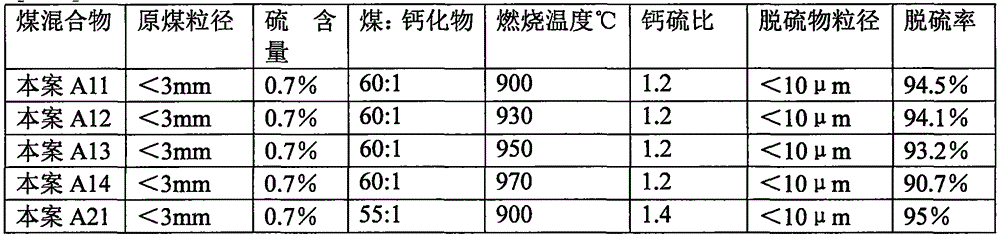

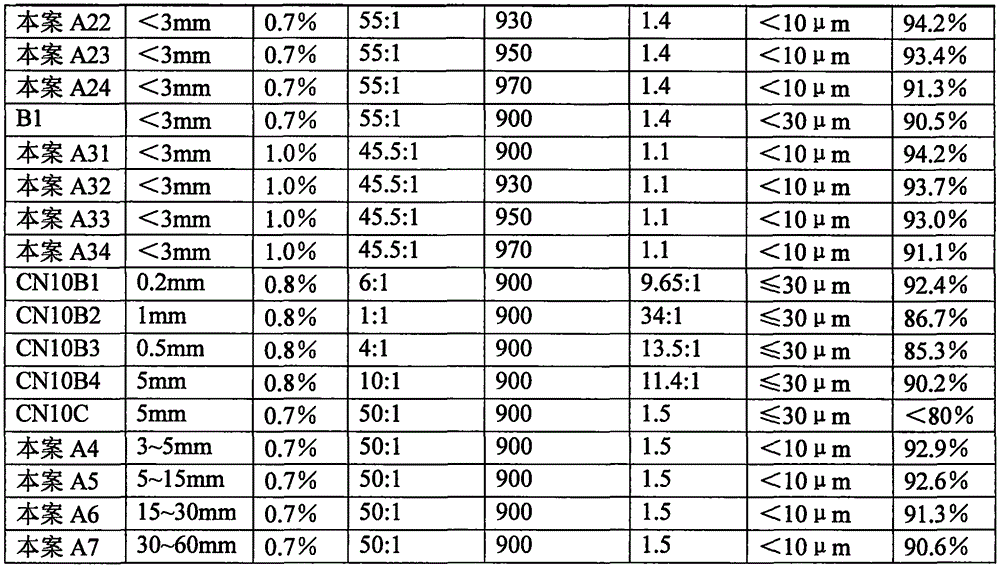

[0048] 1) Add active calcium hydroxide and active magnesium hydroxide fine powders with a particle size of <100 μm into water, the mass ratio of active fine powders to water is 1:1 to 5; stir evenly and let stand for 5 to 10 minutes, then Grind with a high-speed stirring grinder for 20 minutes to obtain nano-active calcium hydroxide and nano-active magnesium hydroxide slurries with a molecular particle size of less than 10 μm;

[0049] 2) According to the sulfur content in the raw coal, under the premise that the calcium-sulfur molar ratio is guaranteed to be 1.2, add water to the nano-active calcium hydroxide and nano-active magnesium hydroxide slurry to dilute the active calcium-magnesium desulfurization slurry;

[0050] 3) Sieve the raw coal with a sulfur content of 0.7% and a particle size of <60mm and pass through the calcium and magnesium desulfurization slurry respectively,

[0051] 4) The calcium-magnesium desulfurization slurry is uniformly mixed with raw coal, the ma...

specific Embodiment approach 2

[0053] 1) Add active calcium hydroxide and active magnesium hydroxide fine powders with a particle size of <100 μm into water, the mass ratio of active fine powders to water is 1:1 to 5; stir evenly and let stand for 5 to 10 minutes, then Grind with a high-speed stirring grinder for 20 minutes to obtain nano-active calcium hydroxide and nano-active magnesium hydroxide slurries with a molecular particle size of less than 10 μm;

[0054] 2) According to the sulfur content in the raw coal, under the premise of ensuring that the calcium-sulfur molar ratio is 1.4, add water to the nano-active calcium hydroxide and nano-active magnesium hydroxide slurry to dilute the active calcium-magnesium desulfurization slurry;

[0055] 3) Sieve raw coal with a sulfur content of 0.7% and a particle size of <60 mm and pass through the calcium and magnesium desulfurization slurry;

[0056] 4) The calcium-magnesium desulfurization slurry is uniformly mixed with raw coal, the mass ratio of coal to a...

specific Embodiment approach 3

[0058] 1) Add calcium hydroxide and magnesium hydroxide fine powders with a particle size of <100 μm into water, the mass ratio of the fine powders to water is 1:1-5; stir well and let stand for 15-30 minutes, then stir with high speed Grinding with a grinder for 40 minutes, only nano-calcium hydroxide and nano-magnesium hydroxide slurries with a molecular particle size of <30 μm can be obtained;

[0059] 2) According to the sulfur content in the raw coal, under the premise that the calcium-sulfur molar ratio is guaranteed to be 1.4, add water to the nano-calcium hydroxide and nano-magnesium hydroxide slurry to dilute the calcium-magnesium desulfurization slurry;

[0060] 3) Sieve raw coal with a sulfur content of 0.7% and a particle size of <60 mm and pass through the calcium and magnesium desulfurization slurry;

[0061] 4) The calcium-magnesium desulfurization slurry is uniformly mixed with raw coal, the mass ratio of coal to calcium hydroxide is 55:1, and the mass ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com